Simulation of Storage Conditions of Mixed Biomass Pellets for Bioenergy Generation: Study of the Thermodynamic Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of the Samples

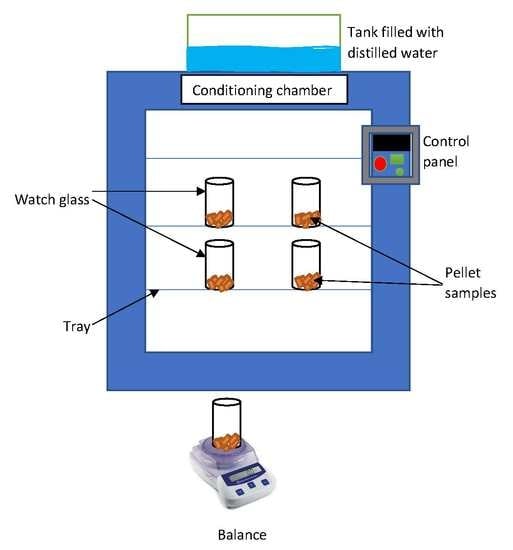

2.2. Instrumentation and Measurments

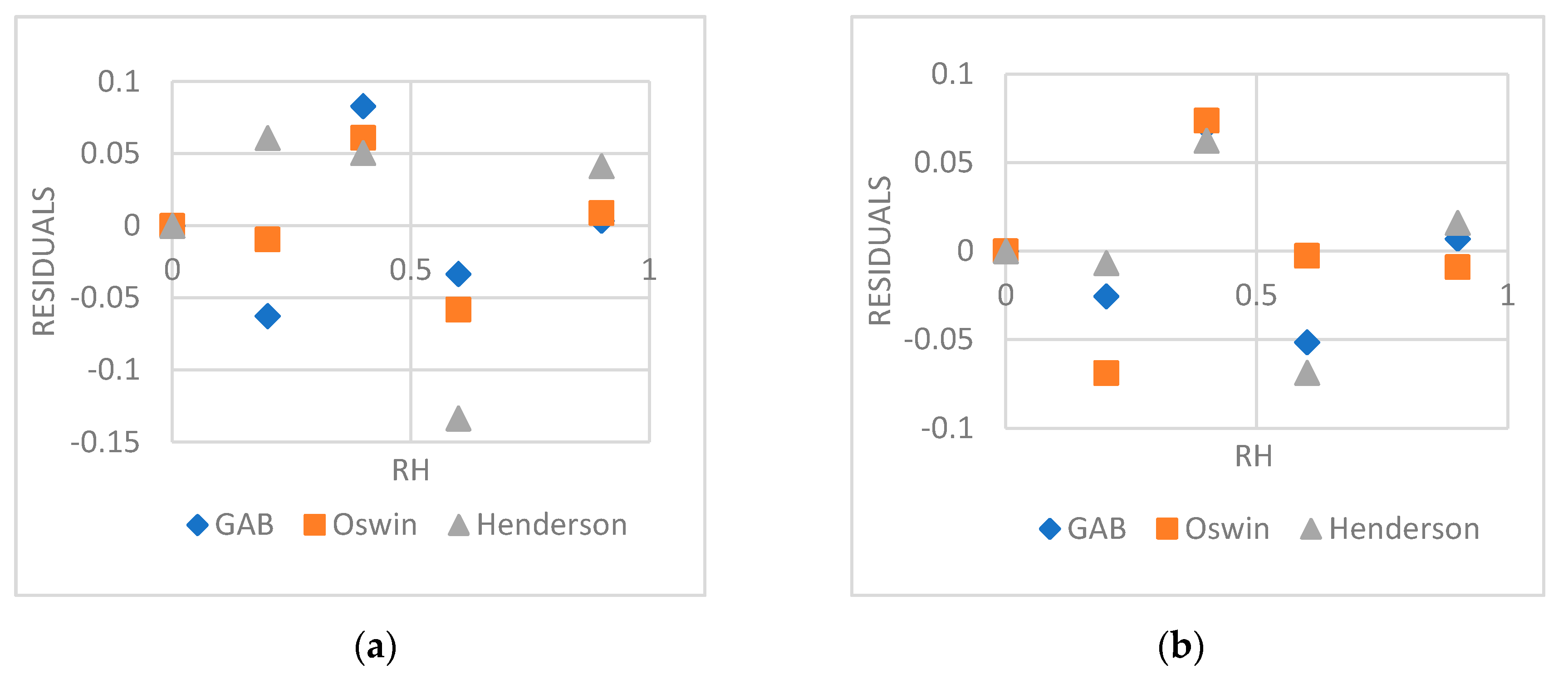

2.3. Mathematical Modeling of the Sorption Isotherms

- For functional applications, particularly drying and storing, it should be possible to describe the experimental curves mathematically.

- Simplicity of the equation that describes the process must be obtained along with limitation of the parameters, as much as possible.

