Investigation of Ultra-High Pressure Gas Control System for Hydrogen Vehicles

Abstract

1. Introduction

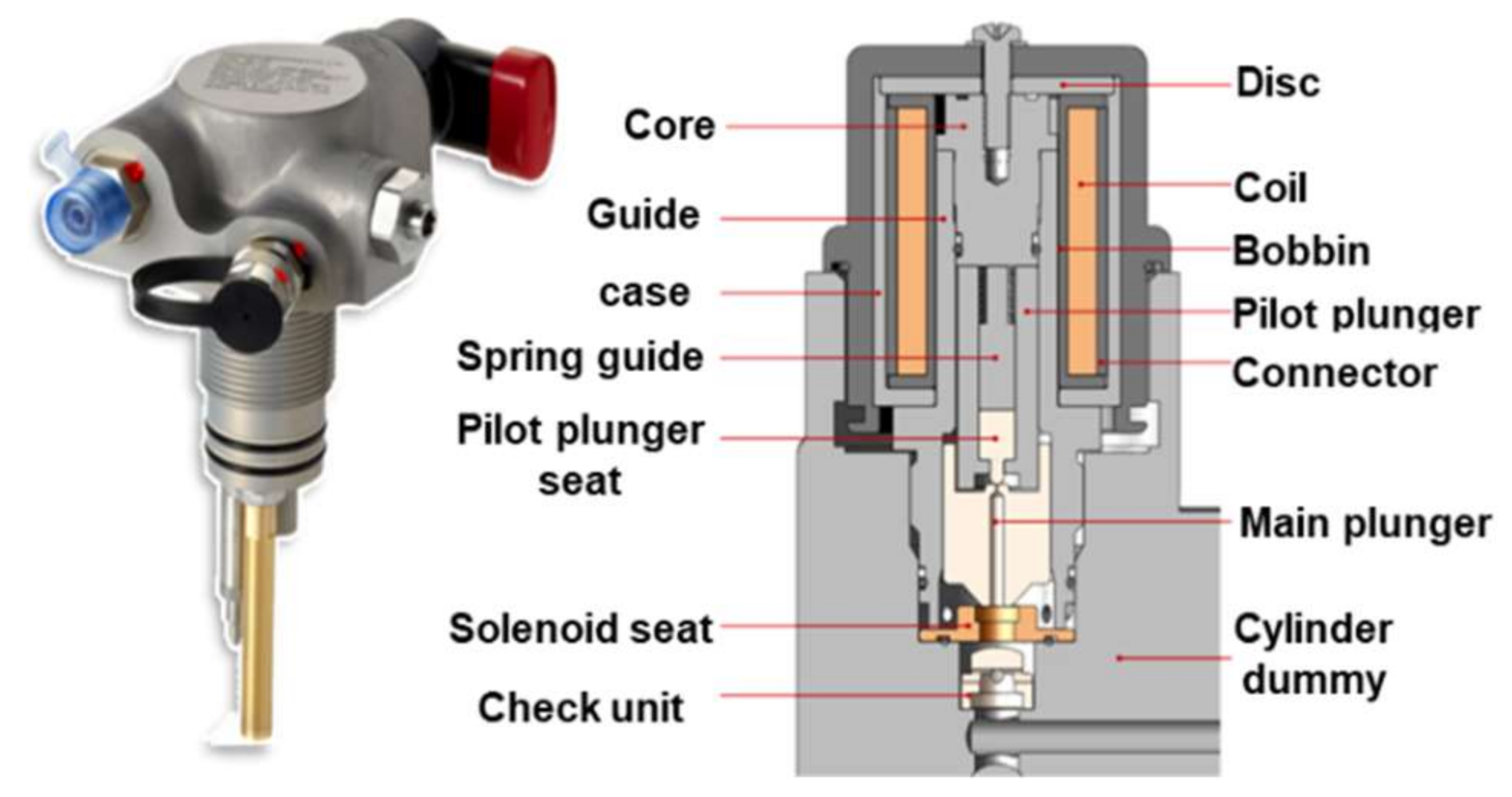

