High-Temperature Geothermal Utilization in the Context of European Energy Policy—Implications and Limitations

Abstract

1. Introduction

1.1. Overview of Current EU Energy and Climate Policy

- No less than a 40% reduction of greenhouse gas emissions compared to 1990 levels. The target is twofold, where sectors under the EU emissions trading system (ETS) must cut emissions by 43%, and non-ETS sectors (emissions under each Member State) need to reduce emissions by 30%, both compared to 2005 levels [11].

1.2. Indicators for Energy Technologies Affecting Key EU Energy and ClimateT

1.2.1. Greenhouse Gas Emission Factors

1.2.2. Primary Energy Factors (PEF) for Different Energy Systems

- For directly combustible energy resources (e.g., lignite, natural gas, gasoline, biogas, firewood, and combustible municipal waste), their primary energy form is defined as the heat generated during combustion [3].

- For energy resources that are not directly combustible, the primary energy form is chosen as:

- -

- the heat content of the working fluid (the fluid that delivers the primary energy to the conversion cycle) for nuclear, geothermal, solar thermal, and ambient heat, and;

- -

- the produced electricity output from the energy conversion cycle for solar photovoltaic, wind, hydro, tide, wave and other ocean energy [3].

1.2.3. Adding Life Cycle Perspectives into the PEF

1.2.4. Possible Implications of PEFs for Different Energy Systems on EU Climate and Energy Targets

1.2.5. Response to Criticism on the Definition of Primary Energy Content for Renewable Energy Technologies

1.3. High-Temperature Geothermal Energy in the EU’s Energy Policy

1.3.1. GHG Emissions from High-Temperature Geothermal

1.3.2. Primary Energy Factor for Geothermal

1.3.3. Combined Heat and Power Production from High-Temperature Geothermal Resources in Context with EU’s Energy Policy

2. Materials and Methods

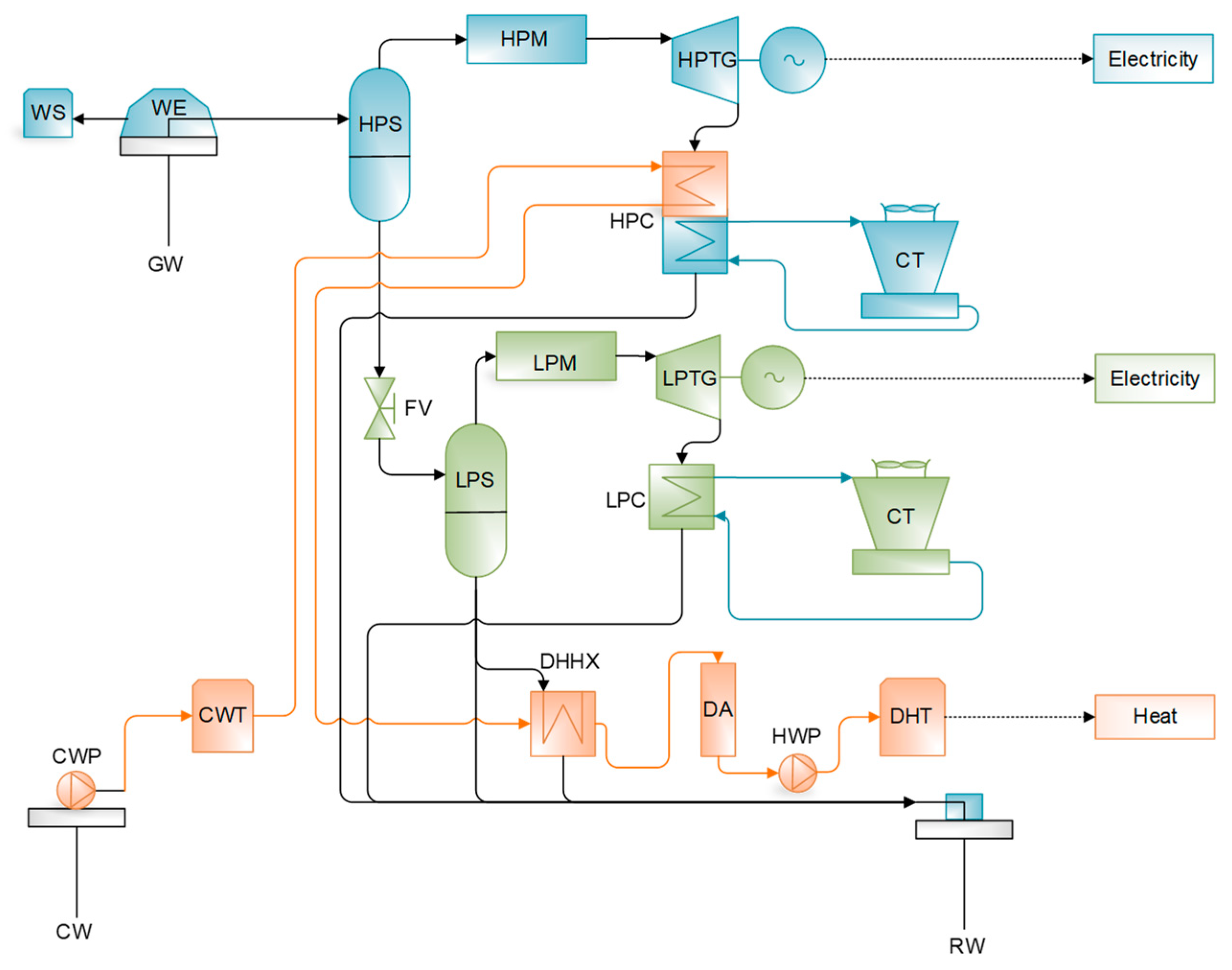

2.1. Case Study: Hellisheidi Geothermal Combined Heat and Power Plant

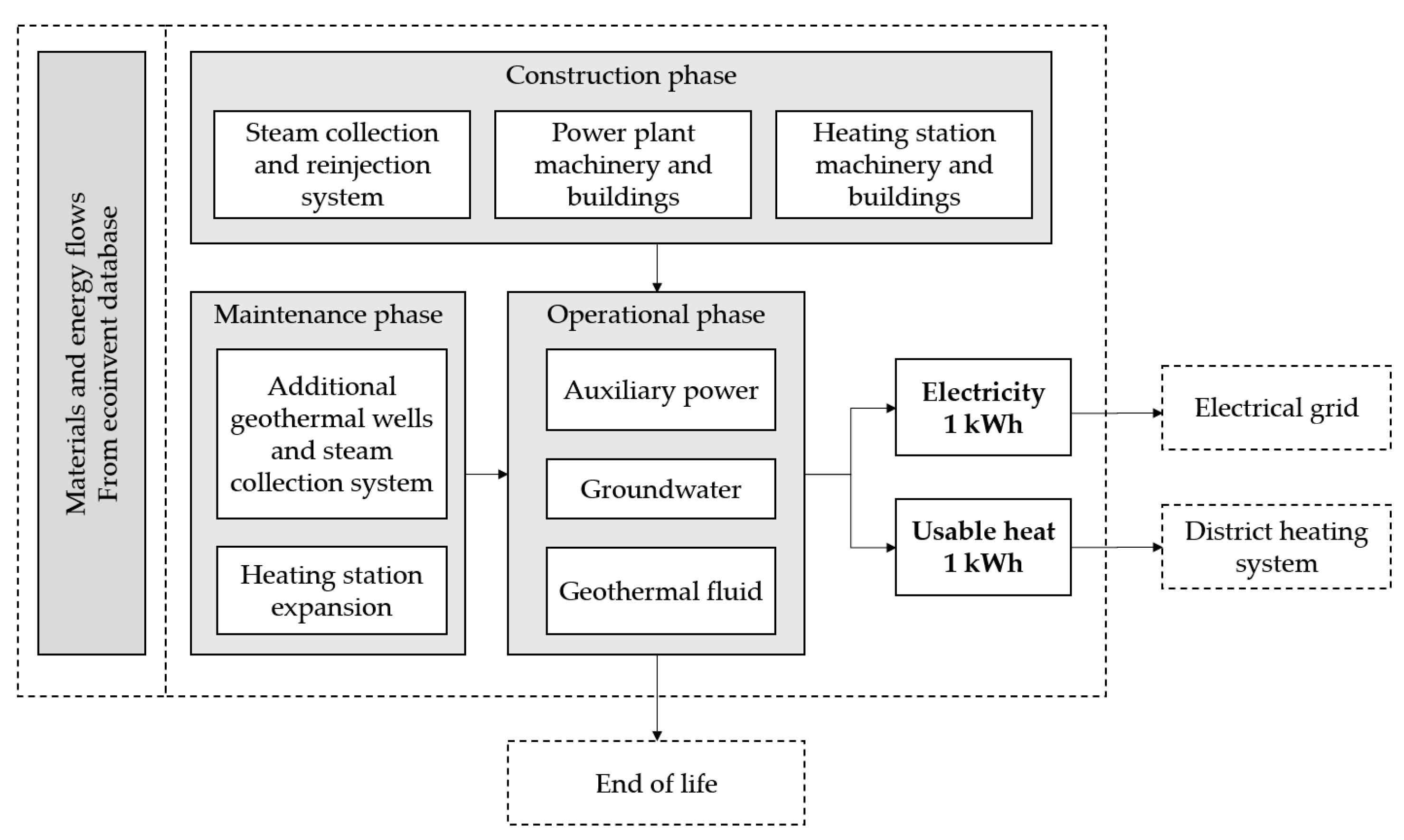

2.2. Life Cycle Assessment (LCA) of the Hellisheidi GCHP Plant

- To provide a detailed dataset for high-temperature geothermal heat- and power generation technology to be used in other LCA studies as a reference, as these studies are scarce [48].

