Experimental Study on Energy Efficiency of Multi-Functional BIPV Glazed Façade Structure during Heating Season

Abstract

1. Introduction

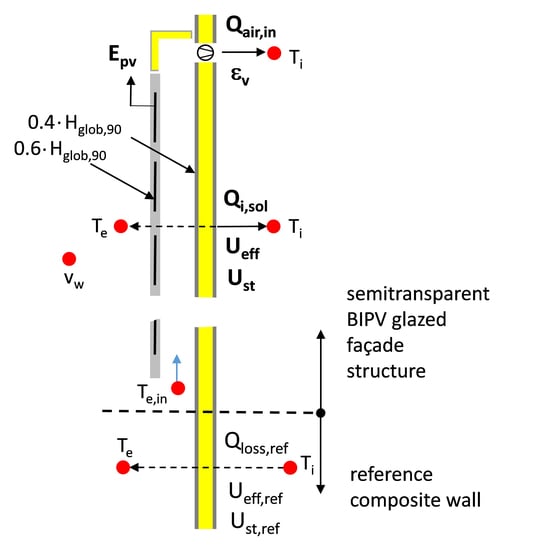

2. Object of Research and Research Methods

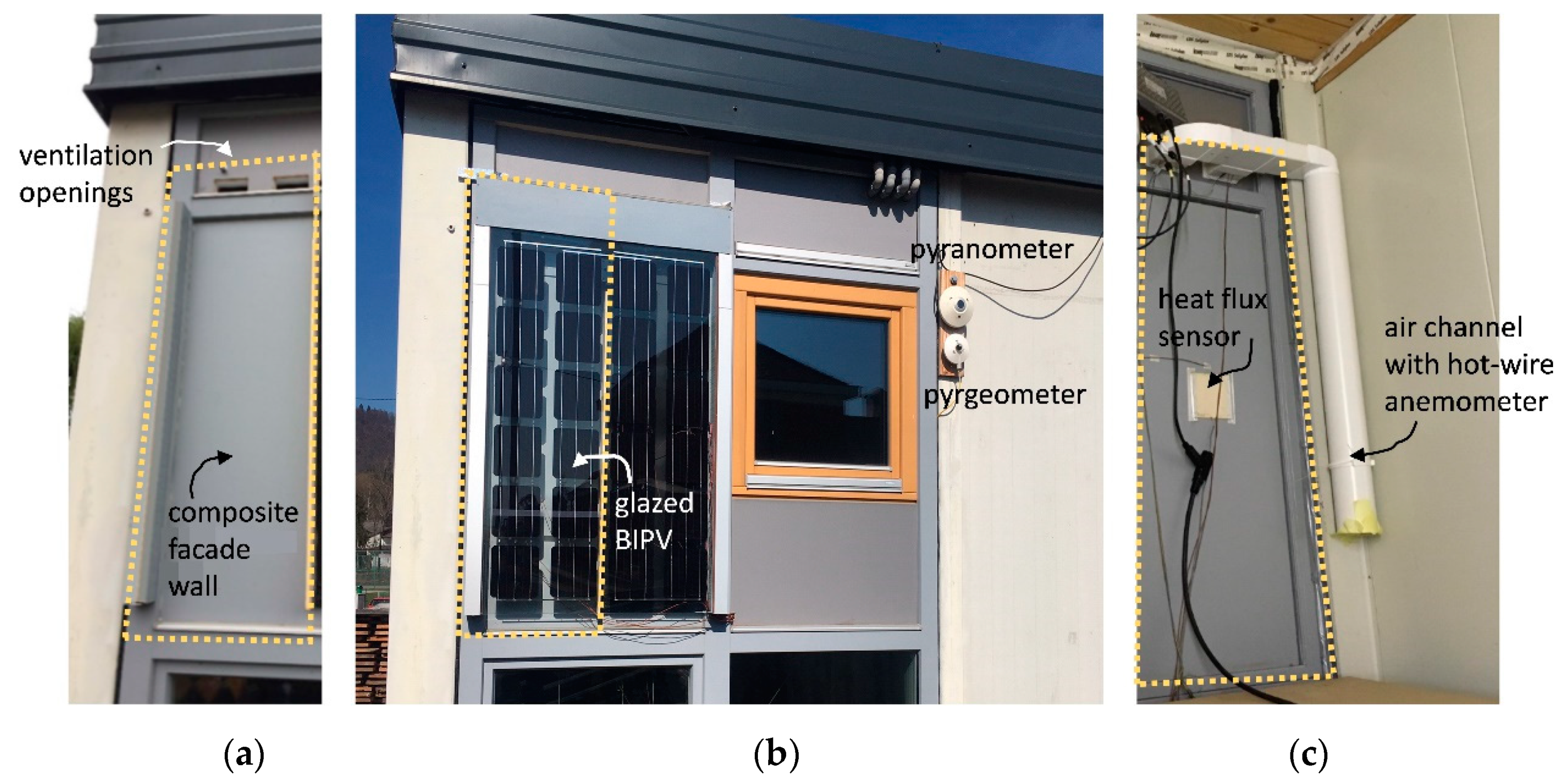

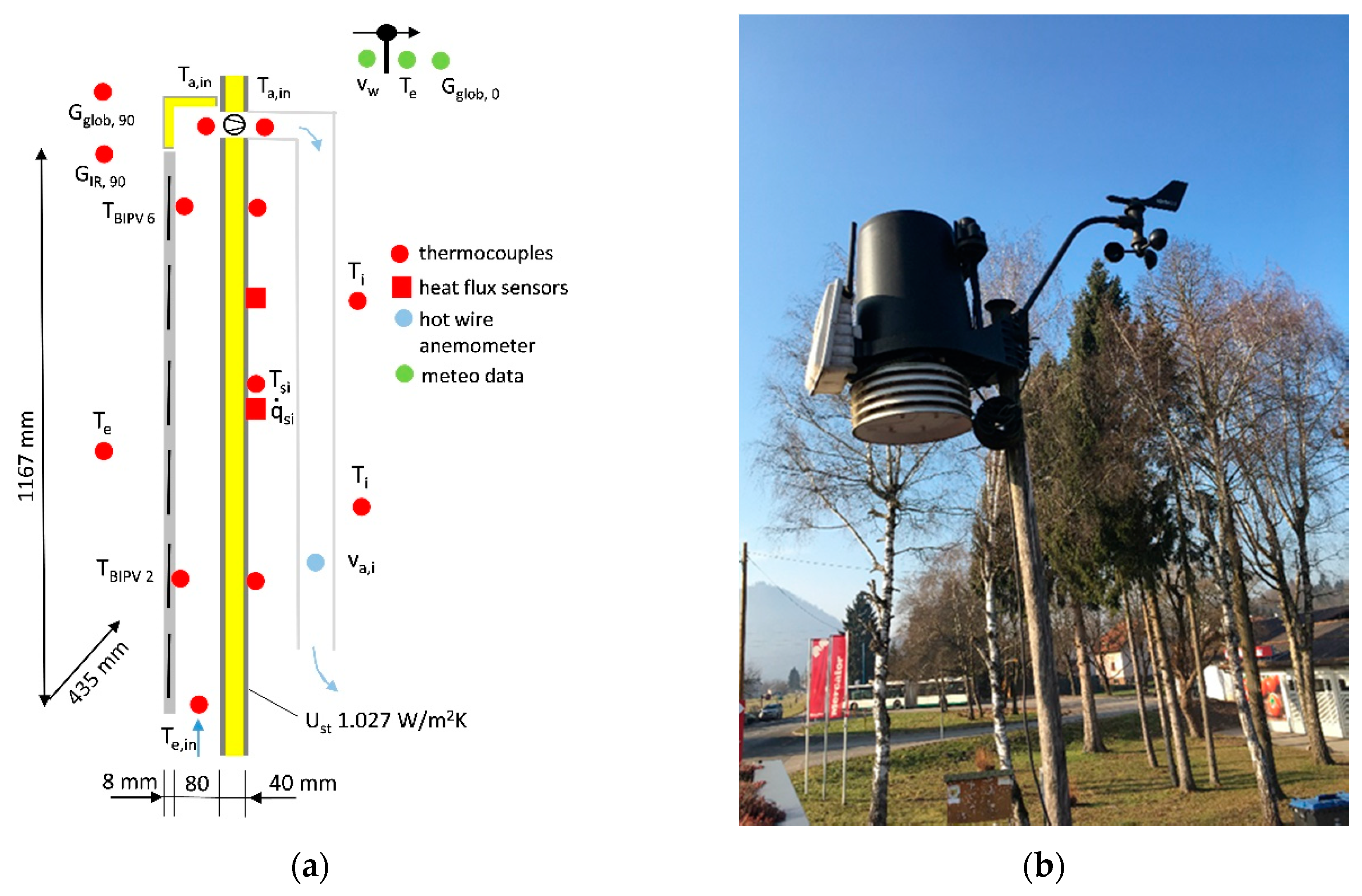

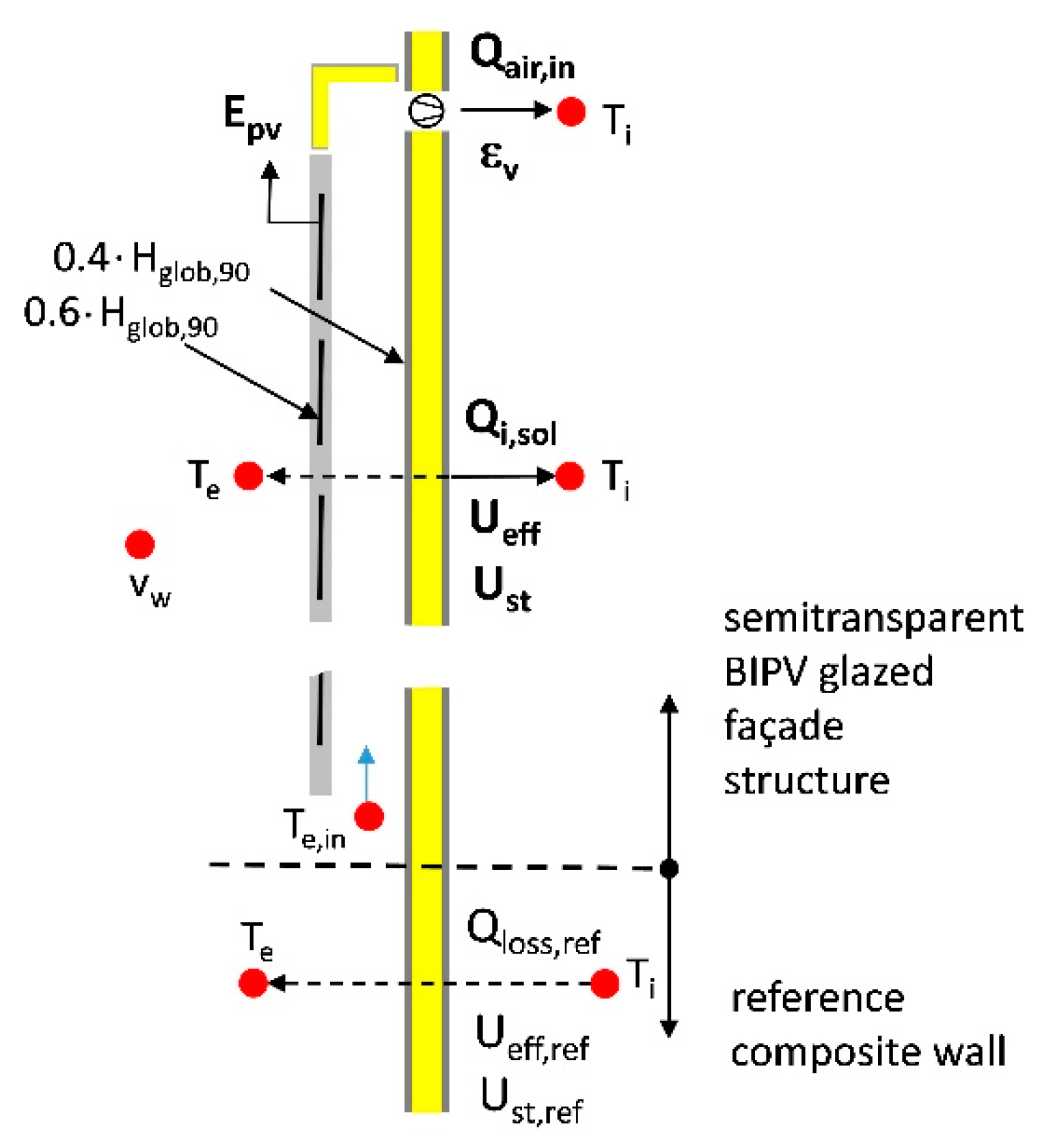

2.1. Semitransparent BIPV Glazed Façade Structure with Forced Ventilated Air Gap

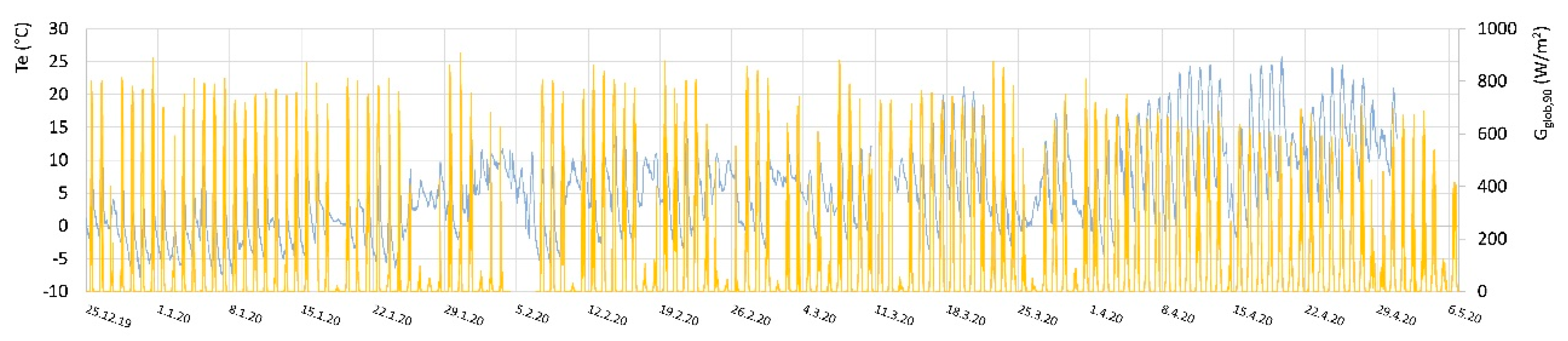

2.2. Experiment Setup

2.3. Research Methods

3. Energy Efficiency Indicators

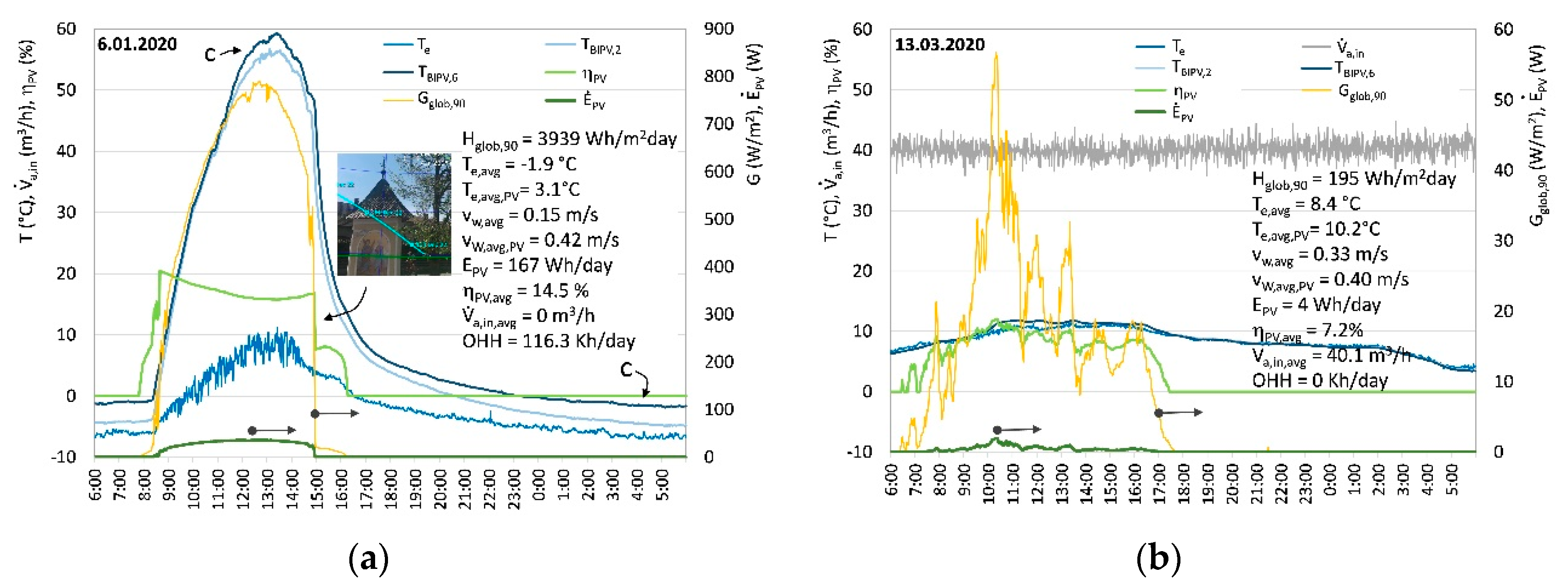

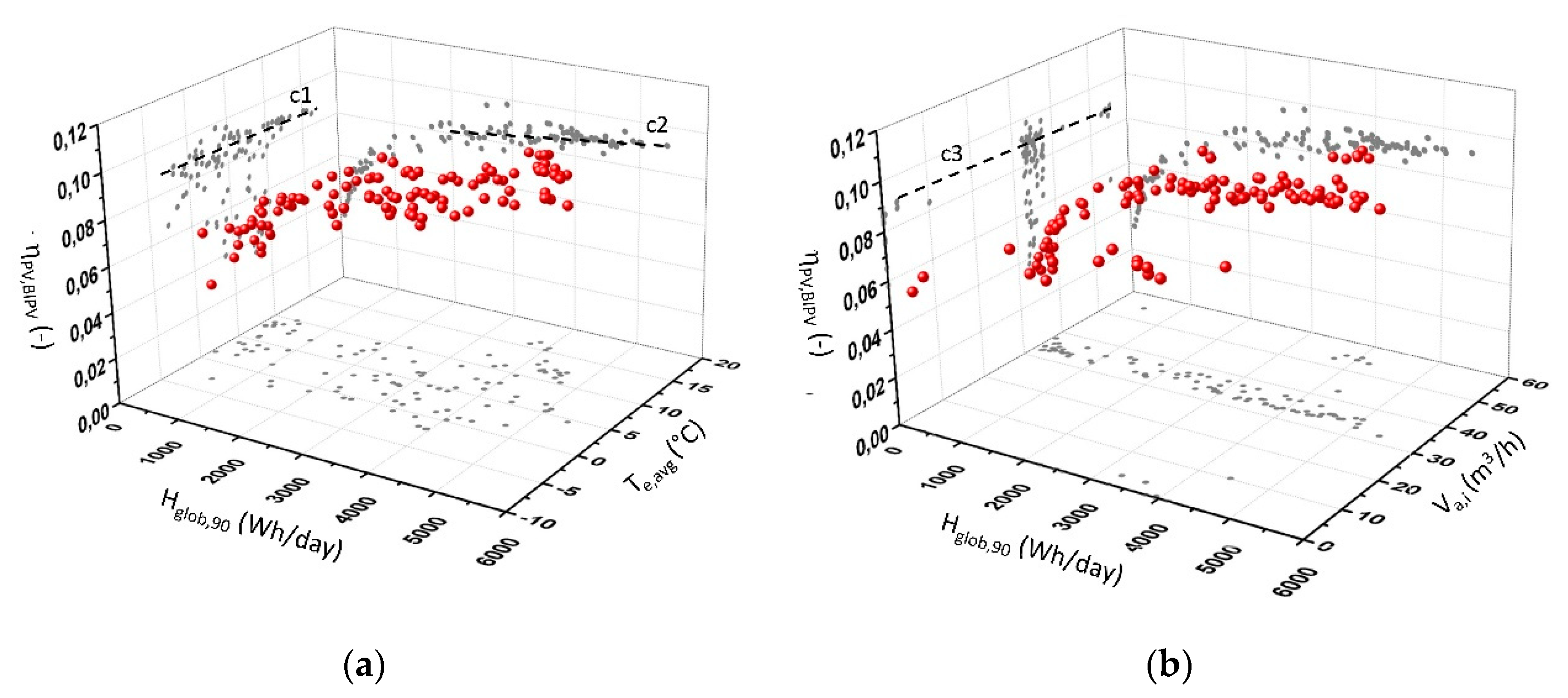

3.1. Electricity Production