2. Solenoid Valve

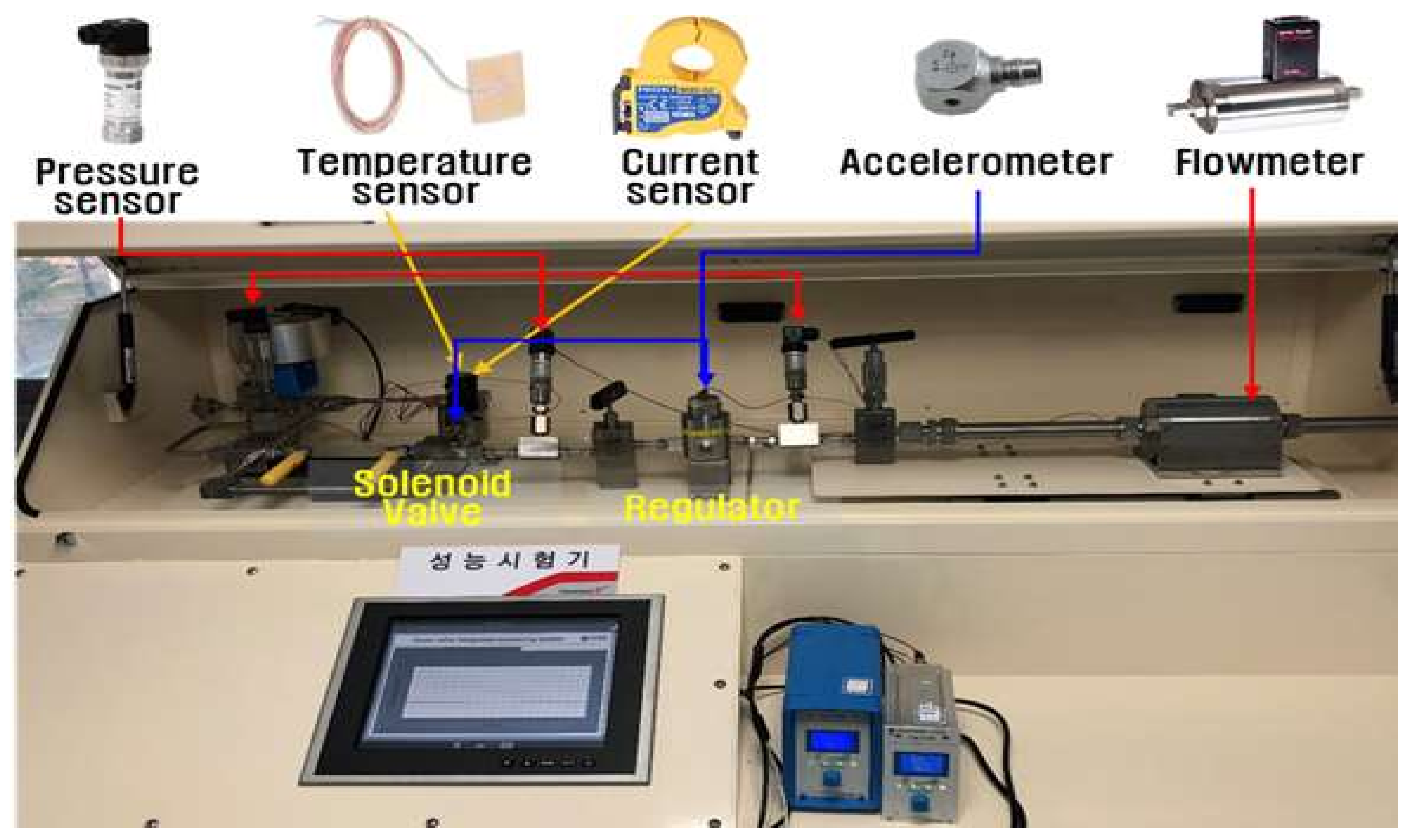

3. Performance Test and Evaluation

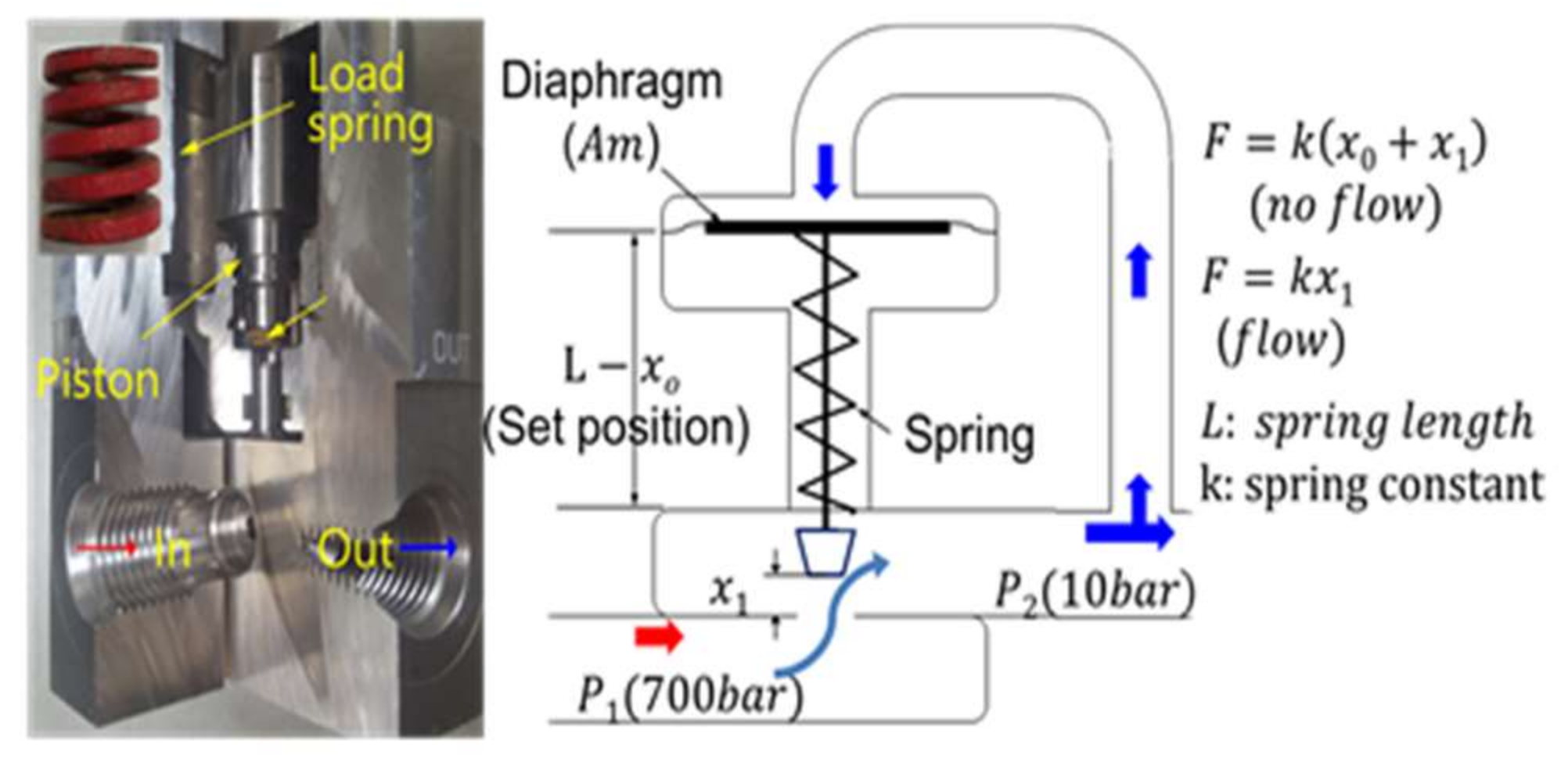