- To investigate the life cycle environmental impacts of high-temperature geothermal heat and power production [8].

- To examine the contribution of different life cycle stages of high-temperature geothermal heat- and power production to the overall environmental impacts to see if hidden impacts occur in upstream or downstream life cycle stages compared to the operational life cycle stage [8].

- To investigate the effects of operational improvements implemented during the first decade of operation of the Hellisheidi CHP plant on the overall life cycle environmental impacts compared to a base case scenario. This was done by comparing the operation scenario from 2012, where no abatement system for gaseous emissions was present, to the operation scenario from 2017 when abatement methods had been installed for gaseous emissions [8].

2.3. Calculation of Primary Energy Factor for Geothermal Utilization

- (1)

- Calculating the primary energy content with basic thermodynamic equations based on the enthalpy (heat content) of the geothermal fluid extracted from the resource as instructed by the EU climate and energy policy framework. Since the spent geothermal fluid is reinjected back down to the reservoir after utilization within the power plant, the primary energy content of the reinjected fluid is subtracted from the extracted primary energy.

- (2)

- Using historical and forecasted operational input and output parameters of primary energy flow and corresponding production of electricity and heat from the plant to calculate the average PEF for the energy products over a 30-year technical lifetime scenario.

- (3)

- Using life cycle assessment (LCA) to account for primary energy use to extract, supply, and convert the geothermal energy to electricity and heat. LCA considers the whole value-chain within the system boundary of the power plant, as explained above in Section 2.2. The Cumulative Energy Demand (CED) method was used to calculate the final primary energy use of the power plant per produced unit of electricity and heat. The results generated by the CED method allows for a break-down of the primary energy factor into non-renewable and renewable PEFs.

- (4)

- Using different allocation methods to divide the primary energy input between electricity and heat outputs to calculate the separate PEF for each energy product. These are further discussed in Section 2.4.

