Abstract

Carbon dioxide transcritical power cycle (CTPC) is suitable for engine waste heat recovery owing to its advantages, such as compact construction and high decomposition temperature. In addition, the addition of refrigerant can further improve the performance of pure carbon dioxide (CO2). Because there are limited studies considering the dynamic performance of CTPC systems with CO2 mixture as the working fluid (CMTPC), let alone the dynamic performance comparison of different structures of the CMTPC system, the object of the current work was to compare the dynamic performance, including the off-design performance and dynamic response speed, of four kinds of CMTPC systems, as well as their sensitivity to system input parameters. The dynamic models of four CMTPC systems were established and validated against experimental data, which includes basic CMTPC (B-CMTPC), CMTPC with a preheater (P-CMTPC), CMTPC with a recuperator (R-CMTPC), and CMTPC with both a recuperator and preheater (PR-CMTPC). Based on the dynamic models, the off-design performance and dynamic response speed of four CMTPC systems were compared by changing the engine load. The fluctuation amplitude and response time of a R-CTPC system are the maximum under off-design conditions. Moreover, the sensitivity analysis demonstrates that different output parameters of four CMTPC systems have differing sensitivity to input parameters. It is necessary to pay attention to the more sensitive input parameters under the specific working condition to avoid system damage or unsafe operation.

1. Introduction

Improving engine efficiency and reducing engine emissions are crucial to alleviating the energy crisis and environmental pollution [1], because more than 50% of the total energy in the engine is usually wasted by low temperature jacket water (60–85 °C) and high temperature exhaust (200–900 °C) [2]. Waste heat recovery (WHR) technology is regarded as a potential way to improve engine efficiency and reduce oil consumption. The organic Rankine cycle (ORC) [3,4,5] has appeared as a promising method in the context of WHR for engines. The reasons lie in their low cost and relatively high conversion efficiency compared with other technologies, such as thermoelectric generation. Some researches concentrated on exploring suitable fluids [6,7,8], and carbon dioxide (CO2) is regarded as a potential candidate [9].

CO2 transcritical power cycles (CTPCs), which are a type of Rankine cycle with CO2 as the working fluid [10,11], have been researched by many scholars. The reasons lie in three aspects: Firstly, CO2 is the natural working fluid, which is non-toxic and non-flammable, and can be released to the environment directly. It is easy to produce and low cost due to its abundance in the environment (0.04% of the atmospheric air) [12]. Chemically, CO2 is an inert gas and safer than organic working fluid [13], and according to American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) 15 and 34, and International Organization for Standardization (ISO) 5149 safety standards [12], CO2 is a safe refrigerant. Secondly, the CTPC is more likely to achieve minimization for engine waste heat recovery because the characteristics of supercritical CO2 permit the system to use compact heat transfer equipment and turbomachinery [9]. Finally, CO2 can recover the energy of engine exhaust and jacket water totally at the same time, attributing to its special physical properties [14]. However, the low critical temperature of CO2 brings some challenges to the condensation of the system, as the system needs to condense below the critical temperature of 31.1 °C [15,16]. It has been proven that CO2 mixtures (adding some refrigerant to improve the performance of pure CO2) can significantly increase the condensation temperature of the system [7]. Therefore, some researches focused on the selection of a refrigerant addition, and this paper used R134a as the addition due to its safety, which is nonflammable and nontoxic, and environmentally friendliness with zero ODP [17,18].

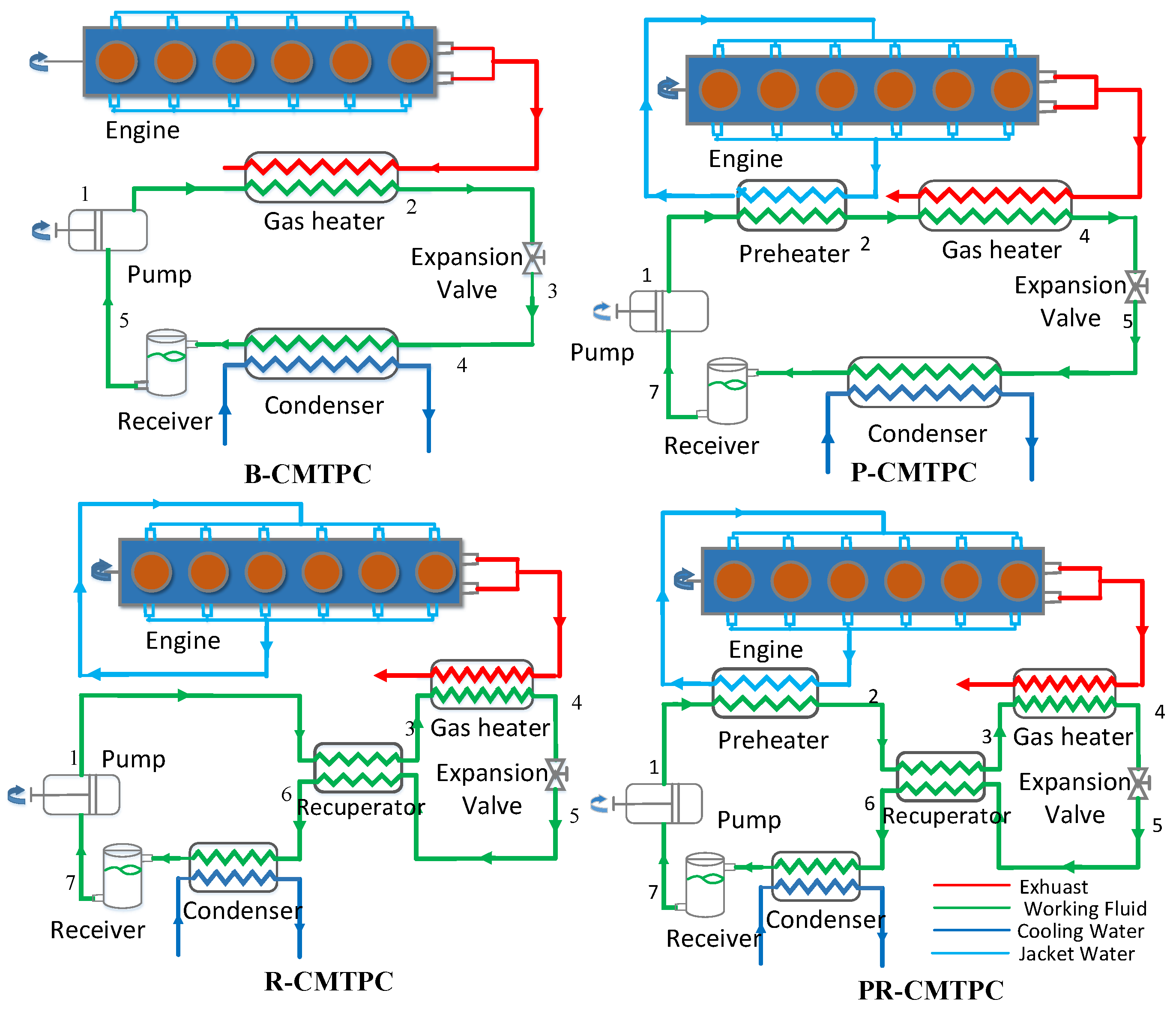

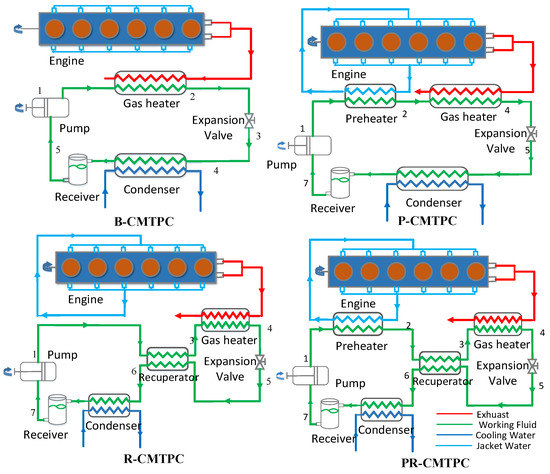

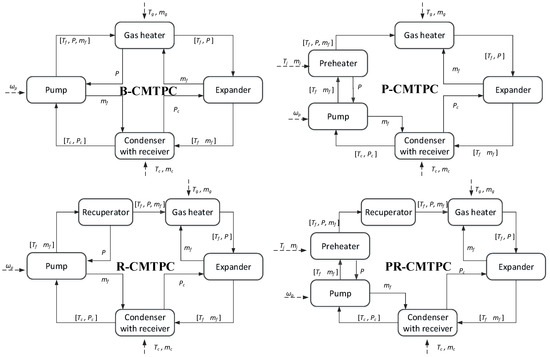

As for the structure of CTPC systems, there are different types to recover different grades of heat sources. This paper compared four types of systems, including a basic system, preheater system, recuperator system, and preheater and recuperator system; the configuration of the systems is shown in Figure 1. The basic CO2 transcritical power cycle (B-CTPC) system only recovers the exhaust energy and consists of four main components. The high temperature and high pressure working fluid expands through the expander and then is cooled in the condenser. Generally, the working fluid after the expander still has considerable energy, which can be adequately recovered by introducing the recuperator. Chen et al. [19] pointed out that the efficiency of a CTPC system with a recuperator (R-CTPC) is 0.19 compared with the basic system efficiency of 0.08. Li et al. [20] indicated that the advisability of a recuperator was not only because of the improvement of the thermal efficiency but also due to the reduction of the condenser load. Apart from high temperature waste heat, such as exhaust gas re-circulation (EGR) and exhaust, low temperature waste heat, such as jacket water (80–90 °C), also has the potential to be recycled [1,21]. Lu et al. [22] adopted both exhaust and jacket water energy as the heat source of an ORC system and the static study concluded that the system efficiency is 3% higher under a full load. Wang et al. [23] studied a dual loop ORC coupled with a light-duty diesel engine and the results showed that the maximum thermal efficiency of the engine can be increased by 8% by recycling jacket water and exhaust at the same time. Therefore, the preheater is also essential for the CTPC system to completely recover the engine waste heat. The PR-CTPC system contains the preheater and recuperator at the same time. Both an experiment and simulation studied the performance differences between B-CTPC and PR-CTPC systems [10,24]. Shu et al. [24] concluded that the net power output of the PR-CTPC system could be increased by 150% compared with the B-CTPC system.

Figure 1.

Schematic layout of four types of CMTPC systems.

Most of the researches about the four types of systems (B-CTPC, P-CTPC, R-CTPC, and PR-CTPC), as mentioned above, concentrated on the system design, including the architecture and components, and optimization of thermodynamic and economic properties without considering the transient heat source of the engine. Shi et al. [25] made a detailed performance comparison of the four configurations, but the systems were operating under static working conditions without consideration of the dynamic system performance. In fact, the engine works mostly under off-design conditions, which results in a variable and highly transient heat source in the WHR systems. The performance of the WHR systems under engine driving conditions is quite different from that under design conditions, so it is necessary to study the dynamic performance. The dynamic performance includes the off-design performance and response speed of the system, which is acquiesced by many researches. Xie et al. [26] pointed out that the efficiency of the WHR system under driving cycles was less than half of that in design condition. Chatzopoulou [27] proposed an off-design optimization tool considering the component time-varying performance, and concluded that the ORC power output was underestimated by 17% when the ORC components operated in off-design conditions without optimizing the performance. Some control strategies are necessary to ensure the normal and satisfactory operation of the system over a broad range of engine operating conditions due to the transient heat source of the engine. Thus, the dynamic response characteristics should be examined at first. For example, Li et al. [10] made an experimental comparison of the dynamic response of different types of CTPC systems and revealed that the B-CTPC system responds almost four times faster than the basic R123-ORC system. Wang et al. [28] studied the effect factors of the part-load performance for various organic Rankine cycles and demonstrated that the part-load performance of ORCs applying a low temperature working fluid with a medium heat transfer cycle (LT-ORC) decreases most slowly.

According to the authors’ knowledge, limited information is available on the dynamic performance of CMTPC, let alone studies about the dynamic comparison among different types of CMTPC systems. The physical properties of pure CO2 and CO2 mixture are different, and relevant research revealed that different physical properties of the working fluid have different effects on the dynamic characteristics of the system [29]. Moreover, the dynamic performance of the system is the basis of future research on control strategies and is worthy of study. Based on the analysis above, it is urgent that the dynamic performance of different CO2 mixture transcritical power cycle systems with various configurations are compared for engine waste heat recovery. The results reveal the dynamic performance of different system structures, which would be helpful for controller design and architecture selection. The structure of this paper is organized as follows: Section 2 describes the configurations of four different CMTPC systems. Section 3 presents the process of dynamic modeling and verifies the model with experimental data to ensure the accuracy of the model. The dynamic performance and sensitivity analysis of different systems are listed in Section 4. Section 5 demonstrates the main conclusions of this paper. The novelty and contribution of this research are as follows:

(1) The dynamic models of four types of CO2 mixture transcritical power cycle systems are established and carefully validated against experimental data.

(2) The dynamic difference among various configurations of the systems are revealed from the aspect of the heat transfer performance of heat exchangers and physical properties of working fluid, which provides a reference for architecture selection and controller design.

(3) The sensitivity effect of the system input parameters on the performance of each system are explored from a quantitative perspective, which is helpful for the selection of system control parameters.

2. System Description

The target engine is an inline 4-stroke 6-cylinder heavy-duty diesel engine and the waste heat source is exhaust and jacket water energy. The main parameters of the target engine are listed in Table 1. The exhaust consists of: N2 = 73.4%. CO2 = 7.11%, H2O = 14.22%, O2 = 5.27%. The jacket water is regarded as pure water without any impurity in the present work.

Table 1.

Basic parameters of the object diesel engine.

The B-CMTPC system only recovers the energy of the exhaust and is mainly composed of a gas heater, condenser, pump, and expander. The P-CMTPC system recovers the energy of the exhaust and jacket water at the same time, and a preheater added to the B-CMTPC system. The R-CMTPC recovers the energy of the exhaust and expanded working fluid of high temperatures after the expander, so a regenerator added to the B-CTMPC. The PR-CMTPC recovers the energy of the exhaust, jacket water, and expanded working fluid. Figure 1 shows the schematic layout of the four types of CMTPC systems. The working process of the PR-CMTPC system is illustrated by an example. The working fluid is pressurized by a pump (7–1) and then heated by the jacket water (1–2). After that, it transfers heat to the recuperator (2–3) and gas heater (3–4) in sequence. The high temperature working fluid expands through the expander to the output power (4–5), and then the energy of the working fluid is rejected through the recuperator (5–6) and condenser (6–7). Finally, the working fluid enters the pump, finishing a cycle (7–1).

