Pathways for Low-Carbon Transition of the Steel Industry—A Swedish Case Study

Abstract

1. Introduction

2. CO2 Abatement in the Steel Industry

3. Method

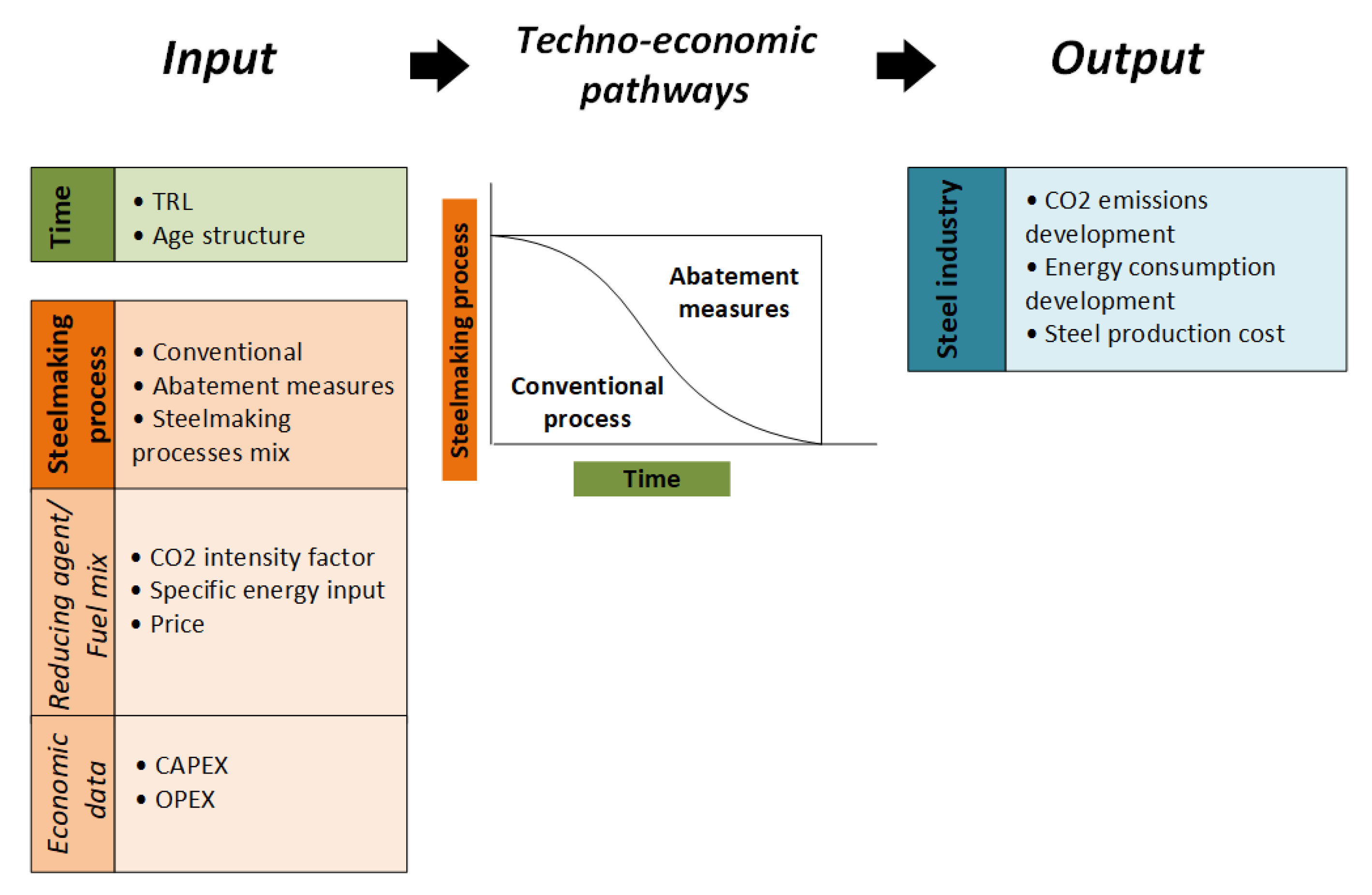

3.1. Techno-Economic Pathways Concept

- The assessment of CO2 abatement measures in the steel industry serves as inputs for the techno-economic pathways as it establishes an upper limit for the emission reduction potential.

- The selection and combination of the CO2 abatement measures are made in line with governmental climate goals and the visions of the steel companies, as well as a comprehensive literature review.

- The pace of retiring the conventional steelmaking technologies and replacing these with technologies which apply CO2 abatement measures is in accordance with the age structure of the existing capital stock and assumptions concerning the average technical lifetime of steelmaking technologies (capital stock turnover). The assumed average technical lifetime of steelmaking technologies is set to 50 years. A timeline of the development CO2 abatement measures throughout technology readiness levels phases, i.e., from concept design to technological maturation and deployment, has been generated based on [39] and industry reports prognosis.

- Based on the technology readiness level timeline, we estimate a timeline for investments in abatement measures to replace current processes, prompting a shift in innovative technology diffusion patterns. The technology readiness level is established by means of a literature review including industry and government agency reports (i.e., these are the ones listed in Table 1). The following outputs from the developed pathways are analysed: development of CO2 emissions and energy consumption over time and steel production cost.

