1. Introduction

The widespread utilization of renewable energy sources such as solar and wind energy is hampered by their intermittency and insufficient storage capacity that cannot always guarantee adequate supply of the electricity demand [

1]. As a result, electricity grids cannot yet rely solely upon renewable energy sources [

2], despite the fact that their utilization is sought for the decarbonization of electricity networks [

3]. Fossil fuels provide energy storage at low cost with high availability and easiness in handling, and in many cases they are still preferred as the means of energy storage [

4] leading to increasing greenhouse gas emissions. To harness energy from renewable energy sources more efficiently and to enable a transition to clean energy, solar panels and wind energy converters should be coupled with energy storage systems. These systems are able to store excess energy during periods of high production and low demand, and subsequently provide energy to the electricity network at periods of high demand when the energy production is not sufficient. Pumped storage hydropower (PSH) is the most popular technology that accommodates such energy storage [

5,

6,

7] and has been successfully utilized in numerous places all over the world (e.g., [

8,

9,

10]). PSH consists of at least two reservoirs at different elevations, which are connected with pipes or tunnels. This system stores energy in the form of potential energy by elevating water in the upper reservoir with the aid of pumps and generates electrical energy by releasing water to the lower reservoir and converting water kinetic energy to electricity with turbines.

However, actual implementation of PSH may not be feasible in certain areas due to societal, topographic, and environmental constraints (e.g., [

11]). PSH reservoirs require large storage areas that may not be available in densely populated or urbanized areas. In addition, the two reservoirs of the PSH need to have a significant elevation difference to secure sufficient head difference for the efficient production of electricity, which excludes flat areas as candidates for a PSH. To avoid such limitations, at least one of the reservoirs could be located underground in cavities or in abandoned mines and quarries. Consequently, energy can be generated and stored with underground pumped storage hydropower (UPSH) [

12,

13]. While there are several options for energy storage in flat areas [

14], including surface quarry pits [

15], the present study focuses on UPSH because it does not affect the landscape, it has a minimal societal impact for the nearby communities and may rejuvenate local economies that were most probably highly dependent on the previous local ore extraction from the quarries or mines. UPSH has gained popularity and is considered a viable option for energy storage [

16,

17,

18,

19]; however, the actual hydraulic behavior in the underground reservoirs must be studied thoroughly, since the reservoir geometry and thus the hydraulic behavior of UPSH can be challenging and more complicated compared to other solutions in flat areas.

The groundwater exchanges between the lower reservoir and the surrounding porous medium might be significantly greater in a UPSH compared to a PSH due to the increased interface area of the reservoir that is in contact with the surrounding medium (here after referred as the ‘aquifer’) and likely below the water table (i.e., in the saturated zone). In addition, the sidewalls of PSH reservoirs are sometimes waterproof, which is not especially the case in mines and quarries that could potentially be used as underground reservoirs in UPSH. Groundwater exchanges are largely influenced by the porosity and hydraulic conductivity of the aquifer, the characteristics of the lower reservoir, the relative elevation of the underground water table compared to the location of the lower reservoir, and the pump/injection cycles [

20,

21]. The induced gradient between the aquifer piezometric head and the head in the lower reservoir (i.e., the abandoned mine or quarry) may affect the economic feasibility of the UPSH system since water intrusion from the aquifer to the reservoir in between the pump/injection cycles may lead to additional pumping of water and increase the costs [

15,

21]. Otherwise, the incoming groundwater flow will reduce the head difference with the upper reservoir as well as the available capacity of the lower reservoir and diminish the amount of water that can be transferred into the lower reservoir, thus decreasing the generated electricity. On another hand, in case of high porosity and hydraulic conductivity in the ground, groundwater exchanges may narrow the variation of the water level in the underground reservoir and subsequently of the head difference between the upper and lower reservoirs, thus facilitating the design and efficiency of the pumps and turbines [

20]. In UPSH, the groundwater exchanges may also affect the water hydrochemistry and lead to adverse environmental consequences through precipitation and dissolution of minerals and the associated variations in pH [

22], which may also affect the efficiency of the USPH plant.

Besides the water exchanges with the surrounding medium, the movement of water within the mine or quarry is of particular interest as well [

23,

24,

25,

26,

27]. A detailed evolution of the water levels in the complex underground reservoir(s) needs to be predicted for feasibility analysis, as the continuous shifting of water level in response to discharge variations during the pump/discharge cycles will affect the head difference between the upper and lower reservoirs and possibly the turbomachinery operation. Water level variations are also needed to assess the structural stability of the system [

28]. The water level variation and the energy efficiency of the UPSH plant are particularly affected by the geometry and the aeration conditions of the underground reservoir [

23,

24]. An underground reservoir may have an overall large volume but with discharge exchange limitations at some specific points, due to narrow cross section for instance. It may also have limited connections with the atmosphere and thus limited possibilities for air to enter/exit the reservoir to counterbalance water volume variations.