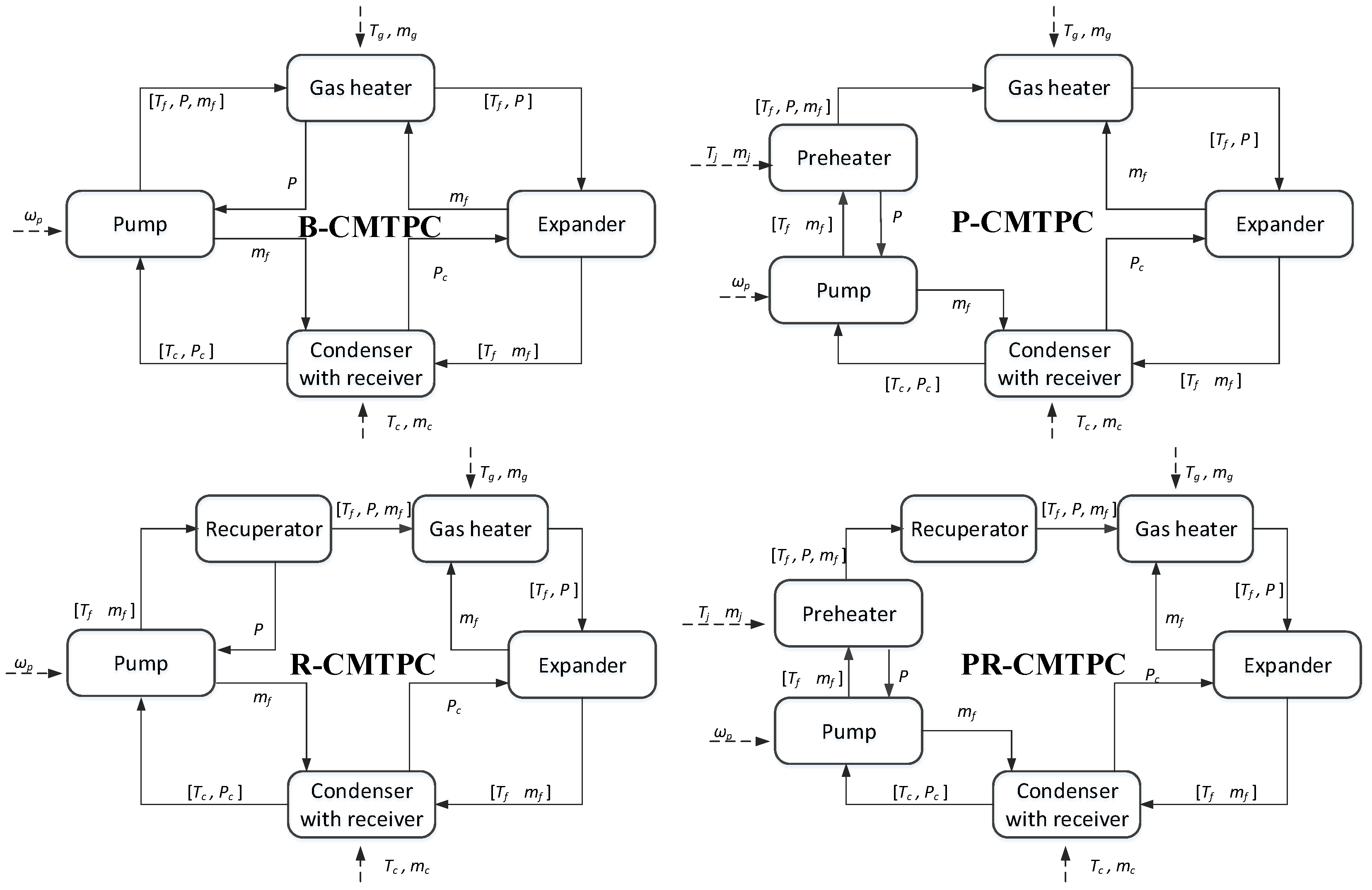

The models of the four CMTPC systems were established in MATLAB/Simulink [30] according to their working process. The components models were established firstly and then the system models were formed according to the interrelationship of the components. Figure 2 shows the transfer relationship among the parameters in the four types of systems built in Simulink. The components modeling process will be introduced in Section 3. The working fluid was CO2 mixture and the proportion of CO2 and R134a was 0.7:0.3.

Figure 2.

The transfer relationship among parameters in the four types of systems.

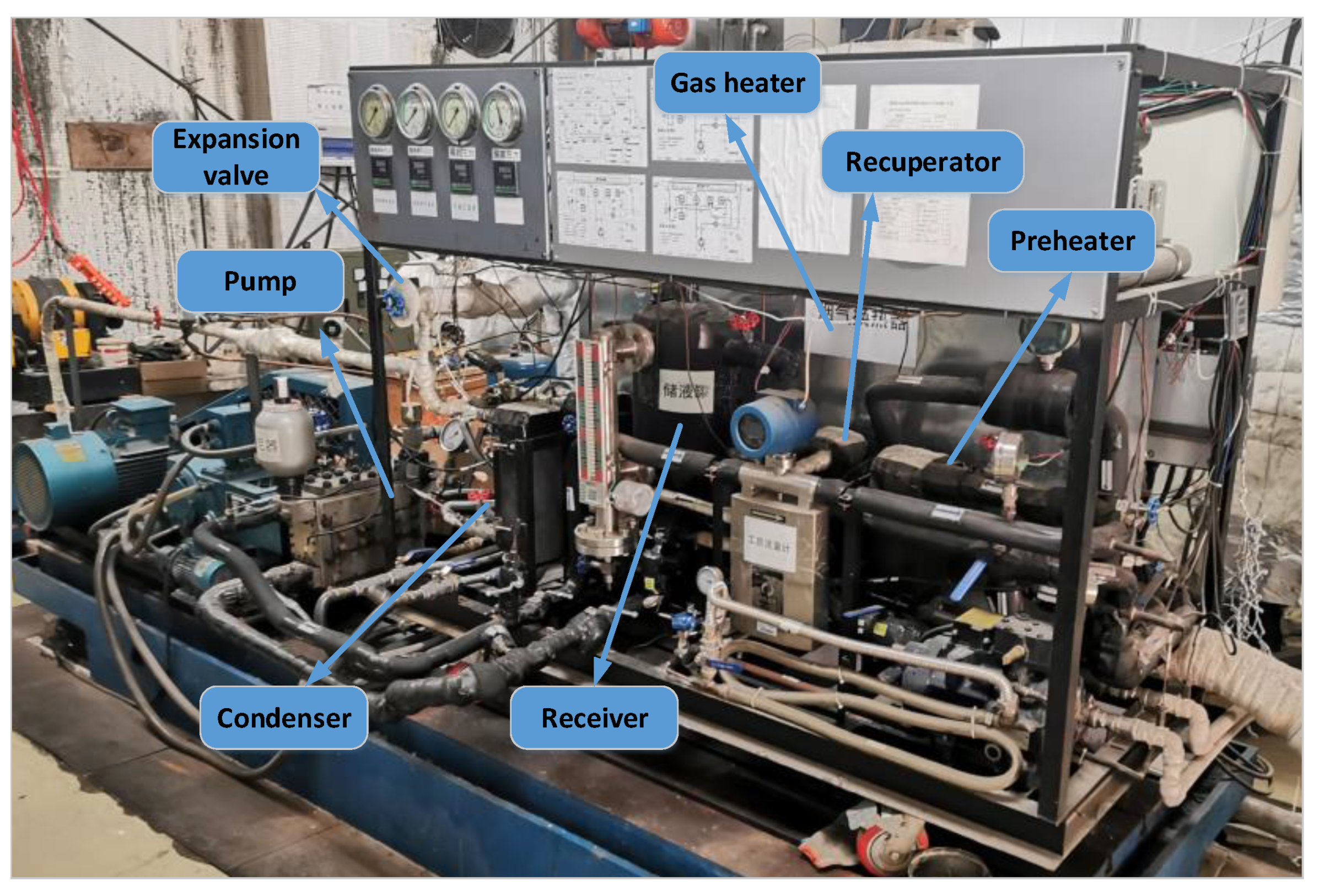

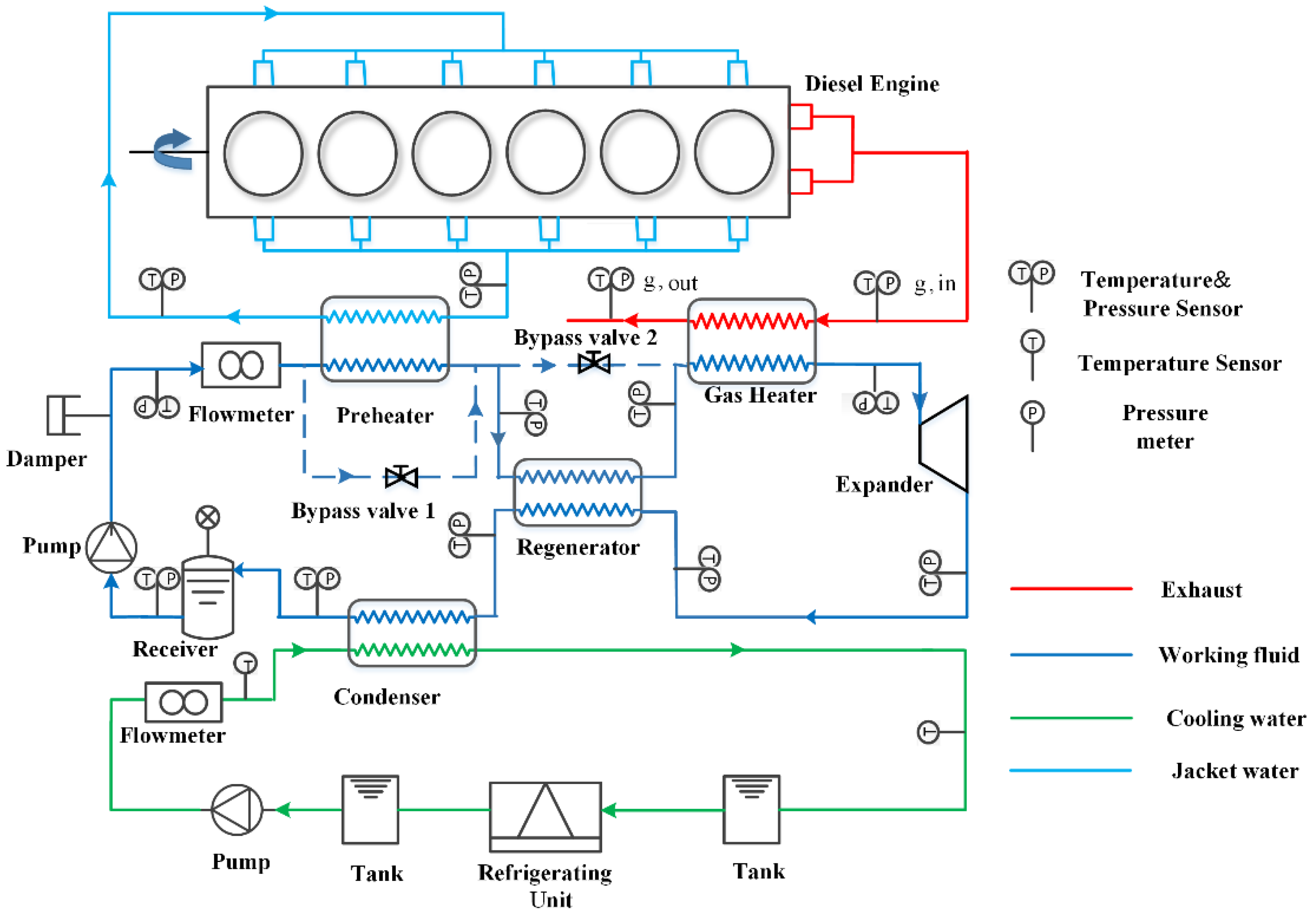

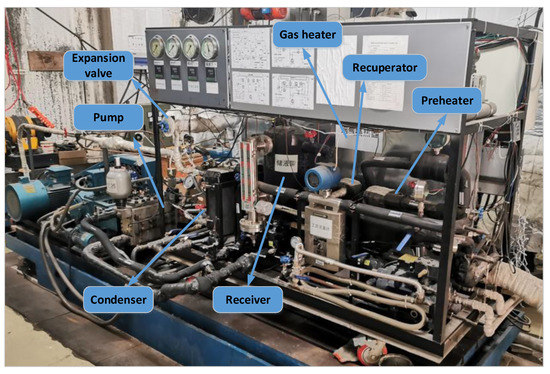

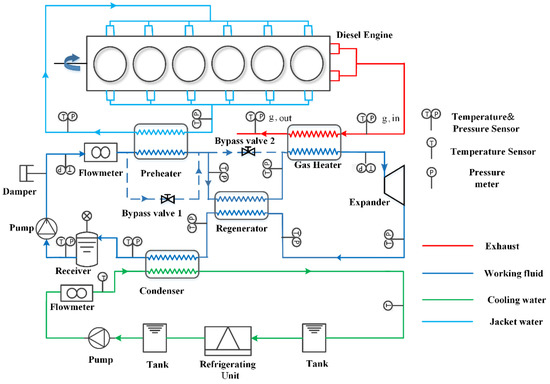

The model was validated against experimental data gathered by the experimental bench built by our group. It should be noted that the expander was replaced with an expansion valve in the bench. The physical diagram of the experiment bench is shown in Figure 3. The detailed schematic diagram of the experiment bench is shown in Figure 4. The experiment bench consisted of an engine cycle, waste heat recovery cycle, and cooling cycle. The connection sequence of components and installation position of sensors in the waste heat recovery system are shown clearly in Figure 4. Switching between systems was carried out by bypass valve 1 and bypass valve 2 as shown in Figure 4. For example, the PR-CMTPC operated when both of the bypass valves were closed; if valve 1 was closed and valve 2 was open, the P-CMTPC operated; if valve 1 was open and valve 2 was closed, the R-CMTPC operated; and the B-CMTPC operated when both of the valves were open. The PR-CMTPC and B-CMTPC systems were validated against experiment data to show the reliability of the model. This will be covered in detail in Section 3.

Figure 3.

The physical diagram of the experiment bench.

Figure 4.

The detailed schematic diagram of the experiment bench.

3. Mathematic Model

The main components of the CMTPC system includes the heat exchanger, condenser, pump, and expander. The heat exchanger includes the gas heater, preheater, and recuperator. On the basis of considering the constitutive relations of the mass and energy conservation equation, the model of all components of the CMTPC system was established by the s-function in Matlab. Based on the components’ models, the system models were built by combining the components according to their interrelationship. Then, the B-CMTPC and PR-CMTPC system models were validated against experimental data. It should be noted that the physical properties of the working fluid and heat sources were obtained by Refprop 9.0 [31].

