Complete Data Inventory of a Geothermal Power Plant for Robust Cradle-to-Grave Life Cycle Assessment Results

Abstract

:1. Introduction

2. Materials and Methods

2.1. Power Plants Description

2.2. LCA Methodological Approach

2.2.1. Goal and Functional Unit

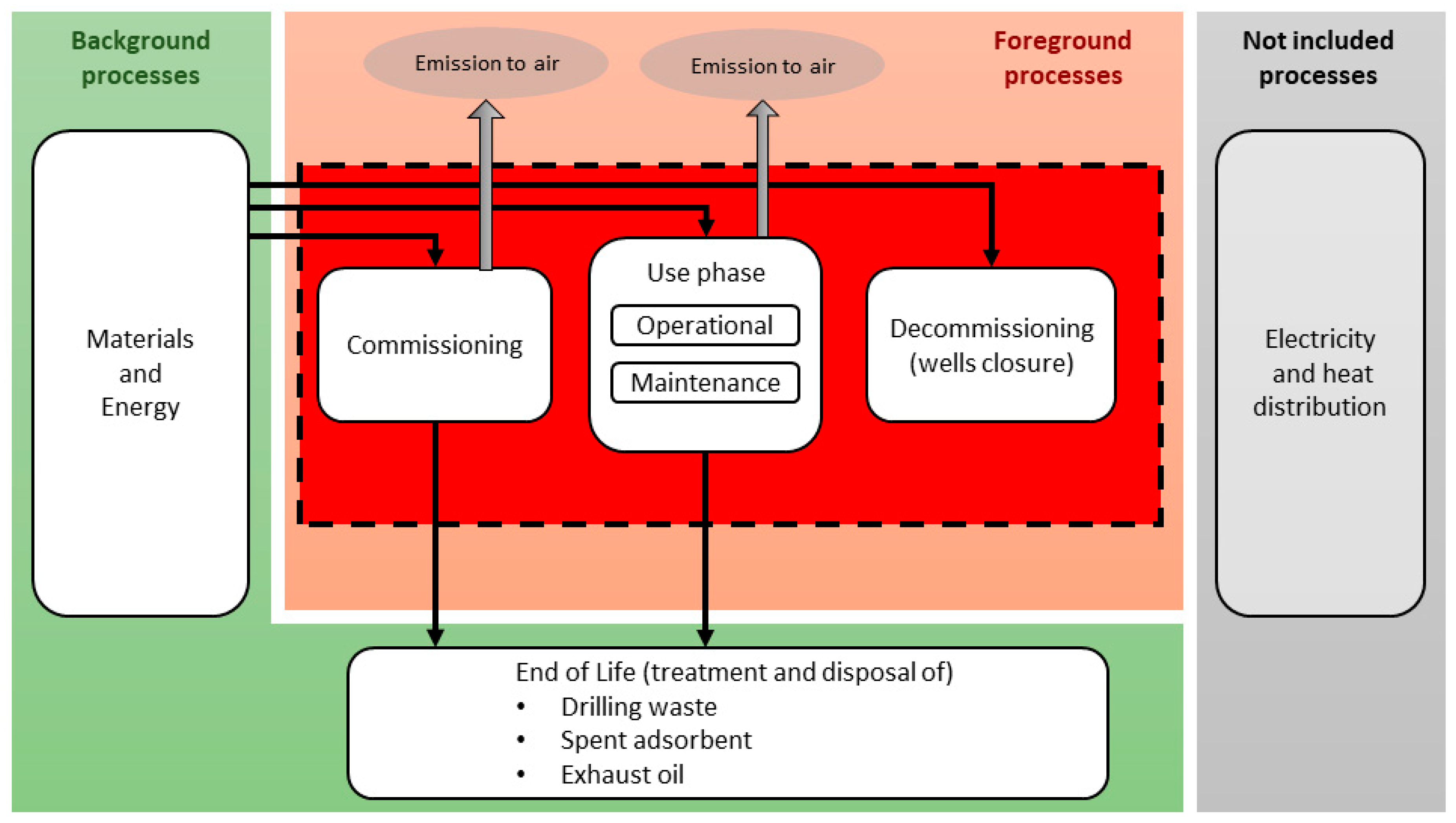

2.2.2. System Boundaries

- (1)

- The commissioning phase included the drilling of production and injection wells and the well-pad construction; the construction of pipelines; the power plants building; all the equipment needed for the power generation plant and the heating station, including the cooling towers, the ORC unit and the production of the working fluid used by the ORC system; the construction of AMIS was also included in the commissioning stage; on the contrary, the exploration and wells’ testing stages were excluded from the analysis, due to lack of data.

- (2)

- The operational phase included the production of sulfuric acid (H2SO4) used in the fluid treatment for the oxidation of (NH3); working fluid losses during normal operation of the ORC system were inventoried as direct emissions to air; the operational phase accounted for direct emissions of NCGs, Arsenic (As) and Hg to air. Maintenance activities included in the system were: AMIS maintenance, which involved the substitution of selenium based sorbent; the evaporative tower maintenance, which involved substitution of plastic parts (drift eliminator, fan); equipment maintenance, which includes lubricant oil refilling, substitution of metals components of various technical parts (i.e., turbine, compressors). More details are given in the Supplementary Materials in the “Inventory” sheet.

- (3)

- When the geothermal power plant runs out of its lifetime, a decommissioning phase was assumed, which included exclusively the closing of the wells with cement. The activities of dismantling and recycling of machinery and equipment were excluded from the decommissioning stage, because they can be employed in other plants operated by EGP.

