Investigating Agglomeration Tendency of Co-Gasification between High Alkali Biomass and Woody Biomass in a Bubbling Fluidized Bed System

Abstract

1. Introduction

2. Methodology

2.1. Biomass Preparation

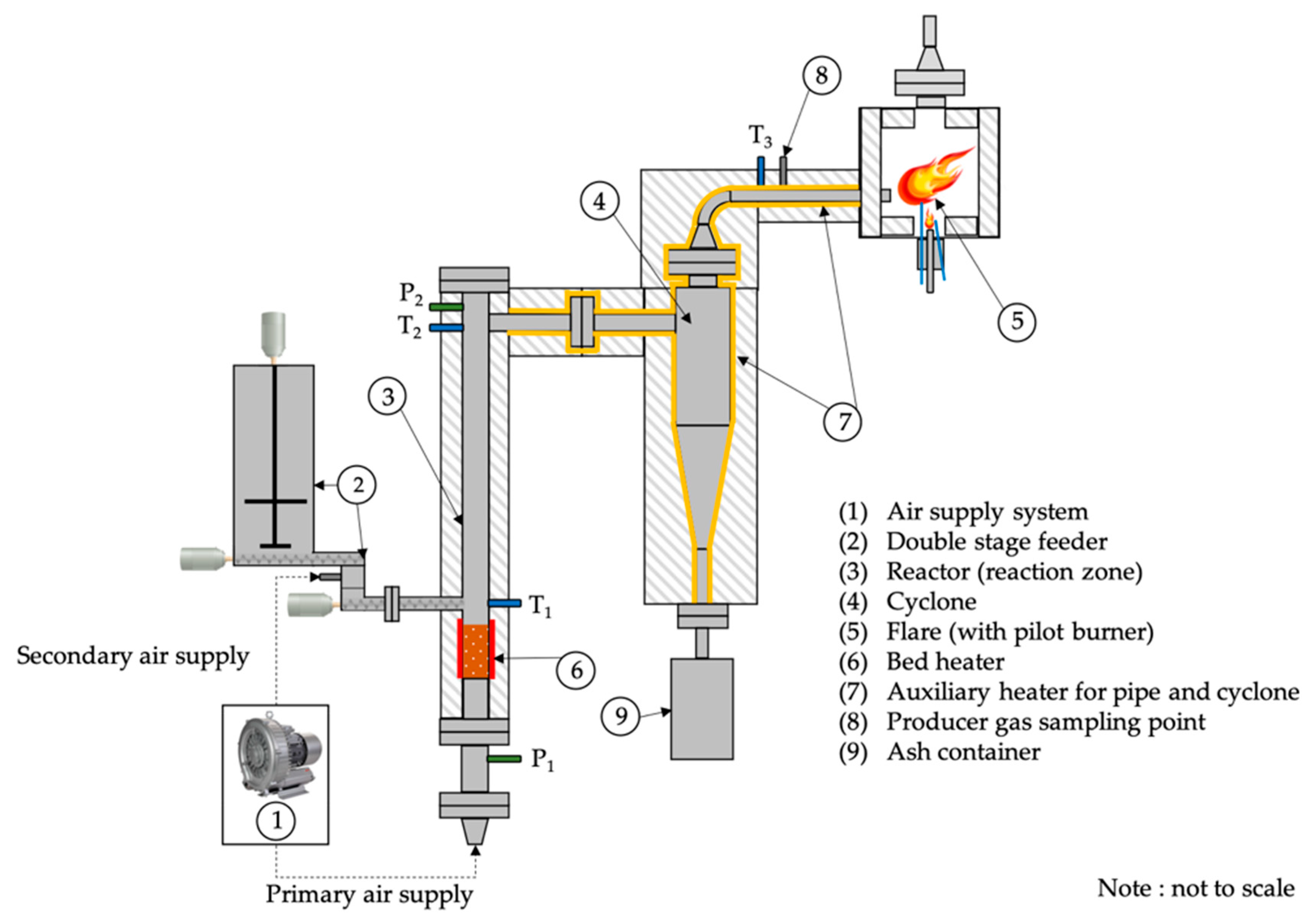

2.2. Bench Scale Fluidized Bed Gasification System

2.3. Experiment Procedure

2.4. Producer Gas Sampling and Analysis Method

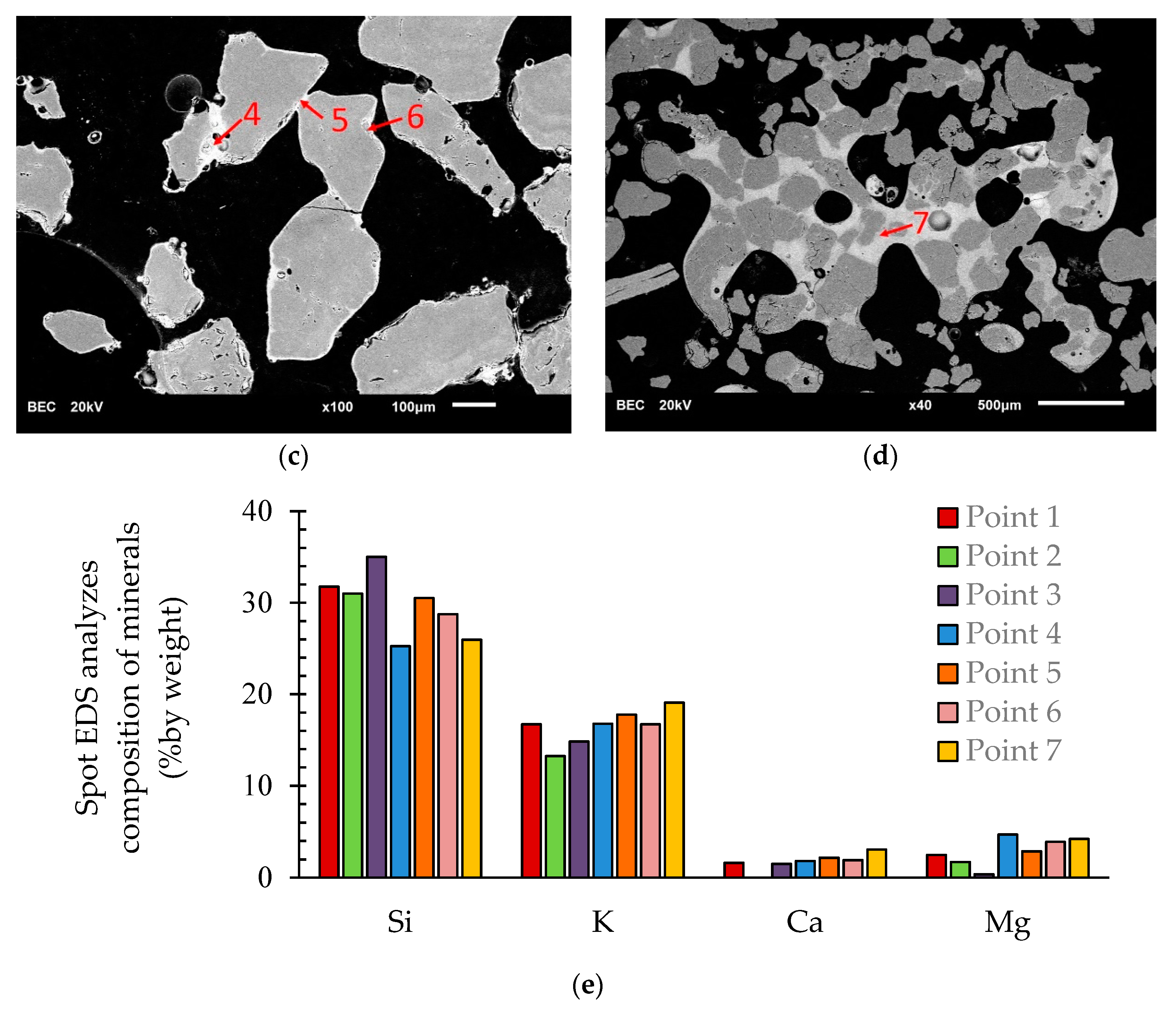

2.5. Agglomeration Analysis

2.6. Error and Uncertainty

3. Results and Discussion

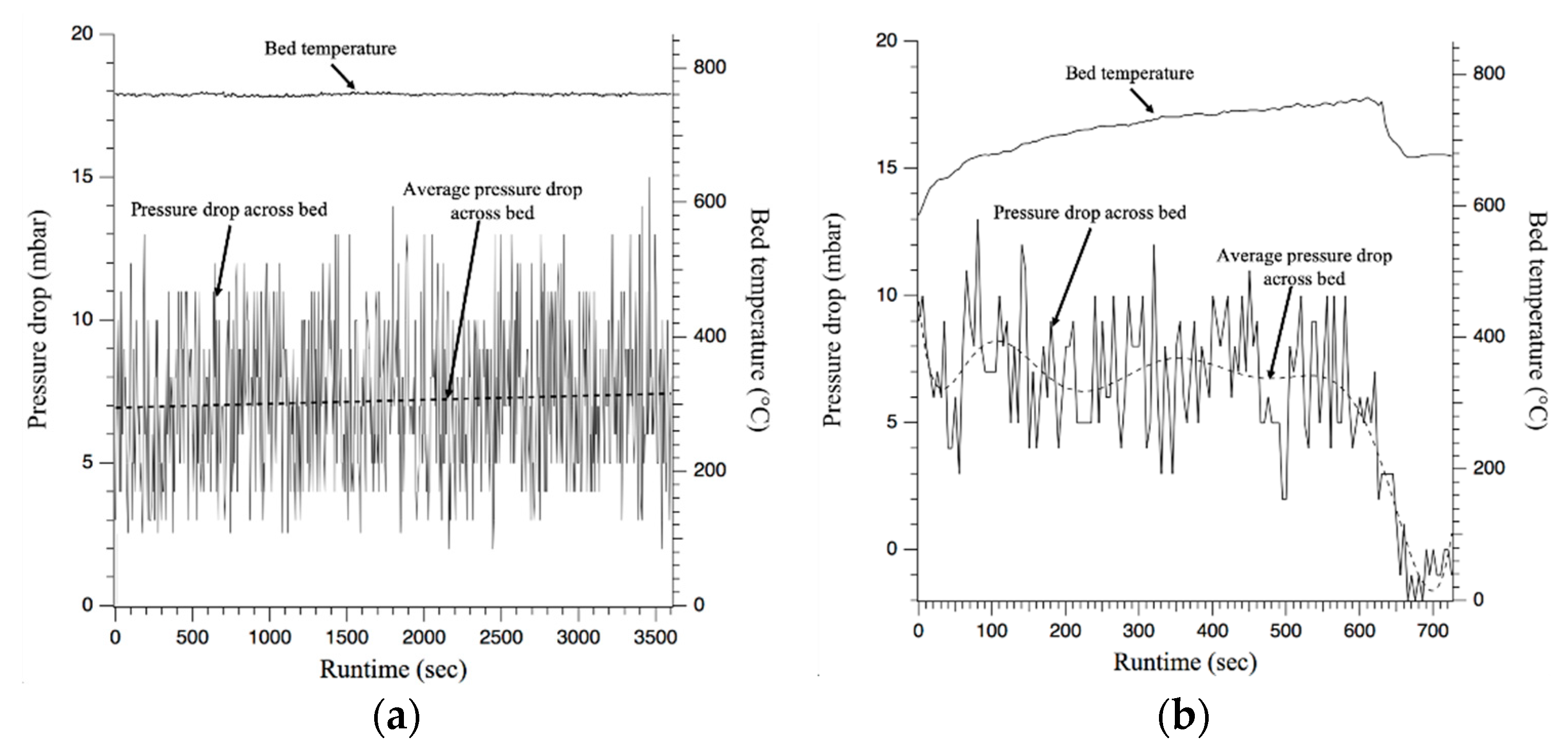

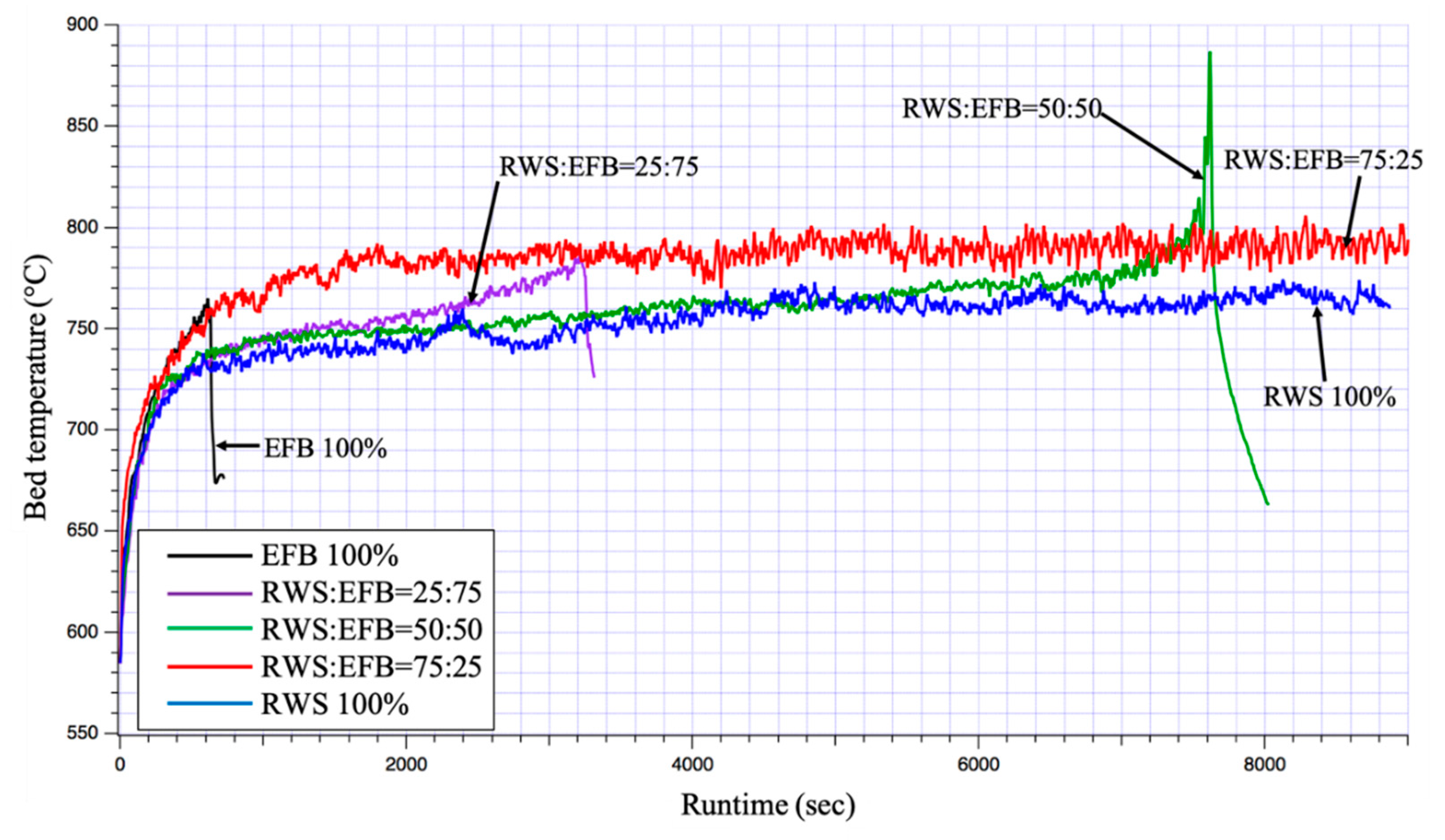

3.1. Gasification Characteristic

3.2. Producer Gas Yield and Gasification Efficiency

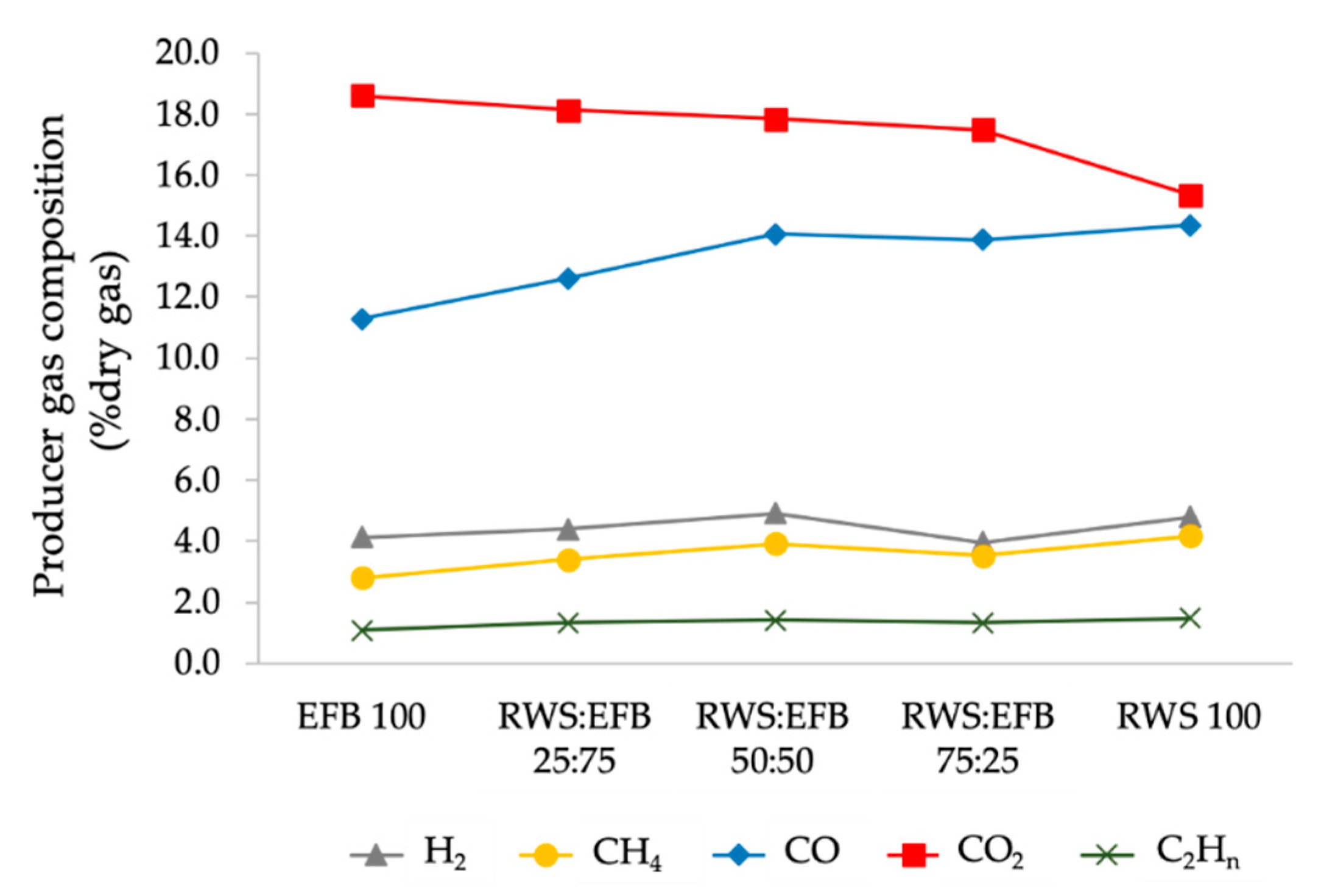

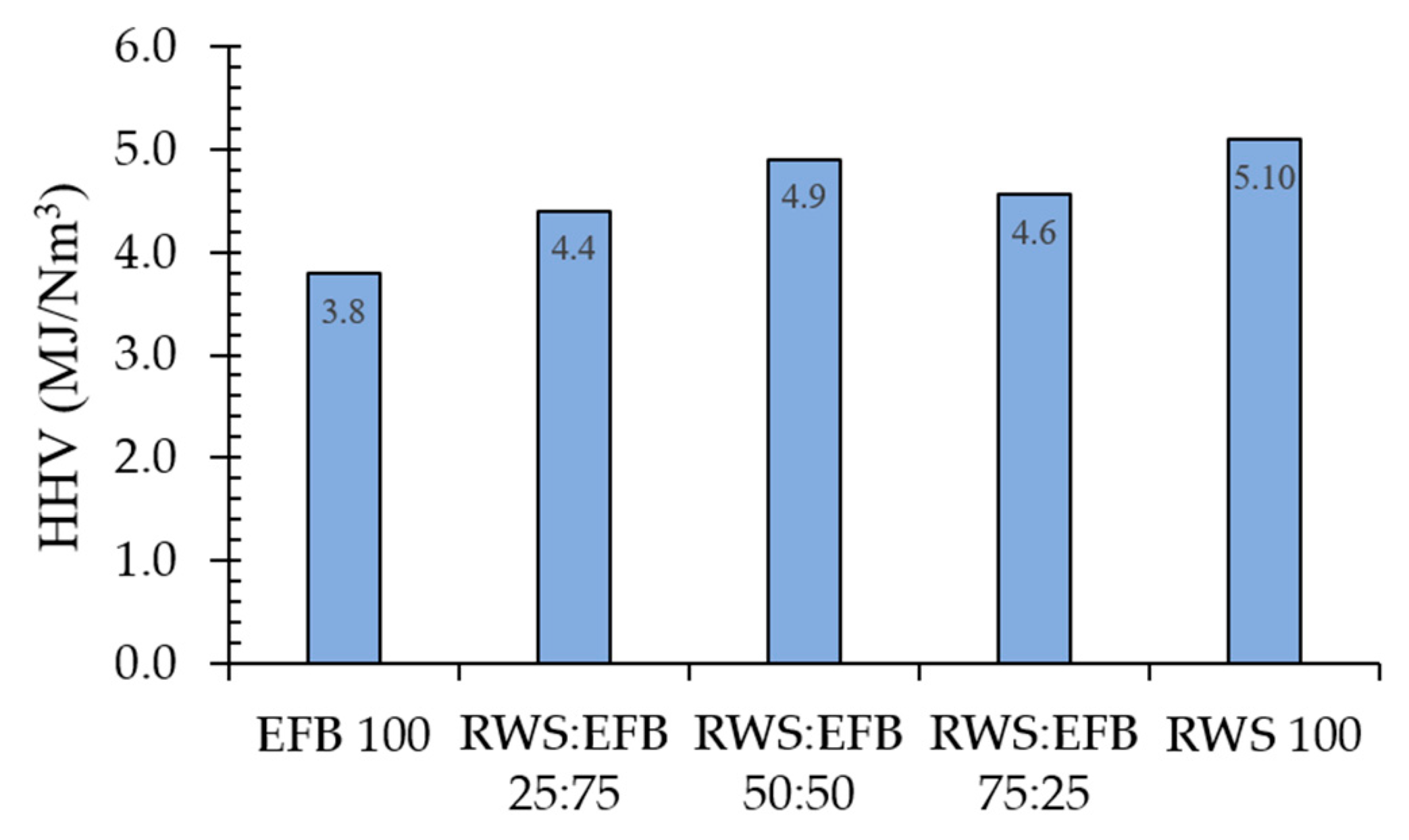

3.2.1. Producer Gas Composition and Higher Heating Value (HHV)

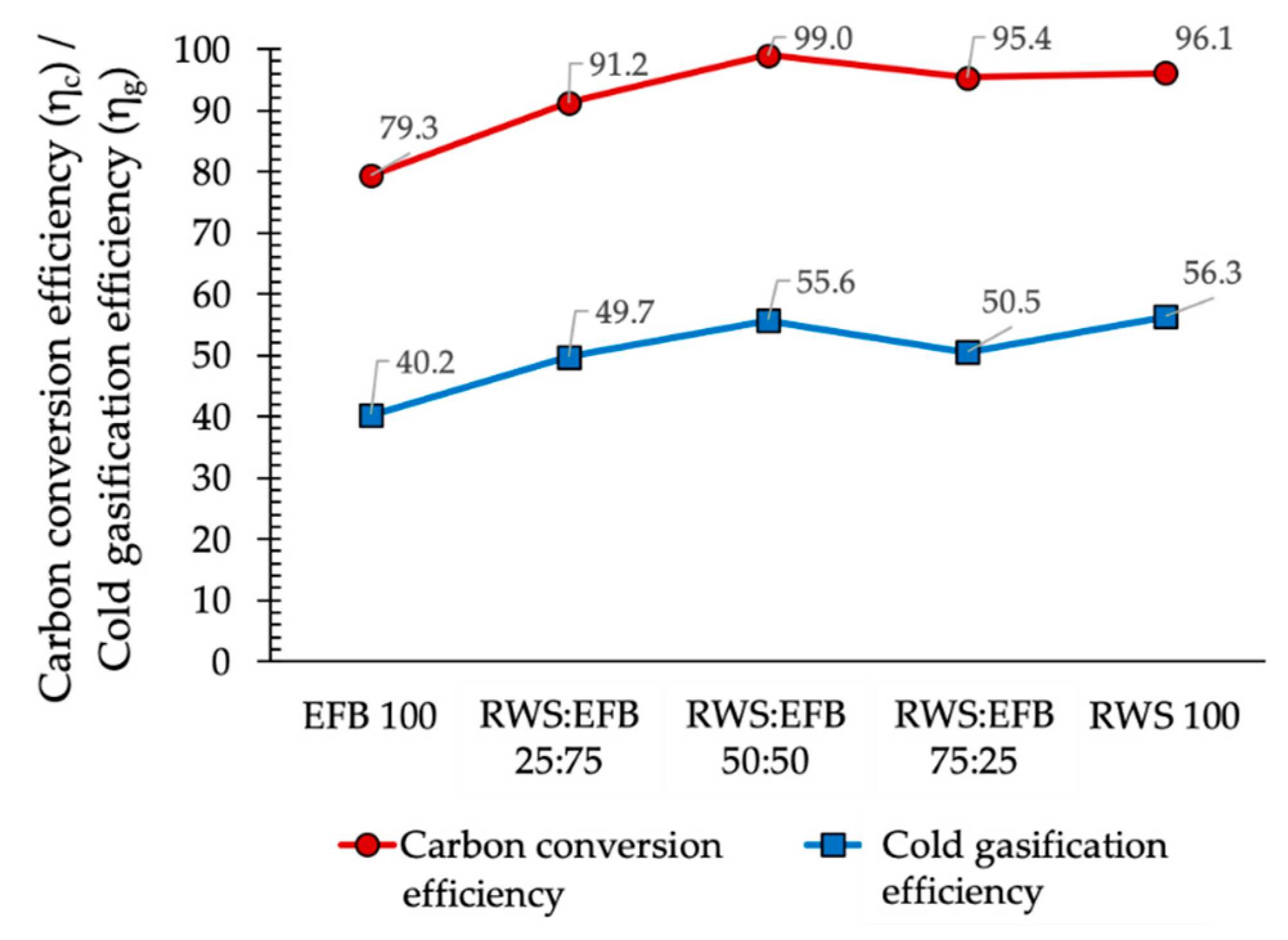