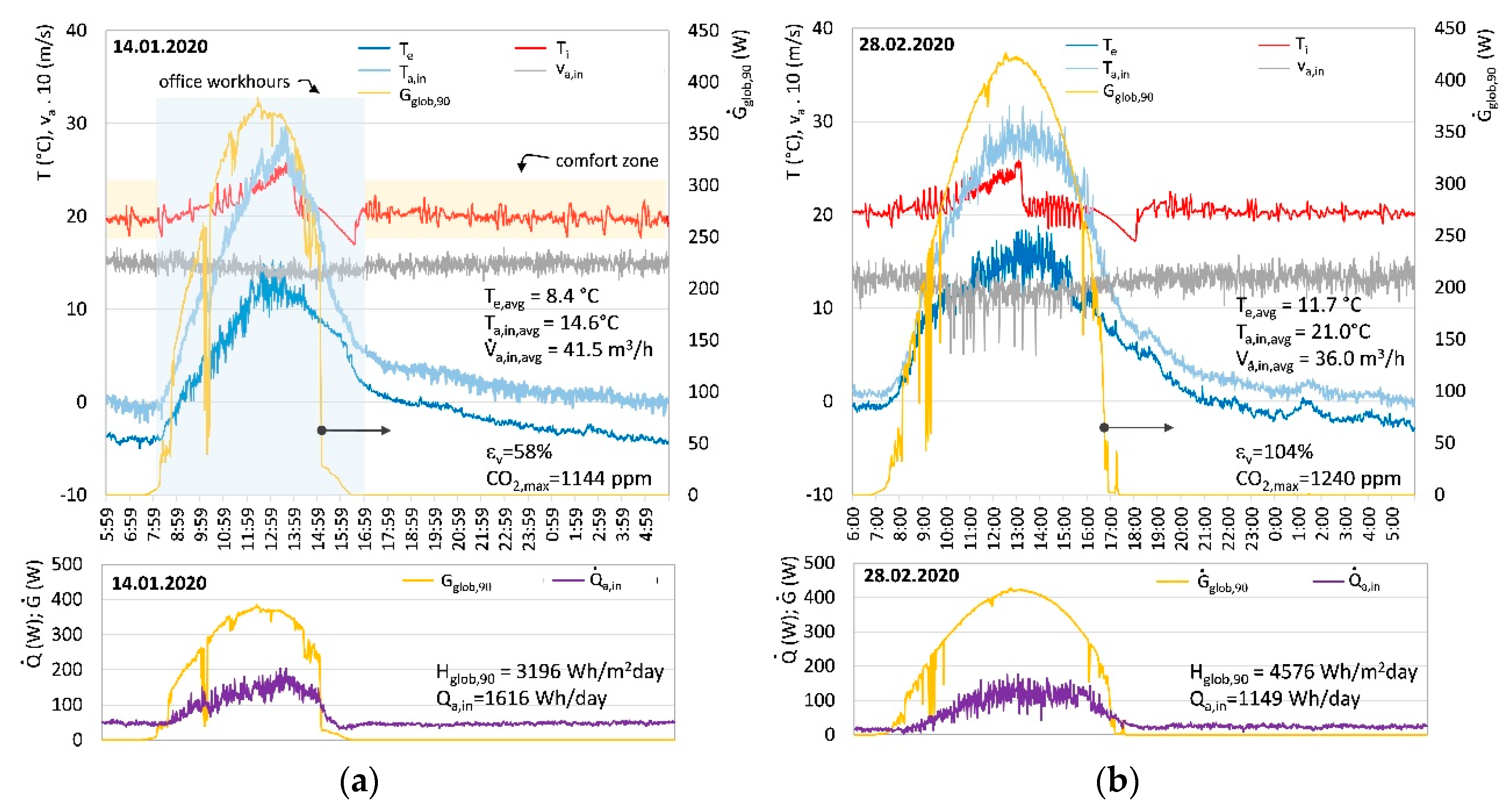

3.2. Preheating of Ventilation Air

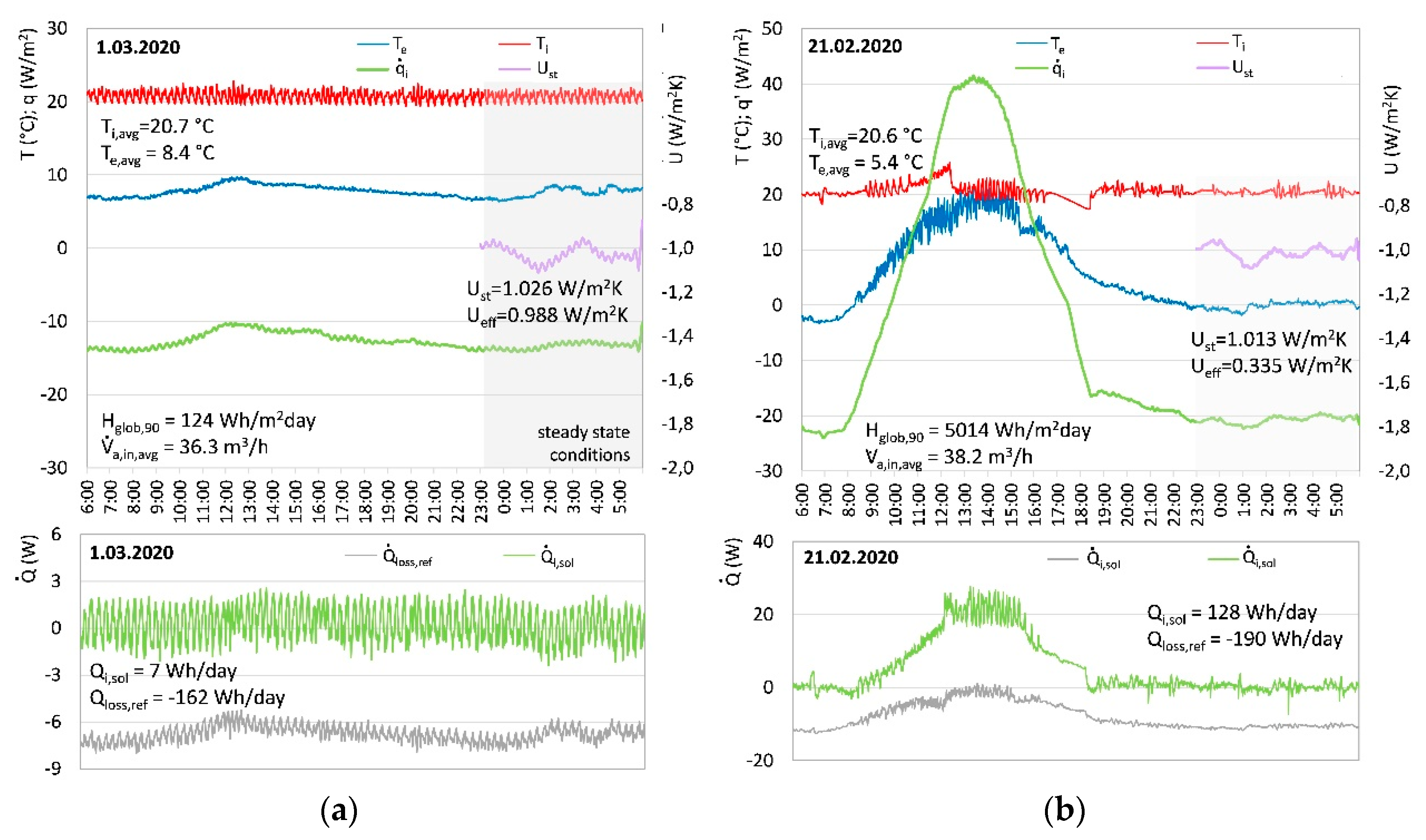

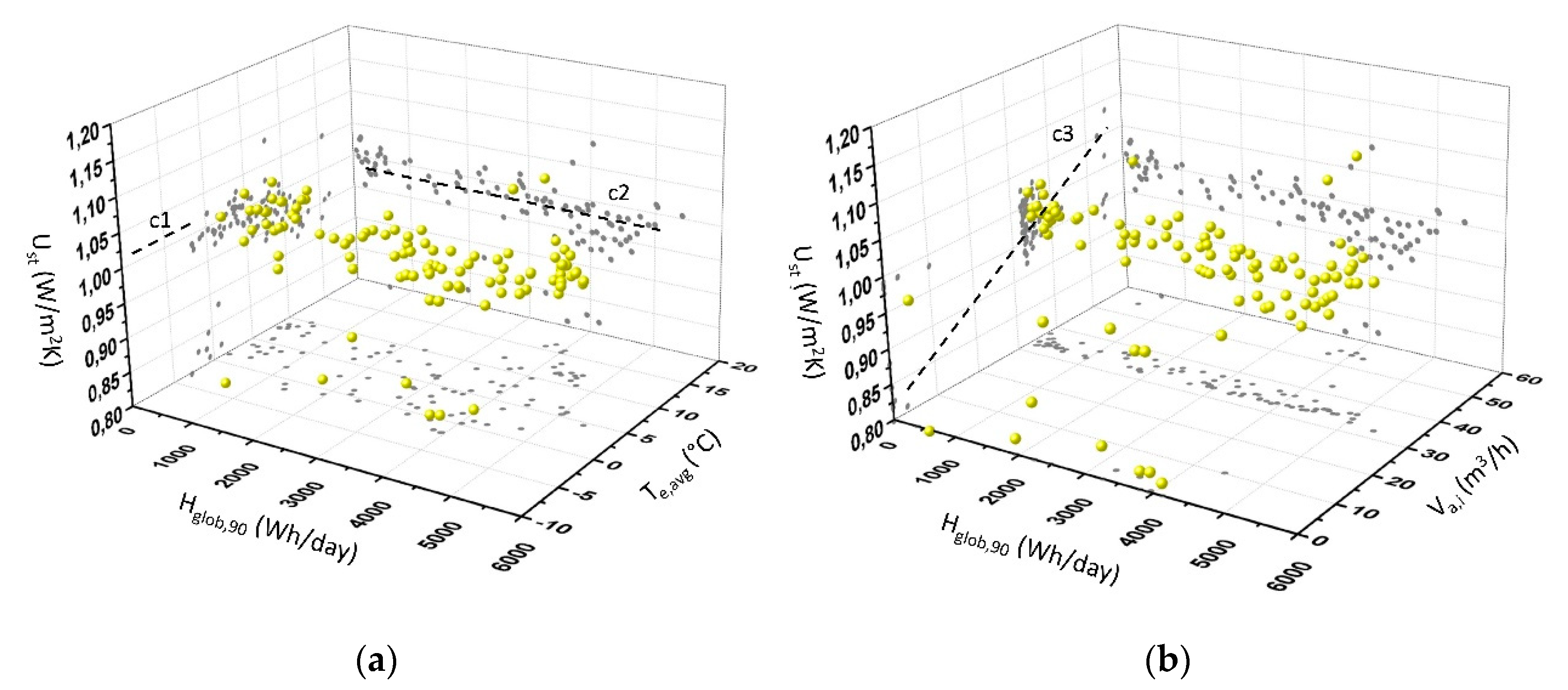

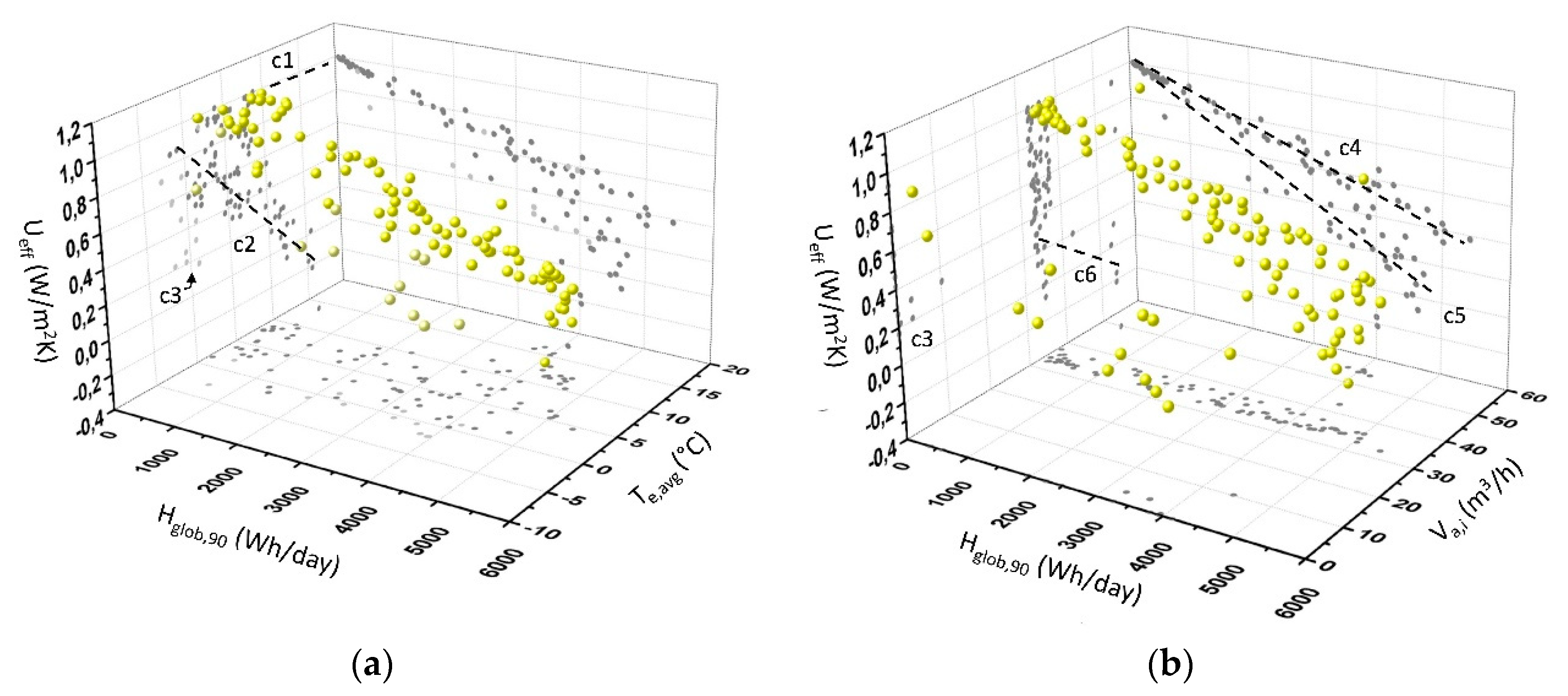

3.3. Dynamic Thermal Insulation

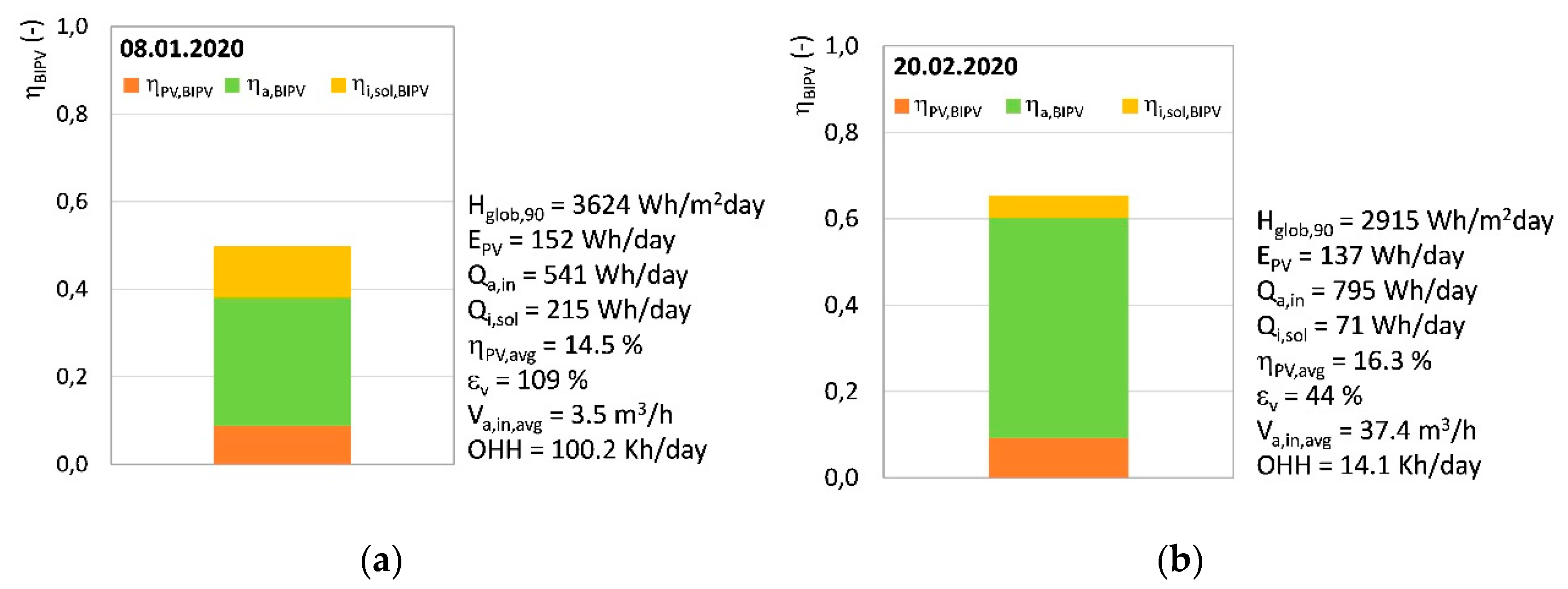

3.4. Overall Efficiency of Solar Energy Utilization

4. Results and Discussion

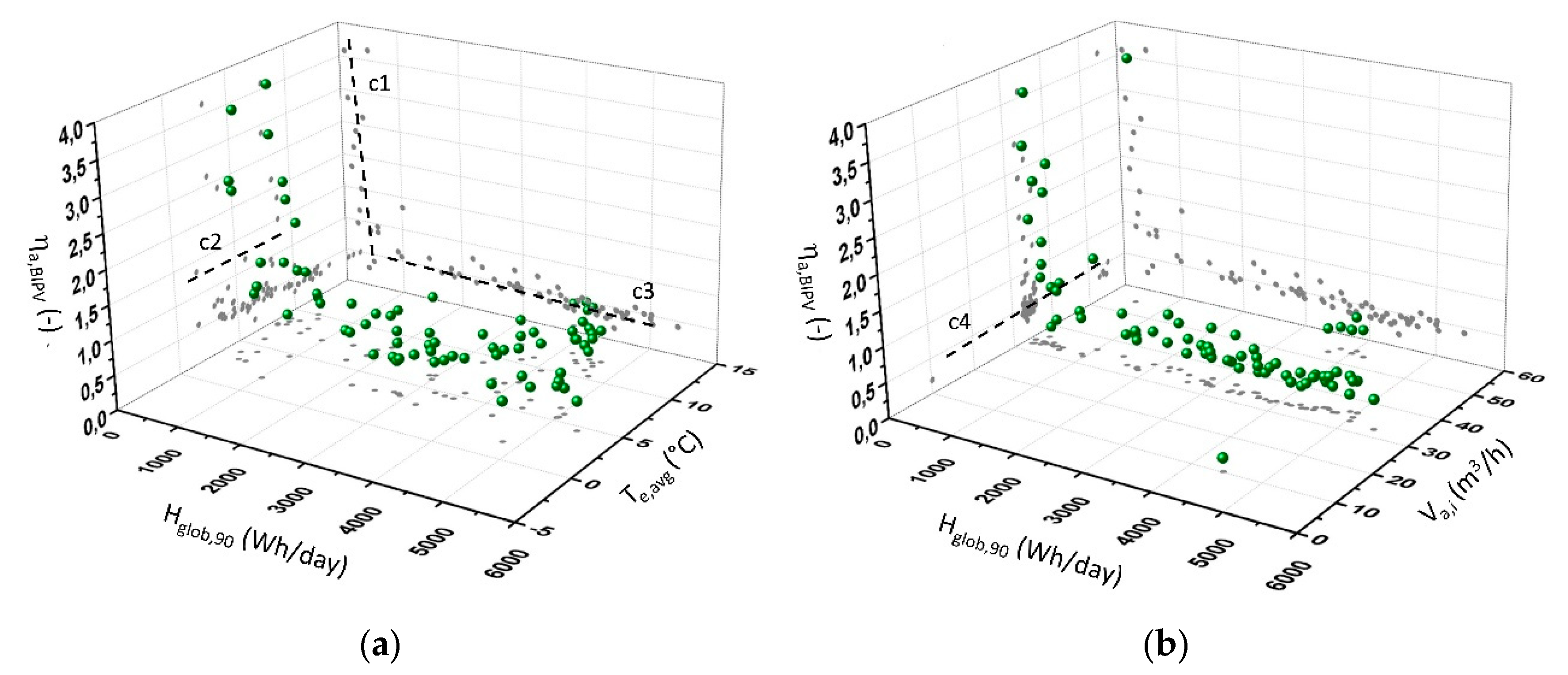

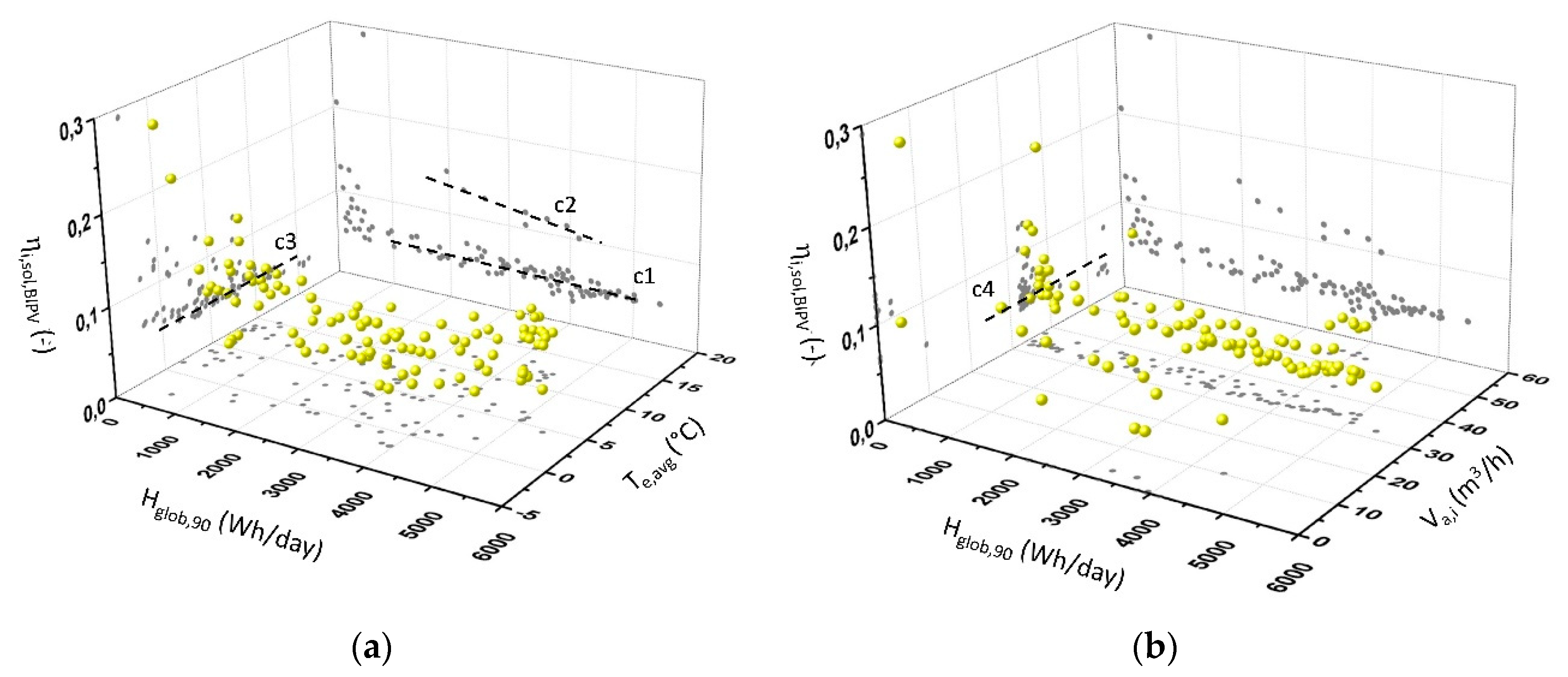

4.1. Parametric Study

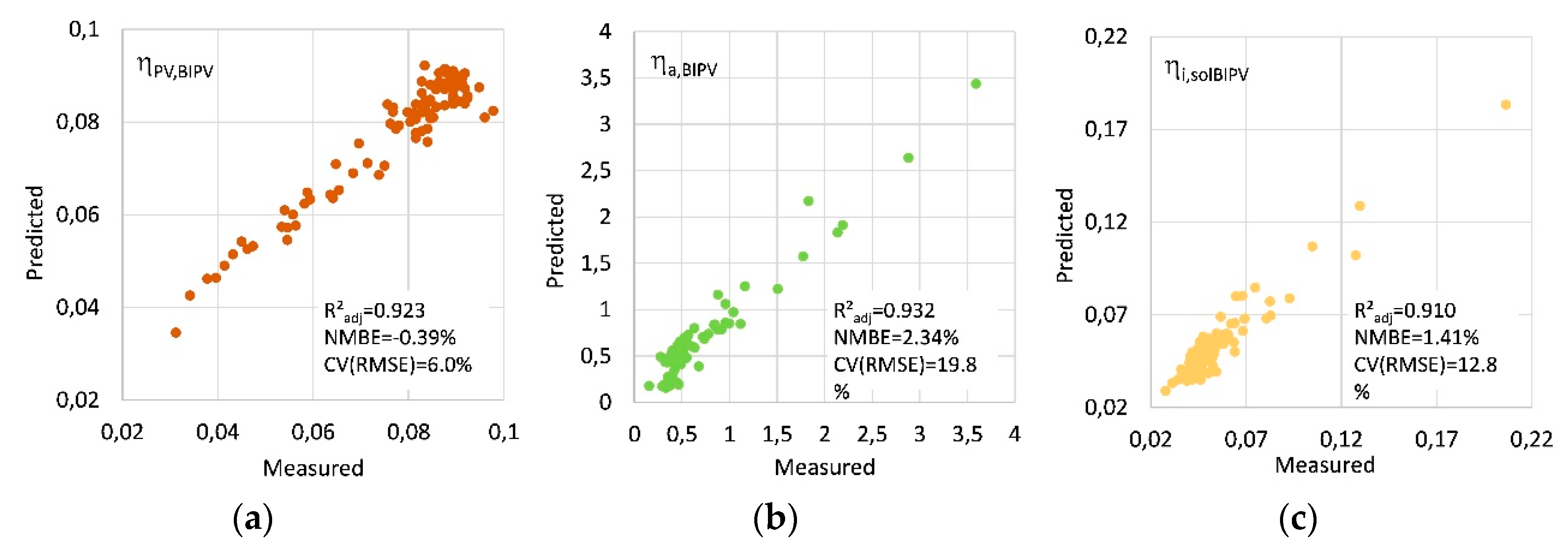

4.2. Multi-Parametric Model of Overall Efficiency of Solar Energy Utilization

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| A | m2 | area |

| α | (-) | absorptivity |