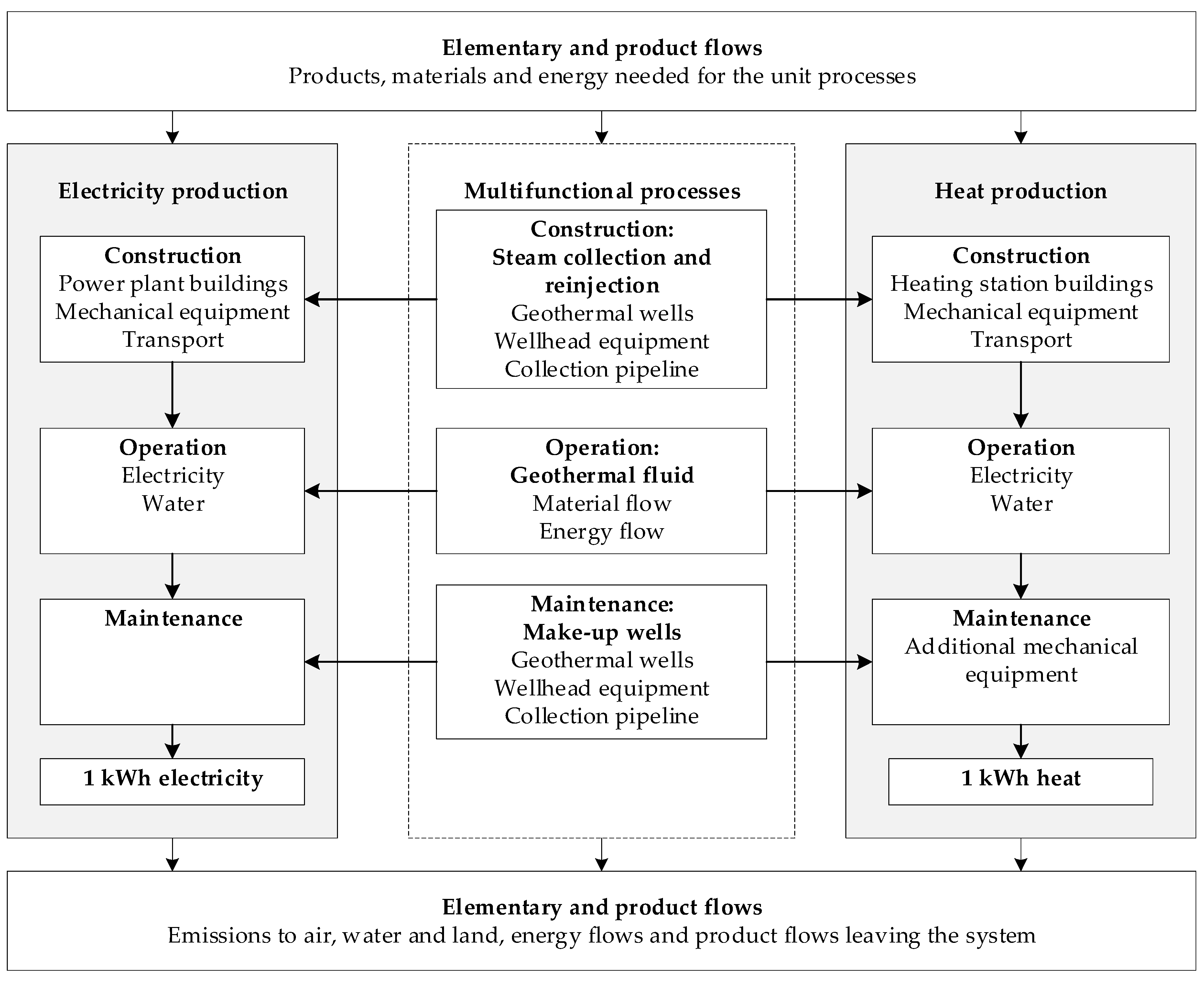

2.4. Allocation of Environmental Impacts and Primary Energy Use

- (1)

- Construction phase: Steam collection and reinjection system that collects, transports, and disposes of the geothermal fluid used for energy production. The processes included here are the energy and material intensive drilling activities (subsurface), as well as the well completion and the construction of the collection pipeline system for transporting the geothermal fluid above-surface.

- (2)

- Operational phase: Includes the use of geothermal fluid. Here, the fluid’s thermal energy content defines the primary energy form for the energy conversion cycle, and its gas- and mineral content is the cause of various potential environmental effects.

- (3)

- Maintenance phase: Includes drilling and completion of make-up wells for maintaining energy supply during the lifetime of the power plant. These wells sustain a constant flow of primary energy needed to produce electricity and heat, as older wells decline during production.

2.4.1. Method A: Avoidance of Allocation with Electricity as a Primary Product

2.4.2. Method B: Avoidance of Allocation with Heat as a Primary Product

- B1

- For steam collection and reinjection during the construction phase: An estimation of the minimum requirement of steam collection and reinjection infrastructure to produce and sustain the heat production throughout the 30-year technical lifetime of the plant was made based on thermodynamic energy balance for stand-alone heat production and the known energy output from wells drilled at Hellisheidi. Here, it is evaluated that a minimum of five out of the 64 production wells and four out of the 17 reinjection wells would have to be drilled solely for the 133 MWth heat production that was installed during the construction phase of the CHP plant (prior to the year 2012 when operation phase is assumed to start in the study).

- B2

- For geothermal fluid: The geothermal energy extraction essential for heat production is calculated separately and compared to the overall energy extraction from the geothermal fluid for the total CHP plant production to calculate the partitioning factor. However, for mass flow and direct emissions due to the use of the geothermal fluid by a heat-alone plant, the same partitioning factor is used for B1, as explained above.

