Possibilities and Challenges for the Inclusion of the Electric Vehicle (EV) to Reduce the Carbon Footprint in the Transport Sector: A Review

Abstract

1. Introduction

2. Electric Vehicles and the Charging Station

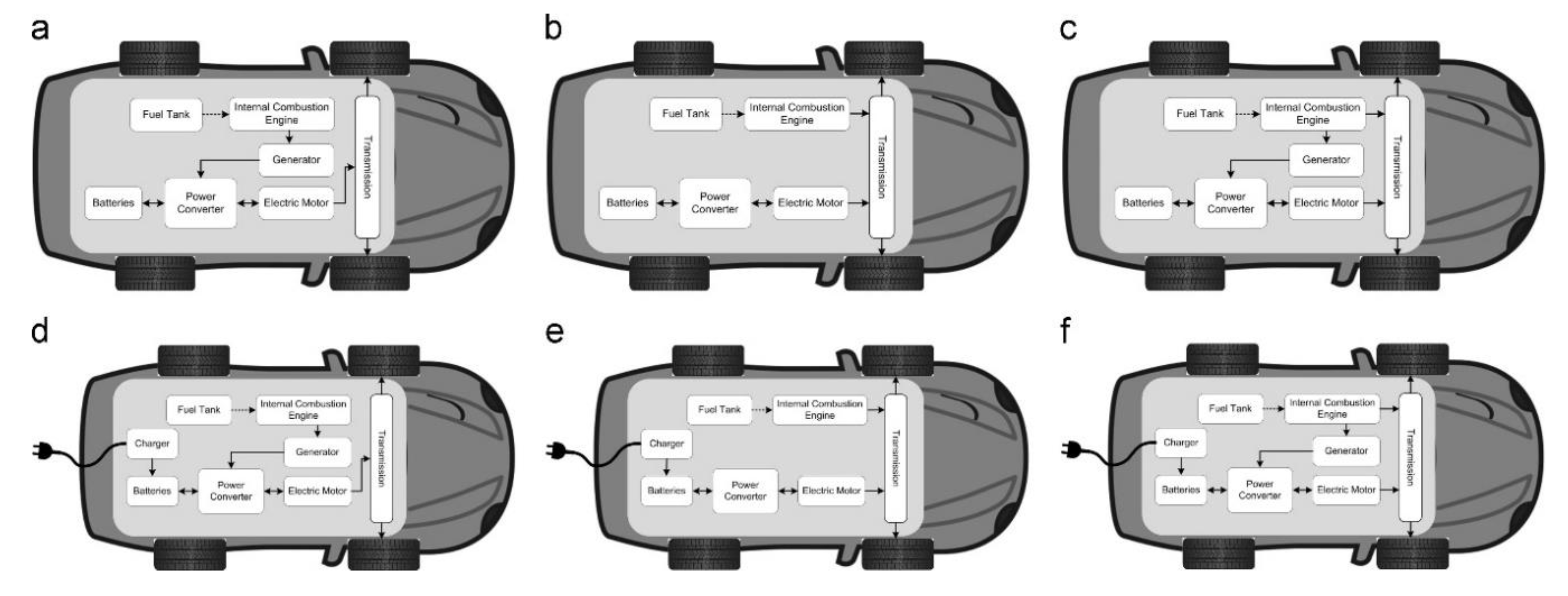

2.1. Hybrid EV (HEV) and Plug-In Hybrid

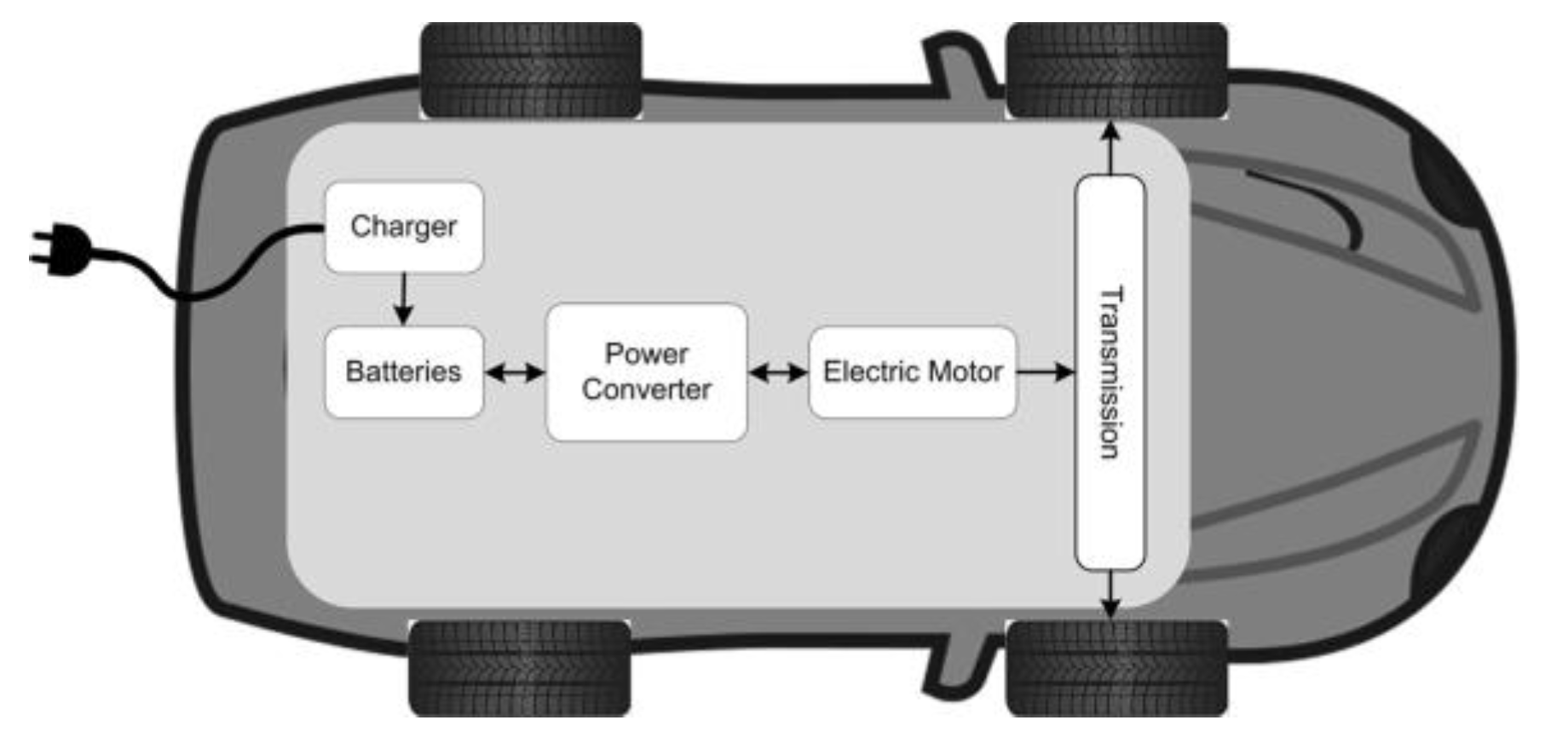

2.2. BEV

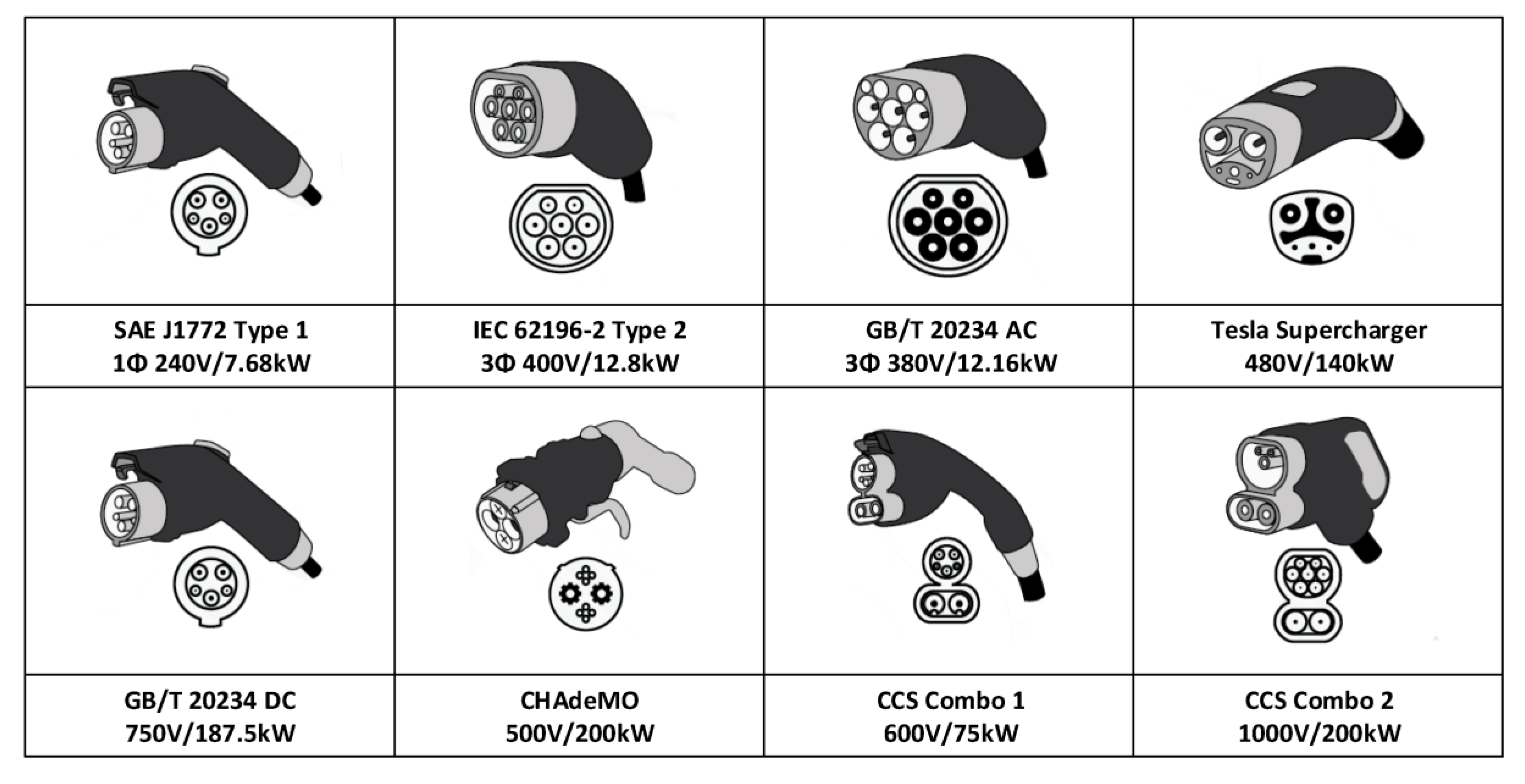

2.3. Charging Station (CS)

2.4. EV Battery

3. Hybrid and Alternative Energy Storage

3.1. Battery/Supercapacitor

3.2. Fuel Cell/Battery/Supercapacitor

4. Integration of Photovoltaic (PV) in EV

4.1. PV for EV Charging

4.2. PV Integrated in the EV (VIPV)

5. Reduction of Greenhouse Gas Emission and Particulate Matter

6. Challenges in EV Uptake

6.1. Technical