3.2.2. Carbon Conversion Efficiency (ηc) and Cold Gasification Efficiency (ηg)

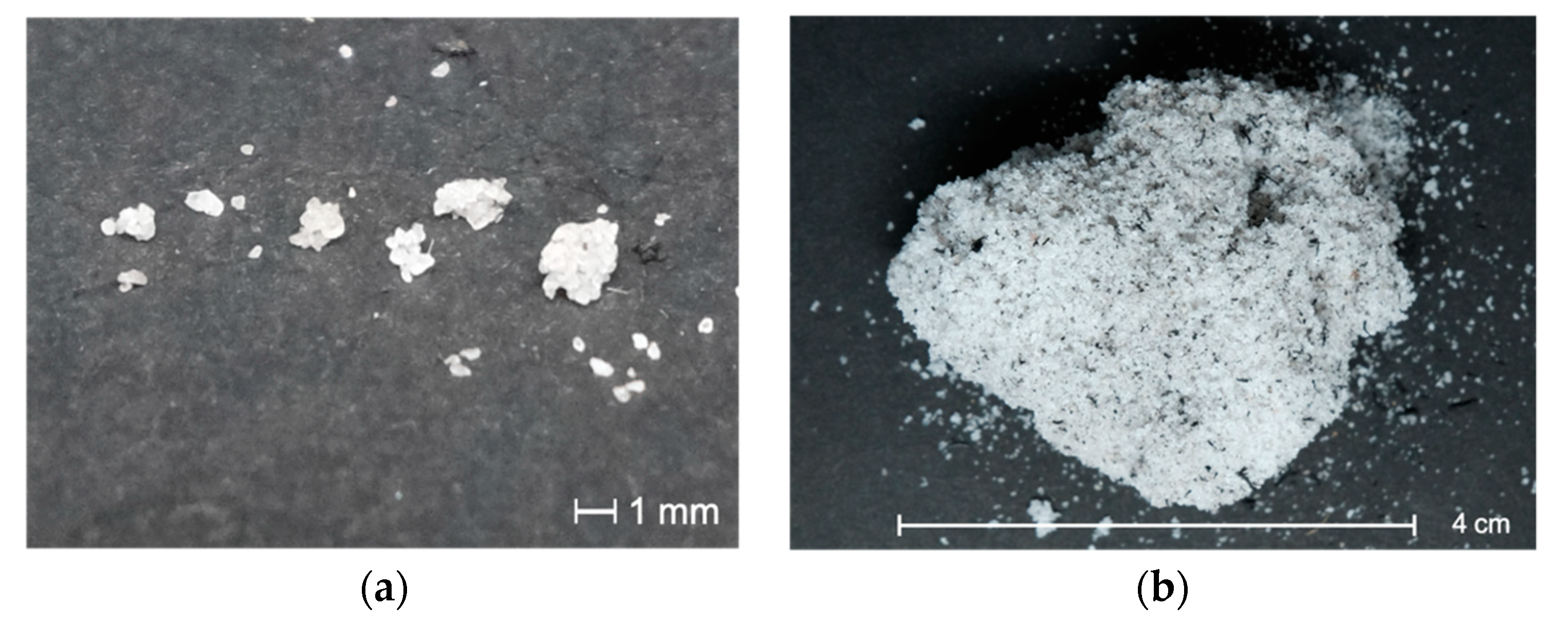

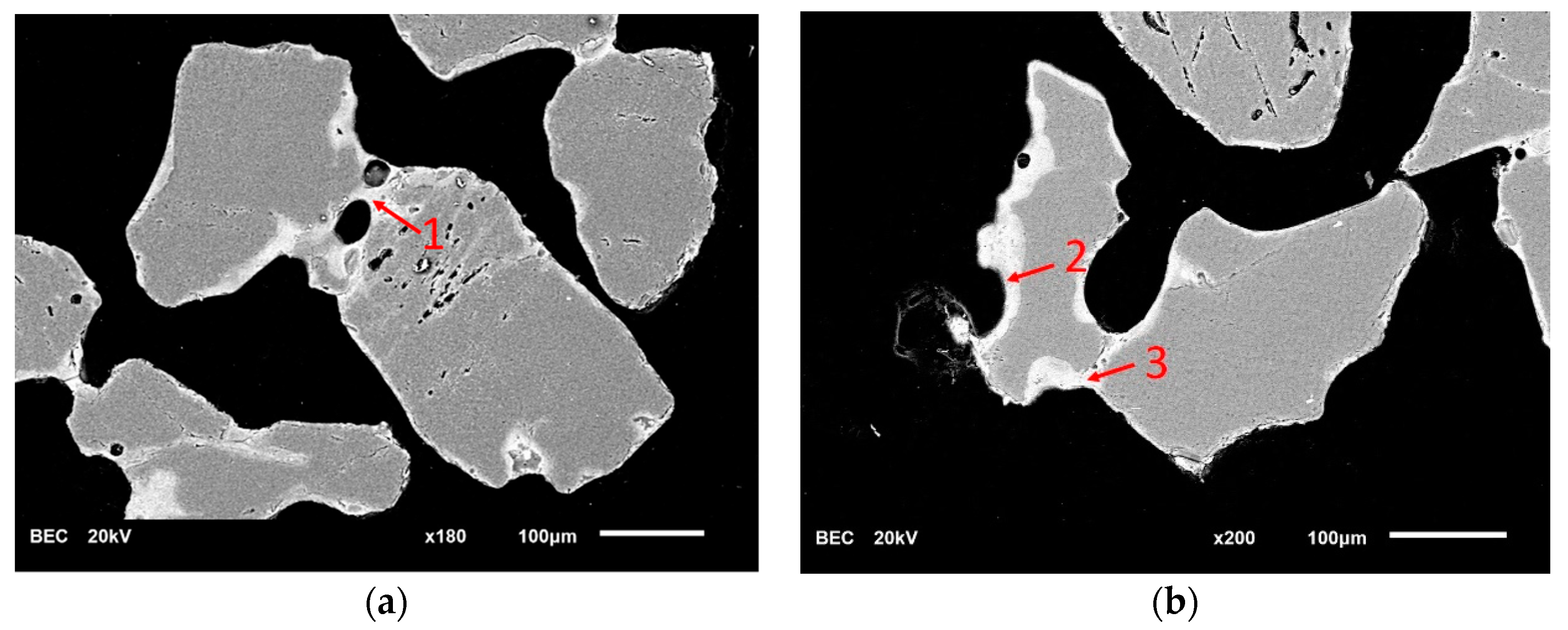

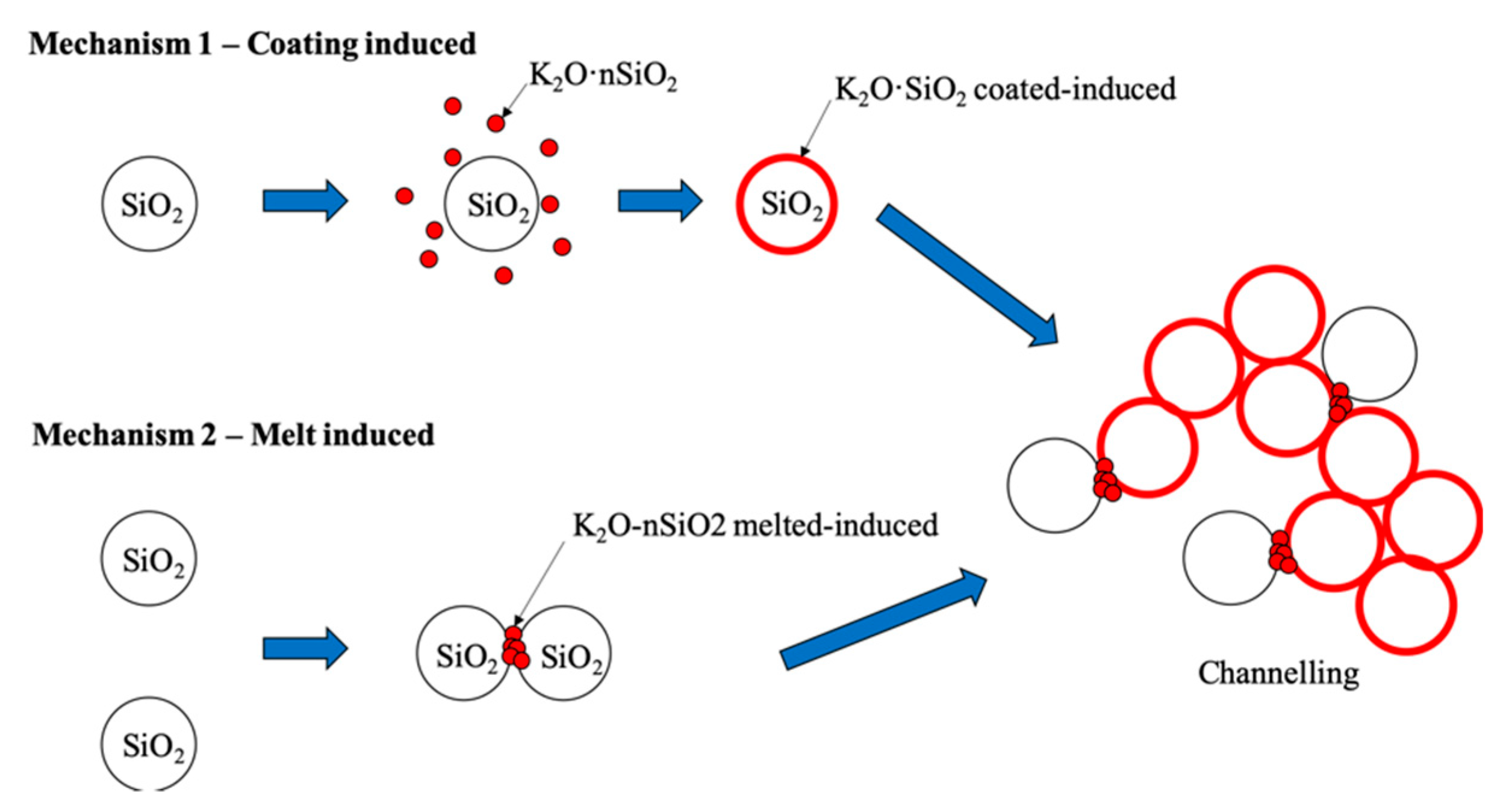

3.3. Bed Agglomeration and Agglomeration Mechanisms

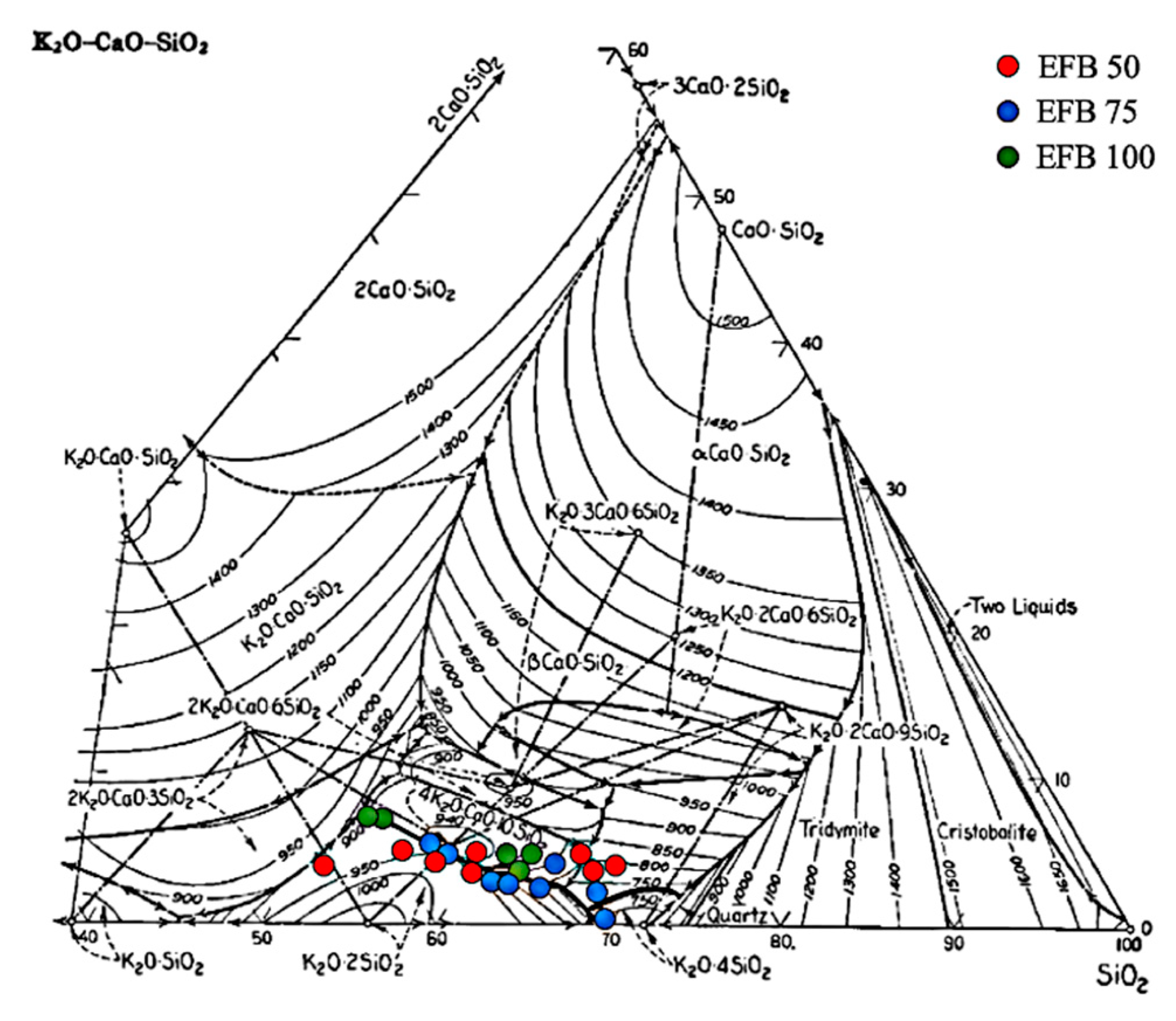

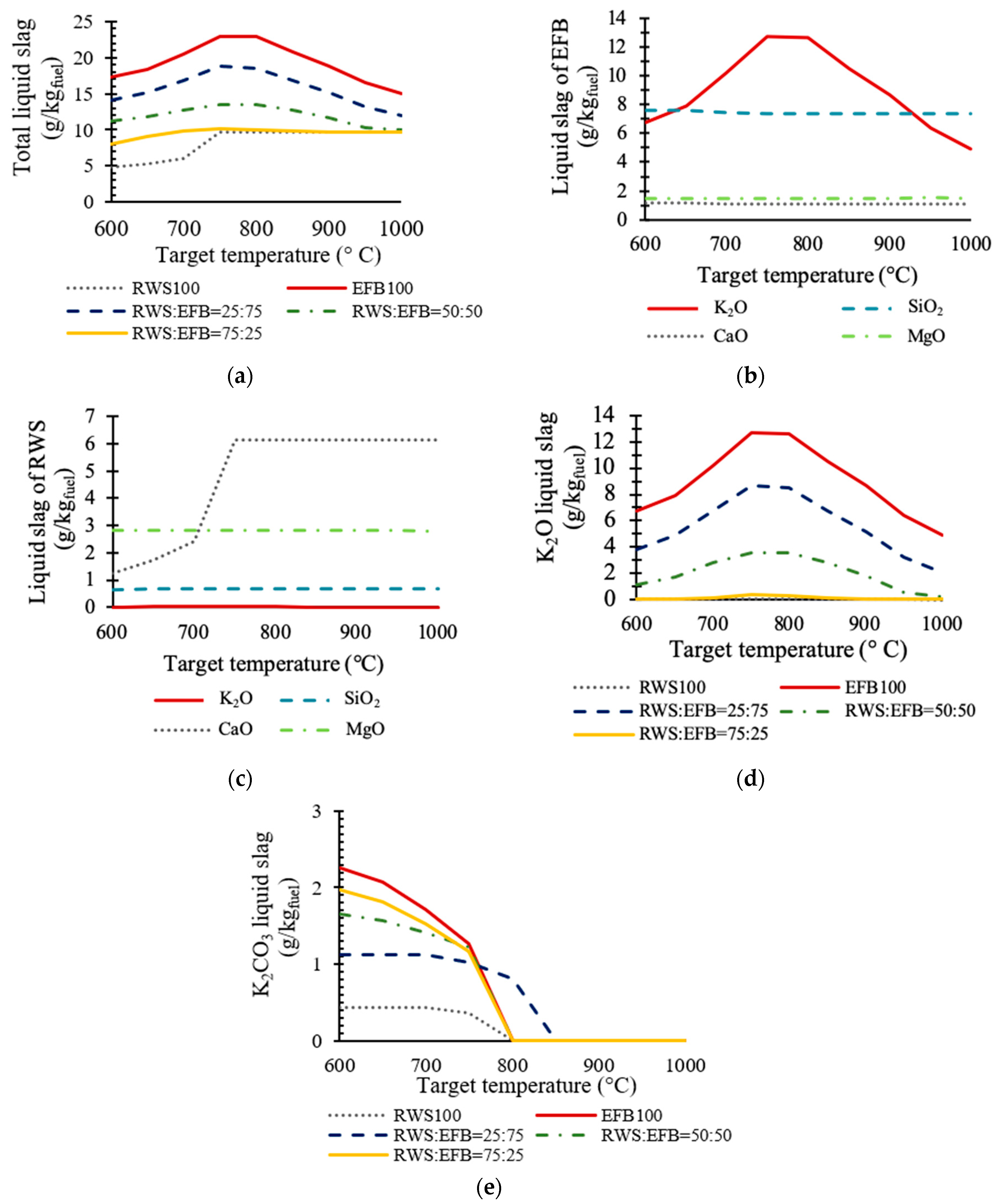

3.4. Ash Melting Behavior Using Thermochemical Simulation (FactSage)

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zainal, Z.; Lahijani, P.; Mohammadi, M.; Mohamed, A.R. Gasification of lignocellulosic biomass in fluidized beds for renewable energy development: A review. Renew. Sustain. Energy Rev. 2019, 14, 2852–2862. [Google Scholar]

- Matas, G.B.; Sandquist, J.; Sørum, L. Gasification of Biomass to Second Generation Biofuels: A Review. ASME J. Energy Resour. Technol. 2012, 135. [Google Scholar] [CrossRef]