- B3

- For the need of make-up wells for maintaining heat production: The assumed decline of geothermal well output due to production was estimated for the maintenance phase of a stand-alone heat plant. Here, the assumption is made that at least one make-up well is needed exclusively for the maintenance of heat production at the plant over a 30-year lifetime (compared to an estimate of 15-60 make-up wells being necessary for the overall CHP plant to sustain both heat and electricity production). The assumed need for make-up wells includes future expansions above the original 133 MWth installed thermal capacity, e.g., the recent 200 MWth expansion in 2020.

2.4.3. Method C: Energy Allocation

2.4.4. Method D: Exergy Allocation

2.4.5. Method E: Economic Allocation

2.4.6. Method F: Alternative Generation Method (AGM)

3. Results

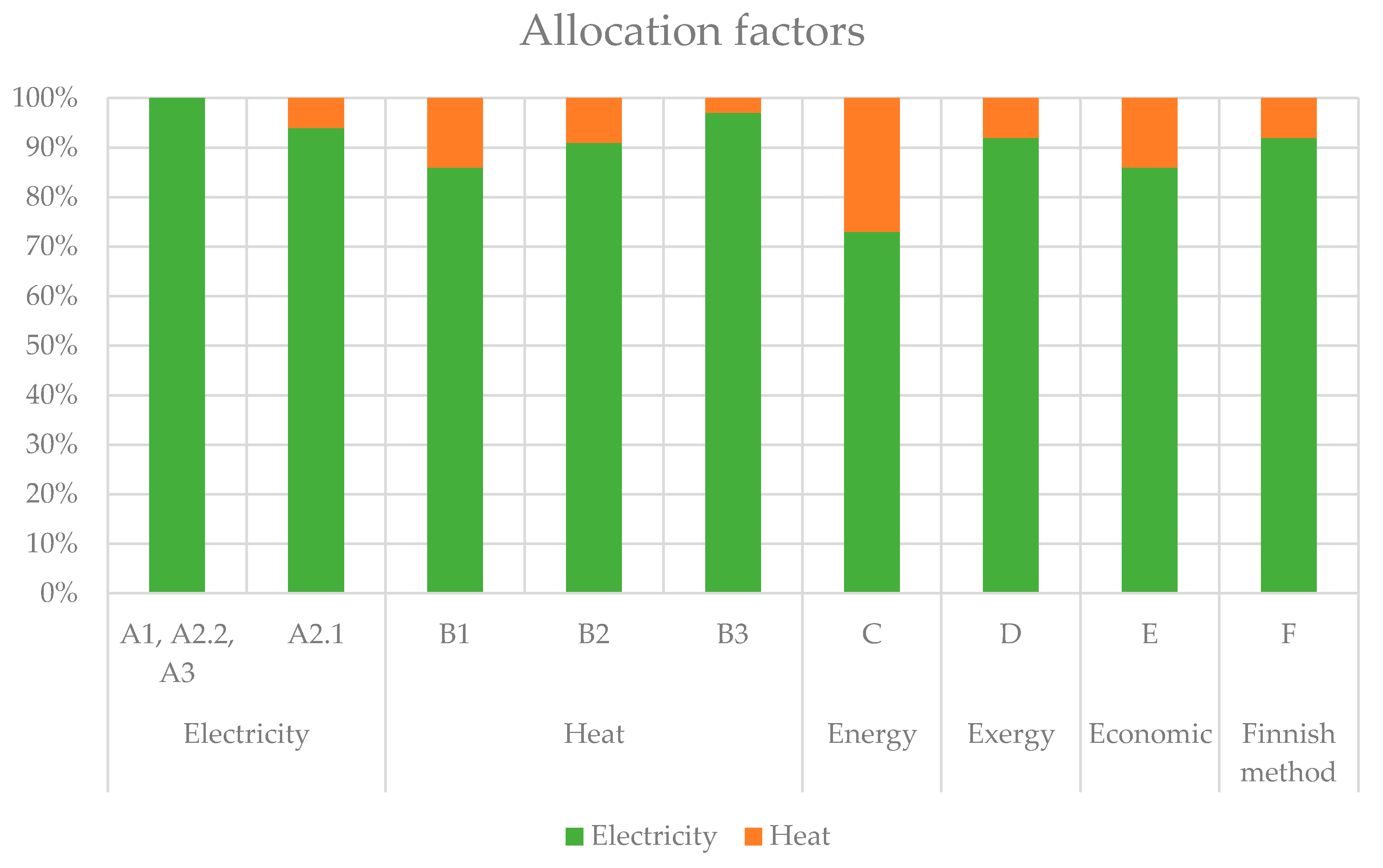

3.1. Allocation Factors

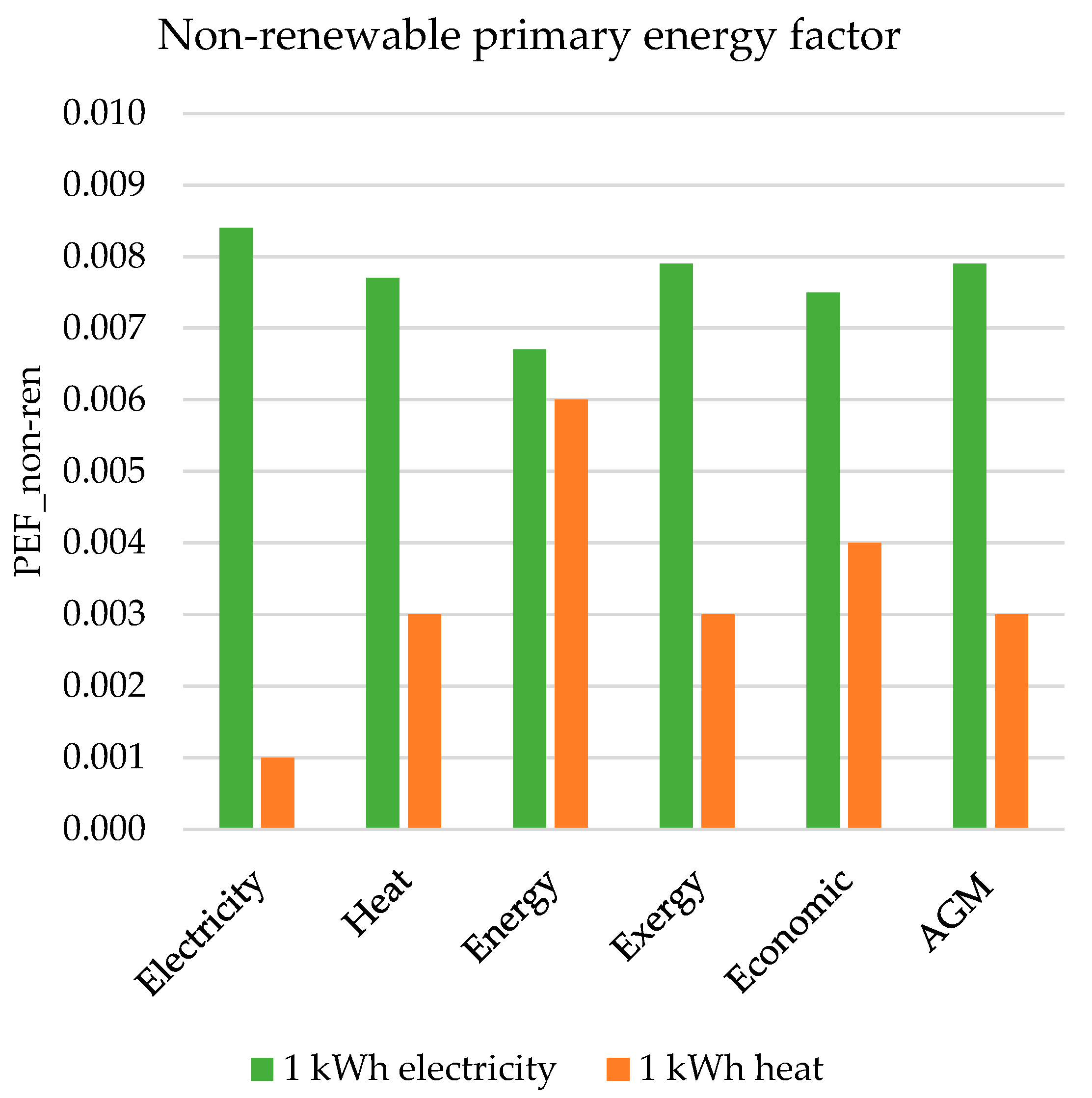

3.2. Indicator Results for Electricity and Heat from Hellisheidi CHP Plant

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| ACER | Agency for the Cooperation of Energy Regulators |

| AGM | Alternative Generation Method |

| CED | Cumulative Energy Demand |

| CEN | The European Committee for Standardization (French: Comité Européen de Normalisation) |

| CHP | Combined Heat and Power |

| CML-IA | Impact Assessment method of the Centrum voor Milieuwetenschappen, Leiden University |

| CT | Cooling tower |

| CW | Coldwater well |

| CWP | Coldwater pumps |

| CWT | Coldwater tank |

| DA | Deaerator |

| DHHX | Heat exchanger District Heat |

| DHT | Hot water tank District Heat |

| ED | Electricity Directive |

| EED | Energy Efficiency Directive |

| EOL | End of life |

| EPB | Energy Performance in Buildings |

| EPBD | Energy Performance in Buildings Directive |

| EPC | Energy Performance Certificate |

| ETS | Emission Trading System |

| EU | European Union |

| FV | Flashing valve |

| GHG | Greenhouse Gas Emissions |

