The Effects of Gravity on the Pressure Drop and Heat Transfer Characteristics of Steam in Microchannels: An Experimental Study

Abstract

:1. Introduction

2. Methodology

2.1. Mathematical Equations

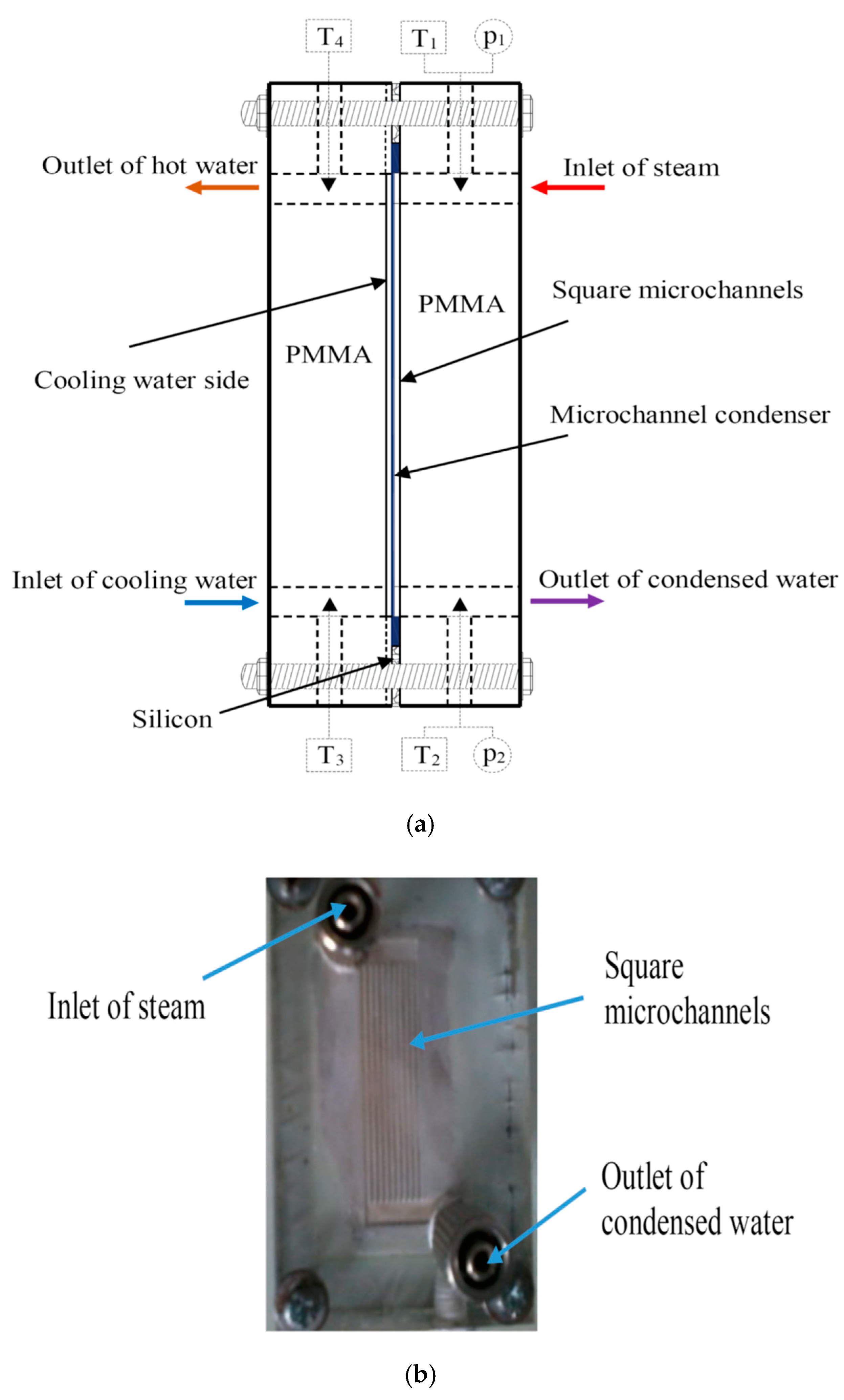

2.2. Microchannel Heat Exchanger Fabrication

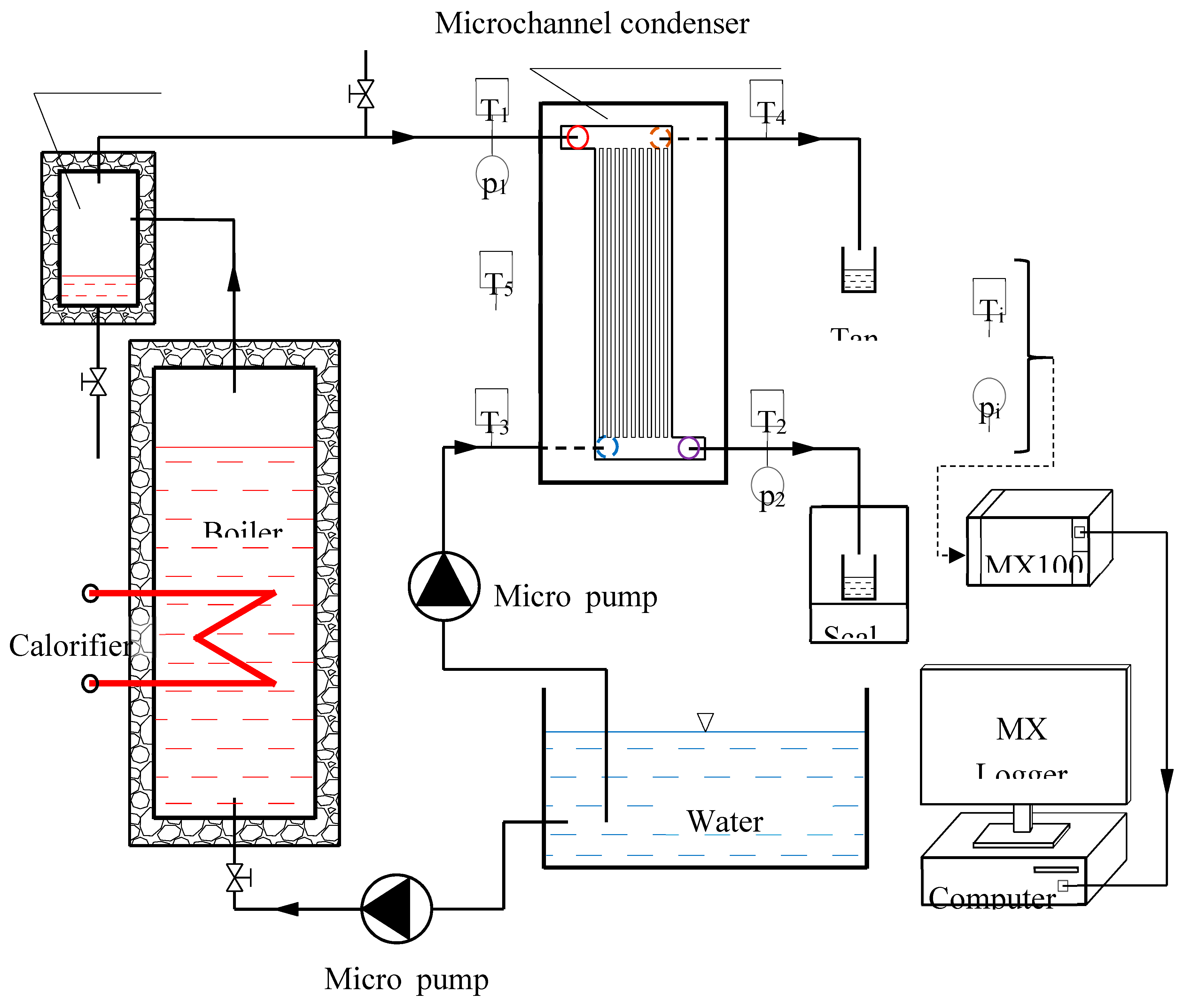

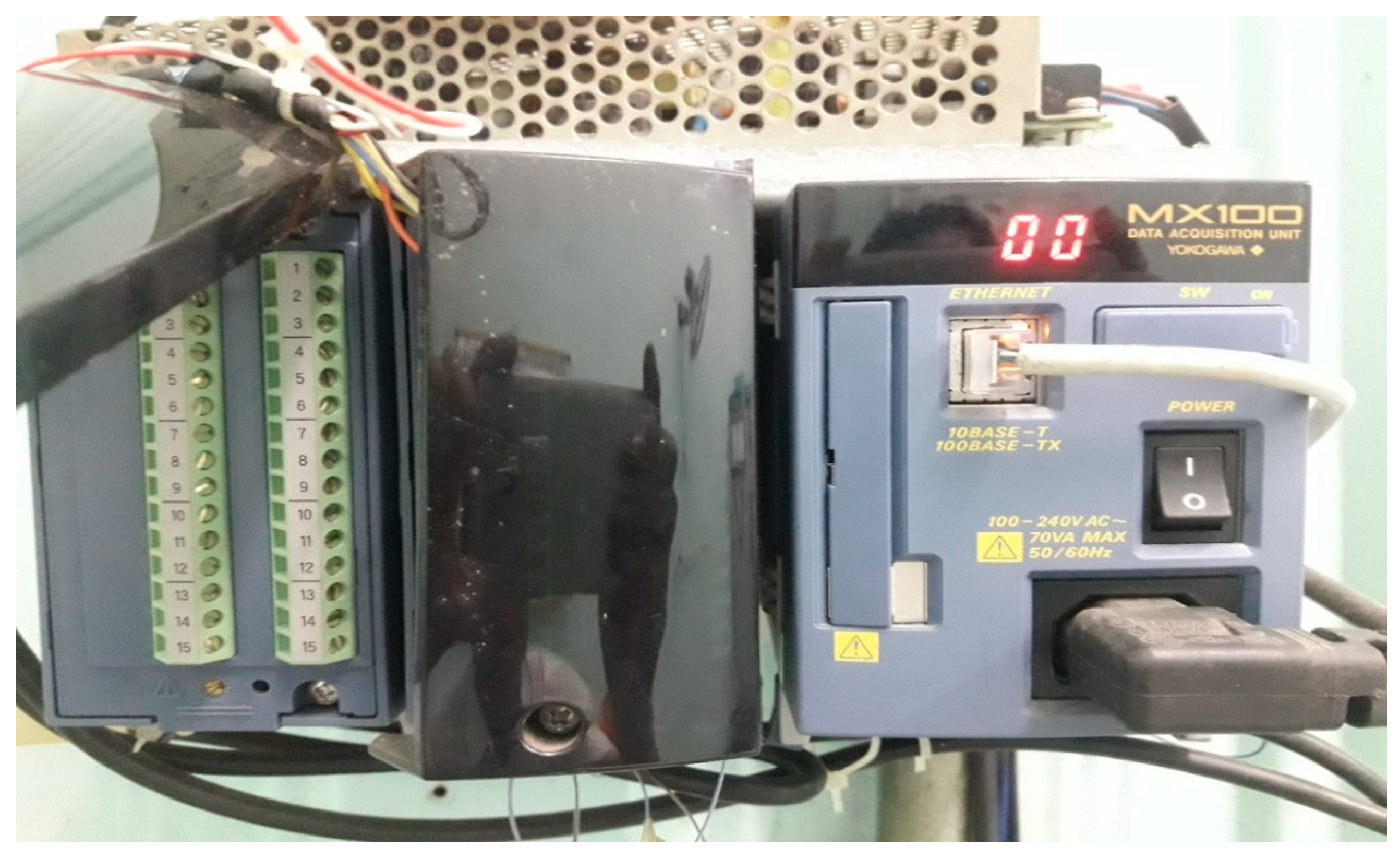