3.1. Regulator Characteristics

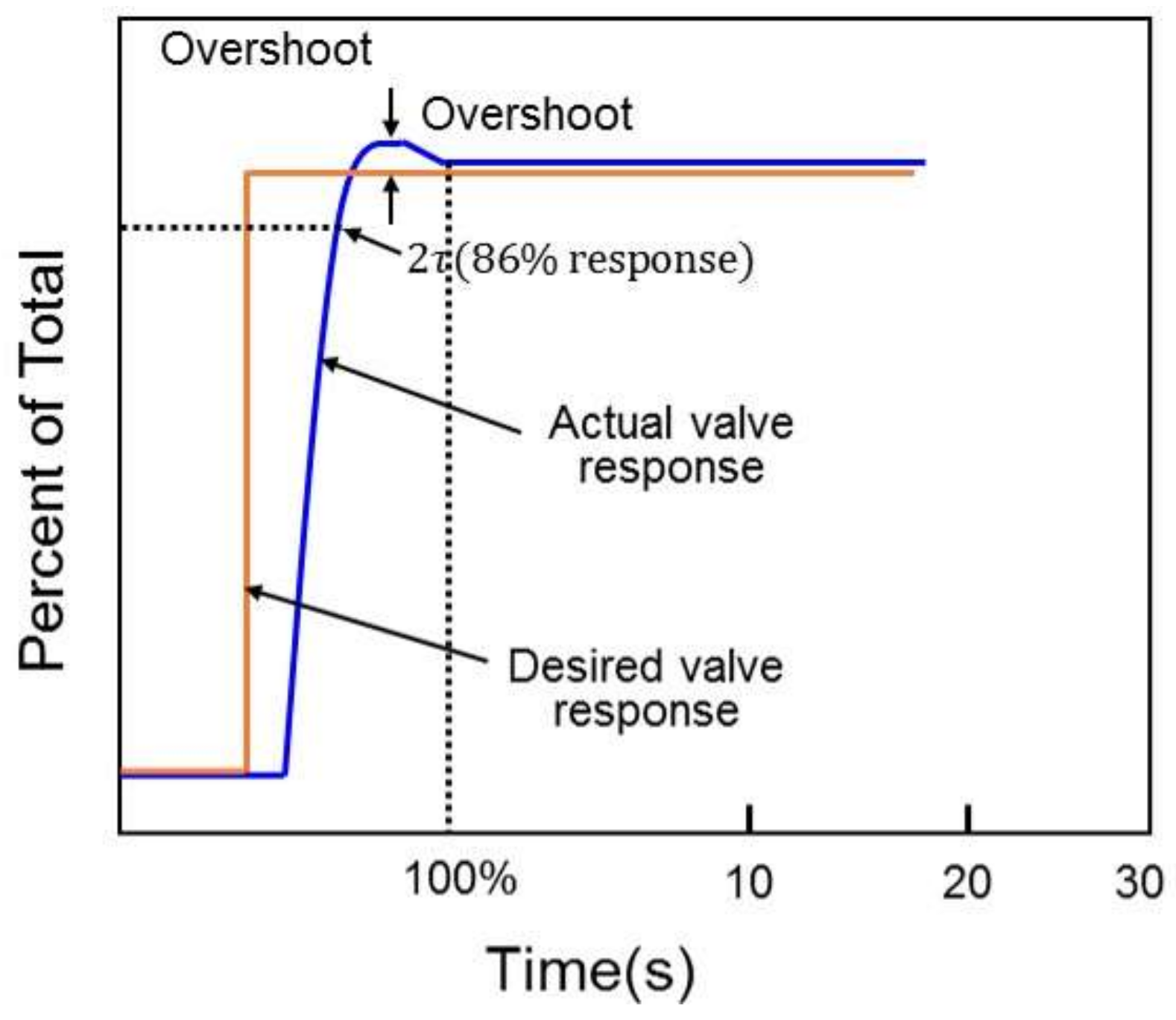

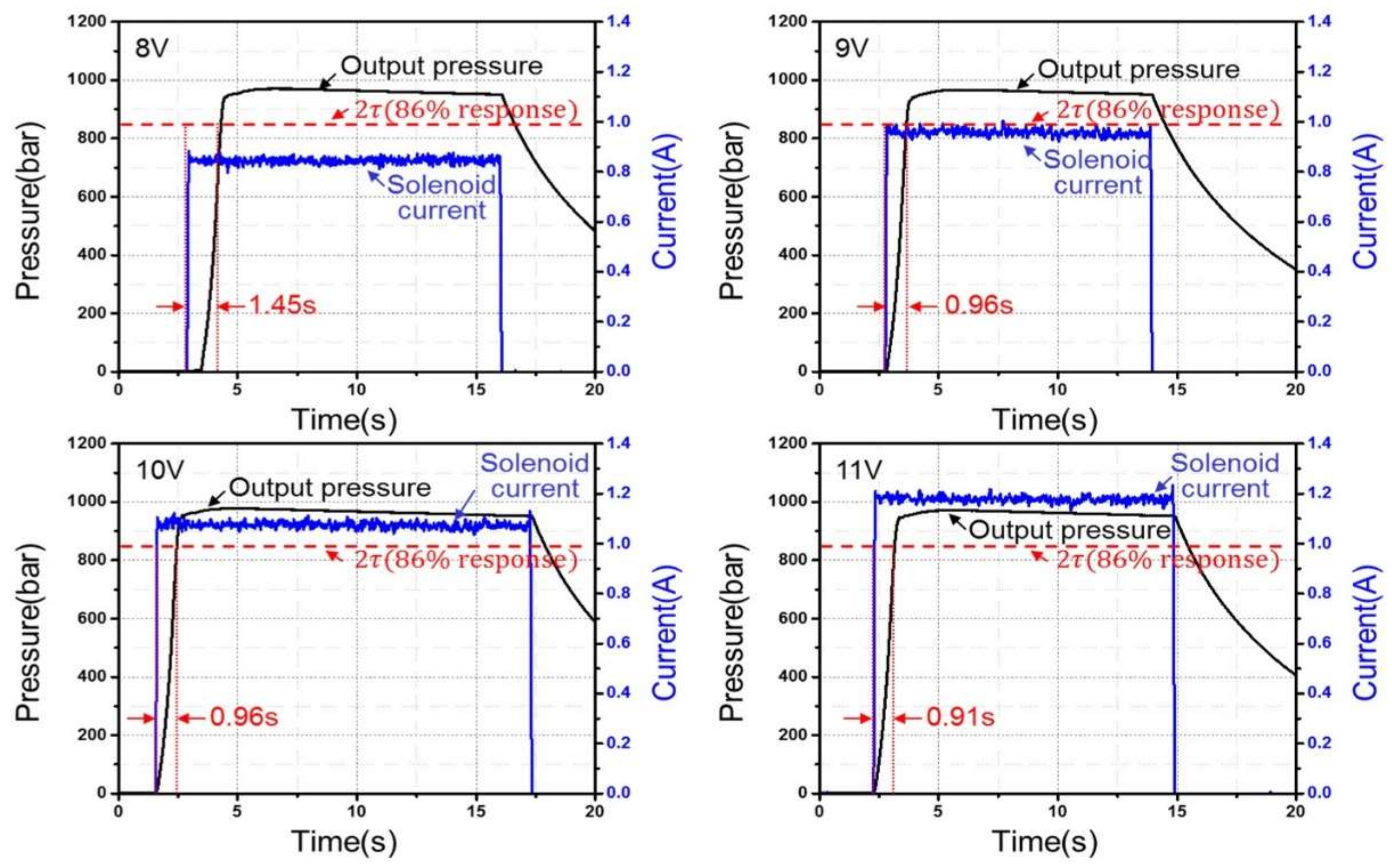