- Basu, P. Chapter 1: Introduction. In Biomass Gasification and Pyrolysis: Practical Design and Theory; Academic Press: Cambridge, MA, USA; Elsevier: Amsterdam, The Netherlands, 2010; pp. 1–25. [Google Scholar]

- Morris, J.; Daood, S.; Chiton, S.; Nimmo, W. Mechanisms and mitigation of agglomeration during fluidized bed combustion of biomass: A review. Fuel 2018, 230, 452–473. [Google Scholar] [CrossRef]

- Narayan, V.; Jensen, P.A.; Henriksen, U.B.; Glarborg, P.; Lin, W.; Nielsen, R.G. Defluidization in fluidized bed gasifiers using high-alkali content fuels. Biomass Bioenergy 2019, 91, 160–174. [Google Scholar] [CrossRef]

- Visser, H.; Van, L.S.; Kiel, J. Biomass Ash-Bed Material Interactions Leading to Agglomeration in FBC. ASME J. Energy Resour. Technol. 2008, 130. [Google Scholar] [CrossRef]

- Anthony, E.; Preto, F.; Jia, L.; Iribarne, J. Agglomeration and Fouling in Petroleum Coke-Fired FBC Boilers. ASME J. Energy Resour. Technol. 1998, 120, 285–292. [Google Scholar] [CrossRef]