- (4)

- Finally, the EoL phase included the treatment and disposal of drilling mud and of the spent sorbent from AMIS maintenance, as well as the treatment of exhaust oil from equipment maintenance activity.

2.2.3. LCA Key Modelling Parameters

2.2.4. Data Representativeness and Quality

2.2.5. Important Assumptions

2.2.6. Allocation Procedure

2.2.7. Life Cycle Impact Assessment Method

3. Life Cycle Inventory Analysis

4. Results

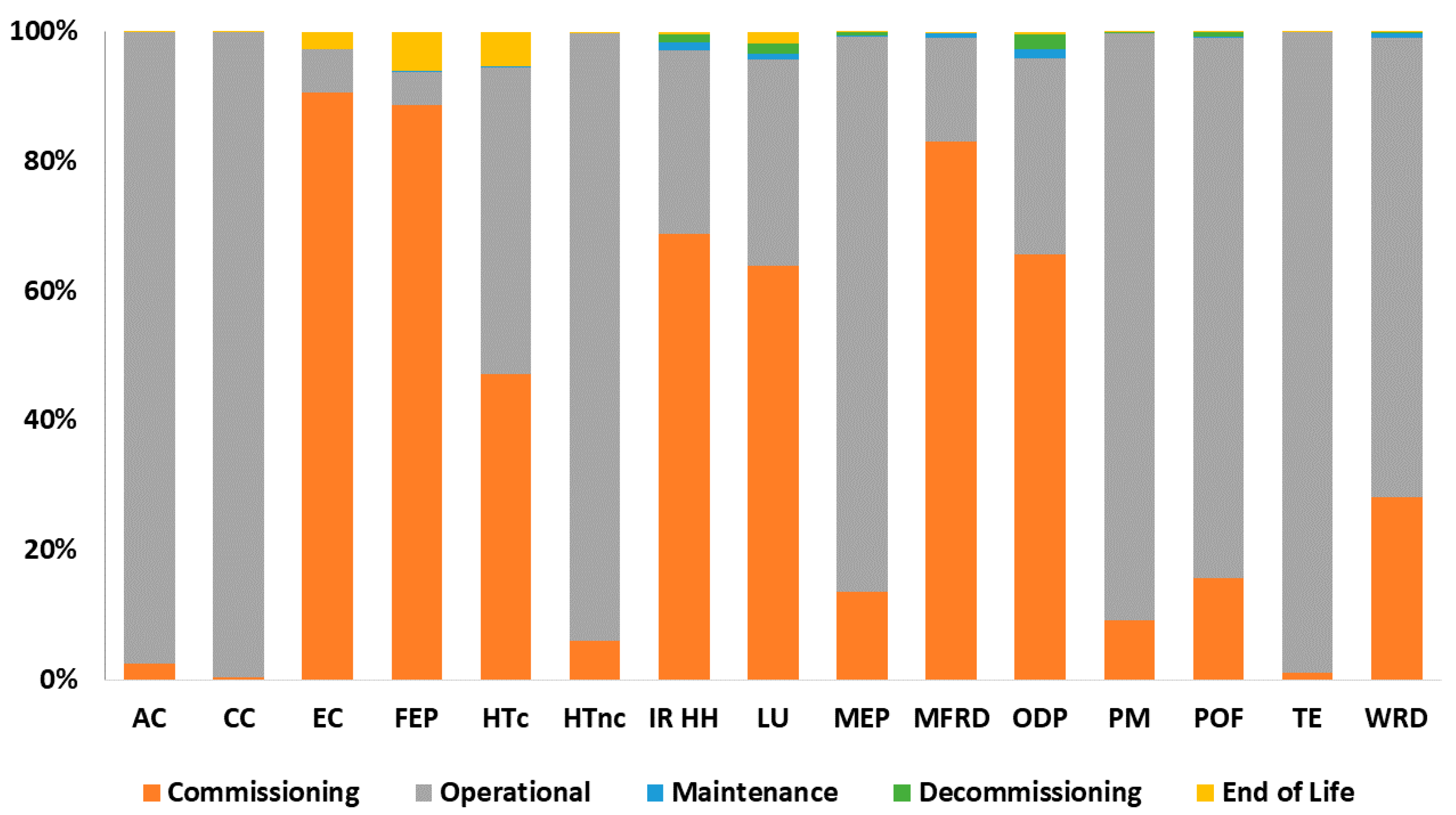

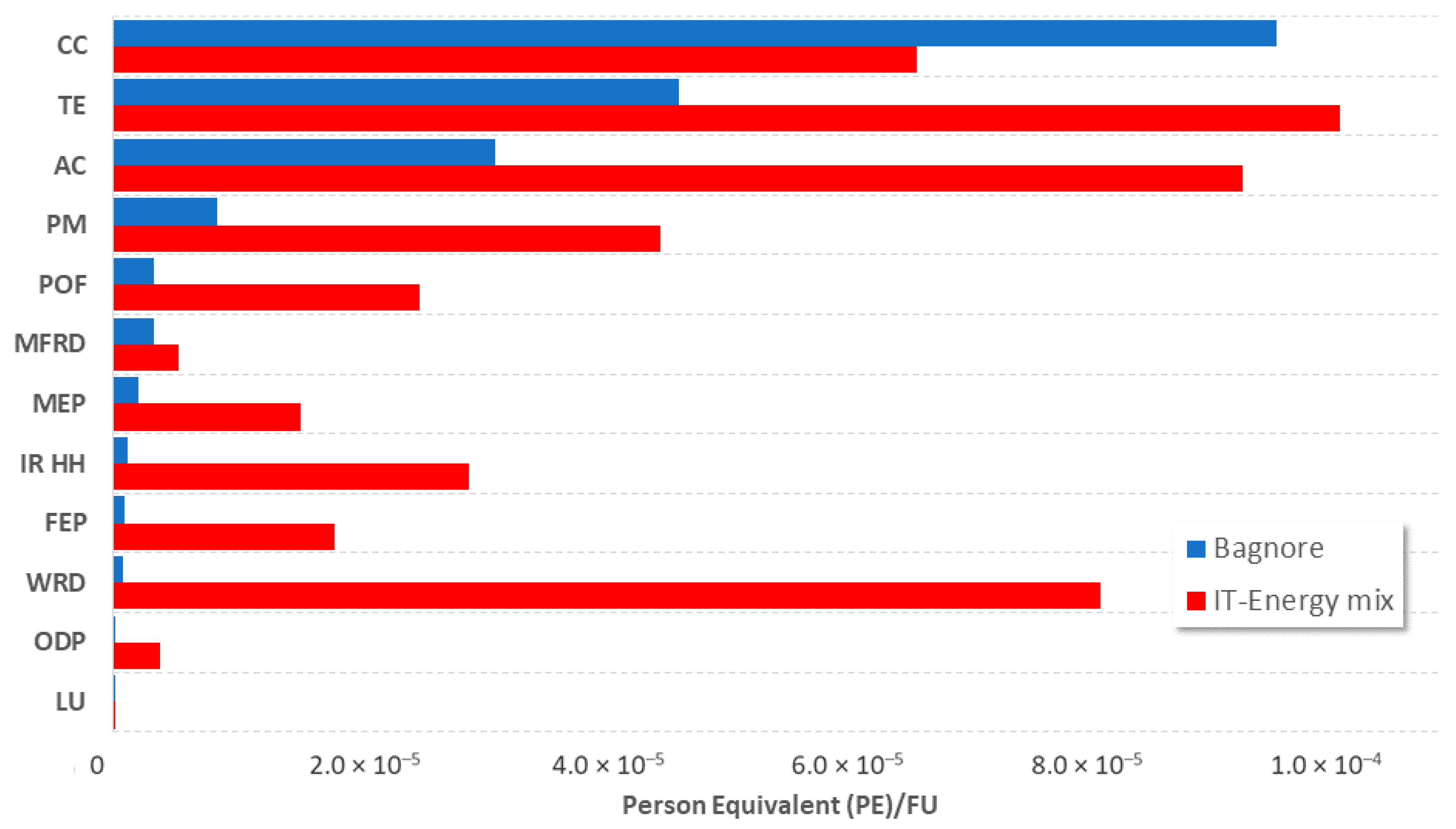

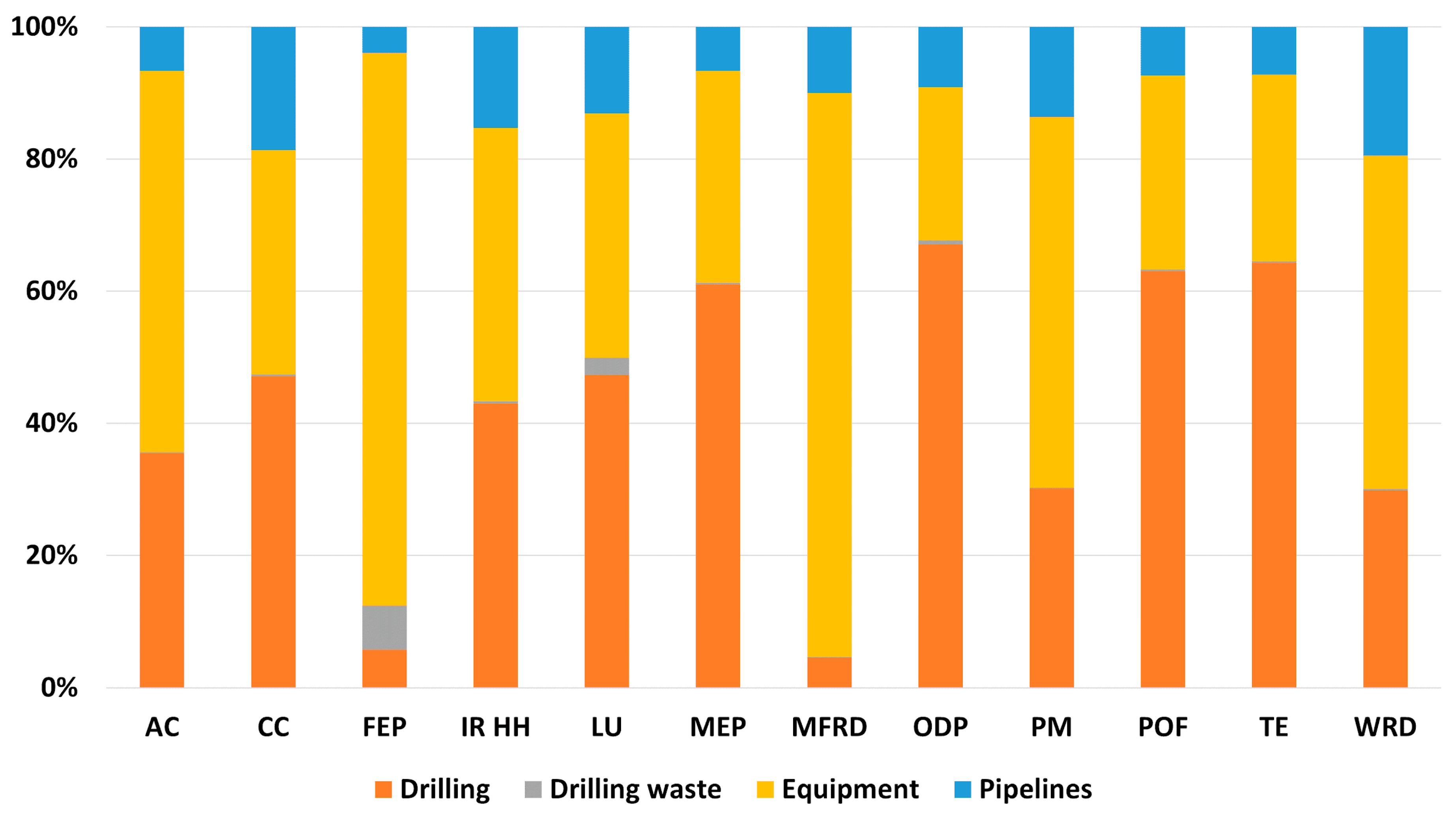