3.1. Heat Exchanger Model

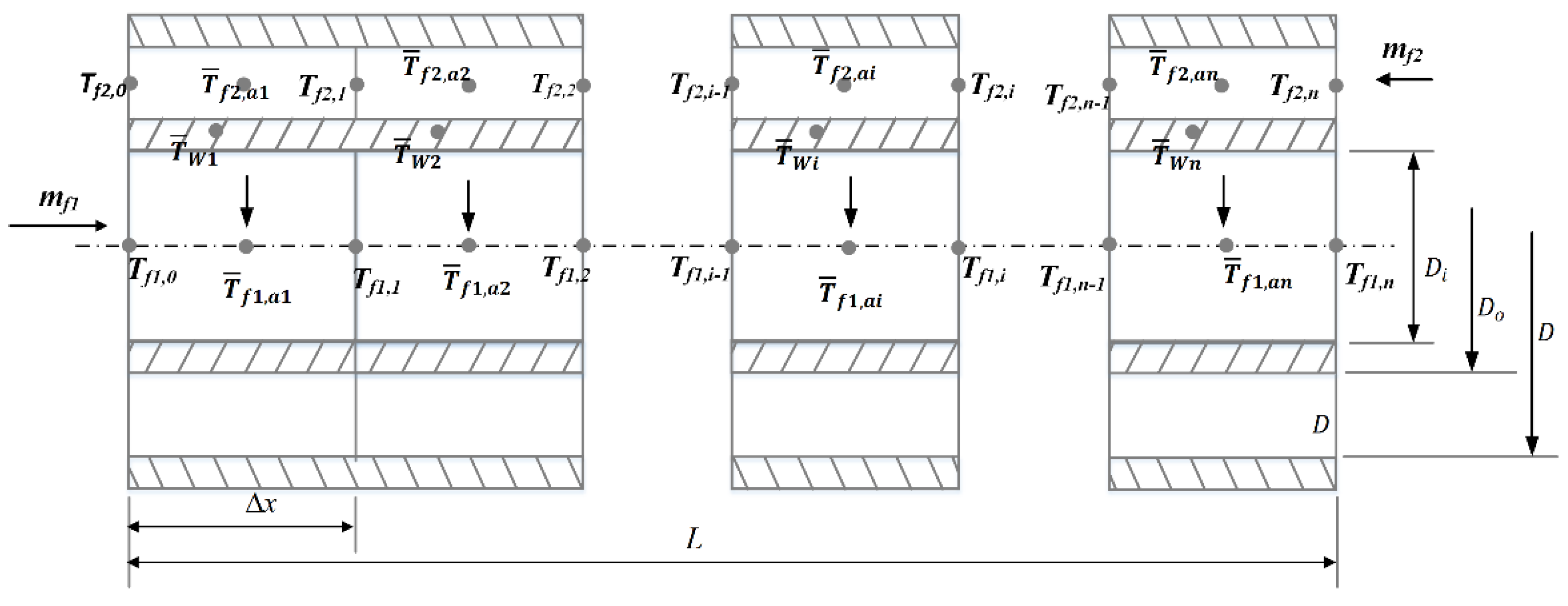

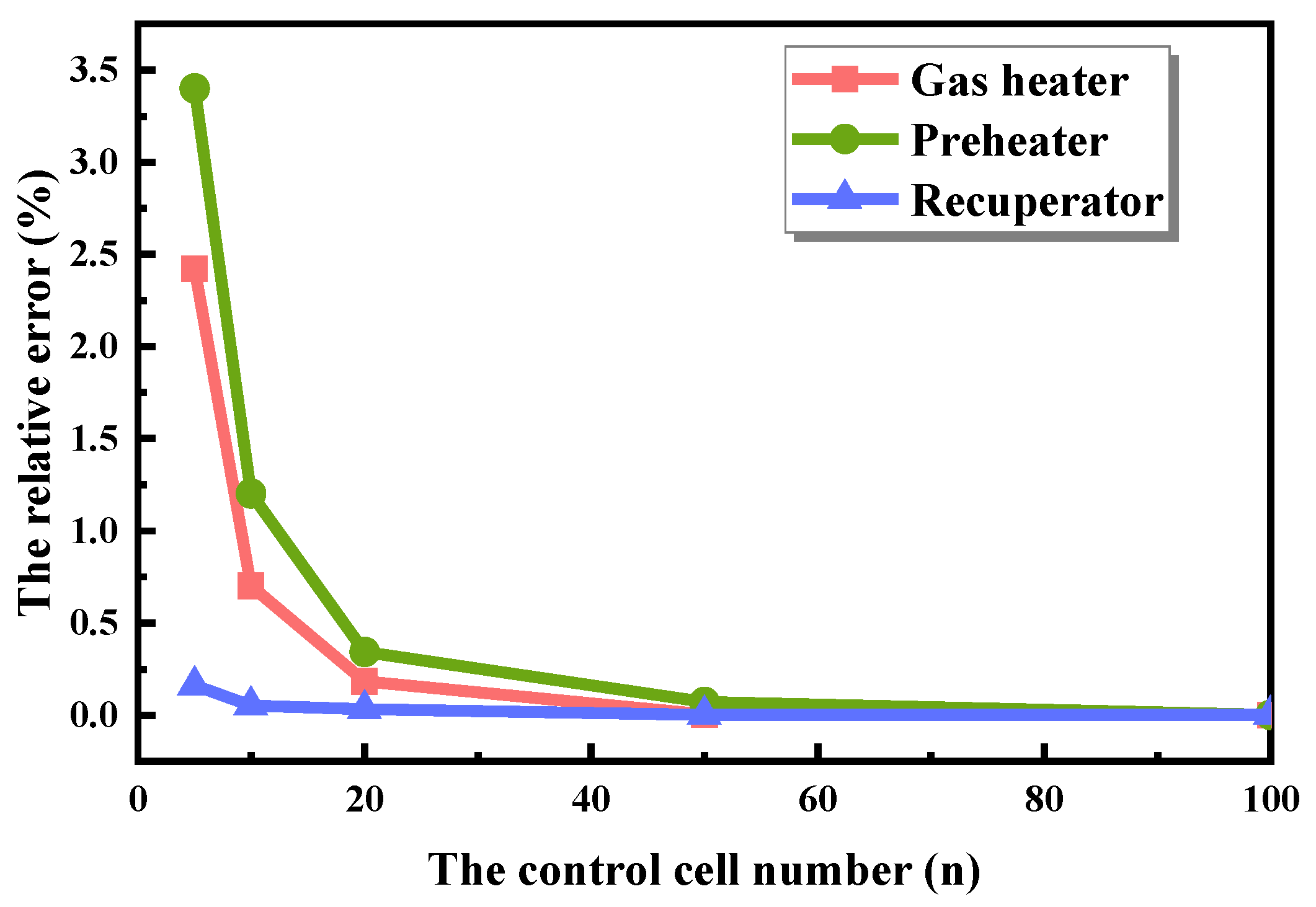

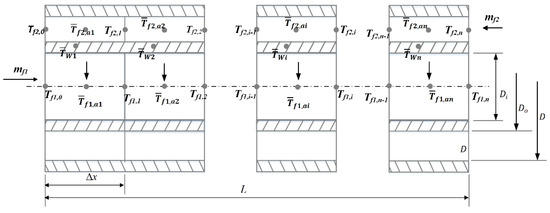

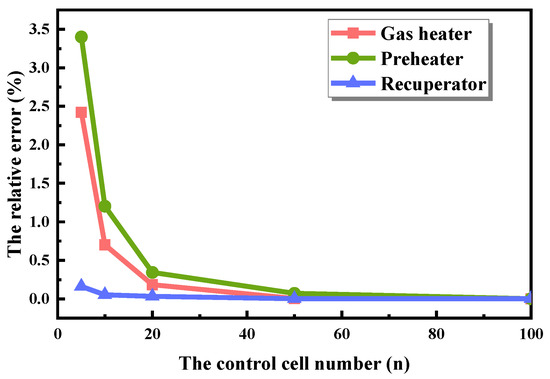

There is no phase change, and the properties of the working fluid change dramatically at the supercritical state during the heating process, so the finite volume (FV) method was used to established the gas heater, preheater, and recuperator to ensure sufficient accuracy. Figure 5 is the schematic layout of the heat exchanger. The heat exchanger is divided into n control cells along the horizontal direction, and the length of each control cell is ∆x. The state of each control cell is represented by the average state of the inlet and outlet, and the mean state parameter is considered at the center of each control cell. Karellas et al. [32] indicated that improving the numbers of the control cell during the modeling process can reduce the finite volume calculation errors. The relationship between the control cell and calculation accuracy for the gas heater, preheater, and recuperator is shown in Figure 6. The prediction errors were calculated for the different control cells against the reference 100 segments model. It can be found that the accuracy of the calculation error is less than 0.5% and the accuracy will hardly improve with the increase of the control cell, when the control cell was set as 20. Chowdhury et al. [33] also came to the same conclusion.

Figure 5.

The schematic model of the heat exchanger.

Figure 6.

Calculation error for heat exchanger models with different control cells.

There are some necessary assumptions for the sake of brevity, and in the course of modeling the condenser, they were also applied:

- The heat exchanger was regarded as a horizontal tube-in-tube type.

- The axial heat conductive and the heat transfer loss was ignored.

- The working fluid is compressible, and the exhaust, jacket water, and cooling water were regarded as incompressible.

- The pressure of working fluid is variable with time while the pressure of the heat source was regarding as constant.

- The pressure drop was completely ignored, and the momentum equations were not taken into consideration.

The differential equations of the working fluid mass conservation, working fluid energy conservation, heat source energy conservation, and tube wall energy conservation are listed in Equations (1)–(4) respectively considering the above assumptions. More details about the FV method can be found in [34]:

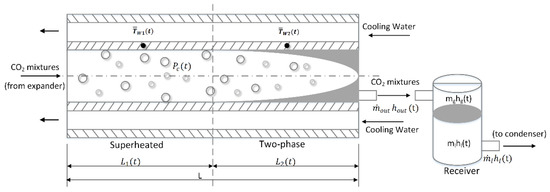

3.2. Condenser and Receiver Model

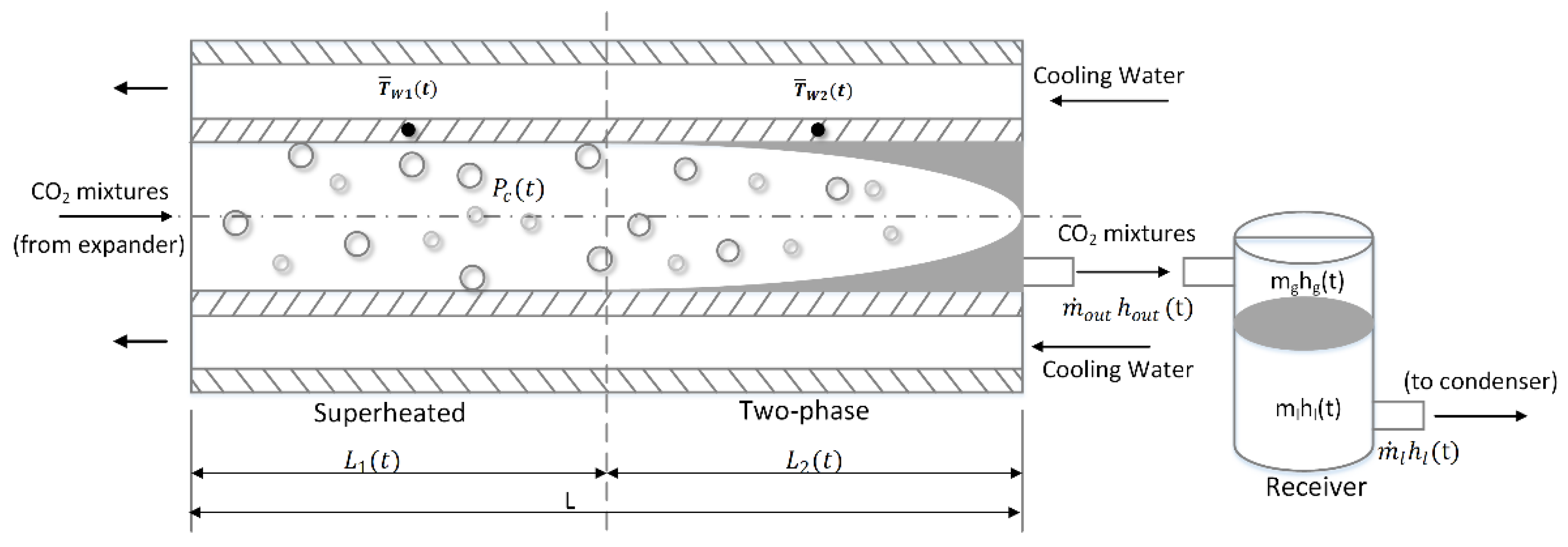

The working fluid enters the condenser at the state of gas and then transits into a two-phase state during the condensation process, and then the working fluid leaves the receiver in a liquid state. The move boundary (MB), with the advantage of fast computation, can clearly indicate the process of phase change. The MB method was used to establish the condenser model because a phase change existed, and the properties of the working fluid changed gently during the condensation process. During the modeling process, the condenser was coupled with a receiver [35], and the schematic model of the condenser is shown in Figure 7. The general mass balance for working fluid, the energy balance differential equations for cooling water and working fluid, and the general energy balance differential equation for the condenser wall are listed in Equations (5)–(7). Moreover, the Leibniz integration rule, as shown in Equation (8), was used to integrate the governing partial differential equations (PDEs) to obtain the MB model. More details about the MB method can be found in [3,36]:

Figure 7.

The schematic model of the condenser.

3.3. Pump and Expander Model

The static models were used to the describe pump and expander considering their faster response speed compared with the heat exchanger [3]. The working fluid mass flow rate, the work consumed by the pump, and the working fluid enthalpy at the outlet of the pump can be described as Equations (9)–(11) respectively:

where , , and represent the pump rotation speed, cylinder volume, and working fluid density at the inlet of pump. and are the working fluid enthalpy at the inlet of the pump and the ideal enthalpy of the working fluid after isentropic pumping. and are the volumetric efficiency and isentropic efficiency of the pump.

The expander was replaced with a nozzle model in this paper [34]. The working fluid mass flow rate, the output power of the expander, and the working fluid enthalpy at the outlet of the expander can be described as Equations (12)–(14), respectively:

where , , and p are the nozzle coefficient, working fluid density at the inlet of the expander, and operating pressure, respectively. and are the expander inlet enthalpy of the working fluid, and the ideal enthalpy of working fluid after isentropic expansion. is the expander isentropic efficiency.

The net power output was obtained by Equation (15):

3.4. Selection of Heat Transfer Correlations

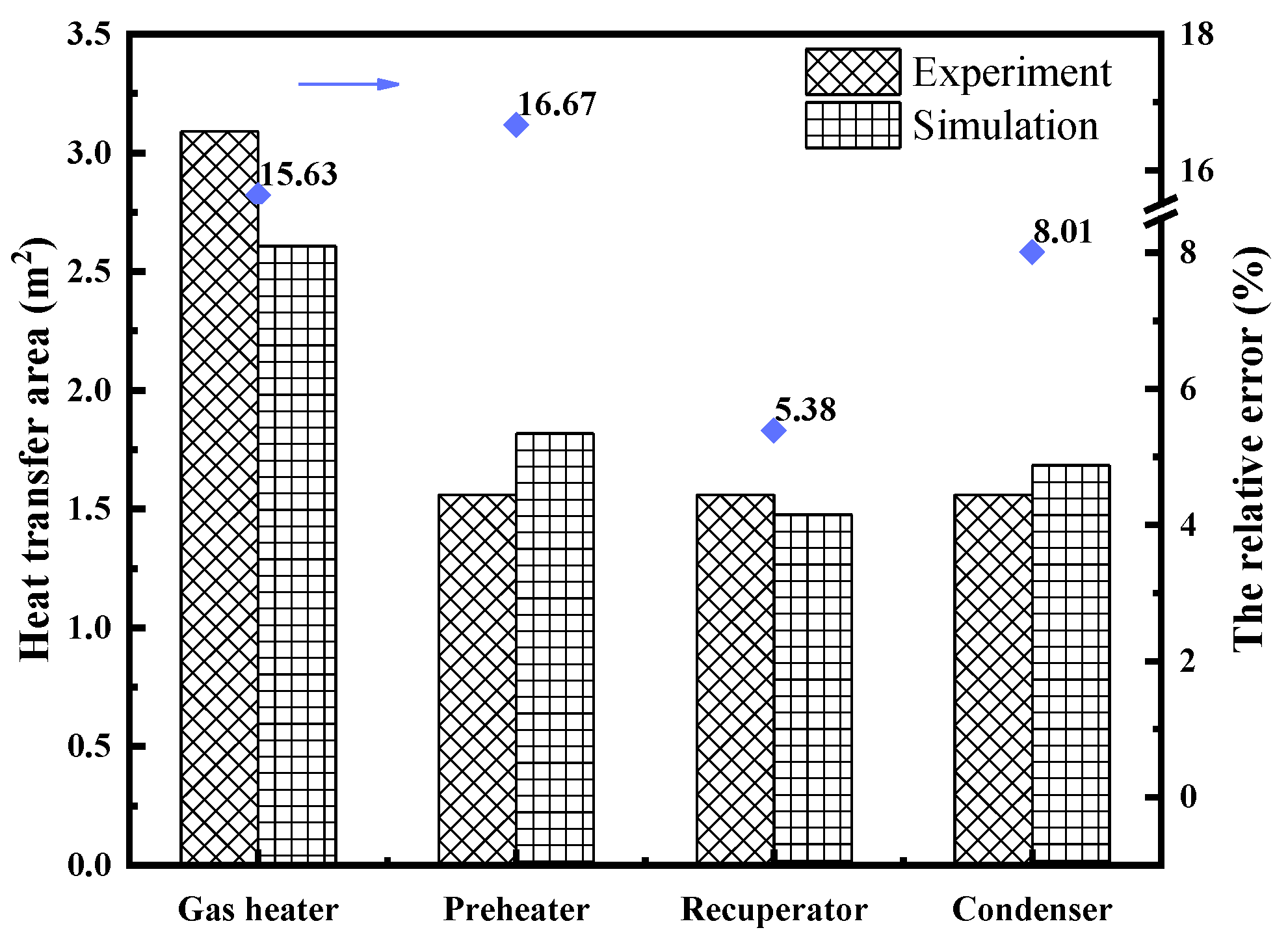

The choice of different internal and external transfer correlations, single-phase, and two-phase flow transfer correlations has a great influence on the heat transfer process. Thus, great emphasis should be placed on the selection of heat transfer correlations. The exhaust heat transfer coefficient should be suitable for high temperature gas and the outside of the tube [37]. The working fluid at the supercritical state take the P-K-P correlations [38]; for the subcritical state single-phase and two-phase, the heat transfer correlations refer to [39] and [40], respectively. The Petukhov–Kirillov correlation [39] was adopted for water in the condenser and preheater. All these heat transfer coefficients are listed in Table 2. The heat transfer correlations were considered as accurate in the context of simulation by comparing the simulation heat transfer area and the actual heat transfer area of the text bench, which will be stated in the following section.

Table 2.

Heat transfer correlations.

3.5. Model Validation

As far as the author knows, limited information is available on the dynamic performance of a WHR system with CO2 mixture as the working fluid. As mentioned above, the B-CMTPC and PR-CMTPC model was validated against experimental data gathered by the experimental bench built by our group. The installed sensors and their accuracy, and the uncertainty analysis in the experiment are shown in Appendix A Table A1 and Table A2, where is the uncertainty of the heat transfer rate and is the relative uncertainty. This was researched by our group and more details can be found in [41].

