Mechanical Behavior and Permeability Evolution of Coal under Different Mining-Induced Stress Conditions and Gas Pressures

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Testing Methods and Facility

2.2.1. The Testing Facility

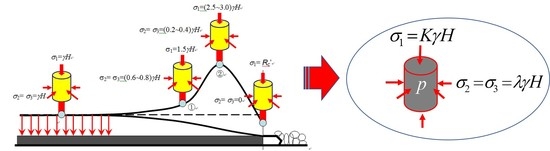

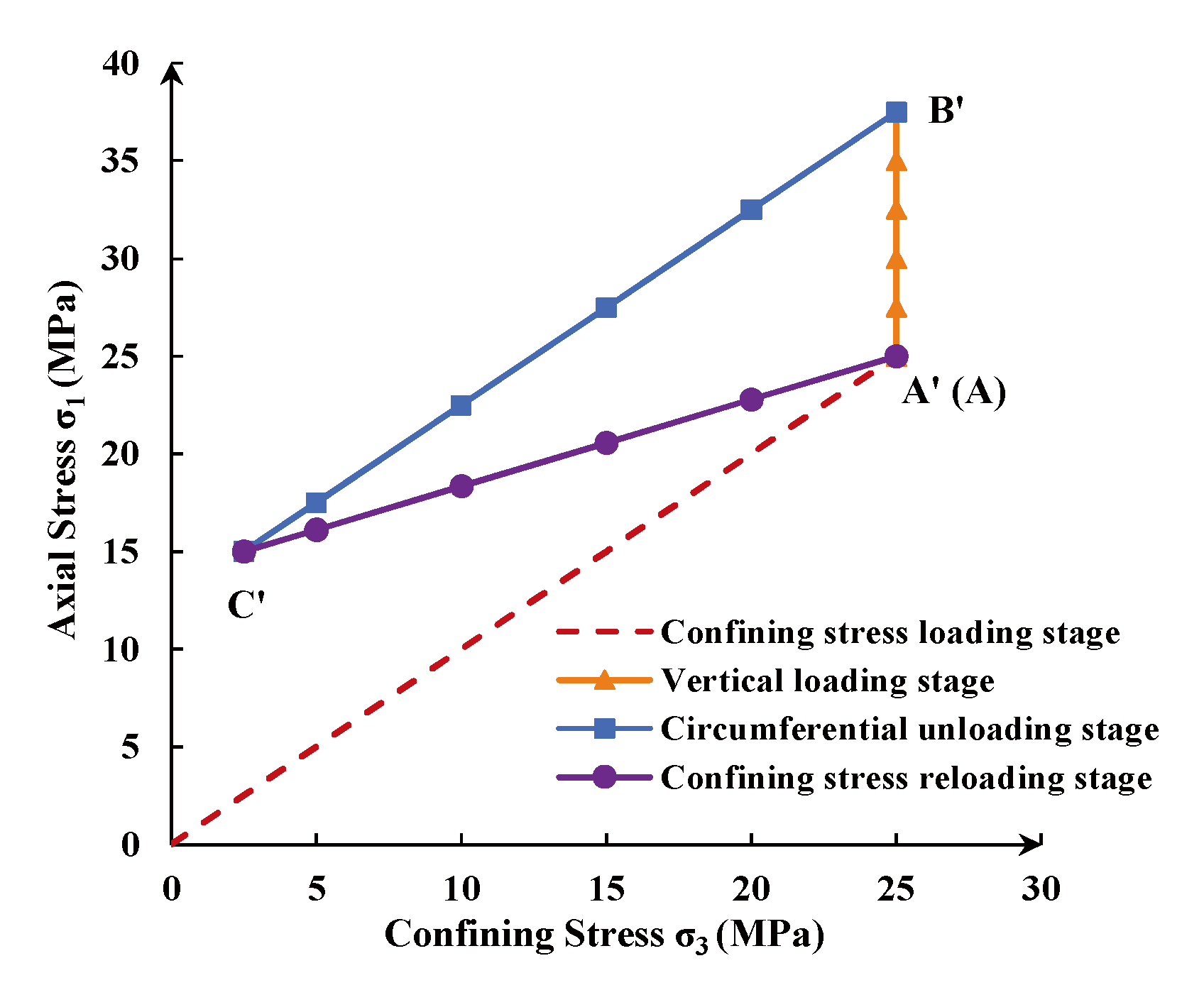