2.3. Experimental Setup

3. Results and Discussion

3.1. Effects of the Inlet Steam Flow Rate on the Pressure Drop in a Horizontal Assembly

3.2. Comparison of the Gravity Effect on Mh and Mv

3.3. Different Temperatures of Cooling Water in Horizontal and Vertical Microchannels

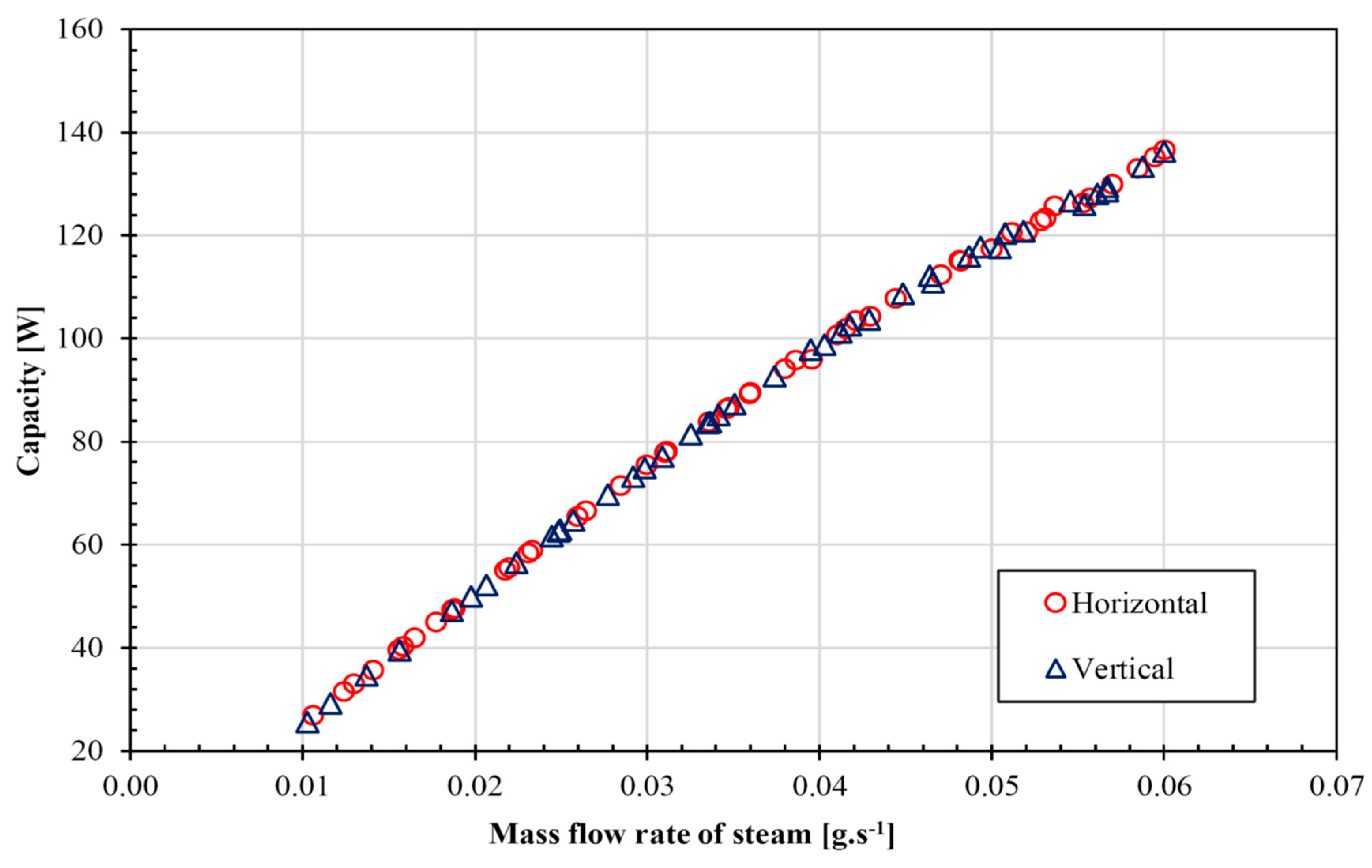

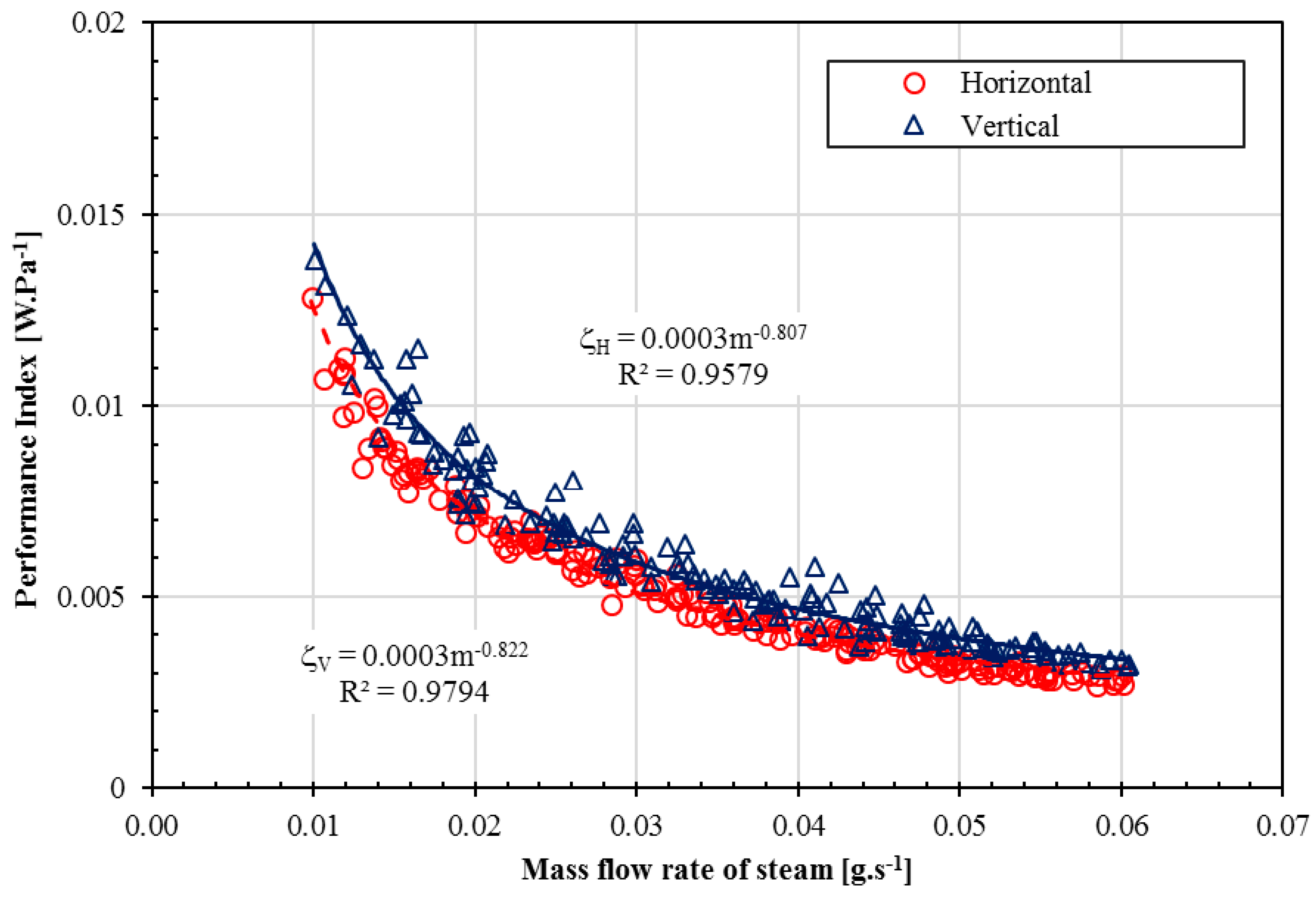