4.1. Life Cycle Assessment of the Bagnore Power Plant System

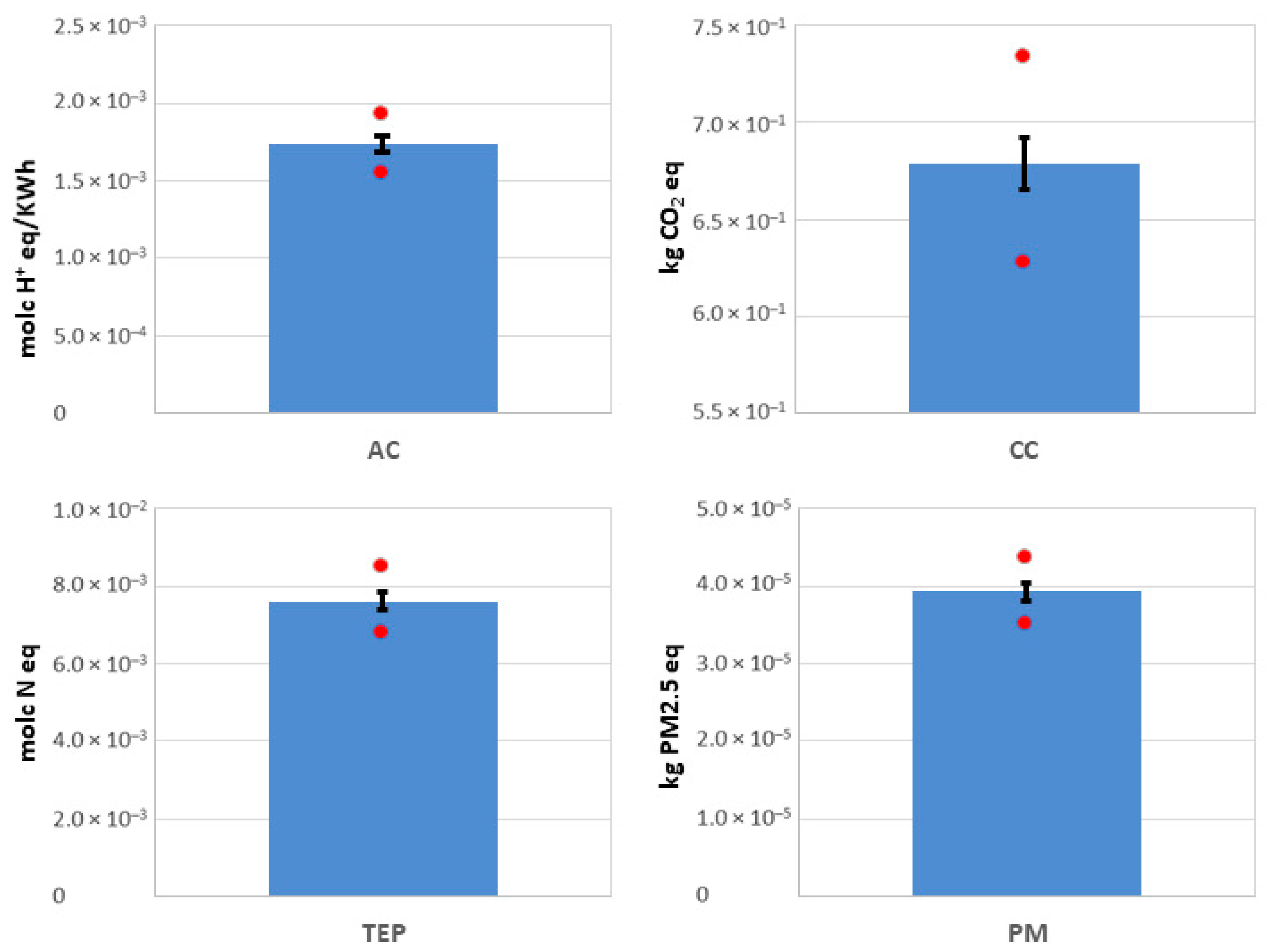

4.2. Uncertainty Analysis of Results

5. Discussion

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| AMIS | Atmospheric emissions abatement system |

