Effect of Single-Row and Double-Row Passive Vortex Generators on the Deep Dynamic Stall of a Wind Turbine Airfoil †

Abstract

1. Introduction

2. Numerical Modelling

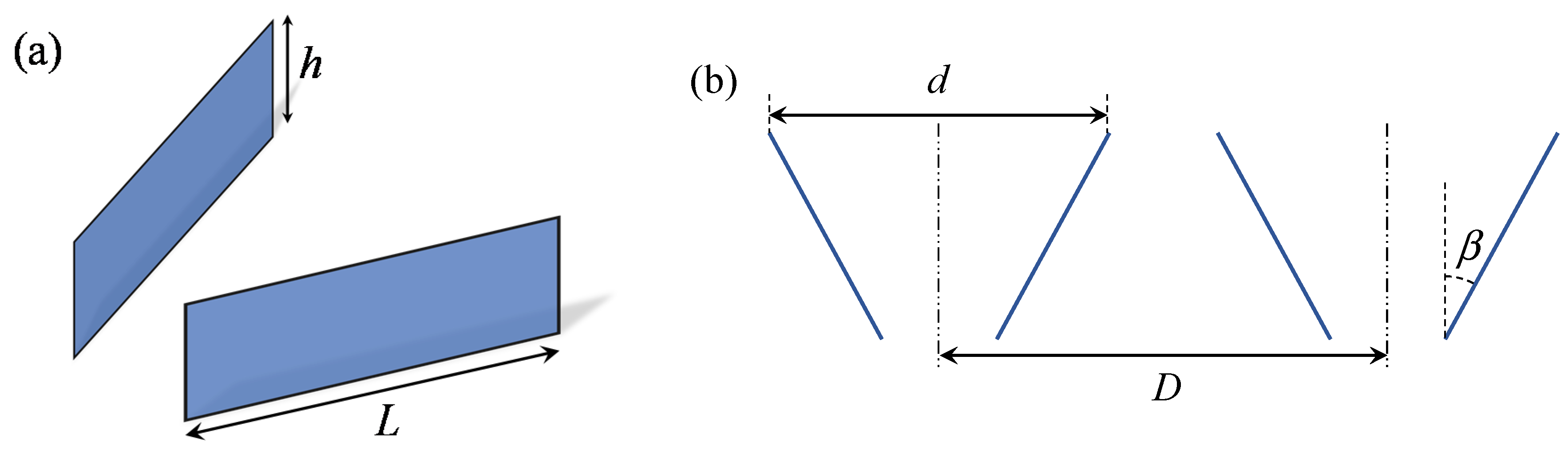

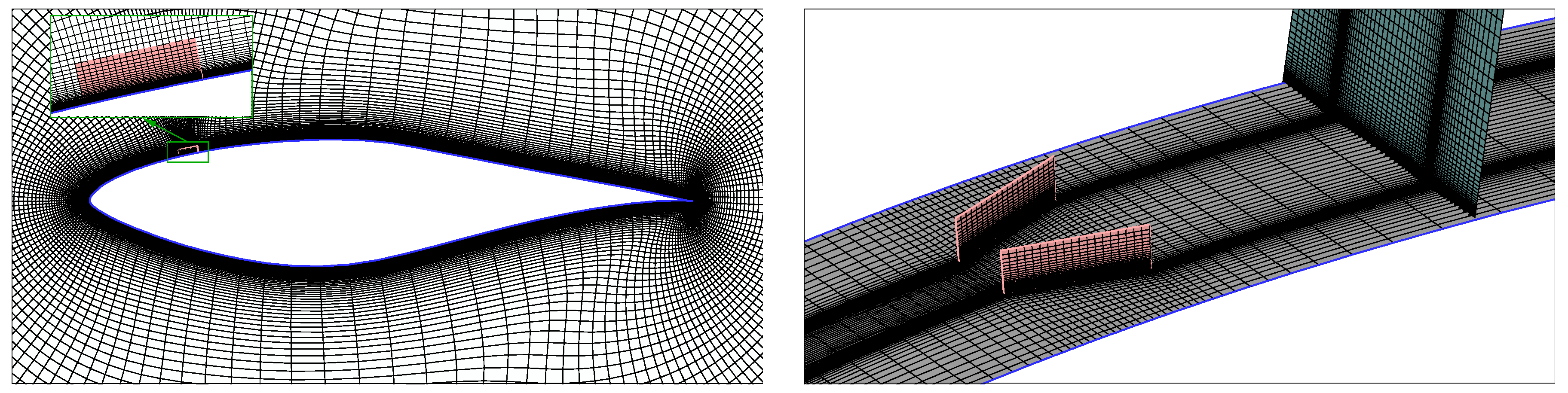

2.1. Geometry and Mesh Generation

2.2. URANS Settings

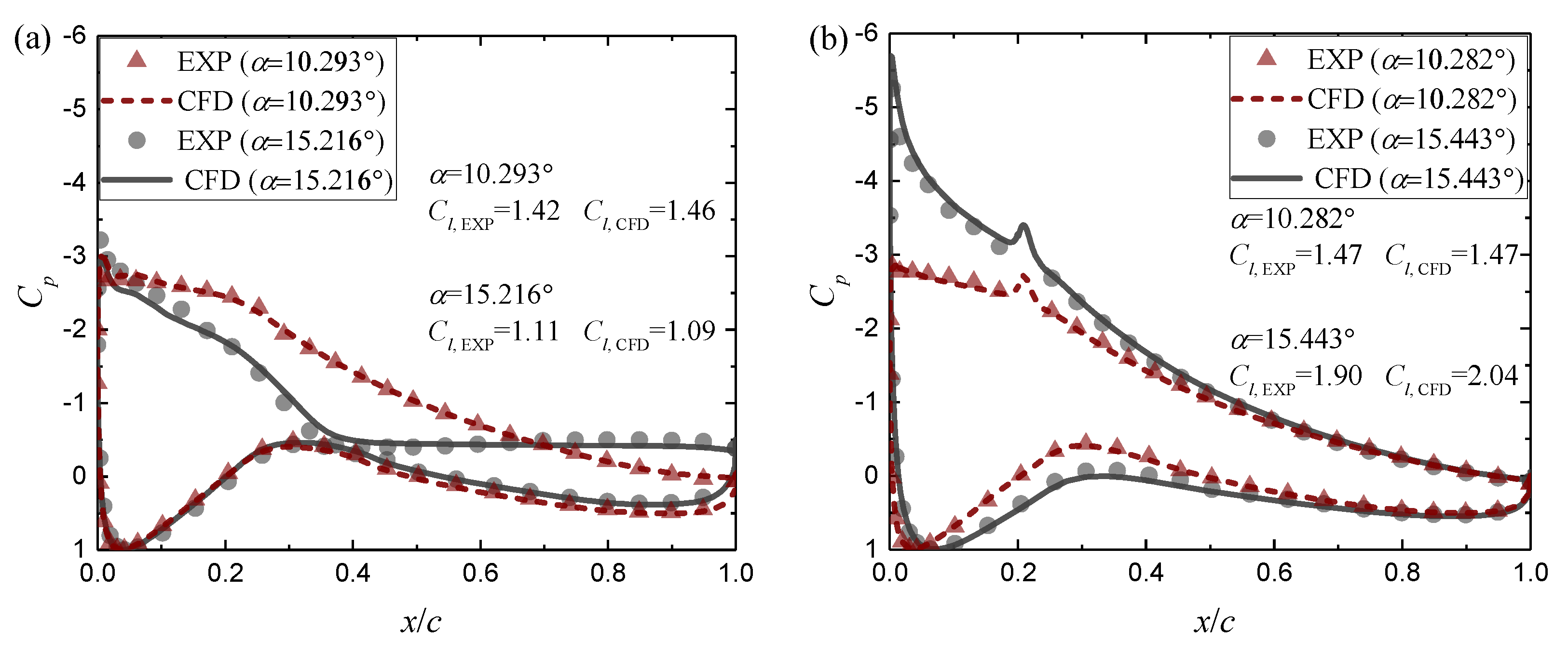

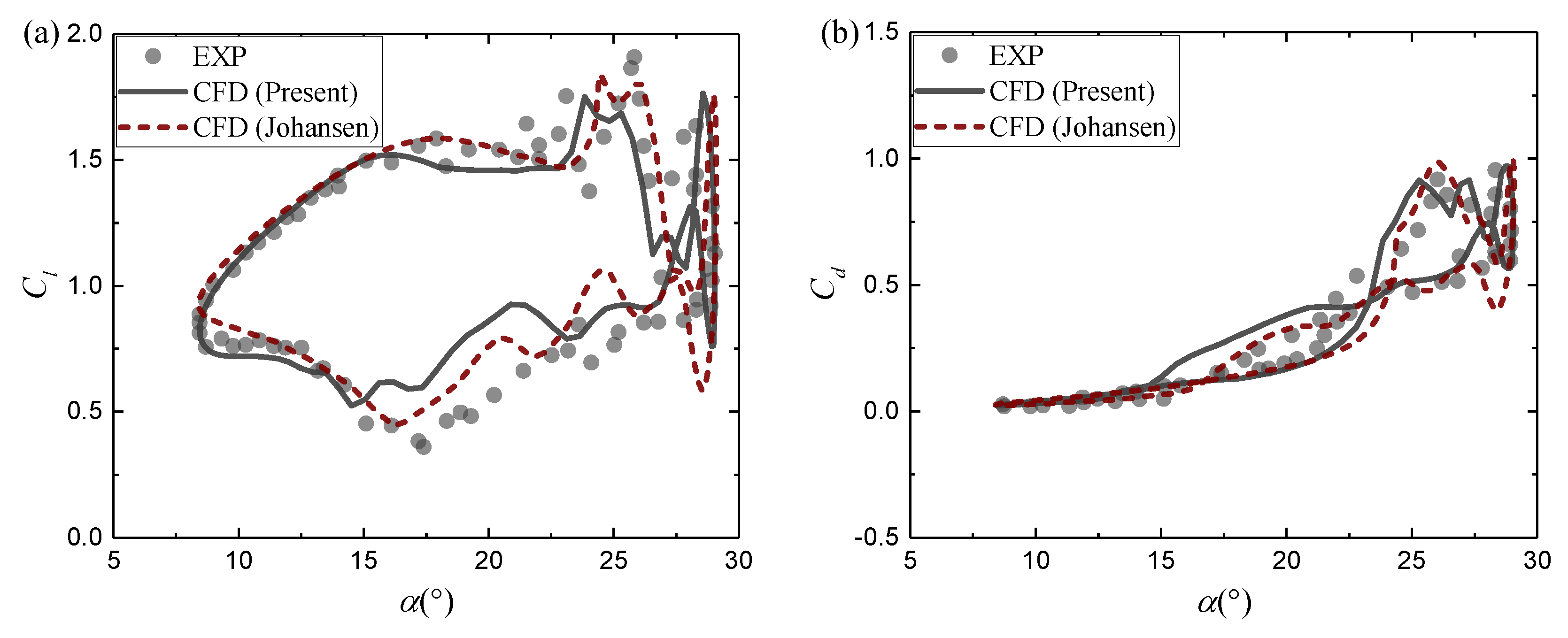

2.3. Validation of Numerical Modelling

