Erosion Characteristics and the Corresponding Self-Resonating Oscillations of Cavitating Jet on Oblique Surfaces

Abstract

1. Introduction

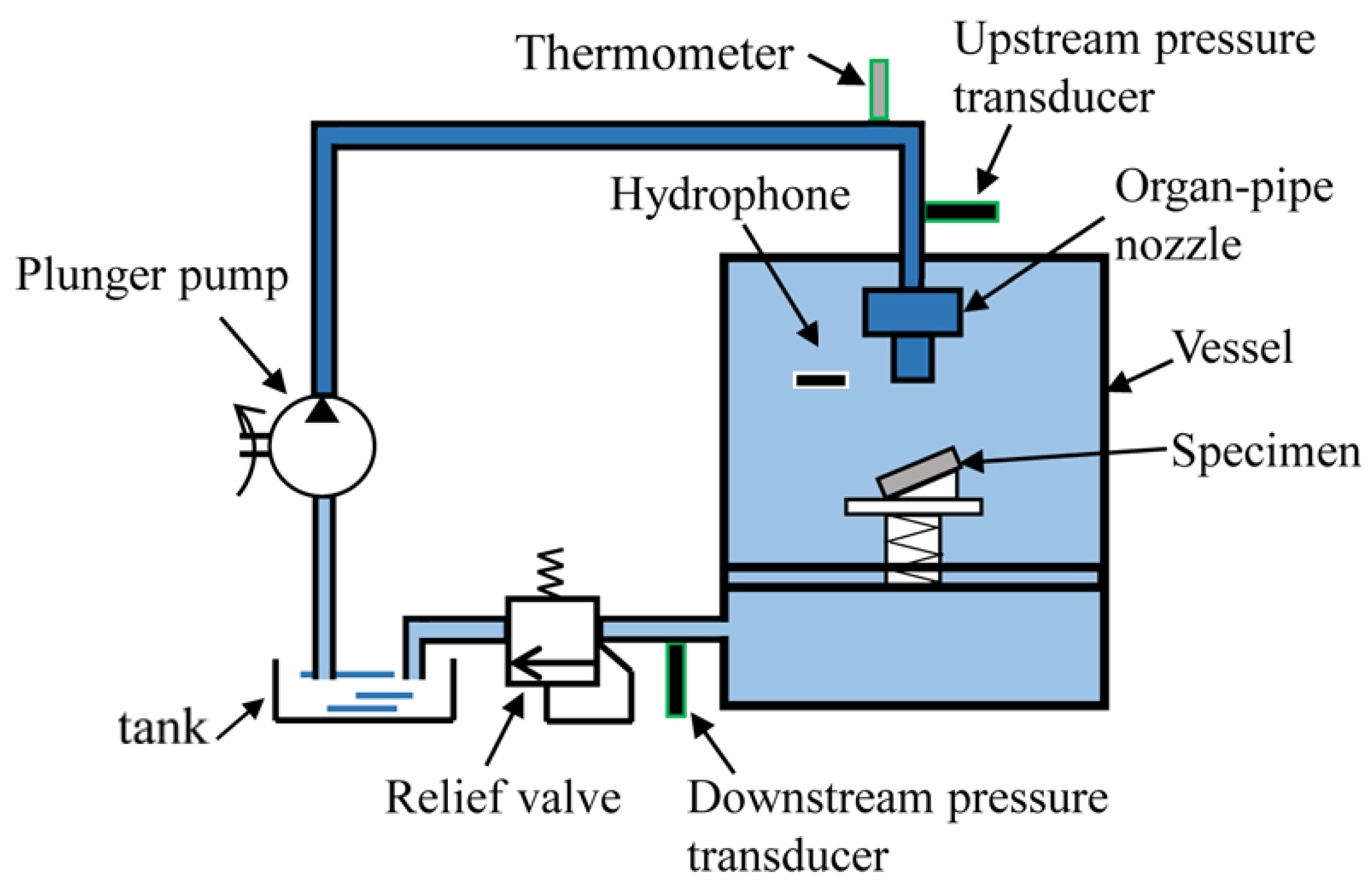

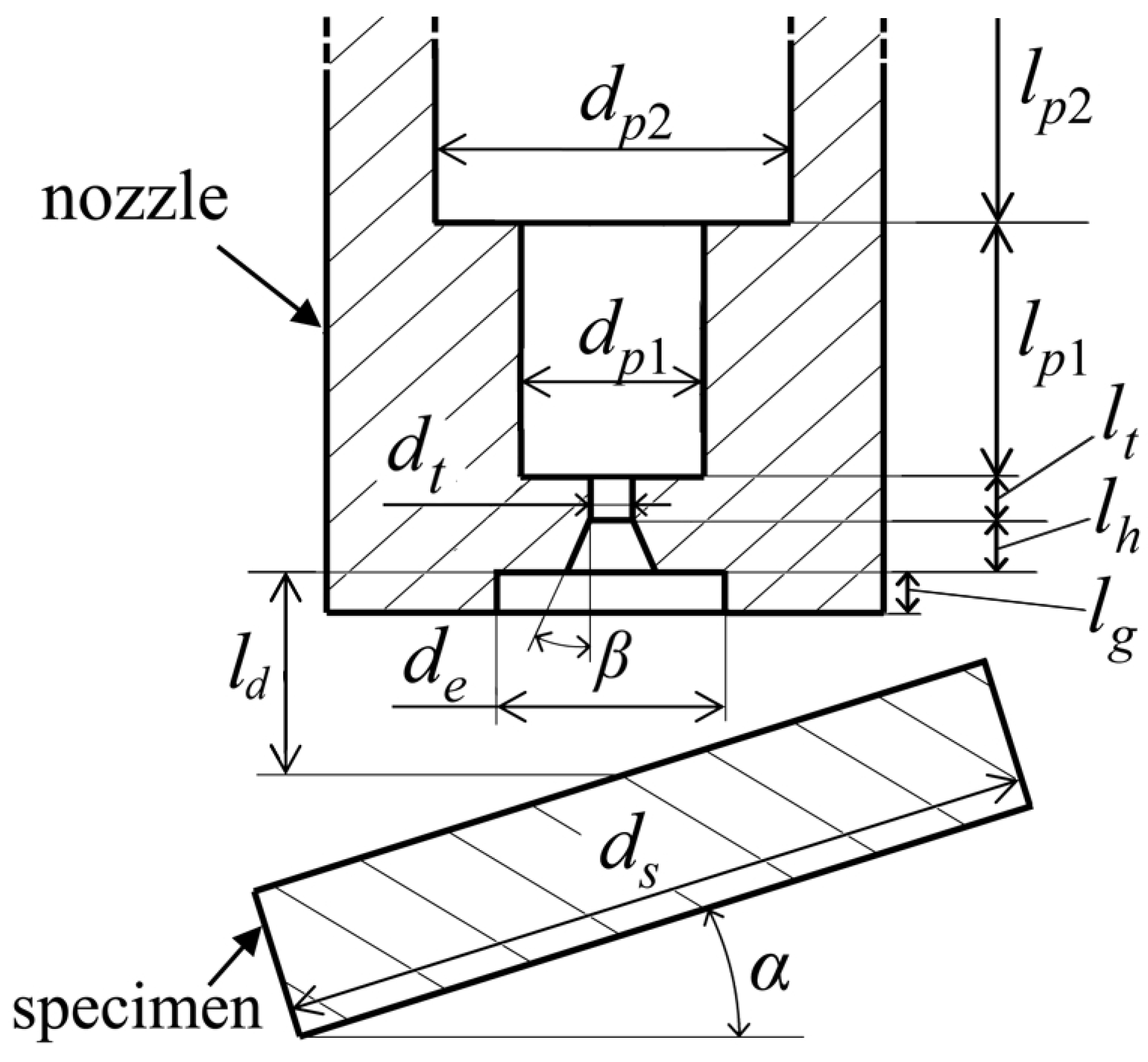

2. Experimental Setup

2.1. Cavitating Jet Apparatus

2.2. Erosion Measurement

3. Results and Discussion

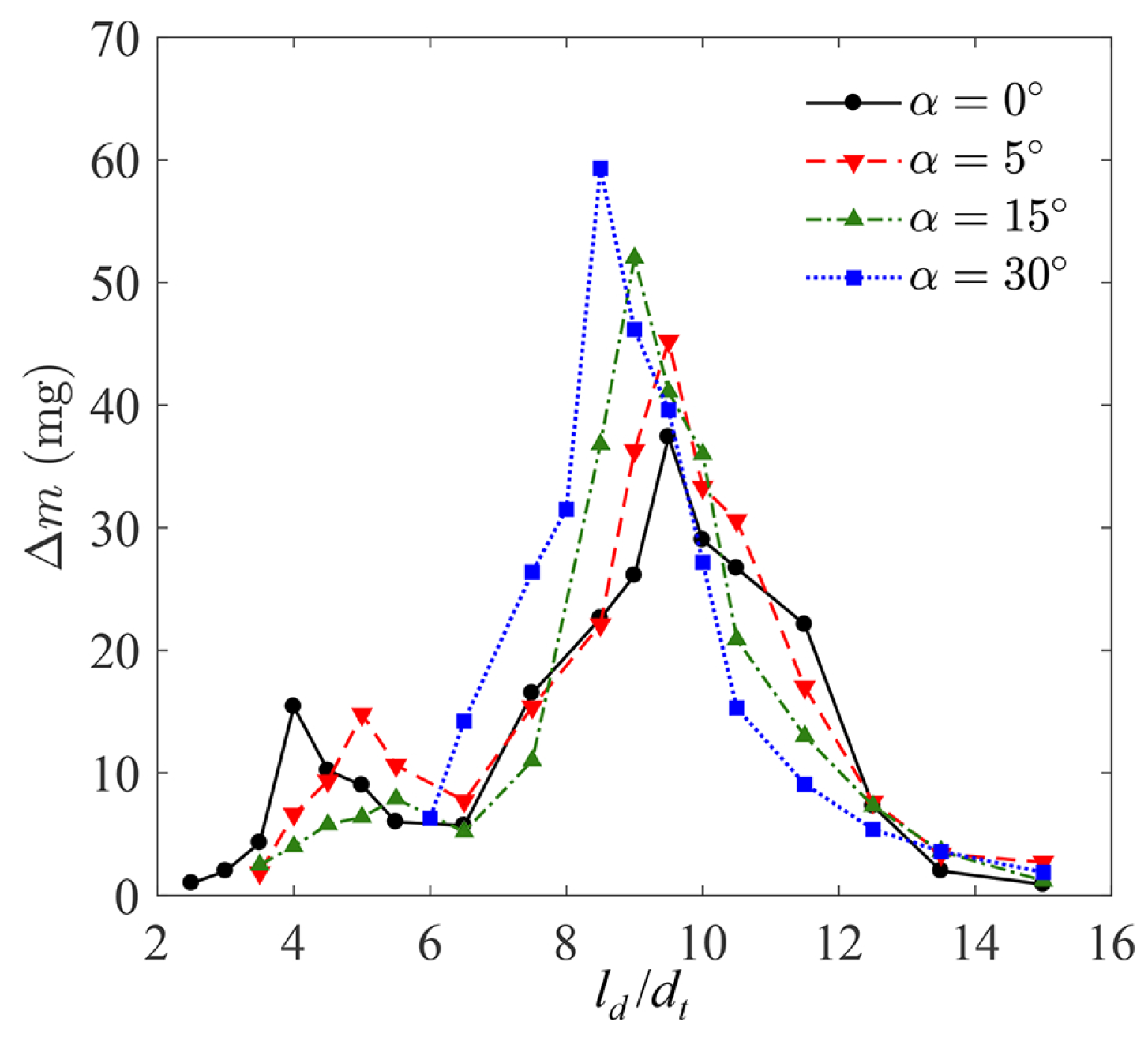

3.1. Mass Loss

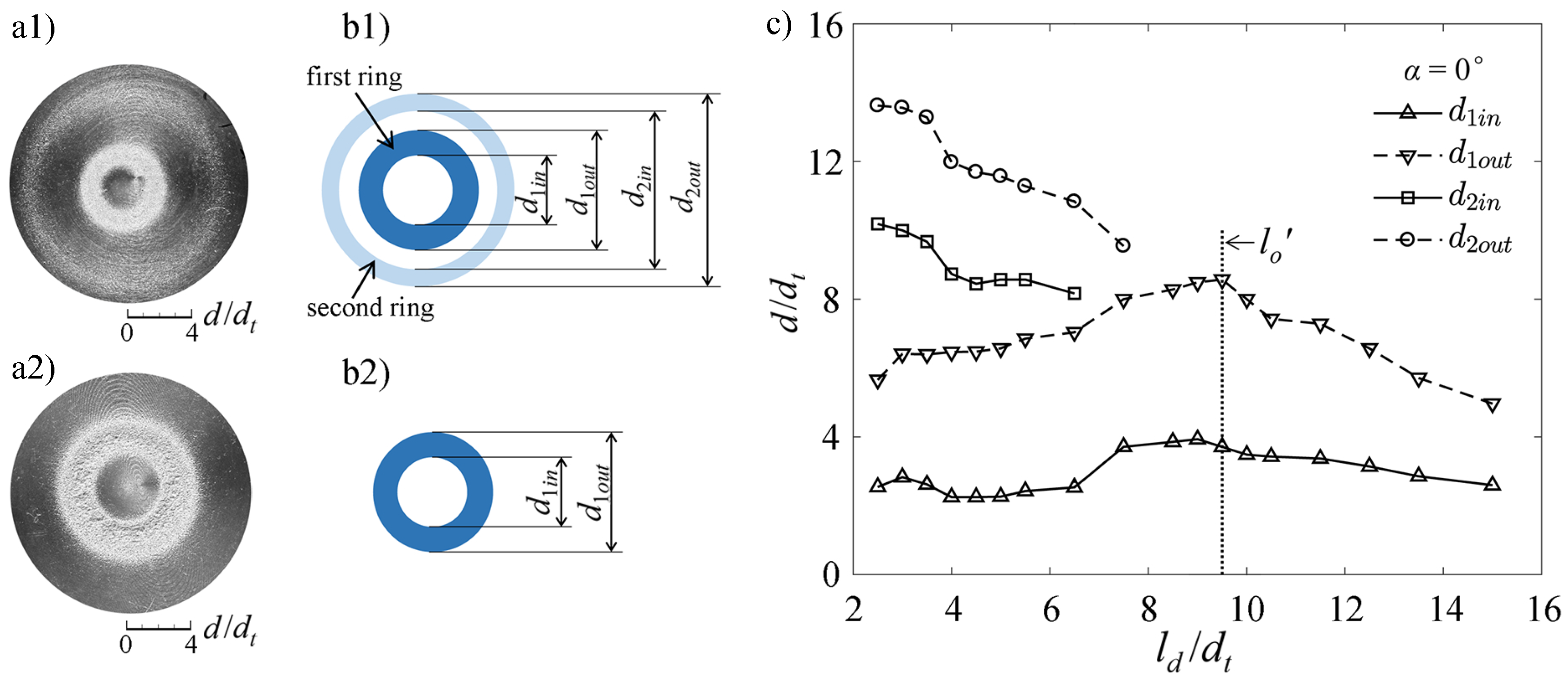

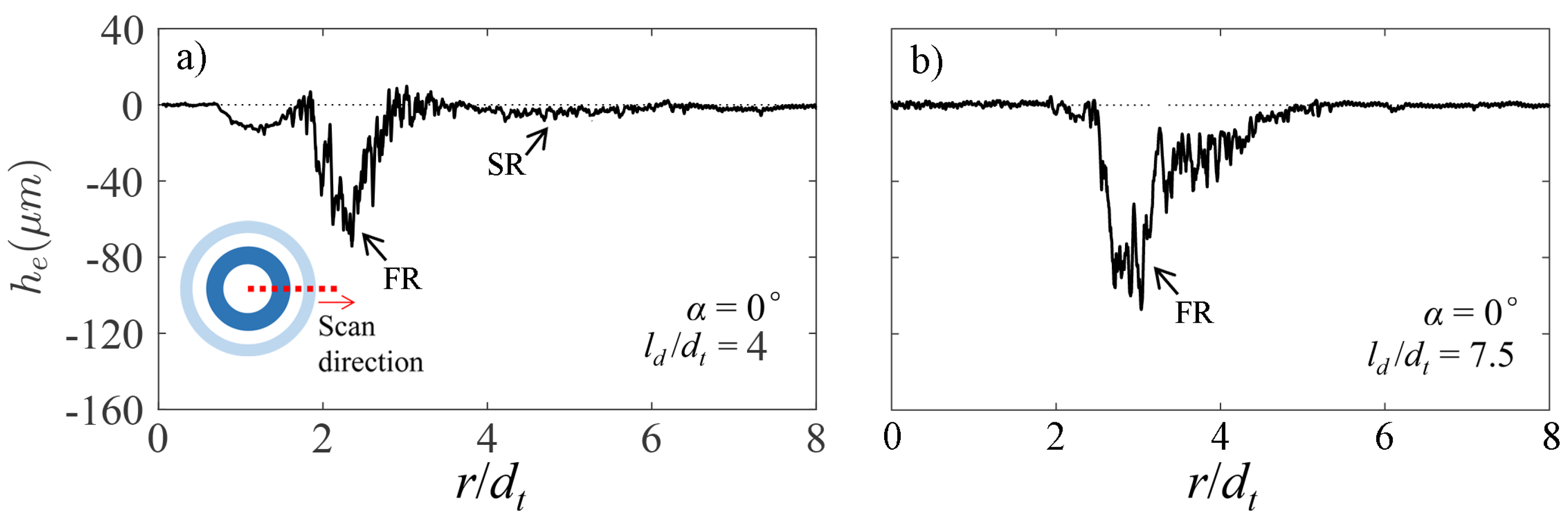