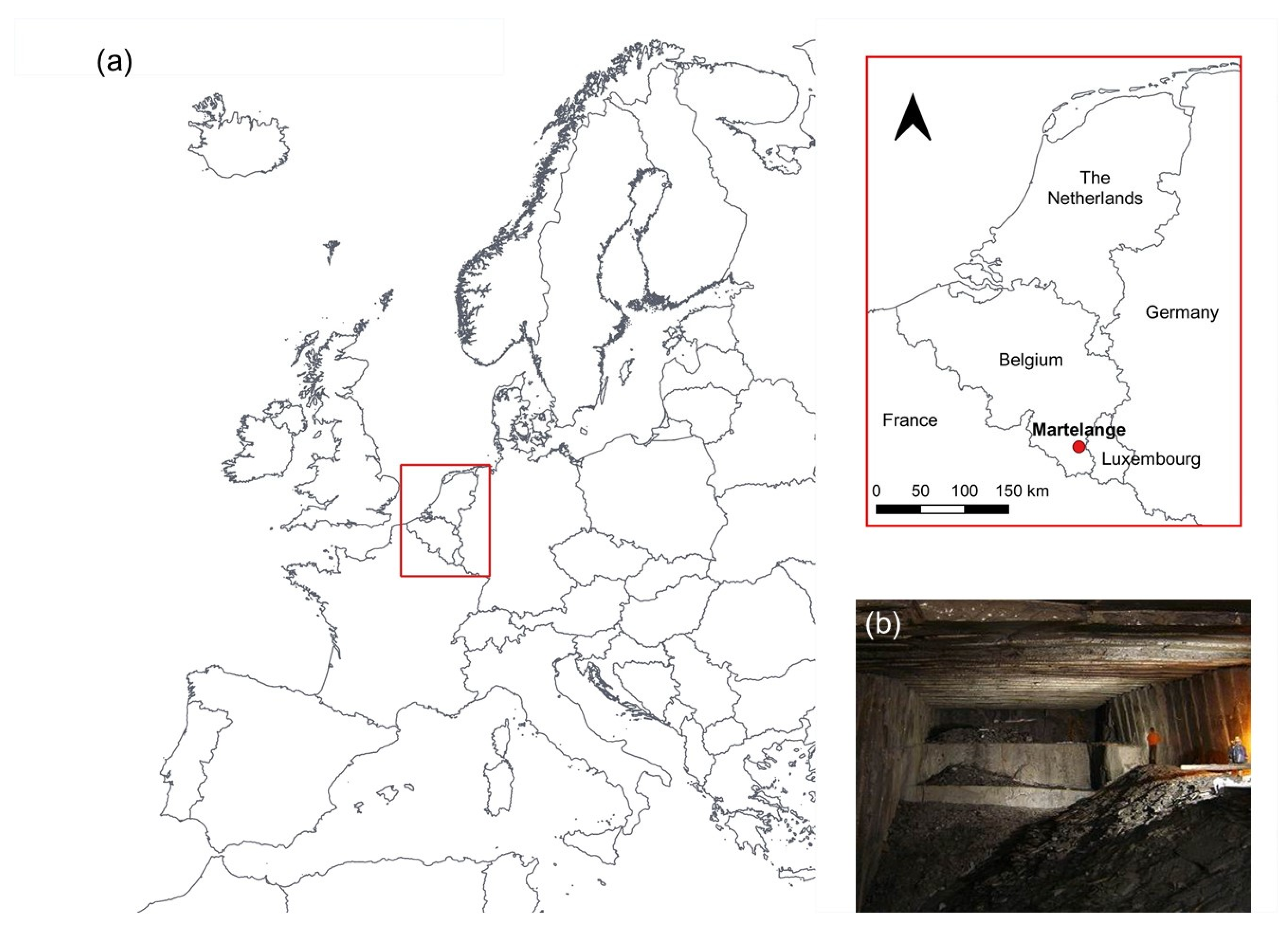

The present study considers an abandoned slate mine in Martelange in Southeast Belgium as a practical example of a multiple chambers underground reservoir for an UPSH plant and investigates the evolution of water levels within a system of nine underground chambers. The large underground chambers are successively connected with small galleries of limited cross section. A hydraulic numerical model has been developed to analyze (a) the effect of the cross sectional area of the connecting galleries and the subsequent inertia effects due to their limited discharge capacity and (b) the effect of aeration of the underground chambers on the water levels. The effect of groundwater exchanges is analyzed separately in a companion paper focusing on the same site [

29].

3. UPSH System Conceptualization

Some assumptions about the underground reservoir geometry were made based on the existing drawings of the mine, to allow for a systematic analysis of the water flow in the chambers. The ground surface is considered horizontal at an elevation of 0 m and each of the nine underground chambers has a rectangular cuboid shape with its top side at −40 m from the surface. All nine chambers are in a row, parallel to each other, and equally spaced by a 10 m distance. Each chamber has a length and width of 15 m and 45 m, respectively, while the height varies. The bottom level of the first chamber, i.e., the deeper one, reaches −150 m and subsequently the bottom level of each successive chamber is elevated by 5 m (

Figure 2 and

Table 1). Two adjacent chambers are connected by two galleries, one at the bottom of the chamber and one 60 m higher, through the 10 m separating distance (

Figure 2). The main shaft, which is considered to house the pumps/turbines is connected to the deeper chamber at its lowest point at −150 m. An aeration shaft with a rectangular cross-section 1.5 × 1.5 m

2 connects the chamber that is farthest away from the main shaft (i.e., the smallest chamber) to the surface (

Figure 2a). A hypothetical scenario where all the chambers are fully aerated with adequately large aeration shafts (

Figure 2b) was also examined. The total volume of the chambers in the Martelange slate mine was estimated to be around 550,000 m

3. The upper reservoir was intended to be constructed on top of a hill 500 m from the mine at an elevation of 100 m above the ground with an estimated capacity of 400,000 m

3. Since the chambers capacity is larger than the volume of water that can be transferred from the upper reservoir, the water level at equilibrium conditions was kept higher than −110 m (

Figure 2) to maintain low water velocities near the bottom of the chambers and minimize sediment entrainment that may be harmful to the pumps/turbines.

Various geometry scenarios were examined to infer the variability of water levels in the nine underground chambers. The number and location of the connecting galleries remained the same in every numerical simulation (

Figure 2). The total cross sectional area of the two connecting galleries varied from 5 to 40 m

2 with a roughness height equal to 5 cm, while for some cases the roughness height was increased to 20 cm, as shown in

Table 2. All cases were simulated for partially and fully aerated conditions.

4. Hydraulic Model

The hydraulic modeling of the system was carried out by interconnecting a model that simulates the flow in the upper reservoir and a model that simulates the water movement in the underground chambers. The upper reservoir is a large and shallow body of water and the flow was modeled based on two-dimensional shallow water equations, i.e., depth averaged mass and momentum conservation equations. The computational tool was provided by the academic software WOLF [

31], which is a finite volume model using an explicit scheme for time integration.

For the modeling of the lower reservoir, which comprises nine interconnected chambers, an efficient lumped model is preferred over a detailed computationally intensive three-dimensional numerical model. Indeed, we are interested mainly in the time evolution of the averaged water levels inside the chambers in the context of long term operation scenarios rather than in hydrodynamic details in the connecting galleries for instance. The lumped model consists of two mass conservation equations for each chamber and a transient Bernoulli equation, as a simplification of the momentum conservation equation, for the small galleries that connect the chambers. The mass conservation equation for water in a chamber is written:

where

V is the volume of water in the chamber,

t is the time,

nin and

nout denote the number of connecting galleries that transfer water in and out of the chamber, respectively, with discharge

Qw, and

µ is a Karush–Kuhn–Tucker multiplier [

32] that takes values greater or equal to zero for constraints on the volume of fluid in each chamber.

Likewise, the mass conservation equation for the air in the chambers is written:

where

ma and

ρα are the air mass and density, respectively, and

Qa is the air discharge.

In non-aerated chambers, the pressure of the air,

pa, varies with the volume of the chamber that is occupied by water, since air is a compressible fluid. Hence, the air pressure was calculated with the polytropic relation:

where

ρα =

ma/

Vα, with

Vα being the air volume,

γ is 1.4 for adiabatic conditions, which are considered here for the relatively short periods of filling/emptying the underground reservoir, and

C is a constant equal to 78,500 (for air density equal to 1.3 kg/m

3 at 1013.25 Pa pressure).

The transient Bernoulli equation for the connecting galleries, both for water and entrapped air, is written:

where

L is the length of the gallery,

g is the acceleration of gravity,

S is the cross-section of the gallery,

f is the friction coefficient calculated with Barr–Bathurst formula [

33],

D is the corresponding hydraulic diameter of the gallery,

k is a coefficient for local head losses (inlet and outlet), and Δ

H is the head difference at the two ends of the connecting gallery, with each head, either for water or for entrapped air, being calculated with:

where

p is the fluid pressure,

ρ is the fluid density, and

Z is the elevation of the considered point.