6.2. Consumer Behaviour in the Context of Socio-Technical Factors

6.3. Government Support and Policy

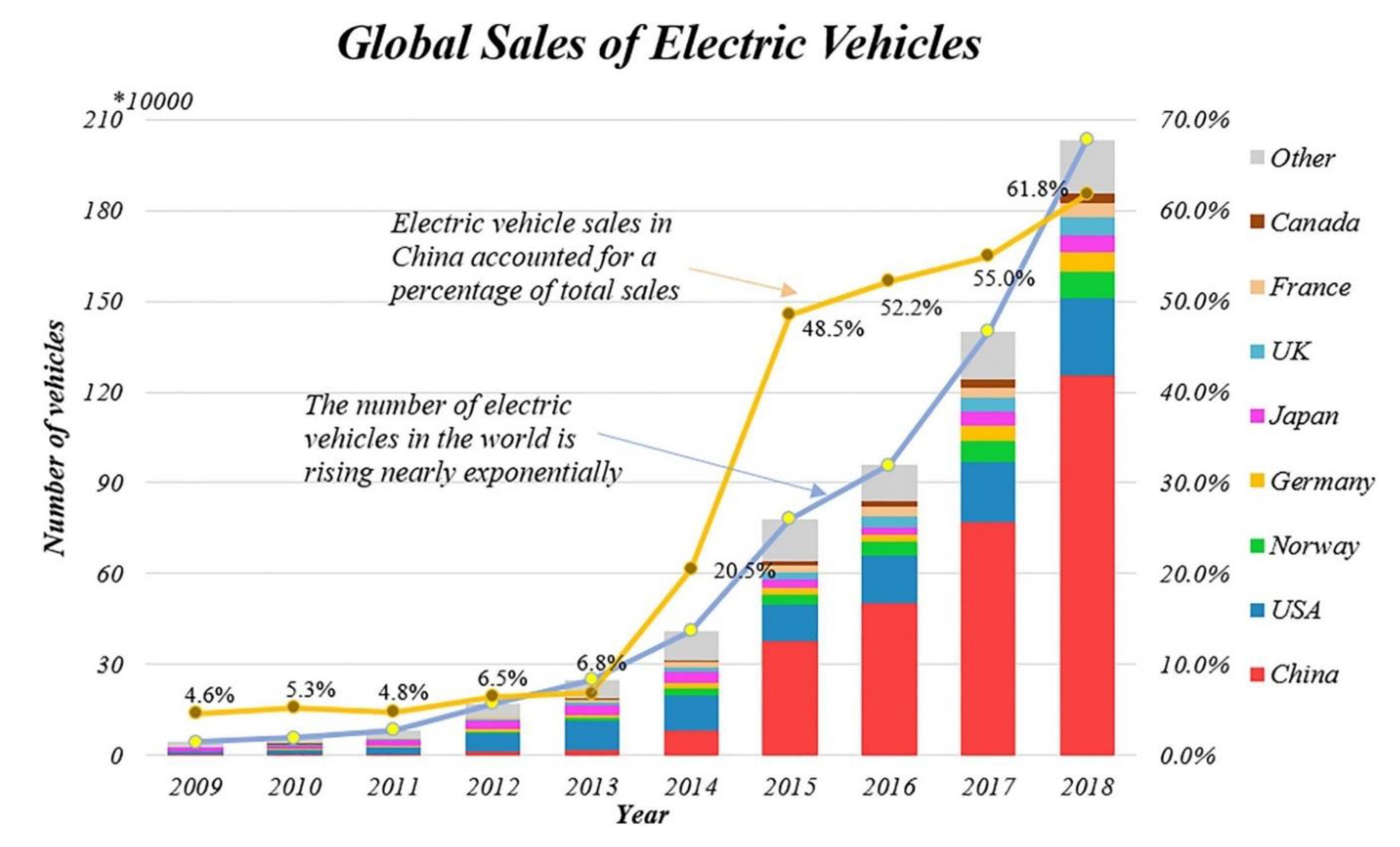

7. EV Status Worldwide

8. Conclusions

Funding

Conflicts of Interest

References

- Allen, M.R.; Dube, O.P.; Solecki, W.; Aragon-Durand, F.; Cramer, W.; Humphreys, S.; Kainuma, M.; Kala, J.; Mahowald, N.; Mulugetta, Y.; et al. Framing and Context. In Global Warming of 1.5 °C. An IPCC Special Report on the Impacts of Global Warming of 1.5 °C above Pre-industrial Levels and Related Global Greenhouse Gas Emission Pathways, in the Context of Strengthening the Global Response to the threat of climate change, sustainable development, and efforts to eradicate poverty; IPCC: Paris, France, 2018. [Google Scholar]

