Machine Learning: A Useful Tool in Geomechanical Studies, a Case Study from an Offshore Gas Field

Abstract

1. Introduction

- simplicity in which other parameters affecting the shear wave velocity are not included,

- the fact that such relationships derived from a particular formation, and

- the fact there are few studies on the carbonate rocks (i.e., most of the empirical relationships are derived from sandstone reservoirs).

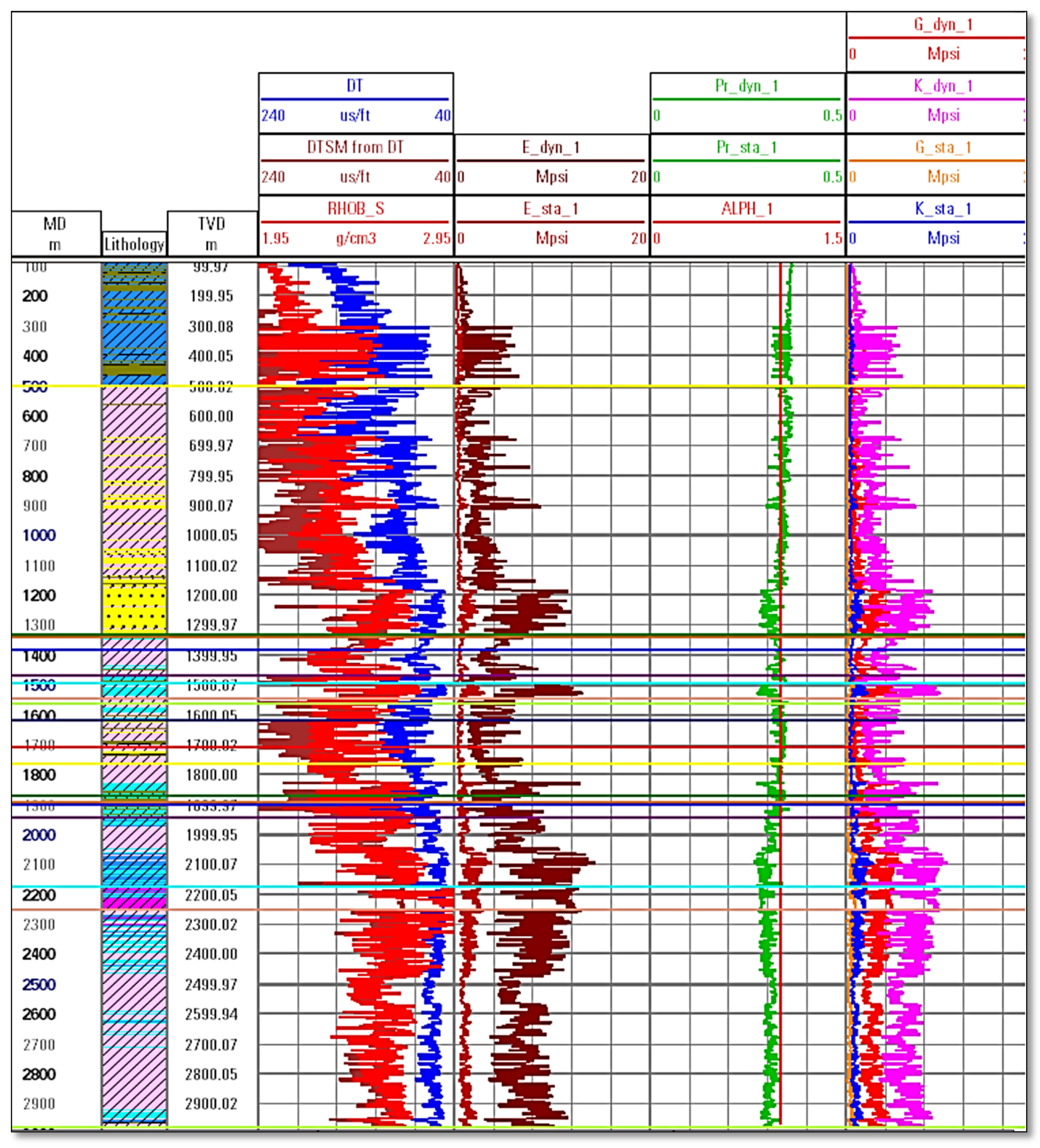

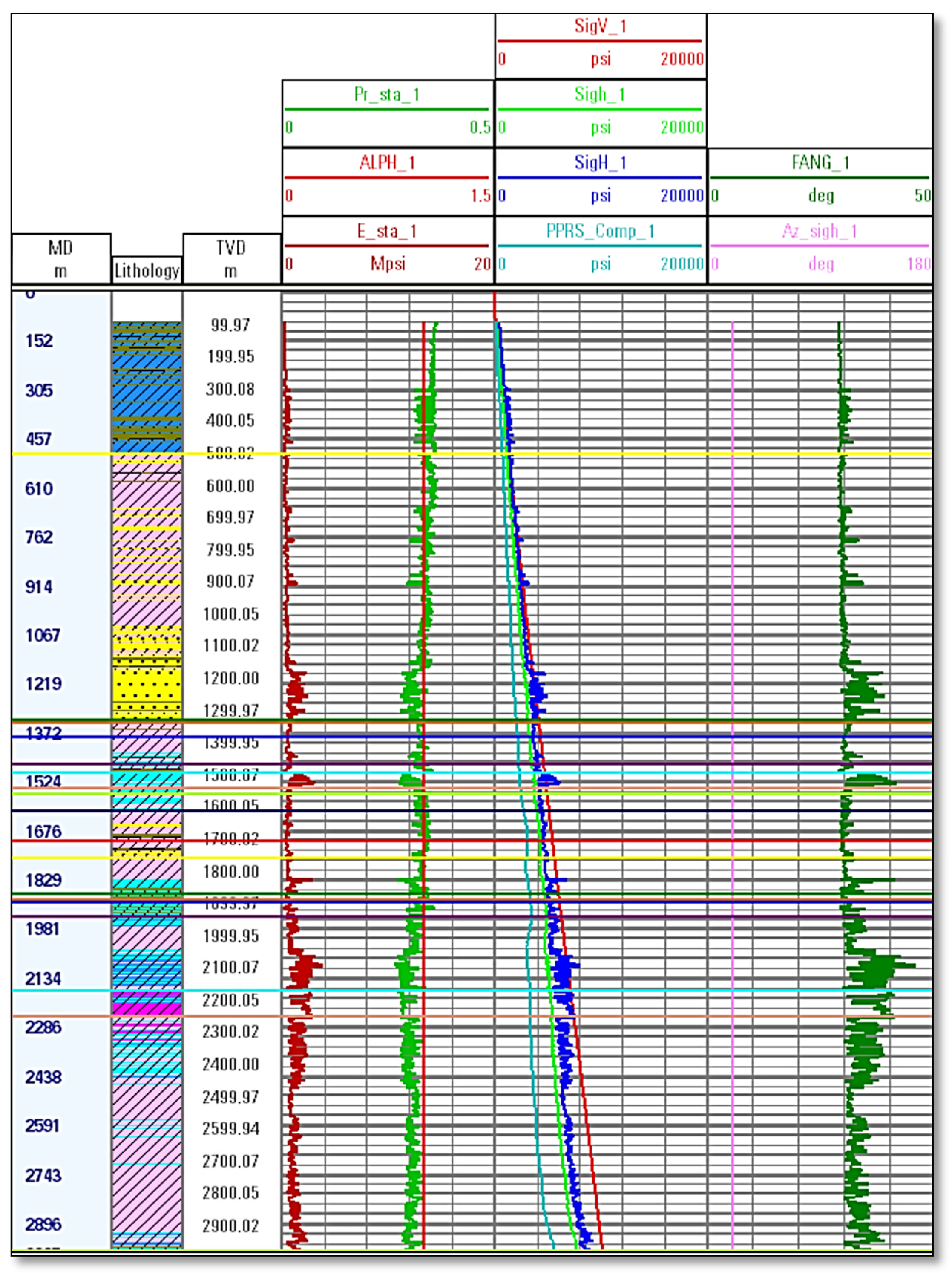

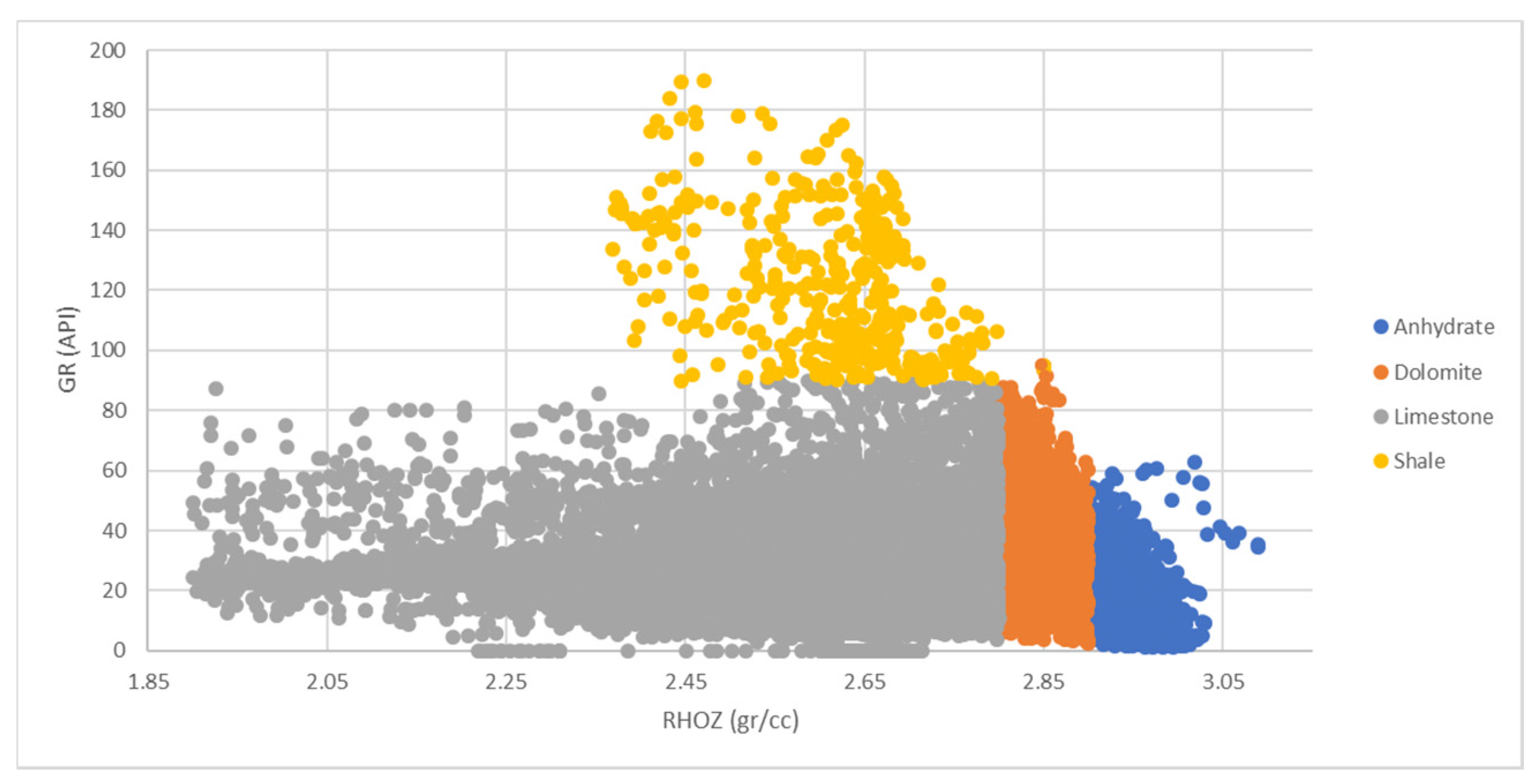

2. Results and Discussion

3. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dusseault, M.B. Geomechanical challenges in petroleum reservoir exploitation. KSCE J. Civ. Eng. 2011, 15, 669–678. [Google Scholar] [CrossRef]