- Physical significance of the parameters

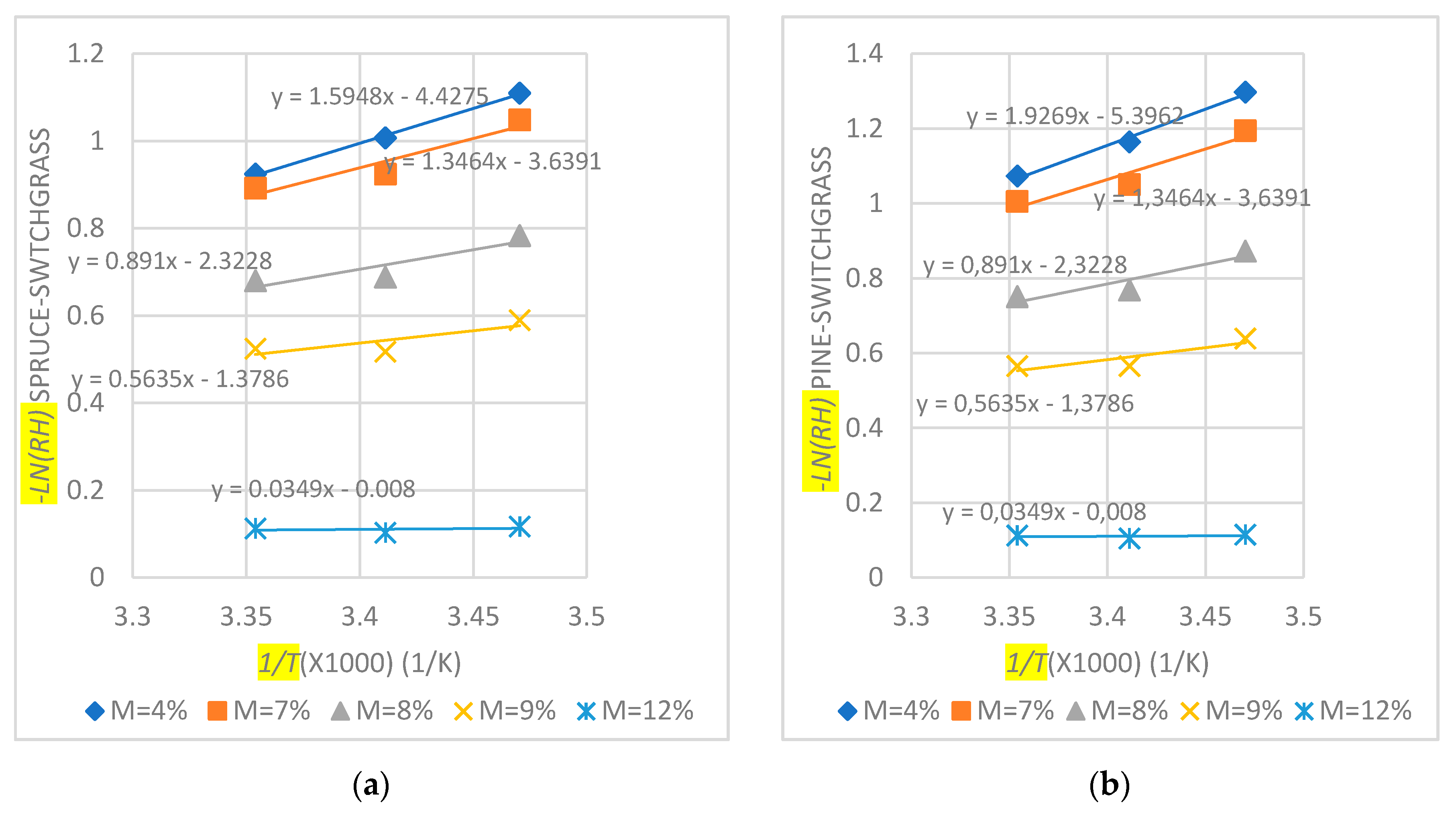

2.4. Determination of the Thermodynamic Properties

2.4.1. Net Isosteric Heat of Sorption

2.4.2. Entropy Changes of Sorption

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Canadian Biomass. Available online: https://www.canadianbiomassmagazine.ca/2020-global-pellet-markets-outlook/ (accessed on 11 April 2020).

- Statistics Canada. Available online: https://www5.statcan.gc.ca/cimt-cicm/topNCountries-pays?lang=eng&getSectionId()=0&dataTransformation=0&refYr=2019&refMonth=3&freq=12&countryId=0&getUsaState()=0&provId=1&retrieve=Retrieve&country=null&tradeType=1&topNDefault=10&monthStr=null&chapterId=44&arrayId=0§ionLabel=&scaleValue=0&scaleQuantity=0&commodityId=440131 (accessed on 11 April 2020).

- Harun, N.Y.; Parvez, A.M.; Afzal, M.T. Process and Energy Analysis of Pelleting Agricultural and Woody Biomass Blends. Sustainability 2018, 10, 1770. [Google Scholar] [CrossRef]

- Nilsson, D.; Bernesson, S.; Hansson, P.A. Pellet production from agricultural raw materials—A systems study. Biomass Bioenergy 2011, 35, 679–689. [Google Scholar] [CrossRef]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. Effects of compressive force, particle size and moisture content on mechanical properties of biomass pellets from grasses. Biomass Bioenergy 2006, 30, 648–654. [Google Scholar] [CrossRef]