- López, I.; Ibarra, E.; Matallana, A.; Andreu, J.; Kortabarria, I. Next generation electric drives for HEV/EV propulsion systems: Technology, trends and challenges. Renew. Sustain. Energy Rev. 2019, 114, 109336. [Google Scholar] [CrossRef]

- Martínez-Lao, J.; Montoya, F.G.; Montoya, M.G.; Manzano-Agugliaro, F. Electric vehicles in Spain: An overview of charging systems. Renew. Sustain. Energy Rev. 2017, 77, 970–983. [Google Scholar] [CrossRef]

- Van Vliet, O.; Brouwer, A.S.; Kuramochi, T.; Van Den Broek, M.; Faaij, A. Energy use, cost and CO2 emissions of electric cars. J. Power Sources 2011, 196, 2298–2310. [Google Scholar] [CrossRef]

- Smith, W.J. Can EV (electric vehicles) address Ireland’s CO2 emissions from transport? Energy 2010, 35, 4514–4521. [Google Scholar] [CrossRef]

- Singh, N.; Mishra, T.; Banerjee, R. Greenhouse Gas Emissions in India’s Road Transport Sector. Clim. Chang. Signals Response 2019, 197–209. [Google Scholar] [CrossRef]

- Guarnieri, M. When cars went electric, Part 2. IEEE Ind. Electron. Mag. 2011, 5, 61–62. [Google Scholar] [CrossRef]

- Thiel, C.; Tsakalidis, A.; Jager-Waldau, A. Will Electric Vehicles Be Killed (again) or Are They the Next Mobility Killer App? Energies 2020, 13, 1828. [Google Scholar] [CrossRef]

- Chan, C.C. An Overview of Electric Vehicle Technology. Proc. IEEE 1993, 81, 1202–1213. [Google Scholar] [CrossRef]

- Kempton, W.; Letendre, S.E. Electric vehicles as a new power source for electric utilities. Transp. Res. Part D Transp. Environ. 1997, 2, 157–175. [Google Scholar] [CrossRef]

- Browne, D.; O’Mahony, M.; Caulfield, B. How should barriers to alternative fuels and vehicles be classified and potential policies to promote innovative technologies be evaluated? J. Clean. Prod. 2012, 35, 140–151. [Google Scholar] [CrossRef]

- Bhatti, A.R.; Salam, Z.; Aziz, M.J.B.A.; Yee, K.P.; Ashique, R.H. Electric vehicles charging using photovoltaic: Status and technological review. Renew. Sustain. Energy Rev. 2016, 54, 34–47. [Google Scholar] [CrossRef]

- Kumar, M.S.; Revankar, S.T. Development scheme and key technology of an electric vehicle: An overview. Renew. Sustain. Energy Rev. 2017, 70, 1266–1285. [Google Scholar] [CrossRef]

- Shamshirband, M.; Salehi, J.; Gazijahani, F.S. Decentralized trading of plug-in electric vehicle aggregation agents for optimal energy management of smart renewable penetrated microgrids with the aim of CO2 emission reduction. J. Clean. Prod. 2018, 200, 622–640. [Google Scholar] [CrossRef]

- Markel, T.; Simpson, A. Cost-benefit analysis of plug-in hybrid electric vehicle technology. World Electr. Veh. J. 2007, 1, 294–301. [Google Scholar] [CrossRef]

- Yong, J.Y.; Ramachandaramurthy, V.K.; Tan, K.M.; Mithulananthan, N. A review on the state-of-the-art technologies of electric vehicle, its impacts and prospects. Renew. Sustain. Energy Rev. 2015, 49, 365–385. [Google Scholar] [CrossRef]

- Wang, F.; Deng, Y.; Yuan, C. Life cycle assessment of lithium oxygen battery for electric vehicles. J. Clean. Prod. 2020, 264, 121339. [Google Scholar] [CrossRef]

- Zhou, Y.; Wen, R.; Wang, H.; Cai, H. Optimal battery electric vehicles range: A study considering heterogeneous travel patterns, charging behaviors, and access to charging infrastructure. Energy 2020, 197, 116945. [Google Scholar] [CrossRef]

- Álvarez Fernández, R. A more realistic approach to electric vehicle contribution to greenhouse gas emissions in the city. J. Clean. Prod. 2018, 172, 949–959. [Google Scholar] [CrossRef]

- Andwari, A.M.; Pesiridis, A.; Rajoo, S.; Martinez-Botas, R.; Esfahanian, V. A review of Battery Electric Vehicle technology and readiness levels. Renew. Sustain. Energy Rev. 2017, 78, 414–430. [Google Scholar] [CrossRef]

- Hannan, M.A.; Hoque, M.M.; Hussain, A.; Yusof, Y.; Ker, P.J. State-of-the-Art and Energy Management System of Lithium-Ion Batteries in Electric Vehicle Applications: Issues and Recommendations. IEEE Access 2018, 6, 19362–19378. [Google Scholar] [CrossRef]

- Ahmadi, L.; Yip, A.; Fowler, M.; Young, S.B.; Fraser, R.A. Environmental feasibility of re-use of electric vehicle batteries. Sustain. Energy Technol. Assess. 2014, 6, 64–74. [Google Scholar] [CrossRef]

- Kwon, Y.; Son, S.; Jang, K. User satisfaction with battery electric vehicles in South Korea. Transp. Res. Part D Transp. Environ. 2020, 82, 102306. [Google Scholar] [CrossRef]

- Li, L.; Wang, Z.; Chen, L.; Wang, Z. Consumer preferences for battery electric vehicles: A choice experimental survey in China. Transp. Res. Part D Transp. Environ. 2020, 78, 102185. [Google Scholar] [CrossRef]

- Abotalebi, E.; Scott, D.M.; Ferguson, M.R. Can Canadian households benefit economically from purchasing battery electric vehicles? Transp. Res. Part D Transp. Environ. 2019, 77, 292–302. [Google Scholar] [CrossRef]

- Ma, C.T. System planning of grid-connected electric vehicle charging stations and key technologies: A review. Energies 2019, 12, 4201. [Google Scholar] [CrossRef]

- Das, H.S.; Rahman, M.M.; Li, S.; Tan, C.W. Electric vehicles standards, charging infrastructure, and impact on grid integration: A technological review. Renew. Sustain. Energy Rev. 2020, 120. [Google Scholar] [CrossRef]

- Sheikhi, A.; Bahrami, S.; Ranjbar, A.M.; Oraee, H. Strategic charging method for plugged in hybrid electric vehicles in smart grids; A game theoretic approach. Int. J. Electr. Power Energy Syst. 2013, 53, 499–506. [Google Scholar] [CrossRef]

- González, L.G.; Siavichay, E.; Espinoza, J.L. Impact of EV fast charging stations on the power distribution network of a Latin American intermediate city. Renew. Sustain. Energy Rev. 2019, 107, 309–318. [Google Scholar] [CrossRef]

- Foley, A.M.; Winning, I.J.; Gallachóir, B.P. State-of-the-art in electric vehicle charging infrastructure. In Proceedings of the 2010 IEEE Vehicle Power and Propulsion Conference, Lille, France, 1–3 September 2010. [Google Scholar]

- Knez, M.; Zevnik, G.K.; Obrecht, M. A review of available chargers for electric vehicles: United States of America, European Union, and Asia. Renew. Sustain. Energy Rev. 2019, 109, 284–293. [Google Scholar] [CrossRef]

