3.1. Effect of Various Catalysts on the Biodiesel Yield Percentage (%)

The effect of different catalysts (acid, base and enzyme) on the percentage yield of biodiesel is shown in

Figure 2a–c. Transesterification using base catalysts is found to be cost effective because of its reusability, wide availability, easy separation from product and longer lifetime [

31,

32]. In base-catalyzed transesterification of

Azadirachta indica oil and its fractions, the maximum biodiesel yield of 99.9% was shown by fraction F4. In another study, the biodiesel yield obtained by whole date seed oil using base catalysts was approximately 80% [

2]. The optimized catalyst level for pure oil, F1 and F4, was 1% KOH (wt. of catalyst/wt. of oil) and for F2 and F3 was 0.2% KOH (wt. of catalyst/wt. of oil). Thus, the result obtained clearly indicated that, for better biodiesel yields, higher alkaline catalyst doses are required in the case of

Azadirachta indica oil, F1 and F2. However, fractions F2 and F3 produced the highest quantity of biodiesel at the lowest KOH dose of 0.2% KOH (wt. of catalyst/wt. of oil). This indicates that after fractionation biodiesel could be produced at much lower levels of base catalyst using some specific fractions. This will be helpful in cutting costs on base catalysts and will also be helpful in reducing environmental pollution caused by base catalysts. The maximum biodiesel yields of acid catalyzed transesterification reactions were 99%, 85%, 97.25%, 76.25% and 94.25%, respectively, for

Azadirachta indica oil, fraction F1, fraction F2, fraction F3 and fraction F4. The most suitable level of HCl for obtaining maximum biodiesel from

Azadirachta indica oil, F3 and F4 was 80% (wt. of HCl/wt. of oil). However, F1 and F2 have shown maximum biodiesel yields at 100% and 60%, respectively. The acid catalysis reaction rate was much slower than base catalysis. The acid-catalyzed transesterification reaction was completed in 4.5 h as compared to the 1.5 h taken by the base-catalyzed reaction. Transesterification is the replacement of original ester groups into desired esters. The best way for transesterification is base-catalyzed as it is a very facile reaction. The enzyme is inhibited in the presence of methanol. Acidic catalysts have low acid site concentration, low micro porosity, and high cost compared with basic types. Acids catalyzes both esterification and transesterification simultaneously and is insensitive to FFA and water. In a previous study, biodiesel productivities of used vegetable oils by acidic catalysis at 25 and 100 °C, respectively, were as follows: Safflower (84.7% and 94.3%), Soybean (85.9% and 94.2%), Sunflower (83.4% and 95.2%), Canola (80.8% and 93.7%), Corn (83.2% and 83.3%), Olive (84.3% and 85.3%), Hazelnut (82.5% and 83.4%) and Waste sunflower (84.3% and 90.4%) [

33].

Enzyme-catalyzed biodiesel production was completed in 24 h. For the biodiesel synthesis, five different lipase concentrations (1–5%) were used. The results obtained show that Azadirachta indica oil and its four fractions have the highest biodiesel yield at different enzyme concentrations. F2, F4, F3, pure oil and F1 produced the maximum quantity of biodiesel at 1%, 2%, 3%, 4% and 5% of lipase, respectively, and the respective maximum yields were 97.75%, 93.75%, 97.25%, 99.1% and 89.75%. The Azadirachta indica oil fractionation process yielded distillates with a variable composition as confirmed by gas chromatographic and mass spectrometric analysis. The variance in composition of fractions and Azadirachta indica oil was responsible for the variable optimized yield. Enzymes have a three-dimensional structure and are large protein biomolecules that can take part in many chemical reactions. Enzymes are highly specific; they function with only one reactant to produce specific products. Comparing acid, base and enzyme catalyst-optimized yields, it is apparent that the highest biodiesel yield was shown by base-catalyzed transesterification. The biodiesel yields of acid and enzyme-catalyzed reactions were comparable.

3.3. Assessment of Fuel Quality Parameters

The acid value (AV) is defined as “the weight of KOH in mg needed to neutralize the organic acids present in 1 g of fat and it is a measure of the free fatty acids (FFA) present in the fat or oil” [

31]. An increment in the amount of FFA in a sample of oil or fat indicates hydrolysis of triglycerides. The acid value (AV) of

Azadirachta indica oil, F1, F2, F3 and F4 were 1.23, 2.91, 6.61, 8.89 and 3.36, respectively. The results obtained show that there was breakdown of fatty acids from triglyceride chains during the molecular distillation process of fractionation. The observed density of all biodiesel samples is given in

Table 3. According to American standards (ASTM), there is no specified range of density of produced biodiesel. However, in European standards (EN), the recommended range of densities of biodiesel should range from 0.86 to 0.90 kg/liter. The density of

Azadirachta indica oil and fraction biodiesel samples ranged from 0.70–0.91 kg/liter. The density value has great influence on some properties of the biodiesel concerning the engine efficiency including injection timing, injection system and spray properties. Lower density biodiesel has lower engine efficiency and higher density value exhibits greater mass of biodiesel introduced into the injection system [

35].