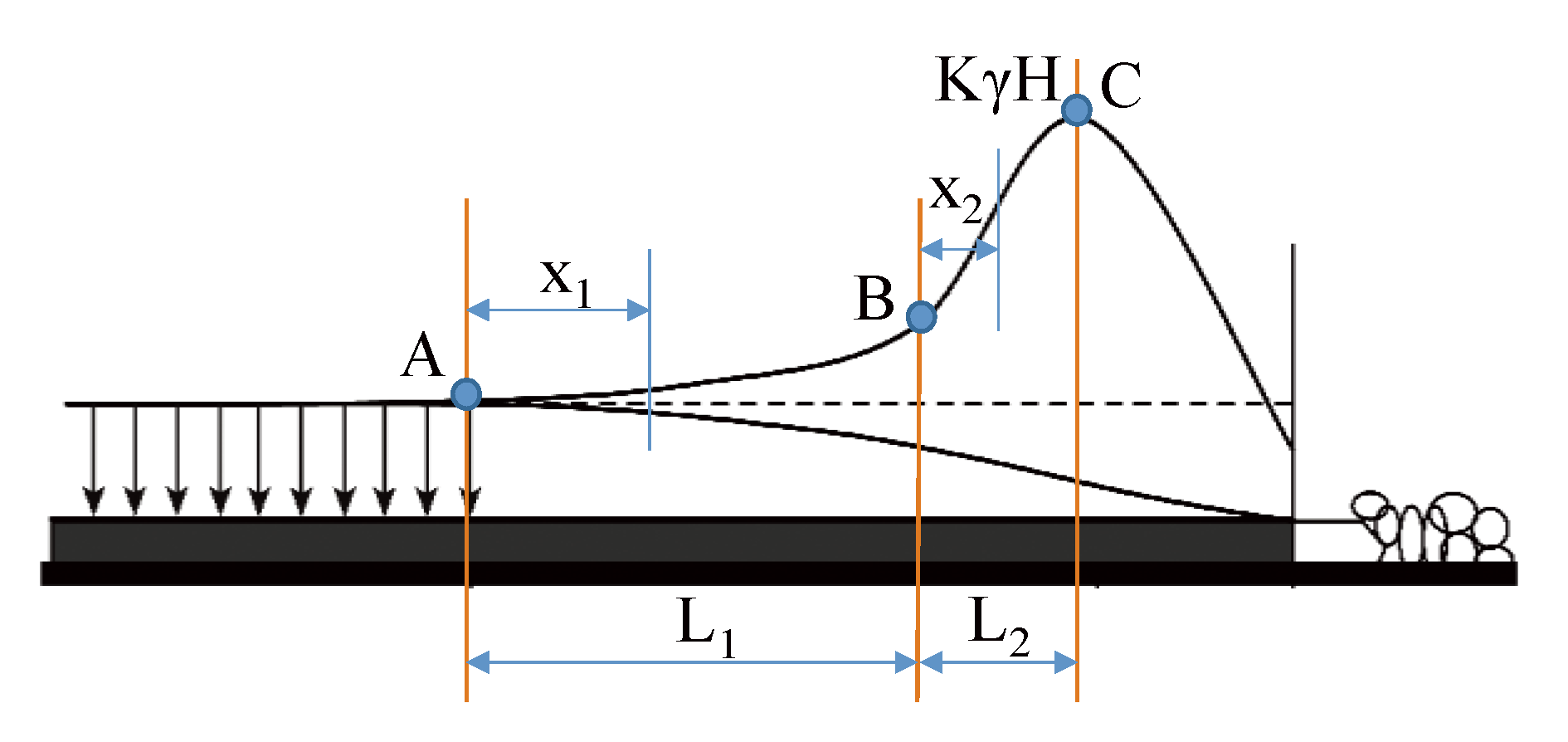

2.2.2. Laboratory Simulations of Different Mining-Induced Stress Conditions

2.3. Formulation of the Rock Permeability Evolution

3. Results

3.1. The Mechanical Behavior and Gas Permeability in Coal under the Conventional Triaxial Stress Condition

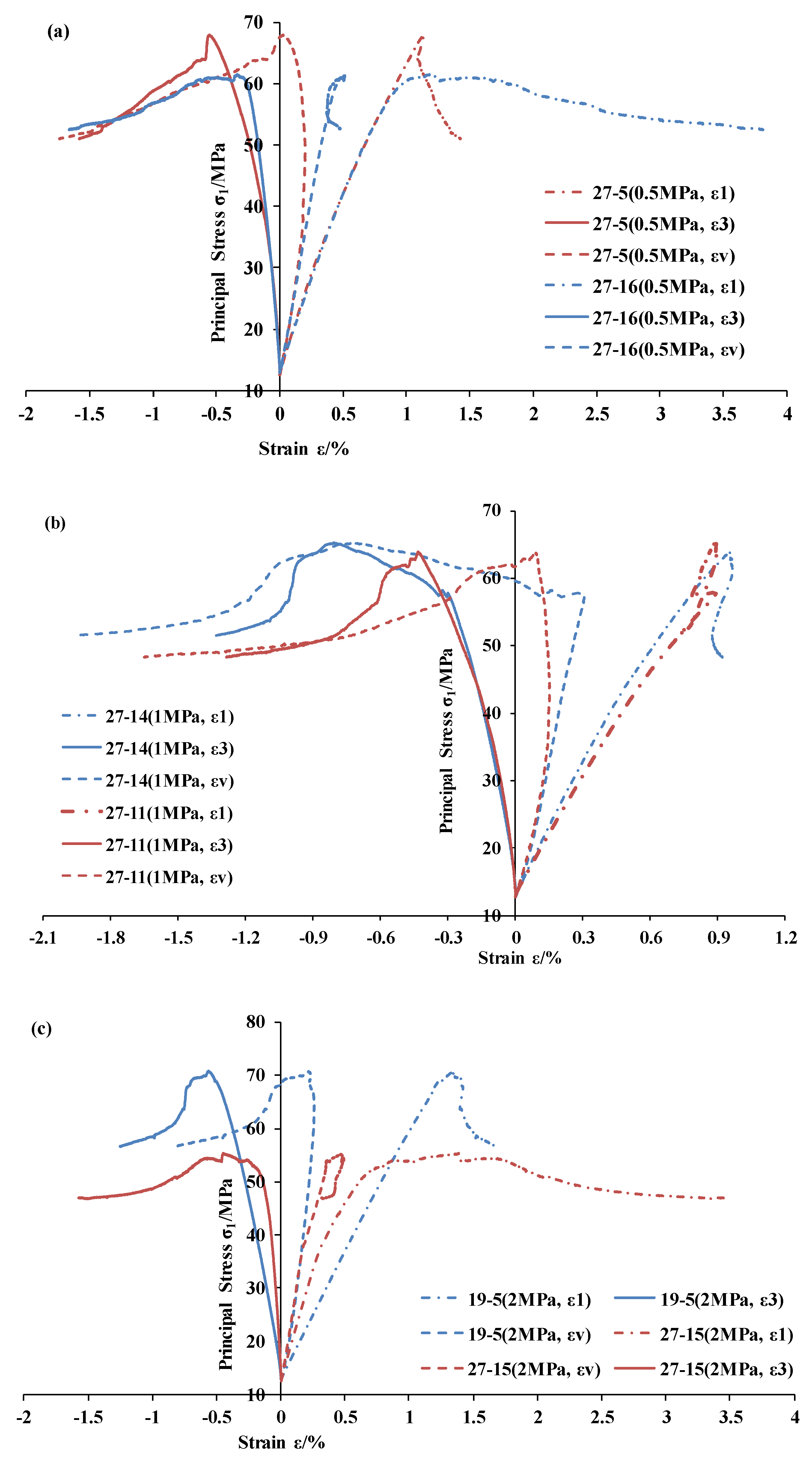