3. Results and Discussion

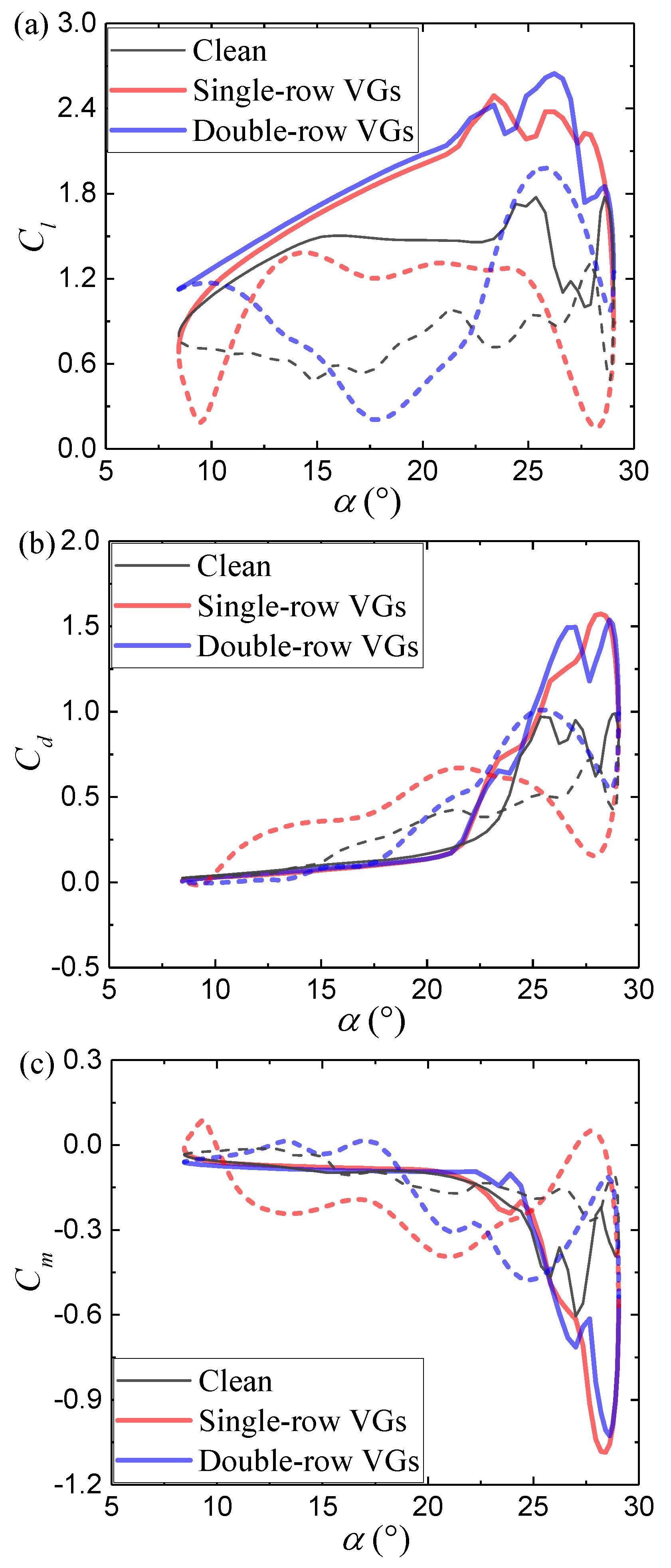

3.1. Aerodynamic Hysteresis Loops

- From αmax to α = 25°, double-row VGs quickly restored the decreases in Cl and Cd in comparison with single-row VGs. This suggests that the second-row VGs impacted greatly on the massive flow separation when the airfoil began to pitch down.

- From α = 25° to α = 13°, the Cl with single-row VGs kept high but was accompanied by high hysteresis intensities of the Cd and Cm. In contrast, the Cl with double-row VGs decreased gradually at first and then increased slowly.

- From α = 13° to αmin, single-row VGs produced considerable increases in hysteresis intensities. The second-row VGs significantly helped the Cl readjust to the linear regime, so that double-row VGs led to low hysteresis intensities.