- Olson, J.E.; Laubach, S.E.; Lander, R.H. Natural fracture characterization in tight gas sandstones: Integrating mechanics and diagenesis. AAPG Bull. 2009, 93, 1535–1549. [Google Scholar] [CrossRef]

- Giani, G.P.; Gotta, A.; Marzano, F.; Rocca, V. How to address subsidence evaluation for a fractured carbonate gas reservoir through a multi-disciplinary approach. Geotech. Geol. Eng. 2017, 35, 2977–2989. [Google Scholar] [CrossRef]

- Grazia, G.; Orsatti, S.; Peter, G.; Rocca, V. A coupled fluid flow—Geomechanical approach for subsidence numerical simulation. Energies 2018, 11, 1804. [Google Scholar]

- Xu, S.; White, R. A new velocity model for clay-sand mixtures 1. Geophys. Prospect. 1995, 43, 91–118. [Google Scholar] [CrossRef]

- Kuster, G.T.; Toksöz, M.N. Velocity and attenuation of seismic waves in two-phase media: Part I. Theoretical formulations. Geophysics 1974, 39, 587–606. [Google Scholar] [CrossRef]

- Greenberg, M.L.; Castagnam, J.P. Shear-wave velocity estimation in porous rocks: Theoretical formulation, preliminary verification and applications1. Geophys. Prospect. 1992, 40, 195–209. [Google Scholar] [CrossRef]

- Mavko, G.; Mukerji, T.; Dvorkin, J. Tools for seismic analysis of porous media. In The Rock Physics Handbook; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar]

- Bukar, I.; Adamu, M.B.; Hassan, U. A machine learning approach to shear sonic log prediction. In Proceedings of the Nigeria Annual International Conference and Exhibition, Lagos, Nigeria, 5–7 August 2019. [Google Scholar]

- Akhundi, H.; Ghafoori, M.; Lashkaripour, G.R. Prediction of shear wave velocity using artificial neural network technique, multiple regression and petrophysical data: A case study in Asmari reservoir (South West Iran). Open J. Geol. 2014, 4, 303–313. [Google Scholar] [CrossRef]

- Rajabi, M.; Bohloli, B.; Ahangar, E.G. Intelligent approaches for prediction of compressional, shear and Stoneley wave velocities from conventional well log data: A case study from the Sarvak carbonate reservoir in the Abadan Plain (Southwestern Iran). Comput. Geosci. 2010, 36, 647–664. [Google Scholar] [CrossRef]

- Asoodeh, M.; Bagheripour, P. Prediction of compressional, shear, and stoneley wave velocities from conventional well log data using a committee machine with intelligent systems. Rock Mech. Rock Eng. 2012, 45, 45–63. [Google Scholar] [CrossRef]

- Maleki, S.; Moradzadeh, A.; Riabi, R.G.; Gholami, R.; Sadeghzadeh, F. Prediction of shear wave velocity using empirical correlations and artificial intelligence methods. NRIAG J. Astron. Geophys. 2014, 3, 70–81. [Google Scholar] [CrossRef]

- Bagheripour, P.; Gholami, A.; Asoodeh, M.; Vaezzadeh-Asadi, M. Support vector regression-based determination of shear wave velocity. J. Pet. Sci. Eng. 2015, 125, 95–99. [Google Scholar] [CrossRef]

- Anemangely, M.; Ramezanzadeh, A.; Tokhmechi, B. Shear wave travel time estimation from petrophysical logs using ANFIS-PSO algorithm: A case study from Ab-Teymour Oilfield. J. Nat. Gas. Sci. Eng. 2017, 38, 373–387. [Google Scholar] [CrossRef]

- Behnia, D.; Ahangari, K.; Moeinossadat, S.R. Modeling of shear wave velocity in limestone by soft computing methods. Int. J. Min. Sci. Technol. 2017, 27, 423–430. [Google Scholar] [CrossRef]

- Mehrgini, B.; Izadi, H.; Memarian, M. Shear wave velocity prediction using Elman artificial neural network. Carbonates Evaporites 2017. [Google Scholar] [CrossRef]

- Akinnikawe, O.; Lyne, S.; Roberts, J. Synthetic well log generation using machine learning techniques. In Proceedings of the Unconventional Resources Technology Conference, Houston, TX, USA, 23–25 July 2018; pp. 1507–1522. [Google Scholar]

- Meng, M.; Qiu, Z.; Zhong, R.; Liu, Z.; Liu, Y.; Chen, P. Adsorption characteristics of supercritical CO2/CH4 on different types of coal and a machine learning approach. Chem. Eng. J. 2019, 368, 847–864. [Google Scholar] [CrossRef]

- Anemangely, M.; Ramezanzadeh, A.; Behboud, M.M. Geomechanical parameter estimation from mechanical specific energy using artificial intelligence. J. Pet. Sci. Eng. 2019, 175, 407–429. [Google Scholar] [CrossRef]

- Wang, D.; Peng, J.; Yu, Q.; Chen, Y.; Yu, H. Support vector machine algorithm for automatically identifying depositional microfacies using well logs. Sustainability 2019, 11, 1919. [Google Scholar] [CrossRef]

- Gholami, A.; Seyedali, S.; Ansari, H.R. Smart model for determining the shear wave velocity from seismic data. J. Pet. Sci. Eng. 2020. [Google Scholar] [CrossRef]