3.4. Effects of the Steam Mass Flow Rate on the Performance Index and Capacity

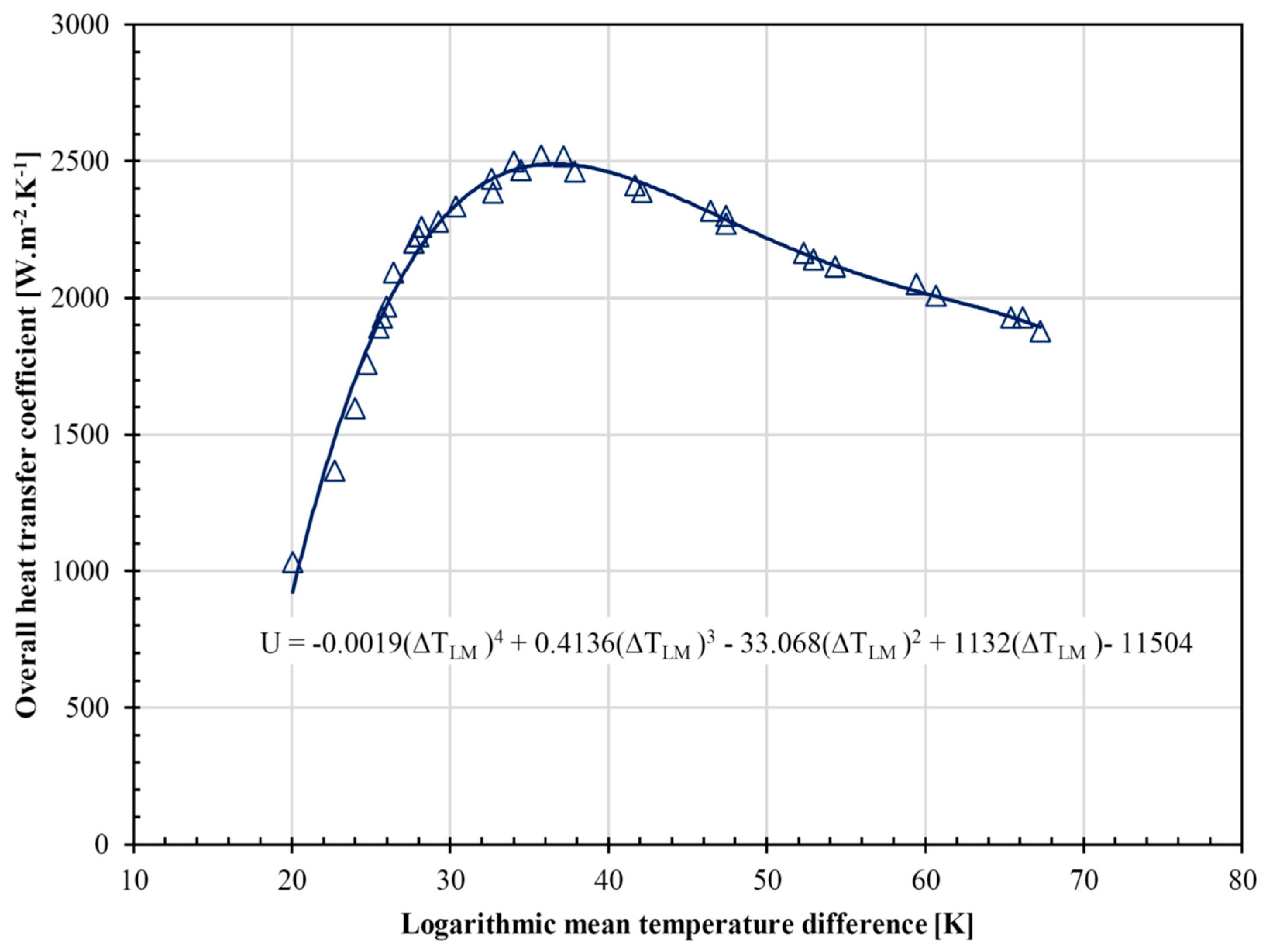

3.5. Overall Heat Transfer Coefficient

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclsature

| Cp | Specific heat at constant pressure (kJ·kg−1·K−1) |

| F | Heat transfer surface of model (m2) |

| h | Specific enthalpy (kJ·kg−1) |