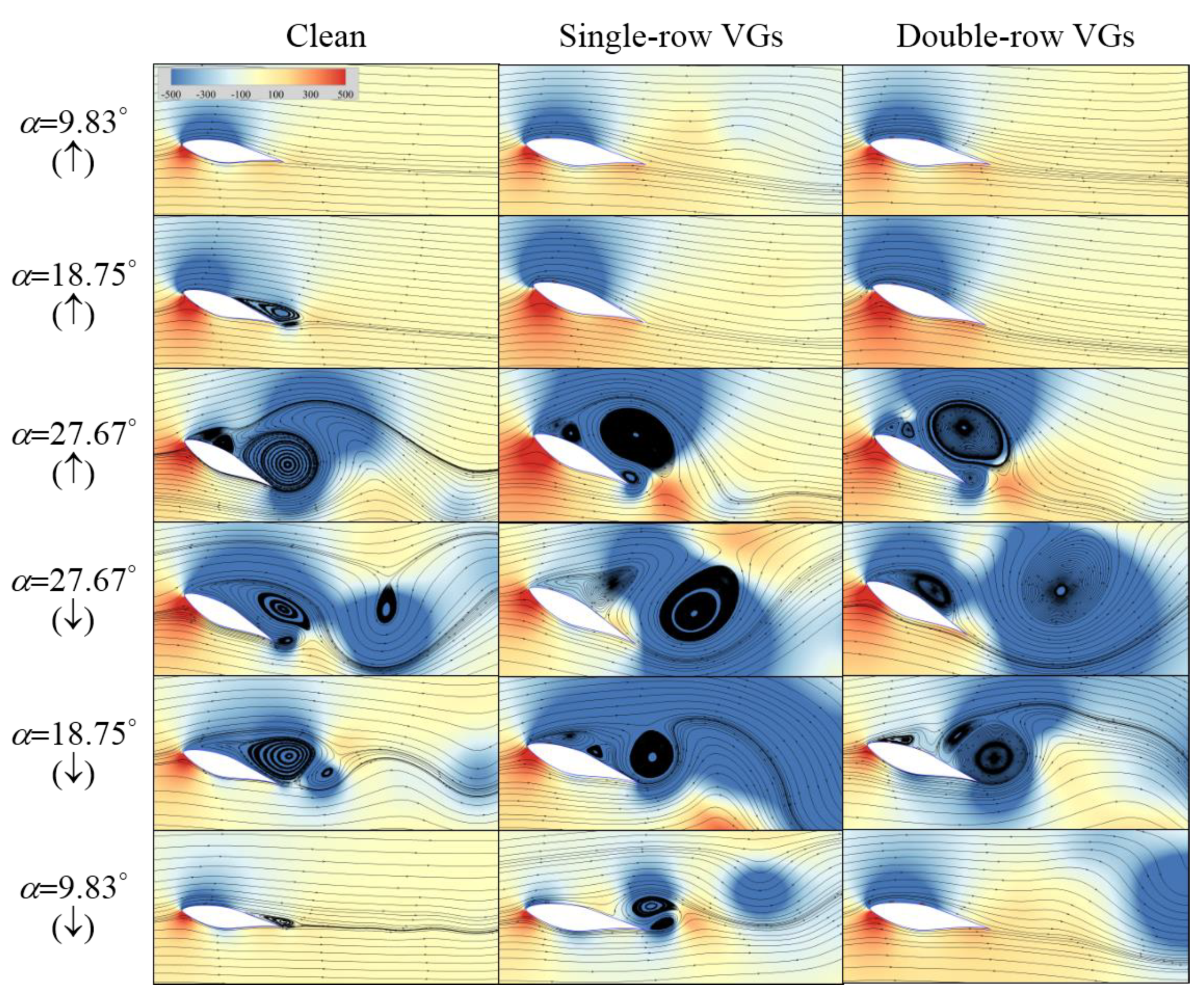

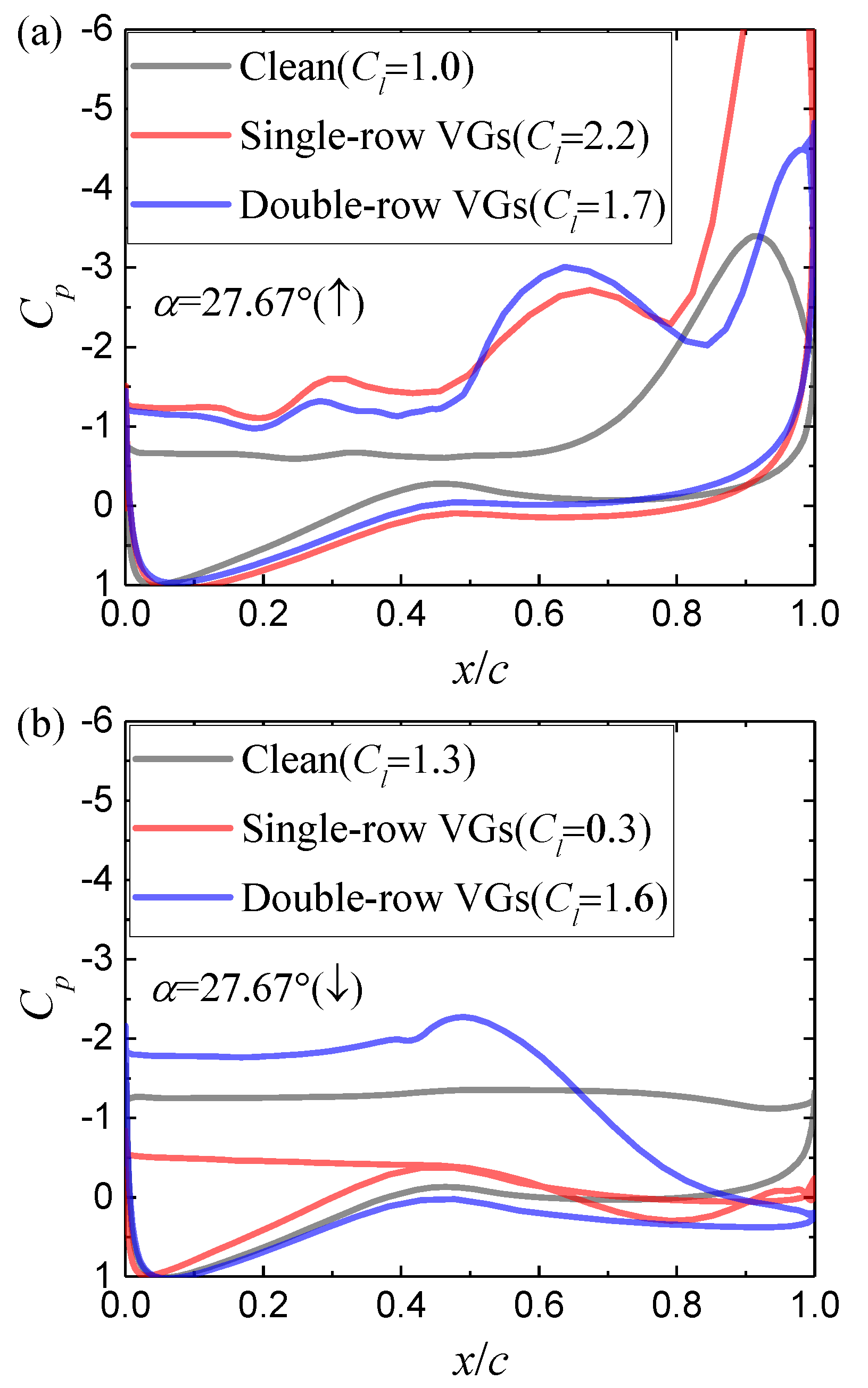

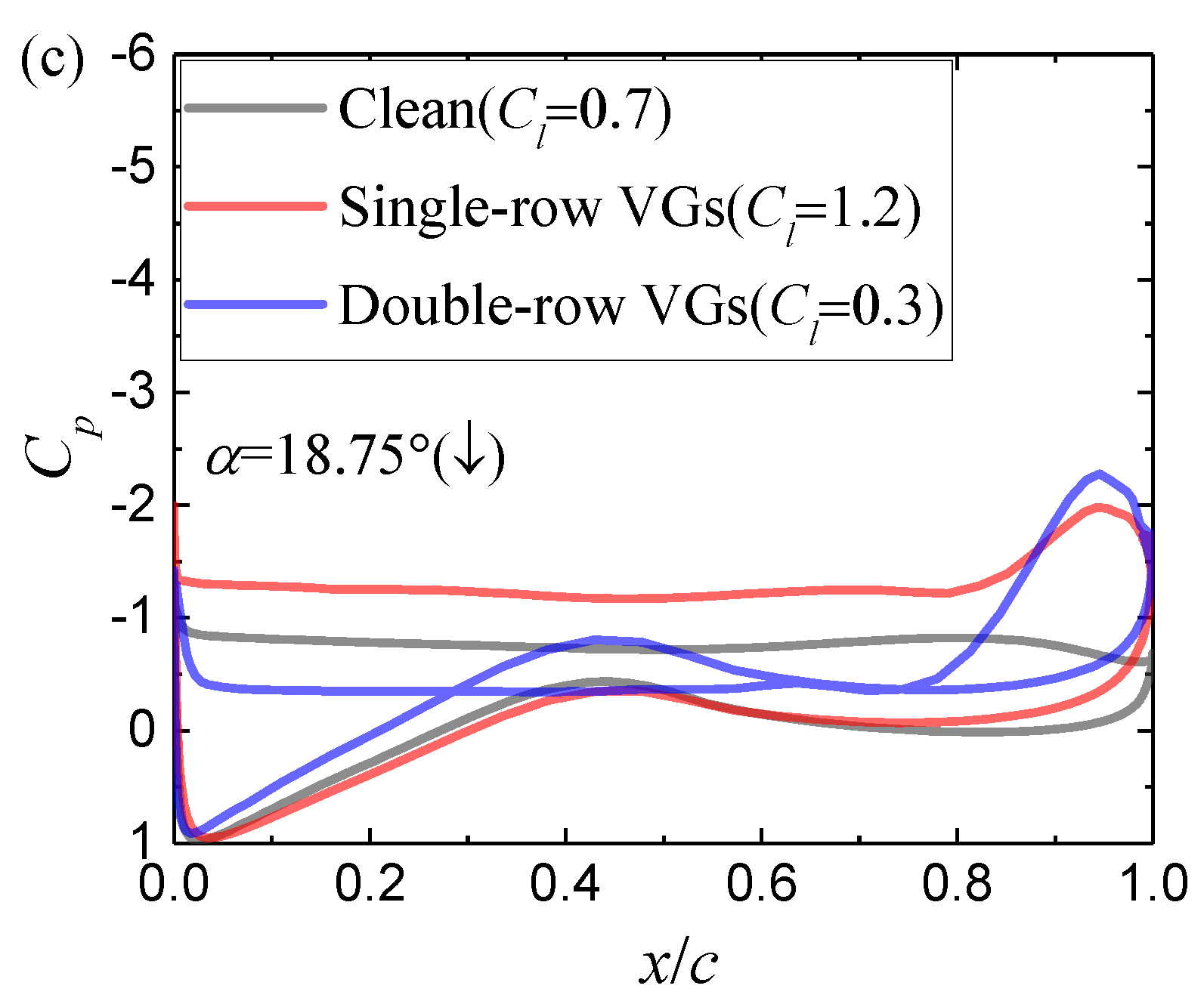

3.2. Flow Field Developments