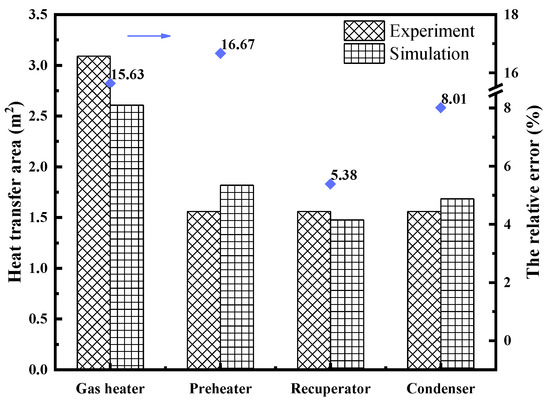

The main components, including the gas heater, preheater, recuperator, and condenser, were validated against the experimental bench by comparing the heat transfer area. Figure 8 shows the heat transfer area, and the relative error between the simulation and experiment. One can see that the relative error of the four components is within the acceptable range. Moreover, the result also strongly proves the accuracy of the heat transfer correlation.

Figure 8.

The results of the components’ model validation.

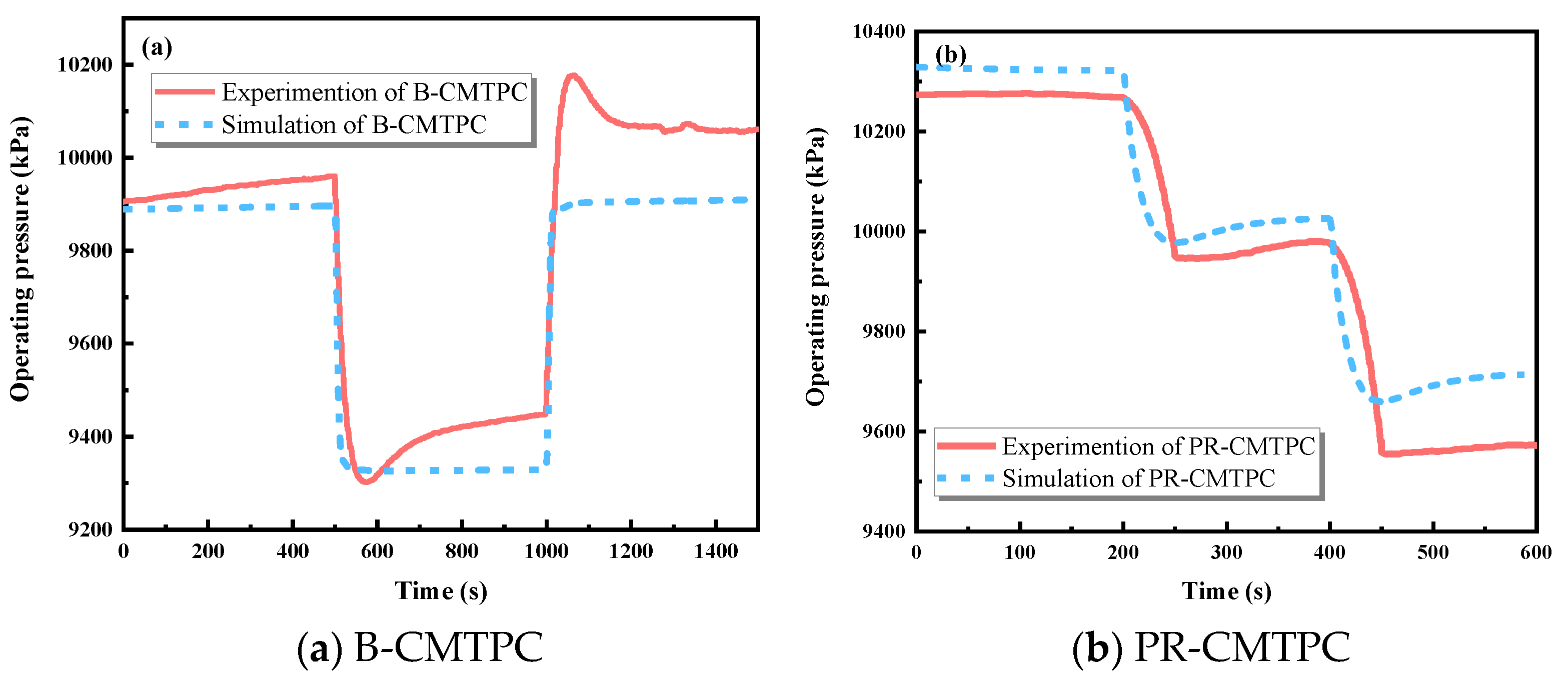

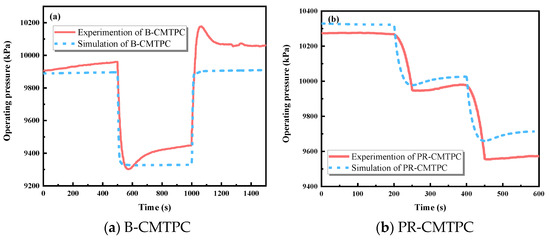

Figure 9 is the results of the system model validation, Figure 9a s the comparison of the operating pressure between the experiment and simulation of the B-CMTPC system. During the experimental process, the engine speed was set at 1100 rpm and the engine torque was 603 N·m. Table 3 is the engine parameters during the process of model validation. The pump speed was set as 80 rpm initially, then declined to 70 rpm. After the system operated smoothly, the pump speed was regulated back to 80 rpm. Figure 9b is the comparison of the operating pressure by the experiment and simulation of the PR-CMTPC system. At 200 s, the valve opening increased by 10.4%; at 400 s, the valve opening increased by 12.3%. The average error of B-CMTPC and PR-CMTPC is 4.74% and 1.57%, respectively; thus, the simulation results are in good agreement with the experimental data. Since the modeling methods of the four systems were consistent with each other, there is good reason to believe that the other two models also have reliable accuracy.

Figure 9.

The results of the system model validation.

Table 3.

Engine parameters during the process of model validation.

4. Simulation and Results Analysis

Four different configurations of the CMTPC systems were compared based on the simulation models, which were based on the same design parameters and boundary conditions to recover the energy of the target engine. The dynamic performance of the systems, including the off-design performance and dynamic response speed, are compared in Section 4.1 and the sensitivity of the four systems is analyzed in Section 4.2.

4.1. Comparison of Dynamic Performance

The dynamic performance of four different CMTPC systems was investigated deeply by changing the engine load. Four types of CMTPC systems were designed at an 80% engine load and 80% engine torque, which is a common high-way engine condition. The engine load was reduced by 10% after each system operated steadily for 500 s under the design condition. At 1000 s, the engine load was restored to the design condition, after the stable operation of the system. The engine load was increased by 10% at 1500 s, and then the system was restored to the design condition after stable operation, and the total simulation time was 2500 s. Table 4 shows the main parameters of the three engine working conditions.

Table 4.

The main parameters of three different engine working conditions.

4.1.1. Off-Design Performance of the System

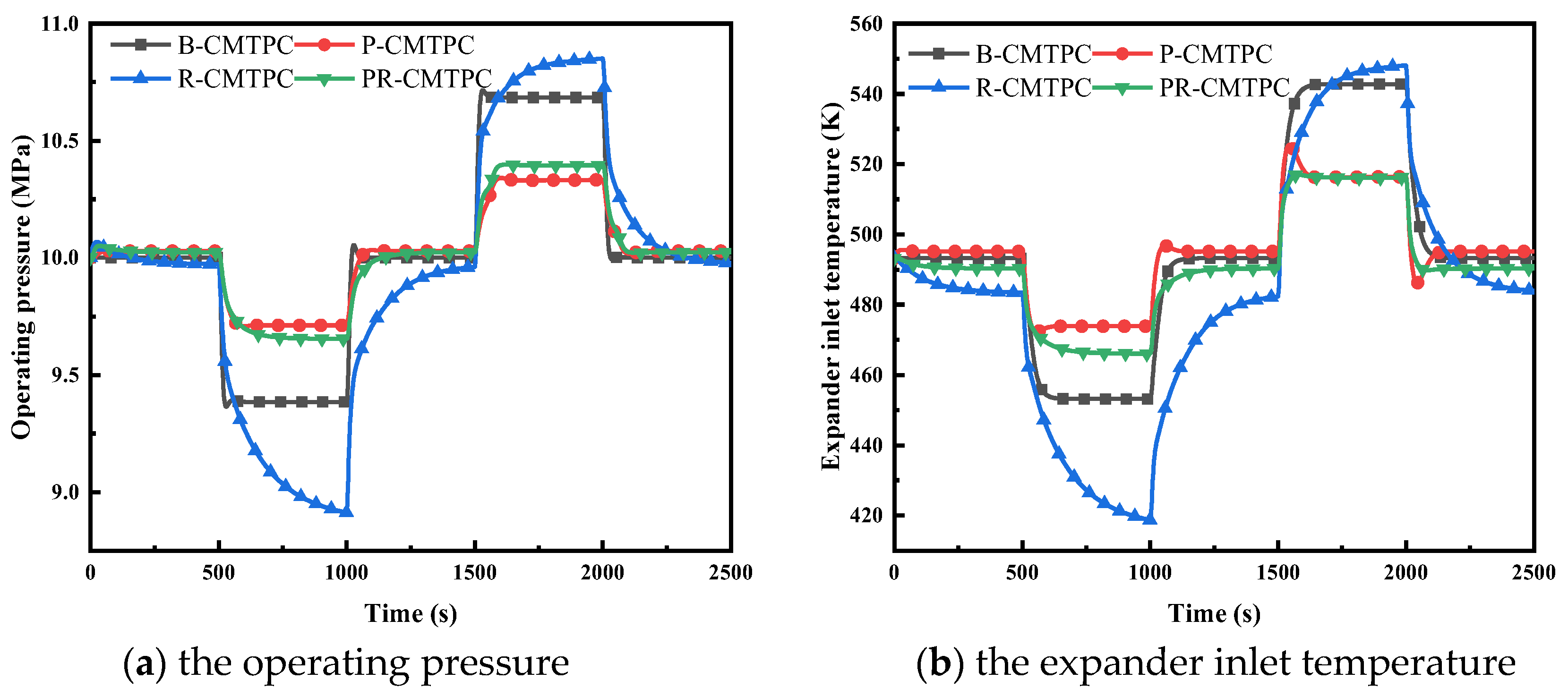

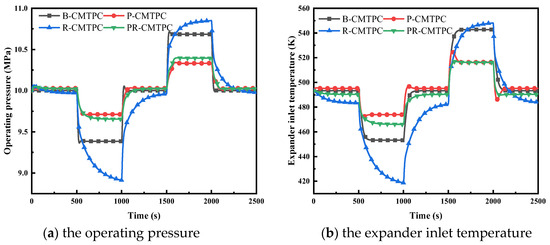

Figure 10 shows the operating pressure and expander inlet temperature of the four different systems. One can see that the change in the pressure and temperature of the four systems is consistent with the engine load. The B-CMTPC, P-CMTPC, and PR-CMTPC systems can respond in time to ensure the stable operation of the system when the engine load is changed while the response time of R-CMTPC is too long to follow the variation of the engine load timely. It also should be noticed that the maximum fluctuation amplitude of the operating pressure and expander inlet temperature is shown by R-CMTPC, followed by B-CMTPC, PR-CMTPC, and P-CMTPC. The heat distribution in the whole system is more uniform with the existence of the preheater. Moreover, the heat source in the preheater is jacket water, which accelerates the heat transfer speed to help the system return to equilibrium. When the engine load decreases, the available energy of the exhaust decreases while that of the jacket water increases. Moreover, the available energy of the exhaust increases while that of the jacket water decreases with the increase of the engine load. Thus, to a certain extent, the energy change of the jacket water can offset that of the exhaust. The operating parameters of the P-CMTPC and PR-CMTPC enjoy a relatively low fluctuation amplitude due to the energy offset as the engine load changes. With respect to the B-CMTPC system, the fluctuation amplitude of its operating parameters is relatively high, because it only recovers the exhaust energy. For the R-CMTPC system, the fluctuation of the exhaust energy directly influences the energy of the working fluid after expansion, and the synclastic superposition of the two available energies results in the highest fluctuation amplitude of the system parameters. Additionally, the system parameters return to the initial values as the engine working condition returns to its set point, indicating that the established model has computational repeatability and reliability.

Figure 10.

The operating pressure and expander inlet temperature of the system under the change of engine load.

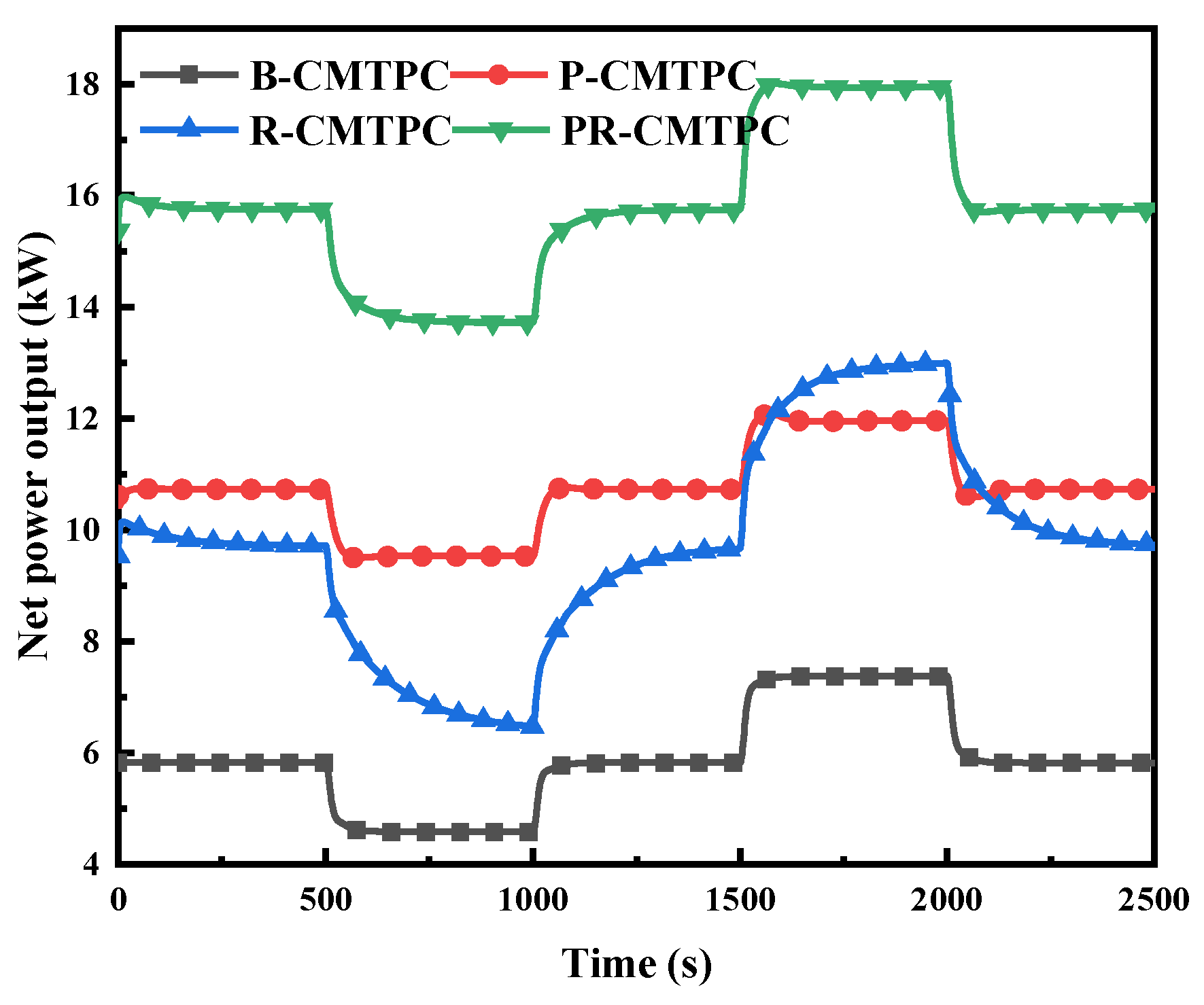

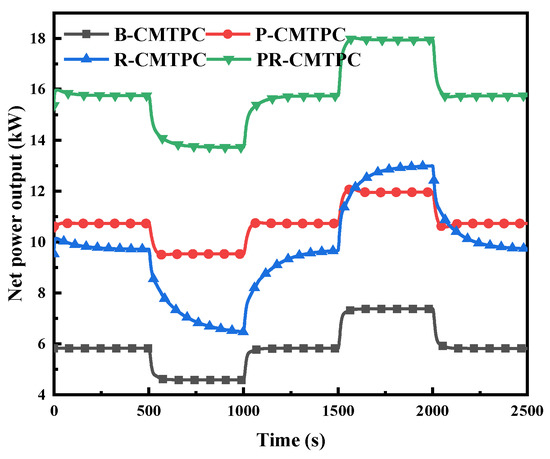

Figure 11 shows the net power output changing with the engine load, and one can see that the variation trend of the net power output is synchronized with the engine load. The mass flow rate of the working fluid is almost constant because the pump speed is maintained at the set point when the engine load changes. Therefore, we can infer that the operating pressure and expander inlet temperature determine the fluctuation amplitude of the net power output. Because there is a distinction in the initial stable power output of the four systems under the design condition, a comparative analysis of the relative value change of the net power output was performed when the operating condition was changed. The fluctuation amplitudes of the net power output for the four CMTPC systems are listed in Table 5. It is discovered that regardless of whether the engine load is increased or decreased, the maximum fluctuation amplitude of the net power output is obtained by R-CMTPC, followed by B-CMTPC, PR-CMTPC, and P-CMTPC, which has a similar trend to the operating pressure and expander inlet temperature. The net power output of P-CMTPC and R- CMTPC is close, whereas the R-CMTPC presents the maximum fluctuation amplitude as the engine load changes, indicating that the recuperator leads to a relatively large fluctuation in the system parameters when the preheater is not adopted, which is not conductive to steady operation. Since the PR-CMTPC recovers the energy of the exhaust, jacket water, and working fluid at the outlet of the expander simultaneously, and three heat exchangers work simultaneously, the heat distribution is relatively uniform. Therefore, the transition of the net power output is very gentle as the engine load changes.

