Figure 1.

Gspeed-2017 Racecar.

Figure 1.

Gspeed-2017 Racecar.

Figure 2.

Gspeed-2018 Racecar.

Figure 2.

Gspeed-2018 Racecar.

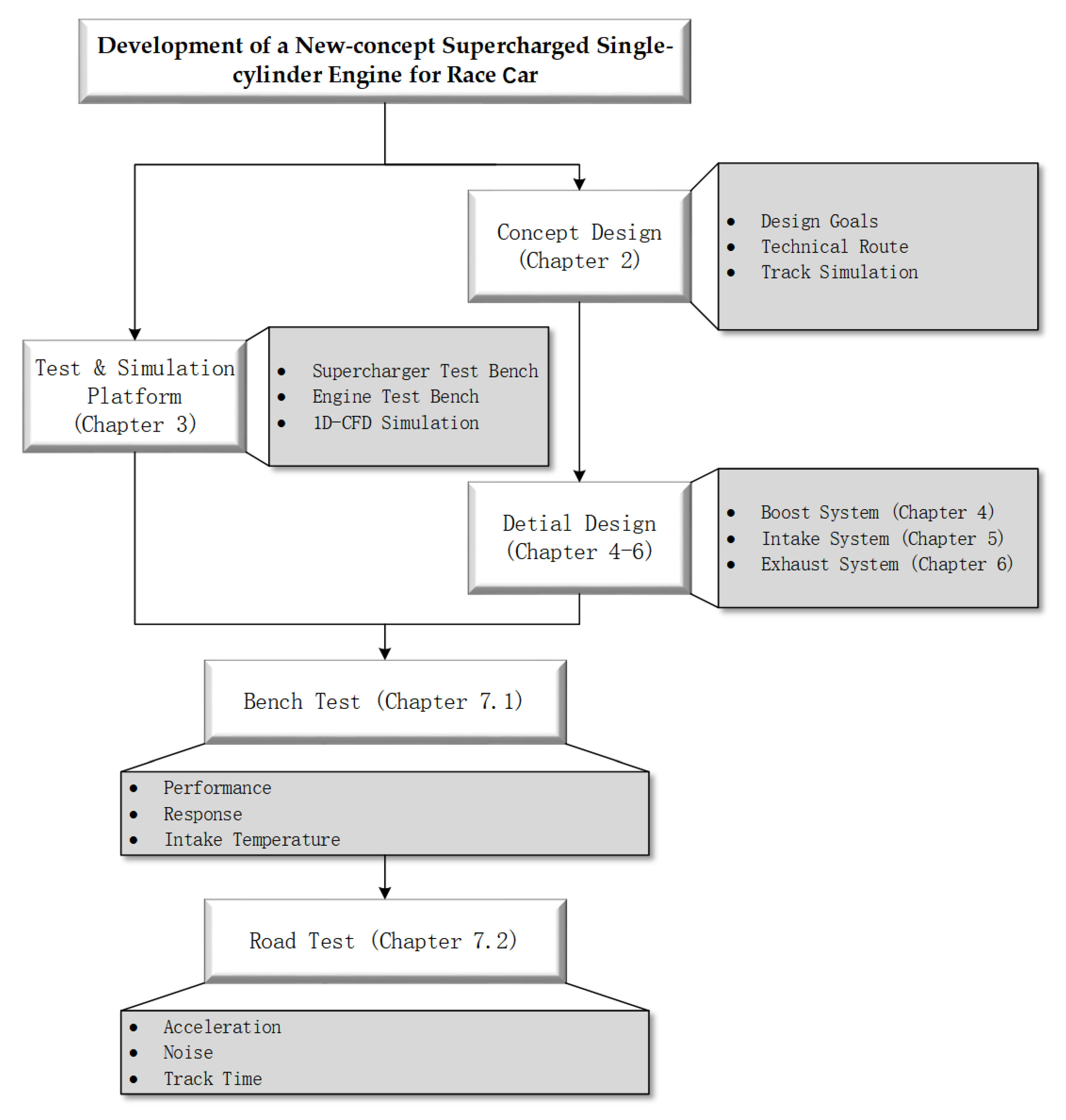

Figure 3.

Overall Structure of the Article.

Figure 3.

Overall Structure of the Article.

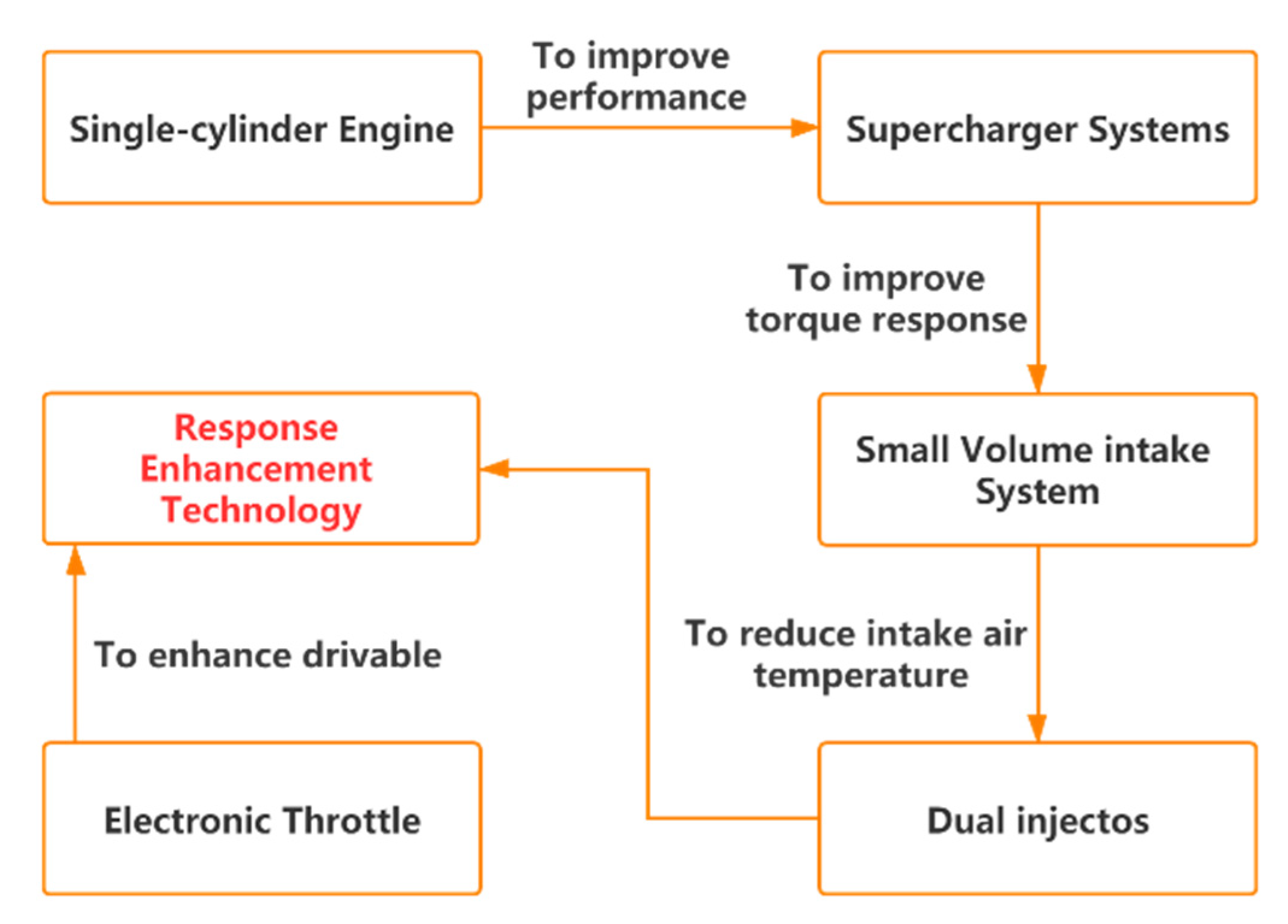

Figure 4.

Technical Route of ‘response enhancement technology’.

Figure 4.

Technical Route of ‘response enhancement technology’.

Figure 5.

Power/Weight Comparison of Selectable Engines.

Figure 5.

Power/Weight Comparison of Selectable Engines.

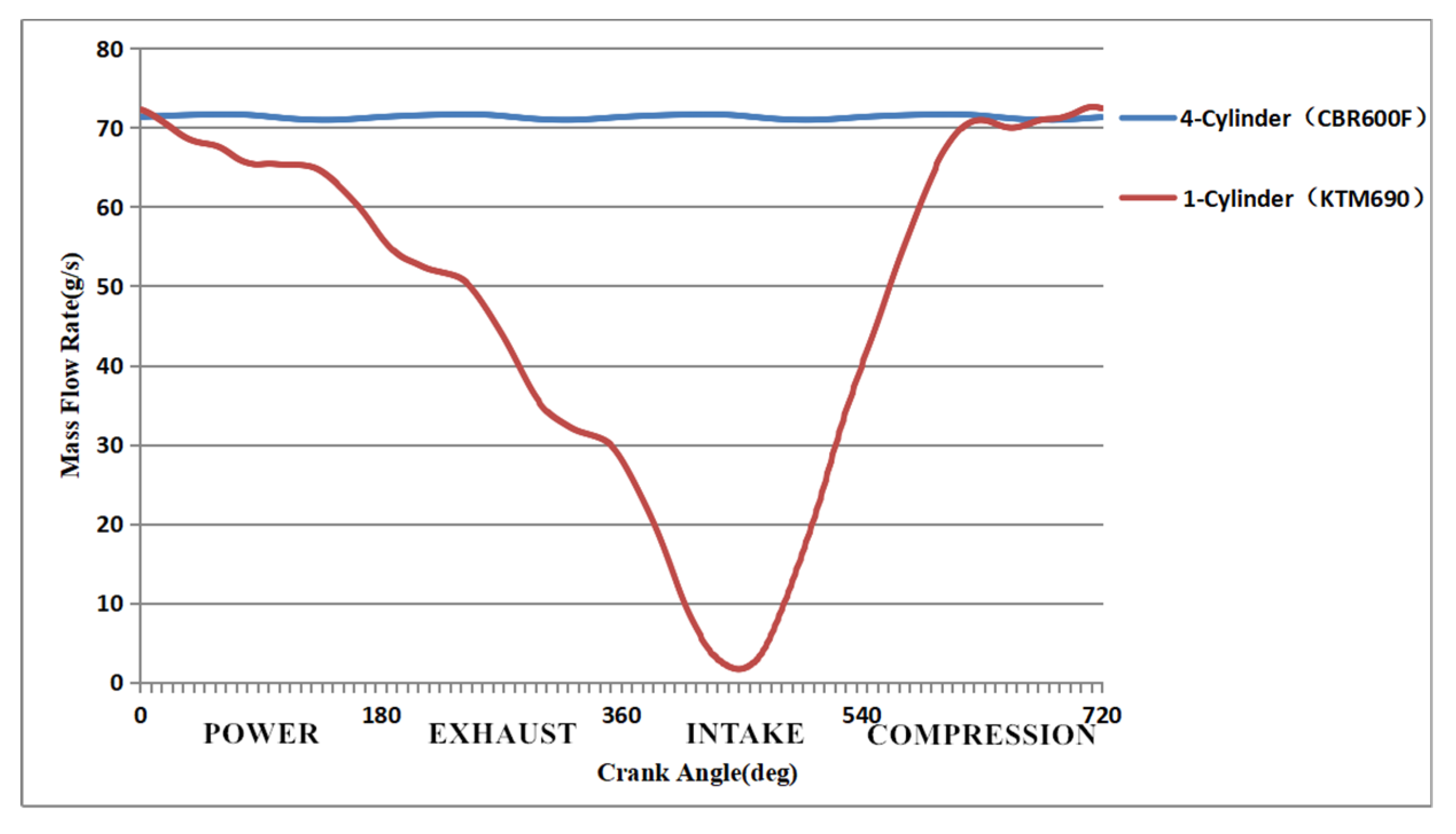

Figure 6.

Flow Rate of 1-Cyl. and 4-Cyl. Engine at Restrictor during One Cycle.

Figure 6.

Flow Rate of 1-Cyl. and 4-Cyl. Engine at Restrictor during One Cycle.

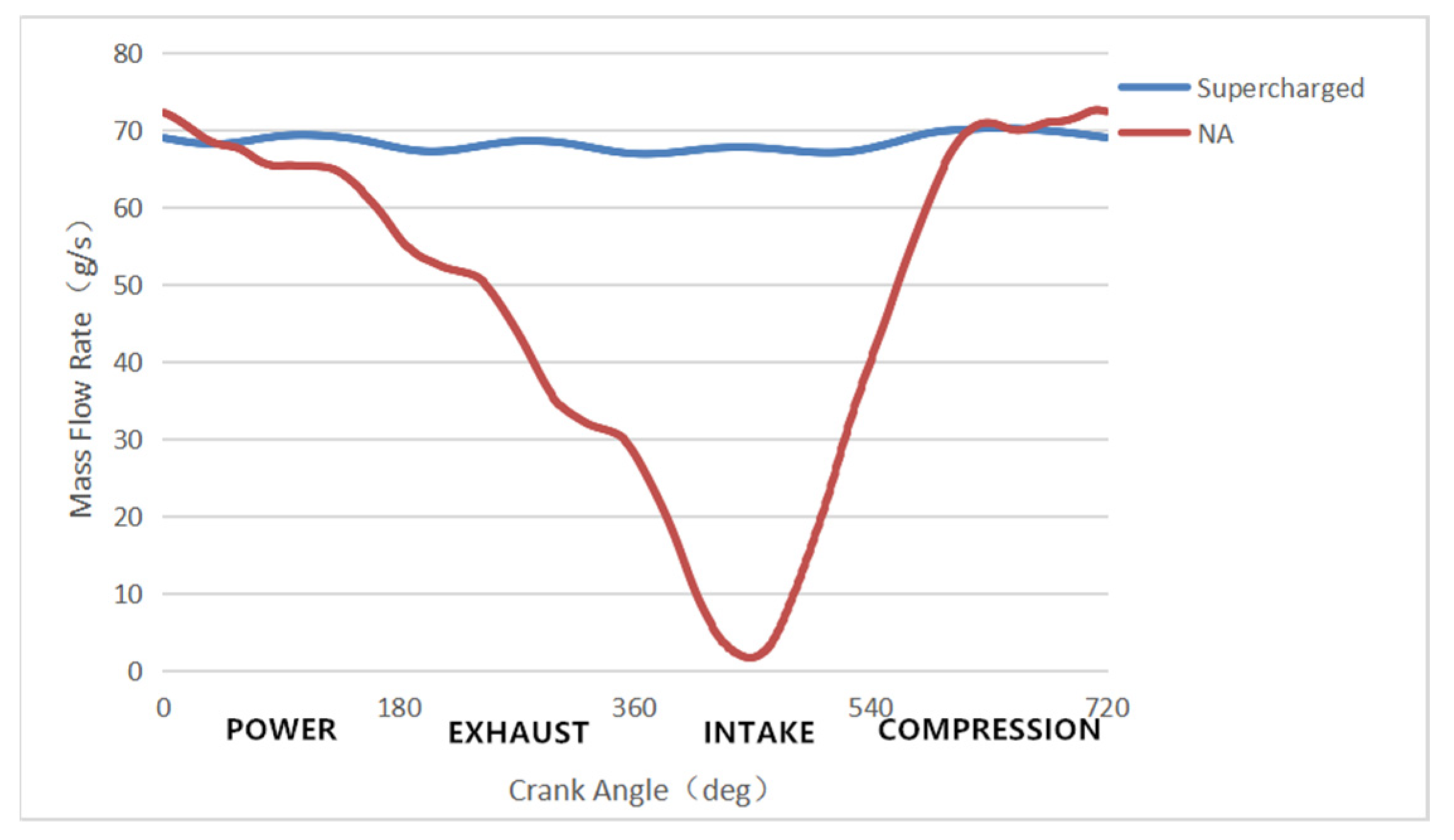

Figure 7.

Flow Rate of Naturally Aspirated and Supercharged 1-Cyl. Engine at Restrictor during One Cycle.

Figure 7.

Flow Rate of Naturally Aspirated and Supercharged 1-Cyl. Engine at Restrictor during One Cycle.