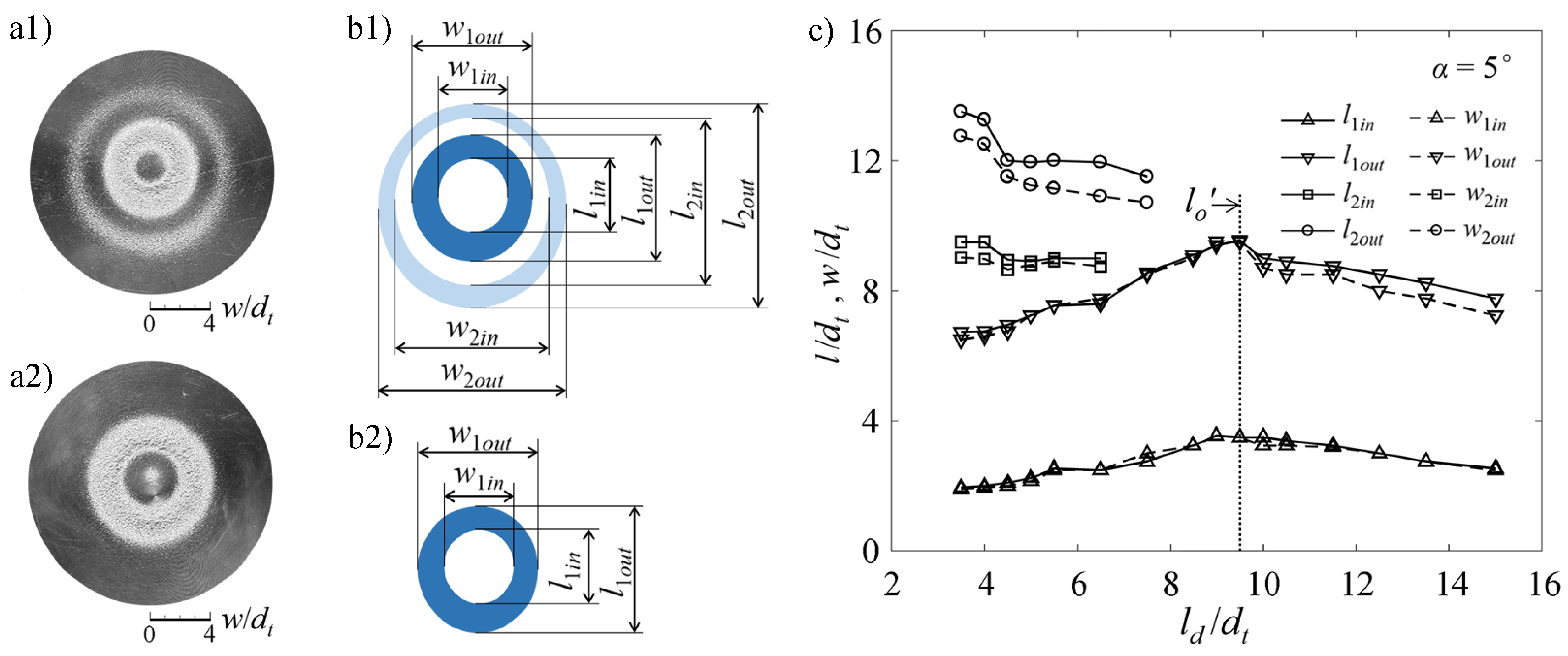

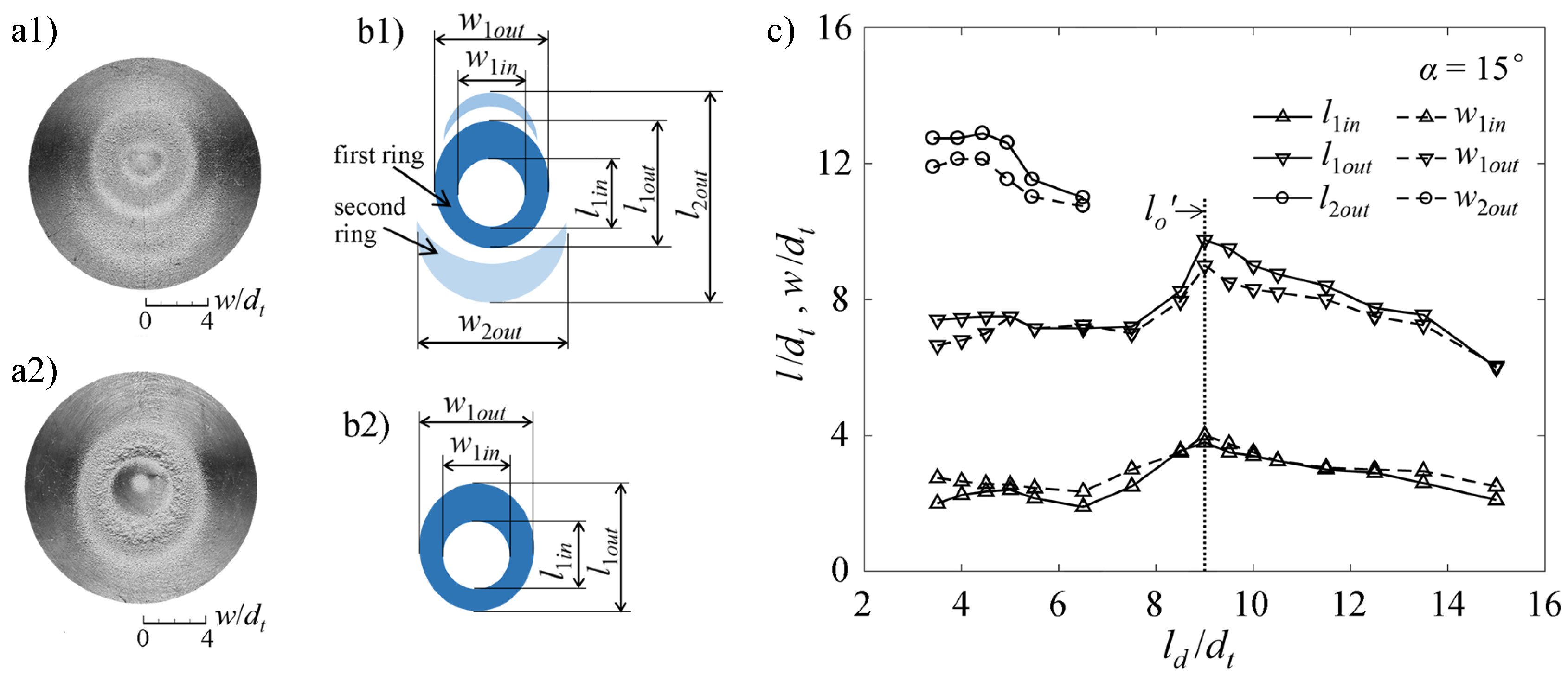

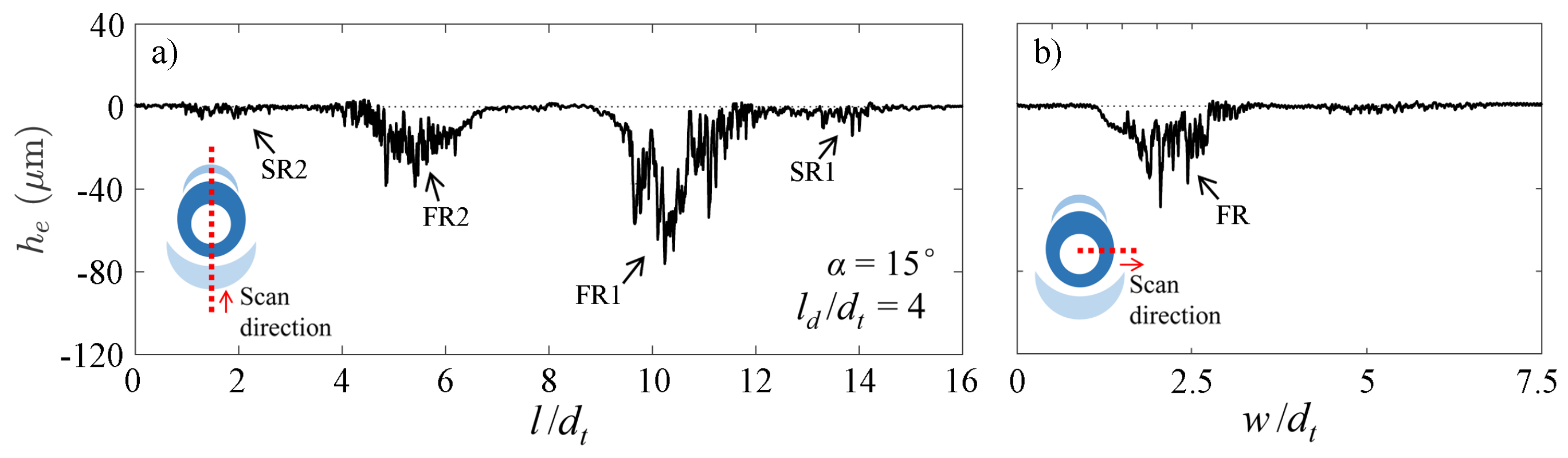

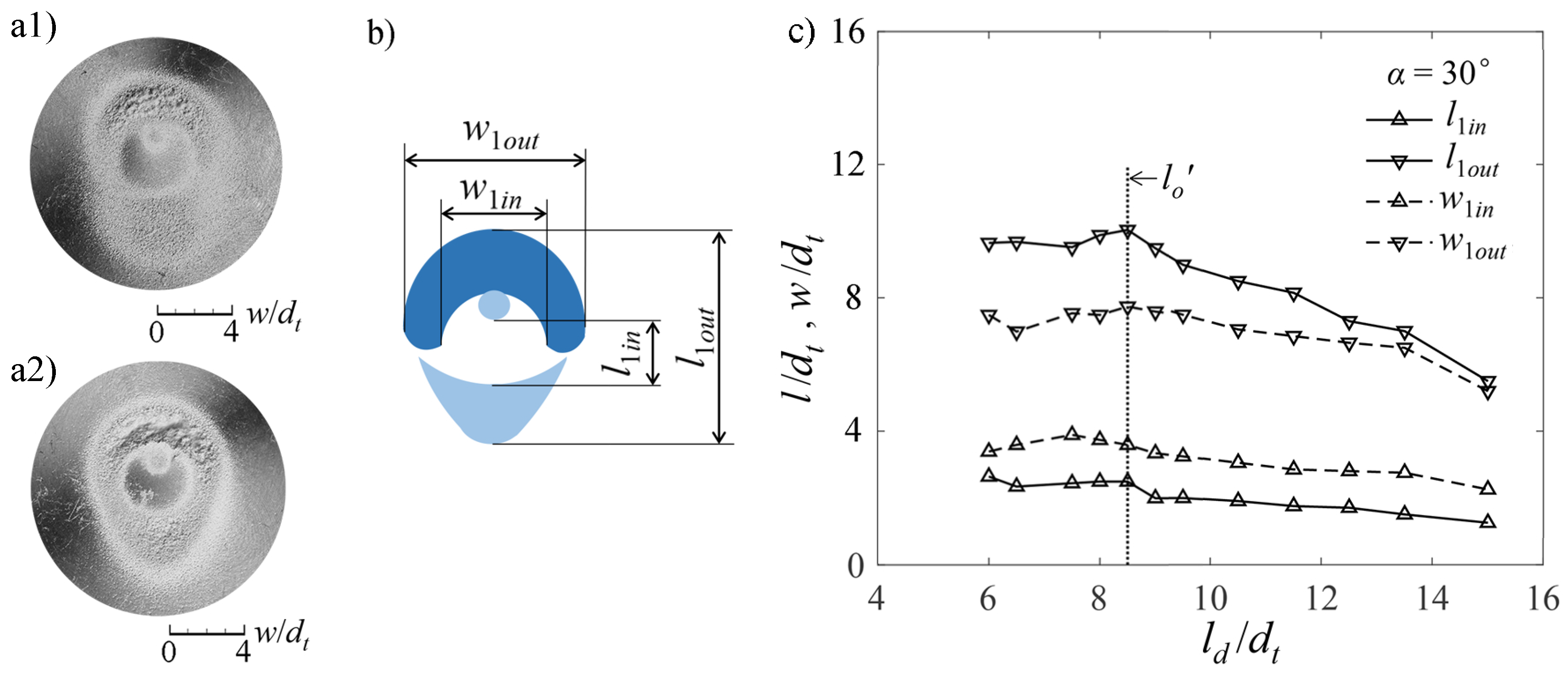

3.2. Erosion Characteristics

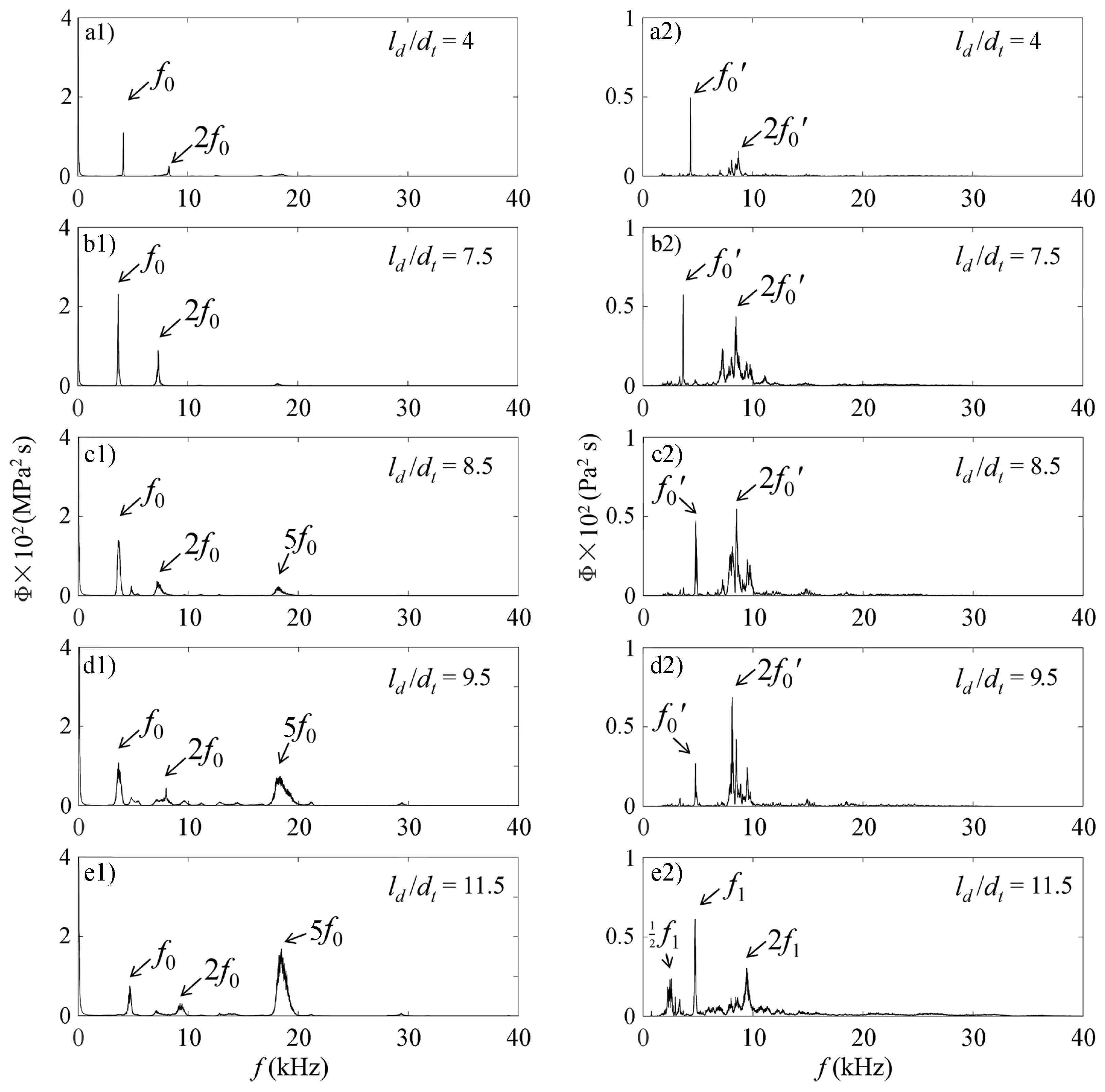

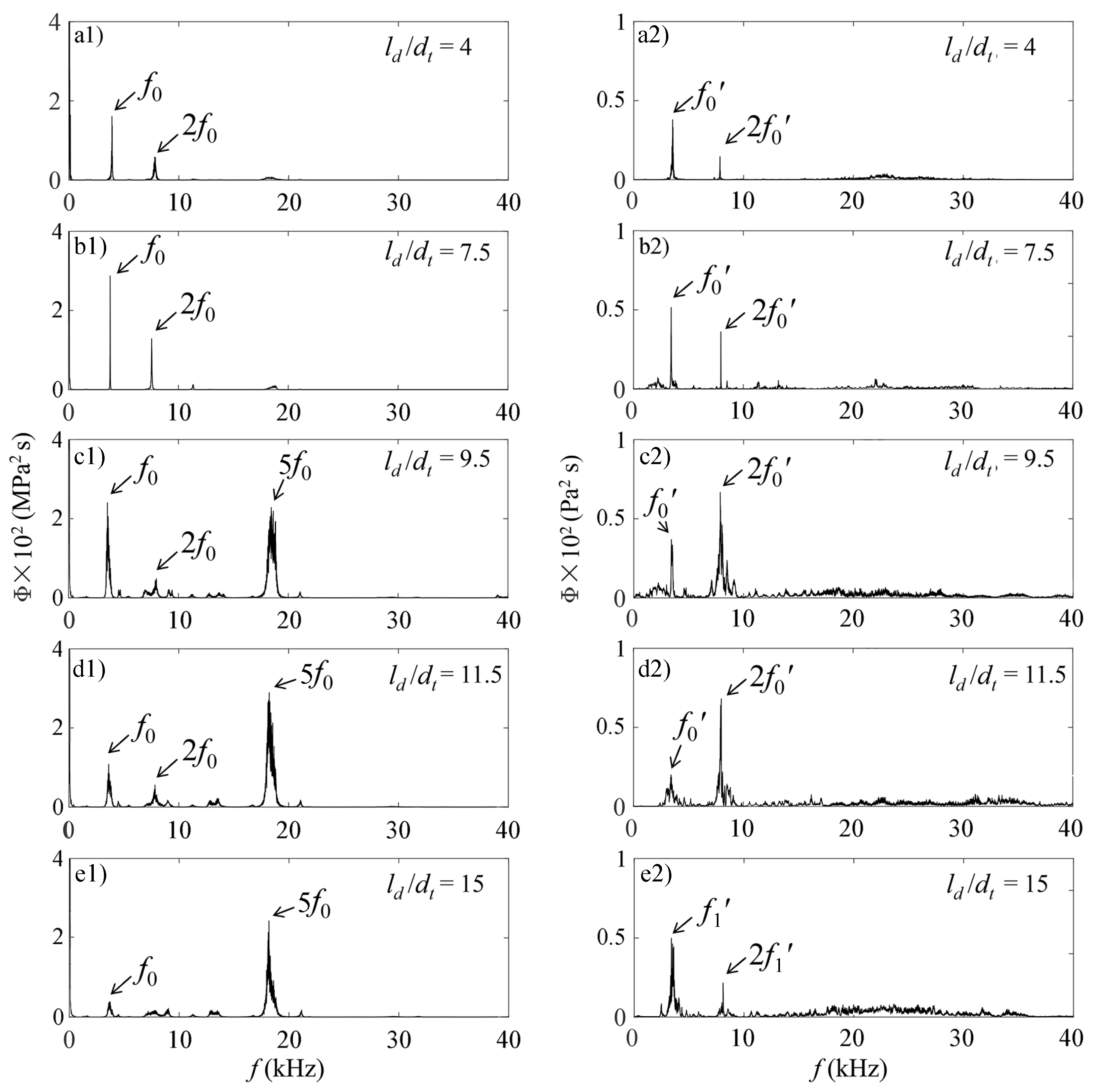

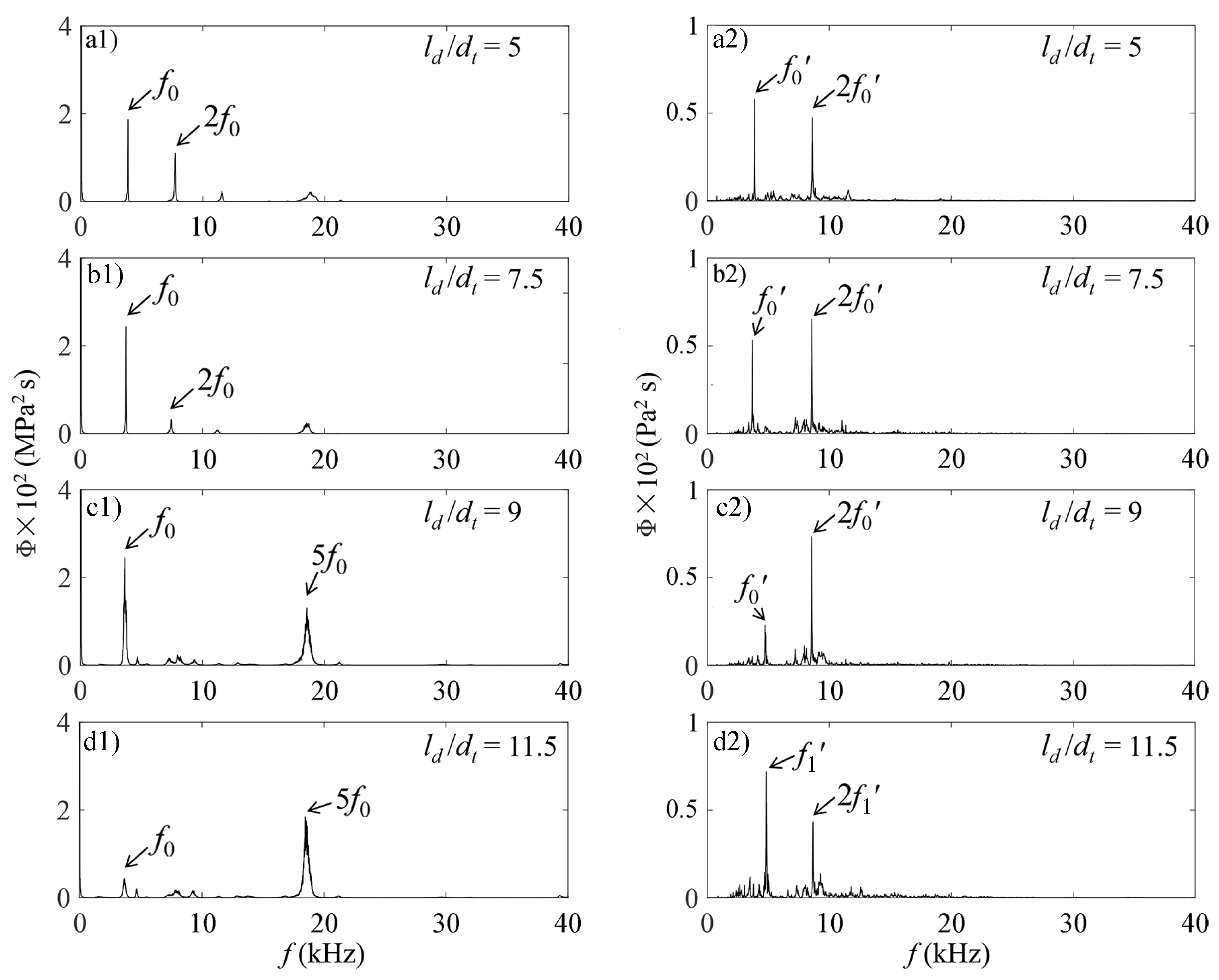

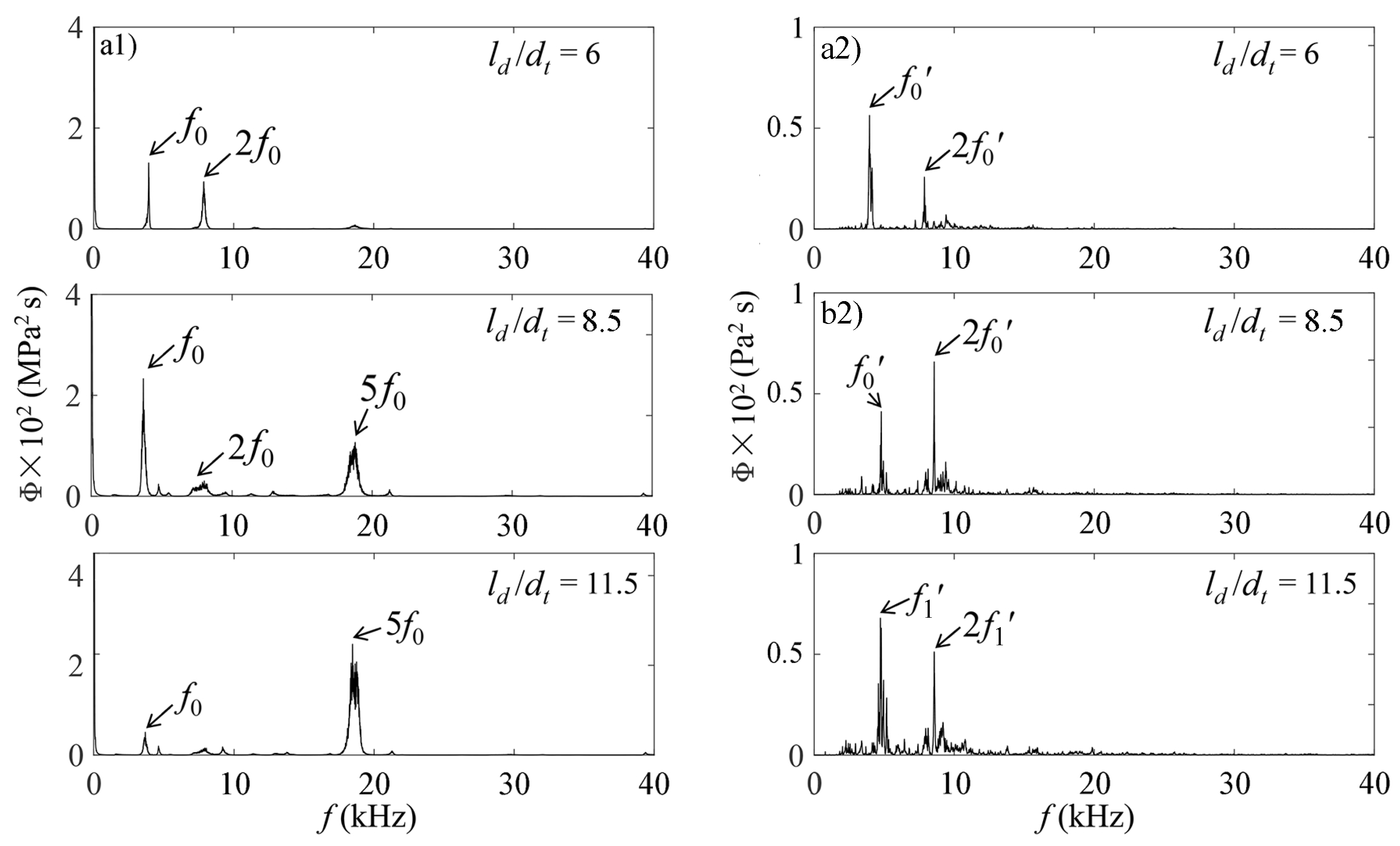

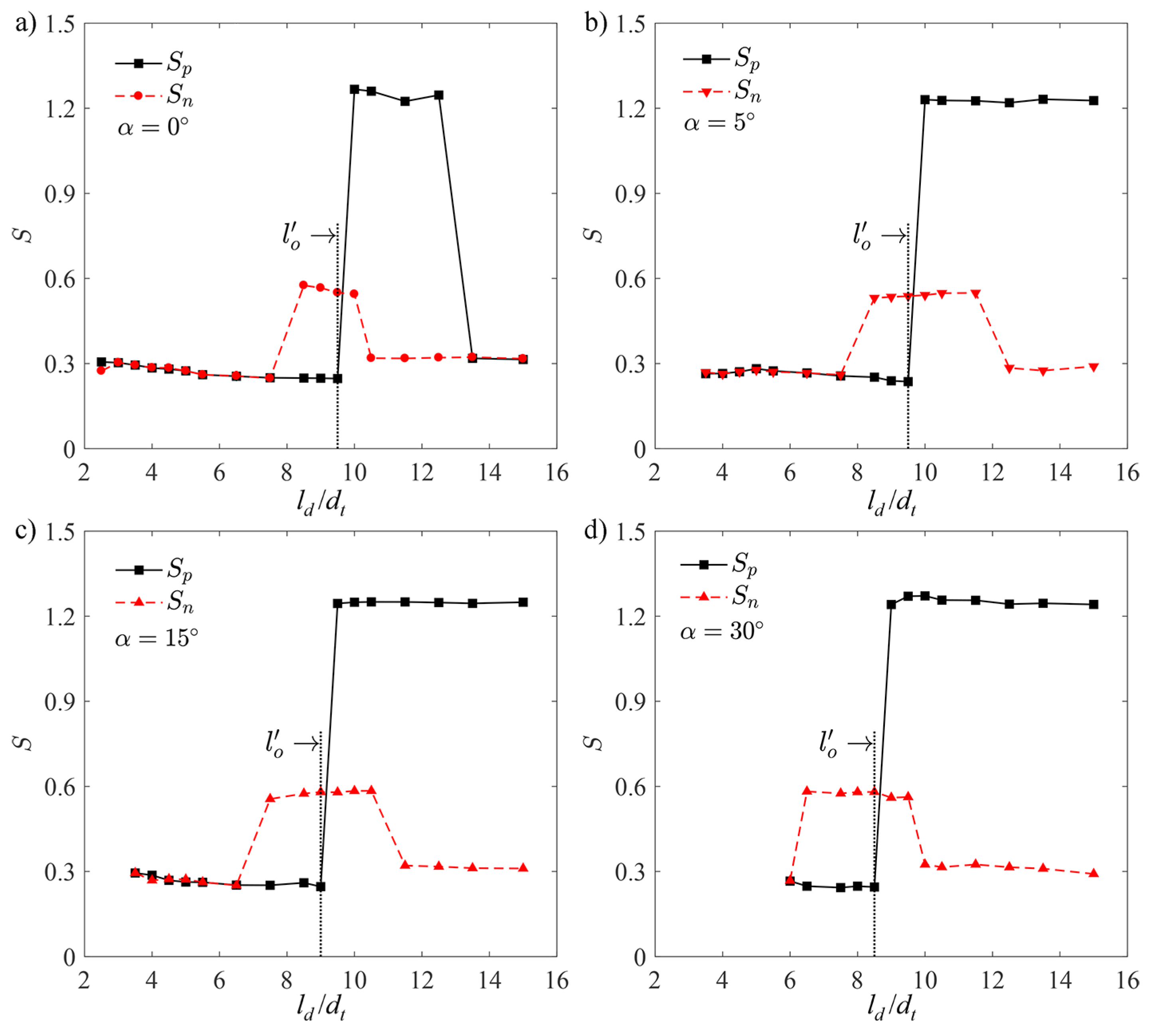

3.3. Self-Resonating Oscillations