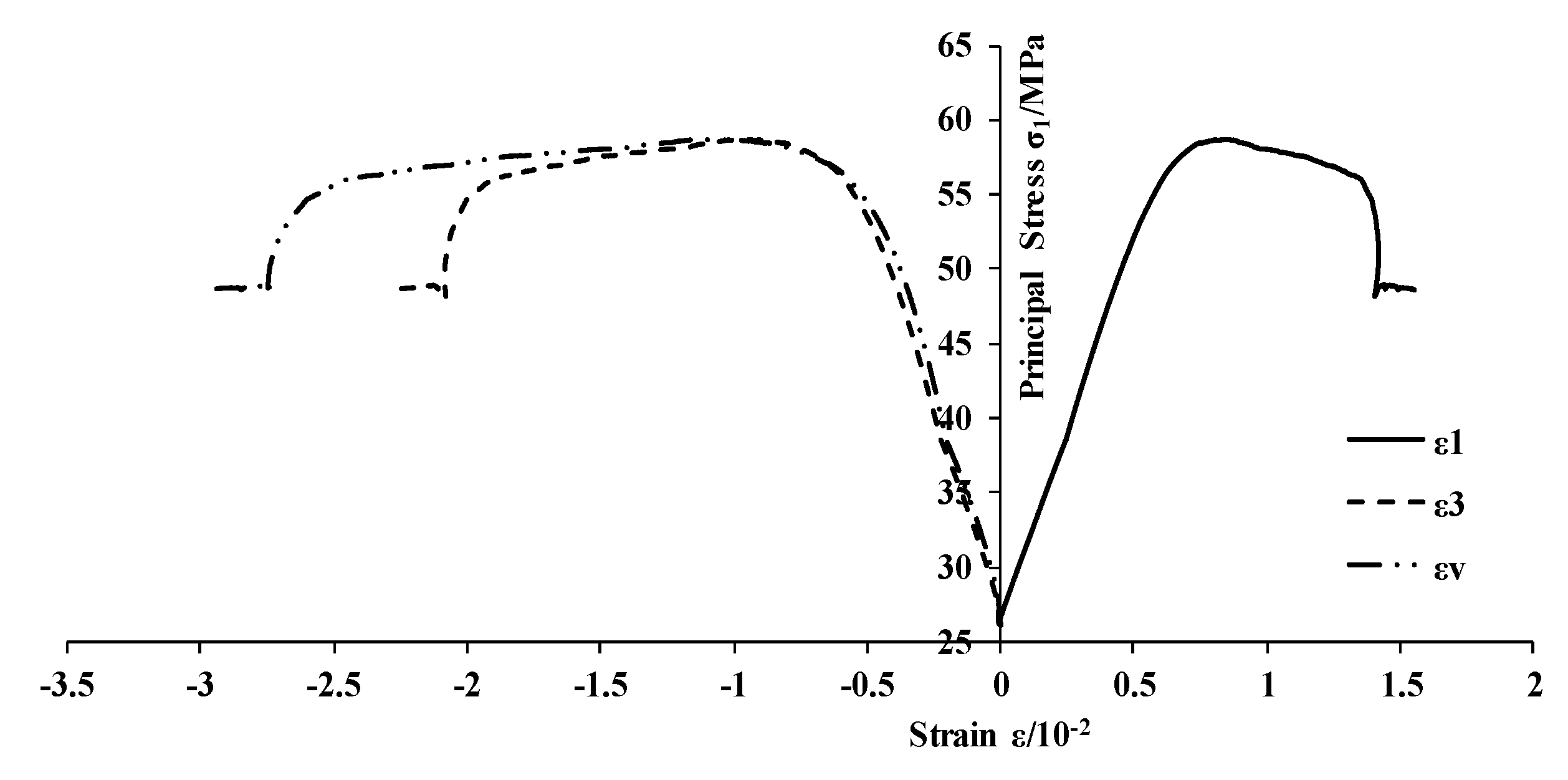

3.1.1. The Mechanical Behavior of Coal under Different Gas Pressures

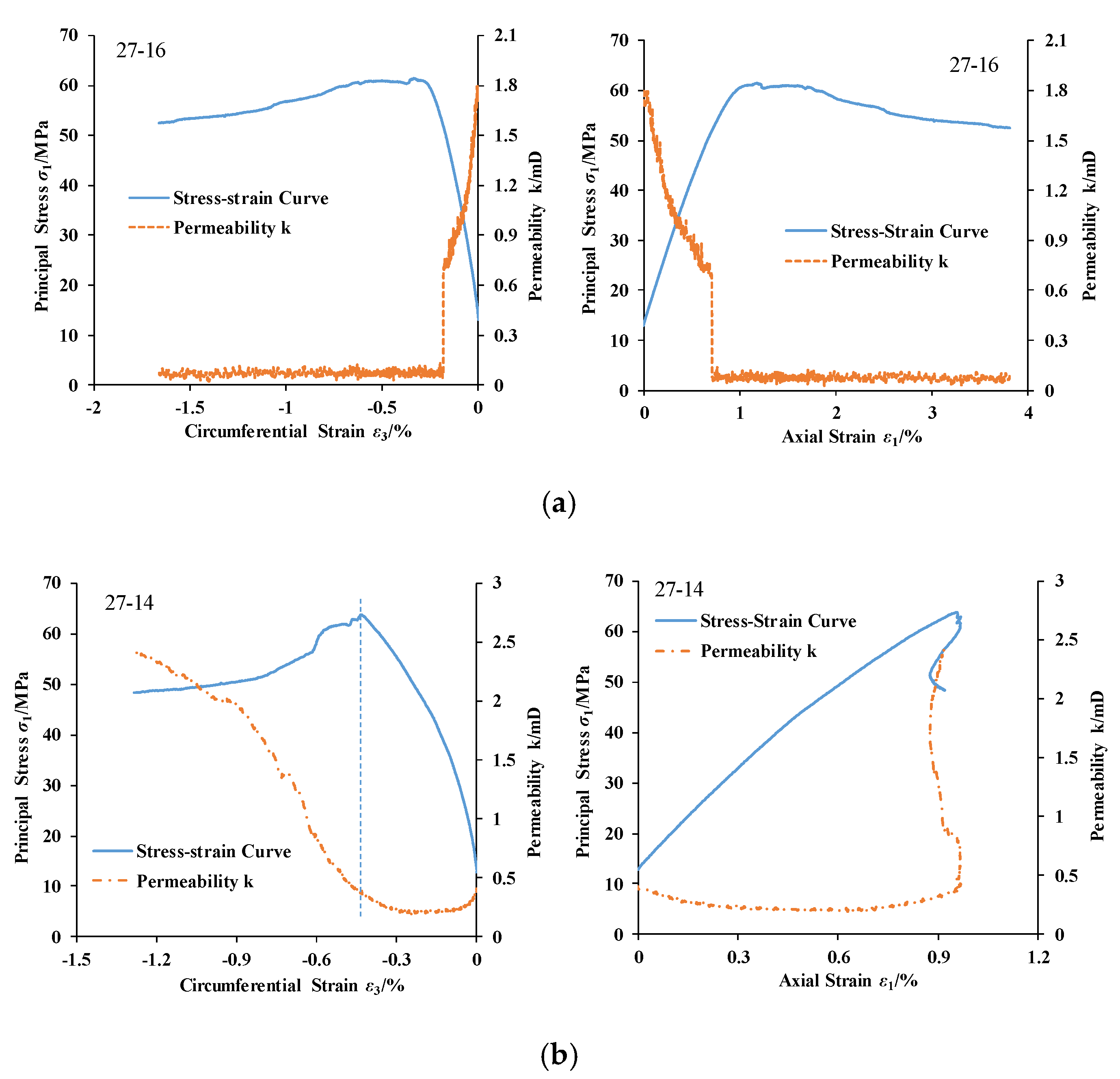

3.1.2. The Gas Permeability Characteristics of Coal under Triaxial Compression Stress Conditions

3.1.3. The Effects of Gas Pressure on the Mechanical Behavior of Coal under Triaxial Stress Conditions