Figure 11.

The net power output under the change of the engine load.

Table 5.

The fluctuation amplitude of the net power output for four CMTPC systems.

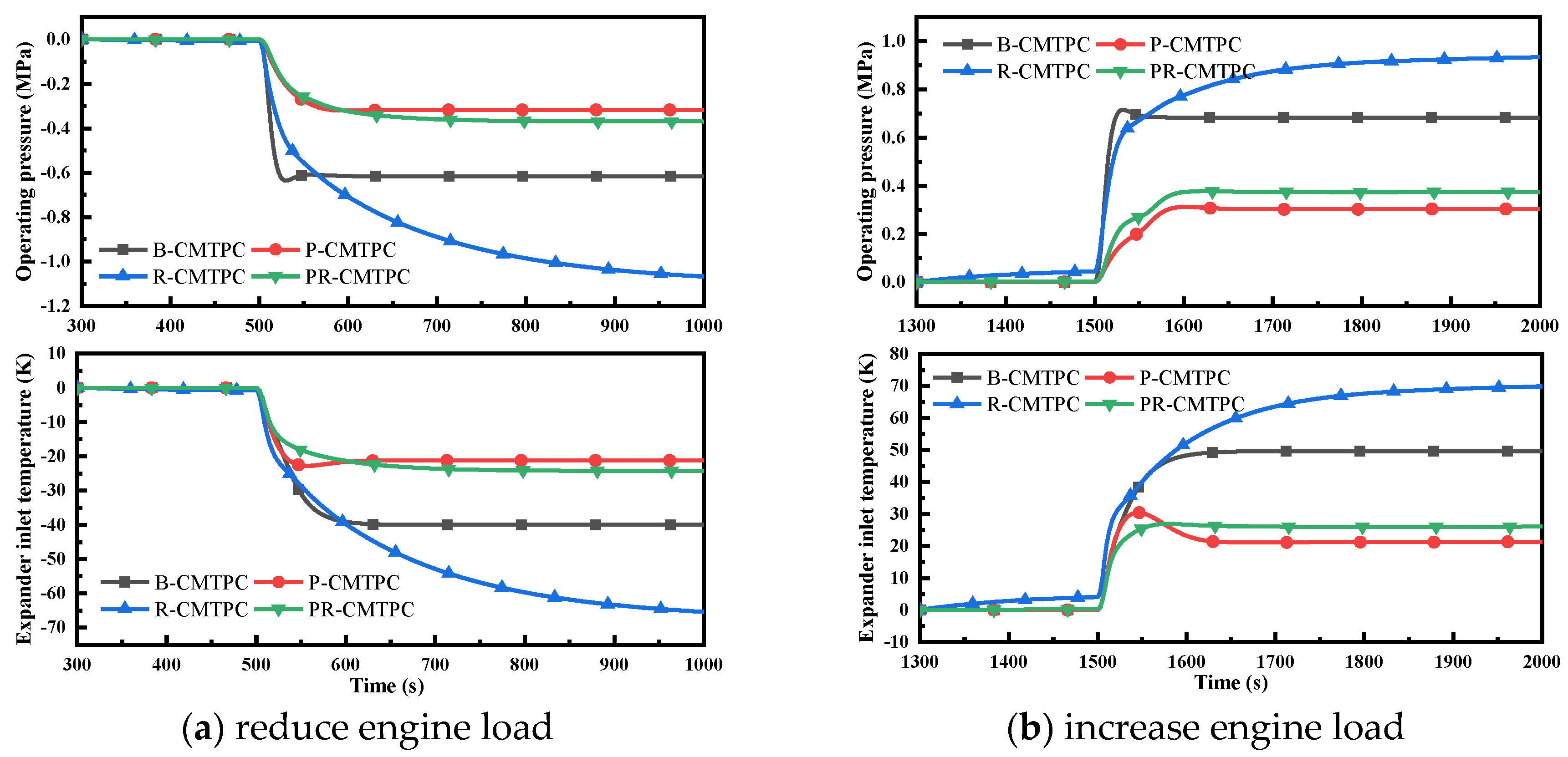

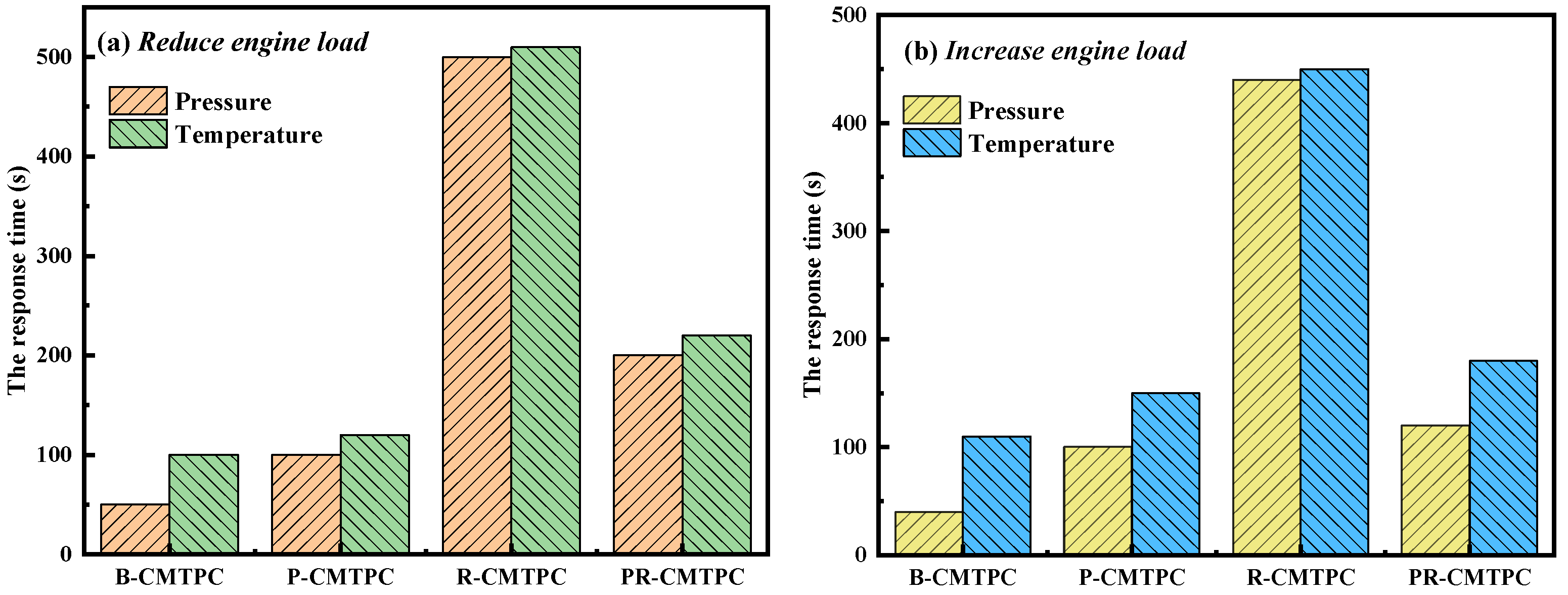

4.1.2. Dynamic Response Speed of the System

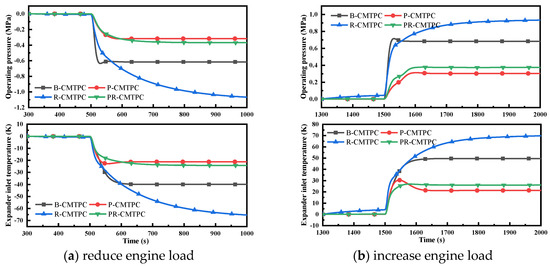

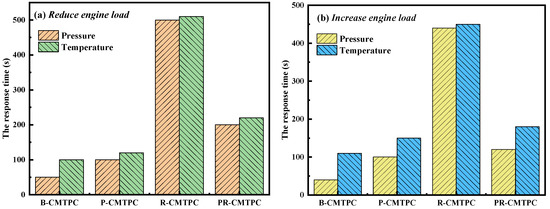

In order to observe the dynamic response speed of different CMTPC systems, the pressure and temperature were treated relative to the steady-state parameters before the engine load was changed, as Figure 12 demonstrates. Figure 12a,b are the dynamic response curves of the operating pressure and expander inlet temperature when the engine load was decreased or increased. The dynamic response time of the operating pressure and expander inlet temperature for the different systems are shown in Figure 13. It is worth noting that the time constant was used to measure the response speed. It can be found that the response time of the temperature is longer than that of the pressure for the same system, when either the engine load is reduced or increased. That is because the response of the temperature depends on the heat transfer in the system at the cost of the time drop while the response of the pressure depends on both the heat transfer and the working fluid mass flow rate, which responds in time with the change of the pump speed. Thus, the response speed of the pressure is faster than that of the temperature. The dynamic response speed of the different systems is obviously different: The fastest is the B-CMTPC system, followed by P-CMTPC, PR-CMTPC, and R-CMTPC.

Figure 12.

The system dynamic response speed under the change of the engine load.

Figure 13.

The dynamic response time of different systems under the change of the engine load.