The saponification value or saponification number of

Azadirachta indica biodiesel synthesized by using several catalyst concentrations is given in the

Table 4. The saponification value or number relies on fatty acid concentration present in the biodiesel and the molecular weight. The existence of fatty acids with short chains of alkyl groups in biodiesel is also indicated by the saponification number. Using a KOH catalyst, higher saponification values of

Azadirachta indica biodiesel were observed. This indicated high volatilities of the synthesized biodiesel. This might be supportive in burning

Azadirachta indica biodiesel easily and efficiently to avoid the backfire. This happens in diesel engines when unburned fuel meets hot parts that are close enough to the tip, where oxygen is present, to explode spontaneously. However, it is quite rare for this to happen. This property is reflected in the existence of the small chained fatty acids or methyl esters.

Furthermore, a high saponification number also articulates the presence of carboxylic groups in high amounts in the biodiesel. In the present study, the maximum saponification value was 376 mg KOH/g of biodiesel sample synthesized by the pure Azadirachta indica oil using 1% KOH catalyst (w/w of oil), while the minimum saponification value (136.6 mg KOH/g) of biodiesel sample produced by the F4 fraction. Using the HCl catalyst, a maximum saponification value (281.4) of pure Azadirachta indica oil biodiesel was shown using 100% HCl catalyst (w/w of oil) and the minimum value (101.9) for the F3 fraction was observed using 60% and 80% HCl catalyst w/w of oil. Using the lipase enzyme catalyst, a maximum saponification value (226.3) was observed for the F3 fraction using 1% lipase enzyme catalyst (w/w of oil), while the minimum SP value (101.9) was observed for the F4 fraction using 3% and 4% lipase enzyme catalyst (w/w of oil).

The iodine values (IV) of

Azadirachta indica biodiesel are shown in

Table 5. The minimum iodine value (37.2) for the

Azadirachta indica biodiesel was found for the biodiesel synthesized using 20% HCl catalyst w/w of oil, while the maximum iodine value (218.4) was shown by pure

Azadirachta indica oil transesterified using KOH 0.8% w/w of oil. Iodine value relies on the unsaturated fatty acid and indicate double bound present in biodiesel sample [

36]. According to European standards, iodine values equal to or less than 120 is preferable for biodiesel produced for consumption. However, in American standards, no iodine value is specified. Unsaturation represented by the iodine value reflects the chance of biofuel solidification [

37]. The greater the unsaturation, the greater the iodine value will be. High unsaturation in the biofuel may cause deposition as breakage of some weak bonds results in polymerization or leads to epoxide formation in the engine at high temperatures. A careful examination of

Table 5 shows that biodiesel produced from

Azadirachta indica oil had higher iodine values. However, fractionation of

Azadirachta indica oil into various components was useful for producing better quality biodiesel with lower iodine values. The production of biodiesel from oil fractions (F1–F4) as compared to whole oil was advantageous, as evidenced by the great oxidative stabilities of oil fractions (F1–F4). Cloud point and pour point are important physical properties of any liquid fuel. Some fractions produced under vacuum produced high-quality biodiesel with comparatively much better cloud, pour points and Cold Filter Plugging Point than

Azadirachta indica oil (

Table 6). In fractionation, oil was separated into various fractions. It was expected that some fractions will have better properties than oil and others. As oil comprises all components so it displayed intermediate properties.

Cetane number (CN) is a biofuel quality parameter. CN is one of the factors that determines the ignition capability and depends on the fatty acid or methyl ester composition in the biodiesel. It influences the engine efficiency and ignition power after injection of biofuel [

38]. In the present study, the CN value ranged from 9.1–87.3 (

Table 7). None of biodiesel sample produced from pure

Azadirachta indica oil met standard biodiesel cetane number requirements. However, the fractionation process improved the centane number of produced biodiesels. Cetane number of all biodiesel samples produced from

Azadirachta indica oil fractions was in the recommended range. Biodiesel offers the advantage of a direct replacement for ordinary diesel. In the present study, we propose a much cheaper and simpler method named high vacuum fractional distillation as an alternative to refining to produce high quality biodiesel with desired fuel properties. The cetane number of commonly occurring fatty acids methyl esters are as follows: palmitic (85.9), palmitoleic (51.0), stearic (101.0), oleic (59.3), and linoleic (38.2).

