A Dynamic Multi-Swarm Particle Swarm Optimizer for Multi-Objective Optimization of Machining Operations Considering Efficiency and Energy Consumption

Abstract

1. Introduction

2. Multi-Objective Optimization Model for Machining

2.1. Energy Consumption

2.2. Machining Cost

2.3. Cutting Time

2.4. Constraints

3. Solution Approach

3.1. Concept of DMS-PSO Algorithm

3.2. Multi-Objective Consideration

- (1)

- If both solutions are feasible, the one with the higher fitness should be selected;

- (2)

- If one solution is feasible and the other is non-feasible, the feasible one should be selected;

- (3)

- If both solutions are non-feasible, the one with the smaller deviation should be selected.

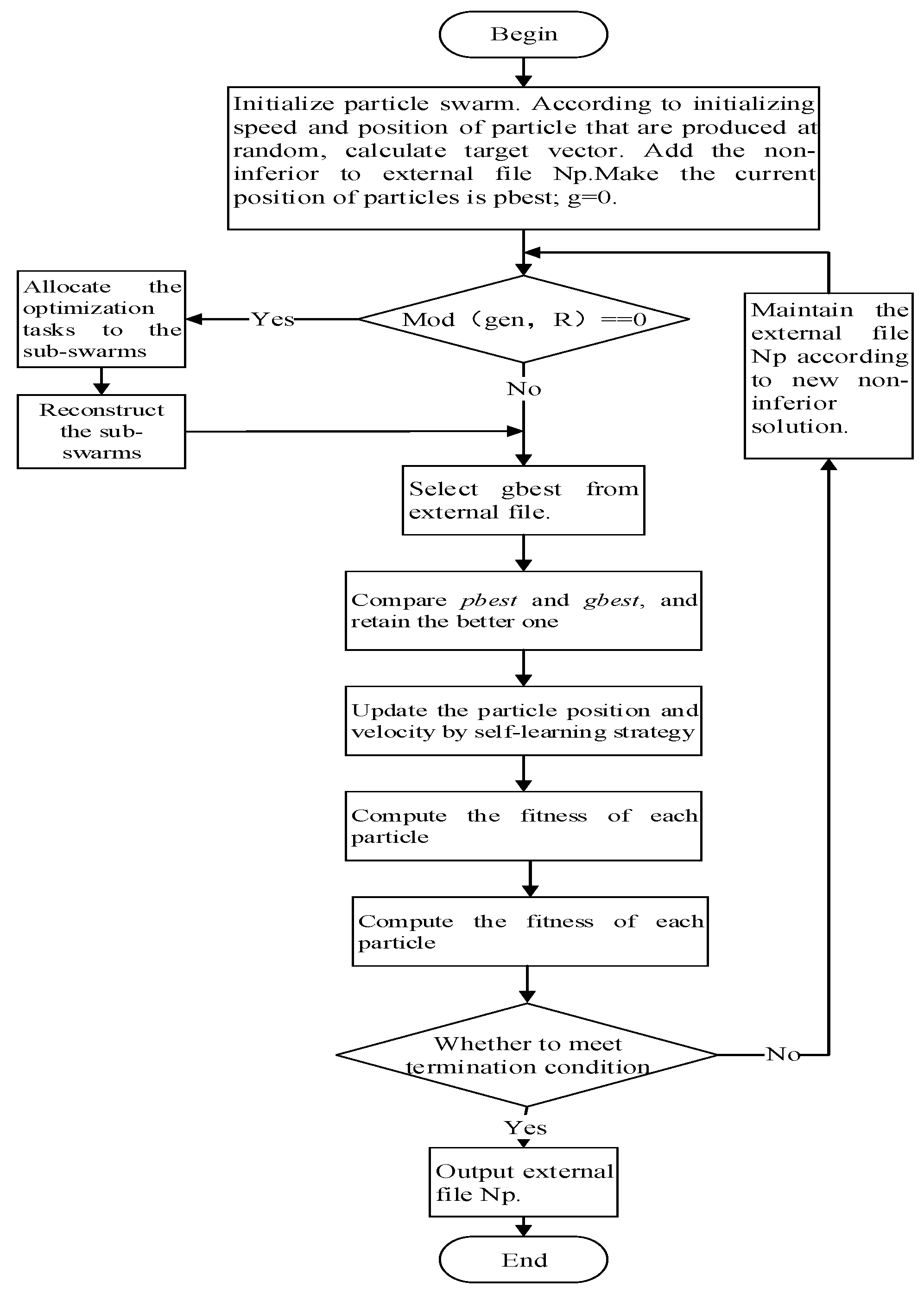

3.3. Procedure of the DMS-PSO Approach

- Step 1.

- Initialize the swarm under the constraints of the model. Determine the initial position and velocity of each particle.

- Step 2.

- Judge if the swarm reaches the condition for division.

- Step 3.

- Allocate the optimization tasks to the sub-swarms.

- Step 4.

- Reconstruct the sub-swarms by the strategy in Section 3.1.

- Step 5.

- Select the global best-known solution gbest from the external file by tournament selection.

- Step 6.

- Compare pbest and gbest, and retain the better one.

- Step 7.

- Update the particle position and velocity by self-learning strategy, while ensuring the flight in the search space.

- Step 8.