| β | (-) | temperature coefficient |

| C | mg/m3, ppm | pollutant concentration |

| cp | (J/kgK) | specific heat capacity |

| d | m | thickness |

| Δτmeas | min | measuring interval |

| W | electrical power | |

| E | Wh/day | diurnal production of electricity |

| ε | (-) | emissivity |

| W | solar irradiation power | |

| G | W/m2 | solar irradiation |

| h | W/m2K | surface heat transfer coefficient |

| H | Wh/m2day | diurnal solar radiation |

| k | 1/day | pollutant decay factor |

| η | (%) | efficiency |

| KG | (-) | solar irradiation factor |

| KT | (-) | temperature factor |

| λ | W/mK | thermal conductivity |

| M | (-) | measured value |

| n | (-) | number of |

| OHH | (Kh/day) | diurnal overheating hours |

| P | (-) | Predicted value |

| (W/m2) | density of heat flux | |

| (W) | heat power | |

| Q | (Wh/day) | diurnal delivered heat |

| ρ | (kg/m3) | density |

| S | mg/min | source of pollutant |

| T | °C | temperature |

| U | W/m2K | thermal transmittance |

| v | m/s | velocity |

| V | m3 | volume |

| m3/h | flow rate | |

| 7, 24 | h/day | constants |

| 60 | min/h | constant |

| Index | ||

| a | air | |

| avg; avg,day | average, diurnal average | |

| avg, PV | diurnal average during PV electricity production | |

| BIPV | pilot building integrated PV glazed façade structure | |

| e | outdoor, external | |