| M | Mass flow rate (g·s−1) |

| p | Pressure (Pa) |

| Qs | Capacity of condenser (W) |

| Qw | Heat transfer rate (W) |

| T | Temperature (K) |

| U | Overall heat transfer coefficient (W·m−2·K−1) |

| ζ | Performance index (W·Pa−1) |

| η | Heat transfer efficiency of condenser |

| ΔTLM | Logarithmic mean temperature difference (K) |

| Subscripts | |

| IS | inlet steam |

| OW | outlet condensed water |

| H | horizontal |

| V | vertical |

| COP | coefficient of performance |

References

- Tuckerman, D.; Pease, R. High-performance heat sinking for VLSI. IEEE Electron Device Lett. 1981, 5, 126–129. [Google Scholar] [CrossRef]

- Fayyadh, E.M.; Mahmoud, M.M.; Sefiane, K.; Karayiannis, T.G. Flow boiling heat transfer of R134a in multi microchannels. Int. J. Heat Mass Transf. 2017, 110, 422–436. [Google Scholar] [CrossRef]

- Yu, X.J.; Xu, J.L.; Yuan, J.D.; Zhang, W. Microscale phase separation condensers with varied cross sections of each fluid phase: Heat transfer enhancement and pressure drop reduction. Int. J. Heat Mass Transf. 2018, 118, 439–454. [Google Scholar] [CrossRef]