3.2. Data

3.3. Modeling Pathways

3.4. Sensitivity Analysis

4. Results

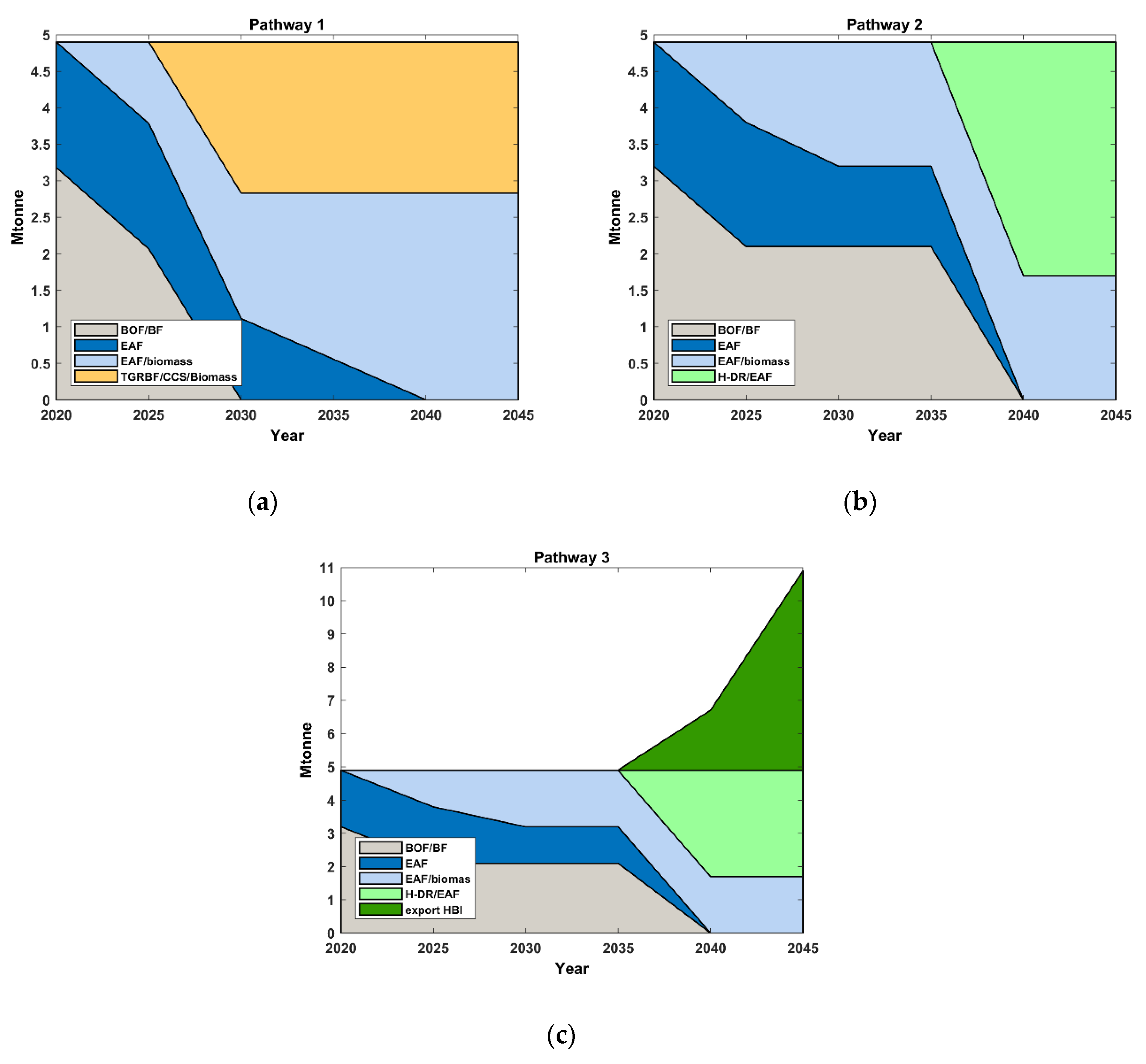

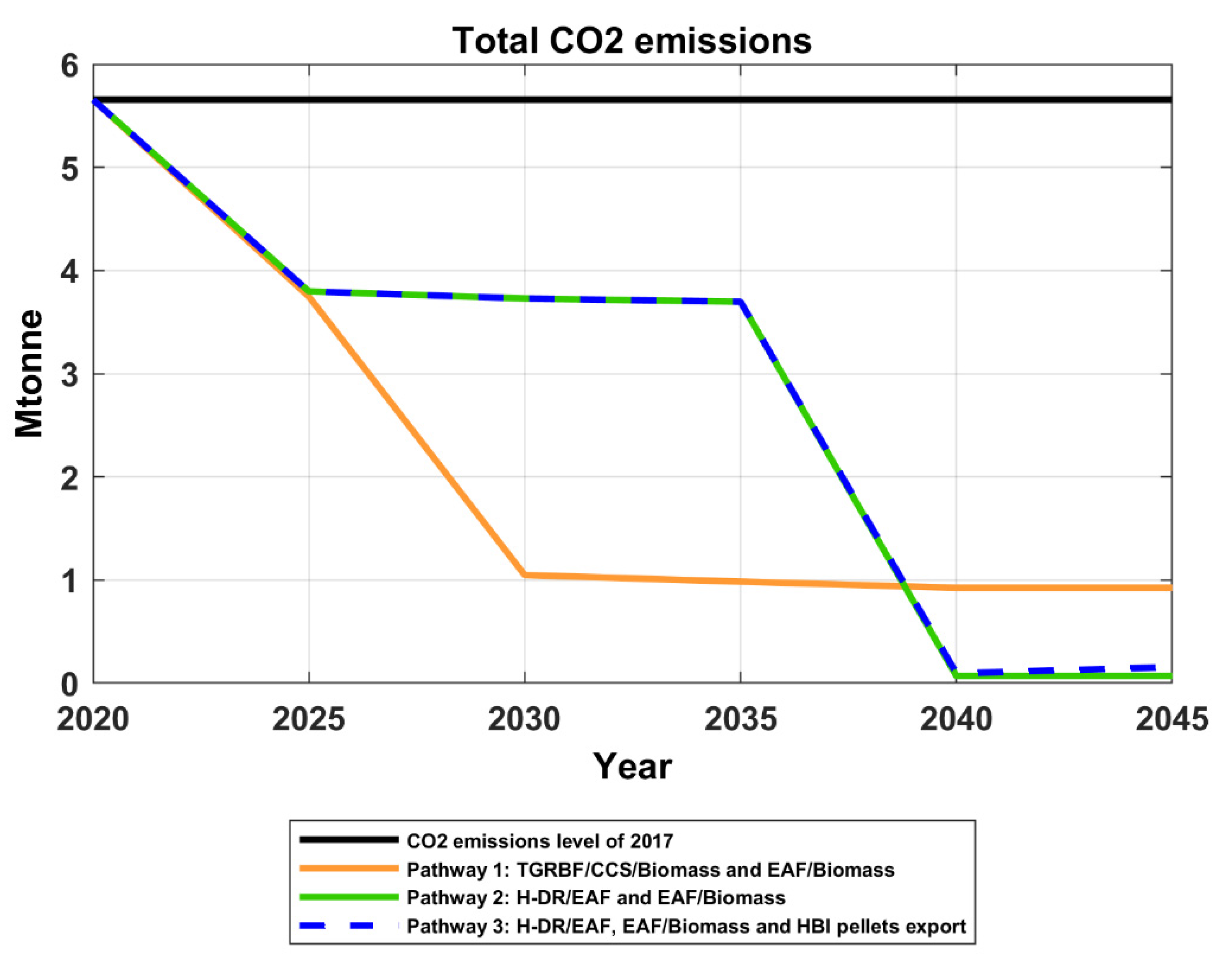

4.1. Future Productivity—Outline of Pathways

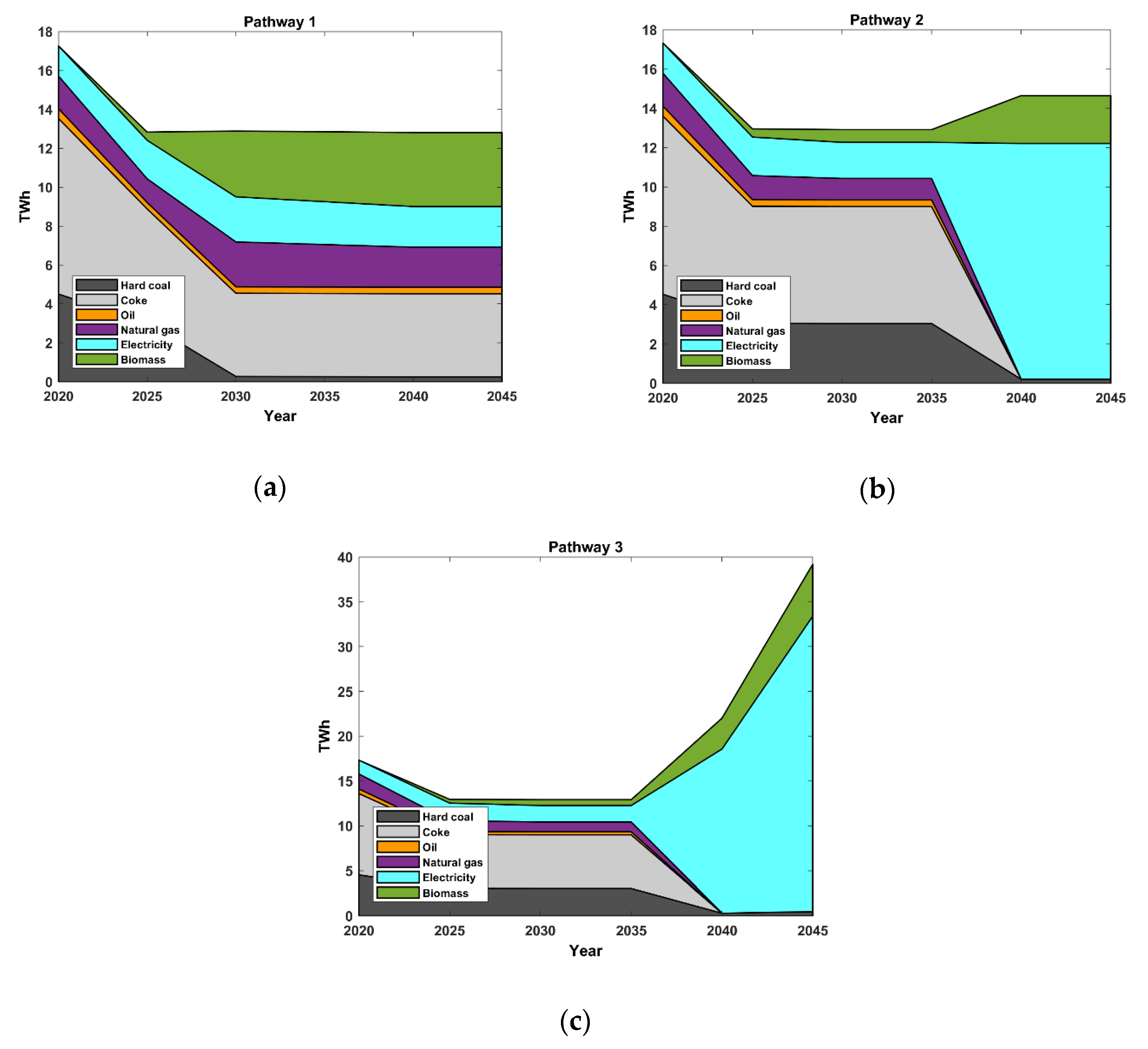

4.2. Energy and Fuel Demand

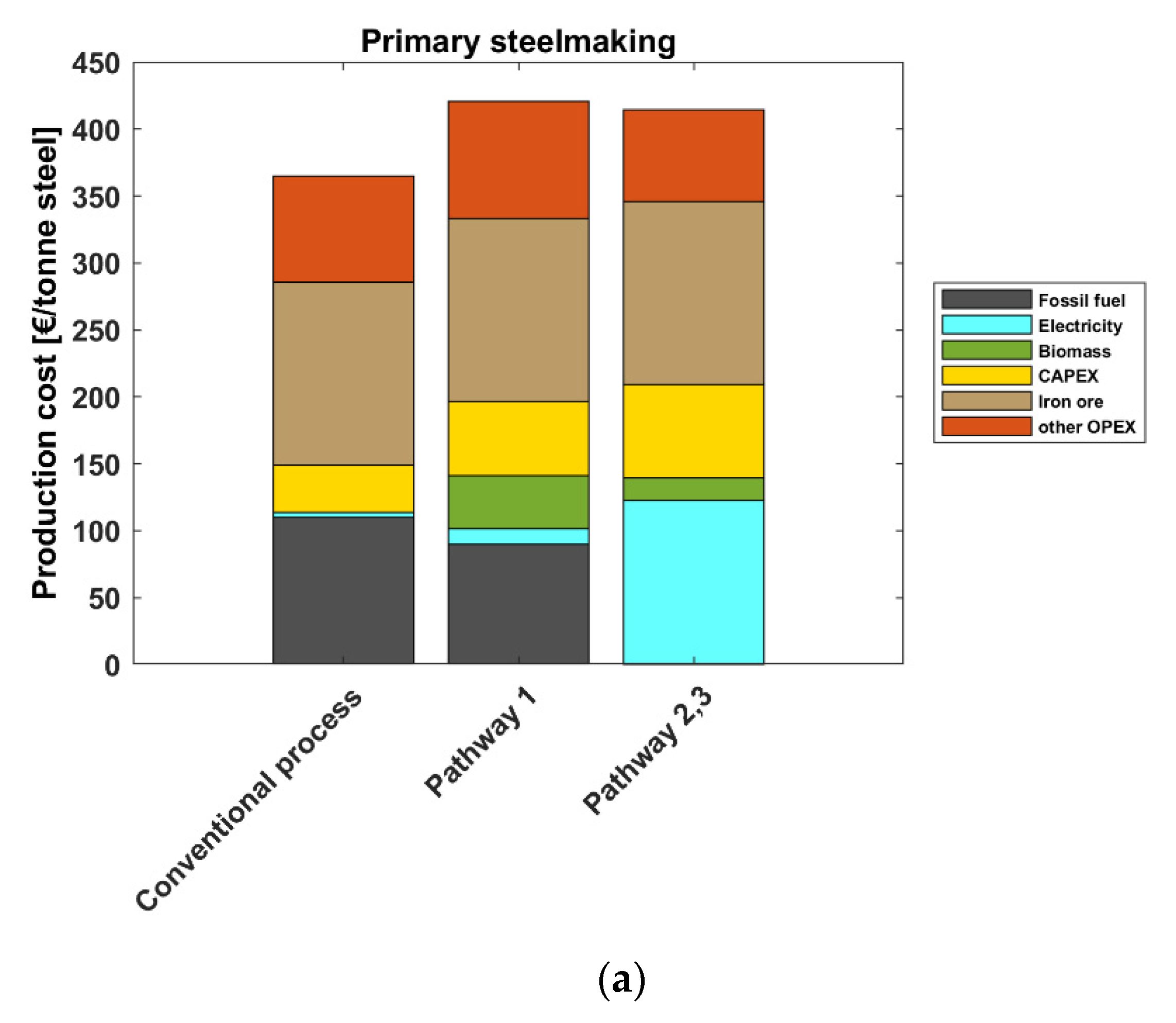

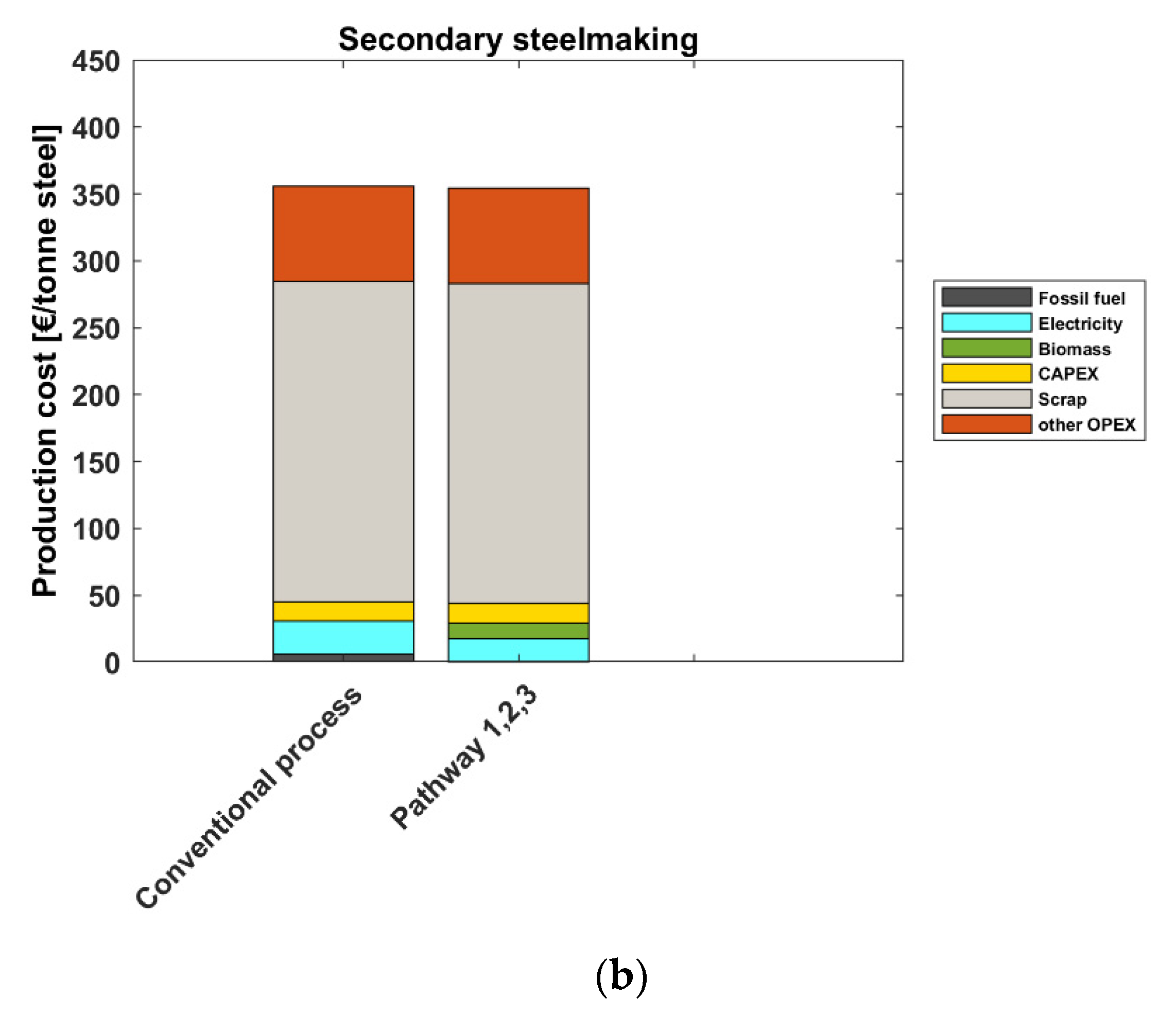

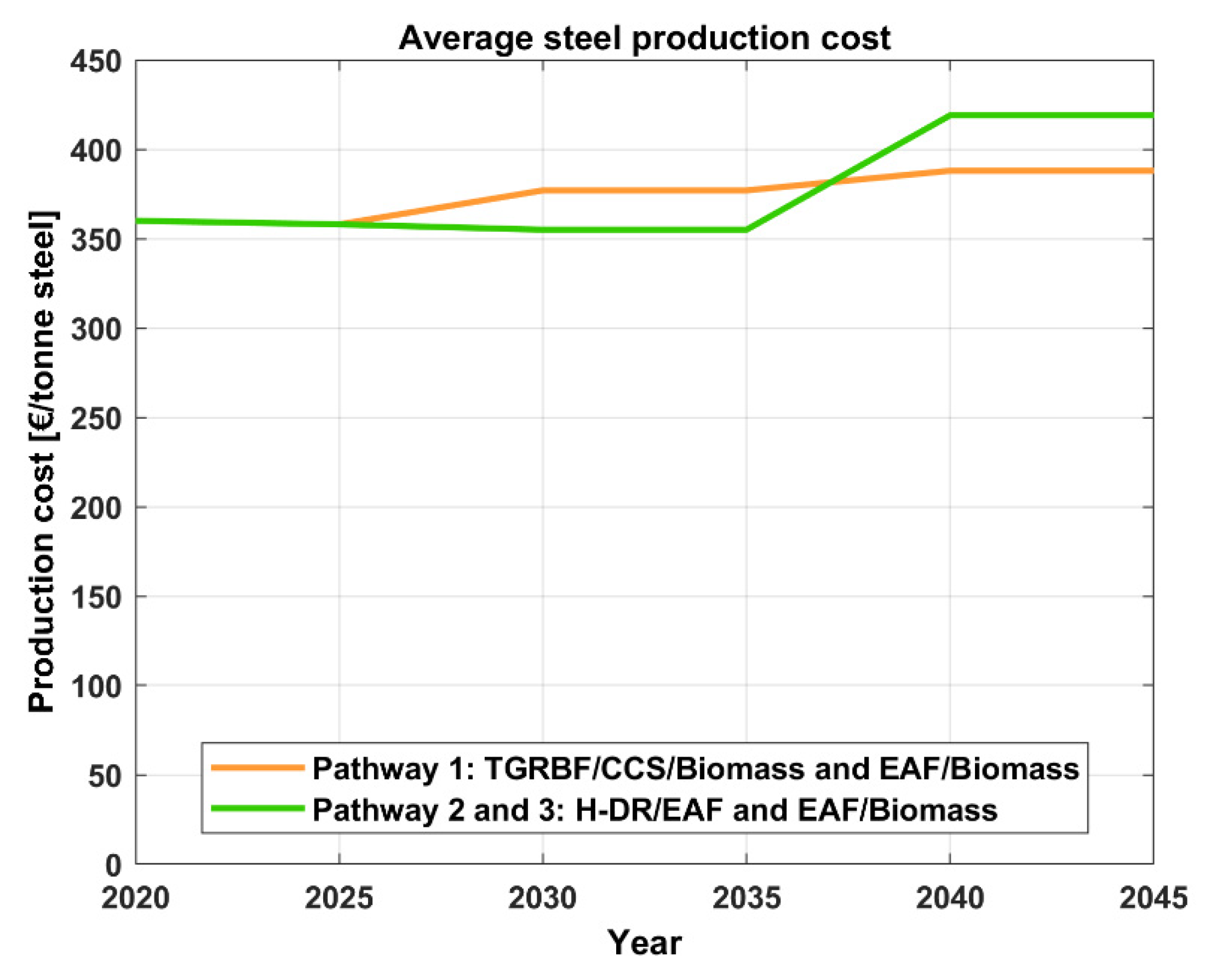

4.3. Steel Production Costs

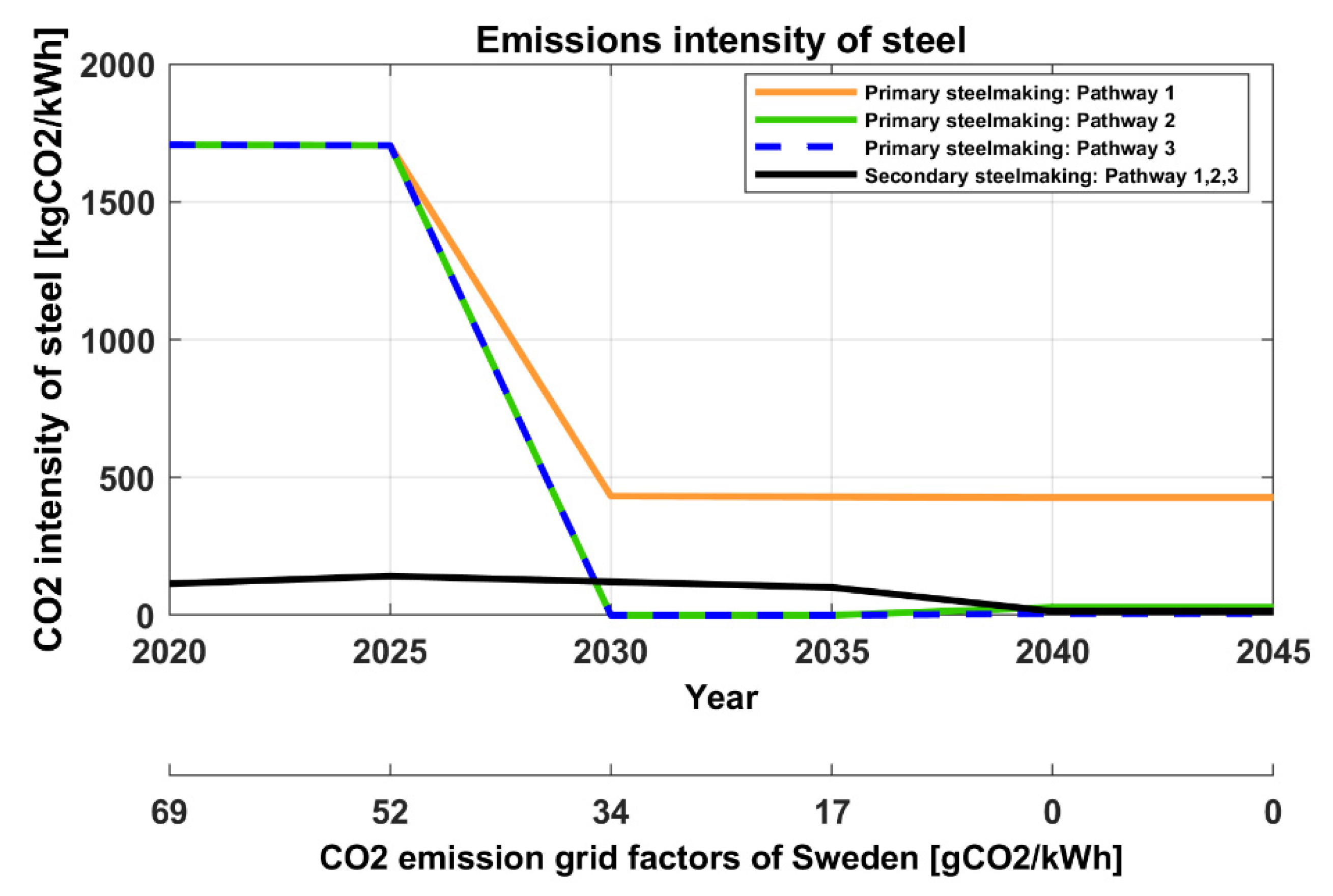

4.4. The Pathways in Relation to the CO2 Emission Targets

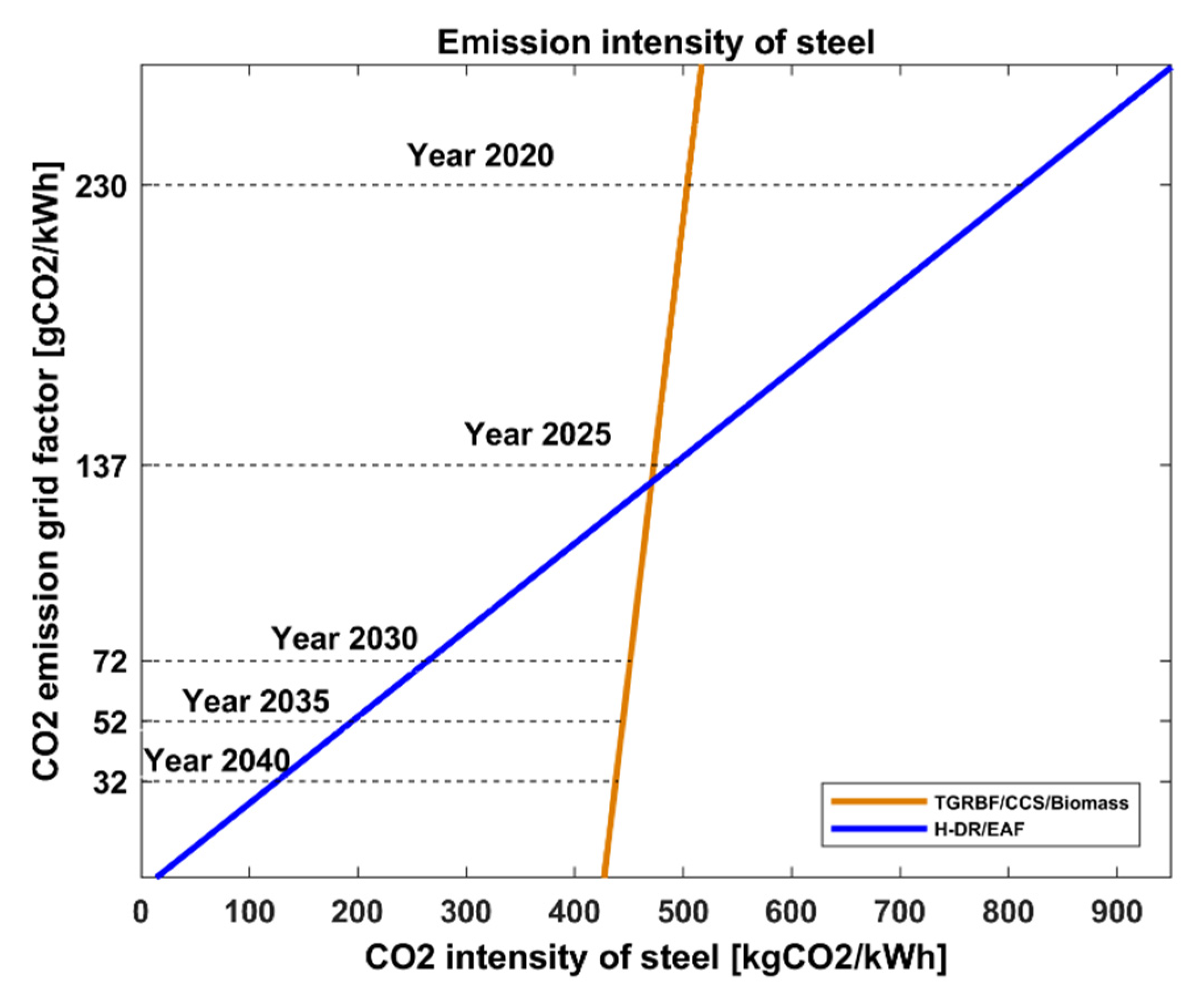

4.5. Sensitivity Analysis

5. Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Specific Energy Input, kWh/Tonne | Primary Steelmaking | Secondary Steelmaking | CO2 Intensity Factor, kg CO2/kWh 4 | Reducing Agent/Fuel Mix Price, €/MWh 5 | |||

|---|---|---|---|---|---|---|---|

| Conventional | Pathway 1 | Pathway 2,3 | Conventional | Pathway 1,2,3 | |||

