Patent Analysis of High Efficiency Tunneling Oxide Passivated Contact Solar Cells

Abstract

1. Introduction

- What countries/companies/applicants filing the patent in the past years are analyzing the patent management charts?

- What technical trends of the current application can be identified by analyzing the IPC classification and technology cluster?

- What future research directions can be indicated by analyzing the technical-function matrix to identify the distribution of technology-intensive areas and technology blank areas?

2. Literature Review

2.1. Review of TOPCon Solar Cell Technology

2.1.1. Development History

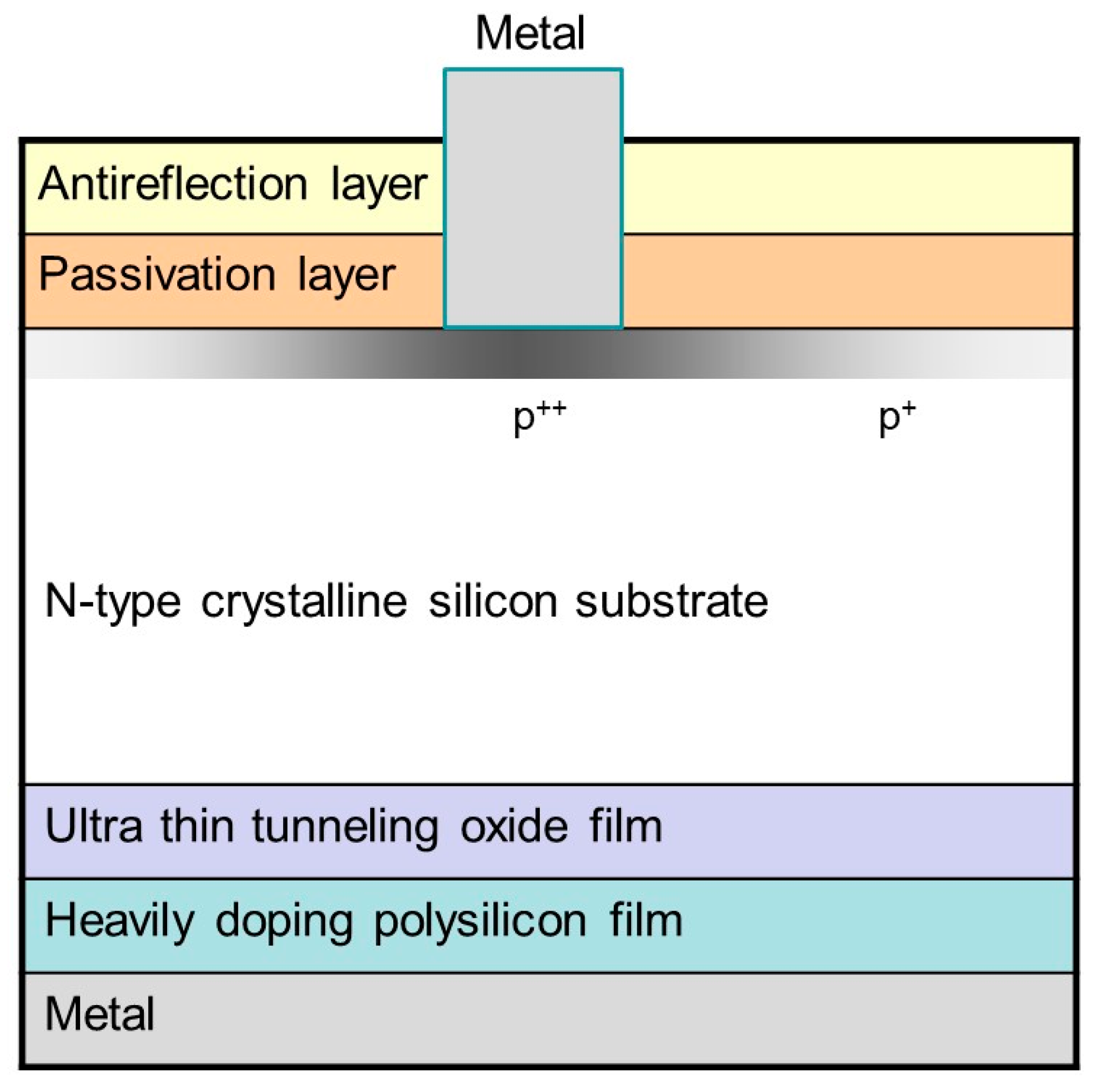

- The ultra-thin oxide layer fills the defects that occur at the single crystal surface, thus increasing the conversion efficiency.

- The ultra-thin oxide layer allows rapid electron/hole migration, depending on the substrate’s conductivity type.

- As a result of the high conductivity of the highly doping polysilicon, the junction resistance can be reduced and the output current can be increased.