- Song, Q.L.; Chen, G.F.; Guo, H.; Shen, J.; Gong, M.Q. Two-phase flow condensation pressure drop of R14 in a horizontal tube: Experimental investigation and correlation development. Int. J. Heat Mass Transf. 2019, 139, 330–342. [Google Scholar] [CrossRef]

- Song, Q.L.; Chen, G.F.; Xue, H.W.; Zhao, Y.X.; Gong, M.Q. R14 flow condensation heat transfer performance: Measurements and modeling based on two-phase flow patterns. Int. J. Heat Mass Transf. 2019, 136, 298–311. [Google Scholar] [CrossRef]

- Dang, T.T.; Teng, J.T. The effects of configurations on the performance of microchannel counter-flow heat exchangerse: An experimental study. Appl. Therm. Eng. 2011, 31, 3946–3955. [Google Scholar] [CrossRef]

- Dang, T.T.; Teng, J.T.; Chu, J.C. A study on the simulation and experiment of a microchannel counter-flow heat exchanger. Appl. Therm. Eng. 2010, 30, 2163–2172. [Google Scholar] [CrossRef]

- Park, C.Y.; Hrnjak, P. CO2 flow condensation heat transfer and pressure drop in multiport microchannels at low temperatures. Int. J. Refrig. 2009, 32, 1129–1139. [Google Scholar] [CrossRef]

- Dang, T.; Vo, K.; Le, C.; Nguyen, T. An experimental study on subcooling process of a transcritical CO2 air conditioning cycle working with microchannel evaporator. J. Therm. Eng. 2017, 3, 1505–1514. [Google Scholar] [CrossRef]

- Kim, S.M.; Kim, J.; Mudawar, I. Flow condensation in parallel microchannels–Part1: experimental results and assessment of pressure drop correlations. Int. J. Heat Mass Transf. 2012, 55, 971–983. [Google Scholar] [CrossRef]

- Kim, S.M.; Mudawar, I. Universal approach to predicting two-phase frictional pressure drop for adiabatic and condensing mini/microchannel flows. Int. J. Heat Mass Transf. 2012, 55, 3246–3261. [Google Scholar] [CrossRef]

- Liu, N.; Li, J.M.; Sun, J.; Wang, H.S. Heat transfer and pressure drop during condensation of R152a in circular and square microchannels. Exp. Fluid Sci. 2013, 47, 60–67. [Google Scholar] [CrossRef]

- Sahara, A.M.; Wissink, J.; Mahmoud, M.M.; Karayiannis, T.G.; Ishak, M.S.A. Effect of hydraulic diameter and aspect ratio on single phase flow and heat transfer in a rectangular microchannel. Appl. Therm. Eng. 2017, 115, 793–814. [Google Scholar] [CrossRef]

- Sahar, A.M.; Özdemir, M.R.; Fayyadh, E.M.; Wissink, J.; Mahmoud, M.M.; Karayiannis, T.G. Single phase flow pressure drop and heat transfer in rectangular metallic microchannels. Appl. Therm. Eng. 2016, 93, 1324–1336. [Google Scholar] [CrossRef]

- Ma, J.; Huang, Y.P.; Huang, J.; Wang, Y.L.; Wang, Q.W. Experimental investigations on single-phase heat transfer enhancement with longitudinal vortices in narrow rectangular channel. Nucl. Eng. Des. 2010, 240, 92–102. [Google Scholar] [CrossRef]

- Cavallini, A.; Del Col, D.; Doretti, L.; Matkovic, M.; Rossetto, L.; Zilio, C. Two-phase frictional pressure gradient of R236ea, R134a and R410A inside multiport minichannels. Exp. Fluid Sci. 2005, 29, 861–870. [Google Scholar] [CrossRef]

- Liu, N.; Li, J. Experimental study on pressure drop of R32, R152a and R22 during condensation in horizontal minichannels. Exp. Fluid Sci. 2016, 71, 14–24. [Google Scholar] [CrossRef]

- Goss, G., Jr.; Passos, J.C. Heat transfer during the condensation of R134a inside eight parallel microchannels. Int. J. Heat Mass Transf. 2013, 59, 9–19. [Google Scholar] [CrossRef]

- Mala, G.M.; Li, D.Q. Flow characteristics of water in microtubes. Int. J. Heat Fluid Flow 1999, 20, 142–148. [Google Scholar] [CrossRef]