| AC | Acidification potential |

| CC | Climate change |

| EC | Freshwater ecotoxicity |

| EGP | Enel Green Power |

| EGS | Enhanced Geothermal System |

| EoL | End of Life |

| FEP | Freshwater eutrophication |

| GHG | Greenhouse gas |

| GWh/y | Giga Watt hour per year |

| HTc | Human toxicity, cancer effects |

| HTnc | Human toxicity, non-cancer effects |

| IRE | Ionizing radiation Environment effect (interim) |

| IRHH | Ionizing radiation Human Health effect |

| LCA | Life cycle assessment |

| LCI | Life cycle inventory |

| LCIA | Life cycle impact assessment |

| LU | Land use |

| MEP | Marine eutrophication |

| MFRD | Mineral, fossil & ren resource depletion |

| MWe | Mega Watt electric |

| NCGs | Non-condensable gasses |

| ODP | Ozone depletion |

| ORC | Organic Rankine cycle |

| PM | Particulate matter |

| POF | Photochemical ozone formation |

| RES | Renewable energy sources |

| TE | Terrestrial eutrophication |

| WRD | Water resource depletion |

References

- European Commission. Clean Energy for all Europeans; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- EU. Directive (EU) 2018/2001 of the European Parliament and of the Council on the promotion of the use of energy from renewable sources. Off. J. Eur. Union 2018, 2018, 82–209. [Google Scholar]

- European Commission. EUR-Lex—52014DC0015—EN 2014; European Commission: Brussels, Belgium, 2014. [Google Scholar]

- European Commission. A Clean Planet for All A European Strategic Long-Term Vision for a Prosperous, Modern, Competitive and Climate Neutral Economy; European Commission: Brussels, Belgium, 2018; pp. 1–25. [Google Scholar]

- European Commission. EUR-Lex—32018R0842—EN 2018; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- European Commission. EUR-Lex—52018DC0716—EN 2018; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Bravi, M.; Basosi, R. Environmental impact of electricity from selected geothermal power plants in Italy. J. Clean. Prod. 2014, 66, 301–308. [Google Scholar] [CrossRef]

- Dumas, P.; Garabetian, T.; Serrani, C.; Pinzuti, V. EGEC Geothermal Market Report 2018; EGEC: Brussels, Belgium, 2019. [Google Scholar]

- Fridleifsson, I.B.; Bertani, R.; Huenges, E. The possible role and contribution of geothermal energy to the mitigation of climate change. In Proceedings of the IPCC Scoping Meeting on Renewable Energy Sources; Hohmeyer, O., Trittin, T., Eds.; The Intergovernmental Panel on Climate Change: Luebeck, Germany, 2008; pp. 59–80. [Google Scholar]

- International Energy Agency. Geothermal—Tracking Power; International Energy Agency: Paris, France, 2019. [Google Scholar]

- International Energy Agency. World Energy Outlook; International Energy Agency: Paris, France, 2019. [Google Scholar]

- Bertani, R. Geothermal power generation in the world 2010–2014 update report. Geothermics 2016, 60, 31–43. [Google Scholar] [CrossRef]

- Sanner, B. Summary of EGC 2019 Country Update Reports on Geothermal Energy in Europe. In Proceedings of the European Geothermal Congress 2019, The Hague, The Netherlands, 11–14 June 2019; p. 18. [Google Scholar]

- Turconi, R.; Boldrin, A.; Astrup, T. Life cycle assessment (LCA) of electricity generation technologies: Overview, comparability and limitations. Renew. Sustain. Energy Rev. 2013, 28, 555–565. [Google Scholar] [CrossRef] [Green Version]

- Parisi, M.L.; Maranghi, S.; Vesce, L.; Sinicropi, A.; Di Carlo, A.; Basosi, R. Prospective life cycle assessment of third-generation photovoltaics at the pre-industrial scale: A long-term scenario approach. Renew. Sustain. Energy Rev. 2020, 121, 109703. [Google Scholar] [CrossRef]

- Rossi, F.; Parisi, M.L.; Maranghi, S.; Basosi, R.; Sinicropi, A. Environmental analysis of a Nano-Grid: A Life Cycle Assessment. Sci. Total Environ. 2019, 700, 134814. [Google Scholar] [CrossRef]

- Basosi, R.; Bonciani, R.; Frosali, D.; Manfrida, G.; Parisi, M.L.; Sansone, F. Life cycle analysis of a geothermal power plant: Comparison of the environmental performance with other renewable energy systems. Sustainability 2020, 12, 2786. [Google Scholar] [CrossRef]

- Buonocore, E.; Vanoli, L.; Carotenuto, A.; Ulgiati, S. Integrating life cycle assessment and emergy synthesis for the evaluation of a dry steam geothermal power plant in Italy. Energy 2015, 86, 476–487. [Google Scholar] [CrossRef]

- Parisi, M.L.; Basosi, R. Geothermal energy production in Italy: An LCA approach for environmental performance optimization. In Life Cycle Assessment of Energy Systems and Sustainable Energy Technologies—The Italian Experience; Basosi, R., Cellura, M., Longo, S., Parisi, M.L., Eds.; Springer: Berlin/Heidelberg, Germany, 2019; pp. 31–43. ISBN 18653529. [Google Scholar] [CrossRef]

- Karlsdottir, M.R.; Heinonen, J.; Palsson, H.; Palsson, O.P. Life cycle assessment of a geothermal combined heat and power plant based on high temperature utilization. Geothermics 2020, 84, 101727. [Google Scholar] [CrossRef]