- Qiang, Z.; Yasin, Q.; Golsanami, N.; Du, Q. Prediction of reservoir quality from log-core and seismic inversion analysis with an artificial neural network: A case study from the Sawan Gas Field, Pakistan. Energies 2020, 13, 486. [Google Scholar] [CrossRef]

- Babaei, A. Longitudinal vibration responses of axially functionally graded optimized MEMS gyroscope using Rayleigh–Ritz method, determination of discernible patterns and chaotic regimes. SN Appl. Sci. 2019, 1, 831. [Google Scholar] [CrossRef]

- Babaei, A.; Yang, C.X. Vibration analysis of rotating rods based on the nonlocal elasticity theory and coupled displacement field. Microsyst. Technol. 2019, 25, 1077–1085. [Google Scholar] [CrossRef]

- Babaei, A.; Noorani, M.-R.S.N.; Ghanbari, A. Temperature-dependent free vibration analysis of functionally graded micro-beams based on the modified couple stress theory. Microsyst. Technol. 2017, 23, 4599–4610. [Google Scholar] [CrossRef]

- Babaei, A.; Rahmani, A. Vibration analysis of rotating thermally stressed gyroscope, based on modified coupled displacement field method. Mech. Base. Des. Struct. Mach. 2020. [Google Scholar] [CrossRef]

- McGregor, A.; Hall, M.; Lorier, P.; Brunskill, J. Flow clustering using machine learning techniques. In International Workshop on Passive and Active Network Measurement; Springer: Berlin/Heidelberg, Germany, 2004; pp. 205–214. [Google Scholar]

- Goldberger, A.S. Best linear unbiased prediction in the generalized linear regression model. J. Am. Stat. Assoc. 1962, 57, 369–375. [Google Scholar] [CrossRef]

- Forkuor, G.; Hounkpatin, O.K.L.; Welp, G.; Thiel, M. High resolution mapping of soil properties using remote sensing variables in south-western Burkina Faso: A comparison of machine learning and multiple linear regression models. PLoS ONE 2017, 12. [Google Scholar] [CrossRef]

- Heiat, A. Comparison of artificial neural network and regression models for estimating software development effort. Inf. Softw. Technol. 2002, 44, 911–922. [Google Scholar] [CrossRef]

- Eskandari, H.; Rezaee, M.R.; Mohammadnia, M. Application of multiple regression and artificial neural network techniques to predict shear wave velocity from wireline log data for a carbonate reservoir South-West Iran. CSEG Recorder 2004, 42, 40–48. [Google Scholar]

- Roden, R.; Smith, T.; Sacrey, D. Geologic pattern recognition from seismic attributes: Principal component analysis and self-organizing maps. Interpretation 2015, 3, SAE59–SAE83. [Google Scholar] [CrossRef]

- Wrona, T.; Pan, I.; Gawthorpe, R.L.; Fossen, H. Seismic facies analysis using machine learning. Geophysics 2018, 83, O83–O95. [Google Scholar] [CrossRef]

- Seyedalireza, K.; Aghajanpour, A.; Ostadhassan, M.; Farzay, O. Evaluating single-parameter parabolic failure criterion in wellbore stability analysis. J. Nat. Gas. Sci. Eng. 2018, 50, 166–180. [Google Scholar]

- Alexopoulos, E.C. Introduction to multivariate regression analysis. Hippokratia 2010, 14, 23–28. [Google Scholar]

- Castagna, J.P.; Batzle, M.L.; Eastwood, R.L. Relationships between compressional and shear-wave velocities in clastic silicate rocks. In Geophysics; Society of Exploration Geophysicists and the European Association of Geoscientists and Engineers: Tulsa, OK, USA, 1985; Volume 50, p. 334. [Google Scholar]

- Hilterman, F.J. Seismic Amplitude Interpretation; Society of Exploration Geophysicists and the European Association of Geoscientists and Engineers: Tulsa, OK, USA, 2001. [Google Scholar]

- Balan, B.; Mohaghegh, S.; Ameri, S. State-of-art in permeability determination from well log data. In Proceedings of the Eastern Regional Conference, Morgantown, WV, USA, 18–20 September 1995. [Google Scholar]

- Fjar Erling, R.M.; Holt, R.M.; Raaen, A.M.; Horsrud, P. Petroleum Related Rock Mechanics; Elsevier Science Publisher: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Eissa, E.A.; Kazi, A. Relation between static and dynamic Young’s moduli of rocks. lnt. J. Rock Mech. Min. Sci. Geomech. Abstr. 1988, 24, 381–385. [Google Scholar] [CrossRef]

- Ciccotti, M.; Mulargia, F. Differences between static and dynamic elastic moduli of a typical seismogenic rock. Geophys. J. Int. 2004, 157, 474–477. [Google Scholar] [CrossRef]

- Słota-Valim, M. Static and dynamic elastic properties, the cause of the difference and conversion methods–case study. Nafta Gaz 2015, 11, 816–826. [Google Scholar] [CrossRef]

- Plumb, R.A. Influence of composition and texture on the failure properties of clastic rocks. In Proceedings of the Rock Mechanics in Petroleum Engineering, Delft, The Netherlands, 29–31 August 1994. [Google Scholar]

- Zhang, J. Pore pressure prediction from well logs: Methods, modifications, and new approaches. Earth Sci. Rev. 2011, 108, 50–63. [Google Scholar] [CrossRef]

- Eaton, B.A. The equation for geopressure prediction from well logs. In Proceedings of the Fall Meeting of the Society of Petroleum Engineers of AIME, Dallas, TX, USA, 28 September–1 October 1975. [Google Scholar]

- Song, L. Measurement of Minimum Horizontal Stress from Logging and Drilling Data in Unconventional Oil and Gas. Ph.D. Thesis, University of Calgary, Calgary, AB, Canada, August 2012. [Google Scholar]