- Compute the fitness of each particle.

- Step 9.

- Add the new non-inferior solutions to the external file Np.

- Step 10.

- Judge if the termination condition is met.

4. Numerical Case

4.1. Machining Scenario

4.2. Simulation Conditions

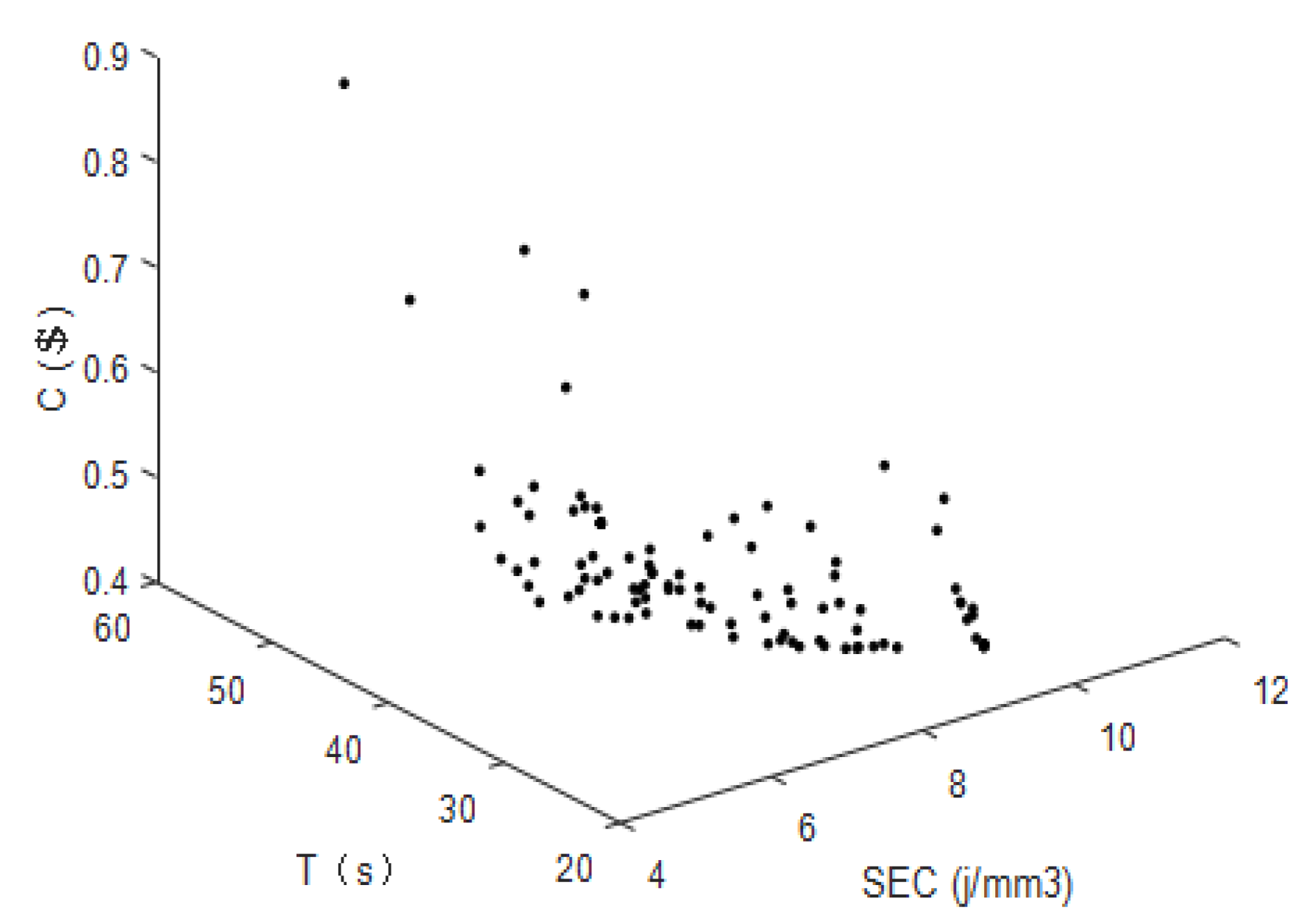

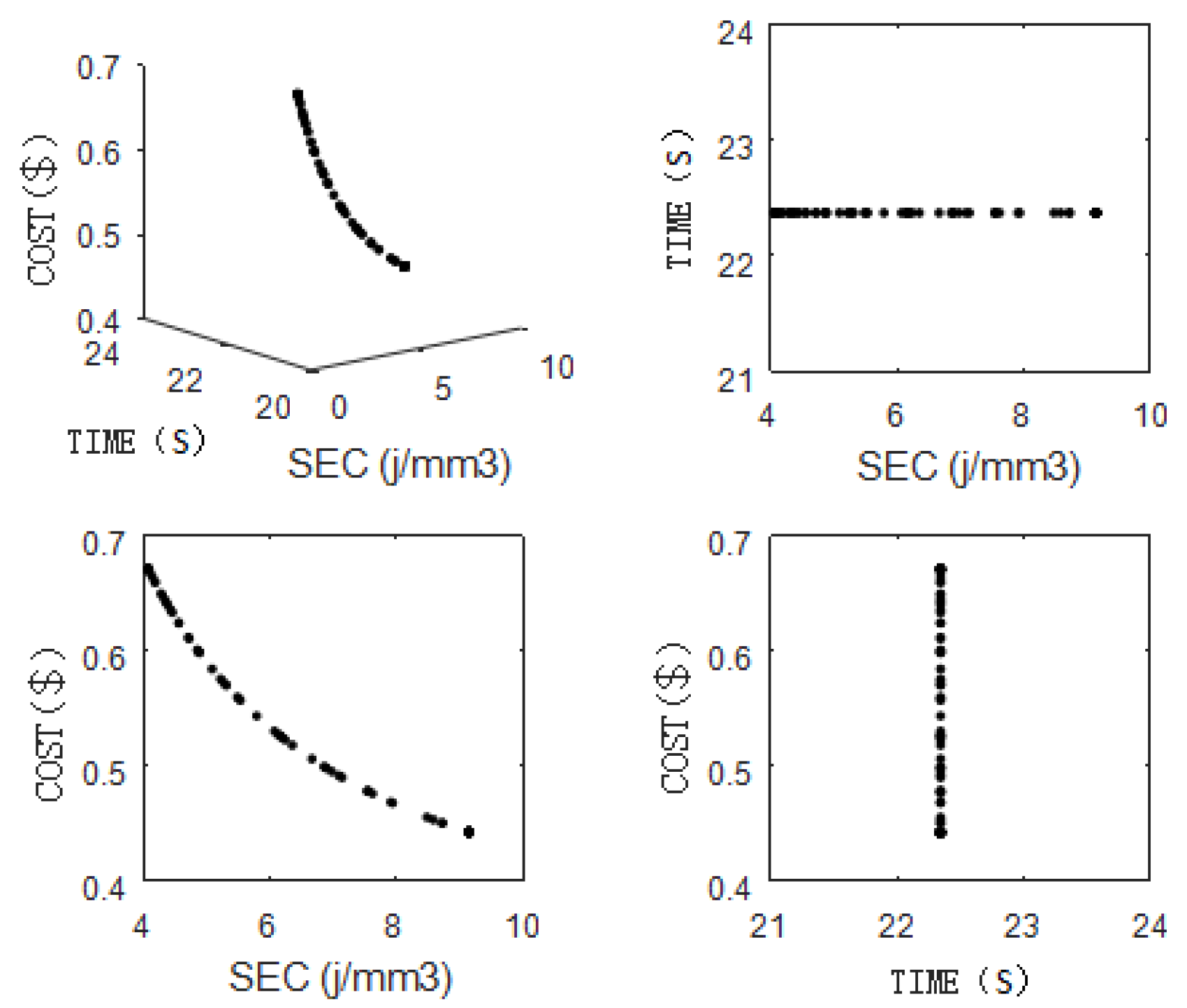

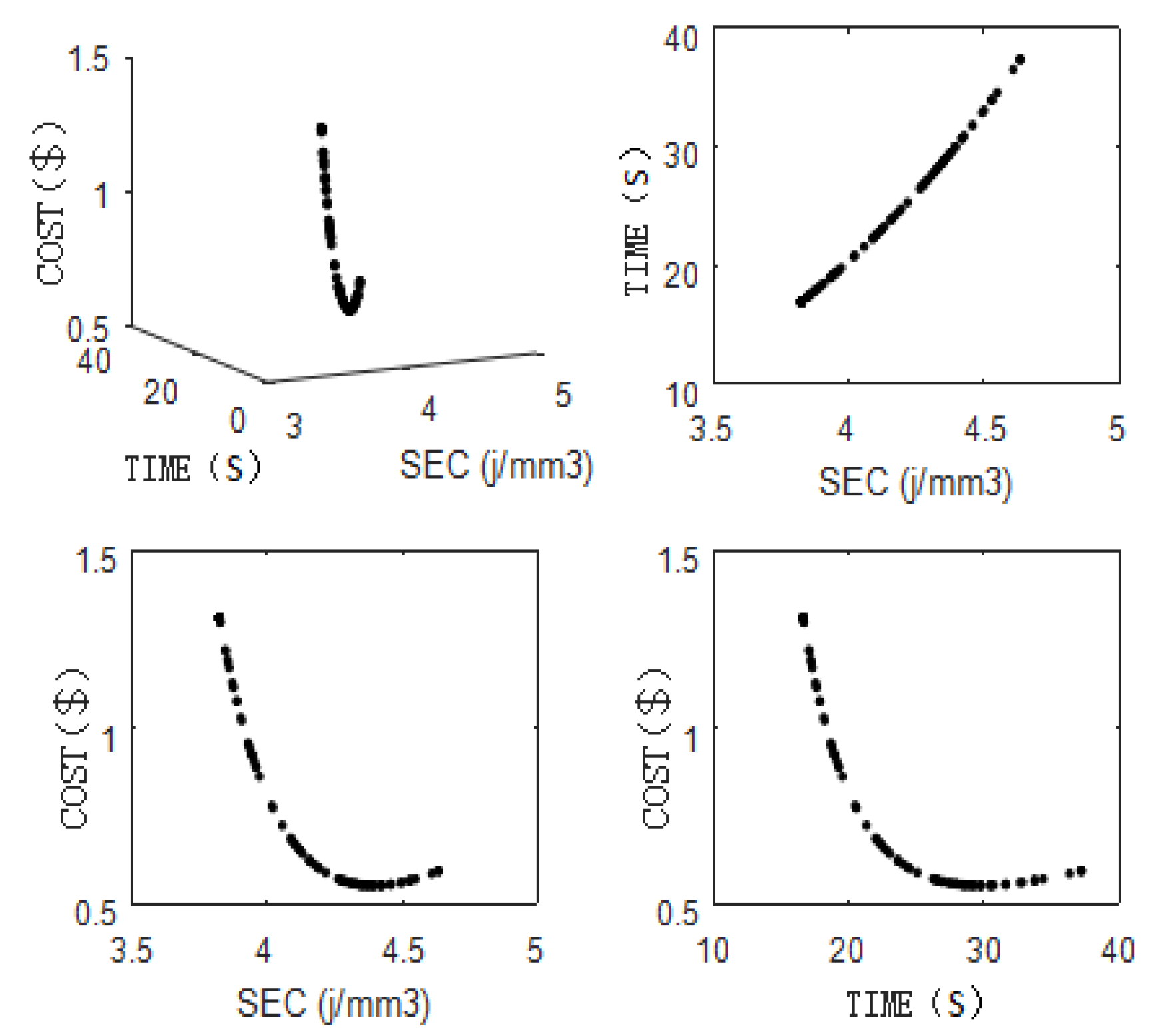

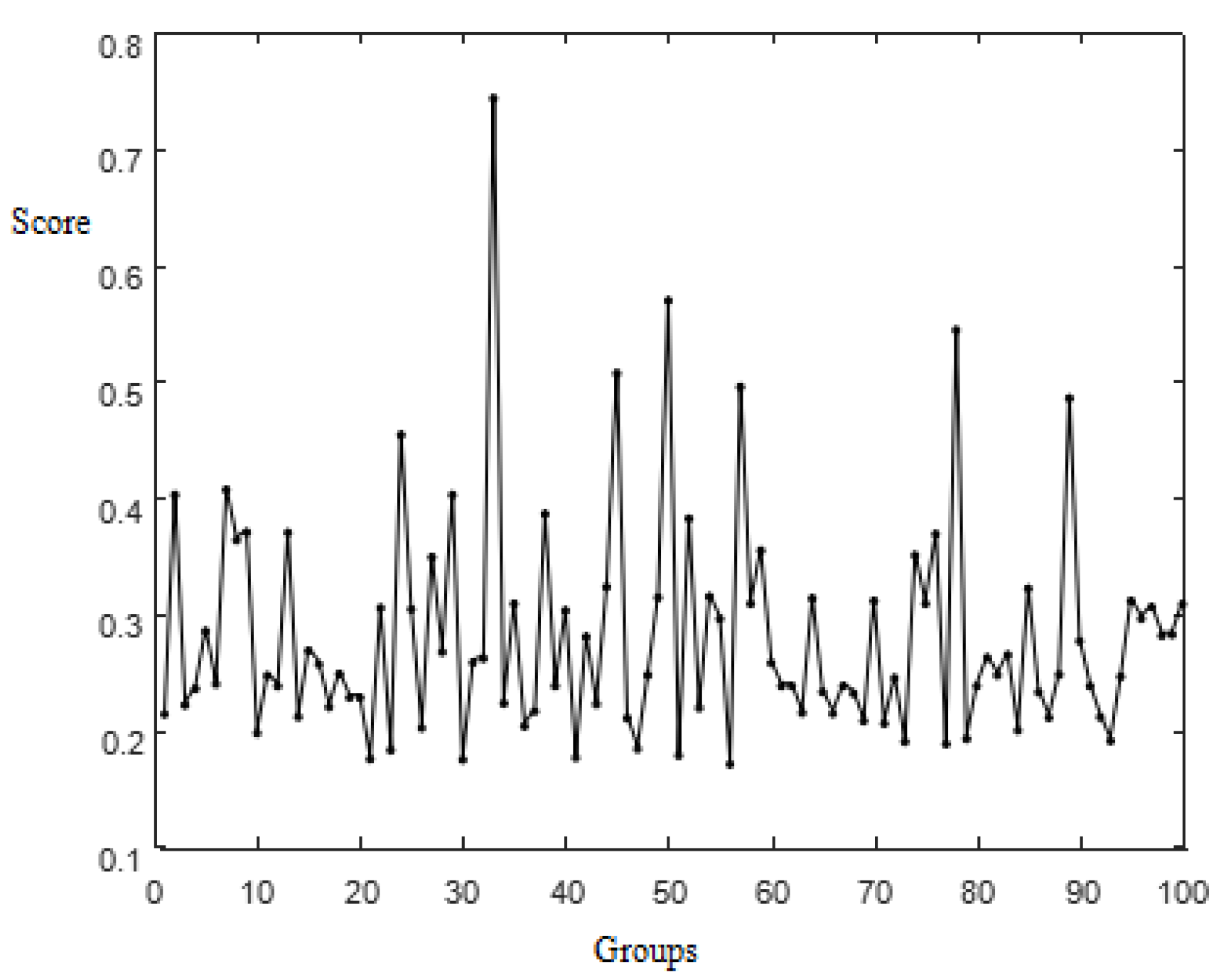

4.3. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Jia, S.; Yuan, Q.; Ren, D.; Lv, J. Energy demand modeling methodology of key state transitions of turning processes. Energies 2017, 10, 462. [Google Scholar] [CrossRef]