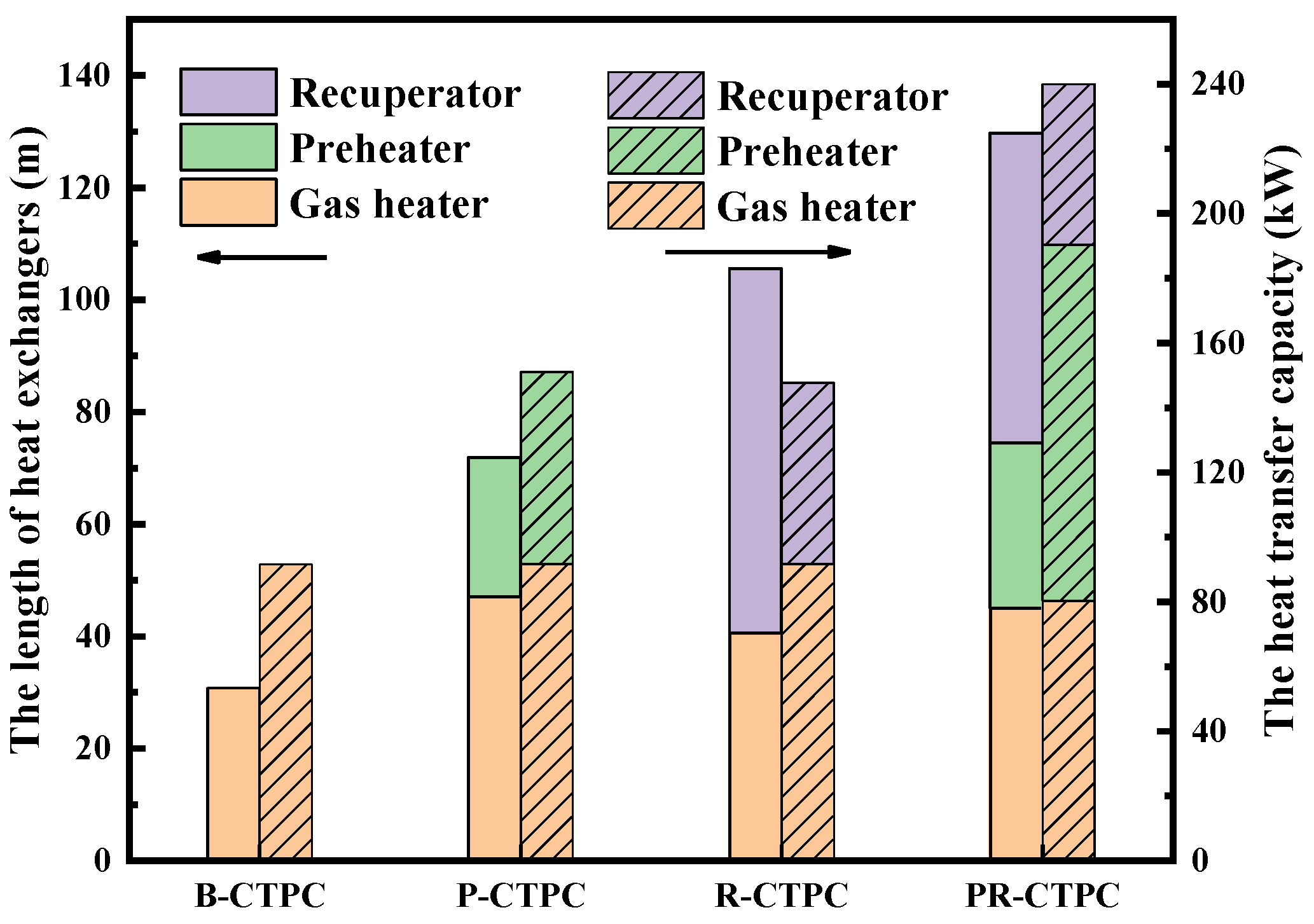

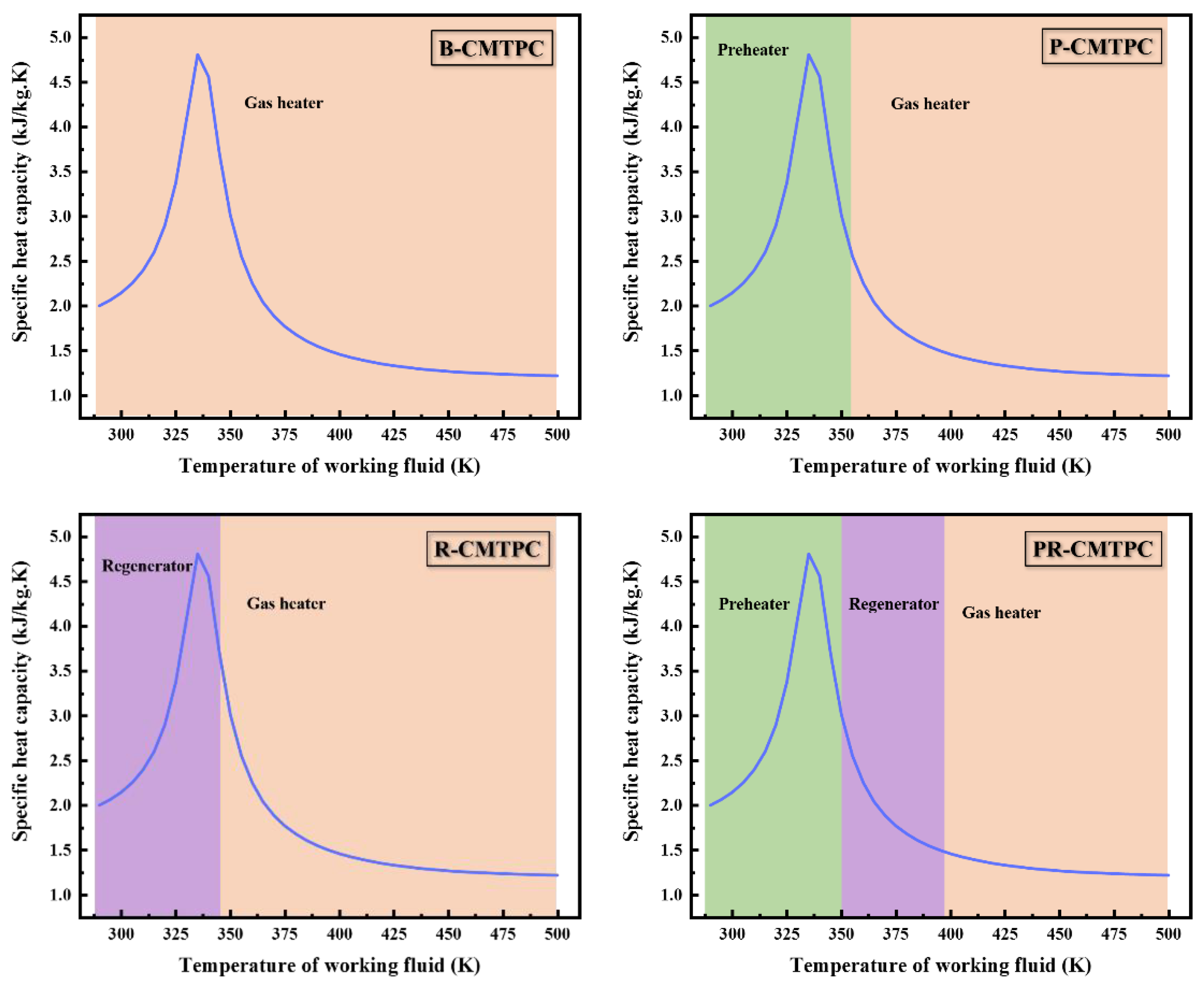

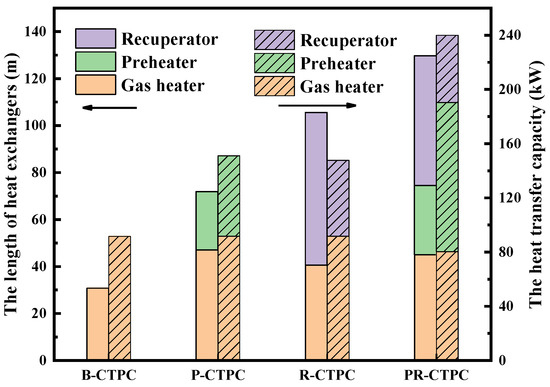

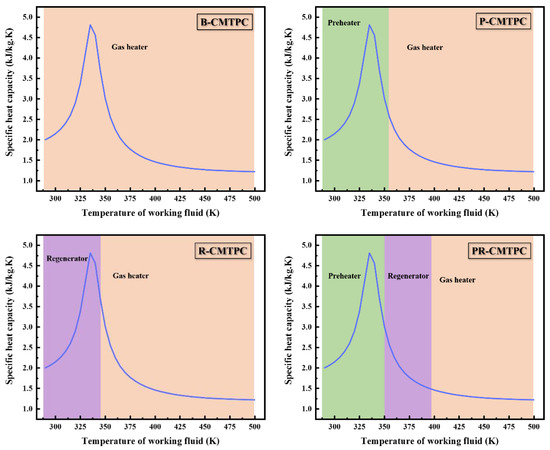

The heat transfer process of the B-CMTPC system occurs in the gas heater. Both the small heat transfer amount and heater transfer area result in the fast response speed. Figure 14 shows the composition of the heat exchangers and heat transfer of the four CMTPC systems. One can see that the addition of the preheater makes the total heat transfer area of the P- CMTPC system 2.3 times larger than that of B-CMTPC while the heat transfer of the whole system is less than 2.3 times. As can be seen from Figure 13, the response time of the P-CMTPC operating pressure is twice that of B-CMTPC, and the response time of the expander inlet temperature is 1.2 times that of B-CMTPC. The specific heat capacity distribution of the working fluid in the heat exchangers for the four CMTPC systems is demonstrated in Figure 15. The higher the specific heat capacity of the working fluid is, the more heat will be absorbed or released if the same temperature is changed, which is not conducive to the timely response of the system. In the P-CMTPC system, the temperature interval corresponding to the high specific heat capacity of the working fluid is just covered by the preheater. The heat source of the preheater is liquid water, leading to a better heat transfer performance, which can alleviate the trend of a slow response speed caused by the increase of the heat transfer area to some extent. As can be seen from Figure 14, the addition of the recuperator increases the heat transfer area of the PR-CMTPC system by 1.8 times compared with P-CMTPC, but the heat transfer of the whole system is less than 1.8 times. Moreover, the heat sources of the recuperator are the working fluid at the outlet of the expander and pump, respectively. The heat transfer temperature difference in the recuperator is little and the heat transfer rate is also small, so the response speed is very slow. Therefore, the recuperator will seriously slow down the response speed of the system. As can be seen in Figure 13, the response time of the PR-CMTPC system is about twice than that of P-CMTPC.

Figure 14.

The heat exchangers and heat transfer composition of four different systems.

Figure 15.

The distribution of the specific heat capacity of thee working fluid in the heat exchangers.

The response time of the R-CMTPC system is the longest; that is, the response speed is the slowest compared with the other three systems. The total heat transfer area of the R-CMTPC system is 0.8 times that of PR-CMTPC while its response time is 2.5 times that of PR-CMTPC, as shown in Figure 13. The main reason lies in the existence of the preheater in the P-CMTPC and PR-CMTPC system, and the high specific heat capacity of the working fluid is just covered by the preheater, with good heat transfer performance. However, as for the R-CMTPC system, as shown in Figure 15, the high specific heat capacity of the working fluid located in the recuperator with a big heat transfer area, and the heat transfer performance is poor. The heat inertia of the working fluid in the recuperator is very large, so the recuperator seriously slows down the response speed of the system.

In conclusion, the heat transfer performance of the heat exchangers and thermal inertia of the working fluid greatly influence the dynamic response speed of the system. When the peak heat capacity of the working fluid appears in the preheater with good heat transfer performance, it will not slow down the system response seriously. However, if the peak of the specific heat capacity of the working fluid occurs in a recuperator with poor heat transfer capacity, the response speed of the system will be seriously slowed down.

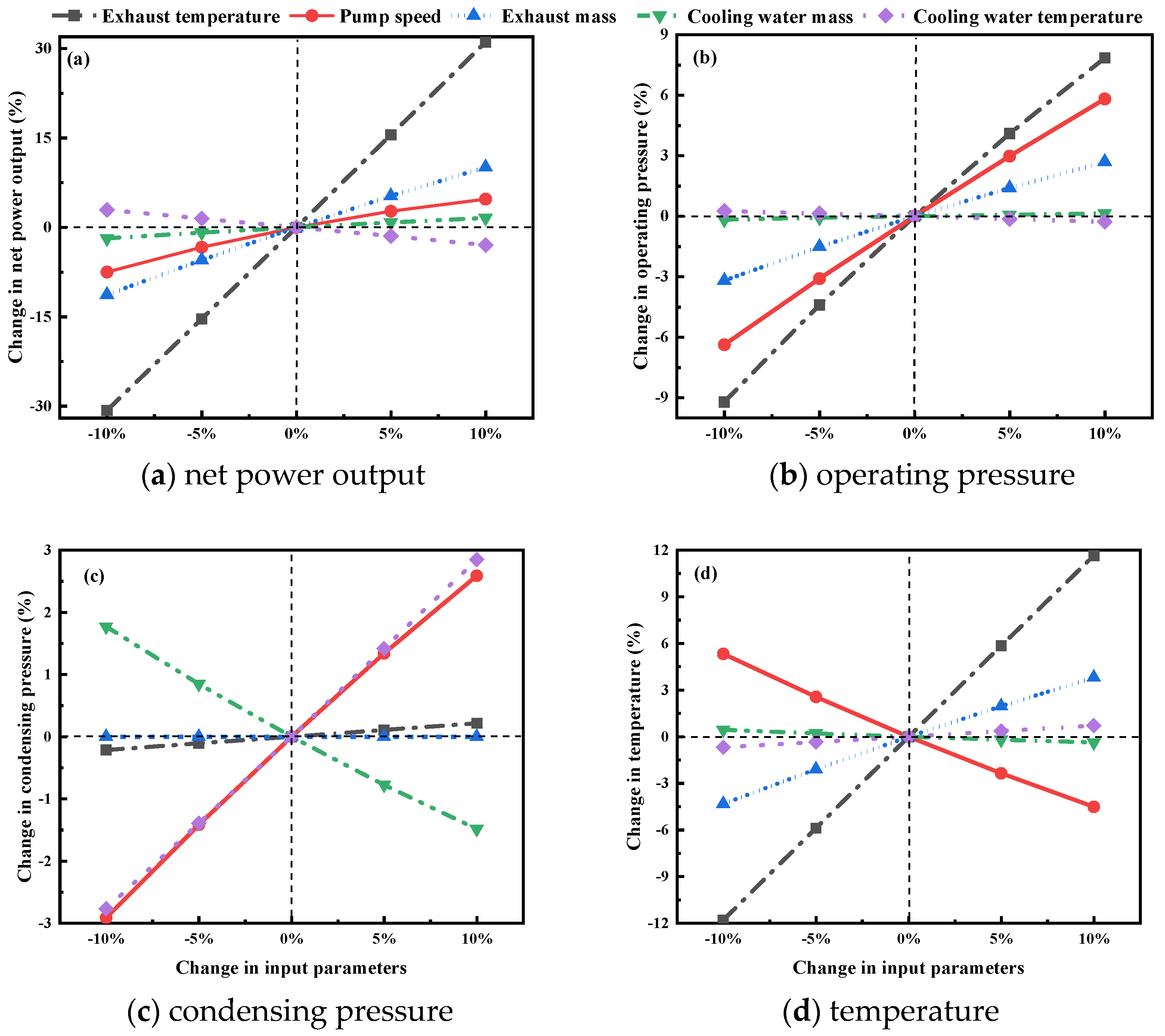

4.2. Comparison of Sensitive Performance

The main input parameters of the heat source change with the variation of the engine operating conditions while other input parameters remain constant during that process. In order to further explore the influence of the system input parameters on the performance of each system, the five input parameters of the system, namely, the exhaust temperature, exhaust mass flow rate, pump speed, cooling water temperature, and cooling water mass flow rate, were respectively studied and the influence degree of each input parameter on the main parameters of the system was analyzed from a quantitative perspective.

4.2.1. Sensitivity Analysis Method

The step change of −10%, −5%, +5%, and +10% to five input parameters (including the exhaust temperature, exhaust mass flow, pump speed, cooling water temperature, and cooling water mass flow) was adopted to the system one by one, making the system transition from one steady state to another. After the system operated at a steady state, parameters of the steady-state point in the off-design condition were extracted respectively to calculate the variation amplitude of the system parameters (the net power output, system operating pressure, condensing pressure, and expander inlet temperature of the working fluid) relative to the design point. The sensitivity of the system performance to different input parameters was explored by the method mentioned above. The larger the variation amplitude is, the more sensitive the system is to the corresponding input parameter.