2.1.2. Structure of TOPCon Solar Cell

2.1.3. Process of TOPCon Solar Cell

2.1.3.1. Ultra-Thin Oxide Layer

2.1.3.2. Doped Polysilicon Layer

2.2. Review of Patent Analysis

2.2.1. Patent

2.2.2. Patent Analysis

3. Methodology

3.1. Patent Search Strategy

3.2. Patent Management Charts

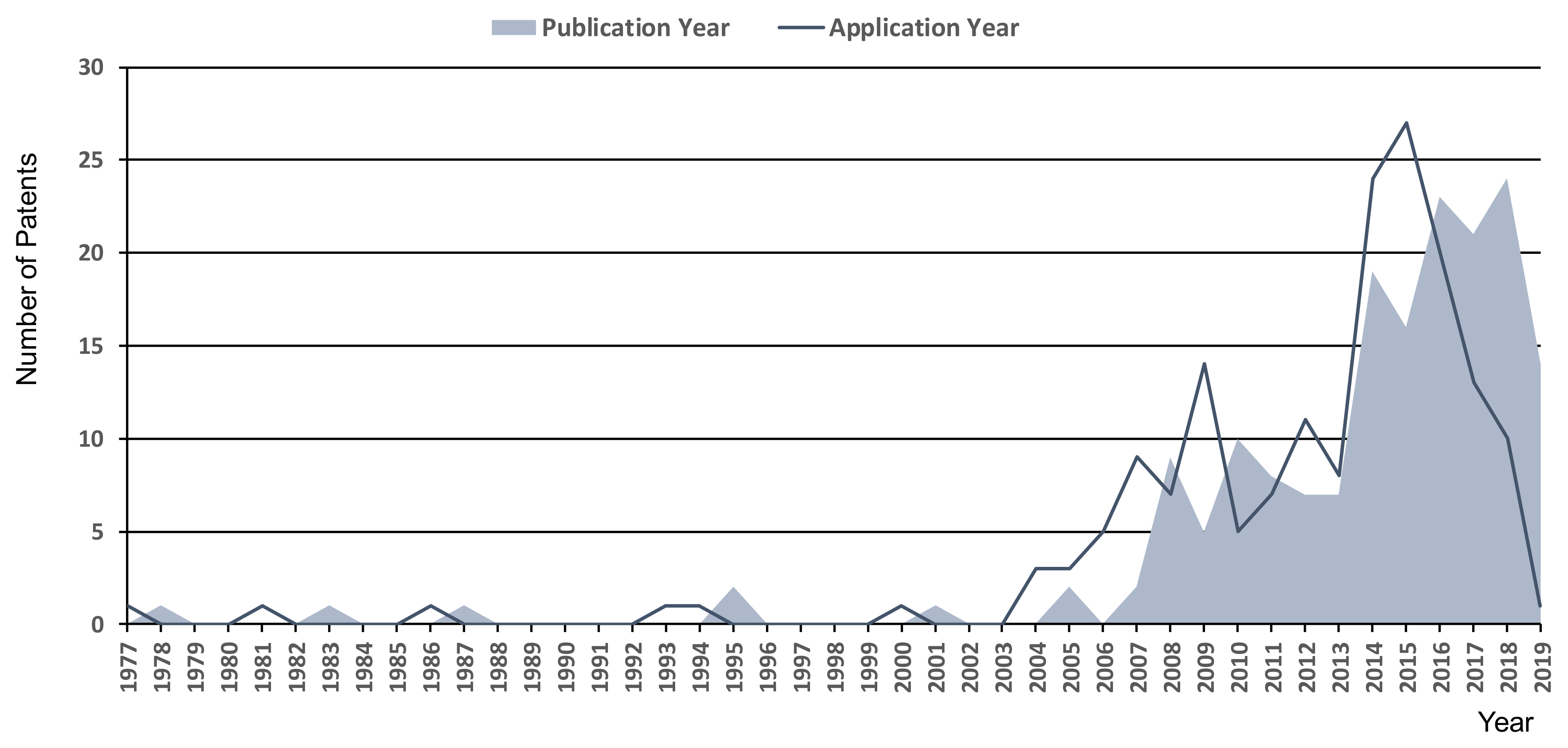

- Analysis of the number of patents over the years: this analysis is used to explore the number of patent applications and publication in each year; thus, to observe the patent development trend of TOPCon solar cell technology over time. The patent application date refers to the date when the patent was filed, and the patent publication date refers to the date on which the patent application is early published.

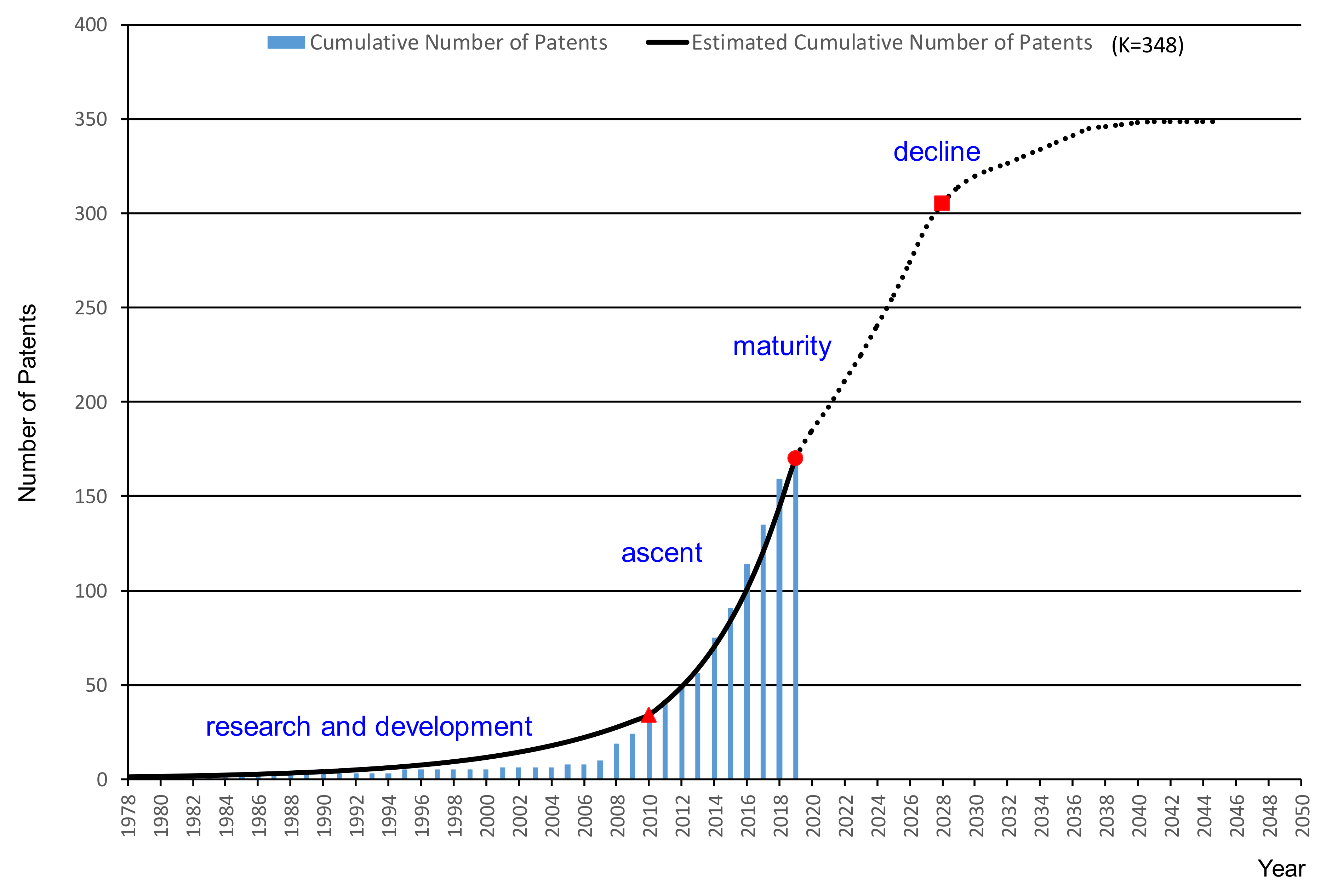

- Analysis of technology life cycle: this analysis has four distinct stages: research and development, ascent, maturity, and decline. This analysis is used to observe the technological development phase of TOPCon solar cells.