A previous study [

39] was undertaken with similar objectives such as development of cost-effective processing technology, and elimination of degumming, esterification and dehydration steps from the oil purification processes by conducting a supercritical extraction using CO

2 [

39].

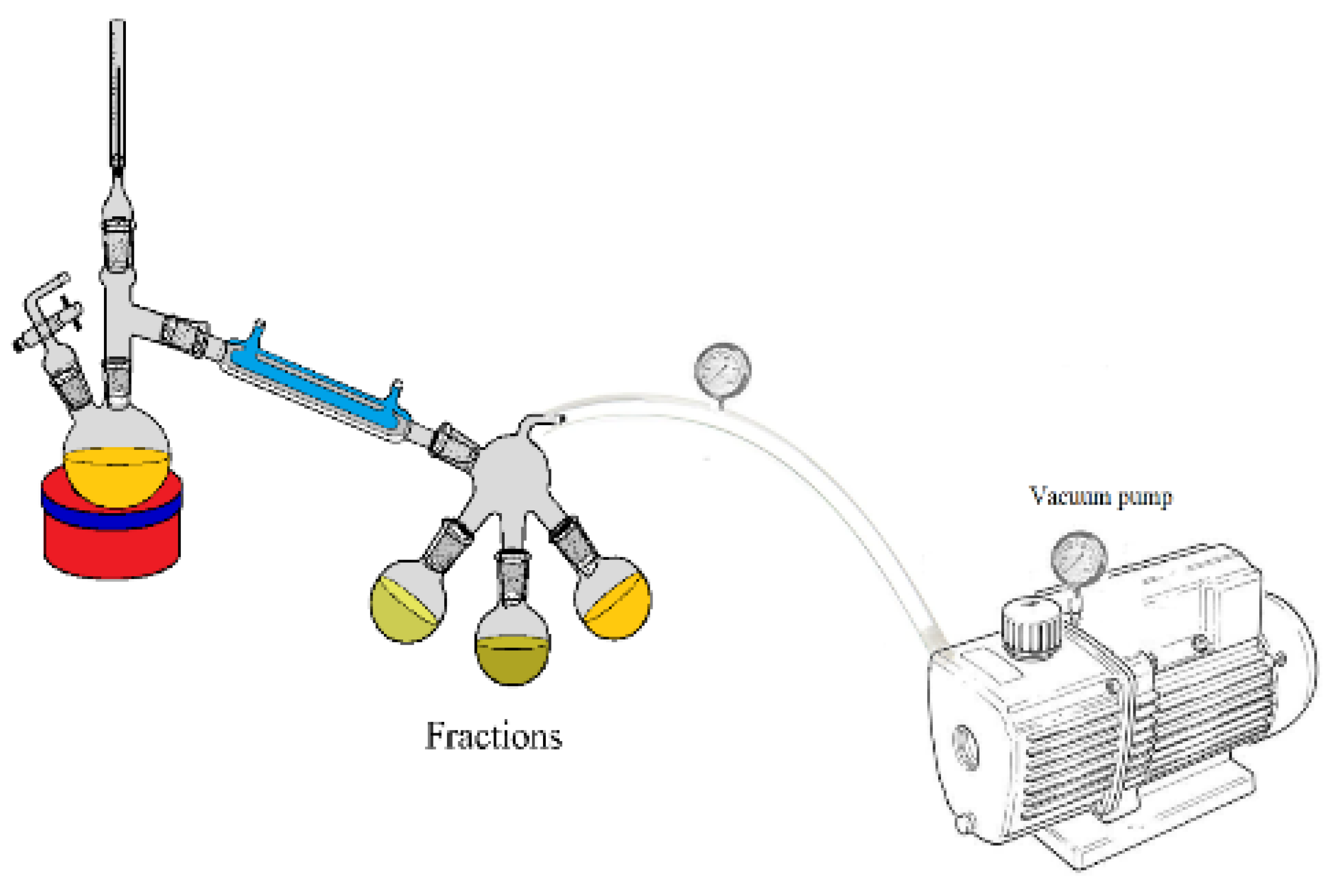

However, when capital investment and processing cost of high vacuum fractional distillation (HVFD) used in the present study is compared with a supercritical extraction using CO

2, HVFD is a much cheaper and simpler alternative. HVFD does not add to the cost of biodiesel as it is an alternative route for oil purification. In another previous study [

40], supercritical fluid carbon dioxide was used to separate out biodiesel fraction from impure fatty acid methyl ester (FAME) solution mixes. The disadvantage of doing fractionation after production of methyl esters is the production of a number of useless byproducts, which does not happen in HVFD. Secondly, the prior methodology does not bring any significant improvements in the cetane number, cloud point or pour point of biodiesel.