- Simon, J.; Guélou, G.; Srinivasan, B.; Berthebaud, D.; Mori, T.; Maignan, A. Exploring the thermoelectric behavior of spark plasma sintered Fe7-x Cox S8 compounds. J. Alloy. Compd. 2020, 819, 152999. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, Z.; Srinivasan, B.; Wang, Z.; Zhang, J.; Li, K.W.; Boussard-Pledel, C.; Troles, J.; Bureau, B.; Wei, L. Ultraflexible Glassy Semiconductor Fibers for Thermal Sensing and Positioning. ACS Appl. Mater. Interfaces 2019, 11, 2441–2447. [Google Scholar] [CrossRef] [PubMed]

- Diaz C, J.L.; Ocampo-Martinez, C. Energy efficiency in discrete-manufacturing systems: Insights, trends, and control strategies. J. Manuf. Syst. 2019, 52, 131–145. [Google Scholar] [CrossRef]

- Srinivasan, B.; Berthebaud, D.; Mori, T. Is LiI a potential dopant candidate to enhance the thermoelectric performance in Sb-Free GeTe systems? A prelusive study. Energies 2020, 13, 643. [Google Scholar] [CrossRef]

- Srinivasan, B.; Gellé, A.; Halet, J.; Boussard-Pledel, C.; Bureau, B. Detrimental Effects of Doping Al and Ba on the Thermoelectric Performance of GeTe. Materials 2018, 11, 2237. [Google Scholar] [CrossRef]

- Triebe, M.J.; Mendis, G.P.; Zhao, F.; Sutherland, J.W. Understanding energy consumption in a machine tool through energy mapping. Procedia Cirp 2018, 69, 259–264. [Google Scholar] [CrossRef]

- Liu, J.; Huang, L.; Wang, Y.; Wang, Y.; Shi, J. Novel continuous machining strategy for cost-effective five-axis CNC milling systems with a four-axis controller. Int. J. Comput. Integr. Manuf. 2020. [Google Scholar] [CrossRef]

- Shabi, L.; Weber, J.; Weber, J. Analysis of the energy consumption of fluidic systems in machine tools. Procedia Cirp 2017, 63, 573–579. [Google Scholar] [CrossRef]

- Jia, S.; Yuan, Q.; Cai, W.; Yuan, Q.; Liu, C.; Lv, J.; Zhang, Z. Establishment of an improved material-drilling power model to support energy management of drilling processes. Energies 2018, 11, 2013. [Google Scholar] [CrossRef]

- Yoon, H.; Lee, J.Y.; Kim, H.; Kim, M.; Kim, E.; Shin, Y.-J. A comparison of energy consumption in bulk forming, subtractive, and additive processes: Review and case study. Int. J. Precis. Eng. Manuf. Green Technol. 2015, 1, 261–279. [Google Scholar] [CrossRef]

- Mori, K.; Bergmann, B.; Kono, D.; Denkena, B.; Matsubara, A. Energy efficiency improvement of machine tool spindle cooling system with on-off control. Cirp J. Manuf. Sci. Technol. 2019, 25, 14–21. [Google Scholar] [CrossRef]

- Newman, S.T.; Nassehi, A.; Imani-Asrai, R.; Dhokia, V. Energy efficient process planning for CNC machining. Cirp J. Manuf. Sci. Technol. 2012, 5, 127–136. [Google Scholar] [CrossRef]

- Arriaza, O.V.; Kim, D.W.; Lee, D.Y.; Msuhaimi, M.A. Trade-off analysis between machining time and energy consumption in impeller NC machining. Robot. Comput. Integr. Manuf. 2017, 43, 164–170. [Google Scholar] [CrossRef]

- Öztürk, B.; Uğur, L.; Yildiz, A. Investigation of effect on energy consumption of surface roughness in X-axis and spindle servo motors in slot milling operation. Measurement 2019, 139, 92–102. [Google Scholar] [CrossRef]

- Hu, L.K.; Tang, R.Z.; Liu, Y.; Cao, Y.L.; Tiwari, A. Optimising the machining time, deviation and energy consumption through a multi-objective feature sequencing approach. Energy Convers. Manag. 2018, 160, 126–140. [Google Scholar] [CrossRef]

- Jang, D.; Jung, J.; Seok, J. Modeling and parameter optimization for cutting energy reduction in MQL milling process. Int. J. Precis. Eng. Manuf. Green Technol. 2016, 3, 5–12. [Google Scholar] [CrossRef]

- Yan, J.; Li, L. Multi-objective optimization of milling parameters—The trade-off between energy, production rate and cutting quality. J. Clean. Prod. 2013, 52, 462–471. [Google Scholar] [CrossRef]

- Subramanian, M.; Sakthivel, M.; Sooryaprakash, K.; Sudhakaran, R. Optimization of cutting parameters for cutting force in shoulder milling of Al7075-T6 using response surface methodology and genetic algorithm. Procedia Eng. 2013, 64, 690–700. [Google Scholar] [CrossRef]