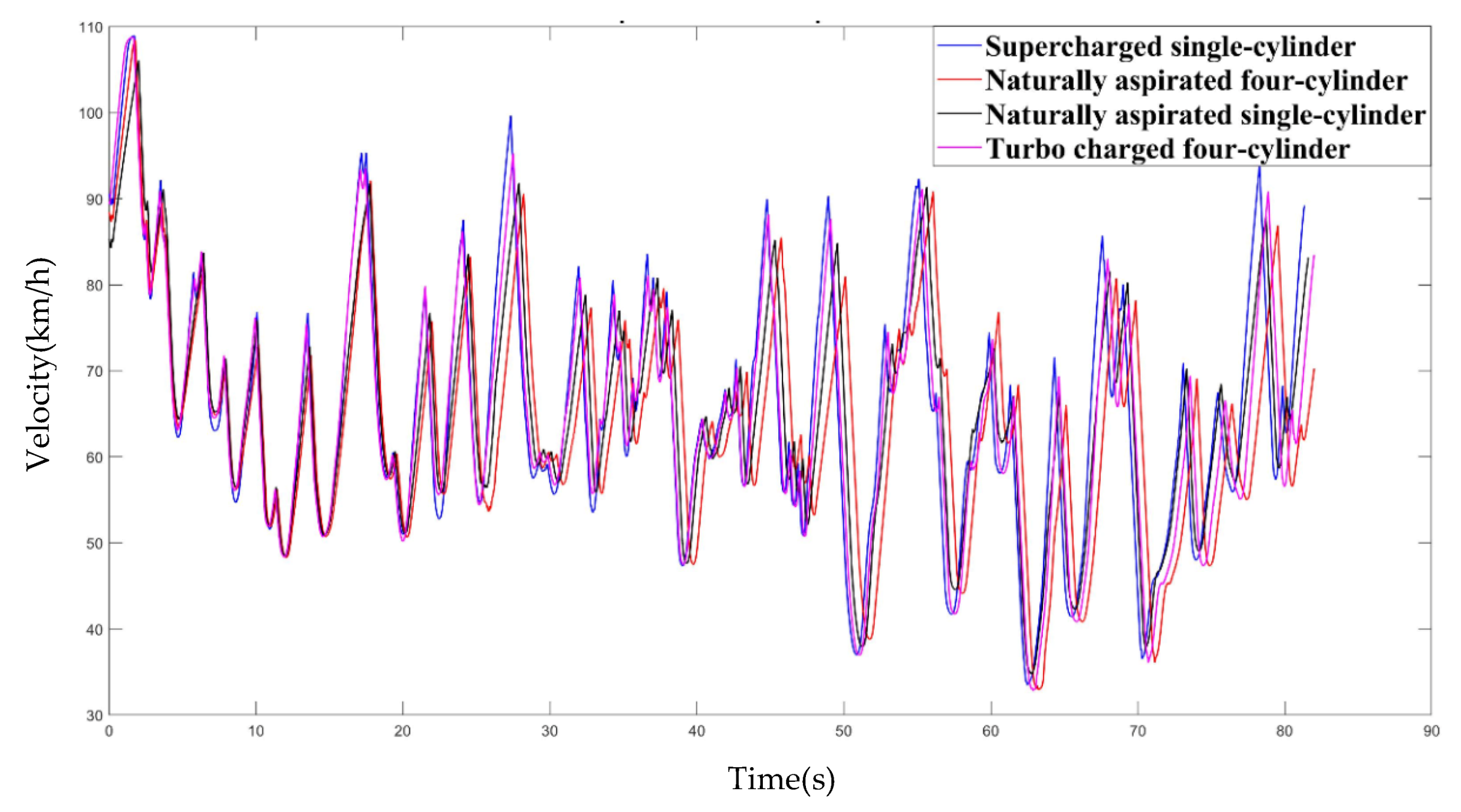

Figure 8.

Vehicle Speed of Racecars with Different Powertrain during Endurance Test.

Figure 8.

Vehicle Speed of Racecars with Different Powertrain during Endurance Test.

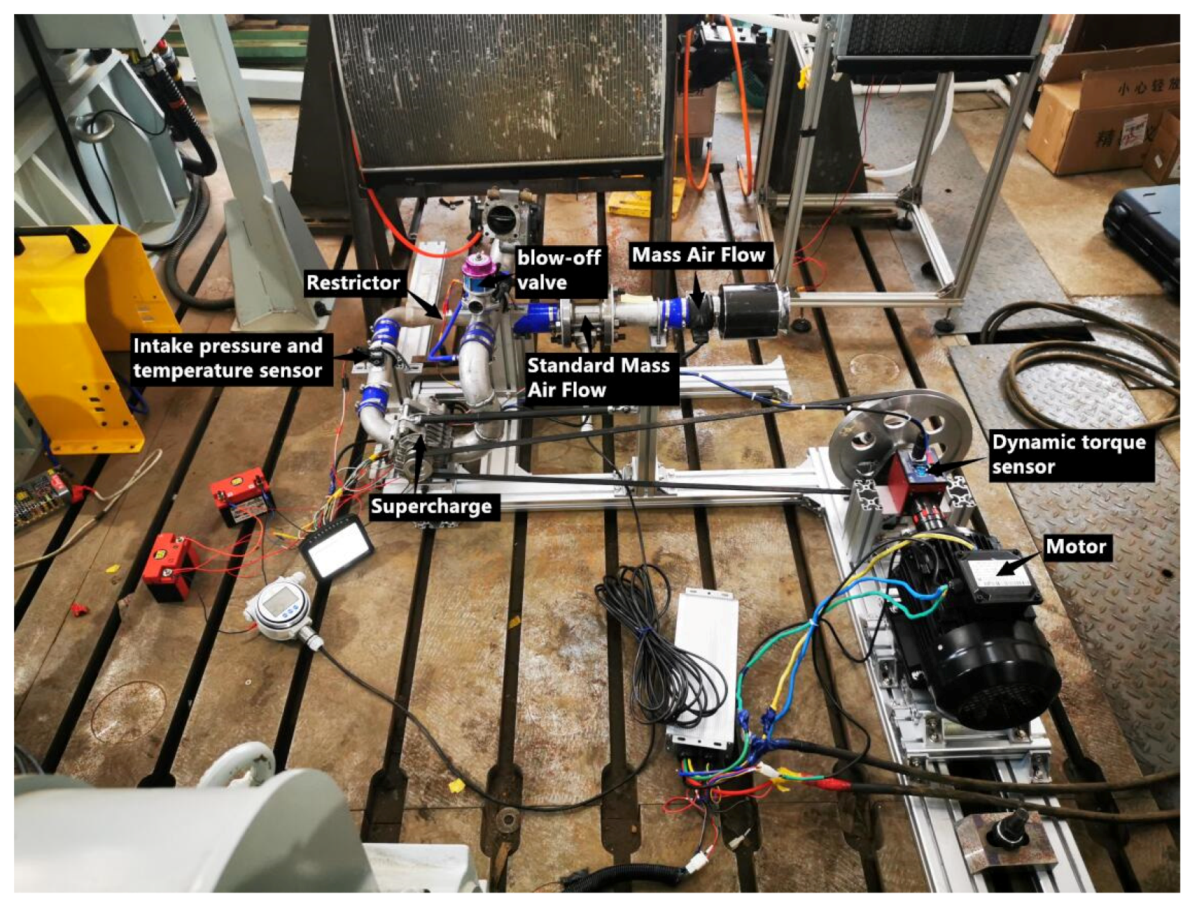

Figure 9.

Supercharger Characteristic Test Bench.

Figure 9.

Supercharger Characteristic Test Bench.

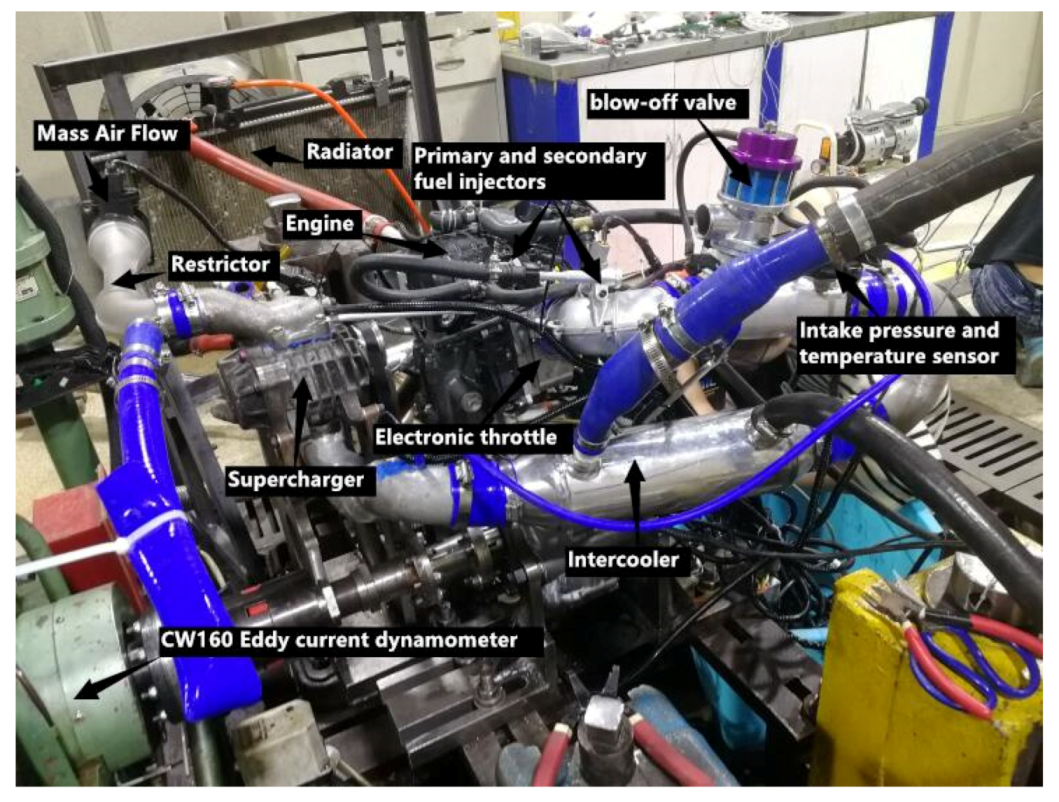

Figure 10.

Engine Performance Test Bench.

Figure 10.

Engine Performance Test Bench.

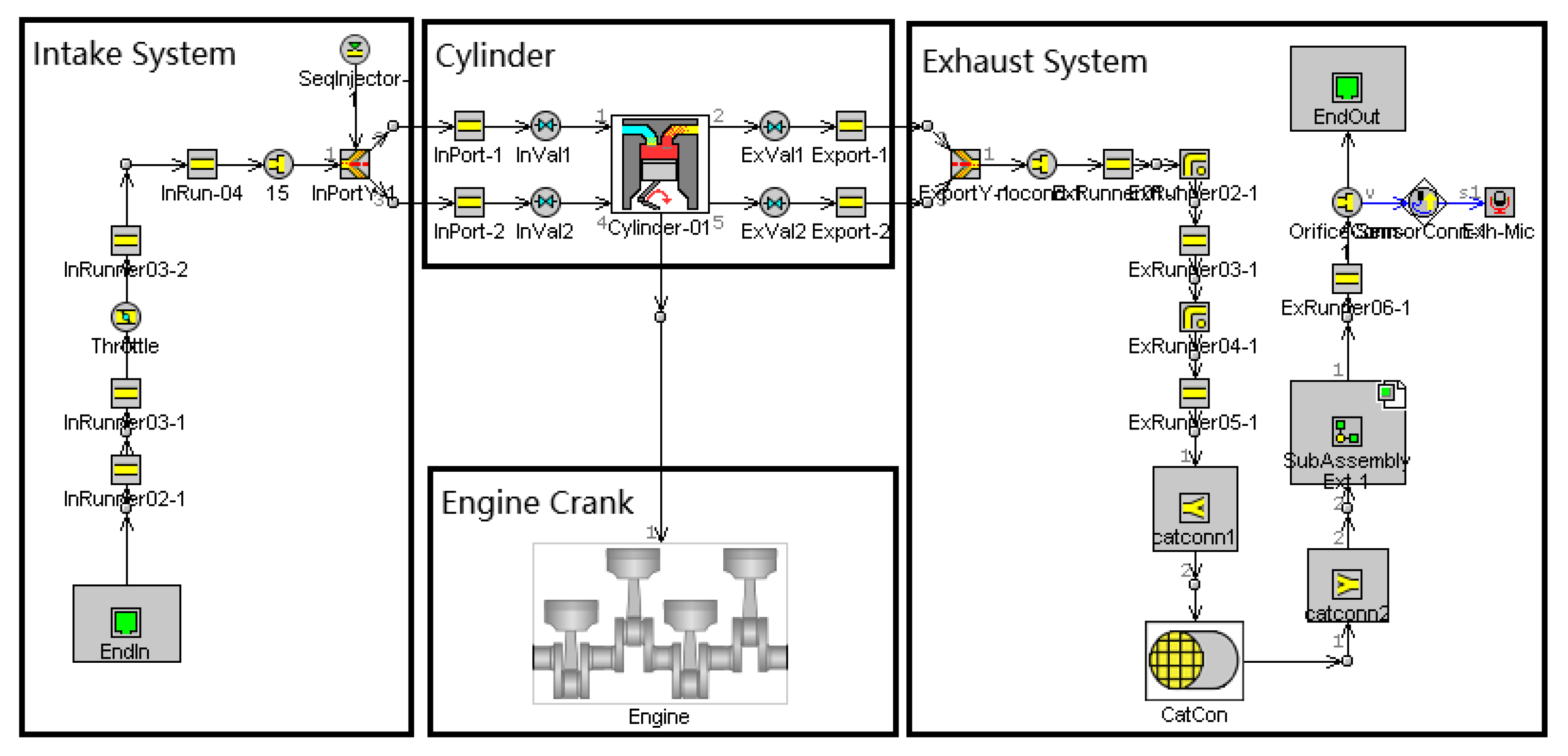

Figure 11.

Simulation Model of Stock Engine.

Figure 11.

Simulation Model of Stock Engine.

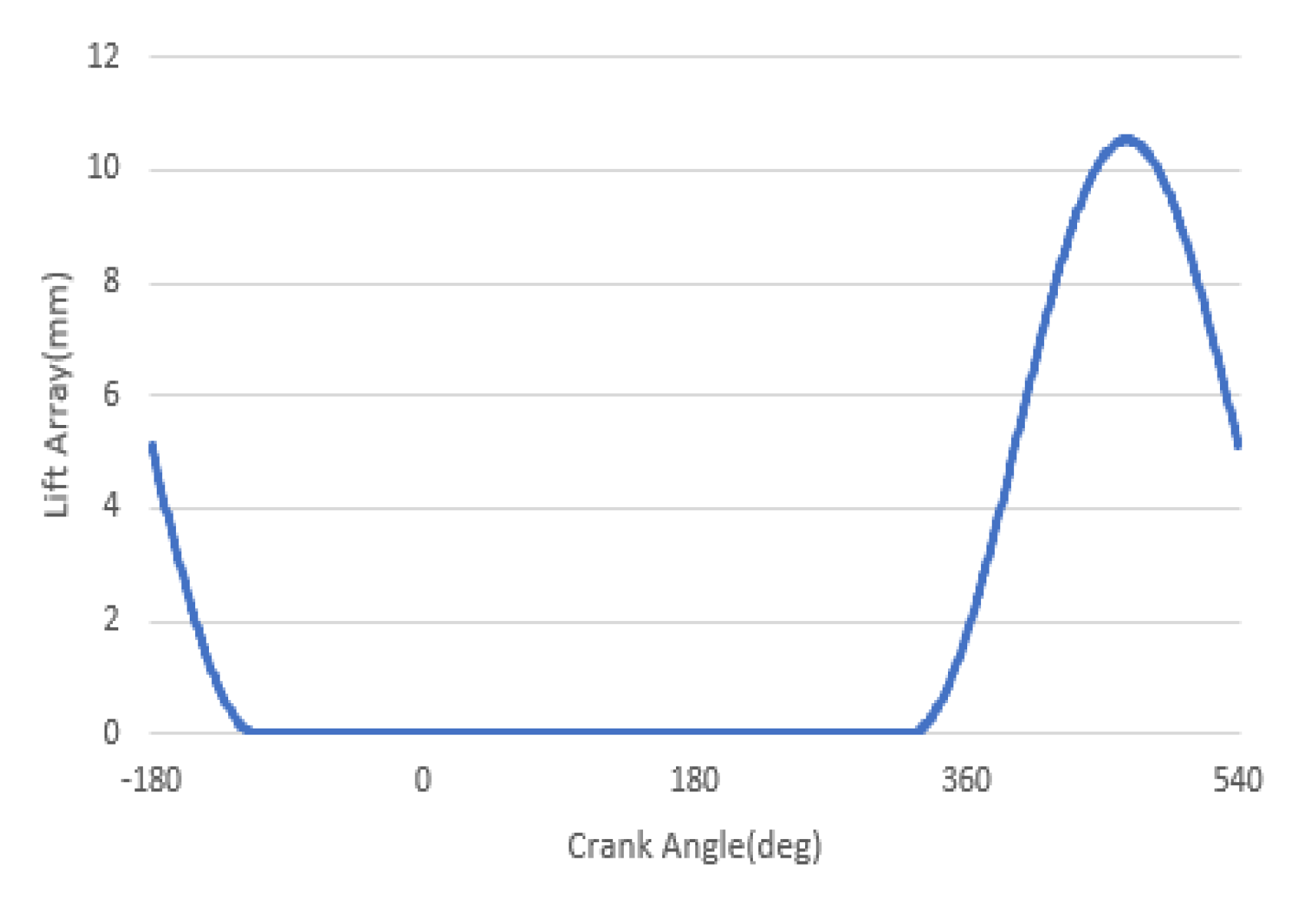

Figure 12.