- Fox, G.H. Electric vehicle charging stations: Are we prepared? IEEE Ind. Appl. Mag. 2013, 19, 32–38. [Google Scholar] [CrossRef]

- Ruiz, V.; Pfrang, A.; Kriston, A.; Omar, N.; Van den Bossche, P.; Boon-Brett, L. A review of international abuse testing standards and regulations for lithium ion batteries in electric and hybrid electric vehicles. Renew. Sustain. Energy Rev. 2018, 81, 1427–1452. [Google Scholar] [CrossRef]

- Kim, J.D. Insights into residential EV charging behavior using energy meter data. Energy Policy 2019, 129, 610–618. [Google Scholar] [CrossRef]

- San Román, T.G.; Momber, I.; Abbad, M.R.; Sánchez Miralles, Á. Regulatory framework and business models for charging plug-in electric vehicles: Infrastructure, agents, and commercial relationships. Energy Policy 2011, 39, 6360–6375. [Google Scholar] [CrossRef]

- Xia, G.; Cao, L.; Bi, G. A review on battery thermal management in electric vehicle application. J. Power Sources 2017, 367, 90–105. [Google Scholar] [CrossRef]

- Hong, S.H.; Jang, D.S.; Park, S.; Yun, S.; Kim, Y. Thermal performance of direct two-phase refrigerant cooling for lithium-ion batteries in electric vehicles. Appl. Therm. Eng. 2020, 173, 115213. [Google Scholar] [CrossRef]

- Luo, X.; Wang, J.; Dooner, M.; Clarke, J. Overview of current development in electrical energy storage technologies and the application potential in power system operation. Appl. Energy 2015, 137, 511–536. [Google Scholar] [CrossRef]

- Palizban, O.; Kauhaniemi, K. Energy storage systems in modern grids—Matrix of technologies and applications. J. Energy Storage 2016, 6, 248–259. [Google Scholar] [CrossRef]

- Taniguchi, A.; Fujioka, N.; Ikoma, M.; Ohta, A. Development of nickel/metal-hydride batteries for EVs and HEVs. J. Power Sources 2001, 100, 117–124. [Google Scholar] [CrossRef]

- Fetcenko, M.A.; Ovshinsky, S.R.; Reichman, B.; Young, K.; Fierro, C.; Koch, J.; Zallen, A.; Mays, W.; Ouchi, T. Recent advances in NiMH battery technology. J. Power Sources 2007, 165, 544–551. [Google Scholar] [CrossRef]

- Ovshinsky, S.R.; Fetcenko, M.A.; Ross, J. A Nickel Metal Hydride battery for electric vehicles. World Sci. 2008, 169–262. [Google Scholar] [CrossRef]

- Chen, W.; Liang, J.; Yang, Z.; Li, G. A review of lithium-ion battery for electric vehicle applications and beyond. Energy Procedia 2019, 158, 4363–4368. [Google Scholar] [CrossRef]

- Gandoman, F.H.; Jaguemont, J.; Goutam, S.; Gopalakrishnan, R.; Firouz, Y.; Kalogiannis, T.; Omar, N.; Van Mierlo, J. Concept of reliability and safety assessment of lithium-ion batteries in electric vehicles: Basics, progress, and challenges. Appl. Energy 2019, 251, 113343. [Google Scholar] [CrossRef]

- Duffner, F.; Wentker, M.; Greenwood, M.; Leker, J. Battery cost modelling: A review and directions for future research. Renew. Sustain. Energy Rev. 2020, 127. Status: Accetped. [Google Scholar] [CrossRef]

- Gonzalez-Castellanos, A.; Pozo, D.; Bischi, A. Detailed Li-ion battery characterization model for economic operation. Int. J. Electr. Power Energy Syst. 2020, 116, 105561. [Google Scholar] [CrossRef]

- Schuster, S.F.; Brand, M.J.; Berg, P.; Gleissenberger, M.; Jossen, A. Lithium-ion cell-to-cell variation during battery electric vehicle operation. J. Power Sources 2015, 297, 242–251. [Google Scholar] [CrossRef]

- Scrosati, B.; Garche, J. Lithium batteries: Status, prospects and future. J. Power Sources 2010, 195, 2419–2430. [Google Scholar] [CrossRef]

- Zhang, W.J. Structure and performance of LiFePO4 cathode materials: A review. J. Power Sources 2011, 196, 2962–2970. [Google Scholar] [CrossRef]

- Tan, P.; Jiang, H.R.; Zhu, X.B.; An, L.; Jung, C.Y.; Wu, M.C.; Shi, L.; Shyy, W.; Zhao, T.S. Advances and challenges in lithium-air batteries. Appl. Energy 2017, 204, 780–806. [Google Scholar] [CrossRef]

- Jaguemont, J.; Boulon, L.; Dubé, Y. A comprehensive review of lithium-ion batteries used in hybrid and electric vehicles at cold temperatures. Appl. Energy 2016, 164, 99–114. [Google Scholar] [CrossRef]

- Huang, C.; Sakamoto, J.S.; Wolfenstine, J.; Surampudi, S. The Limits of Low-Temperature Performance of Li-Ion Cells. J. Electrochem. Soc. 2000, 147, 2893–2896. [Google Scholar] [CrossRef]

- Smart, M.C.; Ratnakumar, B.V.; Surampudi, S. Electrolytes for Low-Temperature Lithium Batteries Based on Ternary Mixtures of Aliphatic Carbonates. J. Electrochem. Soc. 1999, 146, 486–492. [Google Scholar] [CrossRef]

- Zhang, S.S.; Xu, K.; Jow, T.R. Low temperature performance of graphite electrode in Li-ion cells. Electrochim. Acta 2002, 48, 241–246. [Google Scholar] [CrossRef]

- Ji, Y.; Zhang, Y.; Wang, C.Y. Li-ion cell operation at low temperatures. J. Electrochem. Soc. 2013, 160, 636–649. [Google Scholar] [CrossRef]

- Bugga, R.; Smart, M.; Whitacre, J.; West, W. Lithium ion batteries for space applications. In Proceedings of the 2007 IEEE Aerospace Conference, Big Sky, MT, USA, 3–10 March 2007; pp. 1–7. [Google Scholar]

- Guo, S.; Xiong, R.; Wang, K.; Sun, F. A novel echelon internal heating strategy of cold batteries for all-climate electric vehicles application. Appl. Energy 2018, 219, 256–263. [Google Scholar] [CrossRef]

- Lv, Y.; Yang, X.; Zhang, G.; Li, X. Experimental research on the effective heating strategies for a phase change material based power battery module. Int. J. Heat Mass Transf. 2019, 128, 392–400. [Google Scholar] [CrossRef]

- Rahimi-Eichi, H.; Ojha, U.; Baronti, F.; Chow, M.Y. Battery management system: An overview of its application in the smart grid and electric vehicles. IEEE Ind. Electron. Mag. 2013, 7, 4–16. [Google Scholar] [CrossRef]

- Nizam, M.; Maghfiroh, H.; Rosadi, R.A.; Kirana, D. Battery management system design (BMS) for lithium ion batteries Battery Management System Design (BMS) for Lithium Ion Batteries. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2020; p. 030157. [Google Scholar]

- Lu, L.; Han, X.; Li, J.; Hua, J.; Ouyang, M. A review on the key issues for lithium-ion battery management in electric vehicles. J. Power Sources 2013, 226, 272–288. [Google Scholar] [CrossRef]

- Liu, K.; Li, K.; Peng, Q.; Zhang, C. A brief review on key technologies in the battery management system of electric vehicles. Front. Mech. Eng. 2019, 14, 47–64. [Google Scholar] [CrossRef]

- Sbordone, D.; Bertini, I.; Di Pietra, B.; Falvo, M.C.; Genovese, A.; Martirano, L. EV fast charging stations and energy storage technologies: A real implementation in the smart micro grid paradigm. Electr. Power Syst. Res. 2015, 120, 96–108. [Google Scholar] [CrossRef]