| GW | Geothermal well |

| HPC | High-pressure condenser with preheater |

| HPM | method moisture remover |

| HPS | High-pressure steam separator |

| HPTG | High-pressure turbine-generator set |

| HWP | Hot water pump |

| IEA | International Energy Agency |

| IPCC | Intergovernmental Panel on Climate Change |

| IRES | International Recommendations for Energy Statistics |

| ISO | International Organization for Standardization |

| LCA | Life Cycle Assessment |

| LCI | Life cycle inventory |

| LPC | Low-pressure condenser |

| LPM | Low-pressure moisture remover |

| LPS | Low-pressure steam separator |

| LPTG | Low-pressure turbine-generator set |

| PEF | Primary Energy Factor |

| PEFnon-ren | Non-Renewable Primary Energy Factor |

| RED | Renewable Energy Directive |

| RW | Reinjection well |

| WE | Wellhead |

| WS | Well silencer |

References

- European Commission. Clean Energy for All Europeans Package. Available online: https://ec.europa.eu/energy/en/topics/energy-strategy-and-energy-union/clean-energy-all-europeans (accessed on 21 November 2019).

- International Energy Agency. Commentary: Understanding and Using the Energy Balance. Available online: https://www.iea.org/newsroom/news/2017/september/commentary-understanding-and-using-the-energy-balance.html?utm_content=buffer3537d (accessed on 26 November 2019).

- Eurostat. Energy Balance Guide. Methodology Guide for the Construction of Energy Balances & Operational Guide for the Energy Balance Builder Tool. Available online: https://ec.europa.eu/eurostat/documents/38154/4956218/ENERGY-BALANCE-GUIDE-DRAFT-31JANUARY2019.pdf/cf121393-919f-4b84-9059-cdf0f69ec045 (accessed on 26 November 2019).

- Buildings Performance Institute Europe. Is the Primary ENERGY factor the Right Indicator for Determining the Energy Performance of Buildings? Discussion Paper. Available online: http://bpie.eu/wp-content/uploads/2017/09/Policy-paper-PEF_edits_18Sept.pdf (accessed on 22 November 2019).