| eff | effective, dynamic | |

| g | glass | |

| glob,90 | solar on vertical surface | |

| glob,90,day | solar on vertical surface diurnal | |

| i | indoor, internal | |

| in | inlet | |

| IR | infrared, long wavelength | |

| IR,90,day | infra-red on vertical surface diurnal | |

| loss | heat loss | |

| max | maximum, maximum at the end of working hours | |

| n | net | |

| PV | photovoltaic | |

| PV,si | on inner glass surface of BIPV structure | |

| r+c | combined radiative and convection | |

| ref | reference, reference structure | |

| s | solar, short wavelength | |

| si | internal surface | |

| sol | generated by solar energy | |

| st | static | |

| v | ventilation | |

| w | wind | |

| 2, 6 | second row, sixth row of PV |

References

- Sombsthay, A.; Beauvais, A.; Moser, D.; Tecnalia, E.B.; Gaymard, G.; Delmer, G.; Gurdenli, L.; Machado, M.; Po, R.; Krawietz, S.; et al. Solar Skins: An Opportunity for Green Cities; SolarPower Europe and ETIP PV: Brussels, Belgium, 2019. [Google Scholar]

- Farghaly, Y.; Hassan, F. A Simulated Study of Building Integrated Photovoltaics (BIPV) as an Approach for Energy Retrofit in Buildings. Energies 2019, 12, 3946. [Google Scholar] [CrossRef]

- Ramirez-Balas, C.; Fernandez-Nieto, E.; Narbona-Reina, G.; Sendra, J.J.; Suarez, R. Thermal 3D CFD Simulation with Active Transparent Façade in Buildings. Energies 2018, 11, 2264. [Google Scholar] [CrossRef]

- Yang, X.; Zhou, J.; Yuan, Y. Energy Performance of an Encapsulated Phase Change Material PV/T System. Energies 2019, 12, 3929. [Google Scholar] [CrossRef]

- Good, C.; Andersen, I.; Hestnes, A.G. Solar Energy for net Zero Energy Buildings—A Comparison between Solar Thermal, PV and Photovoltaic–Thermal (PV/T) Systems. Solar Energy 2015, 122, 986–996. [Google Scholar] [CrossRef]

- Agathokleous, R.A.; Kalogirou, S.A. Double Skin Facades (DSF) and Building Integrated Photovoltaics (BIPV): A Review of Configurations and Heat Transfer Characteristics. Renew. Energy 2016, 89, 743–756. [Google Scholar] [CrossRef]