Intake Valve Lift of KTM 690.

Figure 12.

Intake Valve Lift of KTM 690.

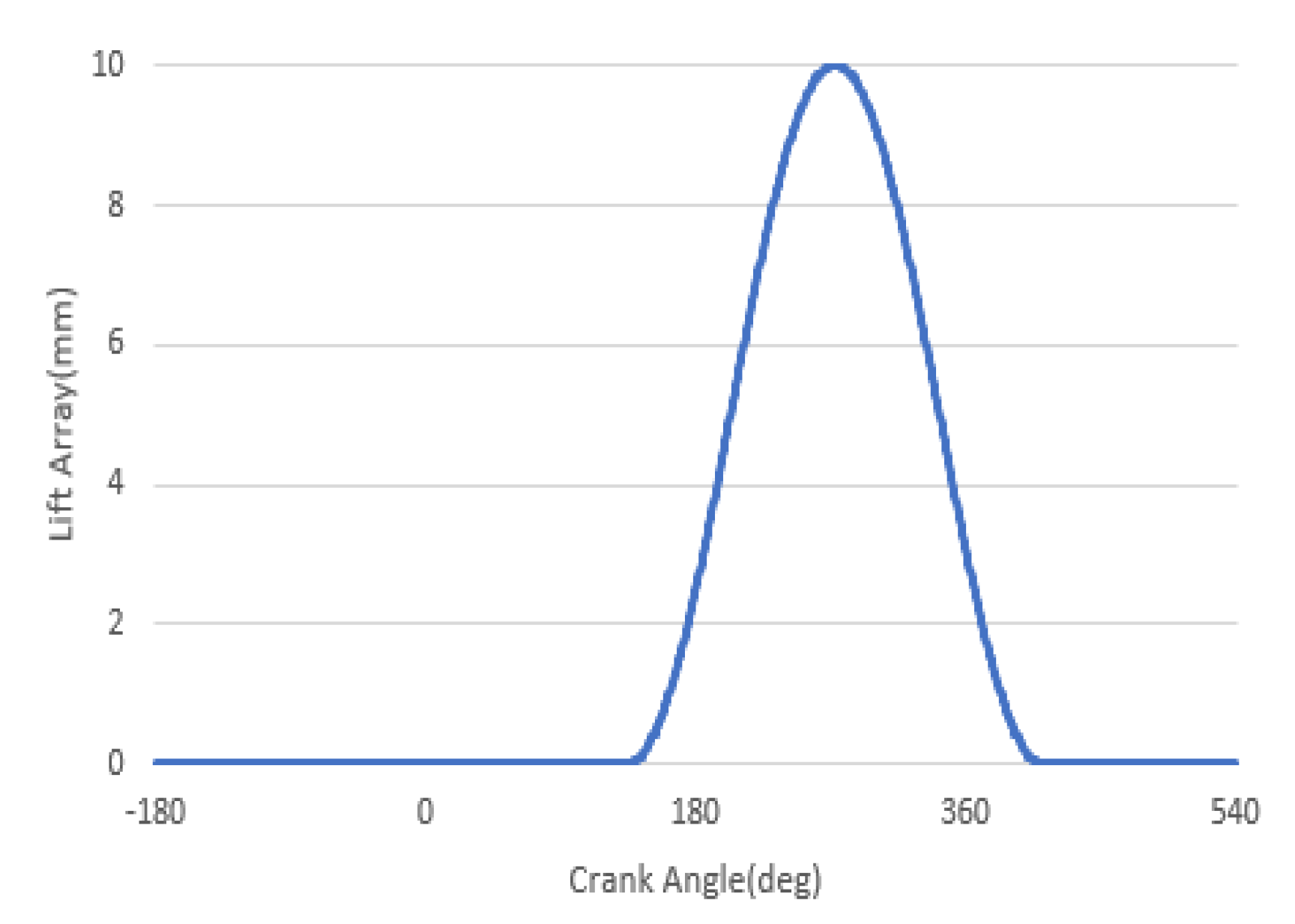

Figure 13.

Exhaust Valve Lift of KTM 690.

Figure 13.

Exhaust Valve Lift of KTM 690.

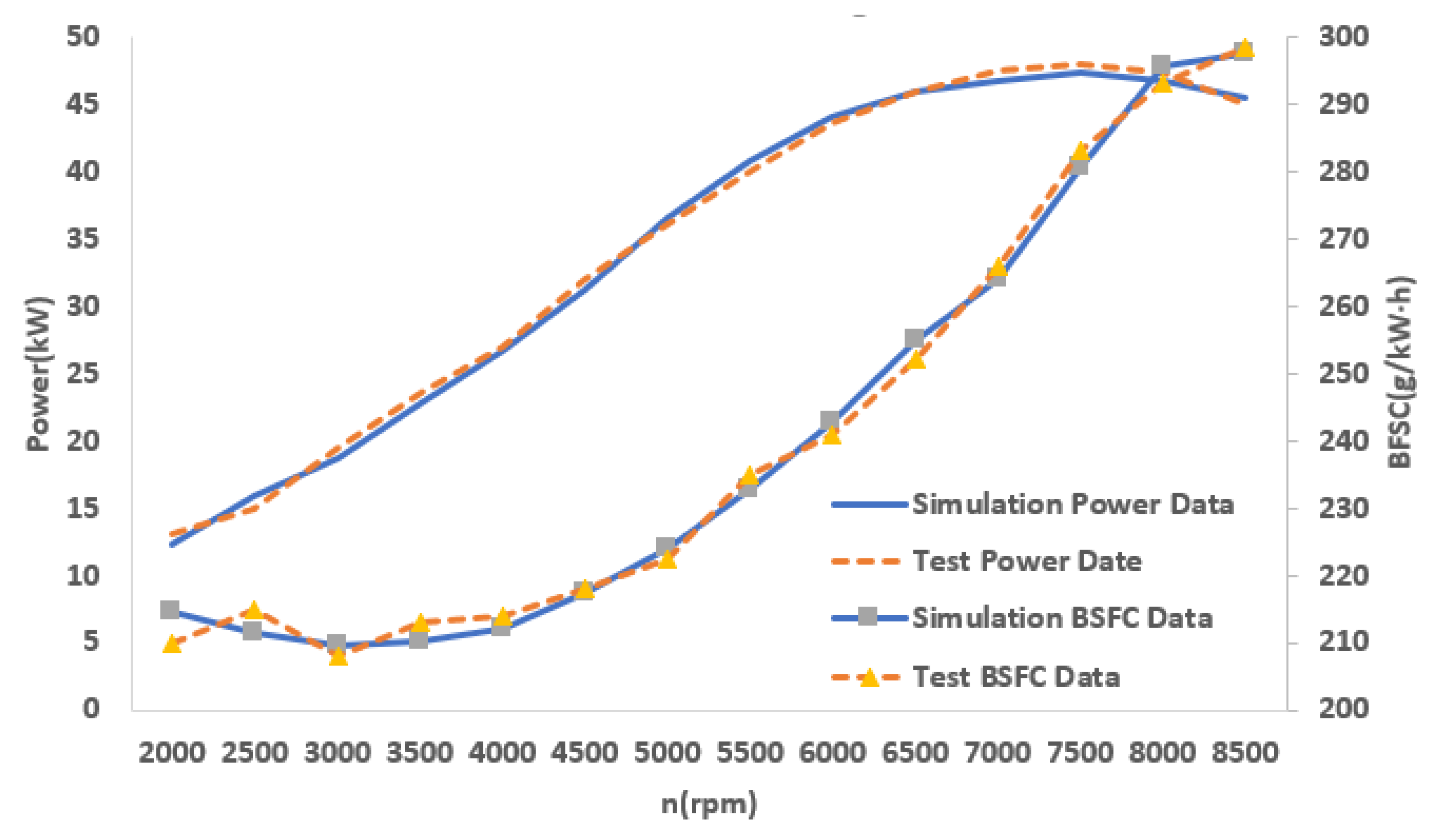

Figure 14.

Result of Simulation and Testing (Stock Engine at WOT).

Figure 14.

Result of Simulation and Testing (Stock Engine at WOT).

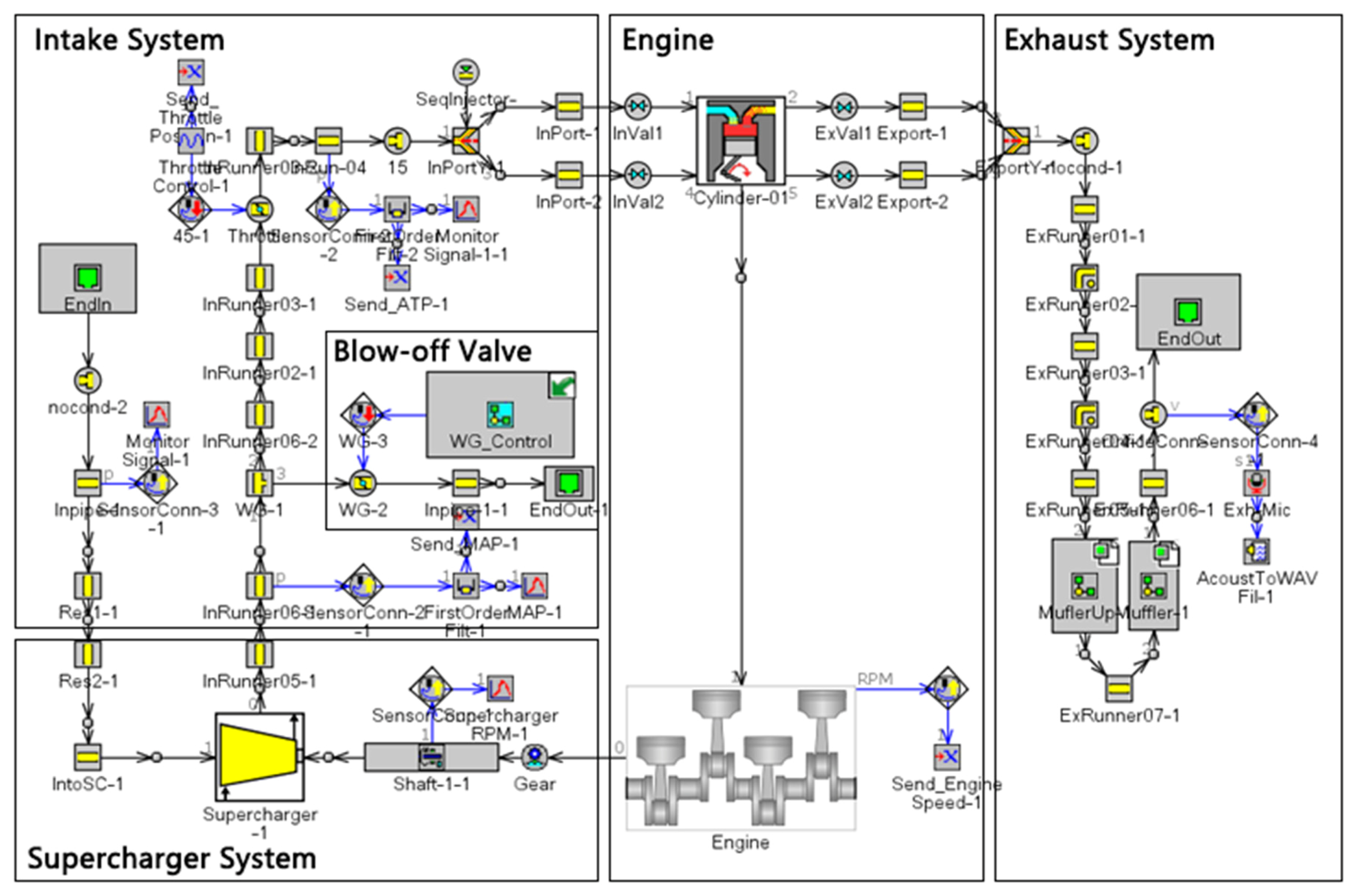

Figure 15.

Simulation Model of the Modified Supercharged Engine.

Figure 15.

Simulation Model of the Modified Supercharged Engine.

Figure 17.

Eaton TVS-R410.

Figure 17.

Eaton TVS-R410.

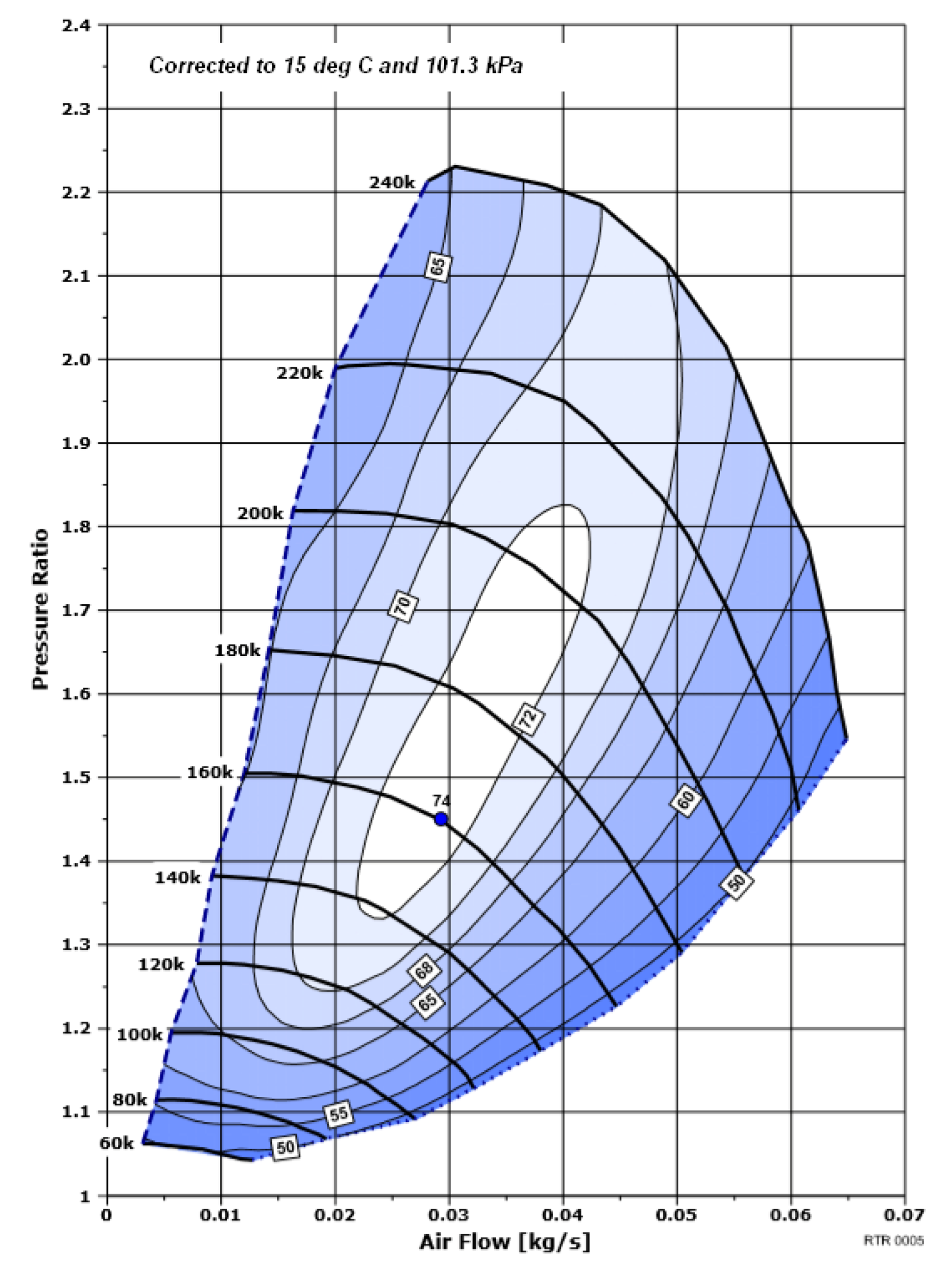

Figure 19.

Performance Map of AISIN AMR300.

Figure 19.

Performance Map of AISIN AMR300.

Figure 20.

Performance Map of Eaton TVS-R410.

Figure 20.

Performance Map of Eaton TVS-R410.

Figure 21.

Performance Map of Rotrex C8-8.

Figure 21.

Performance Map of Rotrex C8-8.