3.2. Solenoid Valve Characteristics

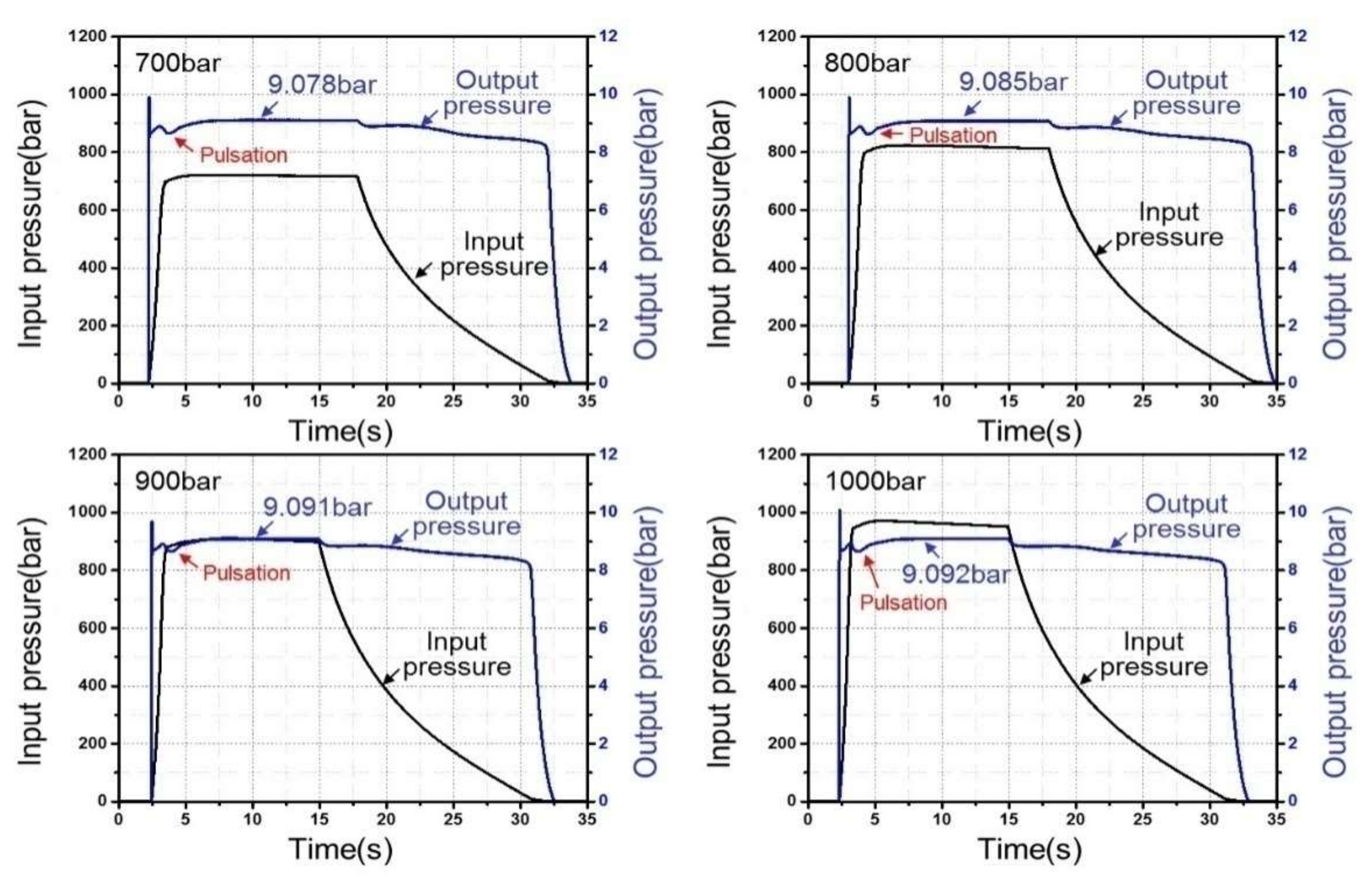

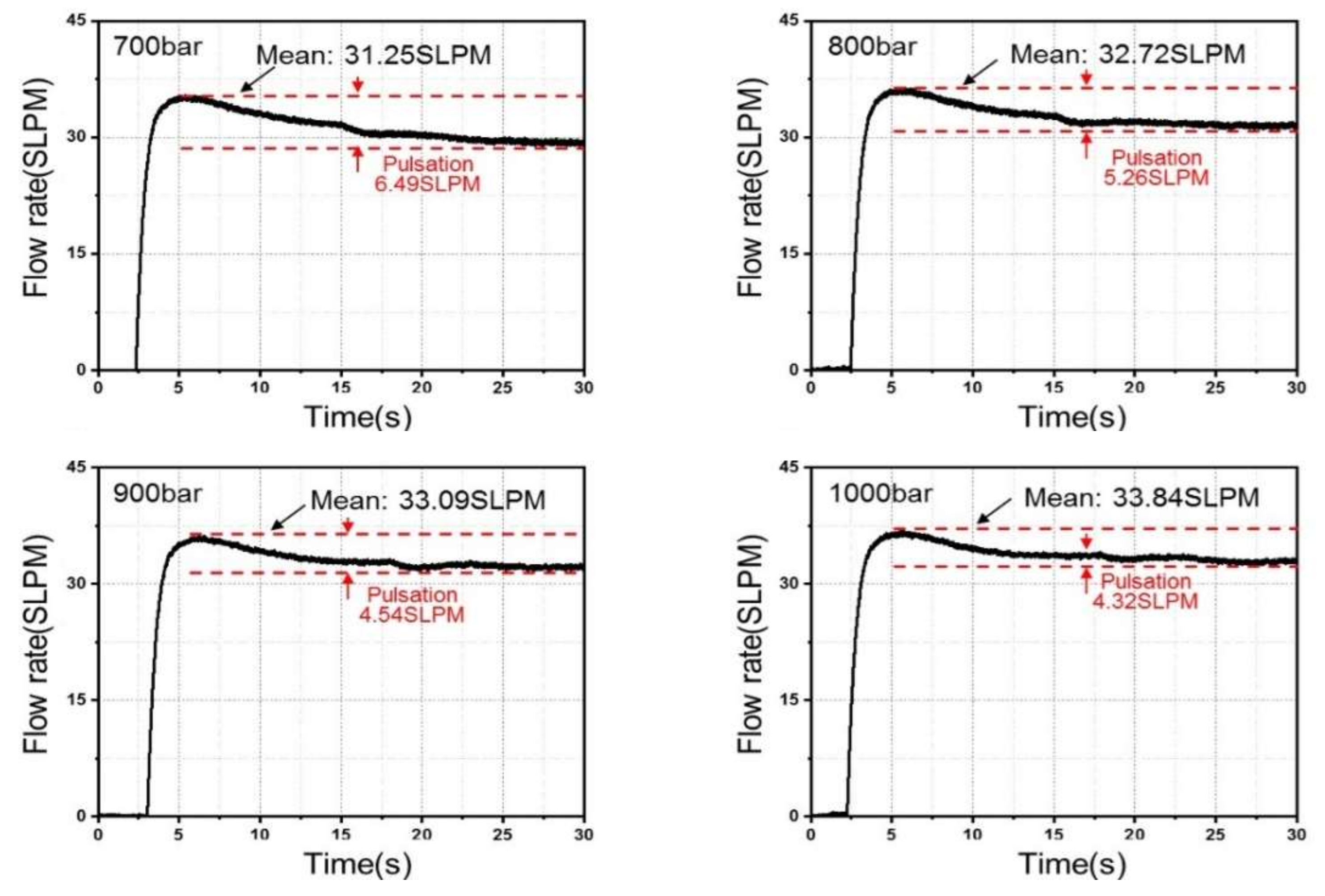