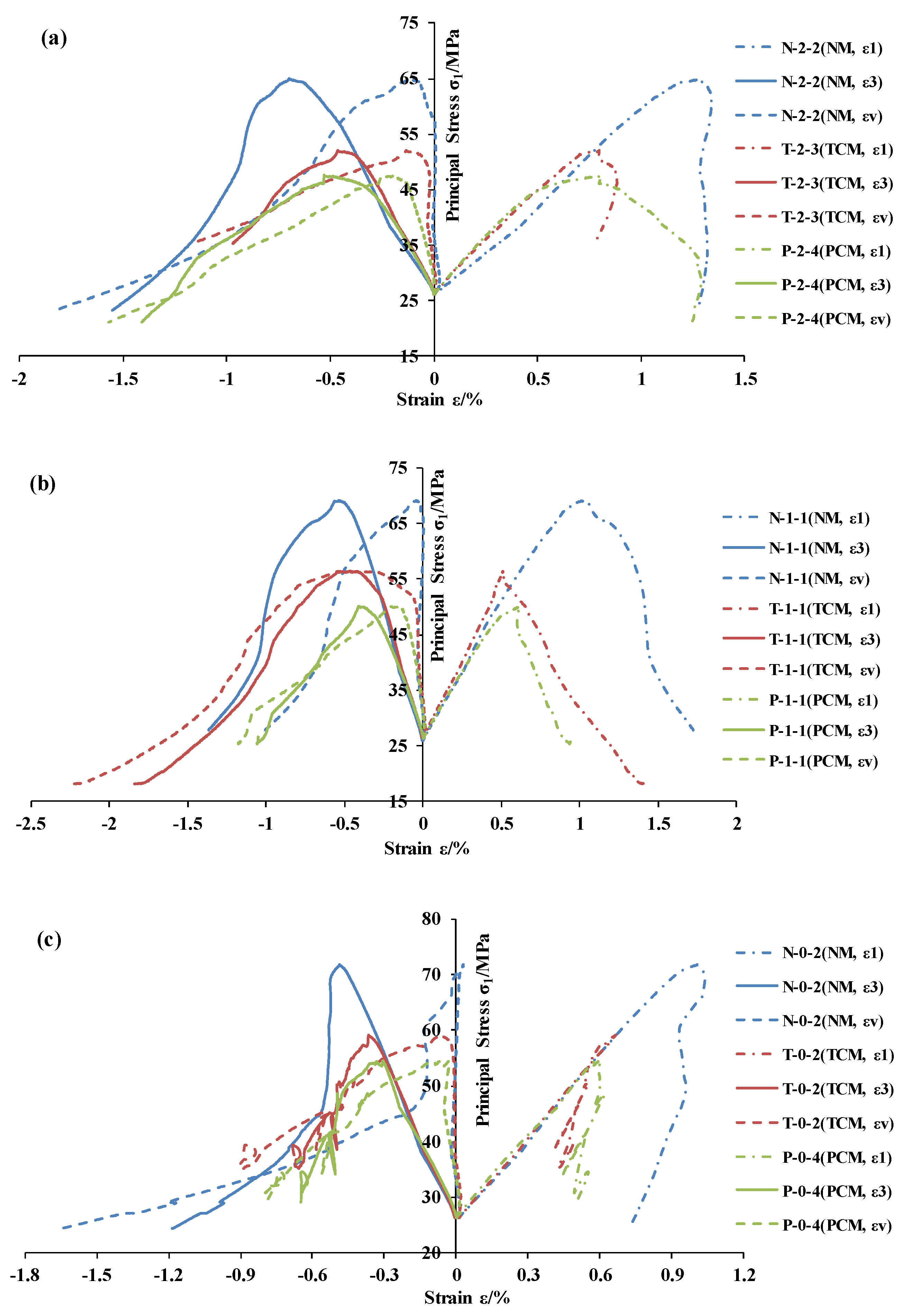

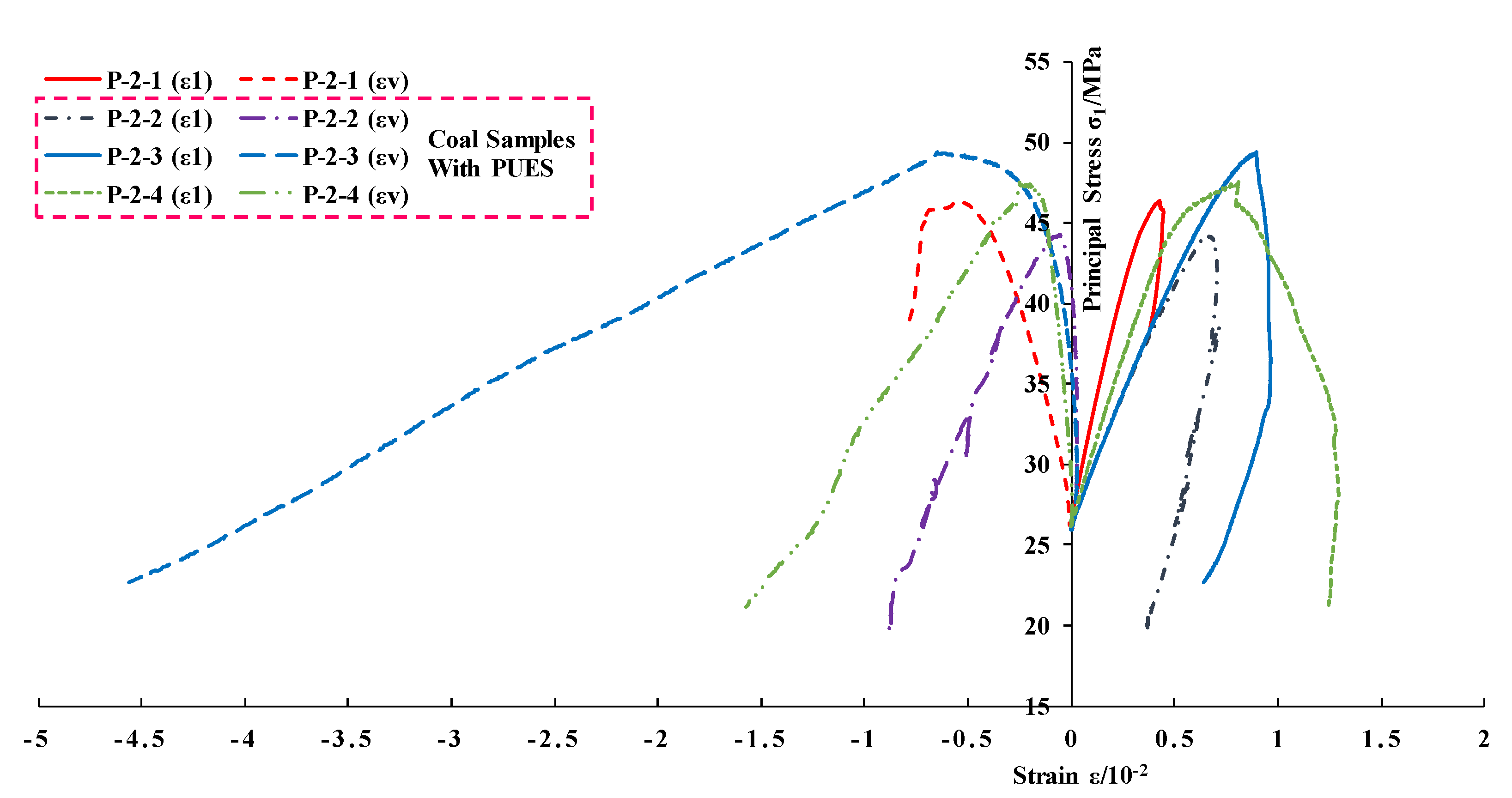

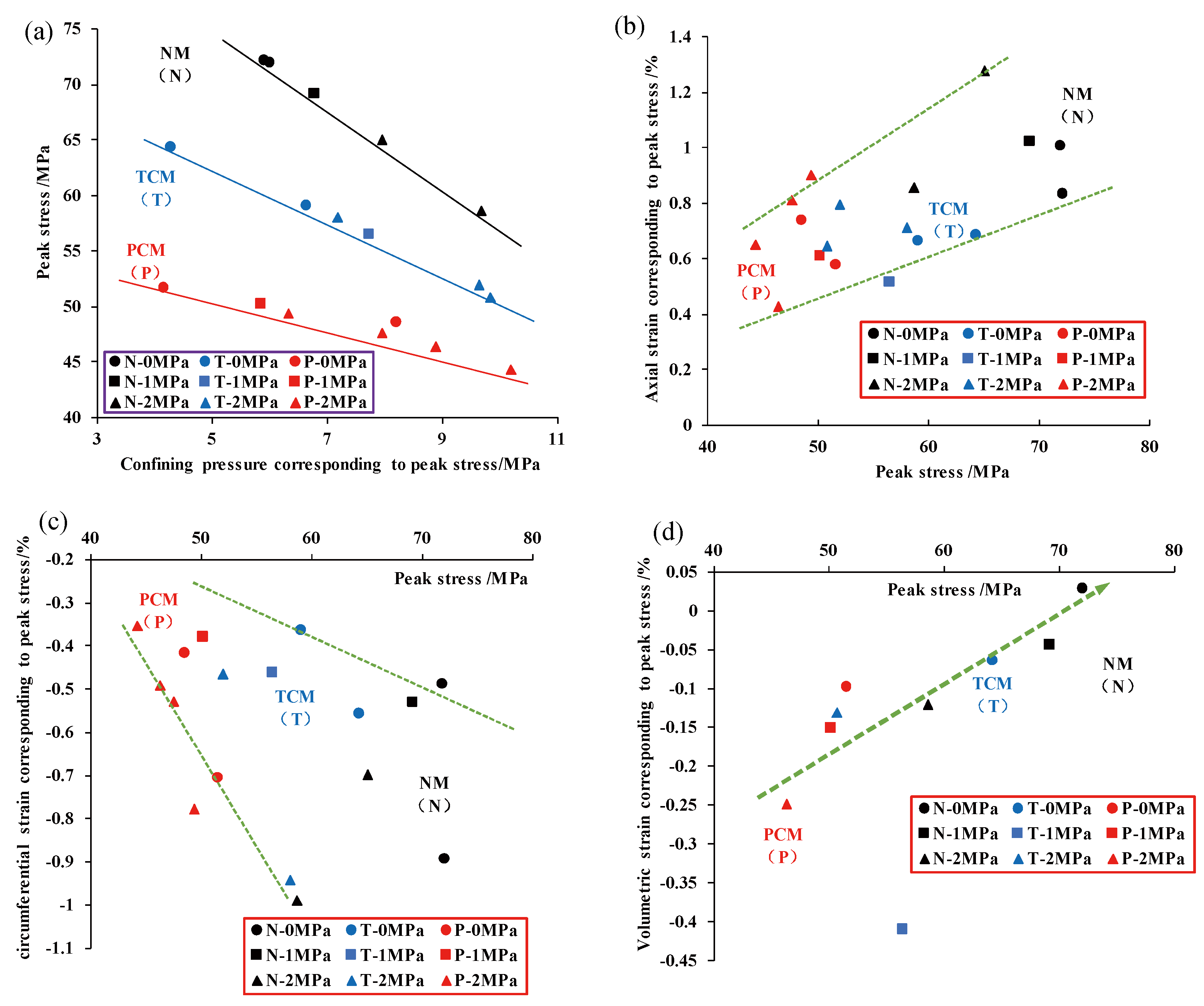

3.2. Mechanical Responses and Gas Permeability Properties of Coal under Different MSU Conditions

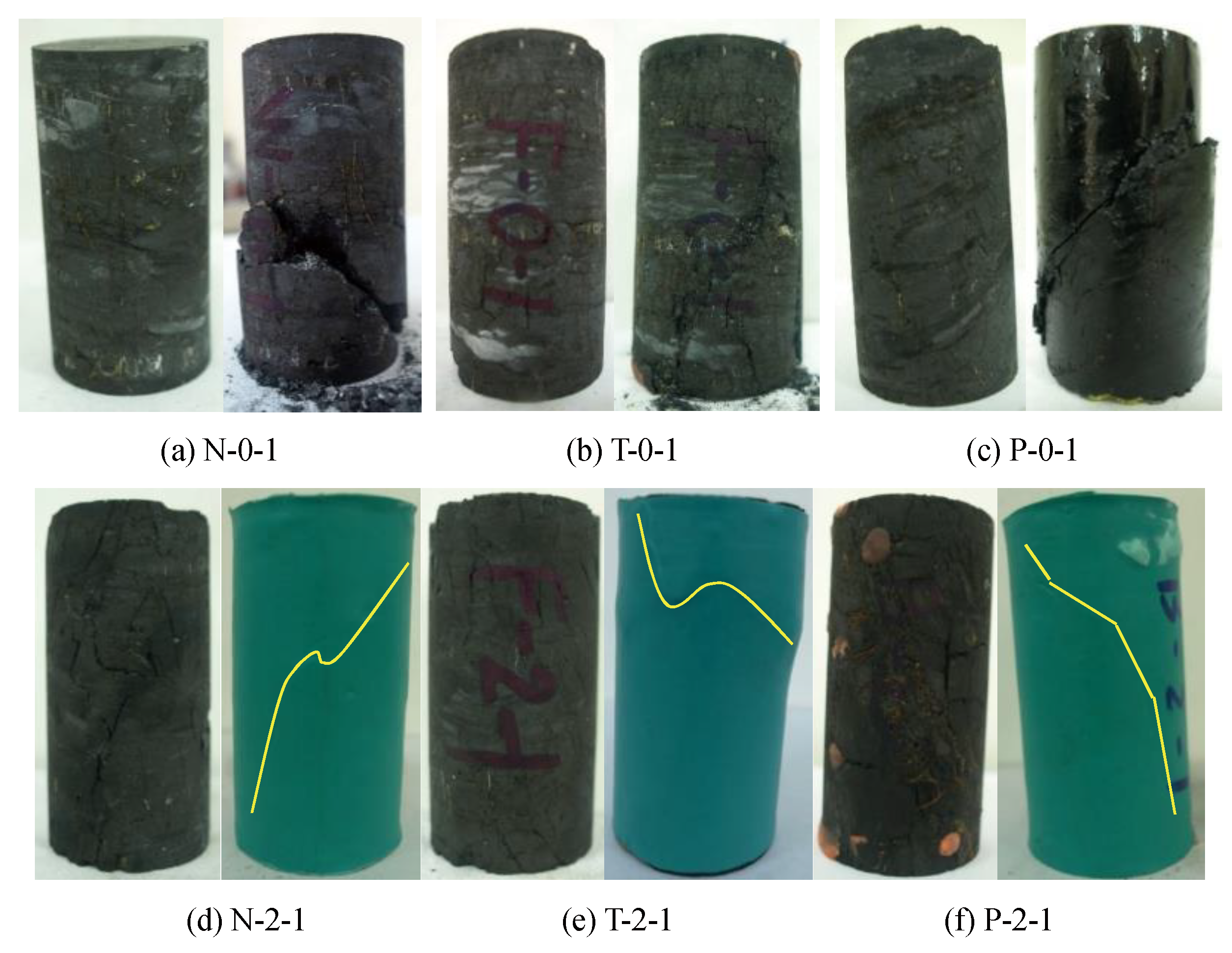

3.2.1. The Mechanical Behavior of Coal under Different MSU Conditions