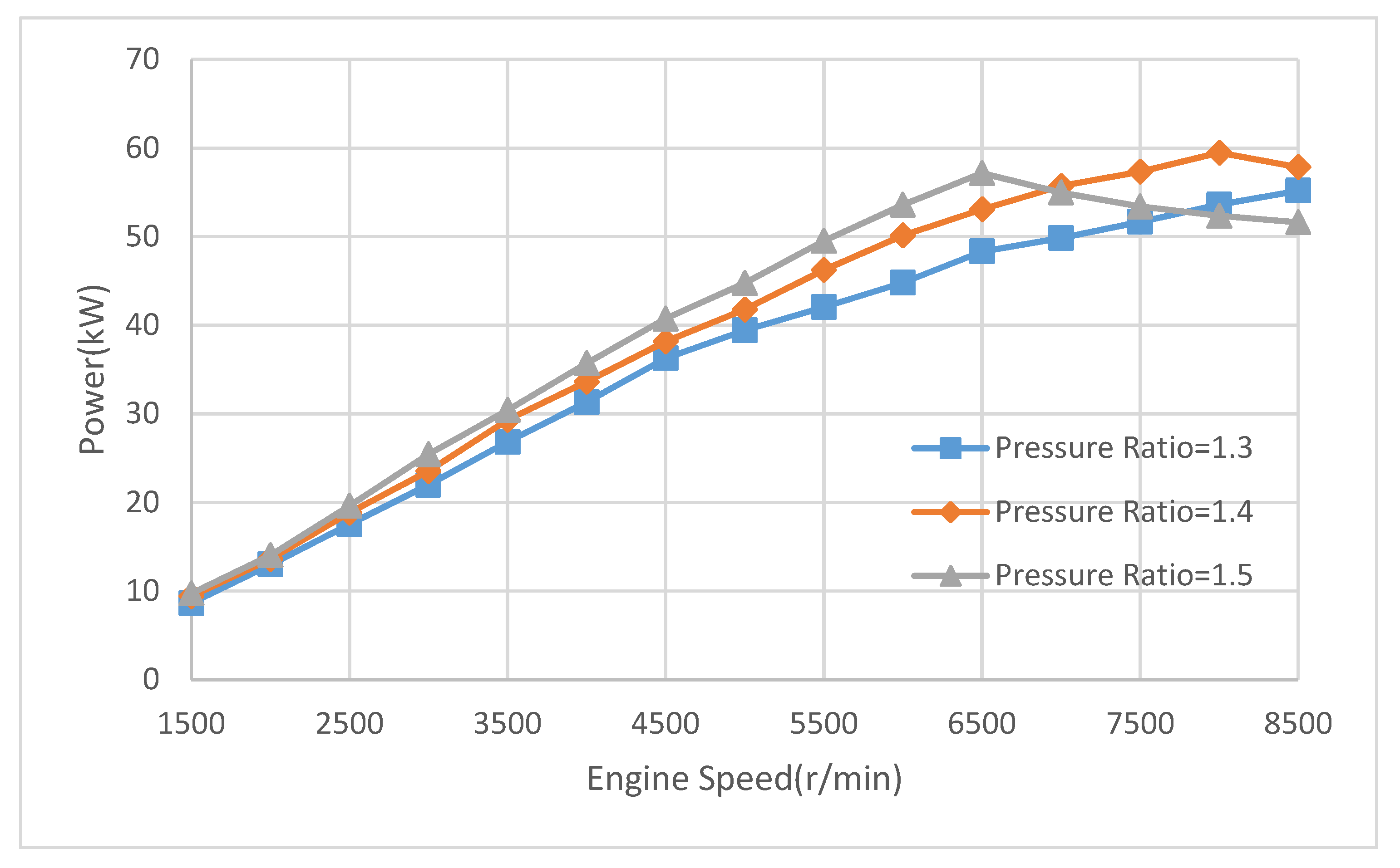

Figure 22.

Full Load Power with Different Pressure Ratio.

Figure 22.

Full Load Power with Different Pressure Ratio.

Figure 23.

Full Load Torque with Different Pressure Ratio.

Figure 23.

Full Load Torque with Different Pressure Ratio.

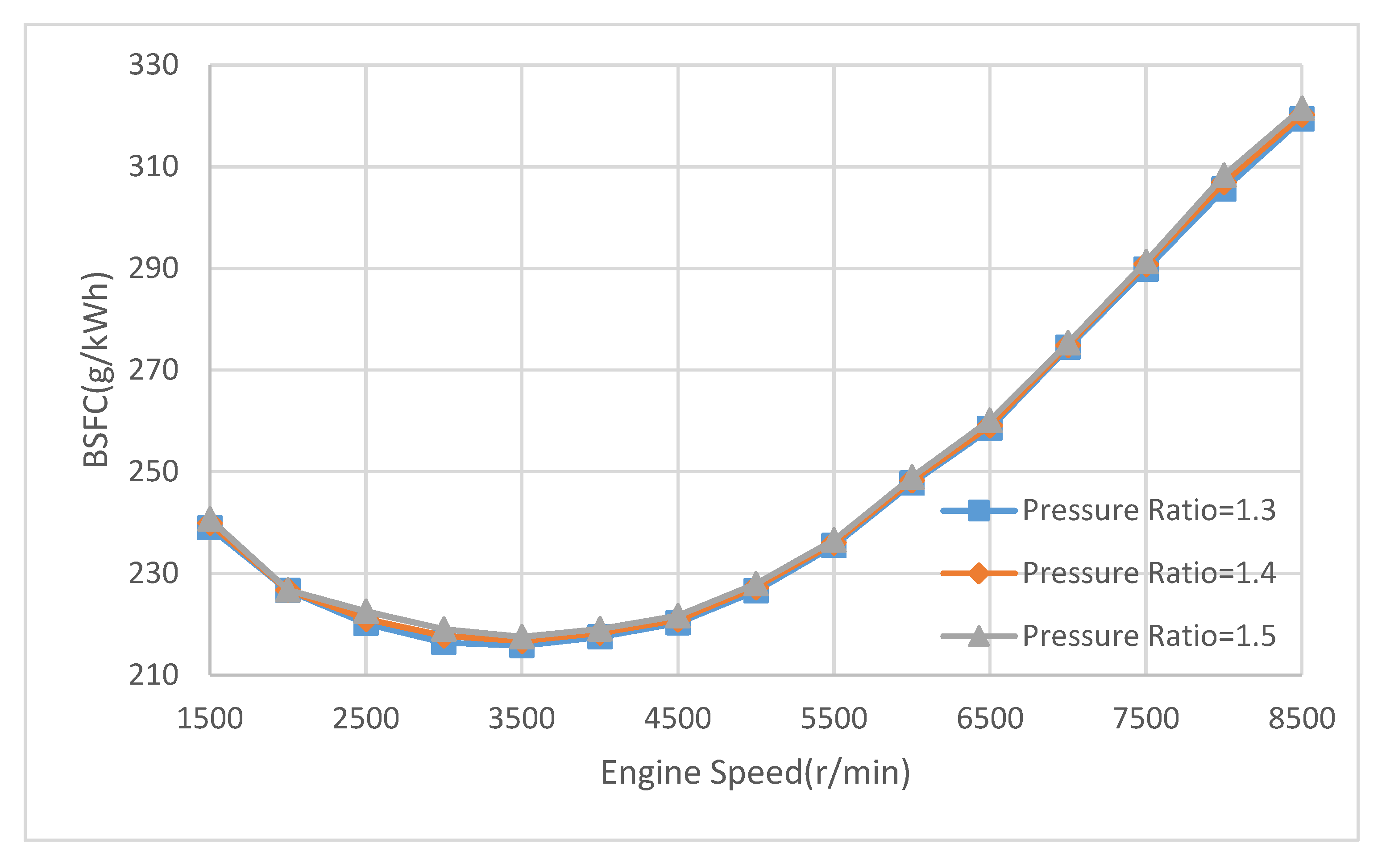

Figure 24.

Full Load Brake Specific Fuel Consumption (BSFC) with Different Pressure Ratio.

Figure 24.

Full Load Brake Specific Fuel Consumption (BSFC) with Different Pressure Ratio.

Figure 25.

The Layout of Intake System ruled by Formula Student.

Figure 25.

The Layout of Intake System ruled by Formula Student.

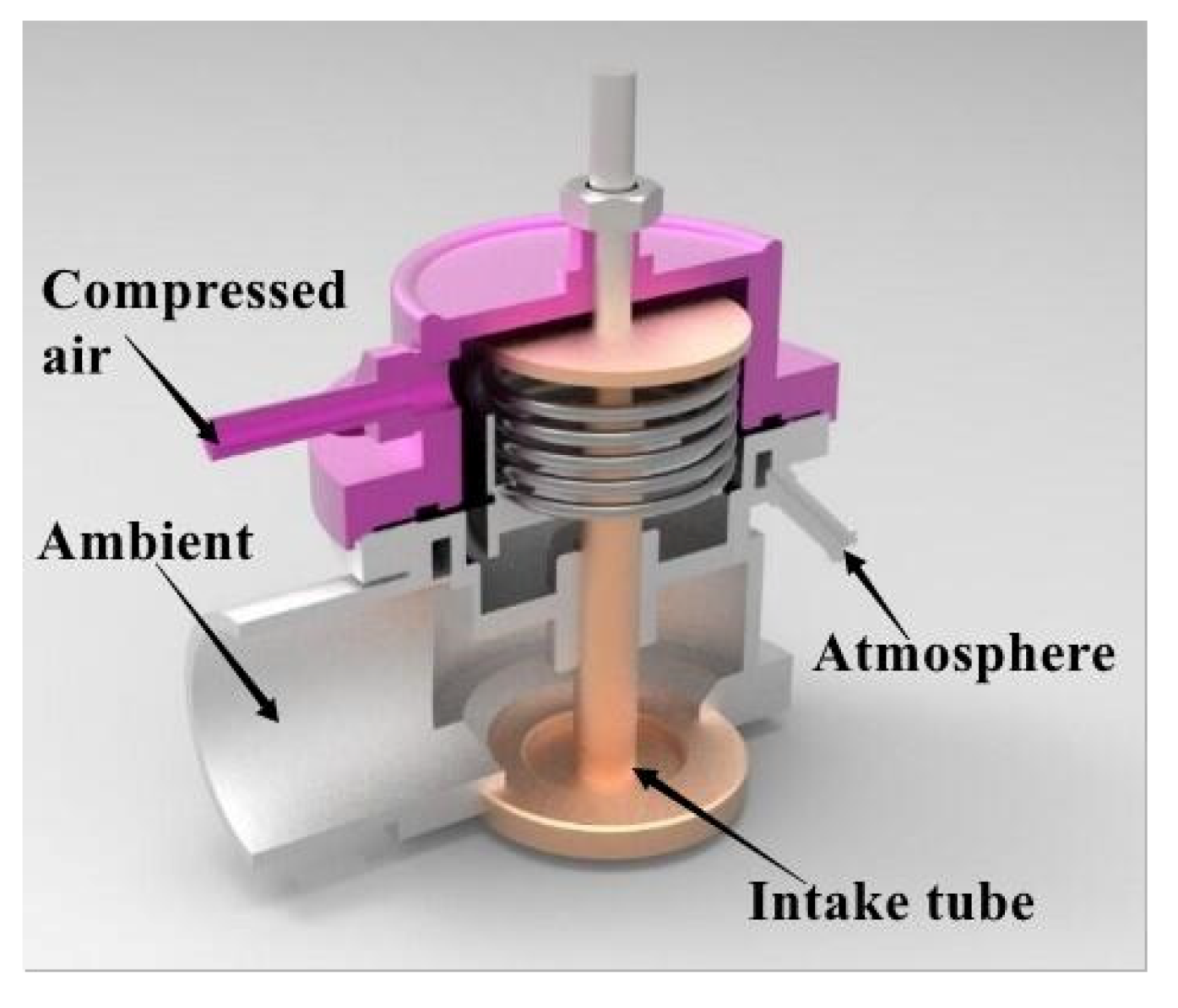

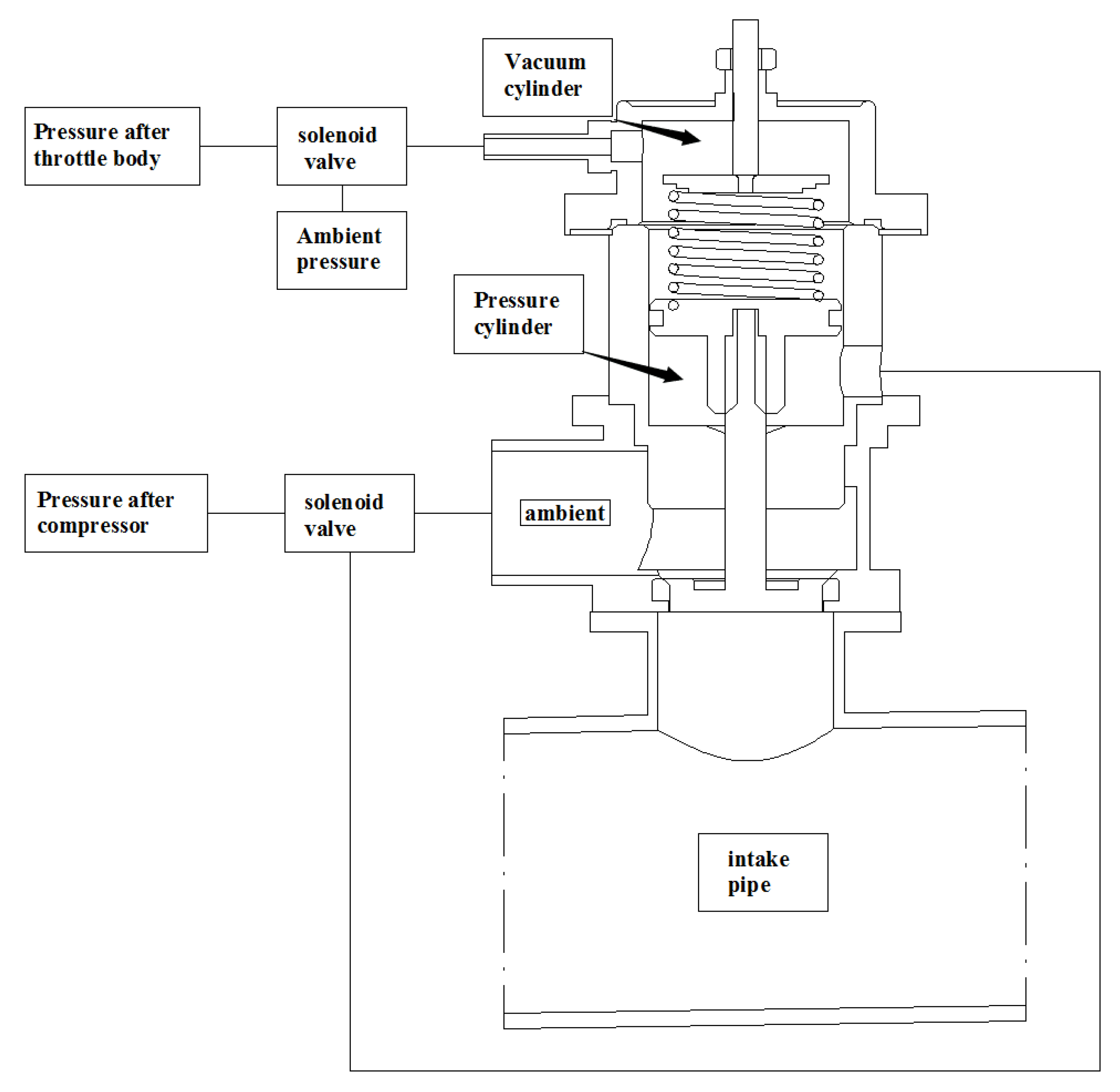

Figure 26.

Typical intake blow-off valve sectional structure diagram.

Figure 26.

Typical intake blow-off valve sectional structure diagram.

Figure 27.

New Blow-off Valve and ‘Dual-line and dual-solenoid’ Pneumatic Connection.

Figure 27.

New Blow-off Valve and ‘Dual-line and dual-solenoid’ Pneumatic Connection.