| BF/BOF 1 | TGRBF +CCS/Biomass 2 | H-DR/EAF 3 | EAF 1 | EAF + Biomass 3 | |||

| Biomass | 0 | 1319 | 560 | 0 | 380 | 0 | 30 |

| Coke | 2835 | 2067 | 0 | 0 | 0 | 0.385 | 28 |

| Electricity | 108 | 333 | 3488 | 700 | 494 | var | 35 |

| Hard coal | 1381 | 62 | 42 | 64 | 42 | 0.342 | 10 |

| Natural gas | 408 | 997 | 0 | 219 | 0 | 0.202 | 25 |

| Oil | 159 | 159 | 0 | 0 | 0 | 0.277 | 42 |

| CO2 Emission Grid Factor, g CO2/kWh | Sweden 1 | European Union 2 |

|---|---|---|

| 2020 | 692 | 230 |

| 2025 | 52 | 137 |

| 2030 | 34 | 72 |

| 2035 | 17 | 52 |

| 2040 | 0 | 32 |

| Primary Steelmaking | Secondary Steelmaking | ||||

|---|---|---|---|---|---|

| Conventional | Pathway 1 | Pathway 2,3 | Conventional | Pathway 1,2,3 | |

| BF/BOF | TGRBF + CCS/Biomass | H-DR/EAF | EAF | EAF + Biomass | |

| CAPEX, €/tonne | 442 1 | 692 2 | 874 3 | 184 1 | 184 4 |

| Total OPEX, €/tonne | 216 | 224 | 205 | 311 | 310 |