- Henriksson, L.; Frodeson, S.; Berghej, J.; Andersson, S.; Ohlson, M. Bioresources for Sustainable Pellet Production in Zambia: Twelve Biomasses Pelletized at Different Moisture Contents. BioResources 2019, 14, 2550–2575. [Google Scholar]

- Theerarattananoon, K.; Xu, F.; Wilson, J.; Ballard, R.; Mckinney, L.; Staggenborg, S.; Vadlani, P.; Pei, Z.J.; Wang, D. Physical properties of pellets made from sorghum stalk, corn stover, wheat straw and big bluestem. Ind. Crops Prod. 2011, 33, 325–332. [Google Scholar]

- Hartley, I.D.; Wood, L.J. Hygroscopic properties of densified softwood pellets. Biomass Bioenergy 2008, 32, 90–93. [Google Scholar] [CrossRef]

- Mostafa, M.E.; Hu, S.; Wang, Y.; Su, S.; Hu, X.; Elsayed, S.A.; Xiang, J. The significance of pelletization operating conditions:An analysis of physical and mechanical characteristics as well as energy consumption of biomass pellets. Renew. Sust. Energ. Rev. 2019, 105, 332–348. [Google Scholar] [CrossRef]

- Fasina, O.; Sokhansanj, S.; Tyler, R. Thermodynamics of moisture sorption in alfalfa pellets. Dry. Technol. 1997, 15, 1153–1570. [Google Scholar] [CrossRef]