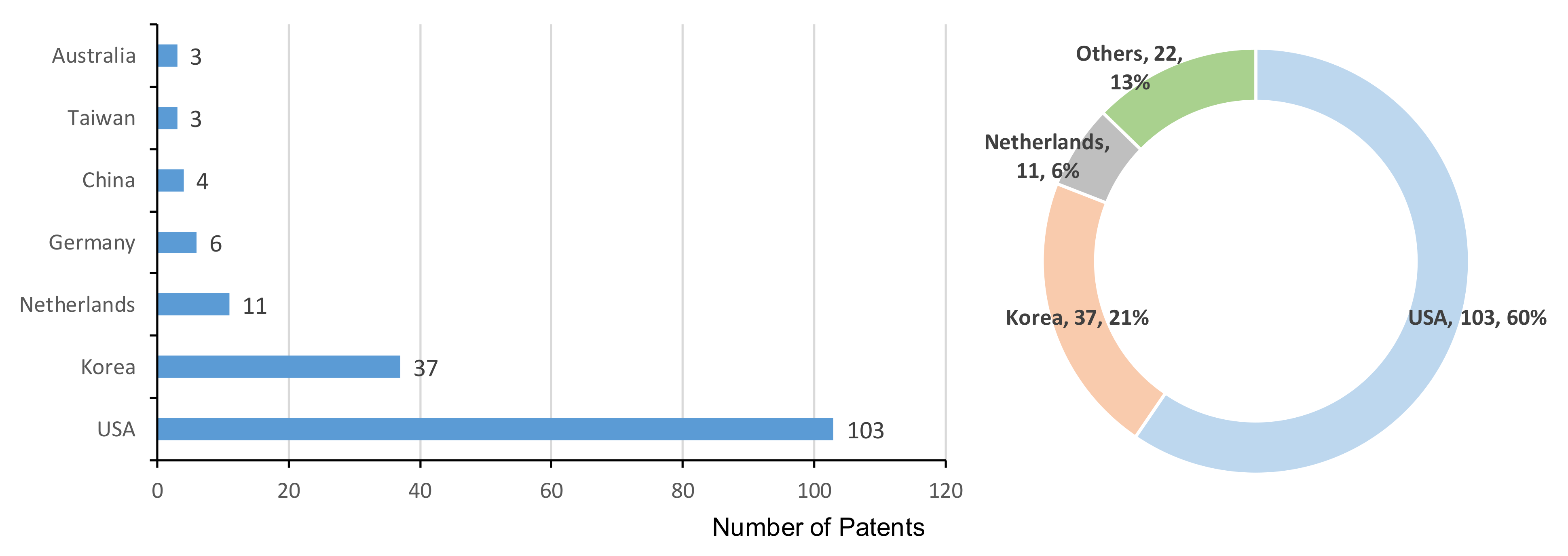

- Analysis of country: this analysis is used to explore the development of TOPCon solar cell technology in various countries, and to understand the distribution of leading countries in the field of TOPCon solar cell technology.