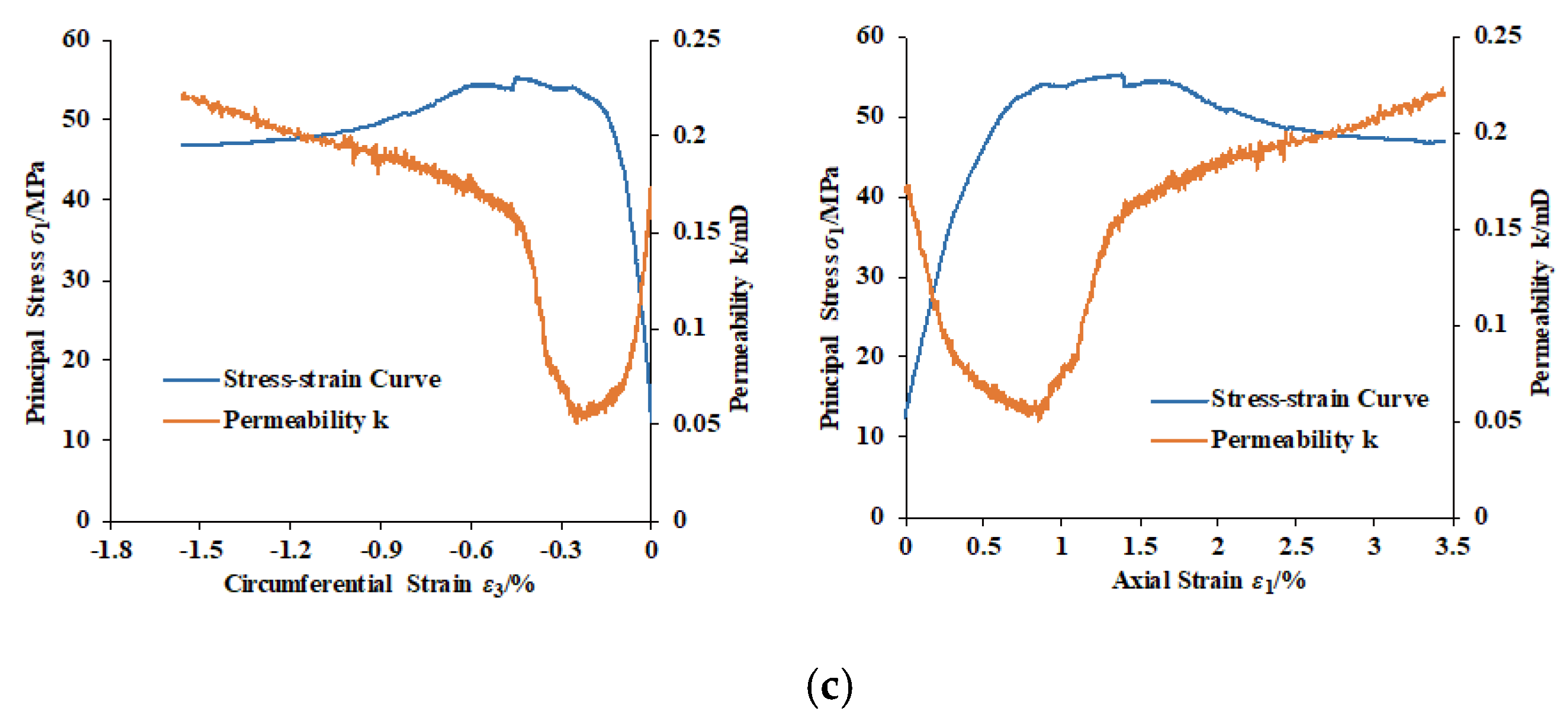

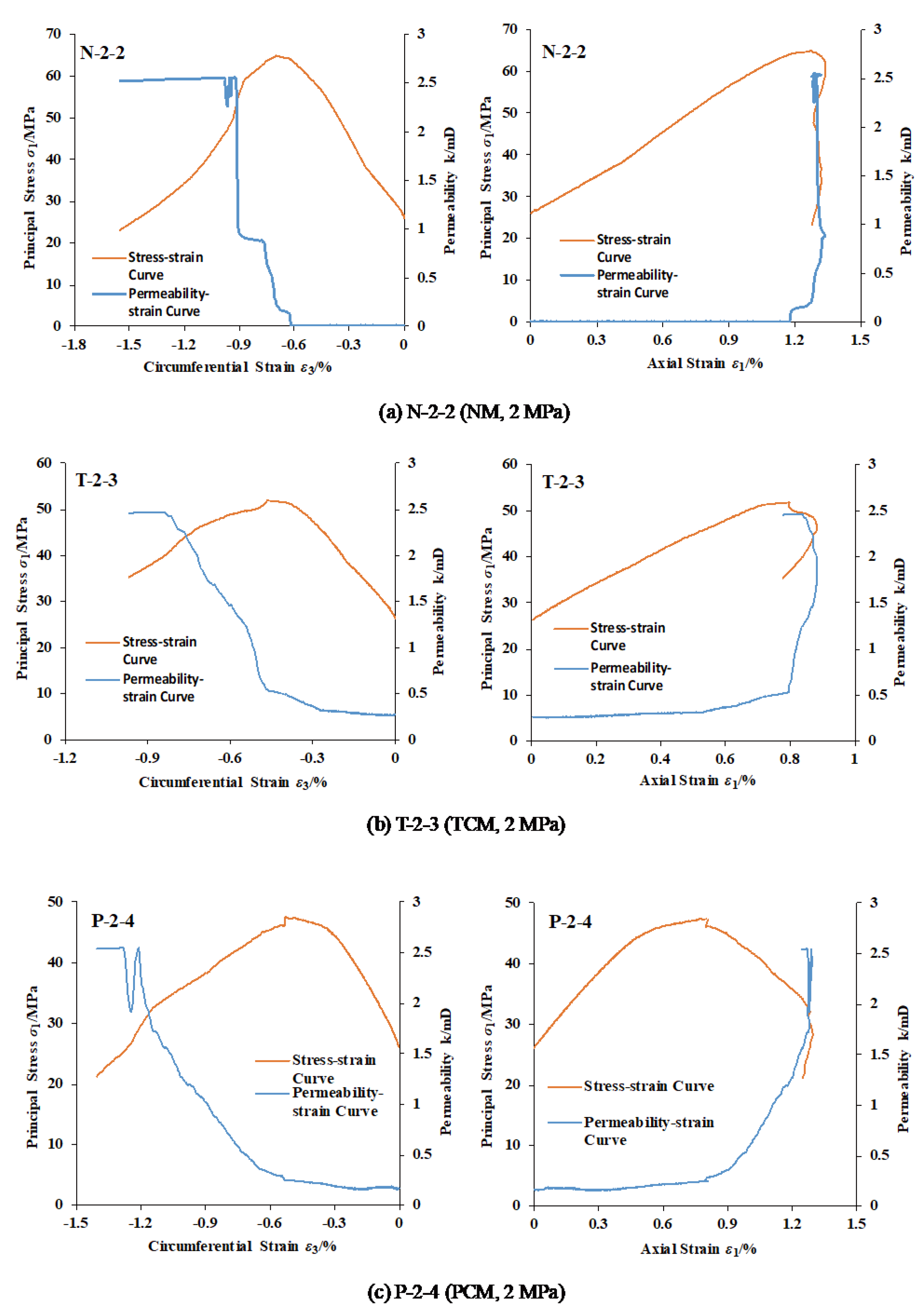

3.2.2. Gas Permeability Characteristics of Coal under Different Mining-Induced Stress Conditions

4. Discussion

4.1. The Effects of Mining-Induced Stress Evolution on Volumetric Deformation and Permeability Enhancement of the Coal Mass