- Tian, H.; Qin, P.; Li, K.; Zhao, Z. A review of the state of health for lithium-ion batteries: Research status and suggestions. J. Clean. Prod. 2020, 261, 120813. [Google Scholar] [CrossRef]

- Varshney, K.; Varshney, P.K.; Gautam, K.; Tanwar, M.; Chaudhary, M. Current trends and future perspectives in the recycling of spent lead acid batteries in India. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Kouchachvili, L.; Yaïci, W.; Entchev, E. Hybrid battery/supercapacitor energy storage system for the electric vehicles. J. Power Sources 2018, 374, 237–248. [Google Scholar] [CrossRef]

- Song, Z.; Li, J.; Hou, J.; Hofmann, H.; Ouyang, M.; Du, J. The battery-supercapacitor hybrid energy storage system in electric vehicle applications: A case study. Energy 2018, 154, 433–441. [Google Scholar] [CrossRef]

- Hannan, M.A.; Hoque, M.M.; Mohamed, A.; Ayob, A. Review of energy storage systems for electric vehicle applications: Issues and challenges. Renew. Sustain. Energy Rev. 2017, 69, 771–789. [Google Scholar] [CrossRef]

- Forse, A.C.; Merlet, C.; Griffin, J.M.; Grey, C.P. New perspectives on the charging mechanisms of supercapacitors. J. Am. Chem. Soc. 2016, 138, 5731–5744. [Google Scholar] [CrossRef] [PubMed]

- Tie, S.F.; Tan, C.W. A review of energy sources and energy management system in electric vehicles. Renew. Sustain. Energy Rev. 2013, 20, 82–102. [Google Scholar] [CrossRef]

- Jinrui, N.; Zhifu, W.; Qinglian, R. Simulation and analysis of performance of a pure electric vehicle with a super-capacitor. In Proceedings of the 2006 IEEE Vehicle Power and Propulsion Conference, Windsor, UK, 6–8 September 2006; pp. 2–7. [Google Scholar] [CrossRef]

- Soni, S.R.; Upadhyay, C.D.; Chandwani, H. Analysis of battery-super capacitor based storage for electrical vehicle. In Proceedings of the 2015 International Conference on Energy Economics and Environment, Noida, India, 27–28 March 2015. [Google Scholar]

- Ostadi, A.; Kazerani, M.; Chen, S.K. Hybrid Energy Storage System (HESS) in vehicular applications: A review on interfacing battery and ultra-capacitor units. In Proceedings of the 2013 IEEE Transportation Electrification Conference and Expo (ITEC), Detroit, MI, USA, 16–19 June 2013. [Google Scholar]

- Valdez-Resendiz, J.E.; Rosas-Caro, J.C.; Mayo-Maldonado, J.C.; Claudio-Sanchez, A.; Ruiz-Martinez, O.; Sanchez, V.M. Improvement of ultracapacitors-energy usage in fuel cell based hybrid electric vehicle. Int. J. Hydrog. Energy 2020. [CrossRef]

- Shen, J.; Dusmez, S.; Khaligh, A. Optimization of sizing and battery cycle life in battery/ultracapacitor hybrid energy storage systems for electric vehicle applications. IEEE Trans. Ind. Inform. 2014, 10, 2112–2121. [Google Scholar] [CrossRef]

- Cao, J.; Emadi, A. A new battery/ultracapacitor hybrid energy storage system for electric, hybrid, and plug-in hybrid electric vehicles. IEEE Trans. Power Electron. 2012, 27, 122–132. [Google Scholar] [CrossRef]

- Debe, M.K. Electrocatalyst approaches and challenges for automotive fuel cells. Nature 2012, 486, 43–51. [Google Scholar] [CrossRef]

- Stephens, I.E.L.; Rossmeisl, J.; Chorkendorff, I. Toward sustainable fuel cells. Science 2016, 354, 1378–1379. [Google Scholar] [CrossRef]

- Priya, K.; Sathishkumar, K.; Rajasekar, N. A comprehensive review on parameter estimation techniques for Proton Exchange Membrane fuel cell modelling. Renew. Sustain. Energy Rev. 2018, 93, 121–144. [Google Scholar] [CrossRef]

- Zhang, G.; Jiao, K. Multi-phase models for water and thermal management of proton exchange membrane fuel cell: A review. J. Power Sources 2018, 391, 120–133. [Google Scholar] [CrossRef]

- Chen, H.; Song, Z.; Zhao, X.; Zhang, T.; Pei, P.; Liang, C. A review of durability test protocols of the proton exchange membrane fuel cells for vehicle. Appl. Energy 2018, 224, 289–299. [Google Scholar] [CrossRef]

- Wang, G.; Yu, Y.; Liu, H.; Gong, C.; Wen, S.; Wang, X.; Tu, Z. Progress on design and development of polymer electrolyte membrane fuel cell systems for vehicle applications: A review. Fuel Process. Technol. 2018, 179, 203–228. [Google Scholar] [CrossRef]

- McNicol, B.D.; Rand, D.A.J.; Williams, K.R. Fuel cells for road transportation purposes—Yes or no? J. Power Sources 2001, 100, 47–59. [Google Scholar] [CrossRef]

- Li, W.; Long, R.; Chen, H.; Chen, F.; Zheng, X.; He, Z.; Zhang, L. Willingness to pay for hydrogen fuel cell electric vehicles in China: A choice experiment analysis. Int. J. Hydrog. Energy 2020, in press. [Google Scholar] [CrossRef]

- Khaligh, A.; Li, Z. Battery, ultracapacitor, fuel cell, and hybrid energy storage systems for electric, hybrid electric, fuel cell, and plug-in hybrid electric vehicles: State of the art. IEEE Trans. Veh. Technol. 2010, 59, 2806–2814. [Google Scholar] [CrossRef]

- Sulaiman, N.; Hannan, M.A.; Mohamed, A.; Majlan, E.H.; Wan Daud, W.R. A review on energy management system for fuel cell hybrid electric vehicle: Issues and challenges. Renew. Sustain. Energy Rev. 2015, 52, 802–814. [Google Scholar] [CrossRef]

- Lü, X.; Wu, Y.; Lian, J.; Zhang, Y.; Chen, C.; Wang, P.; Meng, L. Energy management of hybrid electric vehicles: A review of energy optimization of fuel cell hybrid power system based on genetic algorithm. Energy Convers. Manag. 2020, 205, 112474. [Google Scholar] [CrossRef]

- Fu, Z.; Li, Z.; Si, P.; Tao, F. A hierarchical energy management strategy for fuel cell/battery/supercapacitor hybrid electric vehicles. Int. J. Hydrog. Energy 2019, 44, 22146–22159. [Google Scholar] [CrossRef]

- Haegel, N.M.; Atwater, H.; Barnes, T.; Breyer, C.; Burrell, A.; Chiang, Y.-M.; De Wolf, S.; Dimmler, B.; Feldman, D.; Glunz, S.; et al. Terawatt-scale photovoltaics: Transform global energy. Science 2019, 364, 836–838. [Google Scholar] [CrossRef] [PubMed]

- Richardson, D.B. Electric vehicles and the electric grid: A review of modeling approaches, Impacts, and renewable energy integration. Renew. Sustain. Energy Rev. 2013, 19, 247–254. [Google Scholar] [CrossRef]

- Schey, S.; Scoffield, D.; Smart, J. A first look at the impact of electric vehicle charging on the electric grid in the EV project. World Electr. Veh. J. 2012, 5, 667–678. [Google Scholar] [CrossRef]

- Corchero, C.; Sanmarti, M. Vehicle-to-Everything (V2X): Benefits and barriers. In Proceedings of the 2018 15th International Conference on the European Energy Market (EEM), Lodz, Poland, 27–29 June 2018; pp. 1–4. [Google Scholar]