- Paulillo, A.; Striolo, A.; Lettieri, P. The environmental impacts and the carbon intensity of geothermal energy: A case study on the Hellisheiði plant. Environ. Int. 2019, 133, 105226. [Google Scholar] [CrossRef]

- Bayer, P.; Rybach, L.; Blum, P.; Brauchler, R. Review on life cycle environmental effects of geothermal power generation. Renew. Sustain. Energy Rev. 2013, 26, 446–463. [Google Scholar] [CrossRef]

- Menberg, K.; Pfister, S.; Blum, P.; Bayer, P. A matter of meters: State of the art in the life cycle assessment of enhanced geothermal systems. Energy Environ. Sci. 2016, 9, 2720–2743. [Google Scholar] [CrossRef]

- Tomasini-Montenegro, C.; Santoyo-Castelazo, E.; Gujba, H.; Romero, R.J.; Santoyo, E. Life cycle assessment of geothermal power generation technologies: An updated review. Appl. Therm. Eng. 2017, 114, 1119–1136. [Google Scholar] [CrossRef]

- Asdrubali, F.; Baldinelli, G.; D’Alessandro, F.; Scrucca, F. Life cycle assessment of electricity production from renewable energies: Review and results harmonization. Renew. Sustain. Energy Rev. 2015, 42, 1113–1122. [Google Scholar] [CrossRef]

- Sullivan, J.L.; Clark, C.E.; Han, J.; Wang, M. Life cycle analysis of geothermal systems in comparison to other power systems. Trans. Geotherm. Resour. Counc. 2010, 34, 128–132. [Google Scholar]

- Sullivan, J.L.; Clark, C.E.; Yuan, L.; Han, J.; Wang, M. Life-Cycle Analysis Results for Geothermal Systems in Comparison to Other Power Systems: Part. II; Argonne: Lemont, IL, USA, 2012. [Google Scholar]

- Lacirignola, M.; Meany, B.H.; Padey, P.; Blanc, I. A simplified model for the estimation of life-cycle greenhouse gas emissions of enhanced geothermal systems. Geotherm. Energy 2014, 2, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Lacirignola, M.; Blanc, P.; Girard, R.; Pérez-López, P.; Blanc, I. LCA of emerging technologies: Addressing high uncertainty on inputs’ variability when performing global sensitivity analysis. Sci. Total Environ. 2017, 578, 268–280. [Google Scholar] [CrossRef] [PubMed]

- Marchand, M.; Blanc, I.; Marquand, A.; Beylot, A.; Bezelgues-Courtade, S.; Traineau, H. Life Cycle Assessment of High Temperature Geothermal Energy Systems. In Proceedings of the World Geothermal Congress 2015, Melbourne, Australia, 19–24 April 2015; pp. 19–25. [Google Scholar]

- Martínez-Corona, J.I.; Gibon, T.; Hertwich, E.G.; Parra-Saldívar, R. Hybrid life cycle assessment of a geothermal plant: From physical to monetary inventory accounting. J. Clean. Prod. 2017, 142, 2509–2523. [Google Scholar] [CrossRef]

- Frick, S.; Kaltschmitt, M.; Schröder, G. Life cycle assessment of geothermal binary power plants using enhanced low-temperature reservoirs. Energy 2010, 35, 2281–2294. [Google Scholar] [CrossRef] [Green Version]

- Pratiwi, A.; Ravier, G.; Genter, A. Geothermics Life-cycle climate-change impact assessment of enhanced geothermal system plants in the Upper Rhine Valley. Geothermics 2018, 75, 26–39. [Google Scholar] [CrossRef]

- European Commission. SET Plan Integrated SET—Plan Action 7 “Become Competitive in the Global Battery Sector to Drive E-Mobility and Stationary Storage Forward”; European Commission: Brussels, Belgium, 2018; pp. 1–70. [Google Scholar]

- Karlsdóttir, M.R.; Pálsson, Ó.P.; Pálsson, H.; Maya-Drysdale, L. Life cycle inventory of a flash geothermal combined heat and power plant located in Iceland. Int. J. Life Cycle Assess. 2015, 20, 503–519. [Google Scholar] [CrossRef]

- Fedeli, M.; Mannari, M.; Sansone, F. BAGNORE 4: A benchmark for geothermal power plant environmental compliance. In Proceedings of the European Geothermal Congress, Strasbourg, France, 19–23 September 2016. [Google Scholar]

- Parisi, M.L.; Ferrara, N.; Torsello, L.; Basosi, R. Life cycle assessment of atmospheric emission profiles of the Italian geothermal power plants. J. Clean. Prod. 2019, 234, 881–894. [Google Scholar] [CrossRef]

- Bonciani, R.; Lenzi, A.; Luperini, F.; Sabatelli, F. Geothermal power plants in Italy: Increasing the environmental compliance. In Proceedings of the Conference European Geothermal Congress 2013, Pisa, Italy, 3–7 June 2013. [Google Scholar]