- Öhman, M.; Pommer, L.; Nordin, A. Bed Agglomeration Characteristics and Mechanisms during Gasification and Combustion of Biomass Fuels. Energy Fuels 2005, 19, 1742–1748. [Google Scholar] [CrossRef]

- Mettanat, V.; Basu, P.; Butler, J. Agglomeration of biomass fired fluidized bed gasifier and combustor. Can. Soc. Chem. Eng. 2009, 87, 656–684. [Google Scholar] [CrossRef]

- Öhman, M.; Nordin, A. The Role of Kaolin in Prevention of Bed Agglomeration during Fluidized Bed Combustion of Biomass Fuels. Energy Fuel 2000, 14, 618–624. [Google Scholar] [CrossRef]

- Chi, H.; Pans, M.A.; Sun, C.; Liu, H. An investigation of lime addition to fuel as a countermeasure to bed agglomeration for the combustion of non-woody biomass fuel in a 20 kWth bubbling fluidised bed combustor. Fuel 2019, 240, 349–361. [Google Scholar] [CrossRef]

- Liu, Z.; Peng, T.; Lin, C. Impact of CaO and CaCO3 addition on agglomeration/defluidization and heavy metal emission during waste combustion in fluidized bed. Fuel Process. Technol. 2014, 118, 171–179. [Google Scholar] [CrossRef]

- Lin, C.; Kou, J.; Wey, M.; Chang, S.; Wang, K. Inhibition and promotion: The effect of earth alkali metals and operating temperature on particle agglomeration/defluidization during incineration in fluidized bed. Power Technol. 2009, 189, 57–63. [Google Scholar] [CrossRef]

- Kuprianov, V.; Ninduangdee, P.; Suheri, P. Co-firing of oil palm residues in a fuel staged fluidized-bed combustor using mixtures of alumina and silica sand as the bed material. Appl. Therm. Eng. 2018, 144, 371–382. [Google Scholar] [CrossRef]

- Ninduangdee, P.; Kuprianov, V. Combustion of an oil palm residue with elevated potassium content in a fluidized-bed combustor using alternative bed materials for preventing bed agglomeration. Bioresour. Technol. 2015, 182, 272–281. [Google Scholar] [CrossRef]