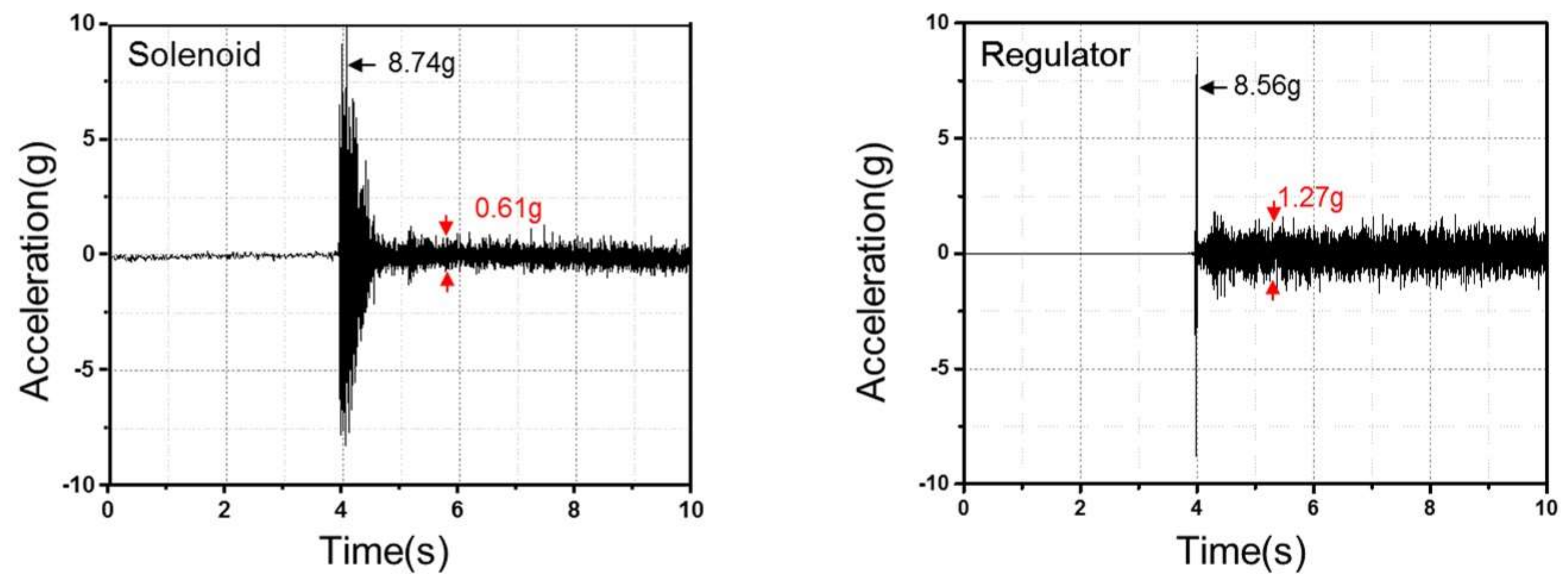

3.3. Evaluation of PulsationCharacteristics

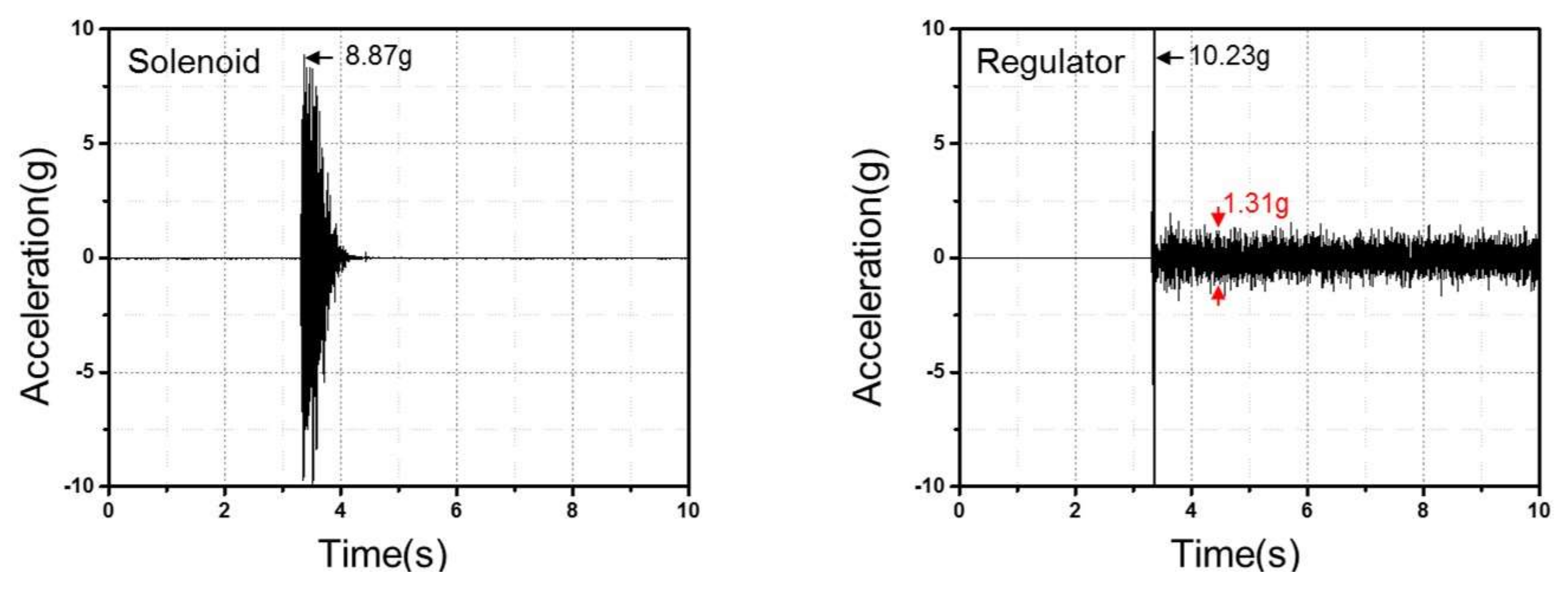

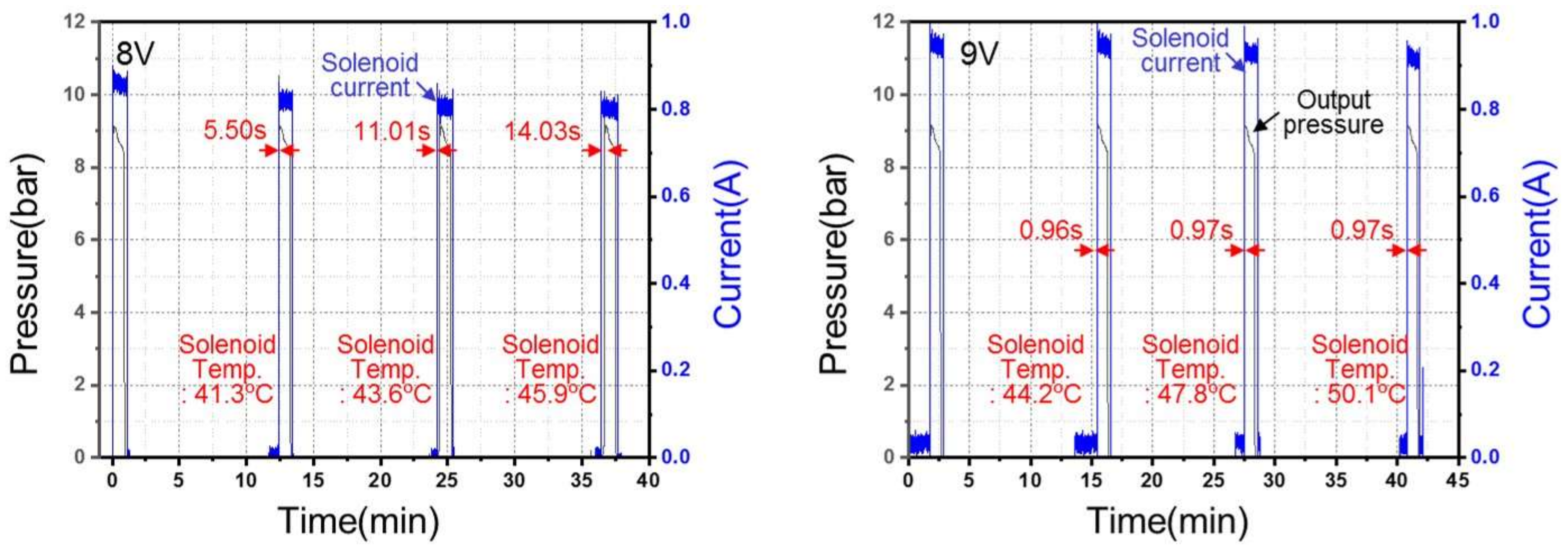

3.4. EnduranceEvaluation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Nicoleti, G. The hydrogen option for energy: A review of technical, environmental and economic aspects. Int. J. Hydrog. Energy 1995, 20, 759–765. [Google Scholar] [CrossRef]