| Iron ore, €/tonne 5 | 136 | 136 | 136 | ||

| Scrap, €/tonne 6 | 239 | 239 | |||

| Other OPEX, €/tonne 1 | 80 | 88 | 69 | 72 | 71 |

References

- SCB Greenhouse Gas Emissions and Removals. Available online: https://www.scb.se/en/finding-statistics/statistics-by-subject-area/environment/emissions/greenhouse-gas-emissions-and-removals/ (accessed on 17 June 2020).

- Ministry of the Environment and Energy. The Swedish Climate Policy Framework; Ministry of the Environment and Energy: Stockholm, Sweden, 2018.

- Ballester, C.; Furió, D. Effects of renewables on the stylized facts of electricity prices. Renew. Sustain. Energy Rev. 2015, 52, 1596–1609. [Google Scholar] [CrossRef]

- Bataille, C.; Åhman, M.; Neuhoff, K.; Nilsson, L.J.; Fischedick, M.; Lechtenböhmer, S.; Solano-Rodriquez, B.; Denis-Ryan, A.; Stiebert, S.; Waisman, H.; et al. A review of technology and policy deep decarbonization pathway options for making energy-intensive industry production consistent with the Paris Agreement. J. Clean. Prod. 2018, 187, 960–973. [Google Scholar] [CrossRef]

- Johansson, M.T.; Söderström, M. Options for the Swedish steel industry–Energy efficiency measures and fuel conversion. Energy 2011, 36, 191–198. [Google Scholar] [CrossRef]

- Wang, C.; Mellin, P.; Lövgren, J.; Nilsson, L.; Yang, W.; Salman, H.; Hultgren, A.; Larsson, M. Biomass as blast furnace injectant–Considering availability, pretreatment and deployment in the Swedish steel industry. Energy Convers. Manag. 2015, 102, 217–226. [Google Scholar] [CrossRef]

- Mandova, H.; Patrizio, P.; Leduc, S.; Kjärstad, J.; Wang, C.; Wetterlund, E.; Kraxner, F.; Gale, W. Achieving carbon-neutral iron and steelmaking in Europe through the deployment of bioenergy with carbon capture and storage. J. Clean. Prod. 2019, 218, 118–129. [Google Scholar] [CrossRef]

- Lechtenböhmer, S.; Nilsson, L.J.; Åhman, M.; Schneider, C. Decarbonising the energy intensive basic materials industry through electrification–Implications for future EU electricity demand. Energy 2016, 115, 1623–1631. [Google Scholar] [CrossRef]

- Fischedick, M.; Marzinkowski, J.; Winzer, P.; Weigel, M. Techno-economic evaluation of innovative steel production technologies. J. Clean. Prod. 2014, 84, 563–580. [Google Scholar] [CrossRef]

- Arens, M.; Worrell, E.; Eichhammer, W.; Hasanbeigi, A.; Zhang, Q. Pathways to a low-carbon iron and steel industry in the medium-term—the case of Germany. J. Clean. Prod. 2017, 163, 84–98. [Google Scholar] [CrossRef]

- LKAB. Annual and Sustainability Report; LKAB: Luleå, Sweden, 2017. [Google Scholar]

- Jernkontoret Companies and Plants. Available online: https://www.jernkontoret.se/en/the-steel-industry/companies-and-plants/ (accessed on 17 June 2020).