4.2. The Effects of Gas Pressure on Coal Permeability under MSU Conditions

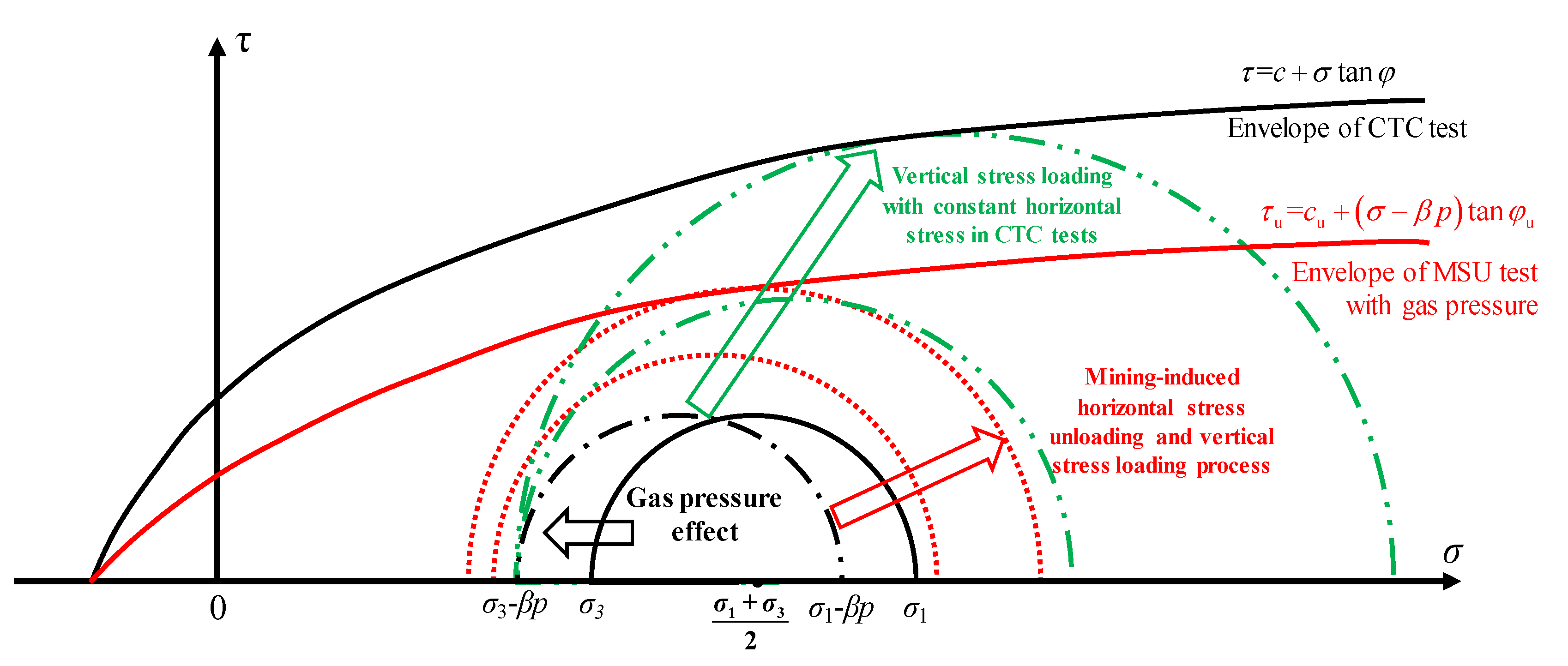

4.3. The Failure Mechanism of a Coal Mass Considering MSU and Gas Pressure Effects

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Latin Symbols | |

| A | Cross section of the specimen, m2; |

| c | Cohension, MPa; |

| Cf | Compressibility of coal fractures, MPa−1; |

| E | Elastic modulus, GPa; |

| f | Partition factor of gas sorption-induced swelling strain contributing to the fracture aperture change, %; |

| H | Depth, m; |

| k | Permeability, mD; |

| K | Volumetric modulus of coal, GPa; |

| L | Length of the coal specimen, m; |

| p | Gas pressure, MPa; |

| pL | Langmuir pressure constant, MPa; |

| q | Flow rate, m3/s; |

| R | General gas constant, J/(mol·K); |

| S | Deviatoric stress, MPa; |

| T | Absolute temperature, K; |

| V | Volume of a mole of gas at standard atmospheric pressure, 22.4 × 10−3 m3/mol; |

| Greek Symbols | |

| α | Stress concentration factor, dimensionless; |

| αϕ | Porosity sensitivity exponent, dimensionless; |

| β | Equivalent pore pressure coefficient, dimensionless; |

| γ | Overburden density, N/m3; |

| ε | Strain, %; |

| εL | Maximum volumetric swelling strain, %; |

| Δ | Increment, dimensionless; |

| μ | Poisson’s ratio, dimensionless; |

| μv | Viscosity coefficient of gas, Pa∙s; |

| ρ | Apparent density of coal, N/m3; |

| σ | Stress, MPa; |

| τ | Shearing strength, MPa; |

| ϕ | Porosity, %; |

| φ | Friction angle, °; |

| Abbreviations | |

| CBM | Coalbed methane; |

| CT | Computed tomography |

| CTC | Conventional triaxial compression |

| ECBM | Enhanced coalbed methane |

| MSU | Mining-induced stress unloading |

| NM | Non-pillar mining |

| PCM | Protective coal-seam mining |

| PUES | Premining unloading-expansion simulation |

| TCM | Top-coal caving mining |

| Superscripts and Subscripts | |

| 0 | Initial value; |

| e | Effective stress; |

| f | Fracture; |

| L | Langmuir; |

| s | Sorption; |

| u | Stress unloading conditions; |

References

- IPCC. Summary for Policymakers. In Global Warming of 1.5 °C. An IPCC Special Report on the Impacts of Global Warming of 1.5 °C Above Pre-Industrial Levels and Related Global Greenhouse Gas Emission Pathways, in the Context of Strengthening the Global Response to the Threat of Climate Change, Sustainable Development, and Efforts to Eradicate Poverty; IPCC: Geneva, Switzerland, 2018; pp. 1–33. [Google Scholar]

- Seneviratne, S.I.; Rogelj, J.; Seferian, R.; Wartenburger, R.; Allen, M.; Cain, M.; Millar, R.J.; Ebi, K.L.; Ellis, N.; Hoegh-Guldberg, O.; et al. The many possible climates from the Paris Agreement’s aim of 1.5 °C warming. Nature 2018, 558, 41–49. [Google Scholar] [CrossRef] [PubMed]

- Yan, H.; Zhang, J.; Zhao, Y.; Zheng, C. CO2 Sequestration from flue gas by direct aqueous mineral carbonation of wollastonite. Sci. China Ser. E Technol. Sci. 2013, 56, 2219–2227. [Google Scholar] [CrossRef]

- Young, A.L. Coalbed Methane: A New Source of Energy and Environmental Challenges. Environ. Sci. Pollut. Res. 2005, 12, 318–321. [Google Scholar] [CrossRef] [PubMed]

- Montzka, S.A.; Dlugokencky, E.J.; Butler, J.H. Non-CO2 greenhouse gases and climate change. Nature 2011, 476, 43–50. [Google Scholar] [CrossRef] [PubMed]

- Tutak, M.; Brodny, J. Forecasting Methane Emissions from Hard Coal Mines Including the Methane Drainage Process. Energies 2019, 12, 3840. [Google Scholar] [CrossRef]

- Solomon, S.; Qin, D.; Manning, M.; Chen, Z.; Marquis, M.; Averyt, K.B.; Tignor, M.; Miller, H.L. (Eds.) Climate Change 2007: The Physical Science Basis. Contribution of Working Group I to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar]

- Jarosław, B.; Magdalena, T. The Use of Artificial Neural Networks to Analyze Greenhouse Gas and Air Pollutant Emissions from the Mining and Quarrying Sector in the European Union. Energies 2020, 13, 1–31. [Google Scholar]

- Zhou, F.; Hou, W.; Allinson, G.; Wu, J.; Wang, J.; Cinar, Y. A feasibility study of ECBM recovery and CO2 storage for a producing CBM field in Southeast Qinshui Basin, China. Int. J. Greenh. Gas Control. 2013, 19, 26–40. [Google Scholar] [CrossRef]

- Busch, A.; Gensterblum, Y. CBM and CO2-ECBM related sorption processes in coal: A review. Int. J. Coal Geol. 2011, 87, 49–71. [Google Scholar] [CrossRef]

- Ujihira, M.; Higuchi, K.; Mizuma, H. On the Triaxial Compression Test of Coal and other Specimens in Which High Pressure Gas is Involved. J. Geophys. Res. 1985, 106, 21475–21494. [Google Scholar]

- Bukowska, M. Mechanical Properties of Carboniferous Rocks in the Upper Silesian Coal Basin under Uniaxial and Triaxial Compression Tests. J. Min. Sci. 2005, 41, 129–133. [Google Scholar] [CrossRef]