- International Organization for Standardization. ISO 14040:2006—Environmental Management—Life Cycle Assessment—Principles and Framework 2006; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- International Organization for Standardization. ISO 14044:2006 Environmental management—Life cycle assessment—Requirements and guidelines 2006; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- European Commission. International Reference Life Cycle Data System (ILCD) handbook: Framework and Requirements for Life Cycle Impact Assessment Models and Indicators; European Commission: Brussels, Belgium, 2010; ISBN 9789279175398. [Google Scholar]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Weidema, B.P.; Bauer, C.; Hischier, R.; Mutel, C.; Nemecek, T.; Reinhard, J.; Vadenbo, C.O.; Wenet, G. Overview and Methodology. Data Quality Guideline for the Ecoinvent Database Version 3. Ecoinvent Report 1 (v3); The ecoinvent Centre: St. Gallen, Switzerland, 2013. [Google Scholar]

- Ferrara, N.; Basosi, R.; Parisi, M.L. Data analysis of atmospheric emission from geothermal power plants in Italy. Data Br. 2019, 25, 104339. [Google Scholar] [CrossRef] [PubMed]

- Saouter, E.; Biganzoli, F.; Ceriani, L.; Versteeg, D.; Crenna, E.; Zampori, L.; Sala, S.; Pant, R. Environmental Footprint: Update of Life Cycle Impact Assessment Methods: Ecotoxicity Freshwater, Human Toxicity Cancer, and Non-Cancer; Publications Office of the European Union: Luxembourg, 2018. [Google Scholar]

- Greendelta OpenLCA V 1.8 2018. Available online: http://www.openlca.org/greendelta/ (accessed on 11 January 2020).

- ARPAT. Geothermal Emissions Monitoring; Tuscany Regional Agency for Environmental Protection: Pisa, Italy, 2018. (In Italian) [Google Scholar]

- Itten, R.; Frischknecht, R.; Stucki, M.; Scherrer, P.; Psi, I. Life Cycle Inventories of Electricity Mixes and Grid; Paul Scherrer Institute: Villigen, Switzerland, 2014; pp. 1–229. [Google Scholar]

- Stocker, T.F.; Qin, D.; Plattner, G.-K.; Tignor, M.; Allen, S.K.; Boschung, J.; Nauels, A.; Xia, Y. Climate Change 2013: The Physical Science Basis. Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; IPCC: Geneva, Switzerland, 2013. [Google Scholar]

| Geothermal Source Type | Hydrothermal | |

|---|---|---|

| Energy generation technology | Flash | |

| Final energy use | Electricity production | |

| Average Reservoir Depth (shallow|deep) (m) | 700|3000 | |

| Field Average Temperature (°C) | 300–350 | |

| Parameter | Unit | Value |

| Installed power | ||

| Electric | MWe | 61 |

| Thermal | MWth | 21.1 |

| District Heating SUPPLY| RETURN temperature | °C | 100|60 |

| Net energy output (annual) | ||

| Electric | GWhe/y | 544 |

| Thermal | GWhth/y | 32 |

| Predicted lifetime | Years | 40 |

| Total Energy Produced | ||

| Electric | GWhe | 21,760 |

| Thermal | GWht | 1280 |

| Production and injection wells | Number | 8 production/6 injection |

| Total length drilled | Meters | 31,823 |

| Pipelines length | Meters | 10,400 |

| Load factor | % | 99 |

| Indicators | Scores | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Reliability | Verified data based on measurements | Verified data partly based on assumptions or non-verified data based on measurements | Non-verified data partly based on qualified estimates | Qualified estimate (e.g., by industrial expert) | Non-qualified estimates |

| Completeness | Representative data from all sites relevant for the market considered, over and adequate period to even out normal fluctuations | Representative data from >50% of the sites relevant for the market considered, over an adequate period to even out normal fluctuations | Representative data from only some sites (<<50%) relevant for the market considered or >50% of sites but from shorter periods | Representative data from only one site relevant for the market considered or some sites but from shorter periods | Representativeness unknown or data from a small number of sites and from shorter periods |

| Temporal correlation | Less than 3 years of difference to the time period of the data set | Less than 6 years of difference to the time period of the data set | Less than 10 years of difference to the time period of the data set | Less than 15 years of difference to the time period of the data set | Age of data unknown or more than 15 years of difference to the time period of the data set |

| Geographical correlation | Data from area under study | Average data from larger area in which the area under study is included | Data from area with similar production conditions | Data from area with slightly similar production conditions | Data from unknown or distinctly different area (North America instead of Middle East, OECD-Europe instead of Russia) |

| Further technological correlation | Data from enterprises, processes and materials under study | Data from processes and materials under study (i.e., identical technology) but from different enterprises | Data from processes and materials under study but from different technology | Data on related processes or materials | Data on related processes on laboratory scale or from different technology |

| Parameter | Karlsdóttir et al. (2015) | This Work |

|---|---|---|

| Data accuracy | Not all the data presents the highest level of accuracy. Sometimes secondary data are employed, or data come from extrapolation of secondary data. | Most of the data comes from primary sources, or data are directly extrapolated by the operator Company. |

| Data coverage | Most of the Life Cycle Stages are analyzed and reported, but

| All of the Life Cycle Stages are fully analyzed and reported. |

| System boundaries | End of life (EoL) processes are not included | EoL processes are included; only heating station building, electric supply machinery and distribution infrastructure are not included in the system boundaries |