- Agrawal, B.; Tiware, G.N. Optimizing the Energy and Exergy of Building Integrated Photovoltaic Thermal (BIPVT) Systems under Cold Climatic Conditions. Appl. Energy 2010, 87, 417–426. [Google Scholar] [CrossRef]

- Saadon, S.; Gaillard, L.; Menezo, C.; Giroux-Julien, S. Exergy, Exergoeconomic and Enviroeconomic Analysis of a Building Integrated Semi-Transparent Photovoltaic/Thermal (BISTPV/T) by Natural Ventilation. Renew. Energy 2020, 150, 981–989. [Google Scholar] [CrossRef]

- Vats, K.; Tiwari, G.N. Performance Evaluation of a Building Integrated Semitransparent Photovoltaic Thermal System for Roof and Façade. Energy Build. 2012, 45, 211–218. [Google Scholar] [CrossRef]

- Peng, J.; Lu, L.; Yang, H.; Ma, T. Comparative Study of the Thermal and Power Performances of a Semi-Transparent Photovoltaic Façade under Different Ventilation Modes. Appl. Energy 2015, 138, 572–583. [Google Scholar] [CrossRef]

- Shahrestani, M.; Yao, R.; Essah, E.; Shao, L.; Oliveira, A.C.; Hepbasli, A.; Biyik, E.; del Caño, T.; Rico, E.; Lechón, J.L. Experimental and Numerical Studies to Assess the Energy Performance of Naturally Ventilated PV Façade Systems. Sol. Energy 2017, 147, 37–51. [Google Scholar] [CrossRef]

- Martín-Chivelet, N.; Gutiérrez, J.C.; Alonso-Abella, M.; Chenlo, F.; Cuenca, J. Building Retrofit with Photovoltaics: Construction and Performance of a BIPV Ventilated Façade. Energies 2018, 11, 1719. [Google Scholar] [CrossRef]

- Kosonen, R.; Tan, F. The Effect of Perceived Indoor air Quality on Productivity loss. Energy Build. 2004, 36, 981–986. [Google Scholar] [CrossRef]

- Mofidi, F.; Akbari, H. Integrated Optimization of Energy Costs and Occupants’ Productivity in Commercial Buildings. Energy Build. 2016, 129, 247–260. [Google Scholar] [CrossRef]

- Domjan, S.; Arkar, C.; Begelj, Ž.; Medved, S. Evolution of All-Glass Nearly Zero Energy Buildings with Respect to the Local Climate and Free-Cooling Techniques. Build. Environ. 2019, 160, 106183. [Google Scholar] [CrossRef]

- Kim, M.K.; Baldini, L. Energy Analysis of a Decentralized Ventilation System Compared with Centralized Ventilation Systems in European Climates: Based on Review of Analyses. Energy Build. 2016, 111, 424–433. [Google Scholar] [CrossRef]

- Imbabi, M.S.-E. A Passive–Active Dynamic Insulation System for All Climates. Int. J. Sustain. Built Environ. 2012, 1, 247–258. [Google Scholar] [CrossRef]

- Lai, C.-M.; Lin, Y.-P. Energy Saving Evaluation of the Ventilated BIPV Walls. Energies 2011, 4, 948–959. [Google Scholar] [CrossRef]

- Union Glass, S.r.i, Union Glass High-Technology Glass. Available online: http://unionglass.it/index.php (accessed on 15 January 2019).

- Emmerich, S.J.; Persily, A.K. State-of-the-Art Review of CO2 Demand Controlled Ventilation Technology and Application; NIST: Gaithersburg, MD, USA, 2001. [Google Scholar]

- Masters, G.M.; Ela, W.P. Introduction to Environmental Engineering and Science, International ed.; Prentice-Hall: Englewood Cliffs, NJ, USA, 1991. [Google Scholar]

- Energy Performance of Buildings—Ventilation of Buildings—Part 1: Indoor Environmental Input Parameters for Design and Assessment of Energy Performance of Buildings Addressing Indoor Air Quality, Thermal Environment, Light and Acustics; EN 16798-1:2019; CEN: Brussels, Belgium, 2019.

- Kipp & Zonen. Available online: www.kippzonen.com (accessed on 16 May 2020).

- Davis Instruments. Available online: www.davisinstruments.com (accessed on 16 May 2020).

- Ahlborn Mess—und Regelungstechnik GmbH. Available online: www.ahlborn.com (accessed on 16 May 2020).

- Agilent Technologies, Inc. Available online: www.agilent.com (accessed on 16 May 2020).

- The International Organization for Standardization. Energy Performance of Buildings—Energy Needs for Heating and Cooling, Internal Temperatures and Sensible and Latent Heat Loads—Part 1: Calculation Procedures; CEN: Brussels, Belgium, 2017. [Google Scholar]

- Singh, P.; Ravindra, N.M. Temperature Dependence of Solar Cell Performance—An Analysis. Sol. Energy Mater. Sol. Cells 2012, 101, 36–45. [Google Scholar] [CrossRef]

- Dash, P.K.; Gupta, N.C. Effect of Temperature on Power Output from Different Commercially available Photovoltaic Modules. Int. J. Eng. Res. Appl. 2015, 51, 148–151. [Google Scholar]

- Kamuyu, W.C.L.; Lim, J.R.; Won, C.S.; Ahn, H.K. Prediction Model of Photovoltaic Module Temperature for Power Performance of Floating PVs. Energies 2018, 11, 447. [Google Scholar] [CrossRef]

- Ruiz, G.R.; Bandera, C.F. Validation of Calibrated Energy Models: Common Errors. Energies 2017, 10, 1587. [Google Scholar] [CrossRef]

- Domjan, S.; Medved, S.; Černe, B.; Arkar, C. Fast Modelling of nZEB Metrics of Office Buildings Built with Advanced Glass and BIPV Facade Structures. Energies 2019, 12, 3194. [Google Scholar] [CrossRef]

| Meteorological Variable | Average Exp. Period | Max Daily av. | Min Daily av. | Max | Min |

|---|---|---|---|---|---|

| Outdoor air temperature Te (°C) | 5.75 | 16.3 | −2.8 | 25.6 | −8.7 |

| Solar irradiation Gglob,90 (W/m2) | 11324h | 841 | 46 | ||

| Solar radiation Hglob,90,day (Wh/m2day) | 2706 | 5410 | 274 | ||

| IR sky radiation HIR,90,day (Wh/m2day) | 7858 | 8791 | 6924 | ||

| Wind velocity vw (m/s) | 0.49 | 1.84 | 0.03 | 5.6 | 0.0 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Domjan, S.; Petek, L.; Arkar, C.; Medved, S. Experimental Study on Energy Efficiency of Multi-Functional BIPV Glazed Façade Structure during Heating Season. Energies 2020, 13, 2772. https://doi.org/10.3390/en13112772

Domjan S, Petek L, Arkar C, Medved S. Experimental Study on Energy Efficiency of Multi-Functional BIPV Glazed Façade Structure during Heating Season. Energies. 2020; 13(11):2772. https://doi.org/10.3390/en13112772

Chicago/Turabian StyleDomjan, Suzana, Lenart Petek, Ciril Arkar, and Sašo Medved. 2020. "Experimental Study on Energy Efficiency of Multi-Functional BIPV Glazed Façade Structure during Heating Season" Energies 13, no. 11: 2772. https://doi.org/10.3390/en13112772

APA StyleDomjan, S., Petek, L., Arkar, C., & Medved, S. (2020). Experimental Study on Energy Efficiency of Multi-Functional BIPV Glazed Façade Structure during Heating Season. Energies, 13(11), 2772. https://doi.org/10.3390/en13112772