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Peng, K.; Tian, S.; Li, G.; Huang, Z.; Zhang, Z. Cavitation in water jet under high ambient pressure conditions. Exp. Therm. Fluid Sci. 2017, 89, 9–18. [Google Scholar] [CrossRef]

- Johnson, V.E.; Chahine, G.L.; Lindenmuth, W.T.; Conn, A.F.; Frederick, G.S.; Giacchino, G.J. Cavitating and structured jets for mechanical bits to increase drilling rate—Part I: Theory and concepts. J. Energy Resour. Technol. 1984, 106, 289–294. [Google Scholar] [CrossRef]

- Liu, W.; Kang, Y.; Zhang, M.; Wang, X.; Li, D.; Xie, L. Experimental and theoretical analysis on chamber pressure of a self-resonating cavitation waterjet. Ocean Eng. 2018, 151, 33–45. [Google Scholar] [CrossRef]

- Fujisawa, N.; Fujita, Y.; Yanagisawa, K.; Fujisawa, K.; Yamagata, T. Simultaneous observation of cavitation collapse and shock wave formation in cavitating jet. Exp. Therm. Fluid Sci. 2018, 94, 159–167. [Google Scholar] [CrossRef]

- Soyama, H. Enhancing the aggressive intensity of a cavitating jet by means of the nozzle outlet geometry. J. Fluids Eng. 2011, 133, 101301. [Google Scholar] [CrossRef]

- Soyama, H.; Yamauchi, Y.; Adachi, Y.; Sato, K.; Shindo, T.; Oba, R. High-speed observations of the cavitation cloud around a high-speed submerged water jet. JSME Int. J. Ser. B Fluids Therm. Eng. 1995, 38, 245–251. [Google Scholar] [CrossRef]

- Chahine, G.L.; Hsiao, C.T. Modelling cavitation erosion using fluid–material interaction simulations. Interface Focus 2015, 5, 20150016. [Google Scholar] [CrossRef]

- Lichtarowicz, A. Cavitating jet apparatus for cavitation erosion testing. In STP664-EB Erosion: Prevention and Useful Applications; West Conshohocken: Conshohocken, PA, USA, 1979; pp. 530–549. [Google Scholar]

- Yamaguchi, A.; Shimizu, S. Erosion Due to Impingement of Cavitating Jet. J. Fluids Eng. 1987, 109, 442–447. [Google Scholar] [CrossRef]

- Momma, T.; Lichtarowicz, A. A study of pressures and erosion produced by collapsing cavitation. Wear 1995, 186, 425–436. [Google Scholar] [CrossRef]

- Soyama, H. Surface mechanics design of metallic materials on mechanical surface treatments. Mech. Eng. Rev. 2015, 2, 14-00192. [Google Scholar] [CrossRef]

- Yamauchi, Y.; Soyama, H.; Adachi, Y.; Sato, K.; Shindo, T.; Oba, R.; Oshima, R.; Yamabe, M. Suitable region of high-speed submerged water jets for cutting and peening. JSME Int. J. Ser. B Fluids Therm. Eng. 1996, 38, 31–38. [Google Scholar] [CrossRef]