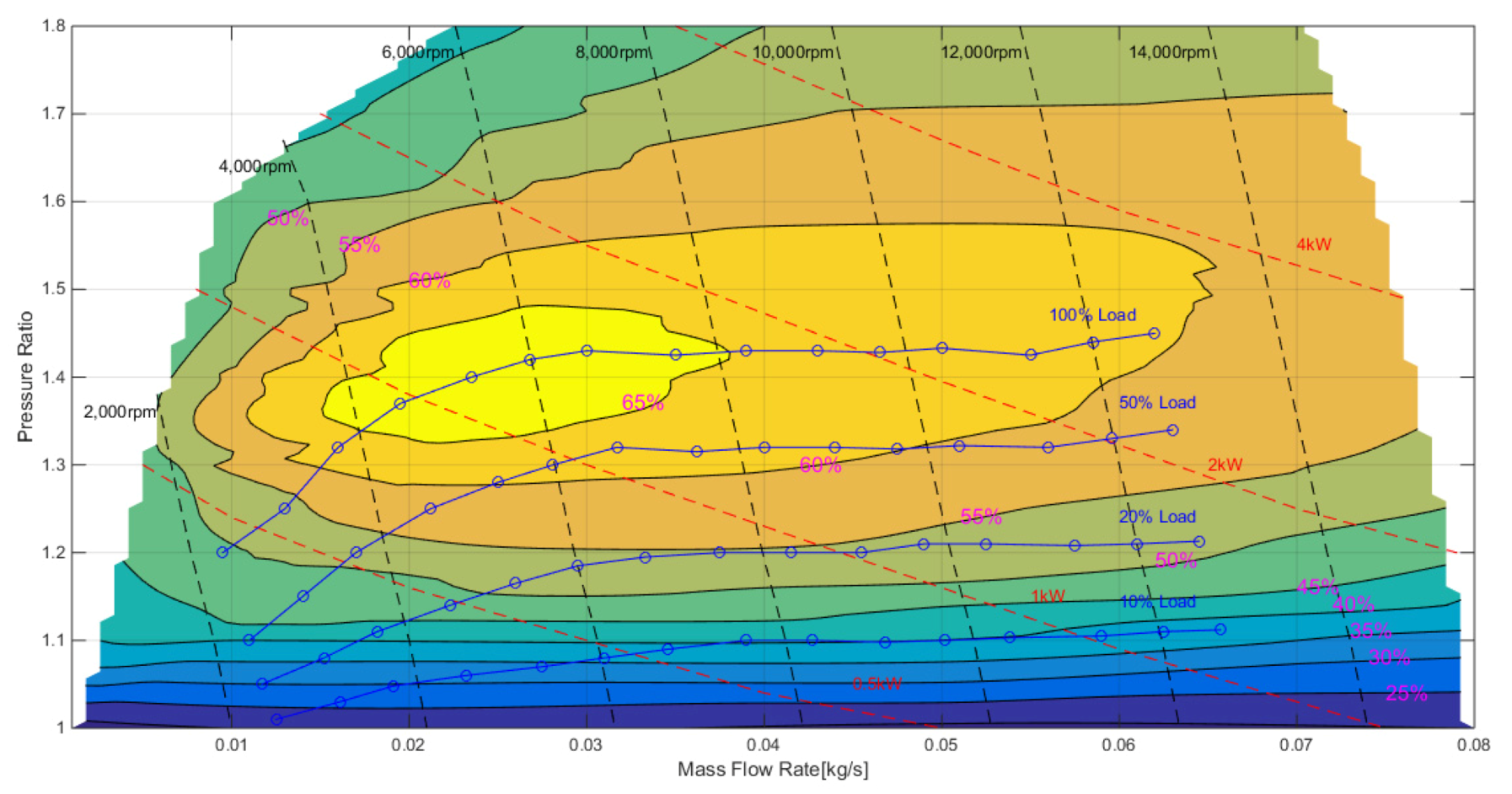

Figure 28.

Supercharger Condition Path-line under Different Load and Compressor Speed.

Figure 28.

Supercharger Condition Path-line under Different Load and Compressor Speed.

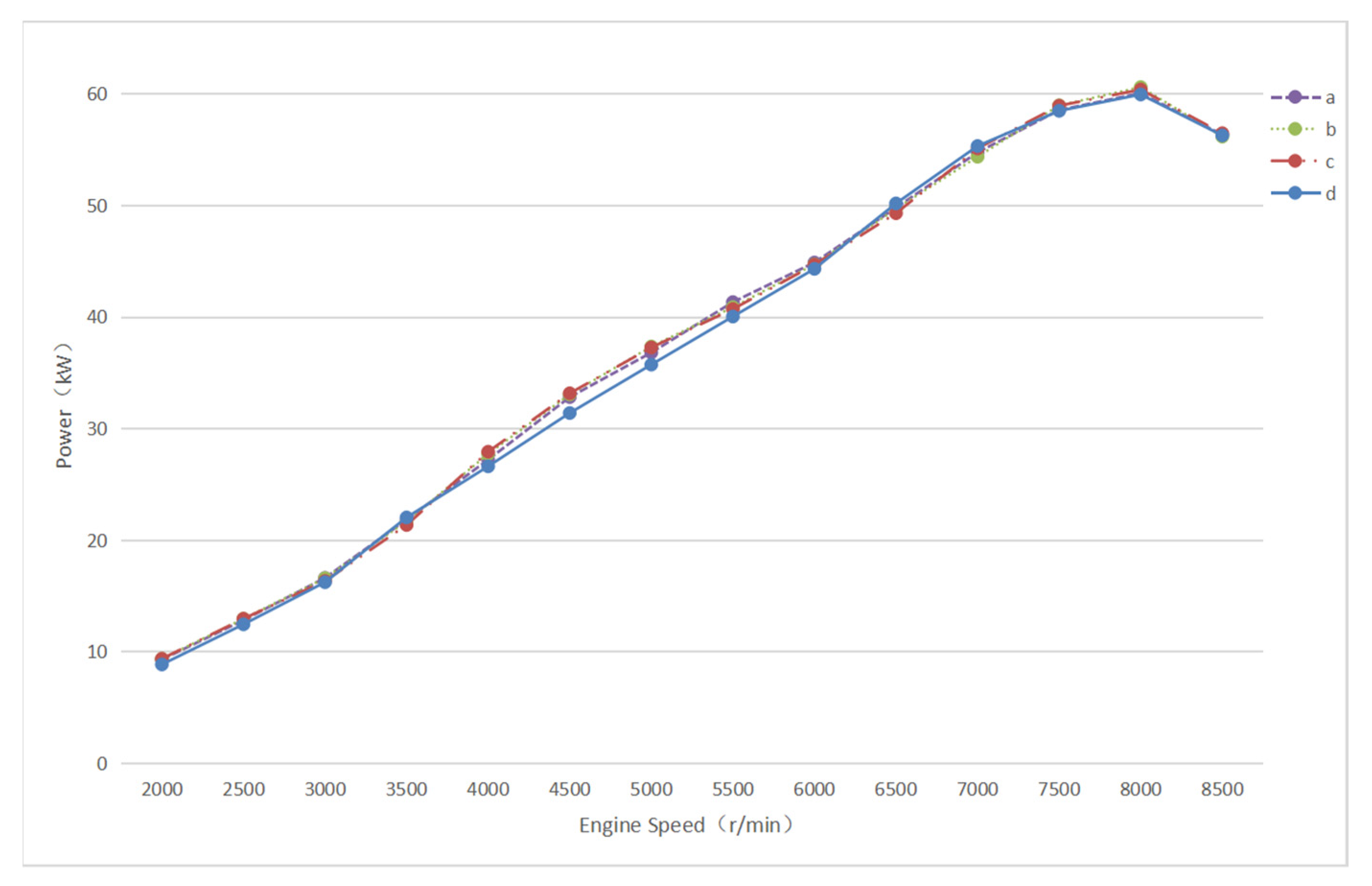

Figure 29.

Power Output of Different Volume after Throttle.

Figure 29.

Power Output of Different Volume after Throttle.

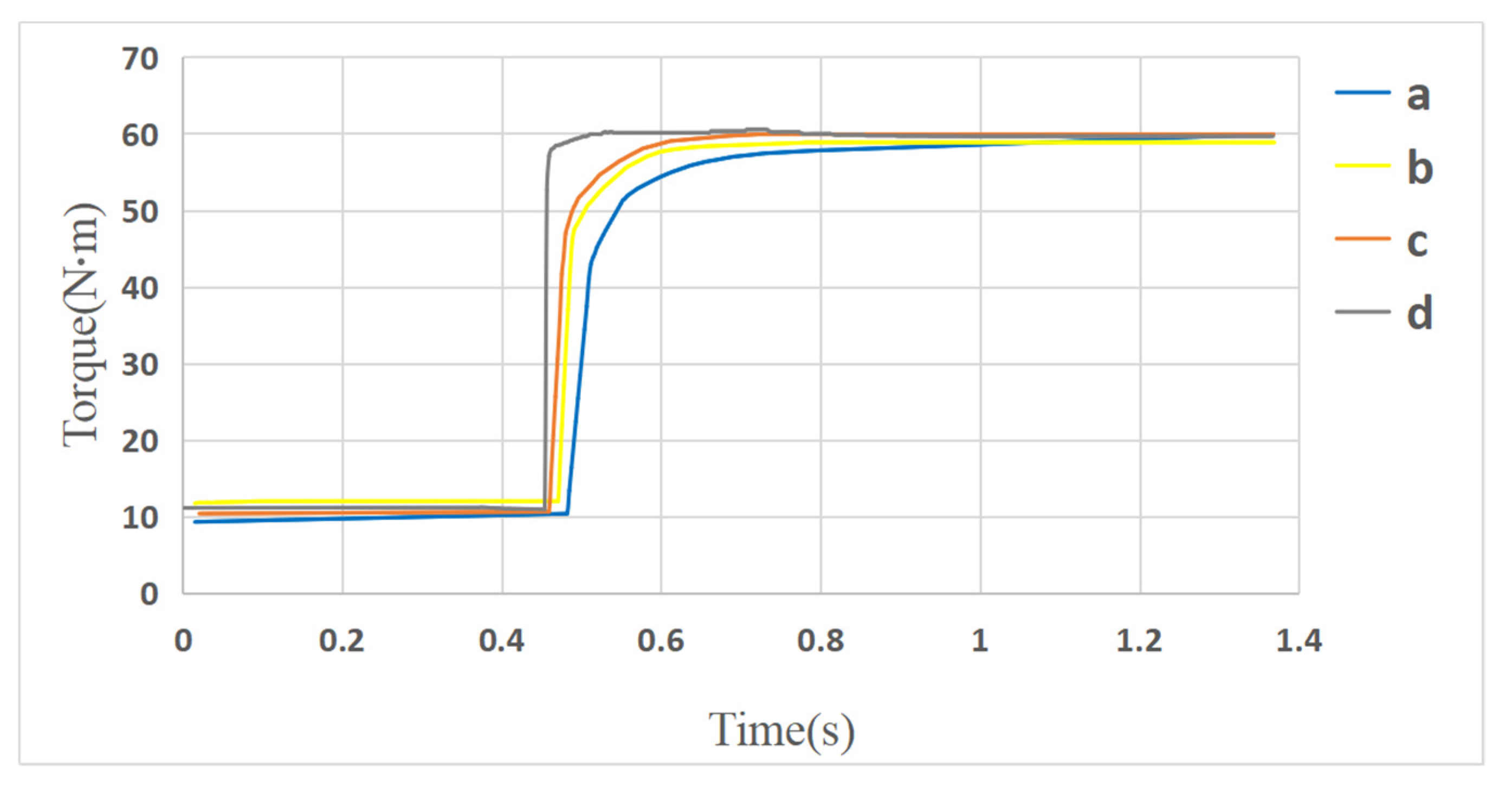

Figure 30.

Torque Response of Different Volume after Throttle (3000 r/min, Throttle Tip-in).

Figure 30.

Torque Response of Different Volume after Throttle (3000 r/min, Throttle Tip-in).

Figure 31.

Power of Different Pipe Lengths before Throttle.

Figure 31.

Power of Different Pipe Lengths before Throttle.

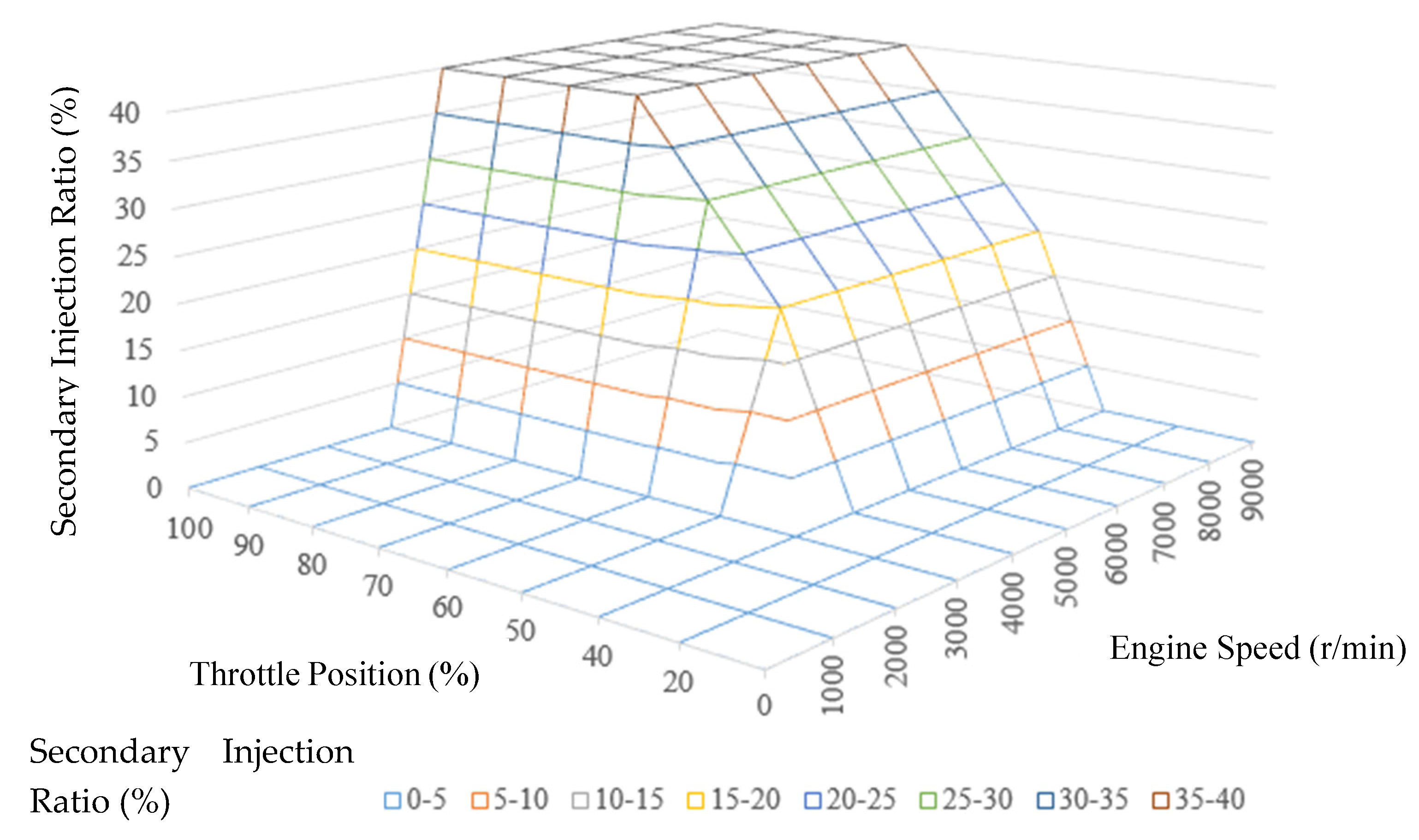

Figure 32.

Injection Ratio of Secondary Fuel Injector.

Figure 32.

Injection Ratio of Secondary Fuel Injector.

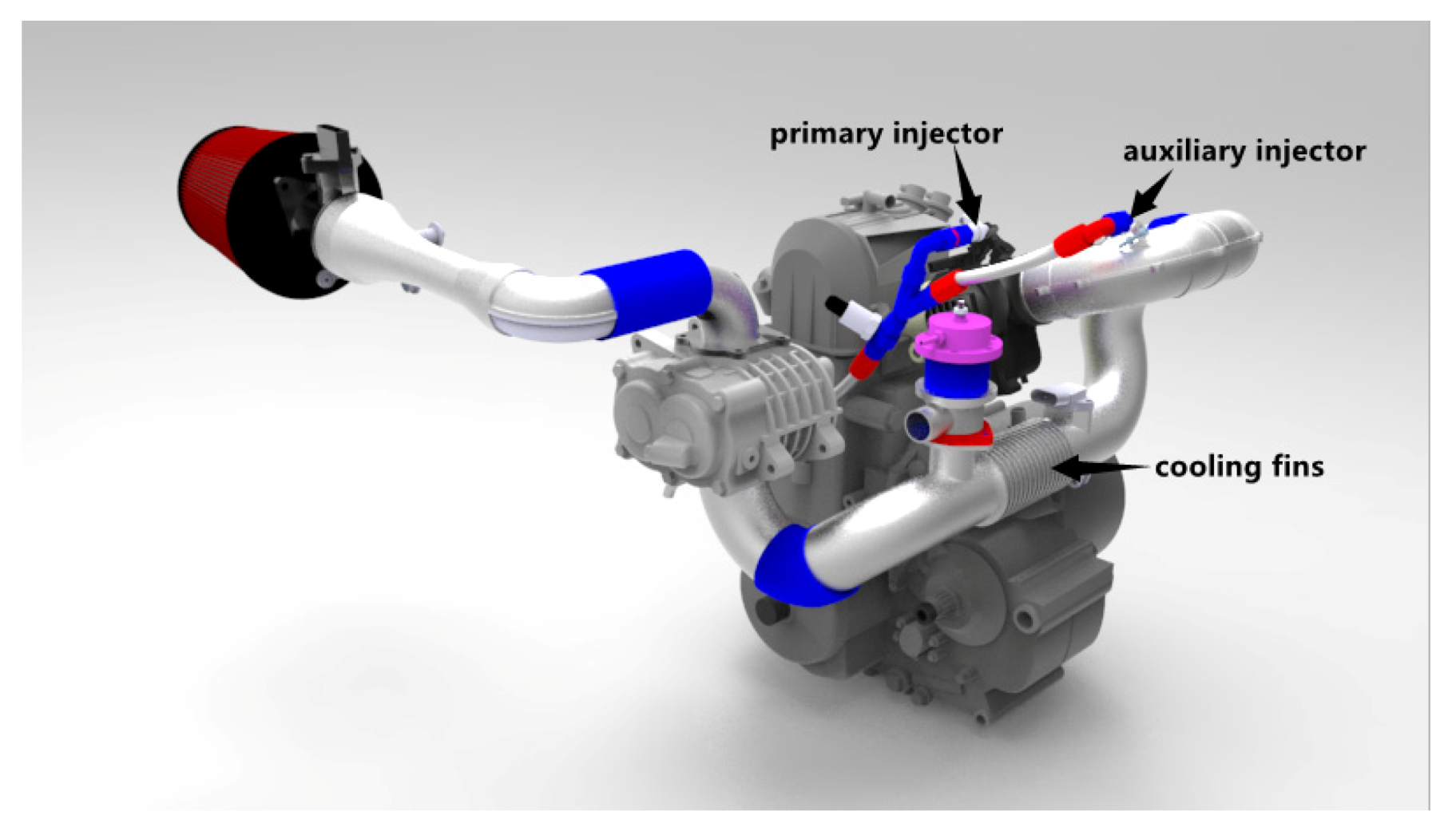

Figure 33.