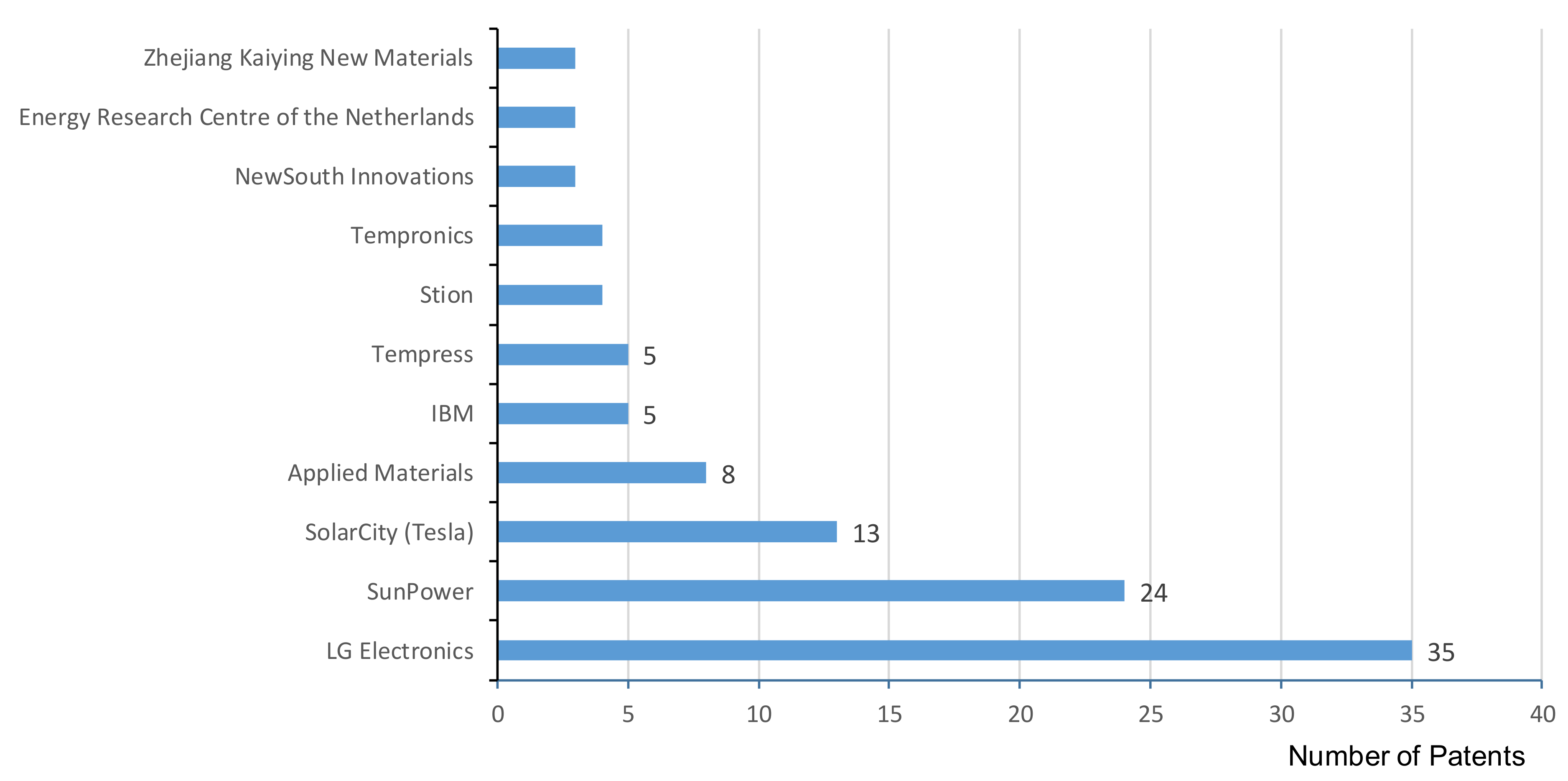

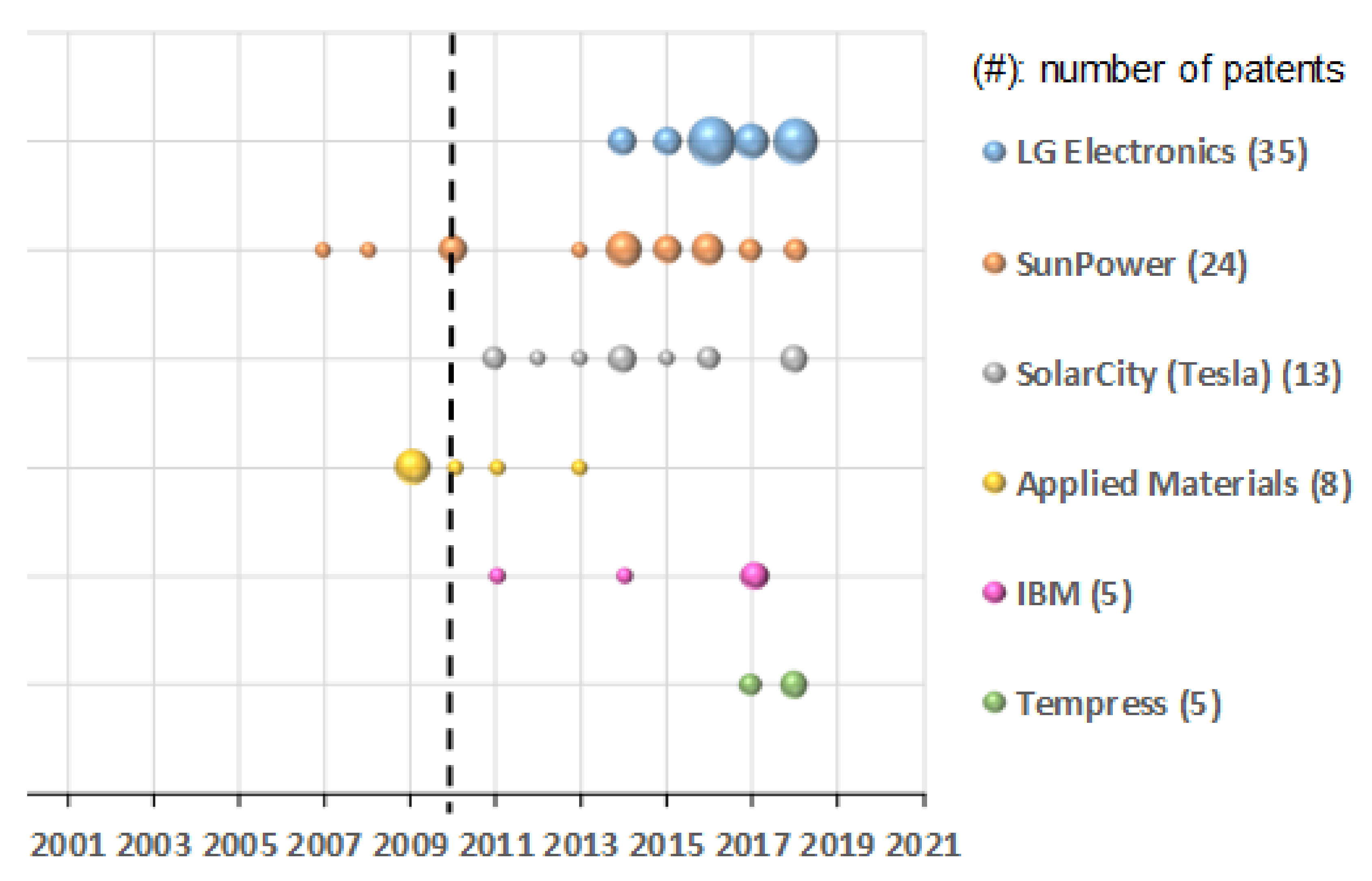

- Analysis of patent assignee: this analysis is used to explore the technological development and the patent portfolio status of leading companies in the field of TOPCon solar cell technology, and to learn more about the R&D direction of the competitors.

- Analysis of IPC classification: typically, it is not easy for patent analysts to evaluate and screen a large number of patent search results. Therefore, this analysis is used to explore the IPC, to help the patent analysts, to screen and classify the patents more precisely.