- Hua, T.Q.; Ahluwalia, R.; Peng, J.K.; Cromer, M.; Lasher, S.; Kenney, K.M. Technical assessment of compressed hydrogen storage tank systems for automotive applications. Int. J. Hydrog. Energy 2011, 36, 3037–3049. [Google Scholar] [CrossRef]

- Jinyang, Z.; Xianxin, L.; Ping, X.; Pengfei, L.; Yongzhi, Z.; Jian, Y. Development of high pressure gaseous hydrogen storage technologies. Int. J. Hydrog. Energy 2011, 37, 1048–1057. [Google Scholar]

- Son, D.-S.; Hong, J.-H.; Chang, S.-H. Determination of the autofrettage pressure and estimation of material failures of a Type III hydrogen pressure vessel by using finite element analysis. Int. J. Hydrog. Energy 2012, 37, 12771–12781. [Google Scholar] [CrossRef]

- Qian, J.Y.; Wu, J.-Y.; Gao, A.-X.; Wu, A.; Jin, Z.-J. Hydrogen decompression analysis by multi-stage Tesla valves for hydrogen fuel cell. Int. J. Hydrog. Energy 2019, 44, 13666–13674. [Google Scholar] [CrossRef]

- Klebanoff, L.E.; Pratt, J.W.; LaFleur, C.B. Comparison of the safety-related physical and combustion properties of liquid hydrogen and liquid natural gas in the context of the SF-BREEZE high-speed fuel-cell ferry. Int. J. Hydrog. Energy 2017, 42, 759–774. [Google Scholar] [CrossRef]

- Yanchao, L.; Mingshu, B.; Bei, L.; Yonghao, Z.; Wei, G. Effects of hydrogen and initial pressure on flame characteristics and explosion pressure of methane/hydrogen fuels. Fuel 2018, 233, 269–282. [Google Scholar]

- Chen, F.-Q.; Zhang, M.; Qian, J.-Y.; Chen, L.-L.; Jin, Z.-J. Pressure analysis on two-step high pressure reducing system for hydrogen fuel cell electric vehicle. Int. J. Hydrog. Energy 2017, 42, 11541–11552. [Google Scholar] [CrossRef]

- Ahmadi, P.; Kjeang, E. Realistic simulation of fuel economy and life cycle metrics for hydrogen fuel cell vehicles. Int. J. Energy Res. 2017, 41, 714–727. [Google Scholar] [CrossRef]

- Angadi, S.V.; Jackson, R.L.; Choe, S.Y.; Flowers, G.T.; Suhling, J.C.; Chang, Y.K.; Ham, J.K.; Bae, J.I. Reliability and life study of hydraulic solenoid valve. Part 2: Experimental study. Eng. Fail. Anal. 2009, 16, 944–963. [Google Scholar] [CrossRef]

| Sensor | Specification |

|---|---|

| Pressure | Measuring range: 0–1600 bar, 0–60 bar Accuracy: ±0.5% Response: 1 ms |

| Temperature | Measuring range: 0–400 °C |

| Current | Measuring range: 50 mA–100 A |

| Accelerometer | Measuring range: 10, 50 g Accuracy: ±5% |

| Flow | Measuring range: 0–3000 SLPM Accuracy: ±1% |

| GAS(Leak) | Measuring range: 0–1000 ppm |

| Embedded controller (NI 9039) | Embedded controller 1.91 GHz processor 16 GB nonvolatile storage |

| Parameter | Conditions |

|---|---|

| Input voltage (V) | 7, 8, 9, 10, 11, 12 |

| Input pressure (bar) | 700, 800, 900, 1000 |

| Gas | Nitrogen |

| Sampling rate | 100 Hz |

| Input Pressure | Applied Voltage (V) | |||||

|---|---|---|---|---|---|---|

| 7 V | 8 V | 9 V | 10 V | 11V | 12 V | |

| 700 bar | 1.03 | 1.03 | 1.03 | 1.01 | 1.00 | 0.97 |

| 800 bar | X | 1.03 | 0.99 | 0.98 | 0.98 | 0.96 |

| 900 bar | X | 0.99 | 0.97 | 0.97 | 0.97 | 0.93 |

| 1000 bar | X | 1.45 | 0.96 | 0.96 | 0.91 | 0.91 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, R.-W.; Hwang, K.-H.; Kim, S.-R.; Lee, J.-H. Investigation of Ultra-High Pressure Gas Control System for Hydrogen Vehicles. Energies 2020, 13, 2446. https://doi.org/10.3390/en13102446

Kim R-W, Hwang K-H, Kim S-R, Lee J-H. Investigation of Ultra-High Pressure Gas Control System for Hydrogen Vehicles. Energies. 2020; 13(10):2446. https://doi.org/10.3390/en13102446

Chicago/Turabian StyleKim, Roh-Won, Kyung-Hwan Hwang, Sung-Ryul Kim, and Jae-Hak Lee. 2020. "Investigation of Ultra-High Pressure Gas Control System for Hydrogen Vehicles" Energies 13, no. 10: 2446. https://doi.org/10.3390/en13102446

APA StyleKim, R.-W., Hwang, K.-H., Kim, S.-R., & Lee, J.-H. (2020). Investigation of Ultra-High Pressure Gas Control System for Hydrogen Vehicles. Energies, 13(10), 2446. https://doi.org/10.3390/en13102446