- Blanton, T.L.; Olson, J.E. Stress magnitudes from logs: Effects of tectonic strains and temperature. SPE Reserv. Eval. Eng. 1999, 2. [Google Scholar] [CrossRef]

- Aghajanpour, A.; Fallahzadeh, S.H.; Khatibi, S.; Hossain, M.M.; Kadkhodaie, A. Full waveform acoustic data as an aid in reducing uncertainty of mud window design in the absence of leak-off test. J. Nat. Gas. Sci. Eng. 2017, 45, 786–796. [Google Scholar] [CrossRef]

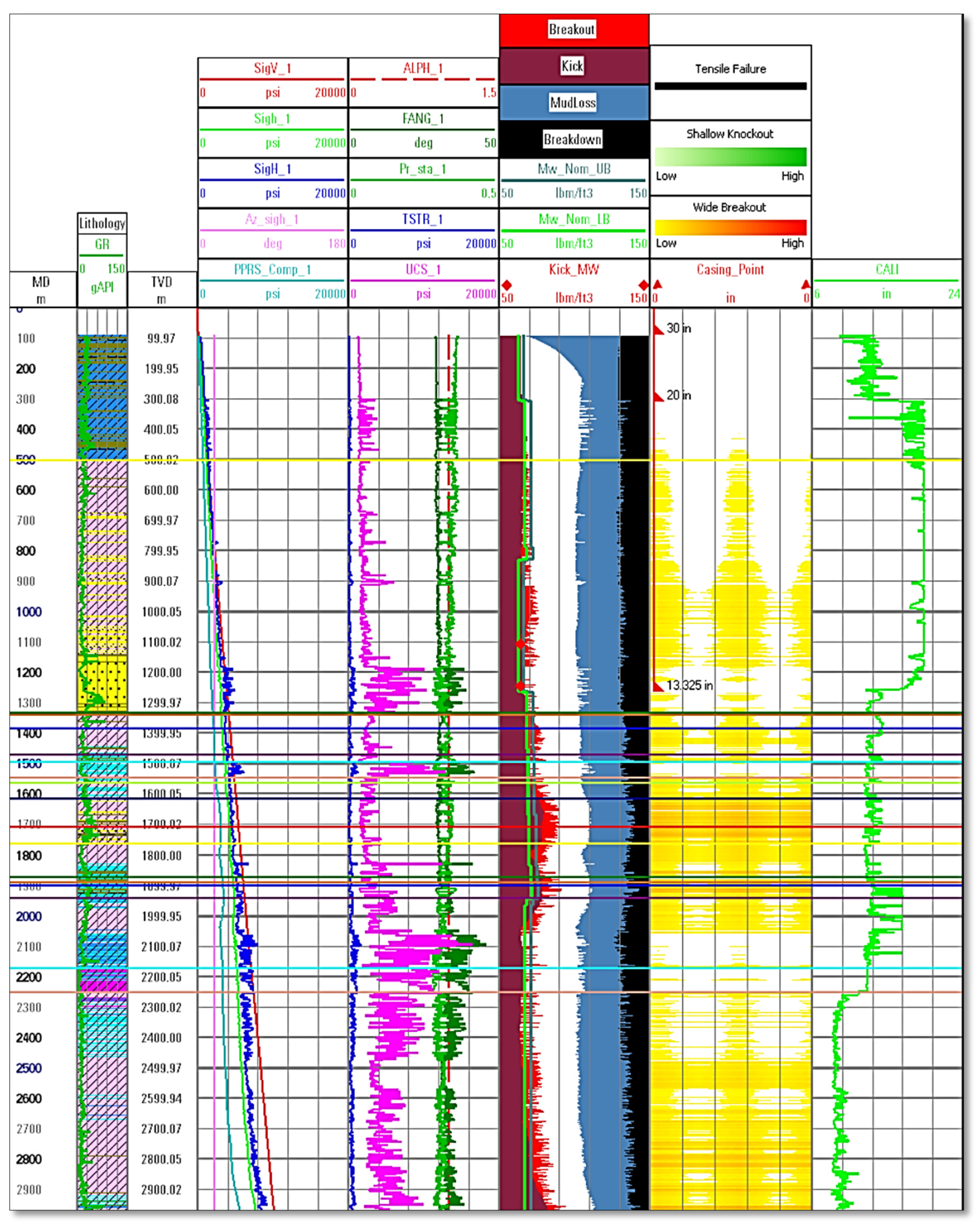

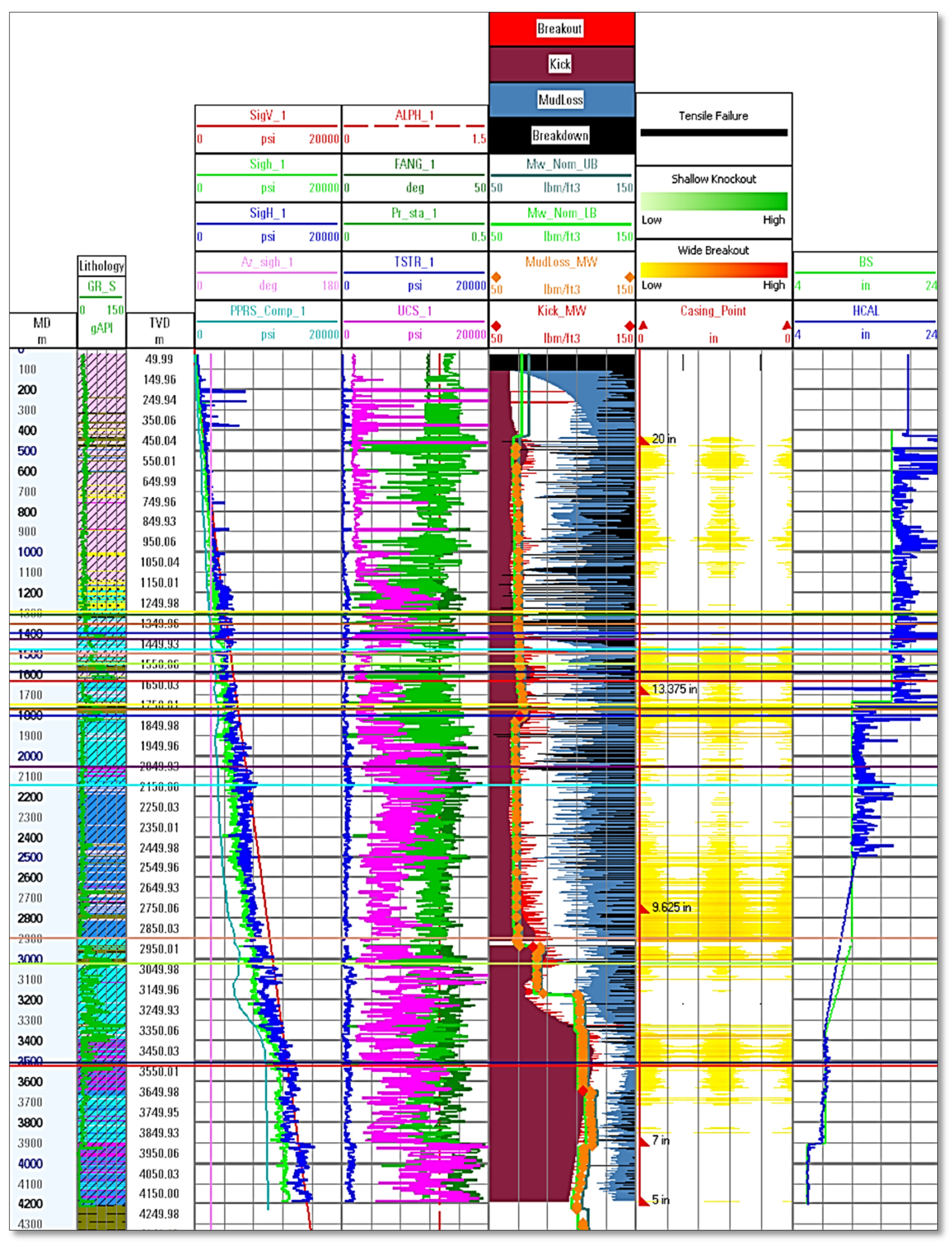

- Khatibi, S.; Ostadhassan, M.; Farzay, O.; Aghajanpour, A. Seismic driven geomechanical studies: A case study in an Offshore Gas Field. In Proceedings of the 53rd US Rock Mechanics/Geomechanics Symposium, New York, NY, USA, 23–26 June 2019. [Google Scholar]

- Zoback, M.D. Reservoir Geomechanics; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar]

- Al-Ajmi, A.M.; Zimmerman, R.W. Stability analysis of vertical boreholes using the Mogi–Coulomb failure criterion. Int. J. Rock Mech. Min. Sci. 2006, 43, 1200–1211. [Google Scholar] [CrossRef]

- Meng, M.; Zhong, R.; Wei, Z. Prediction of methane adsorption in shale: Classical models and machine learning based models. Fuel 2020, 278, 118358. [Google Scholar] [CrossRef]