Final Design of Intake System.

Figure 33.

Final Design of Intake System.

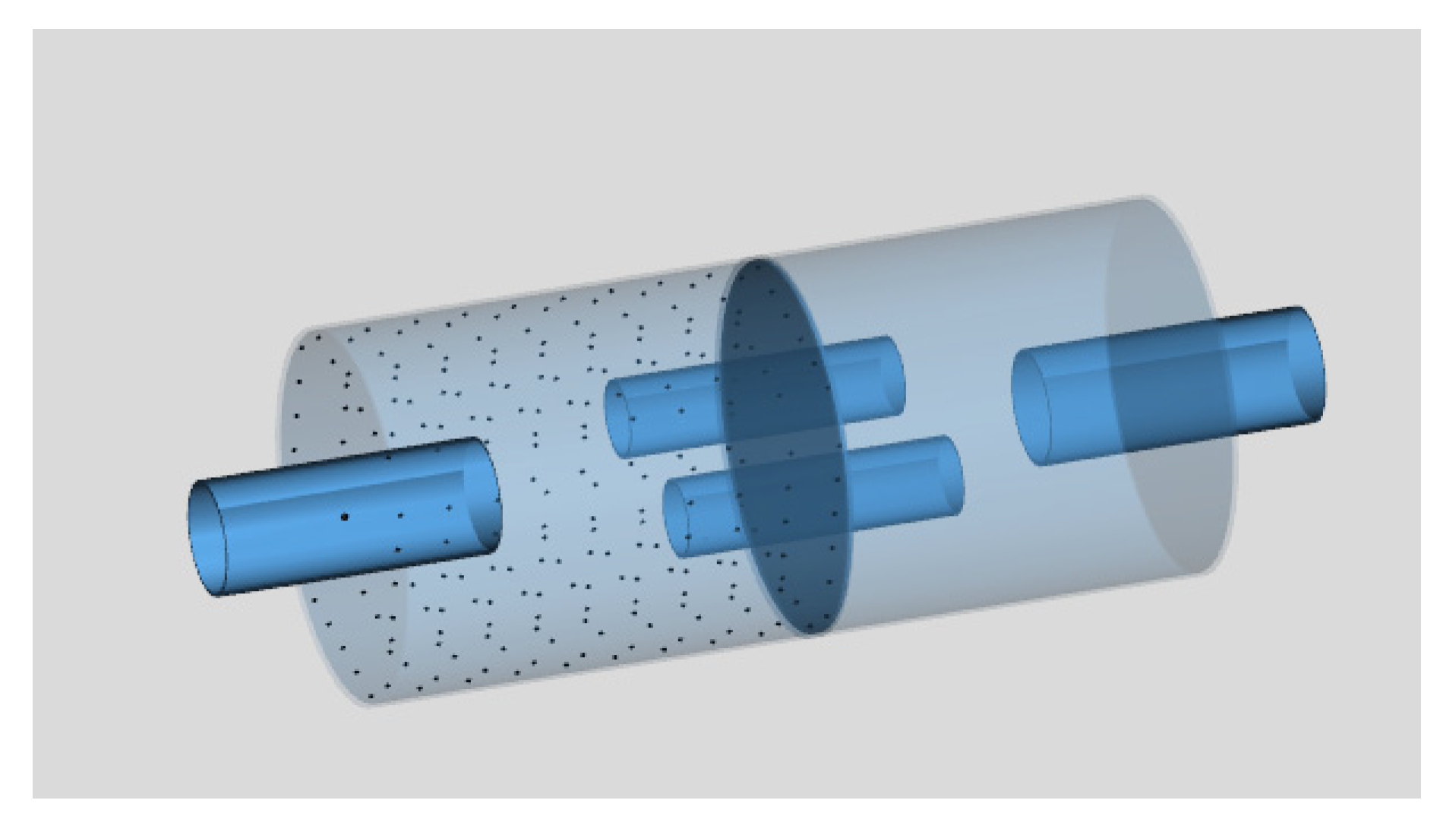

Figure 34.

Initial Structure of Main Muffler.

Figure 34.

Initial Structure of Main Muffler.

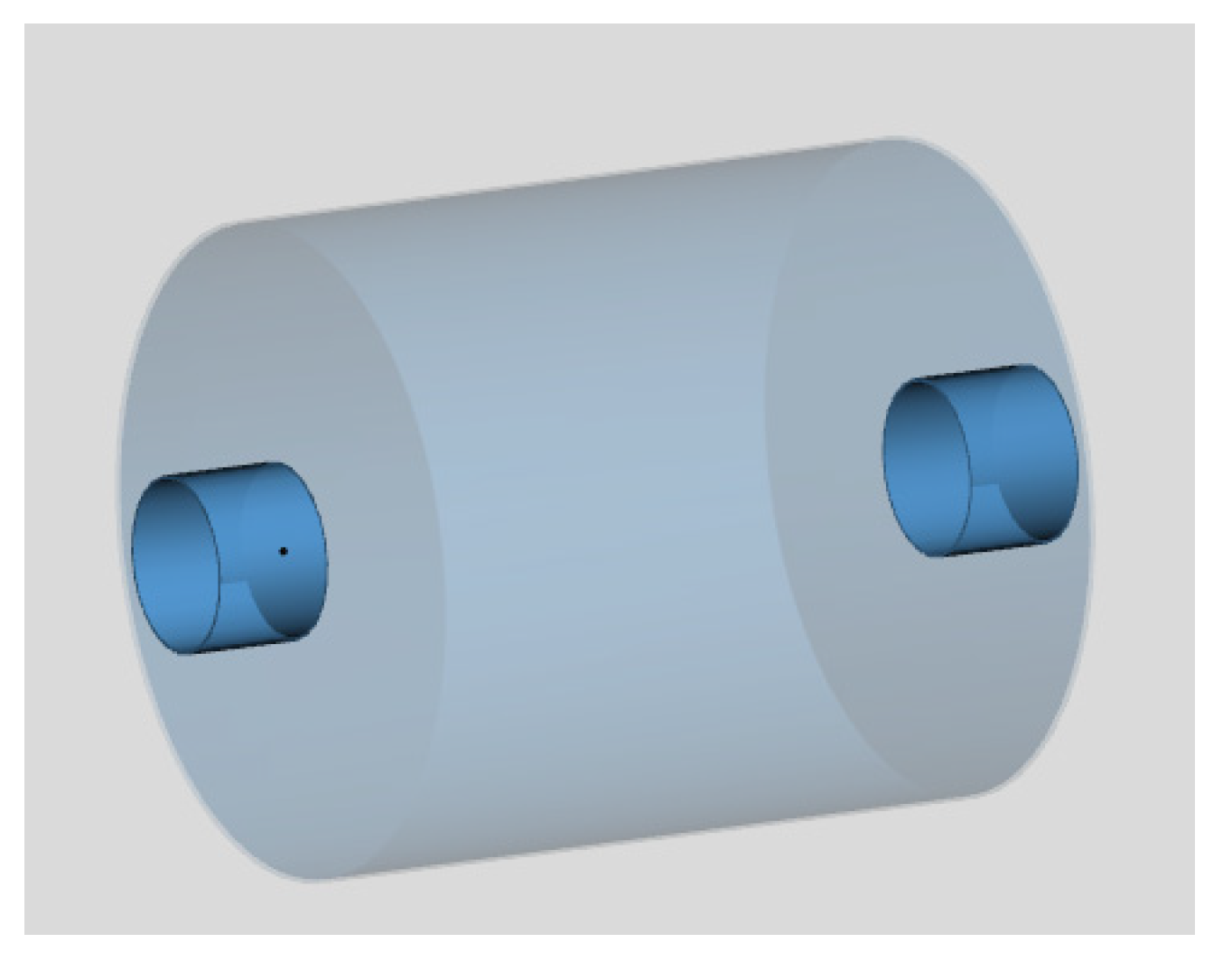

Figure 35.

Initial Structure of Expansion Chamber.

Figure 35.

Initial Structure of Expansion Chamber.

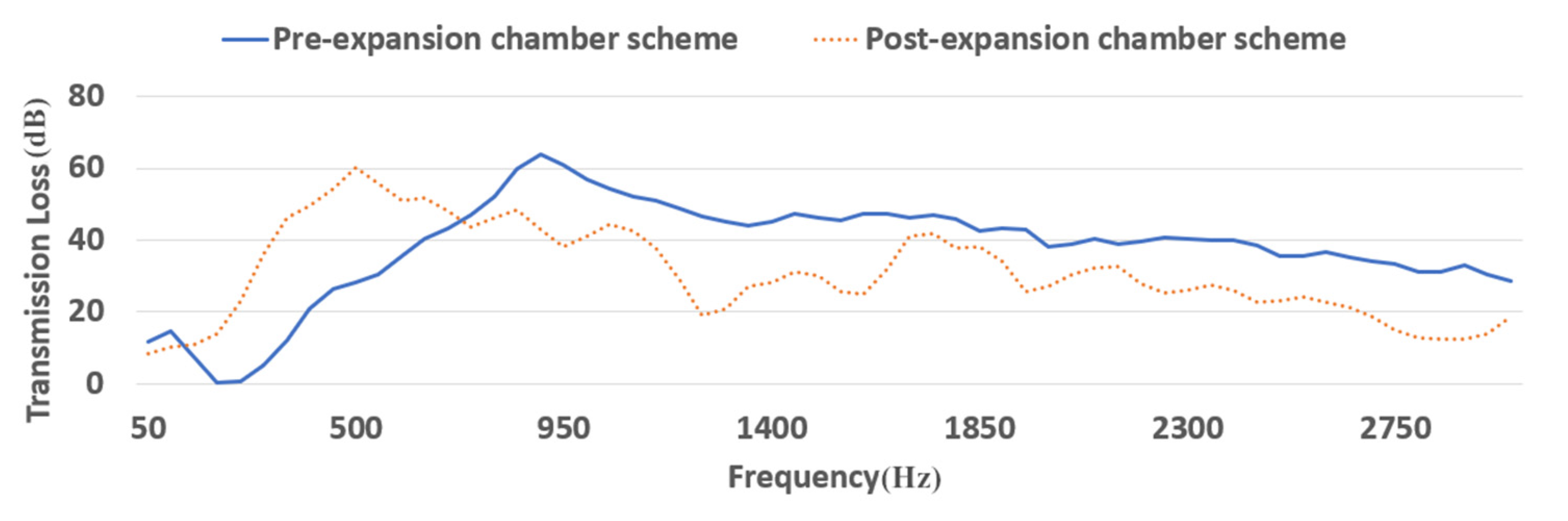

Figure 36.

Transmission Loss of Different Sequence of Expansion Chamber and Main Muffler.

Figure 36.

Transmission Loss of Different Sequence of Expansion Chamber and Main Muffler.

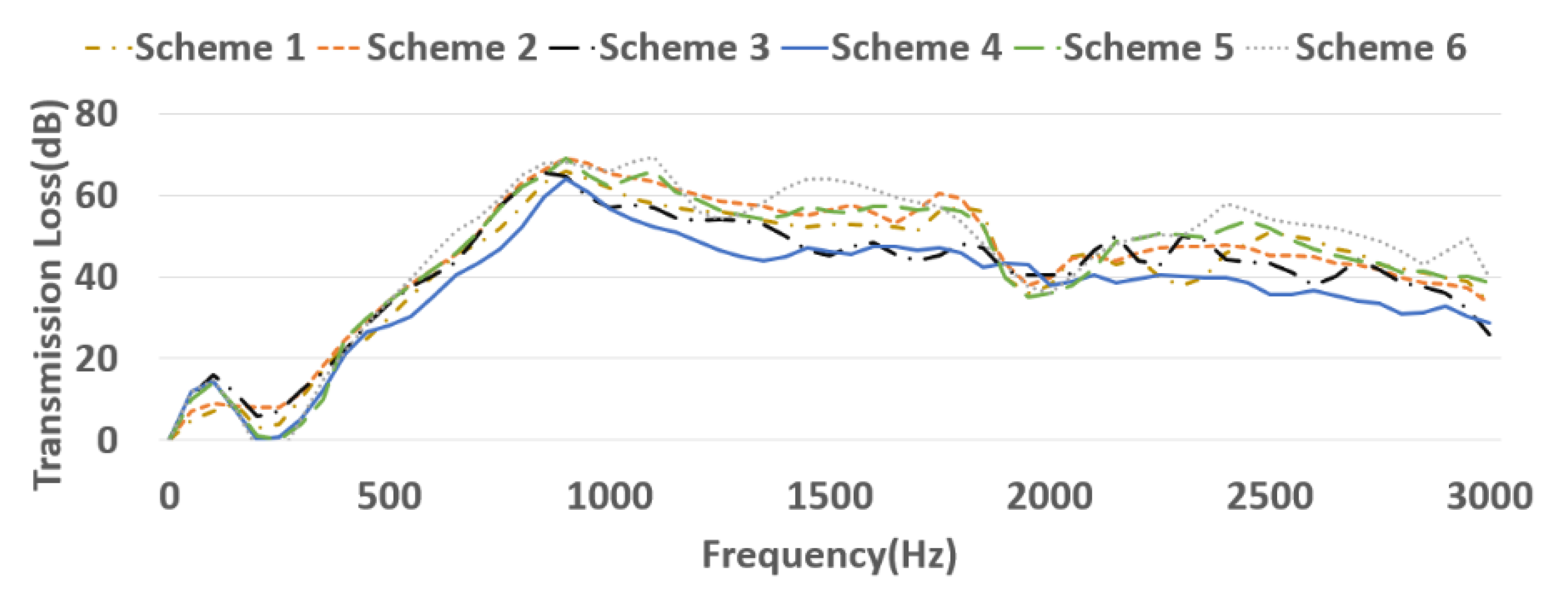

Figure 37.

Noise Transmission Loss of Different Schemes.

Figure 37.

Noise Transmission Loss of Different Schemes.

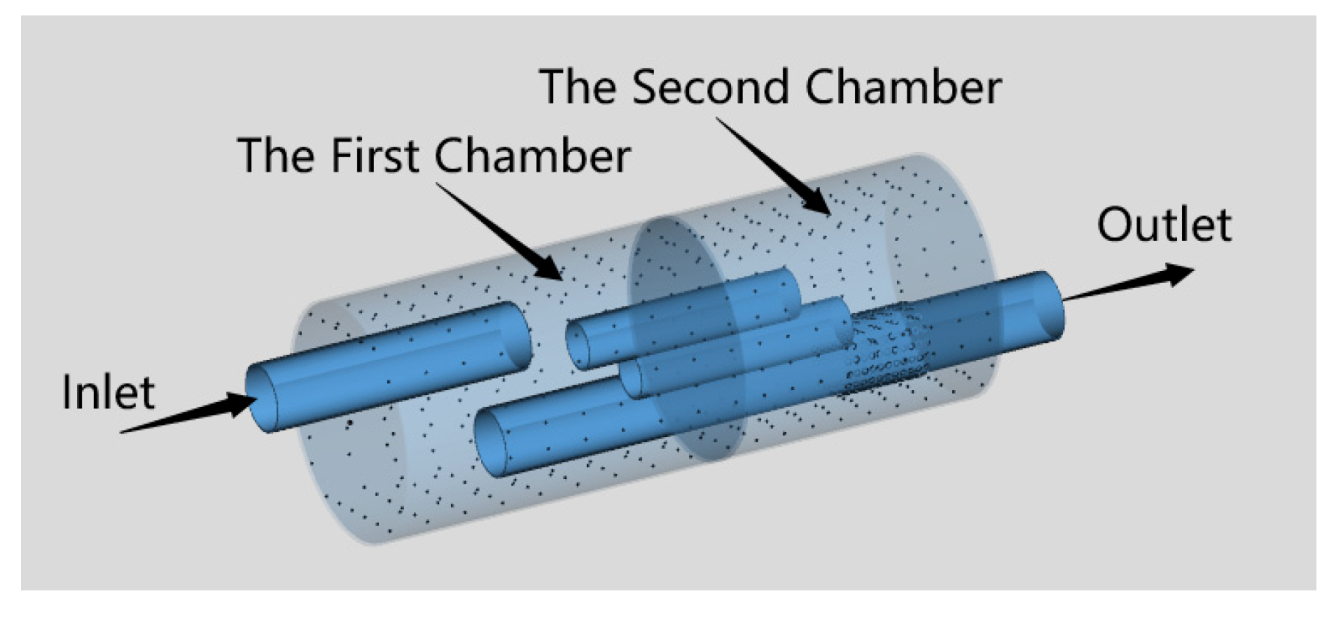

Figure 38.