- Sultana, A.; Kumar, A. Ranking of biomass pellets by integration of economic, environmental and technical factors. Biomass Bioenergy 2012, 39, 344–355. [Google Scholar] [CrossRef]

- Dyjakon, A.; Noszczyk, T. The Influence of Freezing Temperature Storage on the Mechanical Durability of Commercial Pellets from Biomass. Energies 2019, 12, 2627. [Google Scholar] [CrossRef]

- Greinert, A.; Mrówczyn’ska, M.; Grech, R.; Szefner, W. The Use of Plant Biomass Pellets for Energy Production by Combustion in Dedicated Furnaces. Energies 2020, 13, 463. [Google Scholar] [CrossRef]

- Pantaleo, A.; Villarini, M.; Colantoni, A.; Carlini, M.; Santoro, F.; Hamedani, S.R. Techno-Economic Modeling of Biomass Pellet Routes: Feasibility in Italy. Energies 2020, 13, 1636. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Factors affecting strength and durability of densified biomass products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Järvinen, T.; Agar, D. Experimentally determined storage and handling properties of fuel pellets made from torrefied whole-tree pine chips, logging residues and beech stem wood. Fuel 2014, 129, 330–339. [Google Scholar] [CrossRef]

- Nủñez, C.A.F.; Jochum, J.; Vargas, F.E.S. Characterization and feasibility of biomass fuel pellets made of Colombian timber, coconut and oil palm residues regarding European standards. Envir. Biotechnol. 2012, 8, 67–76. [Google Scholar]

- Lee, J.S.; Sokhansanj, S.; Lau, A.K.; Lim, C.J.; Bi, X.T. The effect of storage on the net calorific value of wood pellets Canad. Biosyst. Eng. 2015, 57, 5–12. [Google Scholar]

- ASTM D4442-07. Standard Test Methods for Direct Moisture Content Measurement of Wood and Wood-Base Materials; ASTM: West Conshohocken, PA, USA, 2007. [Google Scholar]

- Karunanithy, C.; Muthukumarappan, K.; Donepudi, A. Moisture sorption characteristics of switchgrass and prairie cord grass. Fuel 2013, 103, 171–178. [Google Scholar] [CrossRef]

- Krupińska, B.; Strømmen, I.; Pakowski, Z.; Eikevik, T.M. Modeling of sorption isotherms of various kinds of wood at different temperature conditions. Dry. Technol. 2007, 25, 1463–1470. [Google Scholar] [CrossRef]

- Haque, M.A.; Shimizu, N.; Kimura, T.; Bala, B.K. Net isosteric heats of adsorption and desorption for different forms of hybrid rice. Inter. J. Food Prop. 2007, 10, 25–37. [Google Scholar] [CrossRef]

- Seth, D.; Dash, K.K.; Mishra, H.N.; Deka, S.C. Thermodynamics of sorption isotherms and storage stability of spray dried sweetened yoghurt powder. J. Food Sci. Technol. 2018, 55, 4139–4147. [Google Scholar] [CrossRef]

- Ouertani, S.; Azzouz, S.; Hassini, L.; Koubaa, A.; Belghith, A. Moisture sorption isotherms and thermodynamic properties of Jack pine and palm wood: Comparative study. Ind. Crops Prod. 2014, 56, 200–210. [Google Scholar] [CrossRef]

- Meze’e, Y.N.N.; Ngamveng, J.N.; Bardet, S. Effect of enthalpy–entropy compensation during sorption of water vapour in tropical woods: The case of Bubinga (Guibourtia Tessmanii J. Léonard; G. Pellegriniana J.L.). Thermochim. Acta 2008, 468, 1–5. [Google Scholar] [CrossRef]

- Koua, B.K.; Koffi, P.M.E.; Gbaha, P.; Toure, S. Thermodynamic analysis of sorption isotherms of cassava (Manihot esculenta). J. Food Sci. Technol. 2014, 51, 1711–1723. [Google Scholar]