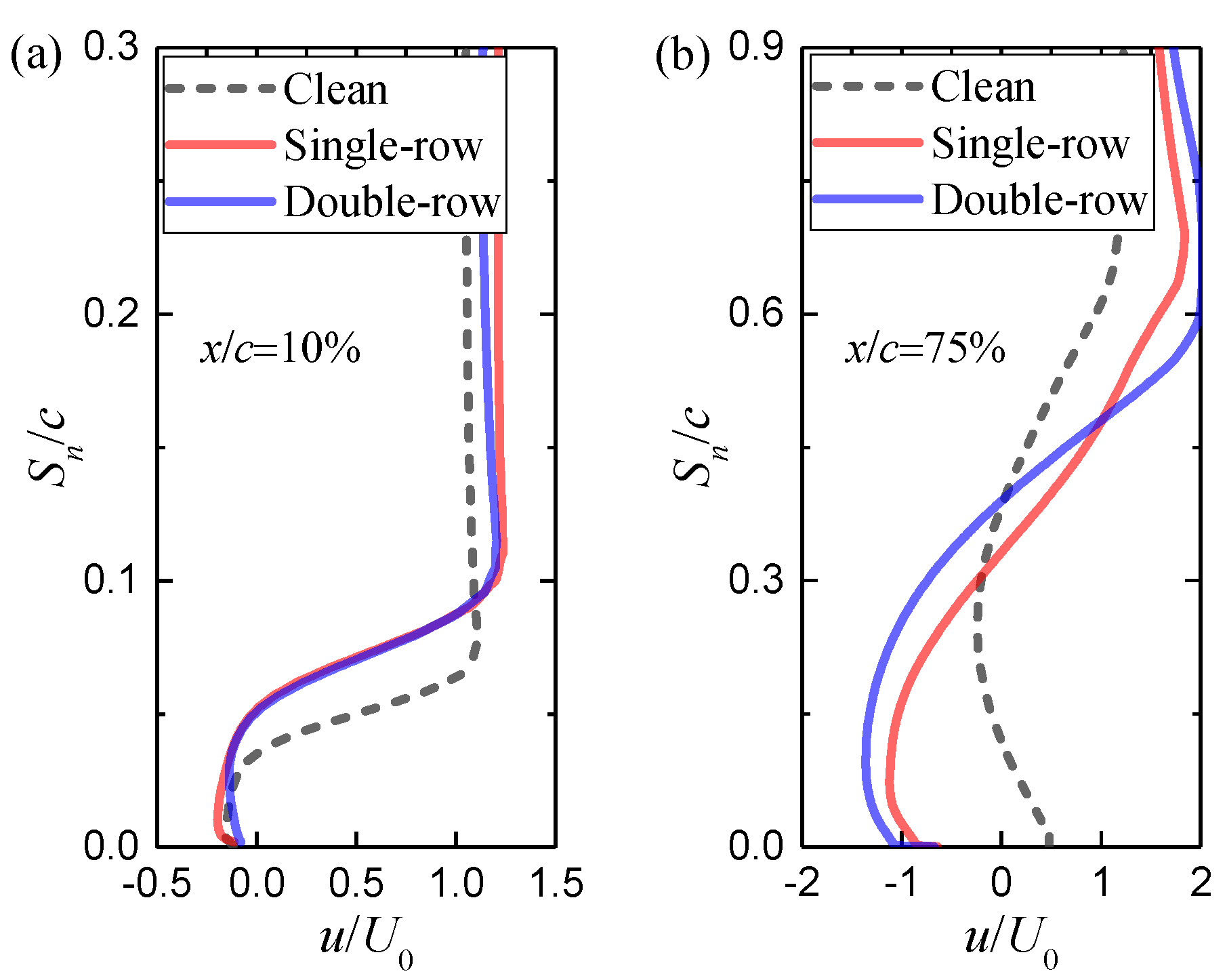

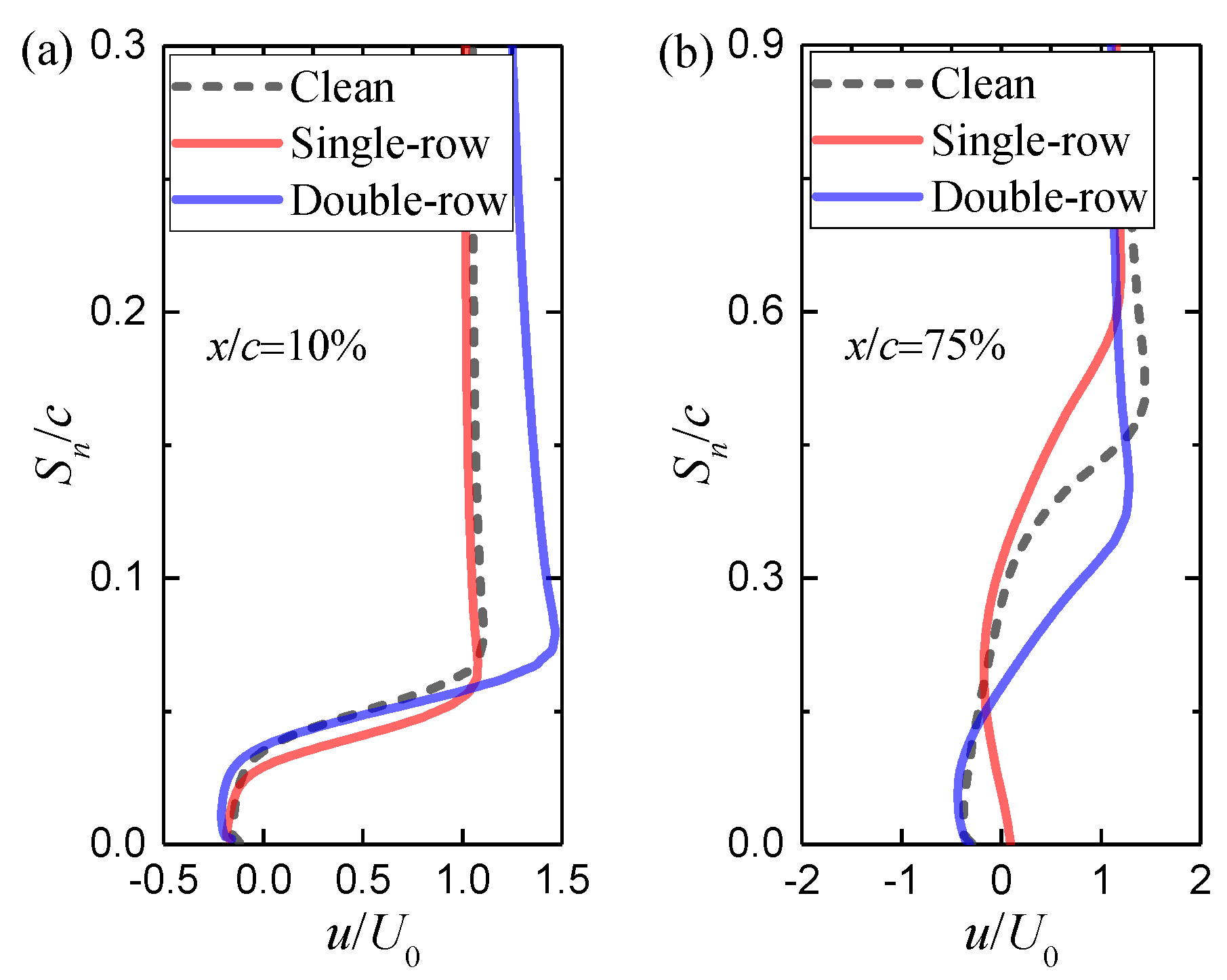

3.3. Boundary-Layer Velocity Profiles

4. Conclusions

- Present numerical modelling can accurately predict the aerodynamic loads of both an airfoil with VGs and an airfoil undergoing deep dynamic stall.