The lumped model is implemented with object oriented programming and a first order implicit time integration scheme [

30] with a time step of 60 s. The numerical simulations for fully aerated chambers were conducted by considering free surface flow in chambers that were open at the top and making sure that the water did not overtop the open chambers. The porous underground medium is considered air impervious and groundwater exchanges are negligible during the pumping/turbining cycles.

5. Operation Scenario

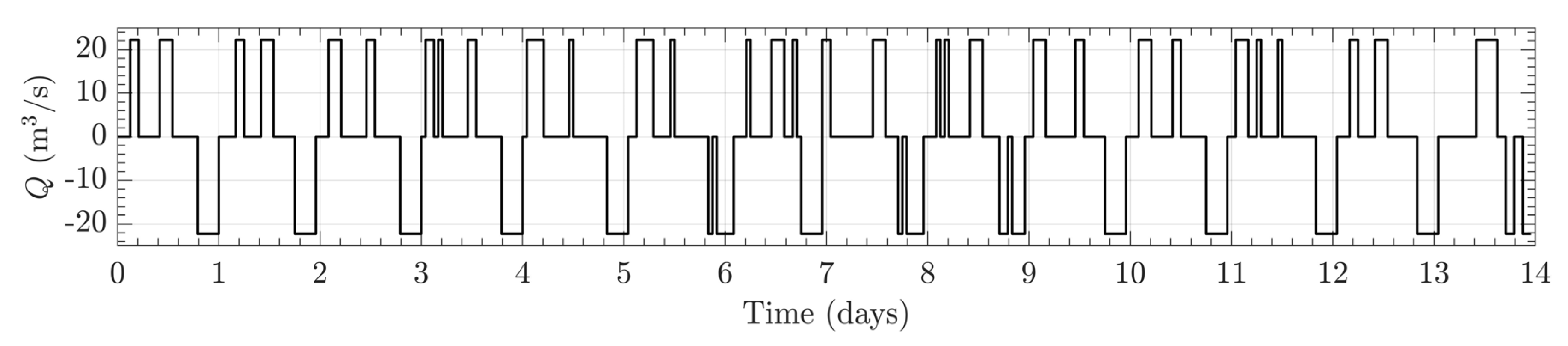

The geometry scenarios listed in

Table 2 were examined based on a 14-day discharge pattern (

Figure 3), which was built considering typical electricity prices variation in the region for the winter of 2013. Specifically, pumping of water from the underground reservoir occurs within periods with a low cost of energy (during the night) while, on the contrary, turbining from the upper to the lower reservoir took place when the price of electricity was high (noon and evening peaks). Such an operation scenario is typical for an existing pumped storage scheme on a grid with a large amount of nuclear and/or thermal energy production. In a future with much more renewable energy production, operation scenarios for pumped storage will probably be more fluctuating. The considered scenario is however sufficient to show that underground reservoirs used for UPSH have additional constraints compared to classical surface ones, which need to be quantified during the design phase.

The net mass balance within a discharge cycle of 24 h is zero, with full exchange of a 400,000 m

3 volume occurring in approximately 5 h (discharge of 22.2 m

3/s), once for pumping and once for turbining per cycle, with intermittencies allowed (

Figure 3). No operations were scheduled in the 14 h that were left in a 24-hour period. Such discharge patterns were also generated for the summer and spring periods of 2013 [

29]; however, only the discharge curve from the winter period was presented in this study. More detailed explanation on the generation of the discharge patterns is provided by Pujades et al. [

29]. Due to the fact that in the present study the discharge cycle needed to start with turbining, the first six hours of the original winter discharge time-series, corresponding to a pumping phase [

29], were moved to the end of the time-series. The water level at the beginning of each simulation was at −110 m, which means that there is water in every chamber except in chamber 9 (i.e., the shallower chamber;

Figure 2).