- Harmsen, R.; Wesselink, B.; Eichhammer, W.; Worrell, E. The unrecognized contribution of renewable energy to Europe’s energy savings target. Energy Policy 2011, 39, 3425–3433. [Google Scholar] [CrossRef]

- Hitchin, R. Primary Energy Factors and the primary energy intensity of delivered energy: An overview of possible calculation conventions. Build. Serv. Eng. Res. Technol. 2018, 40, 014362441879971. [Google Scholar] [CrossRef]

- Segers, R. Three options to calculate the percentage renewable energy: An example for a EU policy debate. Energy Policy 2008, 36, 3243–3248. [Google Scholar] [CrossRef]

- Karlsdottir, M.R.; Heinonen, J.; Palsson, H.; Palsson, O.P. Life cycle assessment of a geothermal combined heat and power plant based on high temperature utilization. Geothermics 2020, 84, 101727. [Google Scholar] [CrossRef]

- Eurostat. Smarter, Greener, More Inclusive? Indicators to Support the Europe 2020 Strategy, 2019 eds.; Publication Office of the European Union: Luxembourg, 2019. [Google Scholar]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. A Policy Framework for Climate and Energy in the Period from 2020 to 2030; Publication Office of the European Union: Luxembourg, 2014. [Google Scholar]

- European Commission. 2030 Climate & Energy Framework. Available online: https://ec.europa.eu/clima/policies/strategies/2030_en (accessed on 21 November 2019).

- Directorate-General for Energy, Clean Energy for All Europeans; Publication Office of the European Union: Luxembourg, 2019.

- European Commission The European Green Deal. Available online: https://ec.europa.eu/commission/presscorner/detail/e%20n/ip_19_6691 (accessed on 17 April 2020).

- European Commission, Directorate-General for Climate Action. Proposal for a regulation of the european parliament and of the council establishing the framework for achieving climate neutrality and amending Regulation (EU) 2018/1999 (European Climate Law); Publication Office of the European Union: Brussels, Belgium, 2020. [Google Scholar]

- European Council Directive. Directive (EU) 2018/844 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2010/31/EU on the Energy Performance of Buildings and Directive 2012/27/EU on Energy Efficiency (Text with EEA Relevance); European Parliamend and European Council, Ed.; Official Journal of the European Union: Luxembourg, 2018. [Google Scholar]

- European Council Directive. Directive (EU) 2018/2002 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources (Recast); Official Journal of the European Union: Luxembourg, 2018. [Google Scholar]

- Cherubini, F.; Birda, N.; Cowie, A.; Jungmeier, G.; Schlamadinger, B.; Woess-Gallasch, S. Energy- and greenhouse gas-based LCA of biofuel and bioenergy systems: Key issues, ranges and recommendations. Resourc. Conserv. Recycl. 2009, 53, 434–447. [Google Scholar] [CrossRef]

- Heinonen, J.; Laine, J.; Pluuman, K.; Säynäjoki, E.-S.; Soukka, R.; Junnila, S. Planning for a Low Carbon Future? Comparing Heat Pumps and Cogeneration as the Energy System Options for a New Residential Area. Energies 2015, 8, 9137–9154. [Google Scholar] [CrossRef]

- Olkkonen, V.; Syri, S. Spatial and temporal variations of marginal electricity generation: The case of the Finnish, Nordic, and European energy systems up to 2030. J. Clean. Prod. 2016, 126, 515–525. [Google Scholar] [CrossRef]

- Zhang, X.; Myhrvold, N.P.; Caldeira, K. Key factors for assessing climate benefits of natural gas versus coal electricity generation. Environ. Res. Lett. 2014, 9, 114022. [Google Scholar] [CrossRef]

- Farsaei, A.; Syri, S.; Olkkonen, V.; Khosravi, A. Unintended Consequences of National Climate Policy on International Electricity Markets—Case Finland’s Ban on Coal-Fired Generation. Energies 2020, 13, 1930. [Google Scholar] [CrossRef]

- Soimakallio, S.; Kiviluoma, J.; Saikku, L. The complexity and challenges of determining GHG (greenhouse gas) emissions from grid electricity consumption and conservation in LCA (life cycle assessment)—A methodological review. Energy 2011, 36, 6705–6713. [Google Scholar] [CrossRef]

- European Council Directive. Directive (EU) 2018/2002 of the European Parliament and of the Council of 11 December 2018 Amending Directive 2012/27/EU on Energy Efficiency; Official journal of the European Union: Luxembourg, 2018. [Google Scholar]

- Bio Intelligence Service; Ronan Lyons. IEEP Energy Performance Certificates in Buildings and Their Impact on Transaction Prices and Rents in Selected EU Countries. Final Report Prepared for European Commission (DG Energy); Publication Office of the European Union: Brussels, Belgium, 2013. [Google Scholar]

- International Organization for Standardization. Energy Performance of Buildings-Overarching EPB Assessment—Part 1: General Framework and Procedures (ISO 52000-1:2017); International Organization for Standardization: Geneva, Switzerland, 2017. [Google Scholar]

- European committee for standardization. Energy Performance of Buildings - Overarching EPB Assessment—Part 2: Explanation and Justification of ISO 52000-1 (CEN ISO/TR 52000-2:2017); International Organization for Standardization: Geneva, Switzerland, 2017. [Google Scholar]

- Curran, M.A.; Mann, M.; Norris, G. The international workshop on electricity data for life cycle inventories. J. Clean. Prod. 2005, 13, 853–862. [Google Scholar] [CrossRef]

- Guinée, J.B.G.M.; Heijungs, R.; Huppes, G.; Kleijn, R.; de Koning, A.; van Oers, L.; Wegener Sleeswijk, A.; Suh, S.; Udo de Haes, H.A.; de Bruijn, H.; et al. Handbook on Life Cycle Assessment. Operational Guide to the ISO Standards. I: LCA in Perspective. IIa: Guide. IIb: Operational Annex. III: Scientific Background; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2002; p. 692. [Google Scholar]

- Guinée, J.B.; Heijungs, R.; Huppes, G.; Zamagni, A.; Masoni, P.; Buonamici, R.; Ekvall, T.; Rydberg, T. Life cycle assessment: Past, present, and future. Environ. Sci. Technol. 2011, 45, 90–96. [Google Scholar] [CrossRef] [PubMed]

- Sauar, E. IEA Underreports Contribution Solar and Wind by A Factor of Three Compared to Fossil Fuels. Available online: https://energypost.eu/iea-underreports-contribution-solar-wind-factor-three-compared-fossil-fuels/ (accessed on 25 November 2019).