- Simo-Tagne, M.; Bennamoun, L.; Léonard, A.; Rogaume, Y. Determination and modeling of the isotherms of adsorption/desorption and thermodynamic properties of obeche and lotofa using nelson’s sorption model. Heat Mass Transfer 2019, 55, 2185–2197. [Google Scholar]

- Panchariya, P.C.; Popovic, D.; Sharma, A.L. Modeling of desorption isotherm of black tea. Dry. Technol. 2001, 19, 1177–1188. [Google Scholar] [CrossRef]

- Fasina, O.; Sokhansanj, S. Equilibrium moisture relations and heat of sorption of alfalfa pellets. J. Agric. Eng. Res. 1993, 56, 51–63. [Google Scholar] [CrossRef]

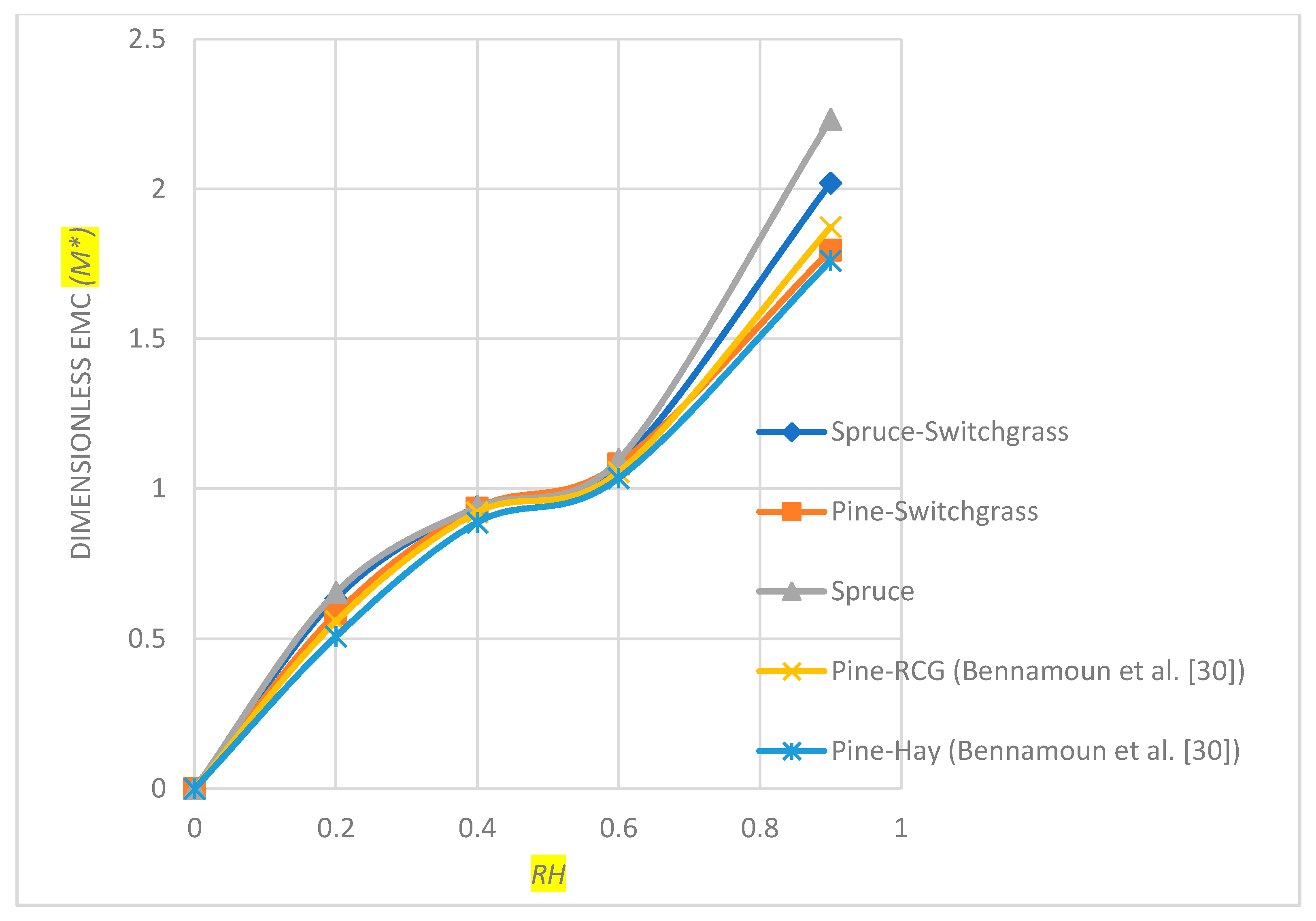

- Bennamoun, L.; Harun, N.A.; Afzal, M.T. Effect of storage conditions on moisture sorption of mixed biomass pellets. Arab. J. Sci. Technol. 2018, 43, 1195–1203. [Google Scholar] [CrossRef]

- Desmorieux, H.; Decaen, N. Convective drying of spirulina in thin layer. J. Food Eng. 2005, 66, 497–503. [Google Scholar] [CrossRef]

- Belahmidi, E.; Belghit, A.; Mira, A.; Kaoua, A. Approche expérimentale de la cinétique de séchage des produits agroalimentaires. Application aux peaux d’oranges et à la pulpe de betteraves. Rev. Géné. Therm. 1993, 32, 444–453. [Google Scholar]

- Chen, C. Evaluation of equilibrium sorption isotherm equations. Open Chem. Eng. J. 2013, 7, 24–44. [Google Scholar] [CrossRef]