- SSAB First in Fossil-Free Steel. Available online: https://www.ssab.com/company/sustainability/sustainable-operations/hybrit (accessed on 17 June 2020).

- Klar, D.; Frishammar, J.; Roman, V.; Hallberg, D. A Technology Readiness Level scale for iron and steel industries. Ironmak. Steelmak. 2016, 43, 494–499. [Google Scholar] [CrossRef]

- Association, E.E.S. A Steel Roadmap for a Low Carbon Europe 2050; The Boston Consulting Group (BCG): Boston, MA, USA, 2013. [Google Scholar]

- Wörtler, M.; Schuler, F.; Voigt, N.; Schmidt, T.; Dahlmann, P.; Lüngen, H.B.; Ghenda, J.-T. Steel’s contribution to a low-carbon Europe 2050: Technical and economic analysis of the sector’s CO2 abatement potential. Lond. BCG Retrieved April 2013, 20, 2015. [Google Scholar]

- Carpenter, A. CO2 abatement in the iron and steel industry. IEA Clean Coal Cent. 2012, 67–70. [Google Scholar]

- GHG, I. IEAGHG Iron and Steel CCS Study (Techno-Economics Integrated Steel Mill); IEA: Paris, France, 2013. [Google Scholar]

- Lee, S.; Pollitt, H.; Fujikawa, K. Energy, Environmental and Economic Sustainability in East Asia: Policies and Institutional Reforms; Routledge: Abingdon, UK, 2019. [Google Scholar]

- Haines, M.; Kemper, J.; Davison, J.; Gale, J.; Singh, P.; Santos, S. Assessment of Emerging CO2 Capture Technologies and Their Potential to Reduce Costs; International Energy Agency (IEA): Paris, France, 2014. [Google Scholar]

- Kuramochi, T.; Ramírez, A.; Turkenburg, W.; Faaij, A. Comparative assessment of CO2 capture technologies for carbon-intensive industrial processes. Prog. Energy Combust. Sci. 2012, 38, 87–112. [Google Scholar] [CrossRef]

- Torp, T.A. Drastic Reduction of CO2 Emissions from Steel Production with CO2 Capture and Storage (CCS)—ULCOS Project. In Proceedings of the Technical Committee Meeting, Rome, Italy, 27 June 2005; 20p. [Google Scholar]

- McKinsey, C. Pathways to a Low Carbon Economy—Version 2 of the Global Greenhouse Gas Abatement Cost Curve; McKinsey Company: New York, NY, USA, 2009. [Google Scholar]

- Kirschen, M.; Badr, K.; Pfeifer, H. Influence of direct reduced iron on the energy balance of the electric arc furnace in steel industry. Energy 2011, 36, 6146–6155. [Google Scholar] [CrossRef]

- Axelson, M.; Robson, I.; Wyns, T.; Khandekar, G. Breaking Through-Industrial Low-CO2 Technologies on the Horizon; Institute for European Studies, Vrije Universiteit Brussel: Bruxelles, Belgium, 2018. [Google Scholar]

- LKAB; SSAB. Vattenfall Fossil-Free Steel—Hybrit. Available online: http://www.hybritdevelopment.com/ (accessed on 5 April 2020).

- Vogl, V.; Åhman, M.; Nilsson, L.J. Assessment of hydrogen direct reduction for fossil-free steelmaking. J. Clean. Prod. 2018, 203, 736–745. [Google Scholar] [CrossRef]

- Siderwin Development of new methodologies for Industrial CO2-free steel production by electrowinning. Available online: https://www.siderwin-spire.eu/ (accessed on 17 June 2020).

- Otto, A.; Robinius, M.; Grube, T.; Schiebahn, S.; Praktiknjo, A.; Stolten, D. Power-to-steel: Reducing CO2 through the integration of renewable energy and hydrogen into the German steel industry. Energies 2017, 10, 451. [Google Scholar] [CrossRef]

- Xylia, M.; Silveira, S.; Duerinck, J.; Meinke-Hubeny, F. Weighing regional scrap availability in global pathways for steel production processes. Energy Effic. 2018, 11, 1135–1159. [Google Scholar] [CrossRef]

- Bianco, L.; Baracchini, G.; Cirilli, F.; Di Sante, L.; Moriconi, A.; Moriconi, E.; Agorio, M.M.; Pfeifer, H.; Echterhof, T.; Demus, T. Sustainable electric arc furnace steel production: GREENEAF. BHM Berg-und Hüttenmännische Monatshefte 2013, 158, 17–23. [Google Scholar] [CrossRef]

- Birat, J.P.; Maizière-lès-Metz, D. Steel Sectoral Report Contribution to the UNIDO Roadmap on CCS1-Fifth Draft JP; Arcelor Mittal Global R and D: Maizières-lès-Metz, France, 2010. [Google Scholar]

- Adams, S.; Schnittger, S.; Kockar, I.; Kelly, N.; Xu, H.; Monari, F.; Edrah, M.; Zhang, J.; Bell, G. Impact of Electrolysers on the Network; Scottish & Southern Electricity Networks: Perth, Scotland, 2016. [Google Scholar]

- Mathieson, J.G.; Rogers, H.; Somerville, M.A.; Jahanshahi, S.; Ridgeway, P. Potential for the Use of Biomass in the Iron and Steel Industry. In Proceedings of the Chemeca 2011: Engineering a Better World: Sydney Hilton Hotel, NSW, Australia, 18–21 September 2011. [Google Scholar]

- Borlée, J. Low CO2 Steels-ULCOS Project (Ultra Low CO2 Steelmaking). In Proceedings of the IEA Deployment Workshop, Paris, France, 8–9 October 2007; Volume 9. [Google Scholar]

- Chunbao Charles, X.U.; Cang, D. A brief overview of low CO2 emission technologies for iron and steel making. J. Iron Steel Res. Int. 2010, 17, 1–7. [Google Scholar]

- HYBRIT. HYBRIT—A Swedish Prefeasibility Study Project for Hydrogen Based CO2—Free Ironmaking; SSAB: Stockholm, Sweden, 2016. [Google Scholar]

- Rosenbloom, D. Pathways: An emerging concept for the theory and governance of low-carbon transitions. Glob. Environ. Chang. 2017, 43, 37–50. [Google Scholar] [CrossRef]

- Forum, O.E. Ocean energy strategic roadmap. Build. Ocean Energy Eur. 2016. Available online: https://webgate.ec.europa.eu/maritimeforum/en/node/3962 (accessed on 22 July 2020).

- IEA Key energy statistics. 2018. Available online: https://www.iea.org/countries/sweden (accessed on 17 June 2020).