- Saemundsson, K.; Axelsson, G.; Steingrimsson, B. Geothermal Systems in Global Perspective; ISOR – Iceland GeoSurvey Reykjavik: Reykjavik, Iceland, 2009. [Google Scholar]

- DiPippo, R. Geothermal Power Plants. Principles, Applications, Case Studies and Environmental Impact; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Eurostat Statistics Explained. Electricity Production, Consumption and Market Overview. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php/Electricity_production,_consumption_and_market_overview#:~:text=Data%20extracted%20in%20June%202019,Planned%20article%20update%3A%20July%202020.&text=Total%20net%20electricity%20generation%20in,2017%20came%20from%20combustible%20fuels (accessed on 5 June 2020).

- Huttrer, G.W. Geothermal Power Generation in the World 2015-2020 Update Report. In World Geothermal Congress; International Geothermal Association: Reykjavik, Iceland, 2020. [Google Scholar]

- Lund, J.W.; Toth, A.N. Direct Utilization of Geothermal Energy 2020 Worldwide Review. In World Geothermal Congress; International Geothermal Association: Reykjavik, Iceland, 2020. [Google Scholar]

- Sullivan, J.L.; Wang, M.Q. Life cycle greenhouse gas emissions from geothermal electricity production. J. Renew. Sustain. Energy 2013, 5, 063122. [Google Scholar] [CrossRef]

- Saner, D.; Juraske, R.; Kubert, M.; Blum, P.; Hellweg, S.; Bayer, P. Is it only CO2 that matters? A life cycle perspective on shallow geothermal systems. Renew. Sustain. Energy Rev. 2010, 14, 1798–1813. [Google Scholar] [CrossRef]

- Bertani, R.; Thain, I. Geothermal power generating plant CO2 emission survey. IGA News, 20 September 2002; 1–3. [Google Scholar]

- Hussy, C.; Klaassen, E.; Koornneef, J.; Wigand, F. International Comparison of Fossil Power Efficiency and CO2 Intensity; Ecofys: Utrecht, The Netherlands, 2014. [Google Scholar]

- Fridriksson, T.; Mateos, A.; Orucu, Y.; Audinet, P. Greenhouse Gas Emissions from Geothermal Power Production. In Stanford Geothermal Workshop; Stanford Geothermal Workshop: Stanford, CA, USA, 2017. [Google Scholar]

- Orkustofnun. OS-2019-T004-01: Gas Emissions of Geothermal Power Plants and Utilities 1969–2018; Orkustofnun: Reykjavik, Iceland, 2019. [Google Scholar]

- Zarrouk, S.J.; Moon, H. Efficiency of geothermal power plants: A worldwide review. Geothermics 2014, 51, 142–153. [Google Scholar] [CrossRef]

- European Environment Agency. Trends and Projections in Europe 2019. Tracking Progress towards Europe’s Climate and Energy Targets; 15/2019; Publication Office of the European Union: Luxembourg, 2019. [Google Scholar]

- Lund, J.W.; Chiasson, A. Examples of combined heat and power plants using geothermal energy. In European Geothermal Congress (EGC); European Geothermal Energy Council (EGEC): Unterhaching, Germany, 2007. [Google Scholar]

- DeLovato, N.; Sundarnath, K.; Cvijovic, L.; Kota, K.; Kuravi, S. A review of heat recovery applications for solar and geothermal power plants. Renew. Sustain. Energy Rev. 2019, 114, 109329. [Google Scholar] [CrossRef]

- EPD INTERNATIONAL AB. Product Category Rules (PCR). Electricity, Steam and Hot Water Generation and Distribution; 2007:08; EPD International AB: Stockholm, Sweden, 2020. [Google Scholar]

- European Committee for Standardization. EN 15316-4-5:2017 (E). Heating Systems in Buildings - Method for Calculation of SYSTEM energy Requirements and System Efficiencies—Part 4–5: District Heating and Cooling; International Organization for Standardization: Geneva, Switzerland, 2017. [Google Scholar]

- Karlsdottir, M.R.; Palsson, H.; Palsson, O.P.; Maya-Drysdale, L. Life cycle inventory of a flash geothermal combined heat and power plant located in Iceland. Int. J. Life Cycle Assess. 2015, 20, 503–519. [Google Scholar] [CrossRef]

- Gunnlaugsson, E.; Gislason, G. Preparation for a New Power Plant in the Hengill Geothermal Area, Iceland In World Geothermal Congress; International Geothermal Association: Antalya, Turkey, 2005. [Google Scholar]

- National Energy Authority. Energy Statistics in Iceland 2016; Orkustofnun National Enery Authority: Reykjavík, Iceland, 2017. [Google Scholar]

- ISO 14040. Environmental Management-Life Cycle Assessment-Principles and Framework (ISO 14040:2006); ISO-International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- ISO 14044. Environmental Management-Life Cycle Assessment-Requirements and Guidelines (ISO 14044:2006); ISO-International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- Hischier, R.; Weidema, B.; Althaus, H.J.; Bauer, C.; Doka, G.; Dones, R.; Frischknecht, R.; Hellweg, S.; Humbert, S.; Jungbluth, N. Implementation of Life Cycle Impact Assessment Methods. Ecoinvent Report No. 3, v2.2; ecoinvent Centre: Dübendorf, Switzerland, 2010. [Google Scholar]

- Sullivan, J.L.; Stephens, T.; Wang, M. Geothermal Power Production: Alternative Scenarios and Critical Issues; Argonne National Lab. (ANL): Lemont, IL, USA, 2014.