- He, K.; Tang, R.; Jin, M. Pareto fronts of machining parameters for trade-off among energy consumption, cutting force and processing time. Int. J. Prod. Econ. 2017, 185, 113–127. [Google Scholar] [CrossRef]

- D’Addona, D.M.; Teti, R. Genetic algorithm-based optimization of cutting parameters in turning processes. Procedia Cirp 2013, 7, 323–328. [Google Scholar] [CrossRef]

- Velchev, S.; Kolev, I.; Ivanov, K.; Gechevski, S. Empirical models for specific energy consumption and optimization of cutting parameters for minimizing energy consumption during turning. J. Clean. Prod. 2014, 80, 139–149. [Google Scholar] [CrossRef]

- Xu, K.; Luo, M.; Tang, K. Machine based energy-saving tool path generation for five-axis end milling of freeform surfaces. J. Clean. Prod. 2016, 139, 1207–1223. [Google Scholar] [CrossRef]

- Camposeco-Negrete, C. Optimization of cutting parameters for minimizing energy consumption in turning of AISI 6061 T6 using Taguchi methodology and ANOVA. J. Clean. Prod. 2013, 53, 195–203. [Google Scholar] [CrossRef]

- Kant, G.; Sangwan, K.S. Predictive modelling for energy consumption in machining using artificial neural network. Procedia Cirp 2015, 37, 205–210. [Google Scholar] [CrossRef]

- Shi, K.N.; Ren, J.X.; Wang, S.B.; Liu, N.; Lu, W.F. An improved cutting power-based model for evaluating total energy consumption in general end milling process. J. Clean. Prod. 2019, 231, 1330–1341. [Google Scholar] [CrossRef]

- Li, C.; Li, L.; Tang, Y.; Zhu, Y.; Li, L. A comprehensive approach to parameters optimization of energy-aware CNC milling. J. Intell. Manuf. 2019, 30, 123–138. [Google Scholar] [CrossRef]

- Shin, S.; Woo, J.; Rachuri, S. Energy efficiency of milling machining: Component modeling and online optimization of cutting parameters. J. Clean. Prod. 2017, 161, 12–29. [Google Scholar] [CrossRef]

- Khan, A.M.; Jamil, M.; Salonitis, K.; Sarfraz, S.; Zhao, W.; He, N.; Mia, M.; Zhao, G. Multi-objective optimization of energy consumption and surface quality in nanofluid SQCL assisted face milling. Energies 2019, 12, 710. [Google Scholar] [CrossRef]

- Davoodi, M.; Panahi, F.; Mohadess, A.; Hashemi, S.N. Multi-objective path planning in discrete space. Appl. Soft Comput. 2013, 13, 709–720. [Google Scholar] [CrossRef]

- Li, F.; Liu, J.C.; Shi, H.T.; Fu, Z.Y. Multi-objective particle swarm optimization algorithm based on decomposition and differential evolution. Control Decis. 2017, 32, 403–410. [Google Scholar]

- Cheng, R.; Jin, Y.; Olhofer, M.; Sendhoff, B. A reference vector guided evolutionary algorithm for many-objective optimization. IEEE Trans. Evol. Comput. 2016, 20, 773–779. [Google Scholar] [CrossRef]

- Alswaitti, M.; Albughdadi, M.; Isa, N.A.M. Density-based particle swarm optimization algorithm for data clustering. Expert Syst. Appl. 2018, 91, 170–186. [Google Scholar] [CrossRef]

- Jordehi, A.R. Particle swarm optimisation (PSO) for allocation of facts devices in electric transmission systems: A review. Renew. Sustain. Energy Rev. 2015, 52, 1260–1267. [Google Scholar] [CrossRef]

- Espitia, H.E.; Sofrony, J.I. Considerations for parameter configuration on Vortex Particle Swarm Optimization. Theor. Comput. Sci. 2019, 773, 1–26. [Google Scholar] [CrossRef]

- Liang, J.J.; Suganthan, P.N.; Chan, C.C.; Huang, V.L. Wavelength detection in FBG sensor network using Tree Search DMS-PSO. IEEE Photonics Technol. Lett. 2006, 18, 1305–1307. [Google Scholar] [CrossRef]

- Zhao, S.Z.; Suganthan, P.N.; Pan, Q.K.; Tasgetiren, M.F. Dynamic multi-swarm particle swarm optimizer with harmony search. Expert Syst. Appl. 2011, 38, 3735–3742. [Google Scholar] [CrossRef]

- Chen, Y.; Li, L.X.; Peng, H.P.; Xiao, J.H.; Wu, Q. Dynamic multi-swarm differential learning particle swarm optimizer. Swarm Evol. Comput. 2018, 39, 209–221. [Google Scholar] [CrossRef]

- Xia, X.; Gui, L.; Zhan, Z.H. A multi-swarm particle swarm optimization algorithm based on dynamical topology and purposeful detecting. Appl. Soft Comput. 2018, 67, 126–140. [Google Scholar] [CrossRef]

- Chen, S.Y.; Wu, C.H.; Hung, Y.H.; Chung, C.T. Optimal strategies of energy management integrated with transmission control for a hybrid electric vehicle using dynamic particle swarm optimization. Energy 2018, 160, 154–170. [Google Scholar] [CrossRef]

- Lathe Machines Market to Be Worth USD 40.22 Billion by 2026, Adoption of Automated Concepts to Aid in Market Expansion. Available online: https://www.fortunebusinessinsights.com/press-release/lathe-machines-market-9451 (accessed on 18 December 2019).