6. Results

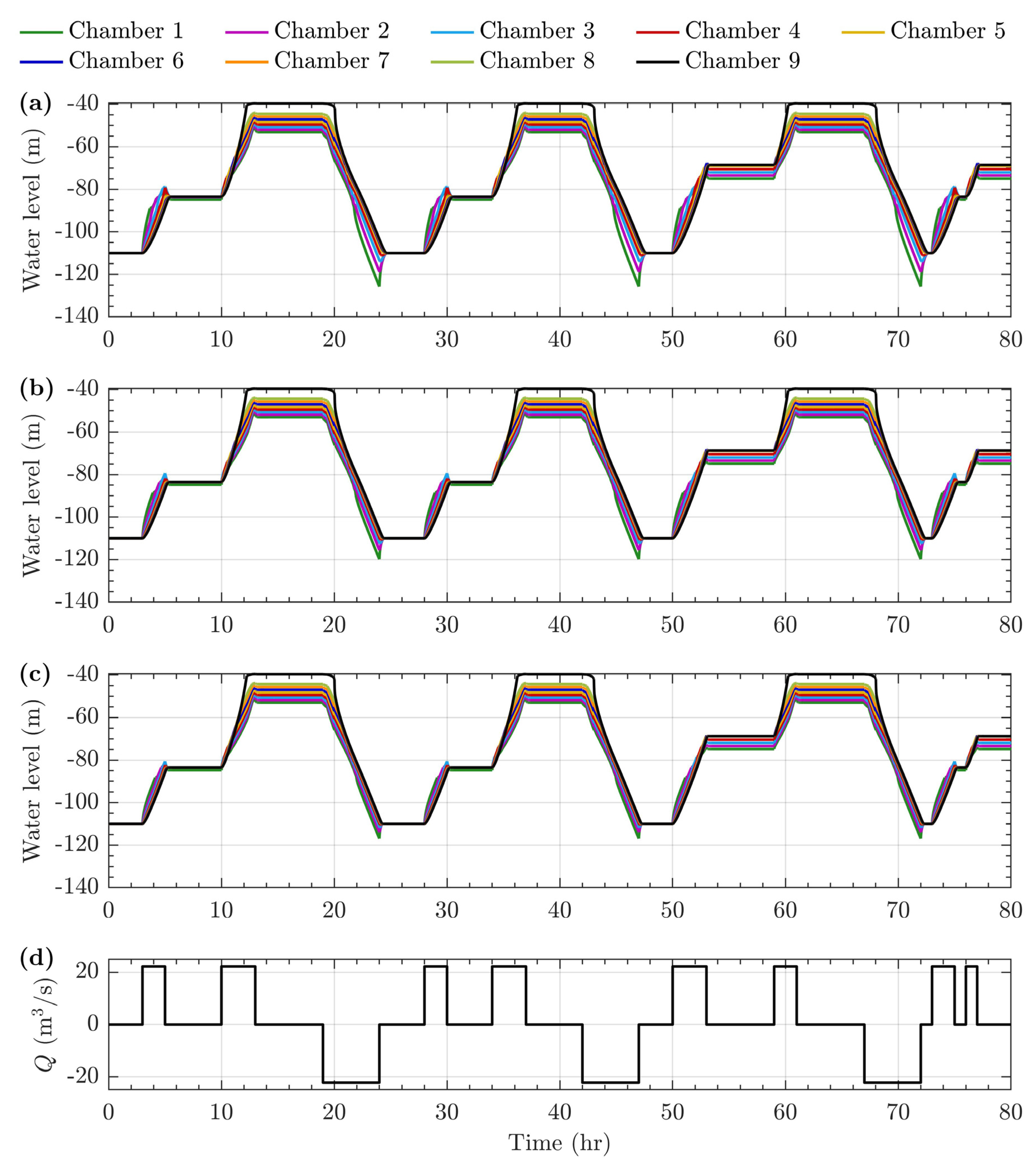

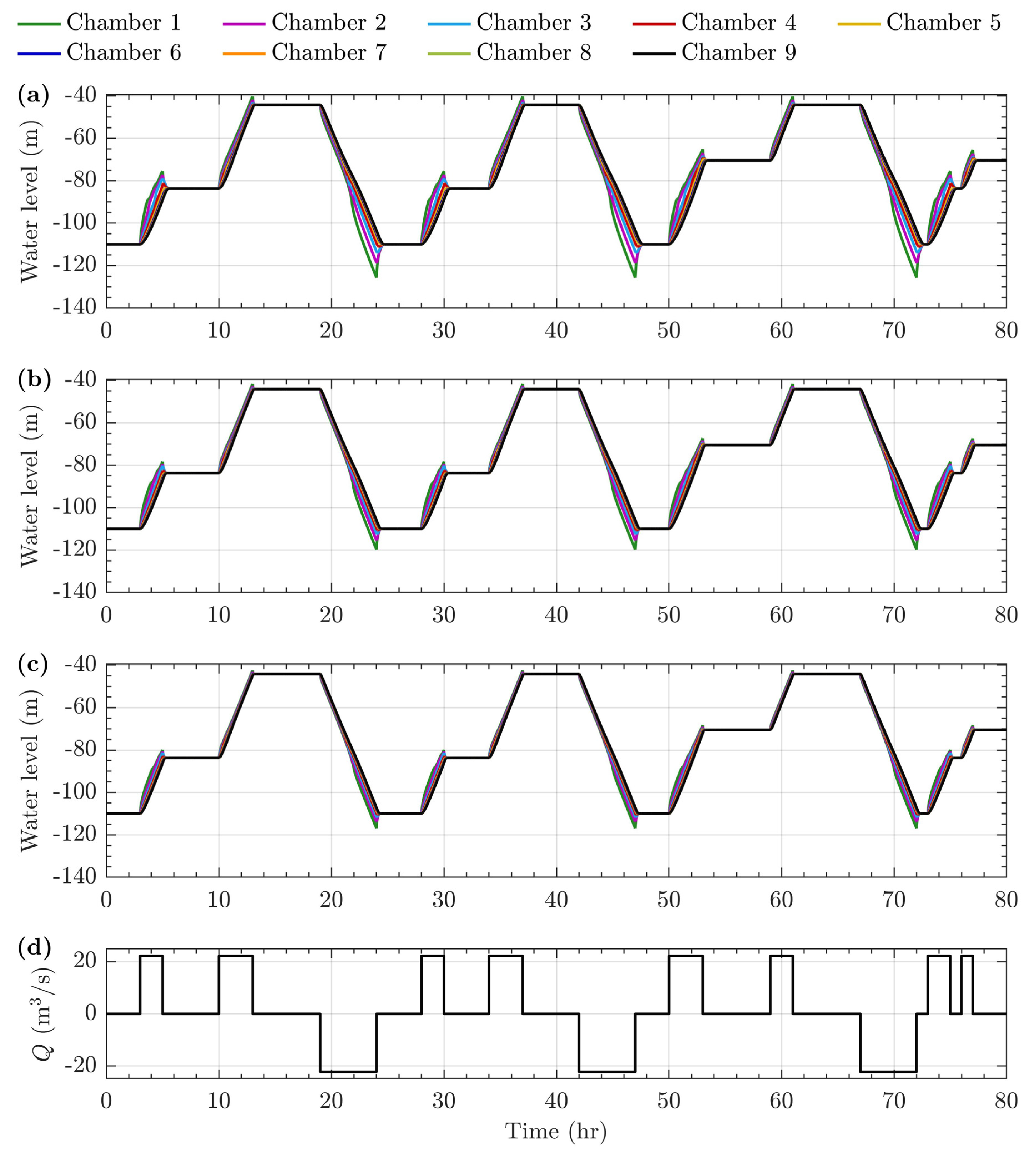

The 14-day discharge scenario (

Figure 3) exhibited a relative periodicity after a certain duration. For easier interpretation of the variation of the water level across all nine chambers, only the first 80 h of the winter discharge pattern,

Q, are presented in

Figure 4 and

Figure 5 for partially aerated and fully aerated underground chambers, respectively, for the three smaller cross sectional areas of the connecting galleries (

Table 2).

Water was initially injected at hour 3 into chamber 1 (i.e., the deepest chamber) through the main shaft and the water level gradually increased in all chambers, both for partially aerated (

Figure 4) and fully aerated (

Figure 5) chambers. The initial increase of the water level until hour 5 occurred at a different rate in each chamber, with the chambers closer to the main shaft exhibiting the steeper gradients. This is attributed to the limited discharge capacity of the connecting galleries, which was significantly lower than the incoming discharge of 22.2 m

3/s from the main shaft. Notably, when the water level in a chamber reached the second connecting gallery at 60 m above its bottom side, the water level gradient became less steep as the water exchanges between adjacent chambers were enhanced. As the cumulative cross-sectional area of the connecting galleries increased, the discharge of water between adjacent chambers also increased and the water levels in the different chambers increased at a more similar rate (e.g.,

Figure 4c and

Figure 5c compared to

Figure 4a and

Figure 5a, respectively). Indeed, when the water injection paused temporarily after hour 5, the water levels in the chambers were much different when the cross sections of the connecting galleries were small (

Figure 4a and

Figure 5a). Nevertheless, eventually water levels in all chambers reached an equilibrium depth after hour 5. For fully aerated chambers, the equilibrium water level was the same in all chambers (

Figure 5), but for partially aerated chambers, the water level in each chamber was slightly different (

Figure 4) due to the presence of entrapped air. After this initial pause, water was again injected in the chambers at hour 10. The water level gradients of the chambers were not that different now as before. This is due to the fact that the water level was high enough to reach the higher connecting gallery in many chambers, thus enhancing the water exchanges between the chambers.

When the water injection was again paused at hour 13, the water level in each chamber reached an equilibrium level that was slightly lower than the top side of the chambers at −40 m for aerated chambers (

Figure 5). For partially aerated chambers, the equilibrium water level between hours 13 and 19 was much different in each chamber (

Figure 4). This was due to the fact that the water level had risen and covered both connecting galleries in the chambers (i.e., at the base and 60 m above the bottom side of each chamber), hence the air in the chambers could not escape to adjacent chambers anymore. As a result, the entrapped air in each chamber was compressed and exerted pressure. Only chamber 9 got completely filled with water (

Figure 4) because in the partially aerated underground reservoir scenario, this specific chamber was connected to a ventilation shaft and was adequately aerated.