| spruce (s) | pine (p) | switchgrass (sw) | s-sw | p-sw | |

|---|---|---|---|---|---|

| HHV (MJ/kg) | 19.15 | 19.75 | 18.20 | 18.46 | 18.44 |

| C% | 47.14 | 46.80 | 45.03 | 47.12 | 47.21 |

| H% | 6.06 | 6.14 | 5.98 | 6.08 | 6.12 |

| N% | 0.04 | 0.04 | 0.12 | 0.033 | 0.027 |

| S% | 0.002 | 0.002 | 0.03 | 0.013 | 0.01 |

| O% | 46.76 | 47.02 | 48.84 | 46.75 | 46.64 |

| Ash% | 0.00 | 0.00 | 3.61 | 1.53 | 1.55 |

| Name of the Model | Mathematical Representation | Number of the Equation |

|---|---|---|

| GAB | (1) | |

| Peleg | (2) | |

| Oswin | (3) | |

| Henderson | (4) |

| Spruce | S-S | P-S | ||

|---|---|---|---|---|

| GAB | a | 0.577 | 0.587 | 0.744 |

| b | 0.823 | 0.788 | 0.668 | |

| c | −1.891 × 109 | −2.881 × 1011 | 1.583 | |

| R2 | 0.998 | 0.997 | 0.998 | |

| S | 0.069 | 0.077 | 0.065 | |

| χ2 | 0.096 | 0.012 | 0.008 | |

| Peleg | a | 1.170 | 1.048 | 0.936 |

| b | 1.029 | 0.907 | 0.802 | |

| c | 1.170 | 1.048 | 0.936 | |

| d | 1.291 | 0.907 | 0.802 | |

| R2 | 0.973 | 0.978 | 0.989 | |

| S | 0.379 | 0.305 | 0.194 | |

| χ2 | 0.143 | 0.093 | 0.038 | |

| Oswin | a | 1.024 | 1.000 | 0.967 |

| b | 0.351 | 0.318 | 0.284 | |

| R2 | 0.998 | 0.998 | 0.997 | |

| S | 0.059 | 0.049 | 0.058 | |

| χ2 | 0.010 | 0.007 | 0.010 | |

| Henderson | a | 0.616 | 0.637 | 0.680 |