4. Analysis Results

4.1. Patent Management Charts

4.1.1. Analysis of Number of Patent over the Years

4.1.2. Analysis of Technology Life Cycle

4.1.3. Analysis of Country

4.1.4. Analysis of Patent Assignee

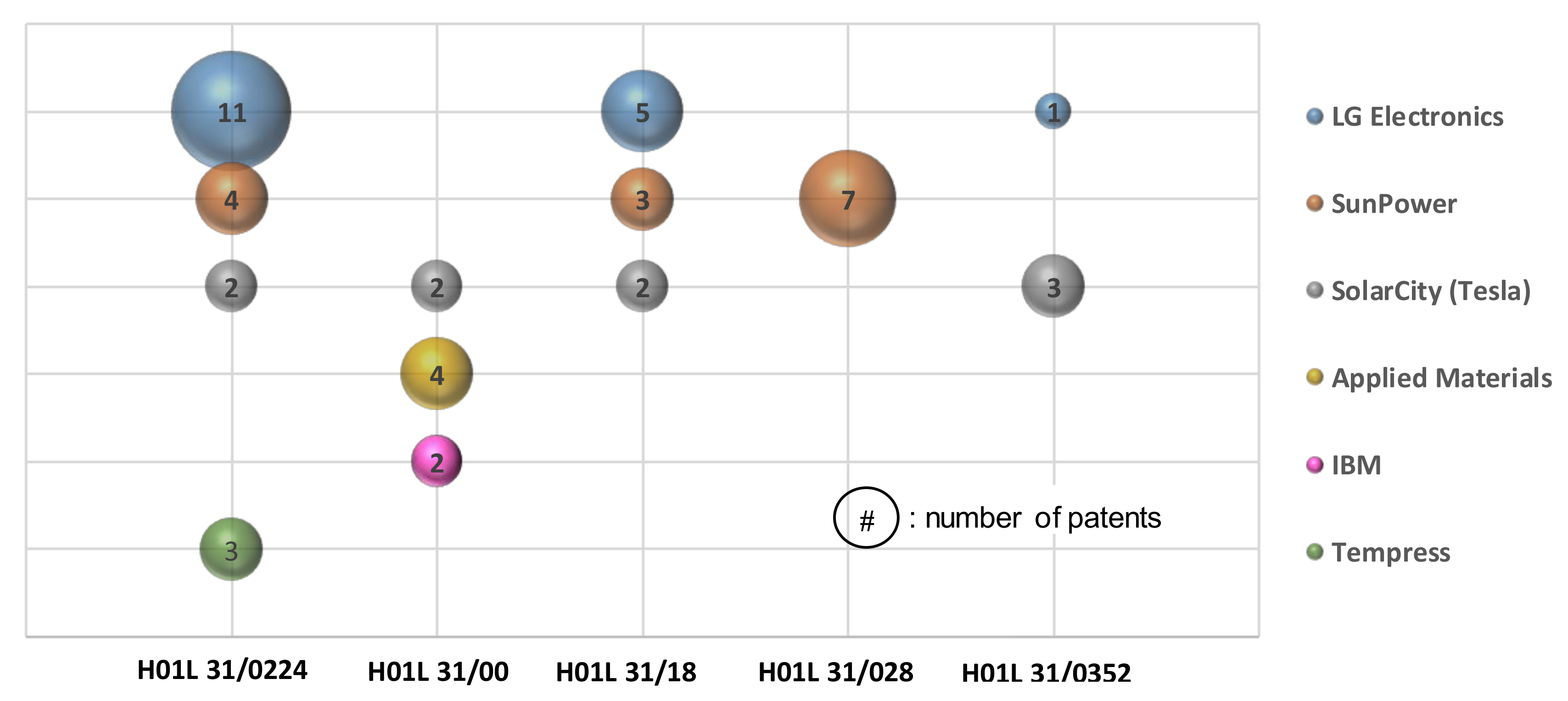

4.1.5. Analysis of IPC Classification

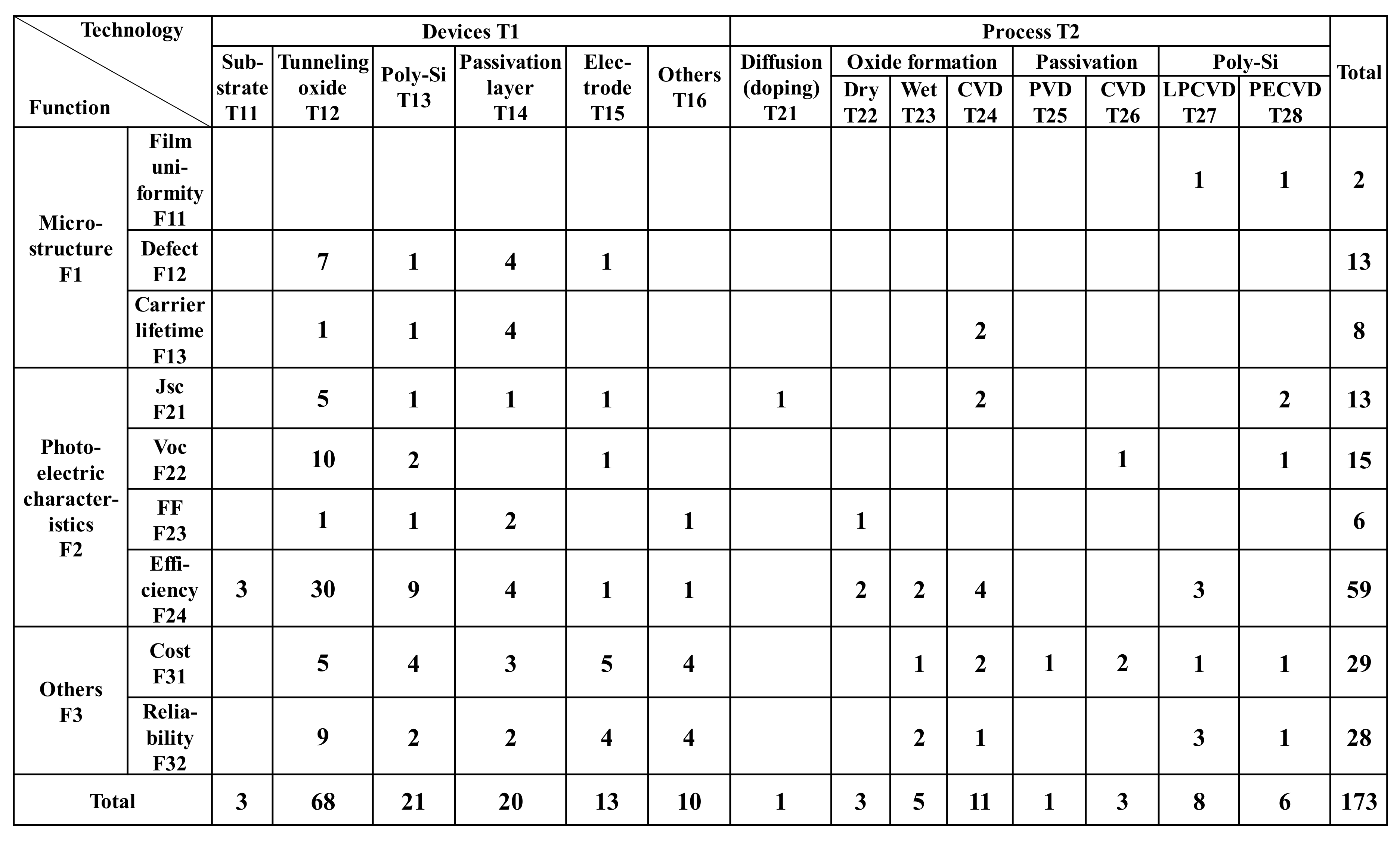

4.2. Patent Technology-Function Matrix

4.2.1. Classification of Technology and Function

4.2.2. Technical-Function Matrix Analysis

5. Conclusions

- The search result has 173 cases, with total of 220 patents, of which 53 were approved and 167 were published in this study.

- The trend of the number of patents shows that there has been obvious output since 2006, with approximately more than five patent applications each year, and a relatively large patent output (more than 20 patent applications) from 2014 to 2016.

- The TOPCon solar cell technology reached the inflection point of technology history and entered into the maturity stage in 2019.

- The countries with the top three number of patents are the United States, South Korea, and the Netherlands, with a total of 103, 37, and 11 patents, respectively.

- The companies with the top three number of patents are LG Electronics, SunPower, and SolarCity (which was acquired by Tesla in 2016) with a total of 35, 24, and 13 patents, respectively.

- LG Electronics has the relative strongest R&D capabilities, followed by SunPower. However, SunPower is the earliest patent assignee among the top six companies, and LG Electronics is the follower among the top six companies, as its patent outputs are heavily concentrated after 2014. It is also worth noting that the patent strategy of LG Electronics is protecting their market with a series of defensive patents, which suppress other companies’ patent activities.

- The IPC subdivisions with the top three number of patents are H01L 31/0224, H01L 31/00, and H01L 31/18, which account for about 18.5%, 11.6% and 7.5%, respectively.

- Patent technology-function matrix shows the development focus of the device-related technologies are tunneling oxide, with a total of 68 patents, and polycrystalline silicon, with a total of 21 patents.