- Services, V. Fault Tolerant Boost Converter with Multiple Serial. Energies 2020, 13, 1694. [Google Scholar]

- Ye, B.; Jiang, J.; Miao, L.; Yang, P.; Li, J.; Shen, B. Feasibility study of a solar-powered electric vehicle charging station model. Energies 2015, 8, 13265–13283. [Google Scholar] [CrossRef]

- Tulpule, P.J.; Marano, V.; Yurkovich, S.; Rizzoni, G. Economic and environmental impacts of a PV powered workplace parking garage charging station. Appl. Energy 2013, 108, 323–332. [Google Scholar] [CrossRef]

- Ma, T.; Yang, H.; Lu, L. A feasibility study of a stand-alone hybrid solar-wind-battery system for a remote island. Appl. Energy 2014, 121, 149–158. [Google Scholar] [CrossRef]

- Vermaak, H.J.; Kusakana, K. Design of a photovoltaic-wind charging station for small electric Tuk-tuk in DR Congo. Renew. Energy 2014, 67, 40–45. [Google Scholar] [CrossRef]

- Nunes, P.; Farias, T.; Brito, M.C. Day charging electric vehicles with excess solar electricity for a sustainable energy system. Energy 2015, 80, 263–274. [Google Scholar] [CrossRef]

- Coffman, M.; Bernstein, P.; Wee, S. Integrating electric vehicles and residential solar PV. Transp. Policy 2017, 53, 30–38. [Google Scholar] [CrossRef]

- Ghotge, R.; Snow, Y.; Farahani, S.; Lukszo, Z.; van Wijk, A. Optimized scheduling of EV charging in solar parking lots for local peak reduction under EV demand uncertainty. Energies 2020, 13, 1275. [Google Scholar] [CrossRef]

- Khan, S.; Ahmad, A.; Ahmad, F.; Shafaati Shemami, M.; Saad Alam, M.; Khateeb, S. A Comprehensive Review on Solar Powered Electric Vehicle Charging System. Smart Sci. 2018, 6, 54–79. [Google Scholar] [CrossRef]

- Esfandyari, A.; Norton, B.; Conlon, M.; McCormack, S.J. Performance of a campus photovoltaic electric vehicle charging station in a temperate climate. Sol. Energy 2019, 177, 762–771. [Google Scholar] [CrossRef]

- Van Roy, J.; Leemput, N.; Geth, F.; Salebien, R.; Buscher, J.; Driesen, J. Operational Electric Vehicle Charging Strategies. IEEE Trans. Sustain. Energy 2014, 5, 264–272. [Google Scholar] [CrossRef]

- Islam, M.S.; Mithulananthan, N. PV based EV charging at universities using supplied historical PV output ramp. Renew. Energy 2018, 118, 306–327. [Google Scholar] [CrossRef]

- Fattori, F.; Anglani, N.; Muliere, G. Combining photovoltaic energy with electric vehicles, smart charging and vehicle-to-grid. Sol. Energy 2014, 110, 438–451. [Google Scholar] [CrossRef]

- Yukita, K.; Kobayashi, Y.; Duy-Dinh, N.; Matsumura, T.; Goto, Y. Suppression of PV output fluctuation using EV in a electric power system. IFAC Pap. 2019, 52, 93–98. [Google Scholar] [CrossRef]

- Chandra Mouli, G.R.; Bauer, P.; Zeman, M. System design for a solar powered electric vehicle charging station for workplaces. Appl. Energy 2016, 168, 434–443. [Google Scholar] [CrossRef]

- Igualada, L.; Corchero, C.; Cruz-Zambrano, M.; Heredia, F.J. Optimal energy management for a residential microgrid including a vehicle-to-grid system. IEEE Trans. Smart Grid 2014, 5, 2163–2172. [Google Scholar] [CrossRef]

- Kramer, B.; Chakraborty, S.; Kroposki, B. A Review of Plug-in Vehicles and Vehicle-to-Grid Capability. In Proceedings of the 2008 34th Annual Conference of IEEE Industrial Electronics, Orlando, FL, USA, 10–13 November 2008; pp. 2278–2283. [Google Scholar]

- Ehsani, M.; Falahi, M.; Lotfifard, S. Vehicle to grid services: Potential and applications. Energies 2012, 5, 4076–4090. [Google Scholar] [CrossRef]

- Sharma, A.; Sharma, S. Review of power electronics in vehicle-to-grid systems. J. Energy Storage 2019, 21, 337–361. [Google Scholar] [CrossRef]

- Barone, G.; Buonomano, A.; Calise, F.; Forzano, C.; Palombo, A. Building to vehicle to building concept toward a novel zero energy paradigm: Modelling and case studies. Renew. Sustain. Energy Rev. 2019, 101, 625–648. [Google Scholar] [CrossRef]

- Khan, A.; Memon, S.; Sattar, T. Integration and management of solar energy for electric vehicle charging station. In Solar World Congress 2017-Innovation for the 100% Renewable Energy Transformation; London South Bank University: London, UK, 2017; pp. 943–953. [Google Scholar] [CrossRef]

- Torreglosa, J.P.; García-Triviño, P.; Fernández-Ramirez, L.M.; Jurado, F. Decentralized energy management strategy based on predictive controllers for a medium voltage direct current photovoltaic electric vehicle charging station. Energy Convers. Manag. 2016, 108, 1–13. [Google Scholar] [CrossRef]

- Kineavy, F.; Duffy, M. Modelling and design of electric vehicle charging systems that include on-site renewable energy sources. In Proceedings of the 2014 IEEE 5th International Symposium on Power Electronics for Distributed Generation Systems (PEDG), Galway, Ireland, 24–27 June 2014; pp. 1–8. [Google Scholar] [CrossRef]

- Chandra Mouli, G.R.; Schijffelen, J.; Van Den Heuvel, M.; Kardolus, M.; Bauer, P. A 10 kW Solar-Powered Bidirectional EV Charger Compatible with Chademo and COMBO. IEEE Trans. Power Electron. 2019, 34, 1082–1098. [Google Scholar] [CrossRef]

- Birnie, D.P. Solar-to-vehicle (S2V) systems for powering commuters of the future. J. Power Sources 2009, 186, 539–542. [Google Scholar] [CrossRef]

- Kronthaler, L.; Maturi, L.; Moser, D.; Alberti, L. Vehicle-integrated Photovoltaic (ViPV) systems: Energy production, Diesel Equivalent, Payback Time; An assessment screening for trucks and busses. In Proceedings of the 2014 Ninth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte-Carlo, Monaco, 25–27 March 2014. [Google Scholar] [CrossRef]

- Manivannan, S.; Kaleeswaran, E. Solar powered electric vehicle. In Proceedings of the First International Conference on Sustainbale Green buildings and Communities, Chennai, India, 18–20 December 2016; pp. 2–5. [Google Scholar]

- Moro, A.; Lonza, L. Electricity carbon intensity in European Member States: Impacts on GHG emissions of electric vehicles. Transp. Res. Part D Transp. Environ. 2018, 64, 5–14. [Google Scholar] [CrossRef]

- Gómez Vilchez, J.J.; Jochem, P. Powertrain technologies and their impact on greenhouse gas emissions in key car markets. Transp. Res. Part D Transp. Environ. 2020, 80, 102214. [Google Scholar] [CrossRef]

- Manjunath, A.; Gross, G. Towards a meaningful metric for the quantification of GHG emissions of electric vehicles (EVs). Energy Policy 2017, 102, 423–429. [Google Scholar] [CrossRef]

- Kim, I.; Kim, J.; Lee, J. Dynamic analysis of well-to-wheel electric and hydrogen vehicles greenhouse gas emissions: Focusing on consumer preferences and power mix changes in South Korea. Appl. Energy 2020, 260, 114281. [Google Scholar] [CrossRef]