- Both single-row and double-row VGs postpone the flow separation from α = 16° to α = 22°, when the airfoil pitches up. Then, the Cl,max of airfoil with VGs is considerably increased beyond 40%.

- Although single-row and double-row VGs produce an additional TE separation vortex, they can reduce the fluctuations in aerodynamic coefficients near the αmax.

- Single-row VGs bring about a vast decrease in the Cl from 2.2 to 0.3 near the αmax when the airfoil begins to pitch down, implying severe dynamic-stall behaviors. Single-row VGs also seriously retard the flow reattachment near the αmin. Therefore, single-row VGs considerably reduce the ζCm by 67% and hence undermine the torsional aeroelastic stability of airfoil.

- Double-row VGs can quickly restore the decrease in Cl and Cd near the αmax in comparison with single-row VGs. Double-row VGs also significantly help the Cl readjust to the linear regime with the flow reattachment effectively accelerated.

- Double-row VGs can effectively counteract the adverse pressure gradient and hence suppress the TE flow separation during the downstroke process, but single-row VGs cannot. This explains the clear difference in aerodynamic responses between single-row and double-row VGs.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| ↑ | upstroke process |

| ↓ | downstroke process |

| α | angle of attack (AOA) |

| αClmax | AOA of Cl,max |

| αm | mean AOA |

| αmax | maximum AOA |

| αmin | minimum AOA |

| β | geometric vane inflow angle |

| ζCm | aerodynamic pitch damping |

| A | AOA amplitude |

| c | chord length |

| Cd | drag coefficient |

| Cl | lift coefficient |

| Cl,dec | Cl at αClmax (↓) |

| Cl,max | maximum Cl |

| Cm | pitching moment coefficient |

| Cm,dec | Cm at αClmax (↓) |

| Cm,inc | Cm at αClmax (↑) |

| Cm,min | minimum (maximum nose-down) Cm |

| Cp | pressure coefficient |

| D | inter-vane spacing |

| d | intra-vane spacing |

| f | frequency of oscillation |

| h | vane height |

| k | reduced frequency |

| L | vane length |

| Sn | normal distance away from the wall surface |

| u | streamwise velocity |

| U0 | freestream velocity |

| x | chordwise location |

| xVG | chordwise location measured between the airfoil and VG leading edges |

References

- Barlas, A.; van Kuik, G. Review of state of the art in smart rotor control research for wind turbines. Prog. Aerosp. Sci. 2010, 46, 1–27. [Google Scholar] [CrossRef]

- Lin, J.C. Review of research on low-profile vortex generators to control boundary-layer separation. Prog. Aerosp. Sci. 2002, 38, 389–420. [Google Scholar] [CrossRef]

- Godard, G.; Stanislas, M. Control of a decelerating boundary layer. Part 1: Optimization of passive vortex generators. Aerosp. Sci. Technol. 2006, 10, 181–191. [Google Scholar] [CrossRef]

- Mueller-Vahl, H.; Pechlivanoglou, G.; Nayeri, C.N.; Paschereit, C.O. Vortex generators for wind turbine blades: A combined wind tunnel and wind turbine parametric study. In Proceedings of the Asme Turbo Expo 2012, New York, NY, USA, 11–15 June 2012; pp. 899–914. [Google Scholar]

- Baldacchino, D.; Ferreira, C.S.; De Tavernier, D.; Timmer, W.; Van Bussel, G.J.W. Experimental parameter study for passive vortex generators on a 30% thick airfoil. Wind Energy 2018, 21, 745–765. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, B.; Qiu, Q.; Xu, X. Flow control on the NREL S809 wind turbine airfoil using vortex generators. Energy 2017, 118, 1210–1221. [Google Scholar] [CrossRef]

- Velte, C.; Hansen, M.O.L.; Cavar, D. Flow analysis of vortex generators on wing sections by stereoscopic particle image velocimetry measurements. Environ. Res. Lett. 2008, 3, 015006. [Google Scholar] [CrossRef]

- Spalart, P.R.; Shur, M.; Strelets, M.K.; Travin, A.K. Direct Simulation and RANS Modelling of a Vortex Generator Flow. Flow Turbul. Combust. 2015, 95, 335–350. [Google Scholar] [CrossRef]

- Jirasek, A. Vortex-Generator Model and Its Application to Flow Control. J. Aircr. 2005, 42, 1486–1491. [Google Scholar] [CrossRef]

- Baldacchino, D.; Manolesos, M.; Ferreira, C.S.; Salcedo, Á.G.; Aparicio, M.; Chaviaropoulos, T.; Diakakis, K.; Florentie, L.; García, N.R.; Papadakis, G.; et al. Experimental benchmark and code validation for airfoils equipped with passive vortex generators. In Science of Making Torque from Wind; Iop Publishing Ltd.: Bristol, UK, 2016; Volume 753. [Google Scholar]

- Troldborg, N.; Zahle, F.; Sørensen, N.N. Simulations of wind turbine rotor with vortex generators. In Science of Making Torque from Wind; Institute of Physics Publishing: Munich, Germany, 2016; Volume 753. [Google Scholar]

- Leishman, J.G. Challenges in modelling the unsteady aerodynamics of wind turbines. Wind Energy 2002, 5, 85–132. [Google Scholar] [CrossRef]

- Zhu, C.; Wang, T. Comparative Study of Dynamic Stall under Pitch Oscillation and Oscillating Freestream on Wind Turbine Airfoil and Blade. Appl. Sci. 2018, 8, 1242. [Google Scholar] [CrossRef]

- Zhu, C.; Wang, T.; Zhong, W. Combined Effect of Rotational Augmentation and Dynamic Stall on a Horizontal Axis Wind Turbine. Energies 2019, 12, 1434. [Google Scholar] [CrossRef]

- Solar Thermal Magazine. Shark-Inspired Vortex Generators Improve Wind Turbine Blade Performance. Available online: https://solarthermalmagazine.com (accessed on 8 February 2018).