At hour 19, water pumping started. For relatively small cross sectional areas of the connecting galleries (and similar to the injection phase), the chambers that were closer to the main shaft emptied at a faster rate as the discharge of the connecting galleries was smaller than the pumping discharge of the main shaft (

Figure 4 and

Figure 5). The lowering rate of the water level increased when the water level became lower than the level of the upper connecting gallery and as a result the water level gradient became steeper since the water that was pumped was much greater than the water that was provided by the adjacent chamber. When the pumping phase was paused, e.g., at hour 24, the water levels in the different chambers were not balanced and after some time they reached equilibrium depths. For the fully aerated case, the equilibrium depths in the chambers were always equal to each other, regardless of the water elevation when the pumping was paused. However, in partially aerated chambers the elevation of the water and the associated air compressibility dictate to a large degree the equilibrium depth in each chamber.

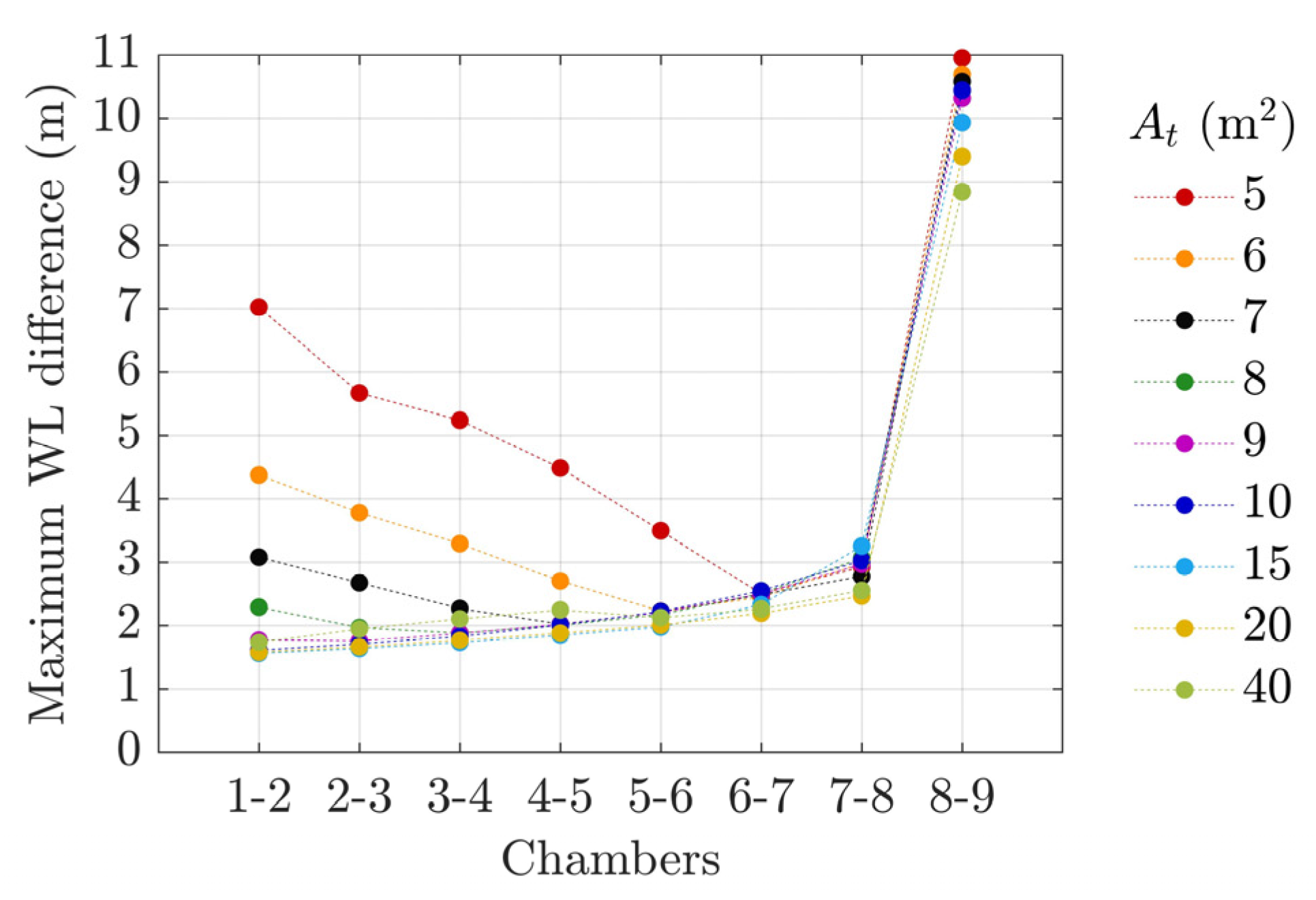

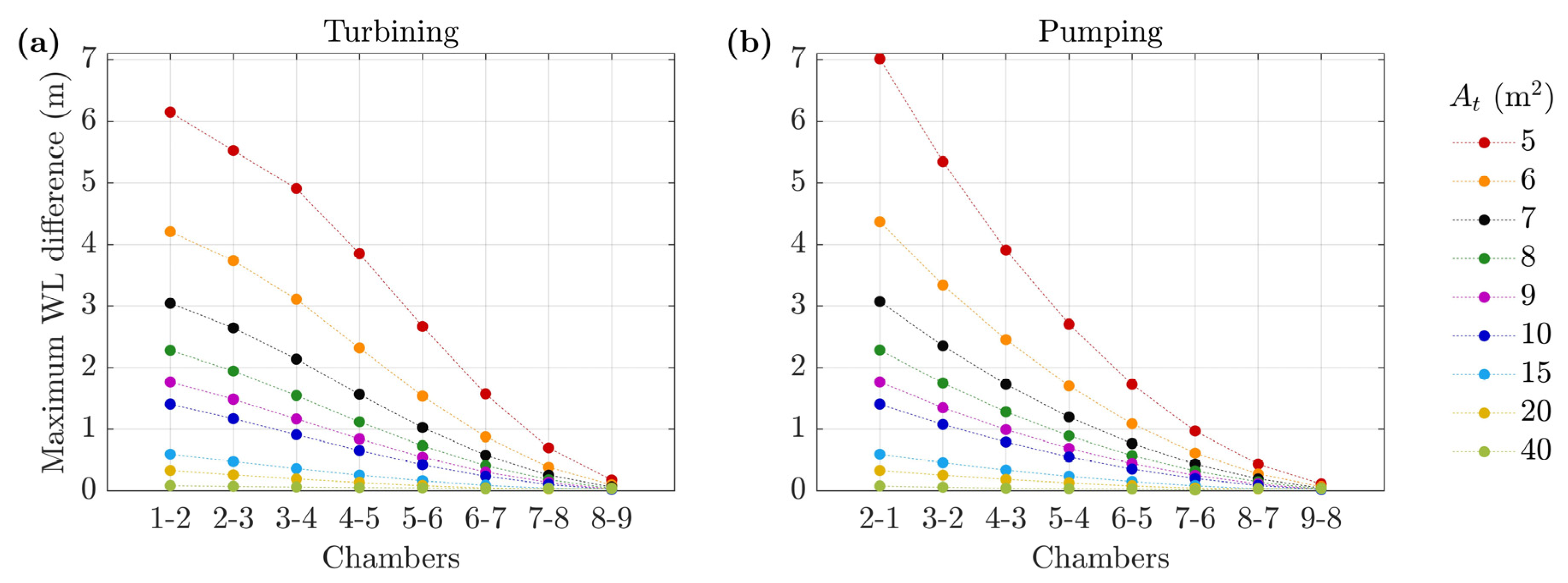

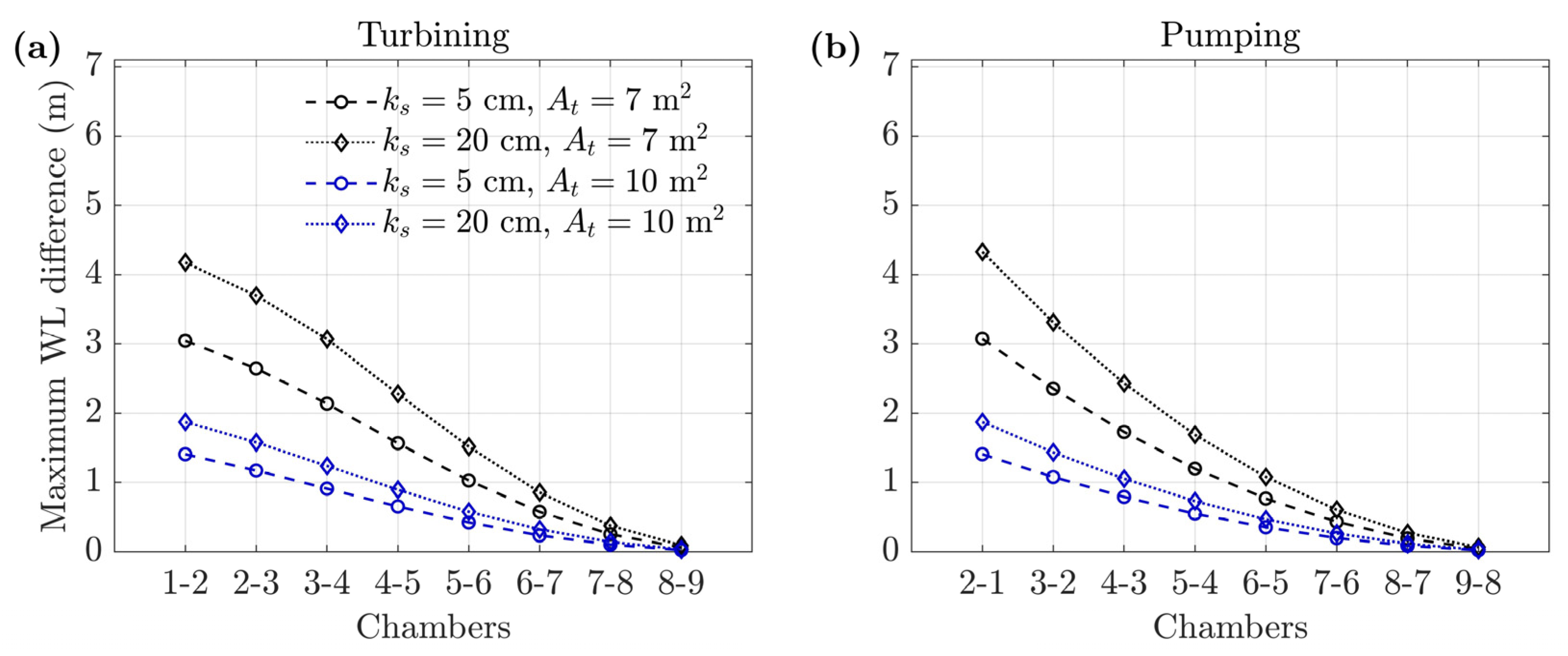

Figure 6 and

Figure 7 show the maximum water level differences between successive chambers across the whole 14-day period for partially and fully aerated chambers, respectively, for the winter discharge scenario. Both in the partially and fully aerated cases, the maximum water level difference dropped rapidly with increasing cumulative cross section of the connecting galleries. For fully aerated chambers, the maximum water level differences between the first two chambers with the smallest connecting galleries were a little higher during the water pumping phase compared to the turbining phase (

Figure 7). However, the water level differences after the second chamber were slightly higher in the turbining phase, most evidently for the smaller cross-sections. The maximum water level differences in fully aerated chambers were always greater for chambers that were closer to the main shaft, which was connected to chamber 1; however, for total cross sectional areas of the connecting galleries greater than 15 m