| b | 1.692 | 1.884 | 2.114 | |

| R2 | 0.992 | 0.994 | 0.997 | |

| S | 0.121 | 0.093 | 0.055 | |

| χ2 | 0.044 | 0.026 | 0.009 |

| Fitting Equation | R2 | Equation Number | |

|---|---|---|---|

| spruce–switchgrass | Qiso = −0.0629 M2 − 0.7118 M+17.51 | 0.9507 | (9) |

| pine–switchgrass | Qiso = 0.0269 M2 − 2.4731 M+25.795 | 0.9773 | (10) |

| Pine–RCG | Qiso = 0.0432 M2 −2.7921 M+27.296 | 0.9806 | (11) |

| Spruce–RCG | Qiso = 0.1203 M2 −4.3046 M+34.411 | 0.9912 | (12) |

| Pine–hay | Qiso = 0.4544 M2 −10.858 M+65.242 | 0.995 | (13) |

| spruce | Qiso = −0.0553 M2 −0.4812 M+13.989 | 0.984 | (14) |

| Fitting Equation | R2 | Equation Number | |

|---|---|---|---|

| spruce–switchgrass | ΔS = 0.003M3 −0.079M2 + 0.0541M− 0.0738 | 0.998 | (15) |

| pine–switchgrass | ΔS = 0.003M3 −0.060M2 + 0.0372M − 0.0237 | 0.999 | (16) |

| Pine–RCG | ΔS = 0.0002M3 −0.053M2 +0.0308M − 0.0049 | 0.999 | (17) |

| Spruce–RCG | ΔS = 0.0002M3 −0.0037M2 + 0.0161M + 0.0389 | 0.999 | (18) |

| Pine–hay | ΔS = 0.012M2 + 0.0289M − 0.1734 | 1.000 | (19) |

| spruce | ΔS = −0.0001M2 − 0.0022M + 0.0404M | 0.979 | (20) |

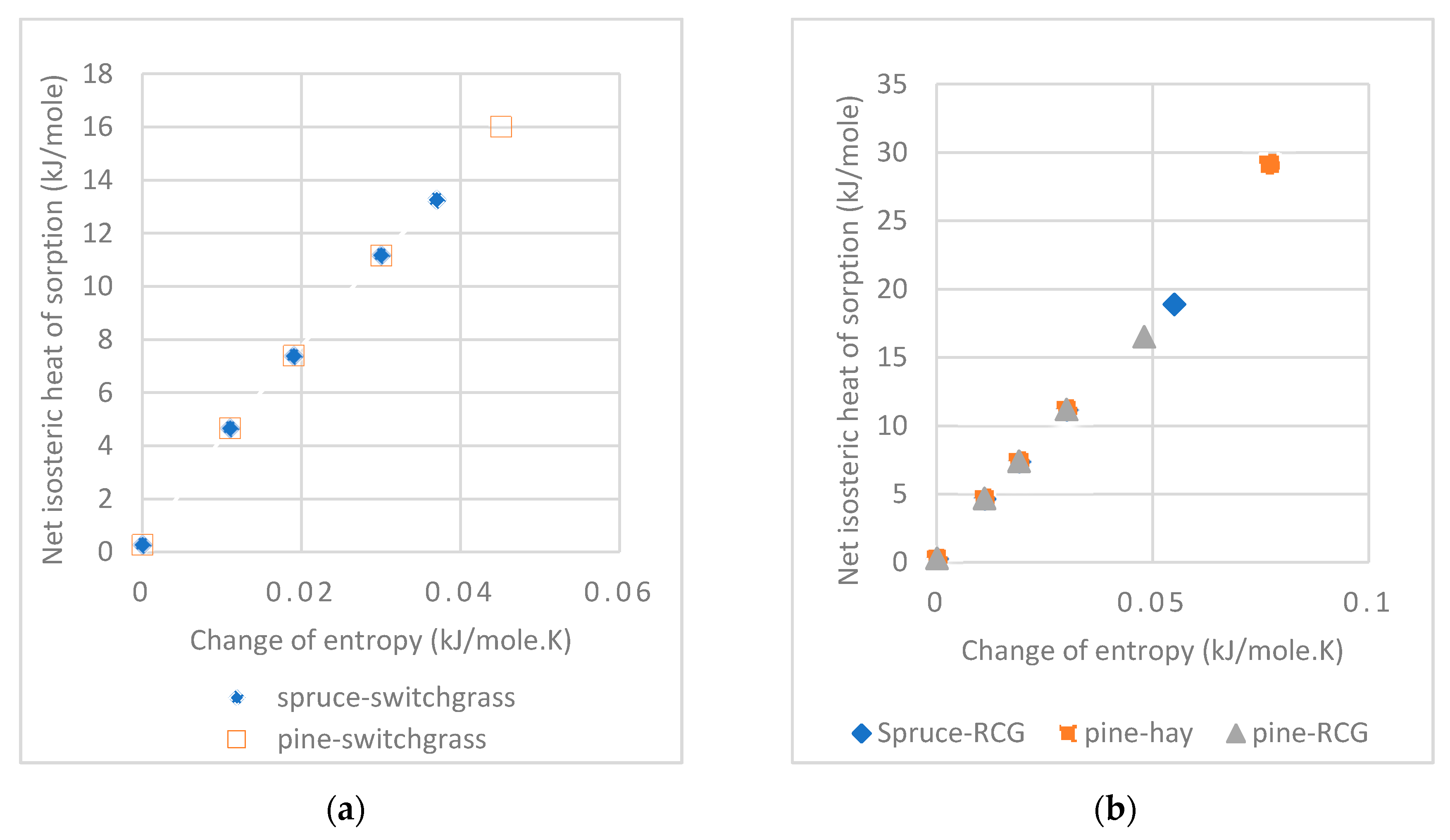

| Fitting Equation | Tβ (K) | ΔGβ (kJ/mole) | R2 | Equation Number | |

|---|---|---|---|---|---|

| spruce–switchgrass | Qiso = 349.85ΔS + 0.5769 | 349.85 | 0.5769 | 0.9976 | (22) |