- Hobbs, D.W. The Strength and the Stress-Strain Characteristics of Coal in Triaxial Compression. J. Geol. 1964, 72, 214–231. [Google Scholar] [CrossRef]

- Kong, X.; Wang, E.; Hu, S.; Shen, R.; Li, X.; Zhan, T. Fractal characteristics and acoustic emission of coal containing methane in triaxial compression failure. J. Appl. Geophys. 2016, 124, 139–147. [Google Scholar] [CrossRef]

- Xie, H.P.; Zhou, H.W.; Liu, J.F.; Gao, F.; Zhang, R.; Xue, D.J.; Zhang, Y. Mining-induced mechanical behavior in coal seams under different mining layouts. J. China Coal Soc. 2011, 36, 1067–1074. [Google Scholar]

- Xie, H.; Gao, F.; Ju, Y. Research and development of rock mechanics in deep ground engineering. Chin. J. Rock Mech. Eng. 2015, 34, 2161–2178. [Google Scholar]

- Diederichs, M.; Kaiser, P.; Eberhardt, E. Damage initiation and propagation in hard rock during tunnelling and the influence of near-face stress rotation. Int. J. Rock Mech. Min. Sci. 2004, 41, 785–812. [Google Scholar] [CrossRef]

- McKee, C.; Bumb, A.; Koenig, R. Stress-Dependent Permeability and Porosity of Coal and Other Geologic Formations. SPE Form. Evaluat. 1988, 3, 81–91. [Google Scholar] [CrossRef]

- Feng, R.; Harpalani, S.; Pandey, R. Laboratory measurement of stress-dependent coal permeability using pulse-decay technique and flow modeling with gas depletion. Fuel 2016, 177, 76–86. [Google Scholar] [CrossRef]

- Burgoyne, M.; Shrivastava, R. A practical workflow for characterizing stress-dependent behaviour of coal from changes in well productivity. J. Nat. Gas Sci. Eng. 2016, 33, 1025–1045. [Google Scholar] [CrossRef]

- Xie, H.P.; Zhang, Z.T.; Feng, G.; Ru, Z.; Gao, M.Z.; Liu, J.F.; University, S. Stress-fracture-seepage field behavior of coal under different mining layouts. J. China Coal Soc. 2016, 41, 2405–2417. [Google Scholar]

- Zhang, Z.; Zhang, R.; Xie, H.; Gao, M.; Xie, J. Mining-Induced Coal Permeability Change Under Different Mining Layouts. Rock Mech. Rock Eng. 2016, 49, 3753–3768. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, J.; Pan, Z.; Connell, L.D.; Elsworth, D. Influence of the effective stress coefficient and sorption-induced strain on the evolution of coal permeability: Model development and analysis. Int. J. Greenh. Gas Control 2012, 8, 101–110. [Google Scholar] [CrossRef]

- Palmer, I.; Mansoori, J. How Permeability Depends on Stress and Pore Pressure in Coalbeds: A New Model. SPE Reserv. Evaluat. Eng. 1998, 1, 539–544. [Google Scholar] [CrossRef]

- Shi, J.-Q.; Durucan, S. Drawdown Induced Changes in Permeability of Coalbeds: A New Interpretation of the Reservoir Response to Primary Recovery. Transp. Porous Media 2004, 56, 1–16. [Google Scholar] [CrossRef]

- Cui, X.; Bustin, M. Volumetric strain associated with methane desorption and its impact on coalbed gas production from deep coal seams. AAPG Bull. 2005, 89, 1181–1202. [Google Scholar] [CrossRef]

- Ju, Y.; Zhang, Q.; Zheng, J.; Wang, J.; Chang, C.; Gao, F. Experimental study on CH4 permeability and its dependence on interior fracture networks of fractured coal under different excavation stress paths. Fuel 2017, 202, 483–493. [Google Scholar] [CrossRef]

- Islam, R.; Hayashi, D.; Kamruzzaman, A. Finite element modeling of stress distributions and problems for multi-slice longwall mining in Bangladesh, with special reference to the Barapukuria coal mine. Int. J. Coal Geol. 2009, 78, 91–109. [Google Scholar] [CrossRef]

- Zhang, M.; Shimada, H.; Sasaoka, T.; Matsui, K.; Dou, L. Evolution and effect of the stress concentration and rock failure in the deep multi-seam coal mining. Environ. Earth Sci. 2013, 72, 629–643. [Google Scholar] [CrossRef]

- Wold, M.; Connell, L.D.; Choi, S. The role of spatial variability in coal seam parameters on gas outburst behaviour during coal mining. Int. J. Coal Geol. 2008, 75, 1–14. [Google Scholar] [CrossRef]

- Singh, A.; Singh, R.; Maiti, J.; Kumar, R.; Mandal, P. Assessment of mining induced stress development over coal pillars during depillaring. Int. J. Rock Mech. Min. Sci. 2011, 48, 805–818. [Google Scholar] [CrossRef]

- Zhang, Q.; Fan, X.; Liang, Y.; Li, M.; Li, G.; Ma, T.; Nie, W. Mechanical Behavior and Permeability Evolution of Reconstituted Coal Samples under Various Unloading Confining Pressures—Implications for Wellbore Stability Analysis. Energies 2017, 10, 292. [Google Scholar] [CrossRef]

- Zhang, R.; Ai, T.; Li, H.; Zhang, Z.; Liu, J. 3D reconstruction method and connectivity rules of fracture networks generated under different mining layouts. Int. J. Min. Sci. Technol. 2013, 23, 863–871. [Google Scholar] [CrossRef]

- Xue, D.J.; Zhou, H.W.; Tang, X.L.; Zhao, Y.F. Mechanism of deformation-induced damage and gas permeability enhancement of coal under typical mining layouts. Chin. J. Geotech. Eng. 2013, 35, 328–336. [Google Scholar]

- Xue, Y.; Dang, F.; Cao, Z.; Du, F.; Ren, J.; Chang, X.; Gao, F. Deformation, Permeability and Acoustic Emission Characteristics of Coal Masses under Mining-Induced Stress Paths. Energies 2018, 11, 2233. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, R.; Xie, H.; Gao, M.; Zha, E.; Jia, Z. An anisotropic coal permeability model that considers mining-induced stress evolution, microfracture propagation and gas sorption-desorption effects. J. Nat. Gas Sci. Eng. 2017, 46, 664–679. [Google Scholar] [CrossRef]

- ASTM. Standard Practices for Preparing Rock Core as Cylindrical Test Specimens and Verifying Conformance to Dimensional and Shape Tolerances; American Society for Testing and Materials: West Conshohocken, PA, USA, 2008; Volume D4543. [Google Scholar]

- Zhang, Z.; Ru, Z.; Liu, J.-F.; Liu, X.-H.; Li, J.-W. Permeability evolution of unloaded coal samples at different loading rates. Therm. Sci. 2014, 18, 1497–1504. [Google Scholar] [CrossRef]

- Xie, H.; Zhao, X.; Liu, J.; Zhang, R.; Xue, D. Influence of different mining layouts on the mechanical properties of coal. Int. J. Min. Sci. Technol. 2012, 22, 749–755. [Google Scholar] [CrossRef]

- Wang, S.; Elsworth, D.; Liu, J. Permeability evolution during progressive deformation of intact coal and implications for instability in underground coal seams. Int. J. Rock Mech. Min. Sci. 2013, 58, 34–45. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, R.; Li, G.; Li, H.; Liu, J. The Effect of Bedding Structure on Mechanical Property of Coal. Adv. Mater. Sci. Eng. 2014, 2014, 1–7. [Google Scholar] [CrossRef]

- Biot, M.A. General Theory of Three-Dimensional Consolidation. J. Appl. Phys. 1941, 12, 155. [Google Scholar] [CrossRef]

- Somerton, W.; Söylemezoḡlu, I.; Dudley, R. Effect of stress on permeability of coal. Int. J. Rock Mech. Min. Sci. Géoméch. Abstr. 1975, 12, 129–145. [Google Scholar] [CrossRef]

- Xie, G.X.; Hu, Z.X.; Wang, L. Coal mining dilatancy characteristics of high gas working face in the deep mine. J. China Coal Soc. 2014, 39, 91–96. [Google Scholar]

- Harpalani, S.; Chen, G. Influence of gas production induced volumetric strain on permeability of coal. Geotech. Geol. Eng. 1997, 15, 303–325. [Google Scholar] [CrossRef]

- George, J.S.; Barakat, M. The change in effective stress associated with shrinkage from gas desorption in coal. Int. J. Coal Geol. 2001, 45, 105–113. [Google Scholar] [CrossRef]

- Terzaghi, K. Theoretical Soil Mechanics; Wiley: New York, NY, USA, 1943. [Google Scholar]