- Gupta, P.; Tong, D.; Wang, J.; Zhuge, W.; Yan, C.; Wu, Y.; Luo, S.; He, X.; Ma, F. Well-to-wheels total energy and GHG emissions of HCNG heavy-duty vehicles in China: Case of EEV qualified EURO 5 emissions scenario. Int. J. Hydrog. Energy 2020, 45, 8002–8014. [Google Scholar] [CrossRef]

- Winyuchakrit, P.; Sukamongkol, Y.; Limmeechokchai, B. Do Electric Vehicles Really Reduce GHG Emissions in Thailand? Energy Procedia 2017, 138, 348–353. [Google Scholar] [CrossRef]

- Ma, H.; Balthasar, F.; Tait, N.; Riera-Palou, X.; Harrison, A. A new comparison between the life cycle greenhouse gas emissions of battery electric vehicles and internal combustion vehicles. Energy Policy 2012, 44, 160–173. [Google Scholar] [CrossRef]

- Abdul-Manan, A.F.N. Uncertainty and differences in GHG emissions between electric and conventional gasoline vehicles with implications for transport policy making. Energy Policy 2015, 87, 1–7. [Google Scholar] [CrossRef]

- Choi, Y.; Rhee, S.-W. Current status and perspectives on recycling of end-of-life battery of electric vehicle in Korea (Republic of). Waste Manag. 2020, 106, 261–270. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhu, D.; Cui, B.; Ding, R.; Shi, X.; He, P. Association between particulate matter air pollution and lung cancer. Thorax 2020, 75, 85–87. [Google Scholar] [CrossRef]

- Jereb, B.; Batkovič, T.; Herman, L.; Šipek, G.; Kovše, Š.; Gregorič, A.; Močnik, G. Exposure to black carbon during bicycle commuting-Alternative route selection. Atmosphere 2018, 9, 21. [Google Scholar] [CrossRef]

- Uherek, E.; Halenka, T.; Borken-Kleefeld, J.; Balkanski, Y.; Berntsen, T.; Borrego, C.; Gauss, M.; Hoor, P.; Juda-Rezler, K.; Lelieveld, J.; et al. Transport impacts on atmosphere and climate: Land transport. Atmos. Environ. 2010, 44, 4772–4816. [Google Scholar] [CrossRef]

- Amato, F.; Cassee, F.R.; Denier van der Gon, H.A.C.; Gehrig, R.; Gustafsson, M.; Hafner, W.; Harrison, R.M.; Jozwicka, M.; Kelly, F.J.; Moreno, T.; et al. Urban air quality: The challenge of traffic non-exhaust emissions. J. Hazard. Mater. 2014, 275, 31–36. [Google Scholar] [CrossRef]

- Timmers, V.R.J.H.; Achten, P.A.J. Non-Exhaust PM Emissions from Battery Electric Vehicles; Elsevier: Amsterdam, The Netherlands, 2018; ISBN 9780128117705. [Google Scholar]

- Milligan, R.; Etxebarria, S.; Muneer, T.; Gago, E.J. Driven performance of electric vehicles in Edinburgh and its environs. Energies 2019, 12, 74. [Google Scholar] [CrossRef]

- Greene, D.L.; Park, S.; Liu, C. Analyzing the transition to electric drive vehicles in the U.S. Futures 2014, 58, 34–52. [Google Scholar] [CrossRef]

- Godina, R.; Rodrigues, E.M.G.; Paterakis, N.G.; Erdinc, O.; Catalão, J.P.S. Innovative impact assessment of electric vehicles charging loads on distribution transformers using real data. Energy Convers. Manag. 2016, 120, 206–216. [Google Scholar] [CrossRef]

- Guo, C.; Chan, C.C. Analysis method and utilization mechanism of the overall value of EV charging. Energy Convers. Manag. 2015, 89, 420–426. [Google Scholar] [CrossRef][Green Version]

- Ronanki, D.; Kelkar, A.; Williamson, S.S. Extreme fast charging technology—Prospects to enhance sustainable electric transportation. Energies 2019, 12, 3721. [Google Scholar] [CrossRef]

- Haddadian, G.; Khodayar, M.; Shahidehpour, M. Accelerating the Global Adoption of Electric Vehicles: Barriers and Drivers. Electr. J. 2015, 28, 53–68. [Google Scholar] [CrossRef]

- Zarazua de Rubens, G. Who will buy electric vehicles after early adopters? Using machine learning to identify the electric vehicle mainstream market. Energy 2019, 172, 243–254. [Google Scholar] [CrossRef]

- Prakash, N.; Kapoor, R.; Kapoor, A.; Malik, Y. Gender Preferences for Alternative Energy Transport with Focus on Electric Vehicle. J. Soc. Sci. 2014, 10, 114–122. [Google Scholar] [CrossRef]

- Hackbarth, A.; Madlener, R. Consumer preferences for alternative fuel vehicles: A discrete choice analysis. Transp. Res. Part D Transp. Environ. 2013, 25, 5–17. [Google Scholar] [CrossRef]

- Hidrue, M.K.; Parsons, G.R.; Kempton, W.; Gardner, M.P. Willingness to pay for electric vehicles and their attributes. Resour. Energy Econ. 2011, 33, 686–705. [Google Scholar] [CrossRef]

- Carley, S.; Krause, R.M.; Lane, B.W.; Graham, J.D. Intent to purchase a plug-in electric vehicle: A survey of early impressions in large US cites. Transp. Res. Part D Transp. Environ. 2013, 18, 39–45. [Google Scholar] [CrossRef]

- Plötz, P.; Schneider, U.; Globisch, J.; Dütschke, E. Who will buy electric vehicles? Identifying early adopters in Germany. Transp. Res. Part A Policy Pract. 2014, 67, 96–109. [Google Scholar] [CrossRef]

- Egbue, O.; Long, S. Barriers to widespread adoption of electric vehicles: An analysis of consumer attitudes and perceptions. Energy Policy 2012, 48, 717–729. [Google Scholar] [CrossRef]

- Vassileva, I.; Campillo, J. Adoption barriers for electric vehicles: Experiences from early adopters in Sweden. Energy 2017, 120, 632–641. [Google Scholar] [CrossRef]

- Wolf, A.; Seebauer, S. Technology adoption of electric bicycles: A survey among early adopters. Transp. Res. Part A Policy Pract. 2014, 69, 196–211. [Google Scholar] [CrossRef]

- Axsen, J.; Goldberg, S.; Bailey, J. How might potential future plug-in electric vehicle buyers differ from current “Pioneer” owners? Transp. Res. Part D Transp. Environ. 2016, 47, 357–370. [Google Scholar] [CrossRef]

- Lieven, T.; Mühlmeier, S.; Henkel, S.; Waller, J.F. Who will buy electric cars? An empirical study in Germany. Transp. Res. Part D Transp. Environ. 2011, 16, 236–243. [Google Scholar] [CrossRef]

- Graabak, I.; Wu, Q.; Warland, L.; Liu, Z. Optimal planning of the Nordic transmission system with 100% electric vehicle penetration of passenger cars by 2050. Energy 2016, 107, 648–660. [Google Scholar] [CrossRef]

- Campbell, A.R.; Ryley, T.; Thring, R. Identifying the early adopters of alternative fuel vehicles: A case study of Birmingham, United Kingdom. Transp. Res. Part A Policy Pract. 2012, 46, 1318–1327. [Google Scholar] [CrossRef]

- Hardman, S.; Shiu, E.; Steinberger-Wilckens, R. Comparing high-end and low-end early adopters of battery electric vehicles. Transp. Res. Part A Policy Pract. 2016, 88, 40–57. [Google Scholar] [CrossRef]