- Boldea, I.; Nasar, S.A. The Induction Machine Handbook; CRC Press: Boca Raton, FL, USA, 2002. [Google Scholar]

- Jiang, Z.; Gao, D.; Lu, Y.; Kong, L.; Shang, Z. Quantitative analysis of carbon emissions in precision turning processes and industrial case study. Int. J. Precis. Eng. Manuf. Green Technol. 2019. [Google Scholar] [CrossRef]

- Cao, T.; Liu, Y.; Xu, Y. Cutting performance of tool with continuous lubrication at tool-chip Interface. Int. J. Precis. Eng. Manuf. Green Technol. 2020, 7, 347–359. [Google Scholar] [CrossRef]

- Kiran, K.; Kayacan, M.C. Cutting force modeling and accurate measurement in milling of flexible workpieces. Mech. Syst. Signal Process. 2019, 133, 106284. [Google Scholar] [CrossRef]

- Daramola, O.O.; Tlhabadira, I.; Olajide, J.L.; Daniyan, I.A.; VanStaden, L.R. Process design for optimal minimization of resultant cutting force during the machining of Ti-6Al-4V: Response surface method and desirability function analysis. Procedia Cirp 2019, 84, 54–86. [Google Scholar] [CrossRef]

- Kumar, R.; Bilga, P.S.; Singh, S. Multi objective optimization using different methods of assigning weights to energy consumption responses, surface roughness and material removal rate during rough turning operation. J. Clean. Prod. 2017, 164, 45–57. [Google Scholar] [CrossRef]

- Tlhabadira, I.; Daniyan, I.A.; Masu, L.; VanStaden, L.R. Process design and optimization of surface roughness during M200 TS milling process using the Taguchi method. Procedia Cirp 2019, 84, 868–873. [Google Scholar] [CrossRef]

- Kennedy, J.; Eberhart, R. Particle swarm optimization. In Proceedings of the ICNN’95 International Conference on Neural Networks, Perth, Australia, 27 November–1 December 1995; pp. 1942–1948. [Google Scholar]

- Eberhart, R.; Kennedy, J. A new optimizer using particle swarm theory. In Proceedings of the 6th Internaltiohnal Symposium on Micro Machine and Human Science, Nagoya, Japan, 4–6 October 1995; Nagoya Municipal Industrial Research Institute: Nagoya, Japan, 1995; pp. 39–43. [Google Scholar]

- Mendes, R.; Kennedy, J.; Neves, J. The fully informed particle swarm: Simpler, maybe better. IEEE Trans. Evol. Comput. 2004, 8, 204–210. [Google Scholar] [CrossRef]

- Meza, J.; Espitia, H.; Montenegro, C.; Giménez, E.; González-Crespo, R. MOVPSO: Vortex multi-objective particle swarm optimization. Appl. Soft Comput. 2017, 52, 1042–1057. [Google Scholar] [CrossRef]

- Tsionas, M.G. Multi-objective optimization using statistical models. Eur. J. Oper. Res. 2019, 276, 364–378. [Google Scholar] [CrossRef]

- Zain, M.Z.B.M.; Kanesan, J.; Chuah, J.H.; Dhanapal, S.; Kendall, G. A multi-objective particle swarm optimization algorithm based on dynamic boundary search for constrained optimization. Appl. Soft Comput. 2018, 70, 680–700. [Google Scholar] [CrossRef]

- Rao, V.; Ali, S.M.; Ali, S.Z.S.; Geethika, V. Multi-objective optimization of cutting parameters in CNC turning of stainless steel 304 with TiAlN nano coated tool. Mater. Today Proc. 2018, 5, 25789–25797. [Google Scholar]

- Yusuf, A. Manufacturing Automation, 2nd ed.; Cambridge University Press: New York, NY, USA, 2012. [Google Scholar]

- Liang, J.J.; Qu, B.Y.; Suganthan, P.N.; Niu, B. Dynamic multi-swarm particle swarm optimization for multi-objective optimization problems. In Proceedings of the WCCI 2012 IEEE World Congress on Computational Intelligence, Brisbane, Australia, 10–15 June 2012. [Google Scholar]

- Liang, J.; Suganthan, P. Dynamic multi-swarm particle swarm optimizer. In Proceedings of the 2005 IEEE Swarm Intelligence Symposium, Pasadena, CA, USA, 8–10 June 2005. [Google Scholar]