- Jorgensen, D.W. Noise from Cavitating Submerged Water Jets. J. Acoust. Soc. Am. 1961, 33, 1334–1338. [Google Scholar] [CrossRef]

- Arndt, R.E.A.; George, W.K. Pressure fields and cavitation in turbulent shear flows. In Twelfth Symposium on Naval Hydrodynamics; National Academy of Sciences: Washington, DC, USA, 1979; pp. 327–339. [Google Scholar]

- Chahine, G.L.; Johnson, V.E., Jr.; Lindenmuth, W.T.; Frederick, G.S. The use of self-resonating cavitating water jets for underwater sound generation. J. Acoust. Soc. Am. 1985, 77, 113–126. [Google Scholar] [CrossRef]

- Tsujino, T. Cavitation damage and noise spectra in a polymer solution. Ultrasonics 1987, 25, 67–72. [Google Scholar] [CrossRef]

- Chahine, G.L.; Johnson, V.E., Jr.; Frederick, G.S. Self resonating pulsed water jets for aircraft coating removal: Feasibility study. In Technical Report; Hydronautics, Inc.: Laurel, MD, USA, 1982; Volume 8268-1. [Google Scholar]

- Sato, K.; Sugimoto, Y.; Ohjimi, S. Pressure-wave formation and collapses of cavitation clouds impinging on solid wall in a submerged water jet. In Proceedings of the 7th International Symposium on Cavitation, Ann Arbor, MI, USA, 16–20 August 2009. [Google Scholar]

- Soyama, H. Enhancing the aggressive intensity of a cavitating jet by introducing a cavitator and a guide pipe. J. Fluid Sci. Technol. 2013, 9, 1300238. [Google Scholar] [CrossRef]

- Momma, T. Cavitation Loading and Erosion Produced by a Cavitating Jet; University of Nottingham: Nottingham, UK, 1991. [Google Scholar]

- Chahine, G.L.; Courbière, P. Noise and Erosion of Self Resonating Cavitating Jets. J. Fluids Eng. 1987, 109, 429–435. [Google Scholar] [CrossRef]

- Sato, K.; Taguchi, Y.; Hayashi, S. High Speed Observation of Periodic Cavity Behavior in a Convergent-Divergent Nozzle for Cavitating Water Jet. J. Flow Control Meas. Vis. 2013, 1, 102–107. [Google Scholar] [CrossRef]

- Testud, P.; Moussou, P.; Hirschberg, A.; Aurégan, Y. Noise generated by cavitating single-hole and multi-hole orifices in a water pipe. J. Fluids Struct. 2007, 23, 163–189. [Google Scholar] [CrossRef]

- Kang, C.; Liu, H.; Soyama, H. Estimation of aggressive intensity of a cavitating jet with multiple experimental methods. Wear 2018, 394, 176–186. [Google Scholar] [CrossRef]

- Okada, T.; Yoshiro, I.; Shuji, H.; Norio, T. Relation between impact load and the damage produced by cavitation bubble collapse. Wear 1995, 184, 231–239. [Google Scholar] [CrossRef]

- Zhou, M.; Liu, H.; Kang, C.; Wei, X. Resistance of curved surfaces to the cavitation erosion produced through high-pressure submerged waterjet. Wear 2019, 440, 203091. [Google Scholar] [CrossRef]

- Chi, P.; Tian, S.; Li, G. Joint experiments of cavitation jet: High-speed visualization and erosion test. Ocean Eng. 2018, 149, 1–13. [Google Scholar]

- Li, D.; Kang, Y.; Wang, X.; Ding, X.; Fang, Z. Effects of nozzle inner surface roughness on the cavitation erosion characteristics of high speed submerged jets. Exp. Therm. Fluid Sci. 2016, 74, 444–452. [Google Scholar] [CrossRef]

- Soyama, H. Key Factors and Applications of Cavitation Peening. Int. J. Peen. Sci. Technol. 2017, 1, 3–60. [Google Scholar]

- Liu, B.; Pan, Y.; Ma, F. Pulse pressure loading and erosion pattern of cavitating jet. Eng. Appl. Comput. Fluid Mech. 2008, 14, 136–150. [Google Scholar] [CrossRef]

- Chahine, G.L.; Johnson, V.E., Jr. Mechanics and Applications of Self-Resonating Cavitating Jets. In International Symposium on Jets and Cavities; ASME: Miami Beach, FL, USA, 1985; Volume 31, pp. 21–33. [Google Scholar]

- Li, D.; Kang, Y.; Ding, X.G.; Liu, W. Experimental study on the effects of feeding pipe diameter on the cavitation erosion performance of self-resonating cavitating waterjet. Exp. Therm. Fluid Sci. 2016, 82, 314–325. [Google Scholar] [CrossRef]

- Liu, B.; Hamed, A.M.; Jin, Y.; Chamorro, L.P. Influence of vortical structure impingement on the oscillation and rotation of flat plates. J. Fluids Struct. 2017, 70, 417–427. [Google Scholar] [CrossRef]

- Liu, B.; Hamed, A.M.; Chamorro, L.P. On the Kelvin–Helmholtz and von Kármán vortices in the near-wake of semicircular cylinders with flaps. J. Turbul. 2017, 12, 270–281. [Google Scholar] [CrossRef]

- Liu, B.; Yan, Q.; Wei, W. Numerical investigations of the flow induced oscillation of a torque converter. Eng. Appl. Comput. Fluid Mech. 2018, 12, 270–281. [Google Scholar] [CrossRef]

- De, M.K.; Hammitt, F.G. New Method for Monitoring and Correlating Cavitation Noise to Erosion Capability. J. Fluids Eng. 1982, 104, 434–441. [Google Scholar] [CrossRef]

| Dimensions (mm) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| value | 26 | 12 | 2 | 14 | 134 | 24 | 0.7 | 2.8 | 2 | 5 |

| (°) | |

|---|---|

| 0 | 2.5, 3, 3.5, 4, 4.5, 5, 5.5, 6.5, 7.5, 8.5, 9, 9.5, 10, 10.5, 11.5, 12.5, 13.5, 15 |

| 5 | 3.5, 4, 4.5, 5, 5.5, 6.5, 7.5, 8.5, 9, 9.5, 10, 10.5, 11.5, 12.5, 13.5, 15 |

| 15 | 3.5, 4, 4.5, 5, 5.5, 6.5, 7.5, 8.5, 9, 9.5, 10, 10.5, 11.5, 12.5, 13.5, 15 |

| 30 | 6, 6.5, 7.5, 8, 8.5, 9, 9.5, 10, 10.5, 11.5, 12.5, 13.5, 15 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, B.; Ma, F. Erosion Characteristics and the Corresponding Self-Resonating Oscillations of Cavitating Jet on Oblique Surfaces. Energies 2020, 13, 2563. https://doi.org/10.3390/en13102563

Liu B, Ma F. Erosion Characteristics and the Corresponding Self-Resonating Oscillations of Cavitating Jet on Oblique Surfaces. Energies. 2020; 13(10):2563. https://doi.org/10.3390/en13102563

Chicago/Turabian StyleLiu, Boshen, and Fei Ma. 2020. "Erosion Characteristics and the Corresponding Self-Resonating Oscillations of Cavitating Jet on Oblique Surfaces" Energies 13, no. 10: 2563. https://doi.org/10.3390/en13102563

APA StyleLiu, B., & Ma, F. (2020). Erosion Characteristics and the Corresponding Self-Resonating Oscillations of Cavitating Jet on Oblique Surfaces. Energies, 13(10), 2563. https://doi.org/10.3390/en13102563