| Energy Input | Amount | Unit |

| Diesel for drilling | 9.4 × 10−3 | MJ/F.U. |

| Material input | Amount | Unit |

| Excavation | 6.7 × 10−7 | m3/F.U. |

| Portland cement | 8.1 × 10−4 | kg/F.U. |

| Steel | 3.3 × 10−4 | kg/F.U. |

| Gravel | 2.5 × 10−4 | kg/F.U. |

| Bentonite | 9.4 × 10−5 | kg/F.U. |

| Copper | 5.0 × 10−5 | kg/F.U. |

| Sodium hydroxide | 3.5 × 10−5 | kg/F.U. |

| Aluminium | 2.7 × 10−5 | kg/F.U. |

| Material output | Amount | Unit |

| Drilling waste to disposal (EoL) | 1.0 × 10−3 | kg/F.U. |

| Material Input | Amount | Unit |

|---|---|---|

| Lubricating oil | 5.5 × 10−6 | kg/F.U. |

| Selenium | 4.1 × 10−6 | kg/F.U. |

| Pentane | 2.8 × 10−6 | kg/F.U. |

| PVC | 8.3 × 10−7 | kg/F.U. |

| Steel | 7.7 × 10−7 | kg/F.U. |

| Material Input | Amount | Unit |

| H2SO4 | 3.7 × 10−3 | kg/F.U. |

| Atmospheric Emissions | Amount | Unit |

| CO2 | 4.1 × 10−1 | kg/F.U. |

| CH4 | 1.2 × 10−2 | kg/F.U. |

| Energy Input | Amount | Unit |

| Diesel | 6.4 × 10−4 | MJ/F.U. |

| Material Input | Amount | Unit |

| Portland | 1.6 × 10−5 | kg/F.U. |

| Gravel | 3.2 × 10−6 | kg/F.U. |

| LC Phase | Unit | AC | CC | PM | TE |

|---|---|---|---|---|---|

| Commissioning | PE/FU | 8.0 × 10−7 | 4.3 × 10−7 | 8.0 × 10−7 | 5.4 × 10−7 |

| Operational | PE/FU | 3.1 × 10−5 | 9.6 × 10−5 | 7.8 × 10−6 | 4.6 × 10−5 |

| End of Life | PE/FU | 1.1 × 10−9 | 2.5 × 10−9 | 1.4 × 10−9 | 1.3 × 10−9 |

| Maintenance | PE/FU | 7.8 × 10−9 | 3.4 × 10−9 | 7.0 × 10−9 | 2.2 × 10−9 |

| Decommissioning | PE/FU | 1.4 × 10−8 | 9.4 × 10−9 | 1.1 × 10−8 | 2.3 × 10−8 |

| Total | PE/FU | 3.2 × 10−5 | 9.6 × 10−5 | 8.6 × 10−6 | 4.7 × 10−5 |

| Impact Category | Impact Result | STDV (%) | Overall Data Quality Indicator 1 | ||||

|---|---|---|---|---|---|---|---|

| R | C | T | G | F | |||

| Acidification (molc H+ eq) 2 | 1.78 × 10−3 | 3 | 1 | 1 | 2 | 1 | 1 |

| Climate change (kg CO2 eq) | 6.82 × 10−1 | 2 | 1 | 1 | 2 | 1 | 1 |

| Freshwater eutrophication (kg P eq) | 5.19 × 10−6 | 58 | 1 | 1 | 4 | 1 | 1 |

| Ionizing radiation HH (kBq 235U eq) | 2.96 × 10−4 | 12 | 1 | 1 | 5 | 2 | 1 |

| Land use (kg C deficit) | 8.37 × 10−3 | 18 | 3 | 4 | 5 | 3 | 1 |

| Marine eutrophication (kg N eq) | 6.16 × 10−5 | 3 | 1 | 1 | 3 | 1 | 1 |

| Mineral, fossil & ren resource depletion (kg Sb eq) | 6.49 × 10−7 | 20 | 3 | 2 | 5 | 2 | 2 |

| Ozone depletion (kg CFC-11 eq) | 4.39 × 10−10 | 47 | 2 | 3 | 4 | 5 | 3 |

| Particulate matter (kg PM2.5 eq) | 4.35 × 10−5 | 3 | 1 | 1 | 2 | 1 | 1 |

| Photochemical ozone formation (kg NMVOC eq) | 1.52 × 10−4 | 3 | 1 | 1 | 3 | 1 | 1 |

| Terrestrial eutrophication (molc N eq) 2 | 7.69 × 10−3 | 3 | 1 | 1 | 2 | 1 | 1 |

| Water resource depletion (m3 water eq) | 5.69 × 10−5 | 11 | 2 | 3 | 5 | 3 | 2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tosti, L.; Ferrara, N.; Basosi, R.; Parisi, M.L. Complete Data Inventory of a Geothermal Power Plant for Robust Cradle-to-Grave Life Cycle Assessment Results. Energies 2020, 13, 2839. https://doi.org/10.3390/en13112839

Tosti L, Ferrara N, Basosi R, Parisi ML. Complete Data Inventory of a Geothermal Power Plant for Robust Cradle-to-Grave Life Cycle Assessment Results. Energies. 2020; 13(11):2839. https://doi.org/10.3390/en13112839

Chicago/Turabian StyleTosti, Lorenzo, Nicola Ferrara, Riccardo Basosi, and Maria Laura Parisi. 2020. "Complete Data Inventory of a Geothermal Power Plant for Robust Cradle-to-Grave Life Cycle Assessment Results" Energies 13, no. 11: 2839. https://doi.org/10.3390/en13112839

APA StyleTosti, L., Ferrara, N., Basosi, R., & Parisi, M. L. (2020). Complete Data Inventory of a Geothermal Power Plant for Robust Cradle-to-Grave Life Cycle Assessment Results. Energies, 13(11), 2839. https://doi.org/10.3390/en13112839