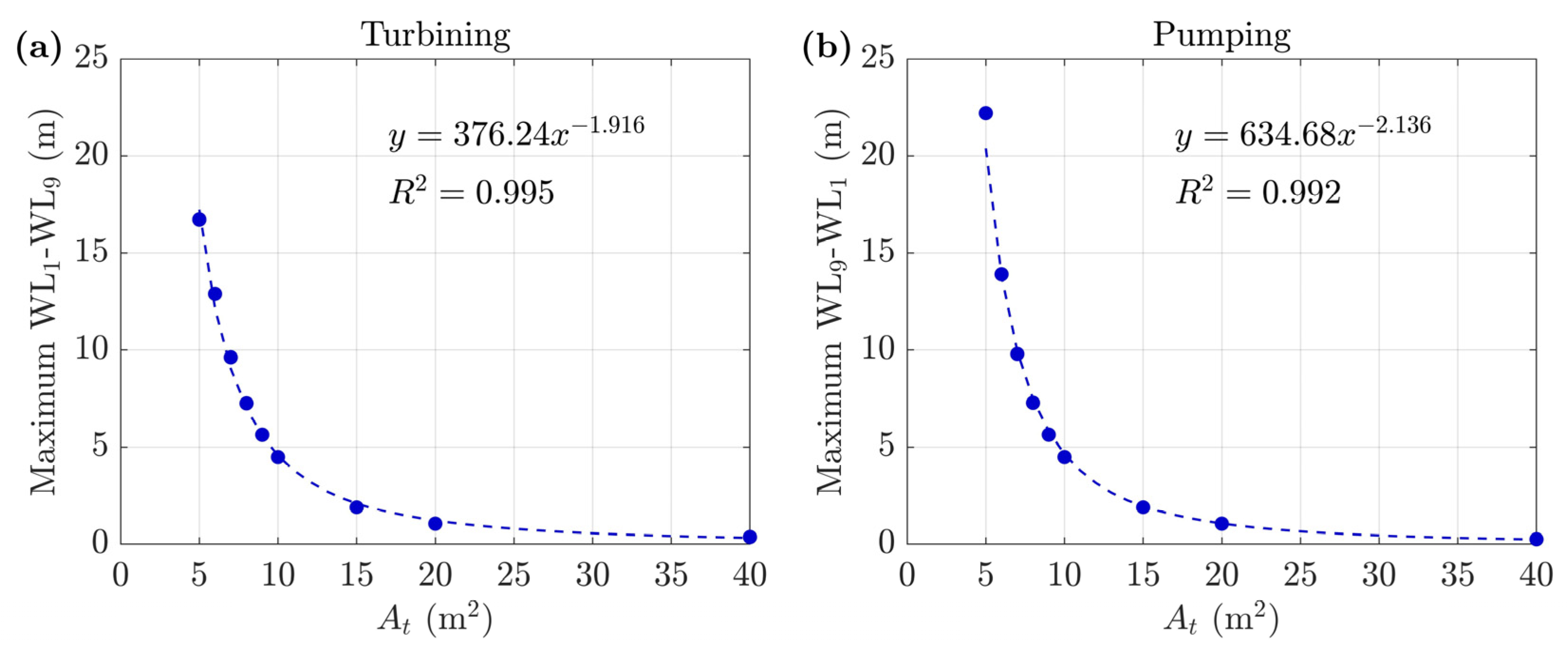

2, the differences became rather negligible. Notably, the maximum water level difference between the first and last chamber in the fully aerated case could be expressed as a power function of the total cross-sectional area of the connecting galleries, both for the turbining and the pumping phase (

Figure 8).

For partially aerated chambers, the water level differences between adjacent chambers exhibited a more complicated pattern compared to fully aerated chambers.

Figure 6 shows that for small connecting galleries with total cross sectional area up to 8 m

2, the water level differences between adjacent chambers initially decreased as the chambers became more distant from the main shaft and after a certain point the water level differences increased. On the contrary, the water level differences between chambers for connecting galleries with cross sections larger than 8 m

2 increased monotonically with increasing distance from the main shaft. The large increase in the last pair of chambers (i.e., chambers 8 and 9) was due to the ventilation shaft that was connected to chamber 9 allowing to become fully filled with water. For partially aerated chambers, some of the maximum water level differences occurred during equilibrium conditions, thus

Figure 6 did not examine separately the turbining and pumping phases like

Figure 7 for the fully aerated chambers.

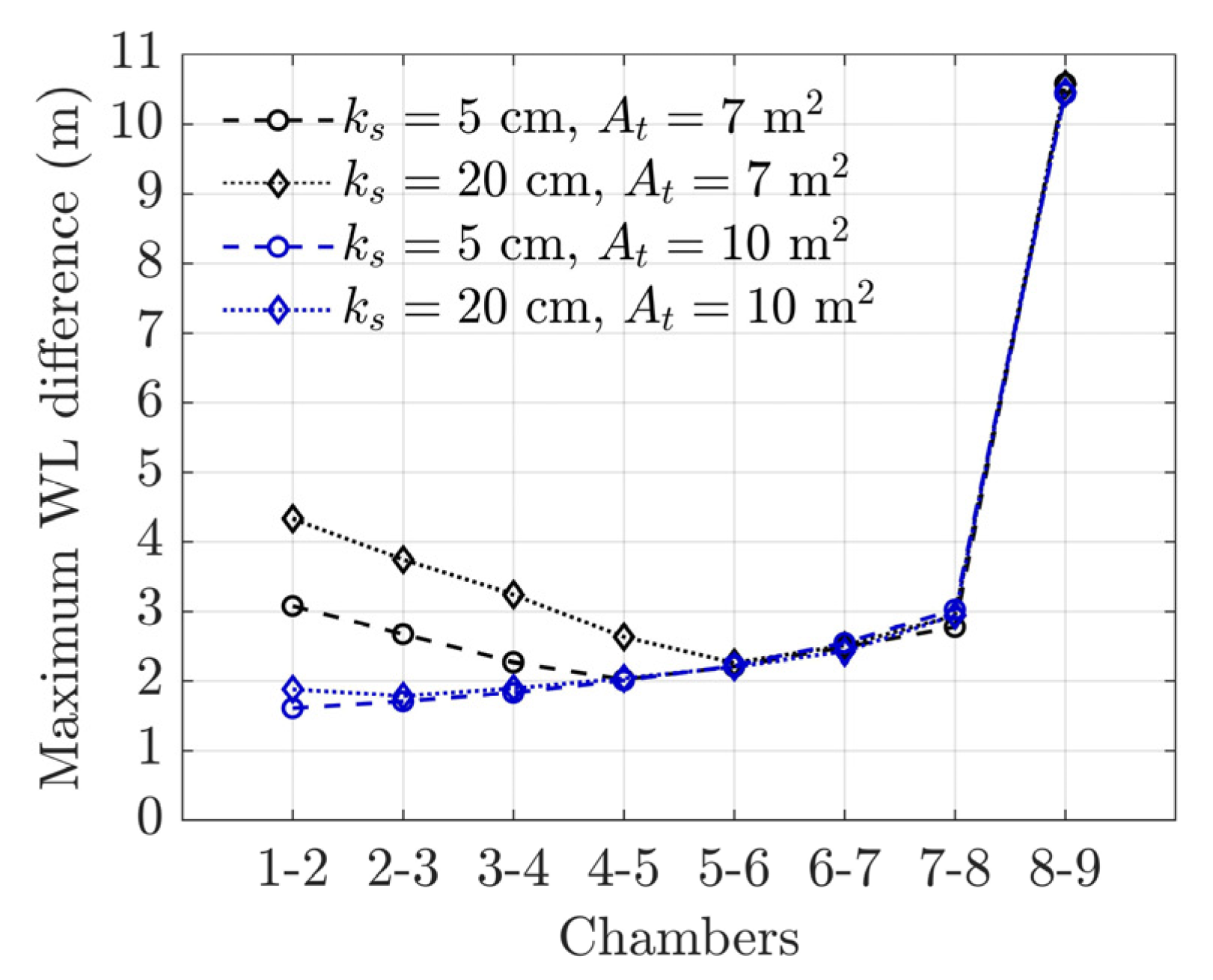

The effect of the hydraulic roughness of the connecting galleries on the water level differences between successive chambers was additionally analyzed. So far, a 5 cm value of the roughness height,

ks, of the connecting galleries was considered. An increase of

ks to 20 cm has been examined. The effect of increased roughness in the connecting galleries on maximum water level differences was more prominent for the chambers closer to the main shaft, both for partially aerated (

Figure 9) and fully aerated (

Figure 10) chambers. The induced differences for a 7 m

2 total cross-sectional area of the connecting galleries exceeded one meter for the first two chambers and became negligible at the chambers away from the main shaft. When the total cross sectional area of the connecting galleries increased from 7 to 10 m

2, the effect of the increasing roughness in the connecting galleries became much less prominent, especially when the chambers were only partially aerated (

Figure 9).