- Buonocore, E.; Vanoli, L.; Carotenuto, A.; Ulgiati, S. Integrating life cycle assessment and emergy synthesis for the evaluation of a dry steam geothermal power plant in Italy. Energy 2015, 86, 476–487. [Google Scholar] [CrossRef]

- Frick, S.; Kaltschmitt, M.; Schroder, G. Life cycle assessment of geothermal binary power plants using enhanced low-temperature reservoirs. Energy 2010, 35, 2281–2294. [Google Scholar] [CrossRef]

- Ertesvåg, I.S. Exergetic comparison of efficiency indicators for combined heat and power (CHP). Energy 2007, 32, 2038–2050. [Google Scholar] [CrossRef]

- Moretti, C.; Corona, B.; Rühlin, V.; Götz, T.; Junginger, M.; Brunner, T.; Obernberger, I.; Shen, L. Combining Biomass Gasification and Solid Oxid Fuel Cell for Heat and Power Generation: An Early-Stage Life Cycle Assessment. Energies 2020, 13, 2773. [Google Scholar] [CrossRef]

- Lelek, L.; Kulczycka, J.; Lewandowska, A.; Zarebska, J. Life cycle assessment of energy generation in Poland. Int. J. Life Cycle Assess. 2016, 21, 1–14. [Google Scholar] [CrossRef]

- Tereshchenko, T.; Nord, N. Uncertainty of the allocation factors of heat and electricity production of combined cycle power plant. Appl. Therm. Eng. 2015, 76, 410–422. [Google Scholar] [CrossRef]

- Shubbak, M.H. Advances in solar photovoltaics: Technology review and patent trends. Renew. Sustain. Energy Rev. 2019, 115, 109383. [Google Scholar] [CrossRef]

- Aradóttir, E.S.P.; Gunnarsson, I.; Sigfússon, B.; Gunnarsson, G.; Júliusson, B.M.; Gunnlaugsson, E.; Sigurdardóttir, H.; Arnarson, M.T.; Sonnenthal, E. Toward Cleaner Geothermal Energy Utilization: Capturing and Sequestering CO2 and H2S Emissions from Geothermal Power Plants. Transp. Porous Media 2015, 108, 61–84. [Google Scholar] [CrossRef]

- Khosravi, A.; Syri, S.; Zhao, X.; El Haj Assad, M. An Artificial Intelligence Approach for Thermodynamic Modeling of Geothermal Based-Organic Rankine Cycle Equipped with Solar System. Geothermics 2019, 80, 138–154. [Google Scholar] [CrossRef]

| Legislative Act | Official Journal Publication (Date and Official Document) |

|---|---|

| Energy Performance in Buildings Directive (EPBD) | 19/06/2018 - Directive 2018/844 |

| Renewable Energy Directive (RED) | 21/12/2018 - Directive 2018/2001 |

| Energy Efficiency Directive (EED) | 21/12/2018 - Directive 2018/2002 |

| Governance of the Energy Union | 21/12/2018 - Regulation 2018/1999 |

| Electricity Regulation | 14/06/2019 - Regulation 2019/943 |

| Electricity Directive (ED) | 14/06/2019 - Directive 2019/944 |

| Risk Preparedness | 14/06/2019 - Regulation 2019/941 |

| Agency for the Cooperation of Energy Regulators (ACER) | 14/06/2019 - Regulation 2019/942 |

| Allocation Methods | Electricity | Heat |

|---|---|---|

| A. Electricity (system expansion) | ||

| A1 Construction: Steam collection and reinjection | 100% | 0% |

| A2.1 Operation: Geothermal fluid, primary energy flow | 94% | 6% |

| A2.2 Operation: Geothermal fluid, material flow | 100% | 0% |

| A3 Maintenance: Make-up wells | 100% | 0% |

| B. Heat (system expansion) | ||

| B.1 Construction: Steam collection and reinjection | 86% | 14% |

| B.2 Operation: Geothermal fluid, primary energy, and material flow | 91% | 9% |

| B.3 Maintenance: Make-up wells | 97% | 3% |

| C. Energy | 73% | 27% |

| D. Exergy | 92% | 8% |

| E. Economic | 86% | 14% |

| F. AGM | 92% | 8% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karlsdottir, M.R.; Heinonen, J.; Palsson, H.; Palsson, O.P. High-Temperature Geothermal Utilization in the Context of European Energy Policy—Implications and Limitations. Energies 2020, 13, 3187. https://doi.org/10.3390/en13123187

Karlsdottir MR, Heinonen J, Palsson H, Palsson OP. High-Temperature Geothermal Utilization in the Context of European Energy Policy—Implications and Limitations. Energies. 2020; 13(12):3187. https://doi.org/10.3390/en13123187

Chicago/Turabian StyleKarlsdottir, Marta Ros, Jukka Heinonen, Halldor Palsson, and Olafur Petur Palsson. 2020. "High-Temperature Geothermal Utilization in the Context of European Energy Policy—Implications and Limitations" Energies 13, no. 12: 3187. https://doi.org/10.3390/en13123187

APA StyleKarlsdottir, M. R., Heinonen, J., Palsson, H., & Palsson, O. P. (2020). High-Temperature Geothermal Utilization in the Context of European Energy Policy—Implications and Limitations. Energies, 13(12), 3187. https://doi.org/10.3390/en13123187