- Shi-Yue, W.U.; Wen, Z. Analysis of effective stress in adsorbed methane-coal system. Chin. J. Rock Mech. Eng. 2005, 24, 1674–1678. [Google Scholar]

- Tao, L.; Zhou, K.; Jianhua, H.U.; Feng, G. Mechanics parameters deterioration laws of unloading rock mass by meso-damage mechanics. J. Central South Univ. 2013, 44, 275–281. [Google Scholar]

| Proximate Analysis | ||||

| Fixed carbon | Volatile matter | Ash | ||

| 75.17% | 7.64% | 16.38% | ||

| Ultimate Analysis | ||||

| Carbon | Hydrogen | Nitrogen | Sulfur | Oxygen |

| 89.56% | 2.7% | 1.13% | 2.97% | 3.64% |

| Constituent of Mineral Matter | ||||

| Kaolinite | Quartz | Calcite | Others | |

| 5.58% | 11.74% | 5.04% | 77.64% | |

| Sample Physical Properties | ||||

| Sample No. | Diameter (mm) | Length (mm) | Density (g/cm3) | Gas pressure (MPa) |

| N-0-1 | 50.13 | 98.78 | 1.51 | 0 |

| N-2-1 | 50.14 | 97.23 | 1.44 | 2 |

| T-0-1 | 50.00 | 97.91 | 1.49 | 0 |

| T-2-1 | 50.09 | 99.42 | 1.50 | 2 |

| T-2-2 | 50.16 | 98.23 | 1.48 | 2 |

| P-0-1 | 50.08 | 97.63 | 1.56 | 0 |

| P-0-3 | 49.64 | 100.77 | 1.50 | 0 |

| P-2-1 | 50.17 | 99.97 | 1.45 | 2 |

| P-2-2 | 50.07 | 100.09 | 1.48 | 2 |

| P-2-3 | 50.09 | 99.86 | 1.46 | 2 |

| Proximate Analysis | ||||

| Fixed Carbon | Volatile matter | Ash | ||

| 49.74% | 33.23% | 15.93% | ||

| Ultimate Analysis | ||||

| Carbon | Oxygen | Silicon | Aluminium | Calcium |

| 58.7% | 27.5% | 4.44% | 4.27% | 2.79% |

| Constituent of Mineral Matter | ||||

| Kaolinite | Siderite | Calcite | Others | |

| 71% | 3.77% | 22.54% | 2.69% | |

| Sample Physical Properties | ||||

| Sample No. | Diameter (mm) | Length (mm) | Density (g/cm3) | Gas pressure (MPa) |

| N-2-2 | 47.74 | 102.46 | 1.31 | 2 |

| T-2-3 | 47.65 | 97.99 | 1.44 | 2 |

| P-2-4 | 47.65 | 102.48 | 1.44 | 2 |

| N-1-1 | 47.69 | 98.23 | 1.54 | 1 |

| T-1-1 | 47.67 | 101.35 | 1.61 | 1 |

| P-1-1 | 47.69 | 102.17 | 1.49 | 1 |

| N-0-2 | 47.70 | 100.64 | 1.52 | 0 |

| T-0-2 | 47.65 | 100.35 | 1.57 | 0 |

| P-0-4 | 47.64 | 100.65 | 1.57 | 0 |

| Sample Number | Average Diameter/mm | Average Length/mm | Density g/cm3 | Gas Pressure/MPa | Peak Strength/MPa | Strain Corresponding to Peak Strength/% | Residual Strength/MPa | Elastic Modulus/GPa | Poisson’s Ratios | Permeability Corresponding to Peak Strength/mD | Perk Permeability/mD | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ε1 | ε3 | εv | |||||||||||

| 27-16 | 47.63 | 101.05 | 1.47 | 0.5 | 61.54 | 1.18 | −0.34 | 0.51 | 53.00 | 72.95 | 0.395 | 0.0670 | 1.8034 |

| 27-5 | 47.62 | 99.08 | 1.52 | 0.5 | 67.99 | 1.14 | −0.55 | 0.03 | 51.74 | 66.13 | 0.404 | No effective penetration during loading | |

| 27-14 | 47.65 | 100.53 | 1.50 | 1.0 | 63.84 | 0.96 | −0.43 | 0.09 | 48.58 | 78.18 | 0.407 | 0.3639 | 2.4328 |

| 27-11 | 47.62 | 100.84 | 1.51 | 1.0 | 65.35 | 2.01 | −0.81 | 0.40 | 49.50 | 67.70 | 0.411 | No effective penetration during loading | |

| 27-15 | 47.72 | 100.96 | 1.67 | 2.0 | 55.40 | 1.38 | −0.45 | 0.48 | 47.00 | 101.62 | 0.395 | 0.1545 | 0.2227 |

| 19-5 | 47.75 | 101.55 | 1.33 | 2.0 | 70.91 | 1.34 | −0.56 | 0.22 | 57.00 | 54.02 | 0.427 | No effective penetration during loading | |

| Sample Number | Peak Stress σ1/MPa | α | Test Values Corresponding to the Peak Stress | Peak Permeability/mD | ||||

|---|---|---|---|---|---|---|---|---|

| σ3/MPa | ε1/10−2 | ε3/10−2 | εv/10−2 | k/mD | ||||

| N-0-1 | 72.14 | 2.89 | 5.92 | 0.831 | −0.895 | −0.959 | No gas flow conditions | |

| N-0-2 | 71.92 | 2.87 | 6.01 | 1.004 | −0.488 | 0.028 | ||

| T-0-1 | 64.32 | 2.57 | 4.30 | 0.683 | −0.558 | −0.433 | ||

| T-0-2 | 59.06 | 2.36 | 6.65 | 0.665 | −0.365 | −0.065 | ||

| P-0-1 | 51.62 | 2.06 | 4.18 | 0.577 | −0.707 | −0.838 | ||

| P-0-3 | 48.60 | 1.94 | 8.21 | 0.739 | −0.418 | −0.098 | ||

| N-1-1 | 69.19 | 2.77 | 6.78 | 1.021 | −0.532 | −0.044 | 0.853 | 9.886 |

| T-1-1 | 56.49 | 2.26 | 7.73 | 0.515 | −0.462 | −0.410 | 0.016 | 9.697 |

| P-1-1 | 50.19 | 2.01 | 5.85 | 0.610 | −0.380 | −0.151 | 0.022 | 10.380 |

| N-2-1 | 58.67 | 2.35 | 9.67 | 0.858 | −0.989 | −1.121 | 0.224 | 0.238 |

| N-2-2 | 65.03 | 2.60 | 7.95 | 1.278 | −0.699 | −0.120 | 0.212 | 2.552 |

| T-2-1 | 50.77 | 2.03 | 9.84 | 0.646 | No data due to equipment failure | |||

| T-2-2 | 58.04 | 2.32 | 7.18 | 0.713 | −0.943 | −1.173 | 0.209 | 0.445 |

| T-2-3 | 52.00 | 2.08 | 9.64 | 0.797 | −0.464 | −0.131 | 0.534 | 2.466 |

| P-2-1 | 46.35 | 1.85 | 8.88 | 0.429 | −0.491 | −0.553 | 0.299 | 0.462 |

| P-2-2 | 44.28 | 1.77 | 10.20 | 0.652 | −0.354 | −0.056 | 0.380 | 1.675 |

| P-2-3 | 49.40 | 1.98 | 6.33 | 0.901 | −0.777 | −0.653 | 0.307 | 2.311 |

| P-2-4 | 47.59 | 1.90 | 7.96 | 0.811 | −0.529 | −0.248 | 0.244 | 2.548 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Zhang, R.; Cao, Z.; Gao, M.; Zhang, Y.; Xie, J. Mechanical Behavior and Permeability Evolution of Coal under Different Mining-Induced Stress Conditions and Gas Pressures. Energies 2020, 13, 2677. https://doi.org/10.3390/en13112677

Zhang Z, Zhang R, Cao Z, Gao M, Zhang Y, Xie J. Mechanical Behavior and Permeability Evolution of Coal under Different Mining-Induced Stress Conditions and Gas Pressures. Energies. 2020; 13(11):2677. https://doi.org/10.3390/en13112677

Chicago/Turabian StyleZhang, Zetian, Ru Zhang, Zhiguo Cao, Mingzhong Gao, Yong Zhang, and Jing Xie. 2020. "Mechanical Behavior and Permeability Evolution of Coal under Different Mining-Induced Stress Conditions and Gas Pressures" Energies 13, no. 11: 2677. https://doi.org/10.3390/en13112677

APA StyleZhang, Z., Zhang, R., Cao, Z., Gao, M., Zhang, Y., & Xie, J. (2020). Mechanical Behavior and Permeability Evolution of Coal under Different Mining-Induced Stress Conditions and Gas Pressures. Energies, 13(11), 2677. https://doi.org/10.3390/en13112677