- Arcelor Mittal. Arcelor Mittal Commissions Midrex to Design Demonstration Plant for Hydrogen Steel Production in Hamburg. Available online: https://corporate.arcelormittal.com/media/news-articles/2019-sep-16-arcelormittal-commissions-midrex-to-design-demonstration-plant (accessed on 5 April 2020).

- Salzgitter AG. Salzgitter AG und Tenova Unterzeichnen Absichtserklärung für das SALCOS-Projekt: CO2-Arme Stahlproduktion auf Wasserstoffbasis. Available online: https://www.salzgitter-ag.com/de/newsroom/pressemeldungen/pressemeldung-der-salzgitter-ag/2019-04-03-1/salzgitter-ag-und-tenova-unterzeichnen-absichtserklrung-fr-das-salcosprojekt-co2arme-stahlproduktion-auf-wasserstoffbasis.html (accessed on 22 July 2020).

- Voestalpine the Three Pillars of Decarbonization. Available online: https://www.voestalpine.com/blog/en/innovation-en/the-three-pillars-of-decarbonization/ (accessed on 5 April 2020).

- IEA Tracking Power. 2019. Available online: https://www.iea.org/reports/tracking-power-2019 (accessed on 24 June 2020).

- IE World Energy Model. Scenario Analysis of Future Energy Trends. Available online: https://www.iea.org/reports/world-energy-model/sustainable-development-scenario#abstract (accessed on 24 June 2020).

- Pauliuk, S.; Milford, R.L.; Müller, D.B.; Allwood, J.M. The steel scrap age. Environ. Sci. Technol. 2013, 47, 3448–3454. [Google Scholar] [CrossRef] [PubMed]

- Consortium, E. Treating Waste as a Resource for the EU Industry: Analysis of Various Waste Streams and the Competitiveness of Their Client Industries; ECSIP Consortium: Rotterdam, The Netherlands, 2013. [Google Scholar]

- Allwood, J.; Azevedo, J.; Clare, A.; Cleaver, C.; Cullen, J.; Dunant, C.F.; Fellin, T.; Hawkins, W.; Horrocks, I.; Horton, P. Absolute Zero: Delivering the UK’s Climate Change Commitment with Incremental Changes to Today’s Technologies; University of Cambridge: Cambridge, UK, 2019. [Google Scholar]

- Feliciano-Bruzual, C. Charcoal injection in blast furnaces (Bio-PCI): CO2 reduction potential and economic prospects. J. Mater. Res. Technol. 2014. [Google Scholar] [CrossRef]

- Mellin, P.; Wei, W.; Yang, W.; Salman, H.; Hultgren, A.; Wang, C. Biomass availability in Sweden for use in blast furnaces. Energy Procedia 2014, 61, 1352–1355. [Google Scholar] [CrossRef]

- Remus, R.; Monsonet, M.A.A.; Roudier, S.; Sancho, L.D. Best available techniques (BAT) reference document for iron and steel production; Publications Office of the European Union: Brussels, Belgium, 2013. [Google Scholar]

- World Steel Association. Worldsteel association CO2 emissions data collection. User Guide 2008, 6, 21. [Google Scholar]

- WorldBank Commodity Markets. Available online: https://www.worldbank.org/en/research/commodity-markets (accessed on 17 June 2020).

- Mandova, H.; Leduc, S.; Wang, C.; Wetterlund, E.; Patrizio, P.; Gale, W.; Kraxner, F. Possibilities for CO2 emission reduction using biomass in European integrated steel plants. Biomass Bioenergy 2018, 115, 231–243. [Google Scholar] [CrossRef]

- NordPool. Day-Ahead Prices. Available online: https://www.nordpoolgroup.com/Market-data1/Dayahead/Area-Prices/ALL1/Yearly/?view=table (accessed on 17 June 2020).

- Moya, J.A.; Boulamanti, A. Production costs from energy-intensive industries in the EU and third countries; Publications Office of the European Union: Luxembourg, 2016. [Google Scholar]

| Process | TRL Status | CO2 Emissions, Tonne CO2/Tonne Steel | Capital Expenses, €/Tonne | References |

|---|---|---|---|---|

| Primary steel production | ||||

| Blast furnace with basic oxygen furnace (BF/BOF) | Commercial (TRL 9) | 1.6–2.2 | 386–442 | [15,16] |

| Top gas recycling blast furnace (TGRBF/BOF) | TRL 7 | 1.44–1.98 | 632 | [17,18,19] |

| CO2 capture technology 1 | TRL 6–9 | CO2 capture efficiency (%): 90 | 25–85 | [17,20,21,22,23] |

| Smelting reduction (SR/BOF) | Commercial (TRL 9) | 1.2–2.25 | 393 | [15,21] |

| Direct reduction using electric arc furnace (DR/EAF) | Commercial (TRL 9) | 0.63–1.15 | 414 | [15,18,24] |

| Hydrogen direct reduction using electric arc furnace (H-DR/EAF) | TRL 1–4 | 0.025 | 550–900 | [25,26,27] |

| Electrowinning (EW) | TRL 4–5 | 0.2–0.29 | 639 | [9,25,28] |

| Secondary steel production | ||||

| Electric arc furnace (EAF) | Commercial (TRL 9) | 0.6 | 169–184 | [15,29,30] |

| Electric arc furnace/biomass (EAF/biomass) | TRL 6-8 | 0.005 | 169–184 | [26,31] |

| Pathway | Primary Steelmaking | Commercially Available 1 | Secondary Steelmaking | Commercially Available 1 | Production Rate |

|---|---|---|---|---|---|

| Pathway 1 | TGRBF/BOF + CCS + biomass | 2030 | EAF/biomass | 2025 | Constant |

| Pathway 2 | H-DR/EAF | 2040 | EAF/biomass | 2025 | Constant |

| Pathway 3 | H-DR/EAF | 2040 | EAF/biomass | 2025 | Increased |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Toktarova, A.; Karlsson, I.; Rootzén, J.; Göransson, L.; Odenberger, M.; Johnsson, F. Pathways for Low-Carbon Transition of the Steel Industry—A Swedish Case Study. Energies 2020, 13, 3840. https://doi.org/10.3390/en13153840

Toktarova A, Karlsson I, Rootzén J, Göransson L, Odenberger M, Johnsson F. Pathways for Low-Carbon Transition of the Steel Industry—A Swedish Case Study. Energies. 2020; 13(15):3840. https://doi.org/10.3390/en13153840

Chicago/Turabian StyleToktarova, Alla, Ida Karlsson, Johan Rootzén, Lisa Göransson, Mikael Odenberger, and Filip Johnsson. 2020. "Pathways for Low-Carbon Transition of the Steel Industry—A Swedish Case Study" Energies 13, no. 15: 3840. https://doi.org/10.3390/en13153840

APA StyleToktarova, A., Karlsson, I., Rootzén, J., Göransson, L., Odenberger, M., & Johnsson, F. (2020). Pathways for Low-Carbon Transition of the Steel Industry—A Swedish Case Study. Energies, 13(15), 3840. https://doi.org/10.3390/en13153840