- Micro AeroDynamics Inc. Available online: https://microaero.com/cessna_150/ (accessed on 14 May 2020).

- McCroskey, W.J. The Phenomenon of Dynamic Stall; National Aeronautics and Space Administration: Washington, DC, USA, 1981.

- Müller-Vahl, H.F.; Strangfeld, C.; Nayeri, C.; Paschereit, C.O.; Greenblatt, D. Control of Thick Airfoil, Deep Dynamic Stall Using Steady Blowing. AIAA J. 2015, 53, 277–295. [Google Scholar] [CrossRef]

- Gerontakos, P.; Lee, T. Dynamic Stall Flow Control via a Trailing-Edge Flap. AIAA J. 2006, 44, 469–480. [Google Scholar] [CrossRef]

- Xu, H.-Y.; Qiao, C.-L.; Ye, Z. Dynamic Stall Control on the Wind Turbine Airfoil via a Co-Flow Jet. Energies 2016, 9, 429. [Google Scholar] [CrossRef]

- Li, G.Q.; Zhang, W.G.; Jiang, Y.B.; Yang, P.Y. Experimental investigation of dynamic stall flow control for wind turbine airfoils using a plasma actuator. Energy 2019, 185, 90–101. [Google Scholar] [CrossRef]

- Johnson, S.J.; van Dam, C.P. Active Load Control Techniques for Wind Turbines; Sandia National Laboratories: Springfield, VA, USA, 2008.

- Zhu, C.; Chen, J.; Wu, J.; Wang, T. Dynamic stall control of the wind turbine airfoil via single-row and double-row passive vortex generators. Energy 2019, 189, 116272. [Google Scholar] [CrossRef]

- Zhu, C.; Wang, T.; Wu, J. Numerical Investigation of Passive Vortex Generators on a Wind Turbine Airfoil Undergoing Pitch Oscillations. Energies 2019, 12, 654. [Google Scholar] [CrossRef]

- Zhu, C.; Wang, T.; Chen, J.; Zhong, W. Flow analysis of the deep dynamic stall of wind turbine airfoil with single-row and double-row passive vortex generators. In Proceedings of the International Conference on Sustainable Energy and Green Technology, Bangkok, Thailand, 11–14 December 2019; IOP Conference Series: Earth and Environmental Science. 2020; Volume 463, p. 012118. [Google Scholar] [CrossRef]

- ANSYS Inc. FLUENT Theory Guide, Release 16.0; ANSYS Inc.: Canonsburg, PA, USA, 2015. [Google Scholar]

- Ramsay, R.F.; Hoffman, M.J.; Gregorek, G.M. Effects of Grit Roughness and Pitch Oscillation on the S809 Airfoil; National Renewable Energy Laboratory: Golden, CO, USA, 1995.

- Ekaterinaris, J.A.; Platzer, M. Computational prediction of airfoil dynamic stall. Prog. Aerosp. Sci. 1998, 33, 759–846. [Google Scholar] [CrossRef]

- Menter, F.R. Two-Equation Eddy-Viscosity Transport Turbulence Model for Engineering Applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Menter, F.R.; Langtry, R.B.; Likki, S.R.; Suzen, Y.B.; Huang, P.G.; Völker, S. A Correlation-Based Transition Model Using Local Variables—Part I: Model Formulation. J. Turbomach. 2006, 128, 413–422. [Google Scholar] [CrossRef]

- Johansen, J. Unsteady Airfoil Flows with Application to Aeroelastic Stability; Risø National laboratory: Roskilde, Denmark, 1999.

| Mesh Configuration | Structured O-Type |

|---|---|

| y+ | Always < 1 |

| Normal growth ratio | 1.08 |

| Far-field Distance | 20 c |

| Mesh size (million) | 2.9 (single-row VGs) 3.5 (double-row VGs) |

| Spatial Discretization | Third-order MUSCL convection scheme |

| Temporal Discretization | Bounded second-order implicit scheme |

| Pressure-Velocity Coupling | Coupled algorithm |

| Time Steps Per Cycle | 540 |

| Inner Iterations | 20 |

| Turbulence Model | SST k-ω model |

| Transition Model | γ-Reθ model |

| Case Name | Cl,max | αClmax (°) | Cl,dec | Cm,inc | Cm,dec | Cm,min | ζCm |

|---|---|---|---|---|---|---|---|

| clean | 1.78 | 28.62 | 0.67 | −0.34 | −0.120 | −0.605 | 0.153 |

| singe-row VGs | 2.49 | 23.37 | 1.26 | −0.23 | −0.280 | −1.086 | 0.055 |

| double-row VGs | 2.65 | 26.24 | 1.95 | −0.60 | −0.399 | −1.028 | 0.124 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, C.; Wang, T.; Chen, J.; Zhong, W. Effect of Single-Row and Double-Row Passive Vortex Generators on the Deep Dynamic Stall of a Wind Turbine Airfoil. Energies 2020, 13, 2535. https://doi.org/10.3390/en13102535

Zhu C, Wang T, Chen J, Zhong W. Effect of Single-Row and Double-Row Passive Vortex Generators on the Deep Dynamic Stall of a Wind Turbine Airfoil. Energies. 2020; 13(10):2535. https://doi.org/10.3390/en13102535

Chicago/Turabian StyleZhu, Chengyong, Tongguang Wang, Jie Chen, and Wei Zhong. 2020. "Effect of Single-Row and Double-Row Passive Vortex Generators on the Deep Dynamic Stall of a Wind Turbine Airfoil" Energies 13, no. 10: 2535. https://doi.org/10.3390/en13102535

APA StyleZhu, C., Wang, T., Chen, J., & Zhong, W. (2020). Effect of Single-Row and Double-Row Passive Vortex Generators on the Deep Dynamic Stall of a Wind Turbine Airfoil. Energies, 13(10), 2535. https://doi.org/10.3390/en13102535