Schematic Diagram of Main Muffler Structure Optimisation.

Figure 38.

Schematic Diagram of Main Muffler Structure Optimisation.

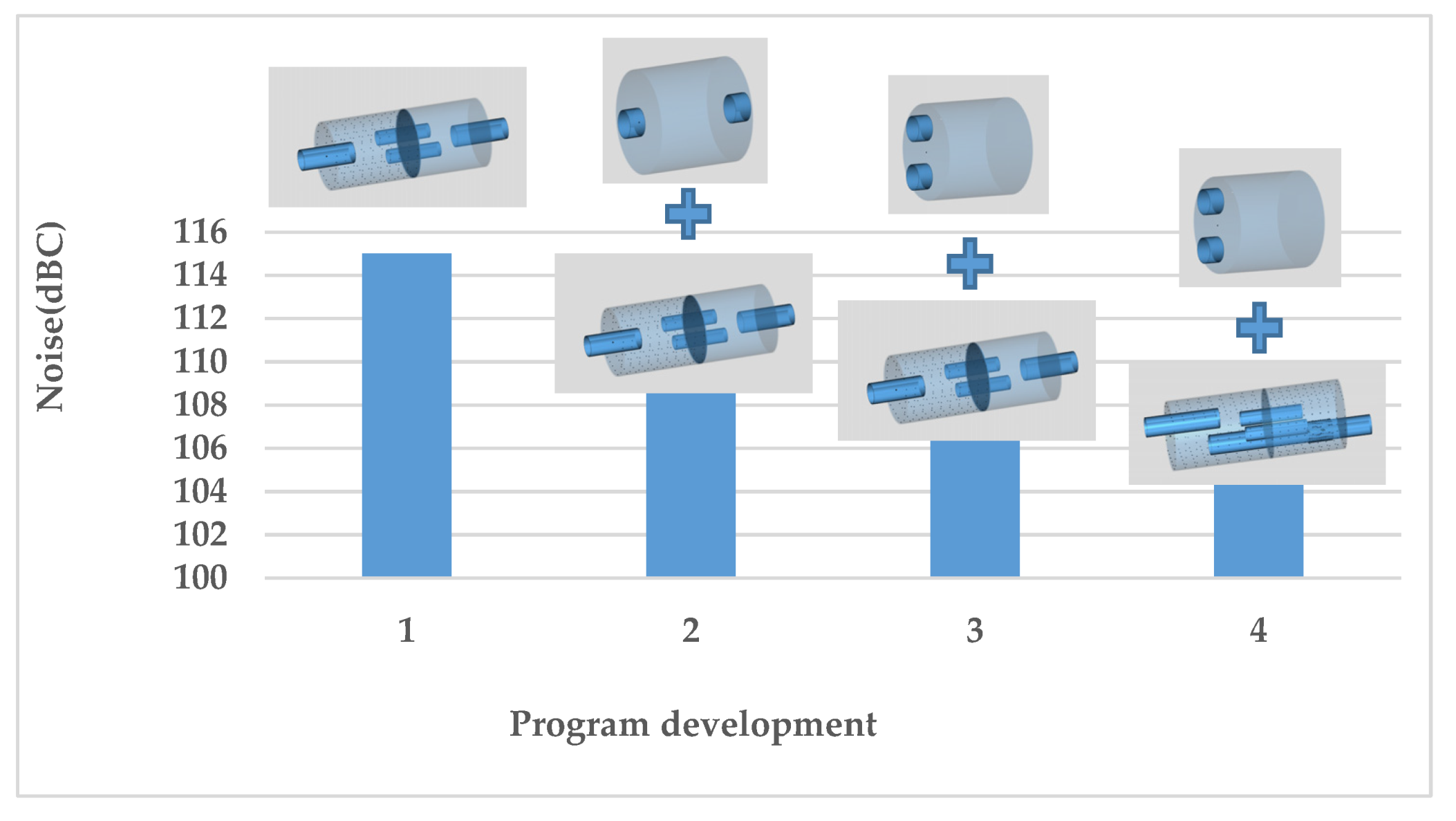

Figure 39.

Evolution of the Exhaust System Design.

Figure 39.

Evolution of the Exhaust System Design.

Figure 40.

Final Structure Diagram of the Exhaust System.

Figure 40.

Final Structure Diagram of the Exhaust System.

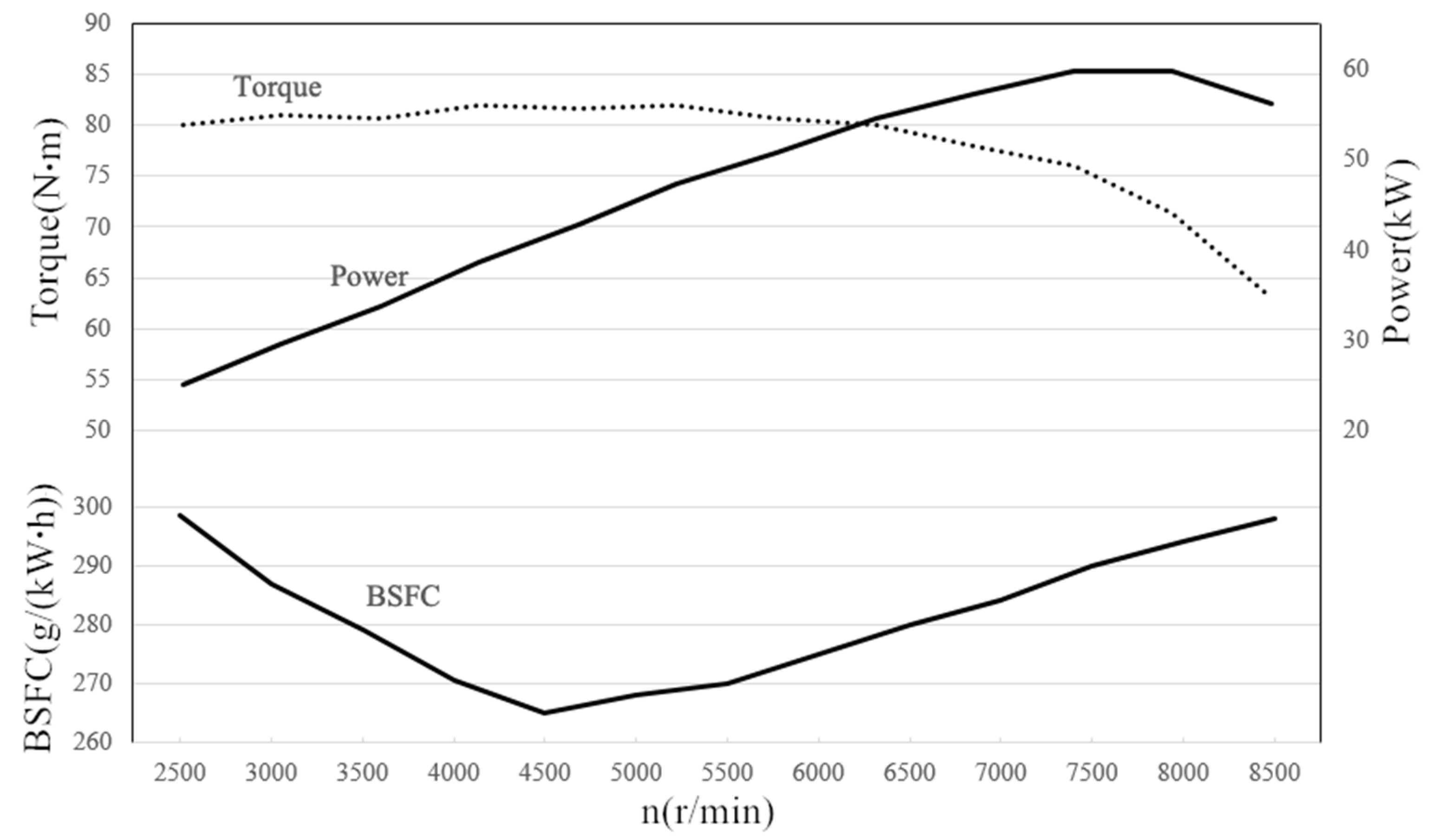

Figure 41.

Performance of the Developed Engine (Full Load).

Figure 41.

Performance of the Developed Engine (Full Load).

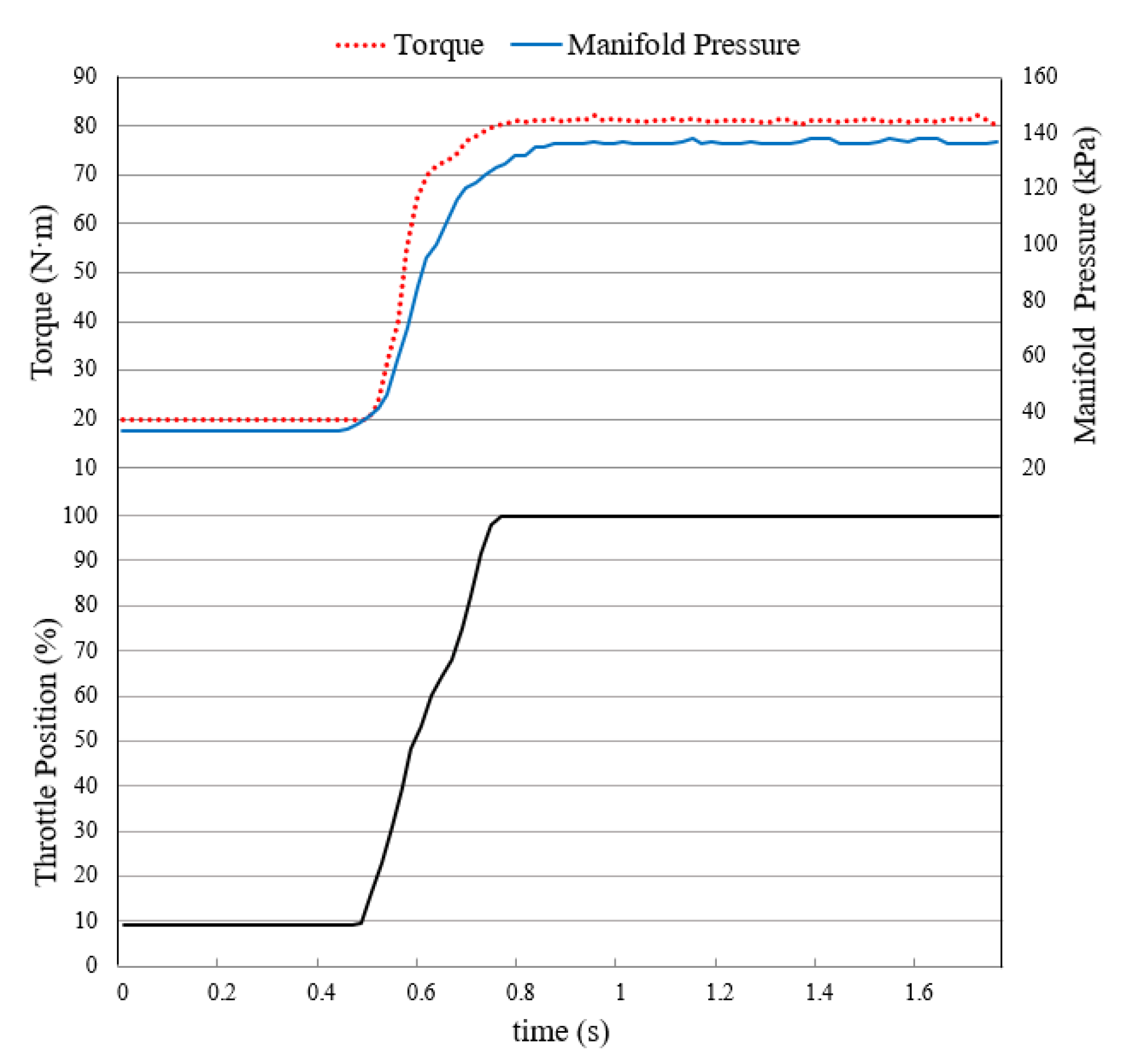

Figure 42.

Torque Response Curve under Tip-in Throttle Input (690mL Supercharged Engine).

Figure 42.

Torque Response Curve under Tip-in Throttle Input (690mL Supercharged Engine).

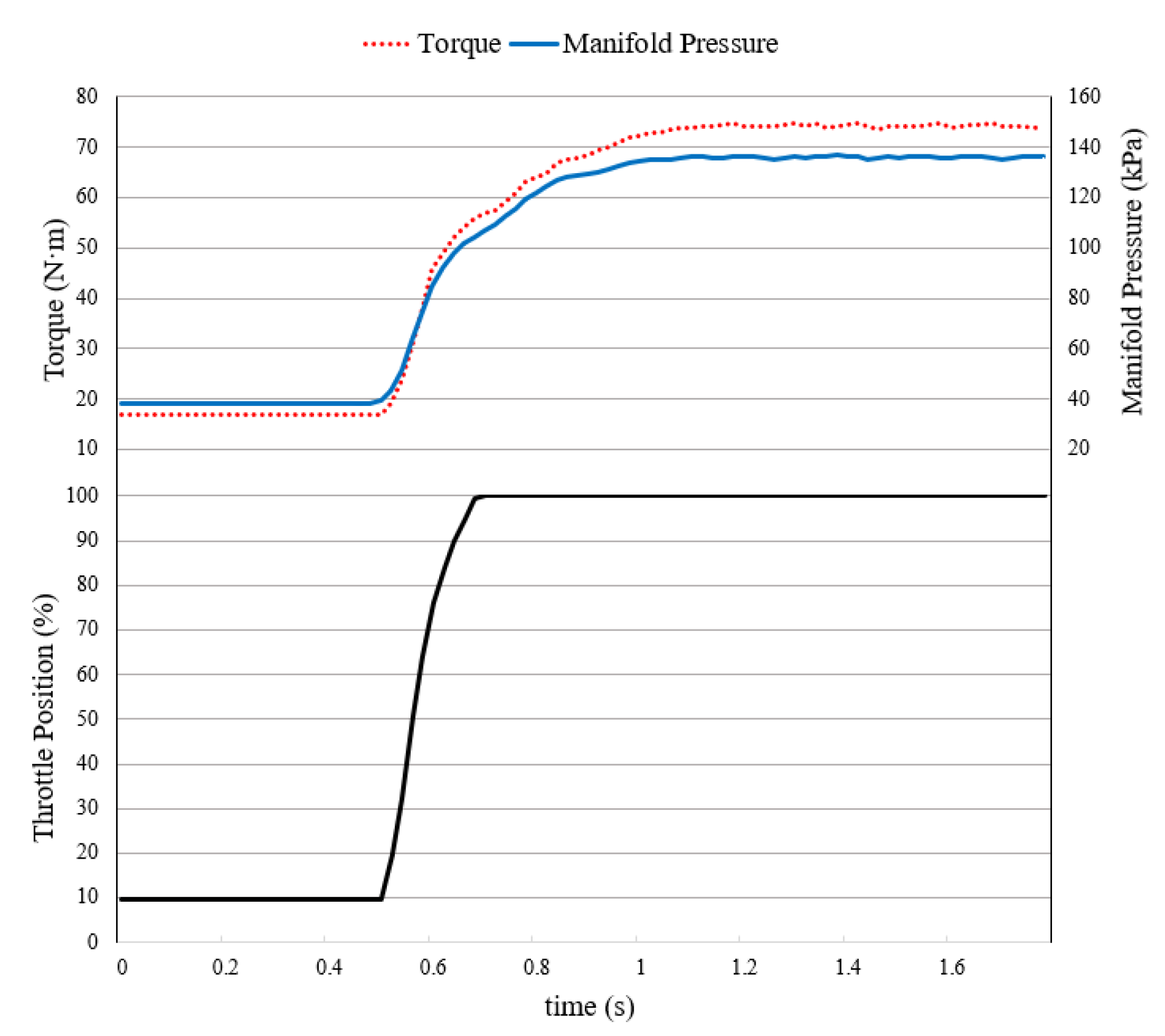

Figure 43.