- Kittivech, T.; Fukuda, S. Effect of bed material on bed agglomeration for palm empty fruit bunch (EFB) gasification in a bubbling fluidized bed system. Energies 2019, 12, 4336. [Google Scholar] [CrossRef]

- Fryda, L.E.; Panopoulos, K.D.; Kakaras, E. Agglomeration in fluidised bed gasification of biomass. Powder Technol. 2008, 181, 307–320. [Google Scholar] [CrossRef]

- Llorente, M.F.; Cuadrado, R.E.; Laplaza, J.M.; García, J.C. Combustion in bubbling fluidised bed with bed material of limestone to reduce the biomass ash agglomeration and sintering. Fuel 2006, 85, 2081–2092. [Google Scholar] [CrossRef]

- Serrano, D.; Sánchez-Delgado, S.; Sobrino, C.; Marugán-Cruz, C. Defluidization and agglomeration of a fluidized bed reactor during Cynara cardunculus L. gasification using sepiolite as a bed material. Fuel Process. Technol. 2015, 131, 338–347. [Google Scholar] [CrossRef]

- Mac an Bhaird, S.T.; Walsh, E.; Hemmingway, P.; Maglinao, A.L.; Capareda, S.C.; McDonnell, K.P. Analysis of bed agglomeration during gasification of wheat straw in a bubbling fluidised bed gasifier using mullite as bed material. Power Technol. 2014, 254, 448–459. [Google Scholar] [CrossRef]

- George, J.; Arun, P.; Muraleedharan, C. Experimental investigation on co-gasification of coffee husk and sawdust in a bubbling fluidized bed gasifier. J. Energy Inst. 2018, 92, 1977–1986. [Google Scholar] [CrossRef]

- Visvanathan, C.; Chiemchaisri, C. Management of Agricultural Wastes and Residue in Thailand: Wastes to Energy Approach. Available online: http://faculty.ait.ac.th/visu/wp-content/uploads/sites/7/2019/01/Agri-waste2energy-Thai.pdf (accessed on 15 October 2019).