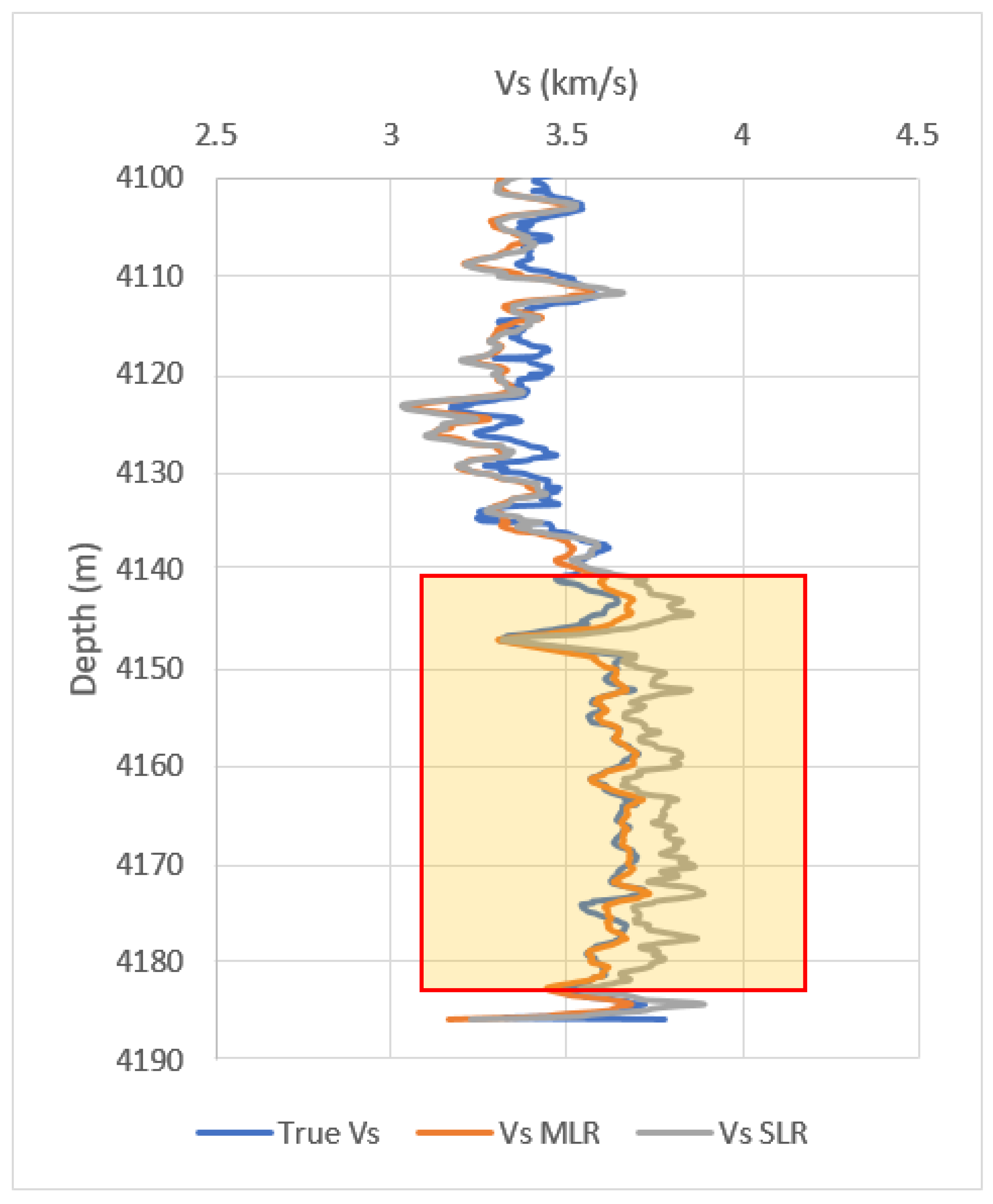

| Model | Standard Error of The Estimate |

|---|---|

| Model from Well-3 | 0.167 |

| Vs Limestone equation | 0.206 |

| Vs Dolomite equation | 0.213 |

| Vs Shale equation | 0.404 |

| Vs Sandstone equation | 0.575 |

| Term | Coefficient | T-Value | Error Analysis |

|---|---|---|---|

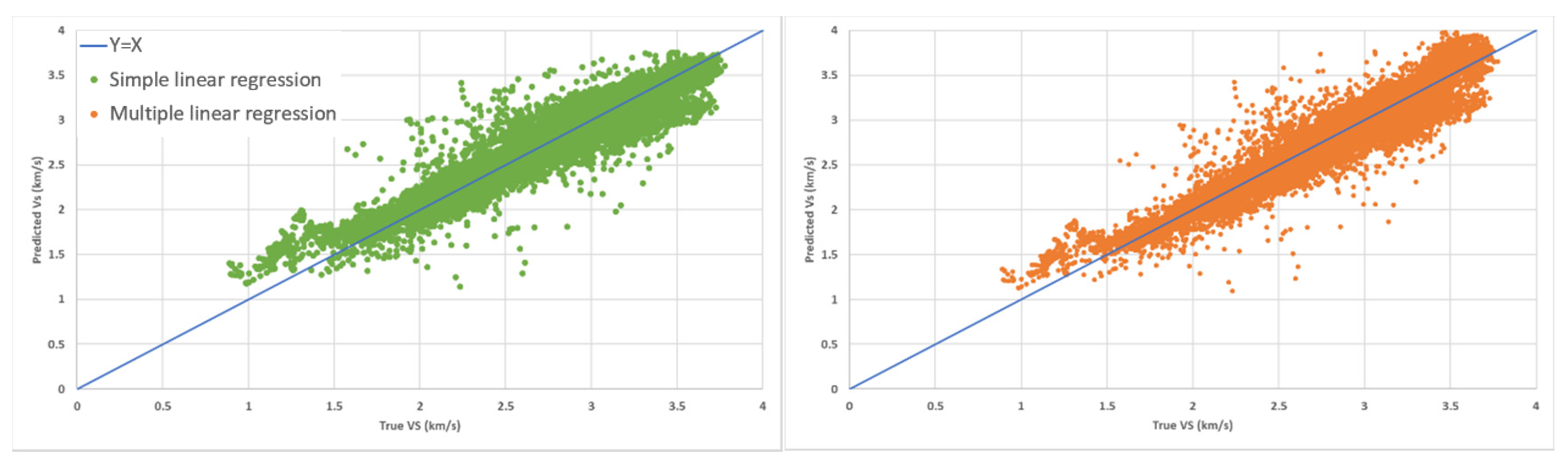

| Constant | −14.067 | −39.35 | R2 = 87% |

| DTC | 2.091 | 359.82 | MSE = 11.32 |

| Term | Coefficient | T-Value | Error Analysis |

|---|---|---|---|

| Constant | 21.51 | 12.91 | R2 = 89% MSE = 9.12 |

| DTC | 2.00851 | 239.96 | |

| GR | −0.09748 | −27.86 | |

| RHOZ | −10.406 | −21.50 |

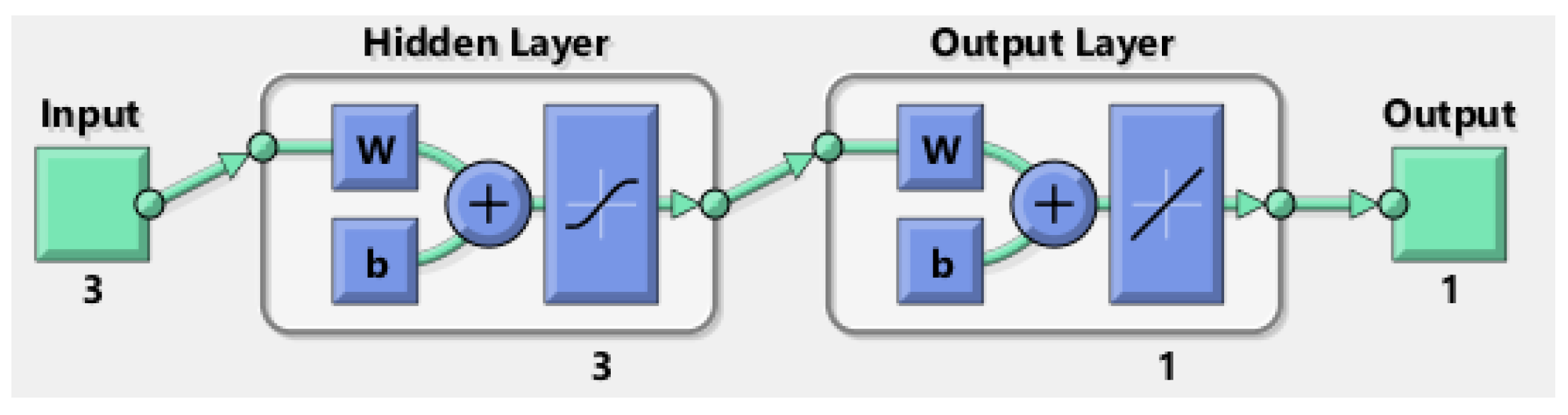

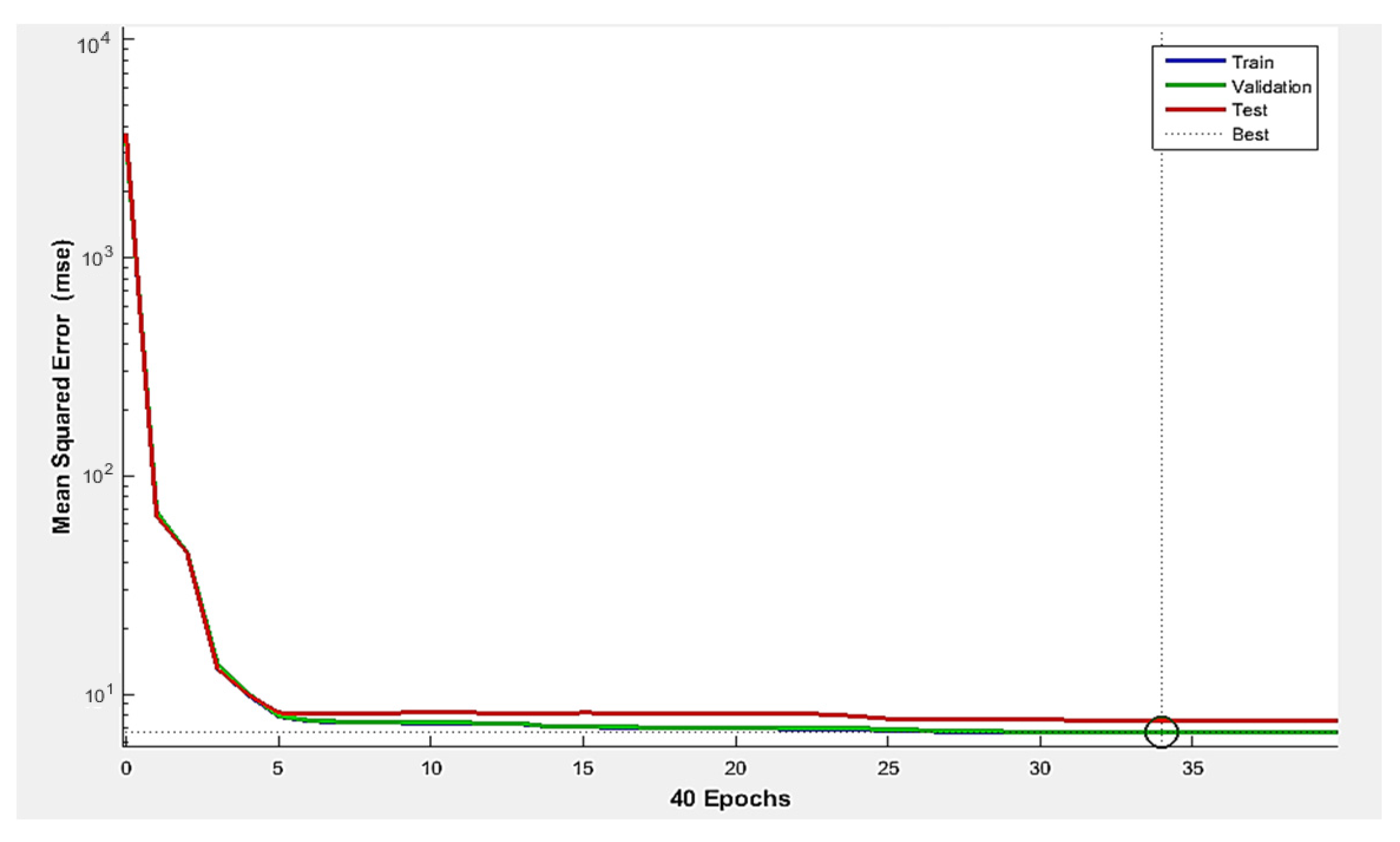

| Method | Step | MSE | R2 |

|---|---|---|---|

| Neural network | Training | 6.31 | 95.58 |

| Testing | 6.87 | 95.21 | |

| Validating | 7.67 | 95.55 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khatibi, S.; Aghajanpour, A. Machine Learning: A Useful Tool in Geomechanical Studies, a Case Study from an Offshore Gas Field. Energies 2020, 13, 3528. https://doi.org/10.3390/en13143528

Khatibi S, Aghajanpour A. Machine Learning: A Useful Tool in Geomechanical Studies, a Case Study from an Offshore Gas Field. Energies. 2020; 13(14):3528. https://doi.org/10.3390/en13143528

Chicago/Turabian StyleKhatibi, Seyedalireza, and Azadeh Aghajanpour. 2020. "Machine Learning: A Useful Tool in Geomechanical Studies, a Case Study from an Offshore Gas Field" Energies 13, no. 14: 3528. https://doi.org/10.3390/en13143528

APA StyleKhatibi, S., & Aghajanpour, A. (2020). Machine Learning: A Useful Tool in Geomechanical Studies, a Case Study from an Offshore Gas Field. Energies, 13(14), 3528. https://doi.org/10.3390/en13143528