- Qu, W.L.; Mala, G.M.; Li, D.Q. Pressure-driven water flows in trapezoidal silicon microchannels. Int. J. Heat Mass Transf. 2000, 43, 353–364. [Google Scholar] [CrossRef]

- Sakamatapan, K.; Kaew On, J.; Dalkilic, A.S.; Mahian, O.; Wongwises, S. Condensation heat transfer characteristics of R-134a flowing inside the multiport minichannels. Int. J. Heat Mass Transf. 2013, 64, 976–985. [Google Scholar] [CrossRef]

- Sakamatapan, K.; Wongwises, S. Pressure drop during condensation of R134a flowing inside a multiport minichannel. Int. J. Heat Mass Transf. 2014, 75, 31–39. [Google Scholar] [CrossRef]

- Viscito;Lips, S.; Revellin, R. Global analysis and development of a predictive tool of the effect of tube inclination on two-phase heat transfer: Boiling, condensation and heated gas-liquid flows. Appl. Therm. Eng. 2019, 162, 114300. [Google Scholar] [CrossRef]

- Hrnjak, P.; Litch, A.D. Microchannel heat exchangers for charge minimization in air-cooled ammonia condensers and chillers. Int. J. Refrig. 2008, 31, 658–668. [Google Scholar] [CrossRef]

- Park, C.Y.; Hrnjak, P. Experimental and numerical study on microchannel and round-tube condensers in a R410A residential air-conditioning system. Int. J. Refrig. 2008, 31, 822–831. [Google Scholar] [CrossRef]

- Hu, J.S.; Chao, C.Y.H. An experimental study of the fluid flow and heat transfer characteristics in micro-condensers with slug-bubbly flow. Int. J. Refrig. 2007, 30, 1309–1318. [Google Scholar] [CrossRef]

- Alm, B.; Imke, U.; Knitter, R.; Chygulla, U.; Zimmermann, S. Testing and simulation of ceramic micro heat exchangers. Chem. Eng. J. 2008, 135, 179–184. [Google Scholar] [CrossRef]

- Jiji, L.M. Heat Convection, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- COMSOL Multiphysics Model Library, version 3.5a Documentation; COMSOL AB: Stockholm, Sweden, September 2008.

| Components | Length | Width | Height | Depth | Number | ||||

|---|---|---|---|---|---|---|---|---|---|

| Model | L | 42 mm | W | 23 mm | H | 700 μm | - | - | 1 |

| Microchannel | Lm | 32 mm | Wm | 500 μm | - | - | Dm | 500 μm | 10 |

| Manifold | A | 13.75 mm | B | 5 mm | - | - | C | 500 μm | 2 |

| Rib (D): 500 μm | 9 | ||||||||

| Testing Apparatus | Accuracy | Range |

|---|---|---|

| Thermocouple (T-TYPE) | ±0.1 °C | 0–200 °C |

| Differential pressure transducer | ±0.025% FS | 0–1 bar |

| Pressure sensor | ±0.05% FS | 0–1 bar |

| Precision balance | ±0.0015 g | 0.0000–220 g |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Doan, M.; Dang, T.; Nguyen, X. The Effects of Gravity on the Pressure Drop and Heat Transfer Characteristics of Steam in Microchannels: An Experimental Study. Energies 2020, 13, 3575. https://doi.org/10.3390/en13143575

Doan M, Dang T, Nguyen X. The Effects of Gravity on the Pressure Drop and Heat Transfer Characteristics of Steam in Microchannels: An Experimental Study. Energies. 2020; 13(14):3575. https://doi.org/10.3390/en13143575

Chicago/Turabian StyleDoan, Minhhung, Thanhtrung Dang, and Xuanvien Nguyen. 2020. "The Effects of Gravity on the Pressure Drop and Heat Transfer Characteristics of Steam in Microchannels: An Experimental Study" Energies 13, no. 14: 3575. https://doi.org/10.3390/en13143575

APA StyleDoan, M., Dang, T., & Nguyen, X. (2020). The Effects of Gravity on the Pressure Drop and Heat Transfer Characteristics of Steam in Microchannels: An Experimental Study. Energies, 13(14), 3575. https://doi.org/10.3390/en13143575