- Department of Alternative Energy Development and Efficiency. Potential of Palm Empty Fruit Bunch. Available online: http://webkc.dede.go.th/testmax/node/2529 (accessed on 15 October 2019).

- Lahijani, P.; Zainal, Z. Gasification of palm empty fruit bunch in a bubbling fluidized bed: A performance and agglomeration study. Bioresour. Technol. 2011, 102, 2068–2076. [Google Scholar] [CrossRef] [PubMed]

- Lahijani, P.; Njafpour, G.; Zainal, Z.; Mohammadi, M. Air gasification of palm empty fruit bunch in a fluidized bed gasifier using various bed materials. In Proceedings of the World Renewable Energy Congress, Linkoping, Sweden, 8–13 May 2011; pp. 3269–3275. [Google Scholar]

- Kittivech, T.; Fukuda, S. Characteristic of Palm empty fruit bunch (EFB) gasification in a bubbling fluidized bed reactor. In Proceedings of the 5th International Conference on Engineering, Energy and Environment, Bangkok, Thailand, 1–3 November 2017; pp. 307–312. [Google Scholar]

- Chaivatamaset, P.; Sricharoon, P.; Tia, S.; Bilitewski, B. The characteristics of bed agglomeration/defluidization in fluidized bed firing palm empty fruit bunch and rice straw. Appl. Therm. Eng. 2014, 70, 737–747. [Google Scholar] [CrossRef]

- Chaivatamaset, P.; Sricharoon, P.; Tia, S. Bed agglomeration characteristics of palm shell and corncob combustion in fluidized bed. Appl. Therm. Eng. 2011, 31, 2916–2927. [Google Scholar] [CrossRef]

- Chaivatamaset, P.; Tia, S. The characteristics of bed agglomeration during fluidized bed combustion of eucalyptus bark. Appl. Therm. Eng. 2015, 75, 1134–1146. [Google Scholar] [CrossRef]

- Kaewluan, S.; Pipatmanomai, S. Gasification of high moisture rubber woodchip with rubber waste in a bubbling fluidized bed. Fuel Process. Technol. 2011, 92, 671–677. [Google Scholar] [CrossRef]

- Rattanaya, T.; Sawasdisan, P.; Srichuay, P.; Samanwiwat, A.; Kongjan, P.; Yuso, P.; Waehamak, M.; Jariyaboon, R.; Reungsand, A. Application of Waste Rubberwood Ash in Carbon Dioxide Absorption. Int. J. Environ. Sci. Educ. 2017, 12, 2275–2287. [Google Scholar]

- Channiwala, S.A.; Parikh, P.P. A unified correlation for estimating HHV of solid, liquid and gaseous fuels. Fuel 2002, 81, 1051–1063. [Google Scholar] [CrossRef]

- Roedder, E. Silicate melt systems. Phys. Chem. Earth 1959, 3, 224–297. [Google Scholar] [CrossRef]

- Bale, C.W.; Bélislea, E.; Chartrand, P.; Decterov, S.A.; Eriksson, G.; Gheribi, A.E.; Hack, K.; Jung, I.-H.; Kang, Y.-B.; Melançona, J.; et al. FactSage thermochemical software and database, 2010-2016. Calphad 2016, 54, 35–53. [Google Scholar] [CrossRef]

| EFB = 100 | RWS:EFB = 25:75 b | RWS:EFB = 50:50 b | RWS:EFB = 75:25 b | RWS = 100 | |

|---|---|---|---|---|---|

| Proximate analysis (dry basis) | |||||

| Volatile matter (VM) | 74.2 | 76.3 | 78.5 | 80.6 | 82.8 |

| Fix carbon (FC) | 20.6 | 19.4 | 18.2 | 17.0 | 15.8 |

| Ash | 5.2 | 4.3 | 3.3 | 2.4 | 1.4 |

| Ultimate analysis (dry basis) | |||||

| C | 43.8 | 44.5 | 45.3 | 46.1 | 46.8 |

| H | 6.2 | 6.5 | 6.9 | 7.2 | 7.6 |

| O | 44.4 | 44.3 | 44.1 | 44.0 | 43.9 |

| N | 0.4 | 0.4 | 0.4 | 0.3 | 0.3 |

| HHVcal (MJ/kg) a | 17.5 | 18.3 | 19.1 | 19.9 | 20.7 |

| RWS:EFB Ratio | De-Fluidization Time (s) | Average Bed Temperature (°C) |

|---|---|---|

| 0:100 | 600 | 725 |

| 25:75 | 3600 | 740 |

| 50:50 | 7800 | 750 |

| 75:25 | n.d. | 780 |

| 100:0 | n.d. | 760 |

| Oxide Composition (% by Weight, Dry Ash Basis) | |||||

|---|---|---|---|---|---|

| EFB = 100 | RWS:EFB = 25:75 a | RWS:EFB = 50:50 a | RWS:EFB = 75:25 a | RWS = 100 | |

| SiO2 | 14.6 | 13.8 | 12.6 | 10.3 | 4.8 |

| Al2O3 | - | 0.1 | 0.3 | 0.7 | 1.6 |

| CaO | 2.2 | 5.6 | 10.9 | 20.6 | 43.8 |

| MgO | 2.9 | 4.3 | 6.5 | 10.6 | 20.2 |

| Fe2O3 | 0.5 | 0.6 | 0.7 | 0.9 | 1.3 |

| K2O | 61.2 | 57.9 | 52.8 | 43.4 | 21.2 |

| SO3 | 2.0 | 1.9 | 1.6 | 1.1 | - |

| Na2O | 0.5 | 0.5 | 0.5 | 0.5 | 0.4 |

| MnO | - | - | 0.1 | 0.2 | 0.5 |

| P2O5 | 2.0 | 2.3 | 2.9 | 3.8 | 6.2 |

| Cl | 14.1 | 13.0 | 11.1 | 7.9 | - |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kittivech, T.; Fukuda, S. Investigating Agglomeration Tendency of Co-Gasification between High Alkali Biomass and Woody Biomass in a Bubbling Fluidized Bed System. Energies 2020, 13, 56. https://doi.org/10.3390/en13010056

Kittivech T, Fukuda S. Investigating Agglomeration Tendency of Co-Gasification between High Alkali Biomass and Woody Biomass in a Bubbling Fluidized Bed System. Energies. 2020; 13(1):56. https://doi.org/10.3390/en13010056

Chicago/Turabian StyleKittivech, Tanakorn, and Suneerat Fukuda. 2020. "Investigating Agglomeration Tendency of Co-Gasification between High Alkali Biomass and Woody Biomass in a Bubbling Fluidized Bed System" Energies 13, no. 1: 56. https://doi.org/10.3390/en13010056

APA StyleKittivech, T., & Fukuda, S. (2020). Investigating Agglomeration Tendency of Co-Gasification between High Alkali Biomass and Woody Biomass in a Bubbling Fluidized Bed System. Energies, 13(1), 56. https://doi.org/10.3390/en13010056