4.2.2. Sensitivity Analysis Results

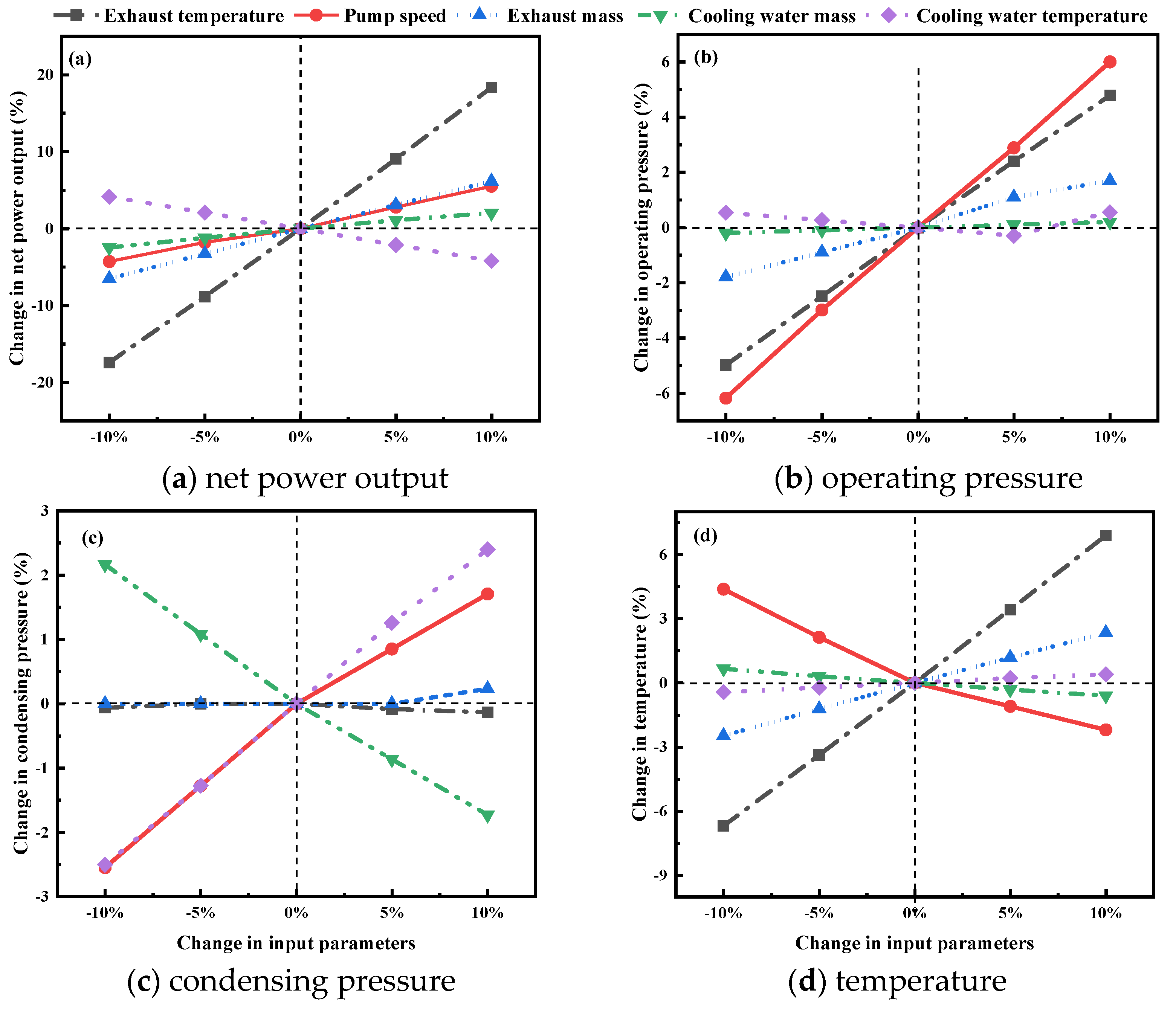

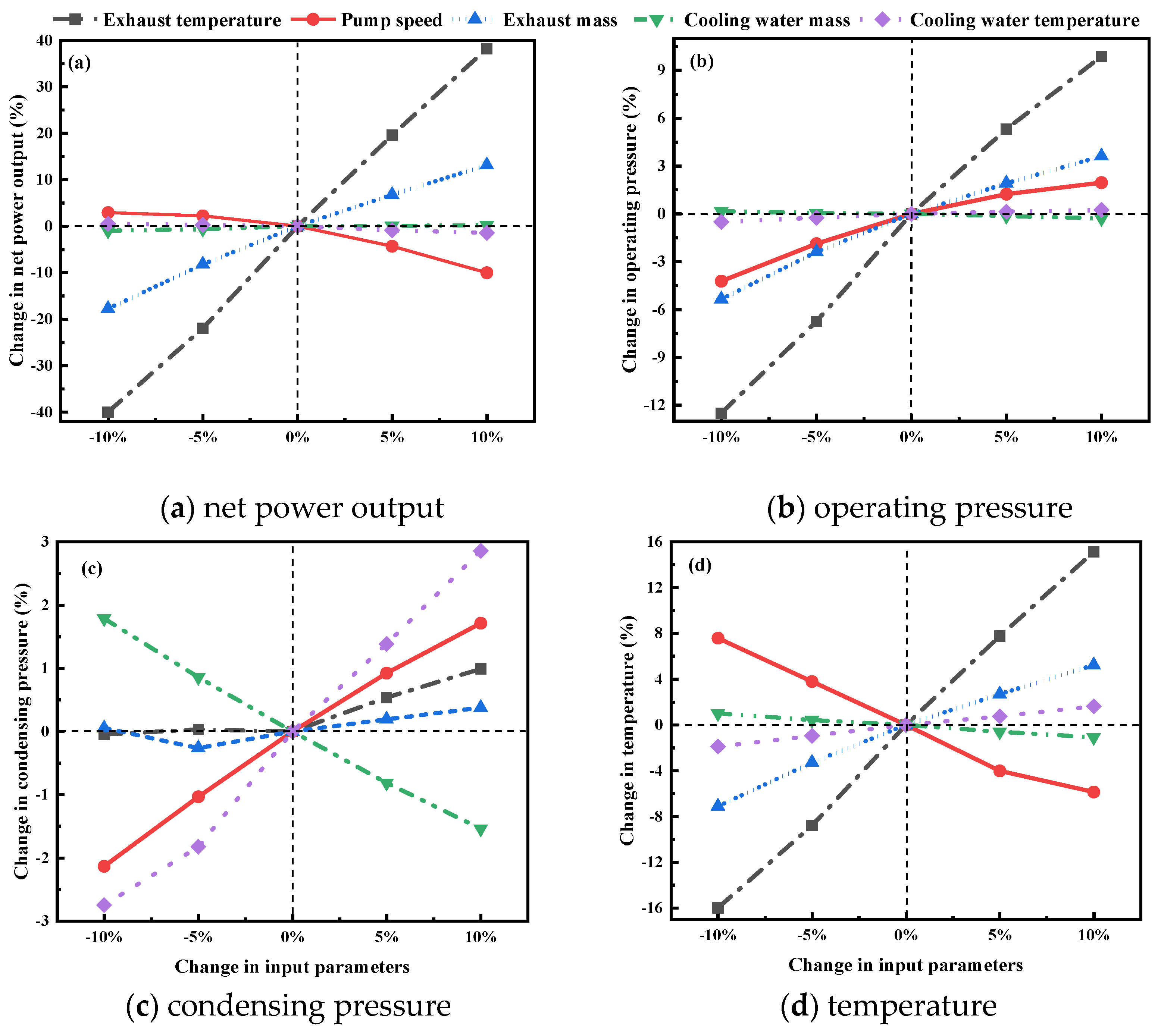

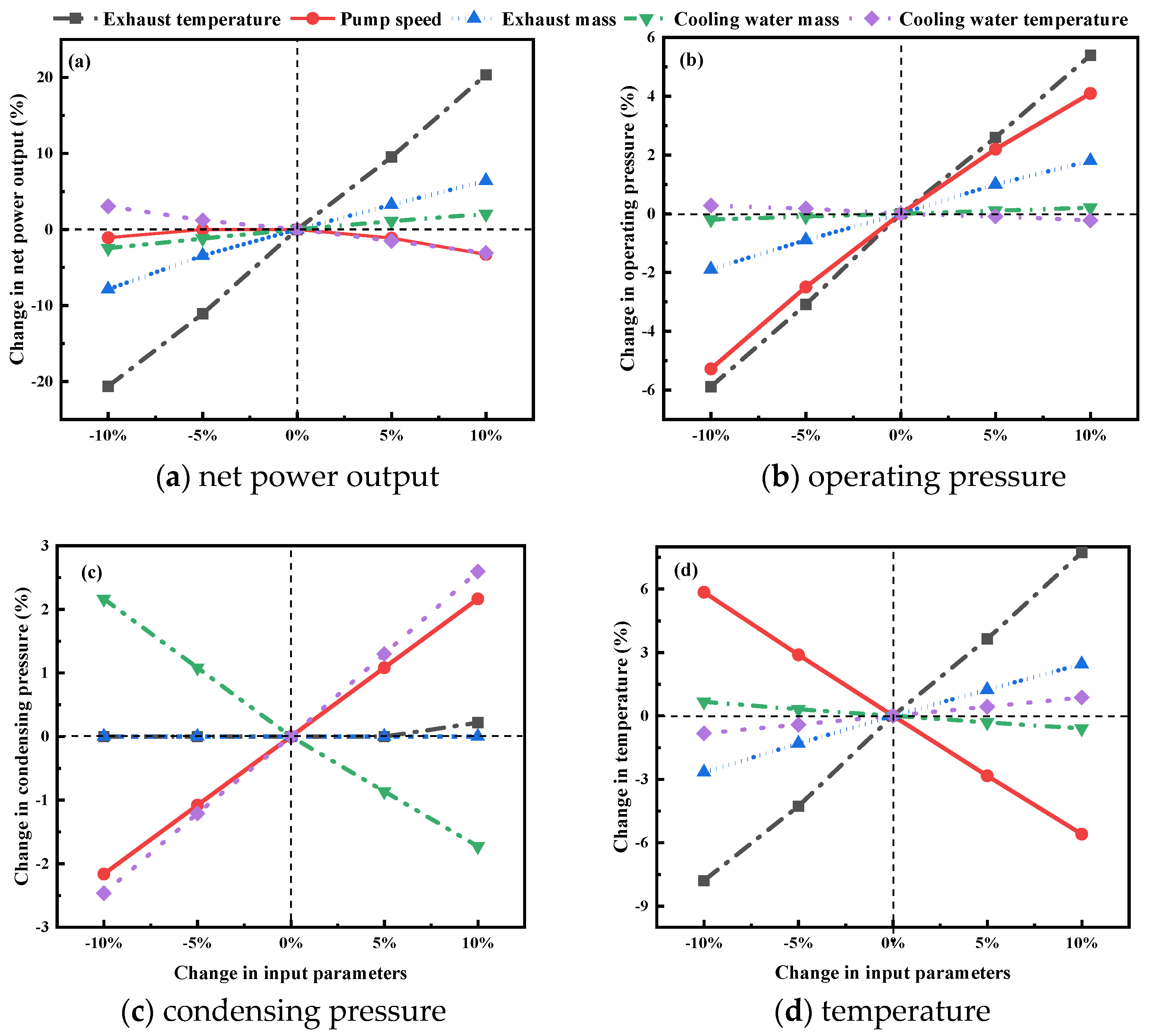

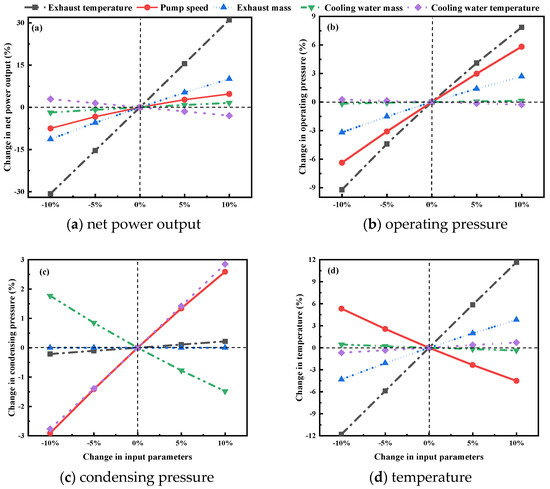

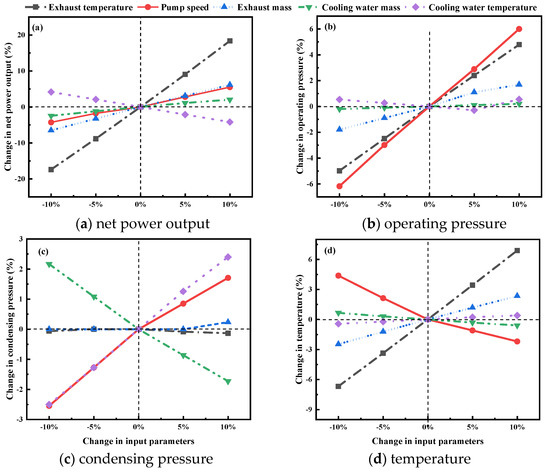

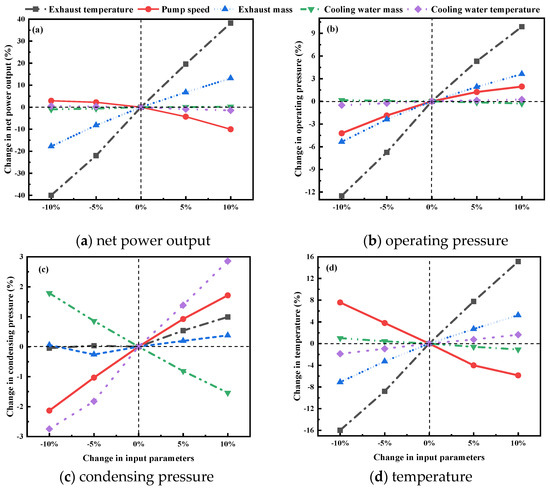

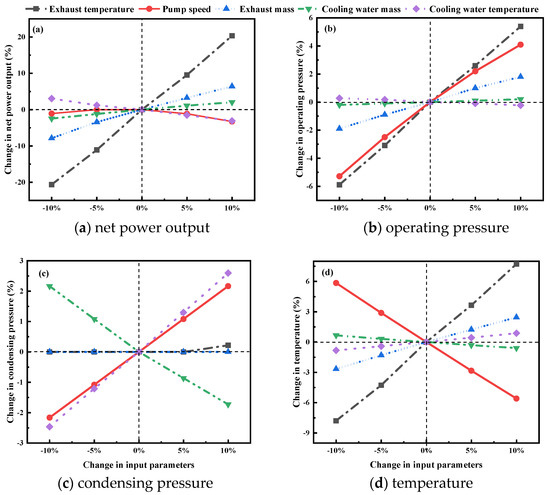

The sensitivity analysis of input parameters was carried out for the four systems by the above method. Figure 16, Figure 17, Figure 18 and Figure 19 show the sensitivity analysis results of the B-CMTPC, P-CMTPC, R-CMTPC, and PR-CMTPC systems, respectively, under the condition of a different step amplitude, and Figure a, b, c, and d represent the net power output, operating pressure, condensing pressure, and expander inlet temperature of the working fluid, respectively. According to Figure 16a, Figure 17a, Figure 18a and Figure 19a of the four systems, the net power is the most sensitive to the exhaust temperature, followed by the exhaust mass flow, and the net power output is positively correlated with both the exhaust temperature and mass flow rate. The exhaust temperature and its mass flow rate directly affect the heat absorption of the system, thus affecting the system net power output. Therefore, the net power output is relatively sensitive to the change of the exhaust parameters. The net power output is less sensitive to the cooling water temperature and mass flow rate, which is because the cooling water has a direct impact on the system condensation process rather than the heating process, which will be further explained below. The sensitivity to the pump speed of the four different CMTPC systems exhibited a inconsistent trend. Relevant research demonstrated that the net power output can reach a maximum value at a certain speed during the process of continuous change of the pump speed [10,11]. As the pump speed corresponded to the maximum power output obtained by the four systems is different, the sensitivity to the pump speed is also inconsistent with each other.

Figure 16.

The sensitivity of the main parameters of the B-CMTPC to the input parameters.

Figure 17.

The sensitivity of the main parameters of the P-CMTPC to the input parameters.

Figure 18.

The sensitivity of the main parameters of the R-CMTPC to the input parameters.

Figure 19.

The sensitivity of the main parameters of the PR-CMTPC to the input parameters.

Figure 16b, Figure 17b, Figure 18b and Figure 19b show that the system operating pressure is almost insensitive to the temperature of the cooling water or its mass flow while it exhibits a positive correlation and strong sensitivity to the other three system input parameters. The system operating pressure mainly depends on the temperature and mass flow rate of the working fluid. The temperature of the exhaust and mass flow rate affect the temperature of the working fluid, and the pump speed directly determines the mass flow of the working fluid. Therefore, the operating pressure is relatively sensitive to these three input parameters. Among them, the sensitivity of B-CMTPC, P-CMTPC, and PR- CMTPC to the exhaust temperature and pump speed is close, and the sensitivity to the exhaust mass flow rate is relatively less. Both the exhaust temperature and mass flow rate will affect the heat transfer process, thus changing the temperature of the working fluid, and thus affecting the operating pressure of the system. It can be found that the influence of the exhaust temperature on the operating pressure is greater than of the exhaust mass flow rate. For the R-CMTPC system, the operating pressure is the most sensitive to the exhaust temperature while the sensitivity to the pump speed is less than that of the exhaust mass flow rate. That is because the working fluid mass flow rate increases with the pump speed, causing a decrease of the expander outlet temperature of the working fluid, namely the heat source temperature of the recuperator. To a certain extent, it will weaken the heat transfer capacity of the recuperator, thus partially offsetting the increase of the heat transfer caused by the increasement of the mass flow rate. Therefore, the operating pressure of the R-CMTPC system changes more gently when the pump speed changes. The change of the pump speed can easily affect the heat absorption of the preheater owing to the small temperature difference between the cold and heat source, which intensifies the energy exchange of the whole system, thus acutely affecting the system operating pressure. That is the reason why even if there is a recuperator in PR-CMTPC, its sensitivity to the pump speed is greater than that of R-CMTPC. If the recuperator is removed from the PR-CMTPC system, that means switching to the P-CMTPC system, and the system will be more sensitive to the pump speed, which can be confirmed in Figure 17b.

It can be seen from Figure 16c, Figure 17c, Figure 18c and Figure 19c that the sensitivity of the condensing pressure to the input parameters of the four systems is consistent. The exhaust temperature and mass flow have little effect on the system condensing pressure. The condensing pressure is sensitive to the mass flow rate of the cooling water and has a negative correlation. The sensitivity to the cooling water temperature and pump speed are also non-negligible. The exhaust directly acts on the gas heater and has little effect on the working fluid in the condenser, so the condensing pressure is extremely insensitive to exhaust parameters. The heat transfer capacity of the cooling water is strong due to the high specific heat capacity. Thus, the change of the cooling water parameters, namely the temperature or mass flow rate, will affect the condensation process in time. The decrease in the cooling water temperature or the increase in the mass flow rate is beneficial to reduce the condensation load. The change of the pump speed directly determines the mass flow of the working fluid in the circulation system. On the one hand, the larger the mass flow rate is, the lower the expander outlet temperature of the working fluid is, which directly reduces the temperature difference during the heat transfer process of the condenser. On the other hand, the increase of the working fluid mass flow rate leads to an increase in the amount of heat transfer, and condensation load. Both the factors force the system to increase the condensing pressure. Therefore, the system condensing pressure is sensitive to the pump speed and is positively correlated with it.

Figure 16d, Figure 17d, Figure 18d and Figure 19d show that the expander inlet temperature of the different types of CMTPC systems exhibits a consistent sensitivity law for different system input parameters. The expander inlet temperature of the working fluid is almost insensitive to the temperature and mass flow of the cooling water. That is because the cooling water mainly affects the heat transfer in the condensation process of the system; that is, it affects the temperature of the working fluid at the outlet of the receiver. The temperature of the working fluid after the pump pressurization and heat exchanger heating is much higher than that at the outlet of the receiver. Thus, the expander inlet temperature is almost insensitive to the cooling water parameters. The exhaust temperature and mass flow rate change the working fluid temperature by affecting the heat transfer process. The pump speed affects the heat transfer process by changing the mass flow rate of the working fluid. Therefore, the expander inlet temperature of the working fluid is sensitive to these three parameters, which is true for all four CMTPC systems.

From the above analysis, the exhaust temperature and the pump speed greatly affect the net power output, operating pressure, and expander inlet temperature of the system, and the condensing pressure of the system is largely affected by the cooling water temperature and mass flow, and the pump speed. Therefore, it is necessary to pay attention to the more sensitive input parameters for the specific working condition to avoid system damage or unsafe operation when the system is operating under off-design conditions. For example, in order to avoid an excessive operating pressure, special attention should be paid to the exhaust temperature and pump speed.