- Bjerkan, K.Y.; Nørbech, T.E.; Nordtømme, M.E. Incentives for promoting Battery Electric Vehicle (BEV) adoption in Norway. Transp. Res. Part D Transp. Environ. 2016, 43, 169–180. [Google Scholar] [CrossRef]

- Erdem, C.; Şentürk, I.; Şimşek, T. Identifying the factors affecting the willingness to pay for fuel-efficient vehicles in Turkey: A case of hybrids. Energy Policy 2010, 38, 3038–3043. [Google Scholar] [CrossRef]

- Li, X.; Clark, C.D.; Jensen, K.L.; Yen, S.T.; English, B.C. Consumer purchase intentions for flexible-fuel and hybrid-electric vehicles. Transp. Res. Part D Transp. Environ. 2013, 18, 9–15. [Google Scholar] [CrossRef]

- Skippon, S.M.; Kinnear, N.; Lloyd, L.; Stannard, J. How experience of use influences mass-market drivers’ willingness to consider a battery electric vehicle: A randomised controlled trial. Transp. Res. Part A Policy Pract. 2016, 92, 26–42. [Google Scholar] [CrossRef]

- Travesset-Baro, O.; Rosas-Casals, M.; Jover, E. Transport energy consumption in mountainous roads. A comparative case study for internal combustion engines and electric vehicles in Andorra. Transp. Res. Part D Transp. Environ. 2015, 34, 16–26. [Google Scholar] [CrossRef]

- Melliger, M.A.; van Vliet, O.P.R.; Liimatainen, H. Anxiety vs reality—Sufficiency of battery electric vehicle range in Switzerland and Finland. Transp. Res. Part D Transp. Environ. 2018, 65, 101–115. [Google Scholar] [CrossRef]

- Li, W.; Long, R.; Chen, H.; Geng, J. A review of factors influencing consumer intentions to adopt battery electric vehicles. Renew. Sustain. Energy Rev. 2017, 78, 318–328. [Google Scholar] [CrossRef]

- Nian, V.; Hari, M.P.; Yuan, J. A new business model for encouraging the adoption of electric vehicles in the absence of policy support. Appl. Energy 2019, 235, 1106–1117. [Google Scholar] [CrossRef]

- Zhang, Y.; Yu, Y.; Zou, B. Analyzing public awareness and acceptance of alternative fuel vehicles in China: The case of EV. Energy Policy 2011, 39, 7015–7024. [Google Scholar] [CrossRef]

- Sang, Y.N.; Bekhet, H.A. Modelling electric vehicle usage intentions: An empirical study in Malaysia. J. Clean. Prod. 2015, 92, 75–83. [Google Scholar] [CrossRef]

- Helveston, J.P.; Liu, Y.; Feit, E.M.D.; Fuchs, E.; Klampfl, E.; Michalek, J.J. Will subsidies drive electric vehicle adoption? Measuring consumer preferences in the U.S. and China. Transp. Res. Part A Policy Pract. 2015, 73, 96–112. [Google Scholar] [CrossRef]

- Naumanen, M.; Uusitalo, T.; Huttunen-Saarivirta, E.; van der Have, R. Development strategies for heavy duty electric battery vehicles: Comparison between China, EU, Japan and USA. Resour. Conserv. Recycl. 2019, 151, 104413. [Google Scholar] [CrossRef]

- IEA. Global EV Outlook 2019; IEA: Paris, France, 2019. [Google Scholar]

| Storage System | Energy Density (Wh/kg) | Power Density (W/kg) | Energy Efficiency (%) |

|---|---|---|---|

| Lead–acid | 20–35 | 25 | 70–80 |

| NiCd | 40–60 | 140 | 60 |

| NiMh | 60–80 | 220 | 50–80 |

| Li-ion | 100–270 | 300–2000 | 85–95 |

| Li-polymer | 100–200 | 300–1000 | 70 |

| Super capacitor | 25–75 | 5000–20,000 | 90+ |

| Country | Target (Published in 2010 [30]) | 2020 Present Status | Target for 2050 |

|---|---|---|---|

| Austria | 2020: 100,000 EVs deployed | 2018: ~25,000 2020: in Feb 6.7% EV sales | |

| Australia | 2012: first cars on road, 2018: mass deployment, 2050: up to 65% of car stock | 2019:1277 EVs sold 2018: 670 EVs sold | 2030: 50% of new cars to be EVs |

| Canada | 2018: 500,000 EVs deployed | 2019: 93,091 EVs on the road, EV sales grew by 125% compared to 2017 | New light-duty zero-emission vehicle sales by 2025: 10%; 2030: 30%; 2040: 100% |

| China | 2011: 500,000 annual production of EVs | 2011: 8159 EVs and in 2015, 331,092 EVs were sold. 2020: 15,000 EV charging stations to accommodate 5 million EVs | 2400: 40% global EV sales |

| Denmark | 2020: 200,000 EVs | 2019: 4618 BEVs and 3623 PHEVs are sold. | 2050: Transport sector will be independent of fossil fuel |

| France | 2020: 2,000,000 EVs | 2018: 2% sold card was either a PHEV or a BEV | 2040: ban on fossil fuel car and Paris will follow this from 2030. |

| Germany | 2020: 1,000,000 EVs deployed | 2019: 24,000 public charging stations | 2030: 1 million charging stations |

| Ireland | 2020: 10% EV market share | 2019: 4825 EVs on the road and another 4054 were registered | 2030: 1 million EVs |

| Israel | 2011: 40,000 EVs, 2012: 40,000 to 100,000 EVs | 2025: 177,000 EVs on road | 2030: full switch to EV |

| Japan | 2020: 50% market share of next generation vehicles | 2017: EVs account for 0.4% of market share | 2030: 20-30% BEV and PHEV market share |

| New Zealand | 2020: 5% market share, 2040: 60% market share | 2021: 64,000 electric vehicles | 2030: EVS constituting100% of new vehicles 2050: 100% all lightweight vehicles are EV |

| Spain | 2014: 1,000,000 EVs deployed | 2018: 8000 EVs | 2040: Banning of diesel, gasoline, hybrid vehicles sale 2050: Permanent ban |

| Sweden | 2020: 600,000 EVs deployed | 2019: PHEVs account for 11% of market share | 2030: Halt fossil fuel car 2045: carbon neutral |

| UK | No target figures, but policy to support EVs | Transport sector accounts 27%GHG emission | Zero emission |

| USA | 2015: 1,000,000 PHEV stock | 2011: 9750 EVs were sold 2015: 71,044 EVs were sold | Los Angeles targets 100% EVs |

| Country | Subsidy |

|---|---|

| Austria |

|

| Australia |

|

| Canada |

|

| China |

|

| Denmark |

|

| France |

|

| Germany |

|

| Ireland |

|

| Israel | |

| Japan |

|

| New Zealand |

|

| Spain |

|

| Sweden |

|

| South Korea |

|

| UK |

|

| USA |

|

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghosh, A. Possibilities and Challenges for the Inclusion of the Electric Vehicle (EV) to Reduce the Carbon Footprint in the Transport Sector: A Review. Energies 2020, 13, 2602. https://doi.org/10.3390/en13102602

Ghosh A. Possibilities and Challenges for the Inclusion of the Electric Vehicle (EV) to Reduce the Carbon Footprint in the Transport Sector: A Review. Energies. 2020; 13(10):2602. https://doi.org/10.3390/en13102602

Chicago/Turabian StyleGhosh, Aritra. 2020. "Possibilities and Challenges for the Inclusion of the Electric Vehicle (EV) to Reduce the Carbon Footprint in the Transport Sector: A Review" Energies 13, no. 10: 2602. https://doi.org/10.3390/en13102602

APA StyleGhosh, A. (2020). Possibilities and Challenges for the Inclusion of the Electric Vehicle (EV) to Reduce the Carbon Footprint in the Transport Sector: A Review. Energies, 13(10), 2602. https://doi.org/10.3390/en13102602