- Patent technology-function matrix shows the main development focus among process-related technologies is the process of tunneling oxide layers, with a total of 19 patents, followed by the process of polysilicon film, with a total of 14 patents.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

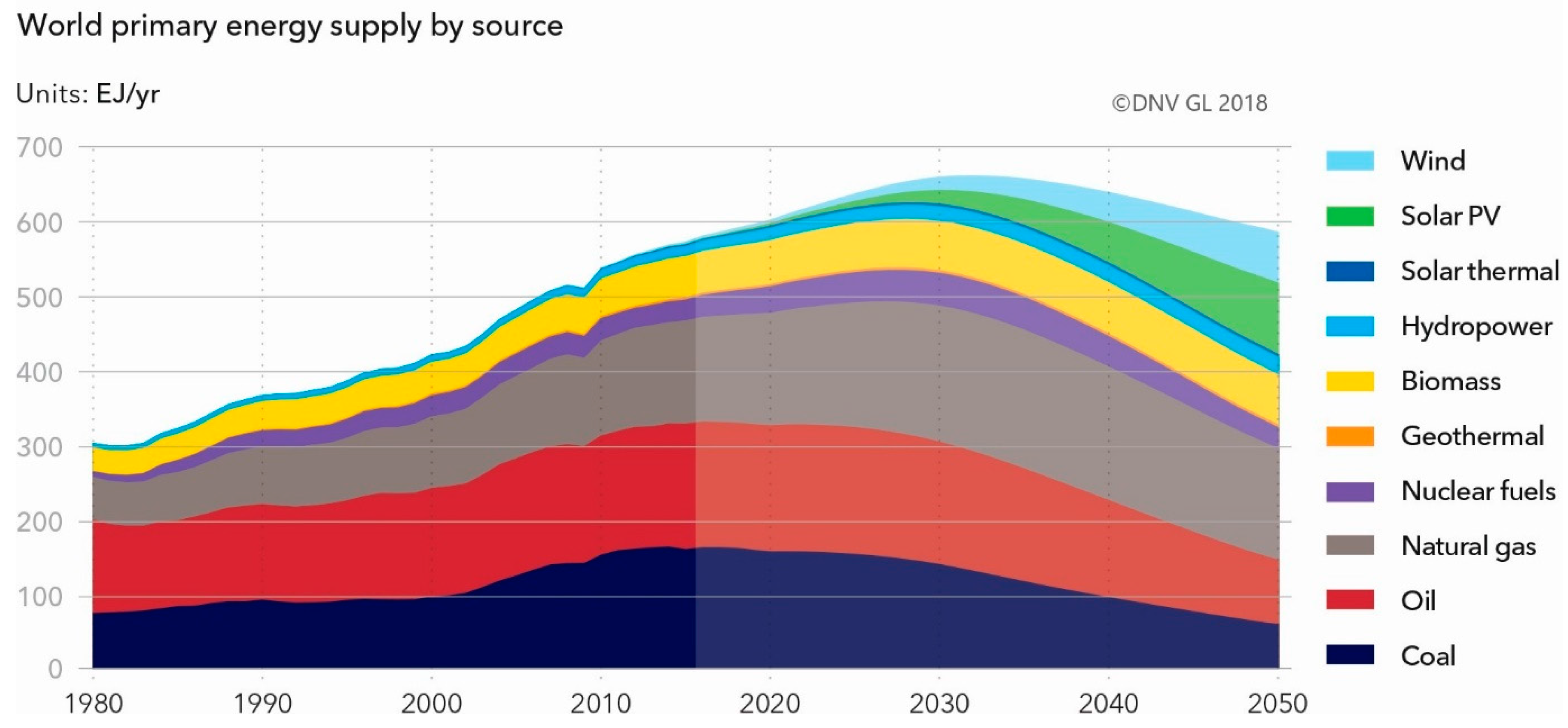

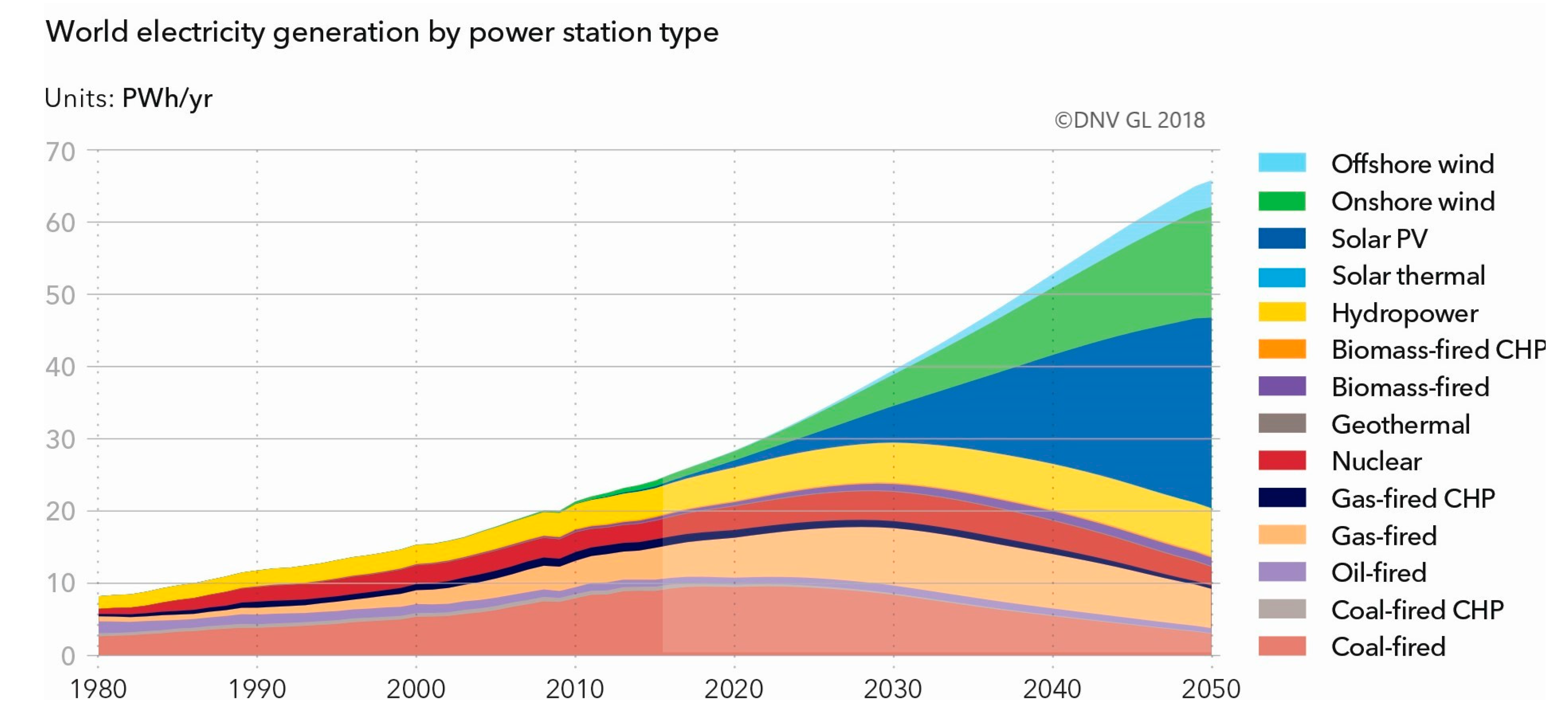

- DNV GL. Energy Transition Outlook 2018: A Global and Regional Forecast to 2050. 2018. Available online: https://eto.dnvgl.com/2018#Energy-Transition-Outlook-2018- (accessed on 18 April 2020).