| pine–switchgrass | Qiso = 347.34ΔS + 0.6219 | 347.34 | 0.6219 | 0.9981 | (23) |

| Pine–RCG | Qiso = 336.25ΔS + 0.753 | 336.25 | 0.753 | 0.9961 | (24) |

| Spruce–RCG | Qiso = 335.06ΔS + 0.7836 | 335.06 | 0.7836 | 0.9971 | (25) |

| Pine–hay | Qiso = 373.49ΔS + 0.3104 | 373.49 | 0.3104 | 0.9996 | (26) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bennamoun, L.; Simo-Tagne, M.; Ndukwu, M.C. Simulation of Storage Conditions of Mixed Biomass Pellets for Bioenergy Generation: Study of the Thermodynamic Properties. Energies 2020, 13, 2544. https://doi.org/10.3390/en13102544

Bennamoun L, Simo-Tagne M, Ndukwu MC. Simulation of Storage Conditions of Mixed Biomass Pellets for Bioenergy Generation: Study of the Thermodynamic Properties. Energies. 2020; 13(10):2544. https://doi.org/10.3390/en13102544

Chicago/Turabian StyleBennamoun, Lyes, Merlin Simo-Tagne, and Macmanus Chinenye Ndukwu. 2020. "Simulation of Storage Conditions of Mixed Biomass Pellets for Bioenergy Generation: Study of the Thermodynamic Properties" Energies 13, no. 10: 2544. https://doi.org/10.3390/en13102544

APA StyleBennamoun, L., Simo-Tagne, M., & Ndukwu, M. C. (2020). Simulation of Storage Conditions of Mixed Biomass Pellets for Bioenergy Generation: Study of the Thermodynamic Properties. Energies, 13(10), 2544. https://doi.org/10.3390/en13102544