7. Discussion

The efficient utilization of an UPSH plant requires accurate predictions of the water levels and the associated hydraulic heads in the complex underground reservoir for the determination of potential energy storage through pumping from the lower to the upper reservoir and for the estimation of the remaining volume capacity for electricity generation through discharging from the upper to the lower reservoir. The use of abandoned mines as lower reservoirs in UPSH plants makes the prediction of head difference between the upper and lower reservoirs difficult for three reasons. First, because of the constraints of ore location and excavation stability, the geometry of a mine is complex and the available volume to store water is not concentrated in a single large cavity. Consequently, the water level in different parts of the mine may exhibit strong differences when water is pumped/injected at a single location, thus impacting the head difference with the upper reservoir. Second, in an underground cavity, there is no infinite connection to the atmosphere. This means that any modification of the water volume in the cavity needs to be compensated by a variation of the volume of air in the cavity. Finally, groundwater exchanges occur with the surrounding medium. The first two factors were addressed in the present study and the third one in Pujades et al. [

29], considering the same test case.

The abandoned slate mine in Martelange that served here as a case study comprises large chambers connected with small galleries with limited discharge capacity. In case the connecting galleries were too narrow, the incoming discharge from the main shaft was significantly greater than the combined cumulative discharge of the connecting galleries and consequently the hydraulic head within the first chamber was significantly increased. This reduced the head difference between the upper and lower reservoirs, and decreased the UPSH plant efficiency. To fully exploit the elevation difference between the upper and the lower reservoir, drilling of additional connecting galleries or widening of the existing ones is effective in reducing the water level differences between the chambers. The reduction of water level difference from side to side of (between chambers) pillars will also restrict the exposure to bending forces. However, such works will increase the investment cost and may also weaken the pillars separating the chambers.

Another option is to fill the lower reservoir by steps, with breaks in between injections of large portions of water from the upper reservoir, so that the water level becomes uniform across all the interconnected chambers and the hydraulic head in the chamber that is connected to the main shaft is reduced. Such an operating way is however not compatible with the level of flexibility required by energy storage systems. With the operation scenario considered in this study, build upon classical use of an existing pumped storage scheme connected to a grid with a large amount of nuclear and/or thermal energy production, the results presented above already show prohibitive water elevation variation in the underground reservoir. In a future with much more renewable energy production, operation scenarios for pumped storage will be more fluctuating and the problem will be exacerbated.

Similarly, the problem of underground reservoir aeration is crucial. Insufficient aeration can affect significantly the water levels variation in the reservoir compared to a lower reservoir with atmospheric pressure. Menendez et al. [

24] showed that entrapped air due to inadequate aeration of an abandoned coal mine reduces significantly the generation of electricity. However, the underground reservoir in their study had a different geometry and the flow was not constrained by narrow galleries with limited discharge capacity such as those in the present study. Air flow is subject to the same constraint as water flow in limited cross sections. The significant costs of opening additional aeration shafts and connecting galleries, or widening the existing ones, should be compared to the efficiency gain. Different technical solutions could be assessed to facilitate air exchange between the chambers and the surface and between adjacent chambers, such as the drilling of several small boreholes instead of a large aeration shaft or the installation of air pipes in the galleries connecting adjacent chambers, respectively. Herein, the porous underground medium was considered air impervious; however, in reality there may be some air leakages that depend on the air pressure in the chambers and on the characteristics of the underground medium. This could decrease the amplitude of air pressure variations and then have an effect on the water level differences between successive chambers. The simulations presented in this paper consider the two extreme scenarios about air behavior and provide the envelope of its effect on water level differences between successive chambers.

Pujades et al. [

29] considered the construction of the same UPSH plant in Martelange and investigated the groundwater exchanges problem with numerical simulation over a period of a year with a 15 min time interval. The operation scenario they used was the same as in the present study. Although the present paper and the paper by Pujades et al. [

29] investigate the same case study, the coupling of the two numerical models to analyze simultaneously the hydraulics within the chambers and the groundwater exchanges would lead to a prohibitive computational cost. Thus, the two studies can be considered complementary to each other since they focus on different time-scales. Pujades et al. [

29] showed that over short time periods the groundwater exchanges can be negligible compared to the pumping/turbining cycles from the upper reservoir in the surface, since the maximum groundwater inflow rate was 0.37 m

3/s, which is much lower than the maximum pumping/turbining discharge rate of 22.2 m

3/s from the main shaft. When combining the findings from the two studies, it can be inferred that the head in the underground reservoir will slowly increase, which will lead to reduced production of electricity, unless the accumulating groundwater inflows are periodically removed. Nevertheless, in case the natural piezometric head was lower, the inflow–outflow groundwater exchanges would be more balanced [

29].

8. Conclusions

Energy production is shifting to renewable energy sources for the reduction of carbon emissions. The intermittent nature of most renewable energy sources requires their coupling with efficient energy storage systems of large capacity, such as PSH plants. To overcome topographic, societal and environmental limitations associated with the construction of new PSH plants, the option of using abandoned mines for the construction of the lower reservoir under the ground with an UPSH plant appears as an attractive alternative. However, the use of abandoned mines as lower reservoirs in UPSH plants makes the prediction of the plant operation difficult for several reasons related to the complex geometry of the available underground volume and its aeration conditions. In particular, in this study, the application of an original hydraulic modelling approach to the specific case of a slate mine in Belgium showed that the water level in the underground reservoir is unlikely to be constant across the whole reservoir, affecting thus significantly the head difference between the upper and lower reservoirs as well as possibly undermining the underground reservoir stability.

It can be inferred that each abandoned mine that is considered a viable option for an UPSH plant may represent a unique case with its own peculiarities. The location of the mine, its geometry, the underground properties, the type of mining activities when the mine was functional, and the aimed energy production lead to a combination of influencing parameters that is probably unique for each mine. A general model for UPSH project feasibility studies should therefore be based on a cross-disciplinary approach with intertwined hydraulic, geotechnical, and economical modeling. From a hydraulic engineering standpoint, the sought cross-sectional area of the limiting reservoir areas should be large enough to supply enough water to the chamber that is connected to the main shaft during pumping phase and convey large portions of water to the neighboring chambers (i.e., maintain a uniform water level across all chambers at all times) during the turbining phase to secure uninterrupted operations and maximize the efficiency of the UPSH plant. However, in such projects the hydraulic modeling of underground reservoirs will be inevitably subject to additional restrictions that may constrain the optimal hydraulic design and the desired widening of connecting tunnels or aeration shafts may not be recommended in order to secure the stability of the cavity, reduce the costs, and maximize the net revenue of the plant. The same problem arises with the air volume possibly entrapped in the underground reservoir, which could significantly alter the water movements. Development of innovative cost-efficient solutions to these problems is required to enable the use of existing underground cavities as reservoirs for UPHS plants. The hydraulic modelling approach presented in this paper offers a quick evaluation of the effect of such solutions.