- Jäger-Waldau, A. PV Status Report 2019; Publications Office of the European Union: Luxembourg, 2019; Available online: https://ec.europa.eu/jrc/en/publication/eur-scientific-and-technical-research-reports/pv-status-report-2019 (accessed on 18 April 2020).

- DNV GL. Energy Transition Outlook 2019: A Global and Regional Forecast to 2050. 2019. Available online: https://eto.dnvgl.com/2019/index.html#ETO2019-top (accessed on 18 April 2020).

- Green, M.A.; Dunlop, E.D.; Hohl-Ebinger, J.; Yoshita, M.; Kopidakis, N.; Ho-Baillie, A.W.Y. Solar cell efficiency tables (Version 55). Prog. Photovolt. Res. Appl. 2020, 28, 3–15. [Google Scholar] [CrossRef]

- Fraunhofer ISE. Photovoltaic Report. 2019. Available online: https://www.ise.fraunhofer.de/en/publications/studies/photovoltaics-report.html (accessed on 17 March 2020).

- Feldmann, F.; Steinhauser, B.; Arya, V.; Büchler, A.; Brand, A.A.; Kluska, S.; Hermle, M.; Glunz, S.W. Evaluation of TOPCon technology on large area solar cells. In Proceedings of the 33rd European PV Solar Energy Conference and Exhibition, Amsterdam, The Netherlands, 25–29 September 2017; pp. 465–467. [Google Scholar]

- Steinhauser, B.; Polzin, J.-I.; Feldmann, F.; Hermle, M.; Glunz, S.W. Excellent surface passivation quality on crystalline silicon using industrial-scale direct-plasma TOPCon deposition technology. Sol. RRL. 2018, 2, 1800068. [Google Scholar] [CrossRef]

- Bae, D.; Pedersen, T.; Seger, B.; Iandolo, B.; Hansen, O.; Vesborg, P.C.K.; Chorkendorff, I. Carrier-selective p- and n-contacts for efficient and stable photocatalytic water reduction. Catal. Today 2017, 290, 59–64. [Google Scholar] [CrossRef]

- Feldmann, F.; Bivour, M.; Reichel, C.; Hermle, M.; Glunz, S. Passivated rear contacts for high-efficiency n-type Si solar cells providing high interface passivation quality and excellent transport characteristics. Sol. Energy Mater. Sol. Cells 2014, 120, 270–274. [Google Scholar] [CrossRef]

- Patents. World Intellectual Property Organization. Available online: www.wipo.int/patents/en (accessed on 31 March 2019).

- Kim, G.; Bae, J. A novel approach to forecast promising technology through patent analysis. Technol. Forecast. Soc. Chang. 2017, 117, 228–237. [Google Scholar] [CrossRef]

- Römer, U.; Peibst, R.; Ohrdes, T.; Lim, B.; Brendel, R. Recombination behavior and contact resistance of n+ and p+ poly-crystalline Si/mono-crystalline Si junctions. Sol. Energy Mater. Sol. Cells 2014, 131, 85–91. [Google Scholar] [CrossRef]

- Yan, D.; Cuevas, A.; Bullock, J.; Wan, Y.; Samundsett, C. Phosphorus-diffused polysilicon contacts for solar cells. Sol. Energy Mater. Sol. Cells 2015, 142, 75–82. [Google Scholar] [CrossRef]

- Fraunhofer ISE. TOPCon – Overcoming Fundamental Bottlenecks to a New World-Record Silicon Solar Cell. 2016. Available online: https://www.ise.fraunhofer.de/en/research-projects/topcon.html (accessed on 18 April 2020).

- Lauinger, T.; Schmidt, J.; Aberle, A.G.; Hezel, R. Record low surface recombination velocities on 1 Ω cm p-silicon using remote plasma silicon nitride passivation. Appl. Phys. Lett. 1996, 68, 1232–1234. [Google Scholar] [CrossRef]

- Grant, N.E.; Markevich, V.P.; Mullins, J.; Peaker, A.R.; Rougieux, F.; Macdonald, D.; Murphy, J.D. Permanent annihilation of thermally activated defects which limit the lifetime of float-zone silicon. Phys. Status Solidi A 2016, 213, 2844–2849. [Google Scholar] [CrossRef]

- Lindekugel, S.; Lautenschlager, H.; Ruof, T.; Reber, S. Plasma hydrogen passivation for crystalline silicon thin-films. In Proceedings of the 23rd European Photovoltaic Solar Energy Conference, Valencia, Spain, 1–5 September 2008; pp. 2232–2235. [Google Scholar]

- Richter, A.; Glunz, S.W.; Werner, F.; Schmidt, J.; Cuevas, A. Improved quantitative description of Auger recombination in crystalline silicon. Phys. Rev. B 2012, 86, 165202. [Google Scholar] [CrossRef]

- Feldmann, F.; Fellmeth, T.; Steinhauser, B.; Nagel, H.; Ourinson, D.; Mack, S.; Lohmüller, E.; Polzin, J.-I.; Benick, J.; Richter, A.; et al. Large area TOPCon cells realized by a PECVD tube process. In Proceedings of the 36th European PV Solar Energy Conference and Exhibition, Marseille, France, 9–13 September 2019; pp. 304–308. [Google Scholar]

- Joung, J.; Kim, K. Monitoring emerging technologies for technology planning using technical keyword based analysis from patent data. Technol. Forecast. Soc. Chang. 2017, 114, 281–292. [Google Scholar] [CrossRef]

- Chen, J.H.; Jang, S.L.; Wen, S.H. Measuring technological diversification: Identifying the effects of patent scale and patent scope. Scientometrics 2010, 84, 265–275. [Google Scholar] [CrossRef]

- Abbas, A.; Zhang, L.; Khan, S.U. A literature review on the state-of-the-art in patent analysis. World Pat. Inf. 2014, 37, 3–13. [Google Scholar] [CrossRef]