5. Conclusions

In current work, the dynamic simulation models of four types of CMTPC with different constructions were developed, and carefully validated against experiment data. With these models, the dynamic performance, including the off-design performance and dynamic response speed of the four systems, was analyzed under the change of the engine load; the system sensitivity to the input parameters was studied by adjusting the system input parameters. Based on the work mentioned above, the following main conclusions are drawn:

(1) The parameter fluctuation amplitude of the CMTPC system is associated with the preheater and recuperator. The preheater is conductive to weakening the fluctuation while the recuperator makes the fluctuation severe. Thus, the maximum fluctuation amplitude of the system parameters is R-CMTPC, followed by B-CMTPC, PR-CMTPC, and P-CMTPC.

(2) The dynamic response speed of different systems is obviously different: The fastest is the B-CMTPC system, followed by P-CMTPC, PR-CMTPC, and R-CMTPC. The heat transfer performance of the heat exchangers and thermal inertia of the working fluid greatly influence the dynamic response speed of the system. The peak specific heat capacity of the working fluid occurs in the recuperator with a poor heat transfer performance, which seriously slows down the system response speed, so the R-CMTPC responds evidently more slowly than the others.

(3) The net power output of the four systems is sensitive to the exhaust temperature and mass flow rate, and the sensitivity to the pump speed exhibited inconsistent trend because the pump speed corresponding to the maximum power output obtained by the four systems is different. The condensing pressure of the four systems is largely affected by the cooling water parameters and the pump speed.

(4) The increase of the pump speed will weaken the heat transfer capacity of the regenerator, thus partially offsetting the enlargement of the heat transfer performance caused by the increase of the mass flow rate. Therefore, the operating pressure of R-CMTPC is the least sensitive to the pump speed followed by PR-CMTPC. The expander inlet temperature of the four CMTPC systems exhibits a consistent and strong sensitivity to the exhaust parameters and pump speed, which affects the heat transfer process.

Author Contributions

Conceptualization, R.W. and X.W.; methodology, R.W. and H.T.; software, R.W.; validation, J.Z., X.B. and Y.G.; resources, G.S.; data curation, R.W. and H.T.; writing—original draft preparation, R.W.; writing—review and editing, R.W.; supervision, G.S.; project administration, G.S.; funding acquisition, H.T. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Key R&D Program of China (No. 2018YFB0105900).

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

Nomenclature

| Cp | Specific heat capacity (kJ/kg·K) |

| A | Arears (m2) |

| ω | Pump rotation (rpm/min) |

| The cylinder volume (m3) | |

| ρ | The density of working fluid (kg/m3) |

| h | Enthalpy (kJ/kg·K) |

| The volume efficiency | |

| Isentropic efficiency of the pump | |

| Nozzle coefficient | |

| Isentropic efficiency of the expander | |

| T | Temperature (K) |

| Mass flow rate (kg/s) | |

| p | Pressure (MPa) |

| Subscripts | |

| P | Pump |

| exp | Expander |

| g | Exhaust |

| j | Jacket water |

| f1 | Working fluid |

| f2 | Heat source (exhaust or jacket water or working fluid after expander) |

| w | Tube wall |

| s | isentropic |

| ai | The average parameters of the ith control cell |

| i | inner |

| in | inlet |

| o | outer |

| Abbreviations | |

| CMTPC | CO2 mixture transcritical Power Cycle |

| B-CMTPC | Basic CO2 mixture transcritical power cycle |

| R-CMTPC | CO2 mixture transcritical power cycle with a recuperator |

| P-CMTPC | CO2 mixture transcritical Power Cycle with a preheater |

| PR-CMTPC | CO2 mixture transcritical Power Cycle with preheater and recuperator |

| WHR | Waste Heat Recovery |

| ORC | Organic Rankine Cycles |

Appendix A

Table A1.

Measuring instruments and accuracy of main parameters.

Table A1.

Measuring instruments and accuracy of main parameters.

| Parameter | Sensor Type | Scale | Accuracy |

|---|---|---|---|

| Exhaust side temperature | sheathed thermocouple sensors with first-class precision | 0–650 °C | ±1% |

| Other places’ temperature | sheathed Pt100 thermo-resistive type with A-class precision | 200–500 °C | ±0.15% |

| High pressure of CO2 | pressure transmitters | 0–14 MPa | ±0.065% |

| Low pressure of CO2 | pressure transmitters | 0–12 MPa | ±0.065% |

| Exhaust pressure | pressure transmitters | 0–0.5 MPa | ±0.065% |

| Cooling water pressure | pressure transmitters | 0–0.5 MPa | ±0.065% |

| CO2 mass flow rate | Coriolis mass flowmeter | 0–1080 kg/h | ±0.2% |

| Cooling water flow rate | turbine flowmeter | 0–12 m3/h | ±1% |

| Fuel flow rate of engine | fuel consumption meter | 5–2000 kg/h | ±0.8% |

| Air intake flow of engine | air flow meter | 0–1350 kg/h | ±0.5% |

Table A2.

Uncertainty analysis of the heat transfer rate.

Table A2.

Uncertainty analysis of the heat transfer rate.

| Parameters | ||

|---|---|---|

| Heat transfer rate of working fluid in the heating process | 0.89 kW | 1.73% |

| Heat transfer rate of exhaust in the heating process | 2.41 kW | 4.51% |

| Heat transfer rate of working fluid in the cooling process | 1.17 kW | 2.28% |

| Heat transfer rate of water in the cooling process | 4.53 kW | 9.17% |

References

- Lion, S.; Michos, C.N.; Vlaskos, I.; Rouaud, C.; Taccani, R. A review of waste heat recovery and Organic Rankine Cycles (ORC) in on-off highway vehicle Heavy Duty Diesel Engine applications. Renew. Sustain. Energy Rev. 2017, 79, 691–708. [Google Scholar] [CrossRef]

- Tian, H.; Chang, L.; Shu, G.; Shi, L. Multi-objective optimization of the carbon dioxide transcritical power cycle with various configurations for engine waste heat recovery. Energy Convers. Manag. 2017, 148, 477–488. [Google Scholar] [CrossRef]

- Wang, X.; Shu, G.; Tian, H.; Liu, P.; Jing, D.; Li, X. Dynamic analysis of the dual-loop Organic Rankine Cycle for waste heat recovery of a natural gas engine. Energy Convers. Manag. 2017, 148, 724–736. [Google Scholar] [CrossRef]

- Sawodny, D.; Seitz, O.; Gehring, C.; Bunz, M.; Brunschier, O. Design of a nonlinear Dynamic Feedforward Part for the Evaporator Control of an ORC in HDE. IFAC-PapersOnLine 2016, 49, 625–632. [Google Scholar]

- Wang, X.; Shu, G.; Tian, H.; Liu, P.; Jing, D.; Li, X. The effects of design parameters on the dynamic behavior of organic ranking cycle for the engine waste heat recovery. Energy 2018, 147, 440–450. [Google Scholar] [CrossRef]

- Shu, G.; Wang, X.; Tian, H.; Liu, P.; Jing, D.; Li, X. Scan of working fluids based on dynamic response characters for Organic Rankine Cycle using for engine waste heat recovery. Energy 2017, 133, 609–620. [Google Scholar] [CrossRef]

- Wu, C.; Wang, S.-S.; Jiang, X.; Li, J. Thermodynamic analysis and performance optimization of transcritical power cycles using CO2-based binary zeotropic mixtures as working fluids for geothermal power plants. Appl. Therm. Eng. 2017, 115, 292–304. [Google Scholar] [CrossRef]

- Yang, M.-H. Payback period investigation of the organic Rankine cycle with mixed working fluids to recover waste heat from the exhaust gas of a large marine diesel engine. Energy Convers. Manag. 2018, 162, 189–202. [Google Scholar] [CrossRef]

- Persichilli, M.; Kacludis, A.; Zdankiewicz, E.; Held, T.; Asia, C. Supercritical CO2 power cycle developments and commercialization: Why sCO2 can displace steam ste. In Proceedings of the Power-Gen India & Central Asia 2012, New Delhi, India, 19–21 April 2012. [Google Scholar]

- Li, X.; Shu, G.; Tian, H.; Huang, G.; Liu, P.; Wang, X.; Shi, L. Experimental comparison of dynamic responses of CO2 transcritical power cycle systems used for engine waste heat recovery. Energy Convers. Manag. 2018, 161, 254–265. [Google Scholar] [CrossRef]

- Li, X.; Shu, G.; Tian, H.; Shi, L.; Wang, X. Dynamic Modeling of CO2 Transcritical Power Cycle for Waste Heat Recovery of Gasoline Engines. Energy Procedia 2017, 105, 1576–1581. [Google Scholar] [CrossRef]

- Rony, R.; Yang, H.; Krishnan, S.; Song, J. Recent Advances in Transcritical CO2 (R744) Heat Pump System: A Review. Energies 2019, 12, 457. [Google Scholar] [CrossRef]

- Sarkar, J. Review and future trends of supercritical CO2 Rankine cycle for low-grade heat conversion. Renew. Sustain. Energy Rev. 2015, 48, 434–451. [Google Scholar] [CrossRef]

- Shi, L.; Shu, G.; Tian, H.; Huang, G.; Chang, L.; Chen, T.; Li, X. Ideal Point Design and Operation of CO2-Based Transcritical Rankine Cycle (CTRC) System Based on High Utilization of Engine’s Waste Heats. Energies 2017, 10, 1692. [Google Scholar] [CrossRef]

- Yang, M.-H. The performance analysis of the transcritical Rankine cycle using carbon dioxide mixtures as the working fluids for waste heat recovery. Energy Convers. Manag. 2017, 151, 86–97. [Google Scholar] [CrossRef]

- Shu, G.; Yu, Z.; Tian, H.; Liu, P.; Xu, Z. Potential of the transcritical Rankine cycle using CO2-based binary zeotropic mixtures for engine’s waste heat recovery. Energy Convers. Manag. 2018, 174, 668–685. [Google Scholar] [CrossRef]

- Zegenhagen, M.T.; Ziegler, F. Feasibility analysis of an exhaust gas waste heat driven jet-ejector cooling system for charge air cooling of turbocharged gasoline engines. Appl. Energy 2015, 160, 221–230. [Google Scholar] [CrossRef]

- Manente, G.; Toffolo, A.; Lazzaretto, A.; Paci, M. An Organic Rankine Cycle off-design model for the search of the optimal control strategy. Energy 2013, 58, 97–106. [Google Scholar] [CrossRef]

- Chen, Y.; Lundqvist, P.; Platell, P. Theoretical research of carbon dioxide power cycle application in automobile industry to reduce vehicle’s fuel consumption. Appl. Therm. Eng. 2005, 25, 2041–2053. [Google Scholar] [CrossRef]

- Li, L.; Ge, Y.T.; Luo, X.; Tassou, S.A. Thermodynamic analysis and comparison between CO2 transcritical power cycles and R245fa organic Rankine cycles for low grade heat to power energy conversion. Appl. Therm. Eng. 2016, 106, 1290–1299. [Google Scholar] [CrossRef]

- Quoilin, S.; Van Den Martijn, B.; Declaye, S.; Dewallef, P.; Lemort, V. Techno-economic survey of Organic Rankine Cycle (ORC) systems. Renew. Sustain. Energy Rev. 2013, 22, 168–186. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, Y.; Dong, C.; Wang, L.; Roskilly, A.P. Design and assessment on a novel integrated system for power and refrigeration using waste heat from diesel engine. Appl. Therm. Eng. 2015, 91, 591–599. [Google Scholar] [CrossRef]

- Wang, E.H.; Zhang, H.G.; Fan, B.Y.; Ouyang, M.G.; Yang, F.Y.; Yang, K.; Wang, Z.; Zhang, J.; Yang, F.B. Parametric analysis of a dual-loop ORC system for waste heat recovery of a diesel engine. Appl. Therm. Eng. 2014, 67, 168–178. [Google Scholar] [CrossRef]

- Shu, G.; Shi, L.; Tian, H.; Li, X.; Huang, G.; Chang, L. An improved CO2 -based transcritical Rankine cycle (CTRC) used for engine waste heat recovery. Appl. Energy 2016, 176, 171–182. [Google Scholar] [CrossRef]

- Shi, L.F.; Shu, G.Q.; Tian, H.; Huang, G.D.; Chen, T.Y.; Li, X.Y.; Li, D. Experimental comparison between four CO2-based transcritical Rankine cycle (CTRC) systems for engine waste heat recovery. Energy Convers. Manag. 2017, 150, 159–171. [Google Scholar] [CrossRef]

- Xie, H.; Yang, C. Dynamic behavior of Rankine cycle system for waste heat recovery of heavy duty diesel engines under driving cycle. Appl. Energy 2013, 112, 130–141. [Google Scholar] [CrossRef]

- Chatzopoulou, M.A.; Simpson, M.; Sapin, P.; Markides, C.N. Off-design optimisation of organic Rankine cycle (ORC) engines with piston expanders for medium-scale combined heat and power applications. Appl. Energy 2019, 238, 1211–1236. [Google Scholar] [CrossRef]

- Wang, X.; Shu, G.; Tian, H.; Feng, W.; Liu, P.; Li, X. Effect factors of part-load performance for various Organic Rankine cycles using in engine waste heat recovery. Energy Convers. Manag. 2018, 174, 504–515. [Google Scholar] [CrossRef]

- Wang, X.; Shu, G.; Tian, H.; Liu, P.; Li, X.; Jing, D. Dynamic Response Performance Comparison of Ranking Cycles with Different Working Fluids for Waste Heat Recovery of Internal Combustion Engines. Energy Procedia 2017, 105, 1600–1605. [Google Scholar] [CrossRef]

- SIMULINK. 2015. Available online: https://ww2.mathworks.cn/products/simulink.html?s_tid=hp_products_simulink (accessed on 15 December 2019).

- Lemmon, E.; Huber, M.; McLinden, M. NIST Standard Reference Database 23: Reference Fluid Thermodynamic and Transport Properties-REFPROP, Version 9.1, Standared Reference Data Program. 2013.

- Karellas, S.; Schuster, A.; Leontaritis, A.-D. Influence of supercritical ORC parameters on plate heat exchanger design. Appl. Therm. Eng. 2012, 33, 70–76. [Google Scholar] [CrossRef]

- Chowdhury, J.I.; Nguyen, K.; Thornhill, D. Dynamic Model of Supercritical Organic Rankine Cycle Waste Heat Recovery System for Internal Combustion Engine. Int. J. Automot. Technol. 2017, 18, 589–601. [Google Scholar] [CrossRef]

- Pangborn, H.; Alleyne, A.G.; Wu, N. A comparison between finite volume and switched moving boundary approaches for dynamic vapor compression system modeling. Int. J. Refrig. 2015, 53, 101–114. [Google Scholar] [CrossRef]

- Shu, G.; Li, X.; Tian, H.; Shi, L.; Wang, X.; Yu, G. Design condition and operating strategy analysis of CO2 transcritical waste heat recovery system for engine with variable operating conditions. Energy Convers. Manag. 2017, 142, 188–199. [Google Scholar] [CrossRef]

- Jensen, J.M.; Tummescheit, H. Moving boundary models for dynamic simulations of two-phase flows. In Proceedings of the 2nd International Modelica Conference, Oberpfaffhenhofen, Germany, 18–19 March 2002; pp. 235–244. [Google Scholar]

- Horst, T.A.; Rottengruber, H.-S.; Seifert, M.; Ringler, J. Dynamic heat exchanger model for performance prediction and control system design of automotive waste heat recovery systems. Appl. Energy 2013, 105, 293–303. [Google Scholar] [CrossRef]

- Pitla, S.S.; Robinson, D.M.; Groll, E.A.; Ramadhyani, S. Heat transfer from supercritical carbon dioxide in tube flow: A critical review. Hvac&R Res. 1998, 4, 281–301. [Google Scholar]

- Gelbe, H.; Ziada, S. O2 Vibration of Tube Bundles in Heat Exchangers. In VDI Heat Atlas; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Faghri, A.; Yaghoubi, M. International Journal of Heat, Transfer Mass. Adv. Heat Transfer 2015, 23, 577. [Google Scholar]

- Li, X.; Shu, G.; Tian, H.; Shi, L.; Huang, G.; Chen, T.; Liu, P. Preliminary tests on dynamic characteristics of a CO2 transcritical power cycle using an expansion valve in engine waste heat recovery. Energy 2017, 140, 696–707. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).