Torque Response Curve under Tip-in Throttle Input (600mL Turbocharged Engine).

Figure 43.

Torque Response Curve under Tip-in Throttle Input (600mL Turbocharged Engine).

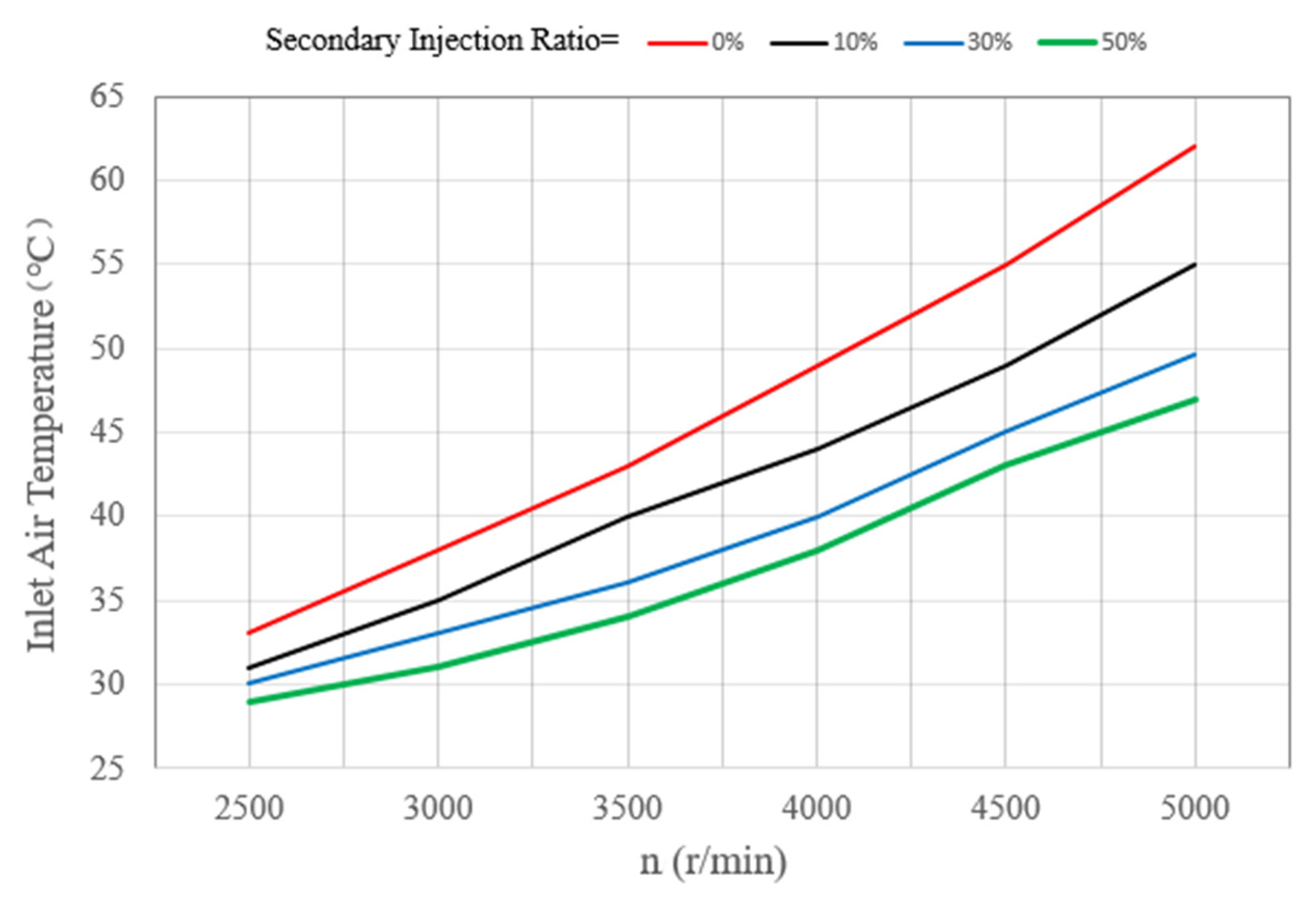

Figure 44.

Intake Air Temperature of Different Secondary Injection Ratio at Full Load.

Figure 44.

Intake Air Temperature of Different Secondary Injection Ratio at Full Load.

Figure 45.

Speed and Longitudinal Acceleration in an Acceleration Test.

Figure 45.

Speed and Longitudinal Acceleration in an Acceleration Test.

Figure 46.

Gspeed Racecar in Acceleration Event of FSG 2019.

Figure 46.

Gspeed Racecar in Acceleration Event of FSG 2019.

Figure 47.

Layout of Expansion Chamber and Main Muffler.

Figure 47.

Layout of Expansion Chamber and Main Muffler.

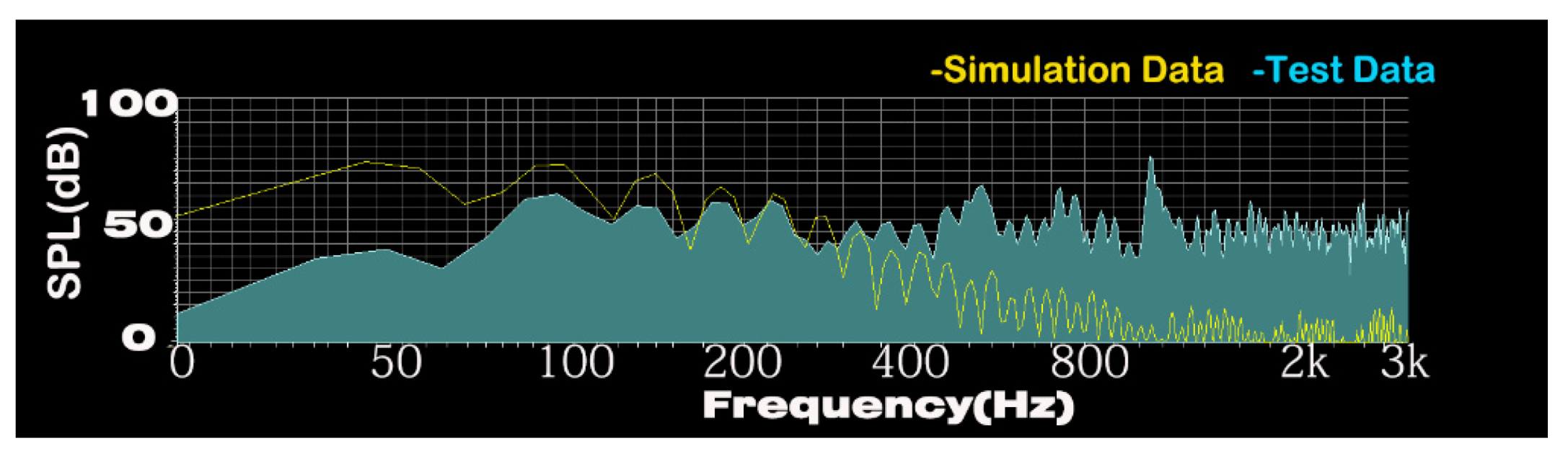

Figure 48.

Comparison of the Spectrum of Simulation and Testing.

Figure 48.

Comparison of the Spectrum of Simulation and Testing.

Figure 49.

Schematic Diagram of the Testing Track.

Figure 49.

Schematic Diagram of the Testing Track.

Figure 50.

Fastest Lap Comparison of Gspeed-2017 and Gspeed-2018 Racecars.

Figure 50.

Fastest Lap Comparison of Gspeed-2017 and Gspeed-2018 Racecars.

Table 1.

Typical performance parameters.

Table 1.

Typical performance parameters.

| Engine | HONDA CBR600F (PC41E) |

| Engine displacement/mL | 599 |

| Compression ratio | 12.2 |

| Intake Method | Turbocharging |

| Bore × stroke/mm | 67 × 42.5 |

| Maximum Intake Pressure/kPa | 165 |

| Maximum Power/kW | 70@9000~10,500 r/min |

| Maximum Torque/Nm | 75@4000~8500 r/min |

| Cooling System | Electronic Coolant Pump |

| lubrication System | Dry-sump |

Table 2.

Technical Parameters of KTM 690 Duke Engine.

Table 2.

Technical Parameters of KTM 690 Duke Engine.

| Engine model | KTM 690 Duke LC4 |

| Number of cylinders | 1 |

| Displacement/mL | 690 |

| Compression Ratio | 12.6:1 |

| Bore/mm | 102 |

| Stroke/mm | 84.5 |

| Valve-train Configuration | SOHC |

| Stock Maximum Power/kW | 48@8000 r/min |

| Stock Maximum Torque/Nm | 70@6500 r/min |

| Number of Spark Plugs | 2 |

Table 3.

Specifications of Gspeed-2018 Racecar.

Table 3.

Specifications of Gspeed-2018 Racecar.

| Frame | Steel Tube Frame |

| Drive Type | FR |

| Total Length (mm) | 2930 |

| Total Width (mm) | 1461 |

| Total Height (mm) | 1190 |

| Wheelbase (mm) | 1590 |

| Wheel Track [front/rear] (mm) | 1220/1180 |

| Curb Weight (kg) | 206 |

| Sprung Weight (kg) | 229.71 |

| Axle Weight Distribution [Front/Rear] (%) | 45:55 |

| Suspension Type | Double-wishbone Independent Suspension with Anti-roll Bar and Heaven-spring |

| Engine | Supercharged KTM690 DUKE |

| Maximum Power (kW) | 60/8000–8500 rpm |

| Maximum Torque (Nm) | 82/2500–6000 rpm |

| Tire | Hoosier 18 × 7.5−10 R25B |

| Differential | Clutch-type Limited Slip Differential |

| Steering Geometry | 90% Positive Ackerman Geometry |

| Suspension Wheel Rate (Frame to Wheel Center) [Front/Rear] (N/mm) | 45.76/52.28 |

| Suspension Roll Rate (Frame to Wheel Center) [Front/Rear] (Nm/deg) | 514.66/569.46 |

| Aerodynamic Coefficient of Lift/Drag | −2.25/1.29 |

Table 4.

Different Powertrains Configuration of Formula Student

Table 4.

Different Powertrains Configuration of Formula Student

| Configuration | Maximum Power | System Weight |

|---|

| 1-Cyl. Supercharged | 60 kW | 62 kg |

| 1-Cyl. NA | 44 kW | 47 kg |

| 4-Cyl. Turbocharged | 68 kW | 85 kg |

| 4-Cyl. NA | 59 kW | 77 kg |

Table 5.

Simulation Results and Normalised Scores of Different Powertrain Configuration.

Table 5.

Simulation Results and Normalised Scores of Different Powertrain Configuration.

| Event | 1-Cyl. Supercharged | 1-Cyl. NA | 4-Cyl. Turbocharged | 4-Cyl. NA |

|---|

| Acceleration(s) | 3.96 | 4.21 | 4.00 | 4.16 |

| Ski-pad(s) | 4.78 | 4.73 | 5.09 | 4.88 |

| Autocross(s) | 57.59 | 59.20 | 58.12 | 58.67 |

| Endurance(s) | 81.32 | 81.59 | 82.00 | 82.59 |

| Normalised Scoring | 570.86 | 545.30 | 531.44 | 525.408 |

Table 6.

Specification of Supercharger Characteristic Test Bench.

Table 6.

Specification of Supercharger Characteristic Test Bench.

| Instruments and Equipment | Model | Characteristic |

|---|

| Brushless DC motor | OK100-72V5.0 | Rated voltage 72 V; rated speed 2800 r/min; rated/peak power (kW) 5/10; rated/peak torque (nm) 16/56; rated current 76a; efficiency 92% |

| Dynamic torque sensor | DYN-200 | Range 0–20 nm; power input DC24V; torque output (±5VDC; 0–10 V; 4–20 mA) |

| Supercharger | AMR300 | Displacement: 300 mL; weight: 2.9 kg; roots supercharger |

| Intake air temperature pressure sensor | Bosch HFM5 | Power input DC5V; signal output is voltage output |

| Vortex Flowmeter | DN65 | Power input DC12V; output signal (square wave pulse: high level ≥ 5 V; low level ≤ 1 V); current 4–20 mA; accuracy ± 1% R |

Table 7.

Engine Performance Test Bench Sensors.

Table 7.

Engine Performance Test Bench Sensors.

| Powertrain integrated sensors | Throttle Angle sensor Throttle Angle backup sensor Crankshaft position sensor Coolant temperature sensor Intake air temperature/pressure sensor Booster temperature/pressure sensor Mass air flow meter Wide band air–fuel ratio sensor Oil pressure sensor

|

| Sensors for test bench only | Atmospheric pressure sensor Atmospheric temperature and humidity sensor Exhaust pressure sensor Exhaust temperature sensor Oil temperature sensor Compressor front pressure sensor

|

Table 8.

Specification of Superchargers.

Table 8.

Specification of Superchargers.

| Model | AISIN AMR300 | Eaton TVS-R410 | Rotrex

C8-8 |

|---|

| Type | Roots | Twin screw | Centrifugal |

| Length × Width × Height/mm | 185 × 170 × 100 | 300 × 145 × 102 | 128 × 91 × 101 |

| Weight/kg | 4.8 | 6.0 | 3.7 (Including lubrication system) |

| Max Speed/r/min | 14,000 | 22,000 | / |

| Max Pressure Ratio | 1.7 | 2.2 | 2.5 |

| Max Mass Flow/g/s | 88 | 180 | 65 |

| Max Efficiency/% | 65 | 66 | 74 |

| Displacement/mL | 300 | 410 | / |

Table 9.

Normalised Scores of Different Superchargers.

Table 9.

Normalised Scores of Different Superchargers.

| Model | AISIN AMR300 | Eaton TVS-R410 | Rotrex

C8-8 |

|---|

| Power | 1 | 1 | 0.8 |

| Torque | 0.9 | 1 | 0.4 |

| Efficiency | 0.7 | 0.8 | 1 |

| Compactness | 0.8 | 0.6 | 1 |

| Lightweight | 0.8 | 0.6 | 1 |

| Cost | 1 | 0.8 | 0.6 |

| Total | 5.2 | 5.0 | 4.8 |

Table 10.

Analysis Results of Different Diffuser Angle of Restrictor.

Table 10.

Analysis Results of Different Diffuser Angle of Restrictor.

| Diffuser Angle | 5° | 6° | 7° |

|---|

| Total length of restrictor (mm) | 207.7 | 184.7 | 168.2 |

| Length of diffuser (mm) | 137.2 | 114.2 | 97.7 |

| Outlet cross-sectional area (mm2) | 1520 | 1520 | 1520 |

| Mass flow (g/s) | 72.74 | 73.18 | 73.07 |

Table 11.

Noise level and Maximum Power of Different Expansion Chamber Scheme.

Table 11.

Noise level and Maximum Power of Different Expansion Chamber Scheme.

| Scheme | Volume & Layout | Idle Noise/dB(C) | Rated Speed Noise/dB(C) | Max Power/kW |

|---|

| 1 | 2.8 L and Same Side | 99.4 | 108.0 | 63.3 |

| 2 | 2.8 L and Opposite Side | 99.3 | 108.0 | 63.3 |

| 3 | 3.6 L and Same Side | 98.7 | 106.9 | 61.1 |

| 4 | 3.6 L and Opposite Side | 98.8 | 107.0 | 61.2 |

| 5 | 4.4 L and Same Side | 98.3 | 106.0 | 60.0 |

| 6 | 4.4 L and Opposite Side | 98.3 | 106.1 | 60.1 |

Table 12.

Noise Level and Maximum Power of Different Outlet Insertion Length.

Table 12.

Noise Level and Maximum Power of Different Outlet Insertion Length.

| Insertion Length/mm | Idle Noise/dB(C) | Rated Speed Noise/dB(C) | Max Power/kW |

|---|

| 50 | 95.7 | 104.9 | 64.6 |

| 75 | 95.6 | 104.7 | 64.5 |

| 100 | 95.4 | 104.5 | 64.3 |

| 120 | 88.9 | 99.8 | 62.8 |

Table 13.

Lap times of Gspeed-2017 and Gspeed-2018 Racecars.

Table 13.

Lap times of Gspeed-2017 and Gspeed-2018 Racecars.

| Laps | Lap Time of 2017 Car | Lap Time of 2018 Car |

|---|

| 1 | 1:26.455 | 1:21.833 |

| 2 | 1:26.213 | 1:21.470 |

| 3 | 1:25.976 | 1:21.382 |

| 4 | 1:25.932 (Fastest Lap) | 1:21.295 |

| 5 | 1:26.064 | 1:20.330 (Fastest Lap) |

| 6 | 1:26.100 | 1:21.470 |

| 7 | 1:25.997 | 1:22.316 |

| Total time | 10:02.737 | 09:30.096 |