- Karvonen, M.; Kässi, T. Patent citations as a tool for analysing the early stages of convergence. Technol. Soc. Chang. 2013, 80, 1094–1107. [Google Scholar] [CrossRef]

- Feng, X.; Leng, F. Patent text mining and informetric-based patent technology morphological analysis: An empirical study. Technol. Anal. Strateg. Manag. 2012, 24, 467–479. [Google Scholar] [CrossRef]

- Kim, K.H.; Han, Y.J.; Lee, S.; Cho, S.W.; Lee, C. Text mining for patent analysis to forecast emerging technologies in wireless power transfer. Sustainability 2019, 11, 6240. [Google Scholar] [CrossRef]

- Tseng, Y.; Lin, C.; Lin, Y. Text mining techniques for patent analysis. Inf. Process. Manag. 2007, 43, 1216–1247. [Google Scholar] [CrossRef]

- Noh, H.; Jo, Y.; Lee, S. Keyword selection and processing strategy for applying text mining to patent analysis. Expert Syst. Appl. 2015, 42, 4348–4360. [Google Scholar] [CrossRef]

- Choi, J.; Hwang, Y. Patent keyword network analysis for improving technology development efficiency. Technol. Forecast. Soc. Chang. 2014, 83, 170–182. [Google Scholar] [CrossRef]

| Type | Used Materials | Conversion Efficiencies (%) AM1.5G at 25 °C | |||

|---|---|---|---|---|---|

| Lab Size | Commercial Size | ||||

| Wafer Based | III-V | GaAs based | GaAs (thin film cell) | 29.1 ± 0.6 (0.998 cm2) | - |

| Multi-Junction GaInP/GaAs/Ge | 37.9 ± 1.2 (1.047 cm2) | - | |||

| Si | Multi-crystal silicon | Poly-Crystalline Si (PERC) | 22.8 ± 0.3 (246.7 cm2) | 19.9% (15,143 cm2) | |

| Single crystal | HIT/IBC | 26.7 ± 0.5 (79 cm2) | 23% (11,562 cm2) | ||

| Thin Film | Si | Amorphous | Amorphous -Crystalline Si | 10.2 ± 0.3 (1.001 cm2) | <8.2% (15,400 cm2) |

| Amorphous/micro-crystallize Stack | Amorphous/Micro-Crystalline Si Tandem | 14 ± 0.4 (1.045 cm2) | 13% (15,400 cm2) | ||

| II-VI | Cd-Te | 21 ± 0.4 (1.0623 cm2) | 18.6% (7039 cm2) | ||

| I-II-VI | CIGS | 23.35 ± 0.5 (1.043 cm2) | 19.2% (7200 cm2) | ||

| Emerging PV | Organic/Inorganic | Dye Sensitized | 11.9 ± 0.4 (1.005 cm2) | - | |

| Perovskite | 21.6 ± 0.6 (1.0235 cm2) | 11.6% (802 cm2) | |||

| Keywords | Fields |

|---|---|

| solar cell photovoltaic tunnel * passivat * oxide silicon | abstract title claims International Patent Classification (IPC) |

| Patent Assignee | Number of Patents | Number of Other-Citations | Number of Self-Citations | Number of Inventors | Average Age of Patents | Activity Year of Patent | Relative R&D Capability |

|---|---|---|---|---|---|---|---|

| LG Electronics | 35 | 0 | 0 | 66 | 2 | 6 | 100% |

| SunPower | 24 | 7 | 3 | 32 | 5 | 10 | 69% |

| SolarCity (Tesla) | 13 | 2 | 3 | 15 | 4 | 7 | 35% |

| Applied Materials | 8 | 0 | 0 | 7 | 9 | 4 | 16% |

| IBM | 5 | 0 | 0 | 12 | 4 | 3 | 14% |

| Tempress | 5 | 0 | 0 | 8 | 1 | 2 | 13% |

| IPC | Definition | Number of Patents | Percentage |

|---|---|---|---|

| H01L | SEMICONDUCTOR DEVICES; ELECTRIC SOLID STATE DEVICES NOT OTHERWISE PROVIDED FOR | ||

| H01L 31 | Semiconductor devices sensitive to infra-red radiation, light, electromagnetic radiation of shorter wavelength, or corpuscular radiation and specially adapted either for the conversion of the energy of such radiation into electrical energy or for the control of electrical energy by such radiation; Processes or apparatus specially adapted for the manufacture or treatment thereof or of parts thereof; Details thereof | 145 | 83.8% |

| H01L 31/0224 | Electrodes | 32 | 18.5% |

| H01L 31/00 | Same as H01L 31 | 20 | 11.6% |

| H01L 31/18 | Processes or apparatus specially adapted for the manufacture or treatment of these devices or of parts thereof | 13 | 7.5% |

| H01L 31/028 | including, apart from doping material or other impurities, only elements of Group IV of the Periodic System | 7 | 4.0% |

| H01L 31/0352 | characterised by their shape or by the shapes, relative sizes or disposition of the semiconductor regions | 7 | 4.0% |

| First-Order Technology | Second-Order Technology | |

|---|---|---|

| Devices | Substrate | |

| Tunneling oxide | ||

| Poly-Si | ||

| Passivation layer | ||

| Electrode | ||

| Others | ||

| Process | Diffusion (doping) | |

| Oxide formation | Dry | |

| Wet | ||

| CVD | ||

| Passivation | PVD | |

| CVD | ||

| Poly-Si | LPCVD | |

| PECVD | ||

| First-Order Function | Second-Order Function |

|---|---|

| Microstructure | Film uniformity |

| Defect | |

| Carrier lifetime | |

| Photoelectric characteristics | Short circuit current (Jsc) |

| Open circuit voltage (Voc) | |

| Filling factor (FF) | |

| Efficiency | |

| Others | Cost |

| Reliability |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsai, C.-W.; Liu, T.-K.; Hsueh, P.-W. Patent Analysis of High Efficiency Tunneling Oxide Passivated Contact Solar Cells. Energies 2020, 13, 3060. https://doi.org/10.3390/en13123060

Tsai C-W, Liu T-K, Hsueh P-W. Patent Analysis of High Efficiency Tunneling Oxide Passivated Contact Solar Cells. Energies. 2020; 13(12):3060. https://doi.org/10.3390/en13123060

Chicago/Turabian StyleTsai, Chieh-Wa, Tung-Kuan Liu, and Po-Wen Hsueh. 2020. "Patent Analysis of High Efficiency Tunneling Oxide Passivated Contact Solar Cells" Energies 13, no. 12: 3060. https://doi.org/10.3390/en13123060

APA StyleTsai, C.-W., Liu, T.-K., & Hsueh, P.-W. (2020). Patent Analysis of High Efficiency Tunneling Oxide Passivated Contact Solar Cells. Energies, 13(12), 3060. https://doi.org/10.3390/en13123060