- Kaganski, S.; Majak, J.; Karjust, K. Fuzzy AHP as a tool for prioritization of key performance indicators. Procedia Cirp 2018, 72, 1227–1232. [Google Scholar] [CrossRef]

| Inertia Weight | Maximum Velocity | ||

|---|---|---|---|

| Iteration cycle | and | Learning factors | |

| Current position | r1r2 | A random number in interval [0,1] | |

| Velocity | N | Quantity of swarm | |

| Individual best-known position | d | Dimension of search space | |

| Global best-known position | Fitness function |

| Parameters | Value |

|---|---|

| Swarm size p | 200 |

| Maximum number of iterations g | 1000 |

| Inertia weight | 0.4 |

| Learning factors c1 and c2 | 2 |

| Capacity of external file | 100 |

| Reconstruction interval R | 50 |

| Self-learning threshold P1 | 0.5 |

| Serial Number | vc m/min | f mm/r | ap mm | SEC j/mm3 | Tc S | Ct $ |

|---|---|---|---|---|---|---|

| 1 | 140.33 | 0.35 | 0.92 | 6.554 | 23.898 | 0.492 |

| 2 | 107.39 | 0.33 | 0.69 | 8.490 | 32.852 | 0.510 |

| 3 | 150.00 | 0.35 | 0.90 | 6.526 | 22.357 | 0.511 |

| 4 | 129.40 | 0.35 | 0.84 | 7.028 | 25.915 | 0.474 |

| 5 | 129.19 | 0.35 | 0.67 | 8.078 | 26.174 | 0.459 |

| 6 | 119.74 | 0.35 | 0.94 | 6.692 | 28.006 | 0.485 |

| 7 | 150.00 | 0.25 | 2.00 | 5.035 | 31.433 | 0.726 |

| 8 | 131.22 | 0.34 | 0.50 | 9.619 | 26.234 | 0.445 |

| 9 | 122.79 | 0.35 | 0.50 | 9.621 | 27.311 | 0.445 |

| 10 | 106.29 | 0.35 | 1.92 | 4.558 | 31.549 | 0.547 |

| 11 | 150.00 | 0.33 | 1.53 | 5.006 | 24.003 | 0.615 |

| 12 | 109.67 | 0.35 | 1.20 | 5.953 | 30.577 | 0.511 |

| 13 | 107.89 | 0.35 | 0.65 | 8.556 | 31.084 | 0.485 |

| 14 | 150.00 | 0.35 | 1.42 | 4.998 | 22.357 | 0.591 |

| 15 | 140.46 | 0.30 | 2.00 | 4.546 | 27.586 | 0.642 |

| 16 | 134.28 | 0.31 | 1.37 | 5.639 | 28.180 | 0.562 |

| 17 | 116.05 | 0.33 | 2.00 | 4.554 | 31.024 | 0.573 |

| 18 | 147.43 | 0.35 | 0.70 | 7.575 | 22.746 | 0.473 |

| 19 | 139.79 | 0.33 | 1.33 | 5.522 | 25.755 | 0.556 |

| 20 | 138.66 | 0.35 | 0.82 | 7.011 | 24.185 | 0.477 |

| 21 | 128.93 | 0.35 | 2.00 | 4.285 | 26.307 | 0.573 |

| 22 | 124.99 | 0.28 | 2.00 | 4.857 | 33.033 | 0.627 |

| 23 | 124.89 | 0.35 | 1.54 | 5.025 | 27.168 | 0.532 |

| 24 | 106.29 | 0.35 | 0.50 | 9.971 | 31.604 | 0.481 |

| 25 | 150.00 | 0.30 | 1.19 | 6.157 | 26.523 | 0.589 |

| 26 | 141.23 | 0.35 | 1.04 | 6.068 | 23.745 | 0.510 |

| 27 | 128.93 | 0.35 | 0.50 | 9.509 | 26.009 | 0.438 |

| 28 | 129.30 | 0.31 | 1.19 | 6.150 | 28.920 | 0.538 |

| 29 | 119.04 | 0.30 | 0.83 | 7.961 | 33.141 | 0.539 |

| 30 | 113.77 | 0.35 | 2.00 | 4.385 | 29.475 | 0.547 |

| … | … | … | … | … | … |

| Items | vc m/min | f mm/r | ap mm | SEC j/mm3 | T s | Ct $ | Score |

|---|---|---|---|---|---|---|---|

| Empirical value | 120 | 0.3 | 1.5 | 5.611 | 32.604 | 0.576 | 0.296 |

| Optimized value | 125.14 | 0.35 | 1.68 | 4.742 | 26.797 | 0.539 | 0.171 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, L.; Shi, J.; Pan, A.; Yang, J.; Xie, J. A Dynamic Multi-Swarm Particle Swarm Optimizer for Multi-Objective Optimization of Machining Operations Considering Efficiency and Energy Consumption. Energies 2020, 13, 2616. https://doi.org/10.3390/en13102616

Song L, Shi J, Pan A, Yang J, Xie J. A Dynamic Multi-Swarm Particle Swarm Optimizer for Multi-Objective Optimization of Machining Operations Considering Efficiency and Energy Consumption. Energies. 2020; 13(10):2616. https://doi.org/10.3390/en13102616

Chicago/Turabian StyleSong, Lijun, Jing Shi, Anda Pan, Jie Yang, and Jun Xie. 2020. "A Dynamic Multi-Swarm Particle Swarm Optimizer for Multi-Objective Optimization of Machining Operations Considering Efficiency and Energy Consumption" Energies 13, no. 10: 2616. https://doi.org/10.3390/en13102616

APA StyleSong, L., Shi, J., Pan, A., Yang, J., & Xie, J. (2020). A Dynamic Multi-Swarm Particle Swarm Optimizer for Multi-Objective Optimization of Machining Operations Considering Efficiency and Energy Consumption. Energies, 13(10), 2616. https://doi.org/10.3390/en13102616