1. Introduction

Lithium-ion batteries have found applications for feeding many types of portable electronics due to their unsurpassed working characteristics. Normally, the lithium-ion battery contains active electrode materials, a separation material, and electrolyte and construction components. The main role of the separator is the prevention of direct contact and consequently shortage of the electrodes. The following requirements are imposed on separation materials in terms of physicochemical and electrochemical characteristics: Low ionic resistance; high mechanical strength and structural stability; high chemical stability in contact with the electrolyte and electrode materials that repeatedly change their oxidation or reduction activity; and the ability to inhibit the transfer of electrolyte solution between the cathode and anode spaces, with the exception of the main charge carriers, the wetting ability by electrolyte solutions, and high uniformity of the structure and properties [

1]. To realize all these properties, the separation material must have a sufficiently high porosity with a predominant content of large pores. One of the requirements for modern separation materials is its ability, in the case of strong battery heating, to prevent short-circuiting of the electrodes as a result of fusion of the separator: The outer layers must seal the porous structure of the material [

2]. Nowadays, polyethylene, polypropylene, and three-layer polymer separators are widely used in commercial LIB due to their high electrochemical stability and excellent mechanical properties. However, the mentioned separation materials are characterized by poor wettability due to the non-polar nature of the polymers used, small pore size, and low total porosity, which reduces the amount of retained electrolyte and causes low ionic conductivity. This leads to an increase in the internal resistance of the battery and, as a consequence, to a decrease in power and an increase in energy loss as a result of heating [

2]. In addition, thermal shrinkage of such separators can cause a short circuit of two electrodes. The literature discusses various methods of dealing with these undesirable phenomena [

3,

4]; however, they cannot be completely eliminated.

At present, three main methods for producing polymer separation materials are used: Die-casting, solvent-free phase separation, and electrospinning. The latter one is usually used to obtain continuous nanoscale polymer fibers under the electric field superimposed on the polymer solution [

5]. The separation material can be a membrane based on such nanofibers having a small thickness, high porosity, and also a fairly high mechanical strength. The properties of PVDF are well known, among them are high polarity, low thermal conductivity, high mechanical strength, good wettability by polar organic solvents, high chemical stability, and good compatibility with many electrode materials [

6]. Currently, mainly, two methods of electrospinning are used: Capillary and capillary-less. In the first case, the polymer solution is supplied through the capillary, and in the second one, a rotating electrode is used, partially immersed in the polymer solution. The performance of a capillary-less electrospinning equipment strongly depends on the ability of the polymer solution to form relatively stable jets, so not all polymers can be used to produce non-woven material according to this technology. The technology of capillary-less electrospinning is more applicable for the industrial production of nanofibers, as it allows high performance to be achieved with a fairly simple equipment design.

In the present work, the capillary-less electrospinning method was adapted for experimental realization of the synthesis of a new polymer separation material with improved electrochemical properties. The method consists of capillary-less electrospinning from a polymer mix of polyvinylidene fluoride (PVDF) and polytetrafluoroethylene (PTFE). The new separation material was characterized by physical methods; electrochemical methods were applied for characterization of the electrochemical properties of the separation and electrode materials, and the evolution of the electrochemical characteristics in the processes of high rate charge and discharge was determined. The electrochemical properties of the separator were studied in the cells with Li4Ti5O12 and metallic Li-based electrodes, as well as with an electrolyte based on lithium perchlorate dissolved in a mixed solvent consisting of propylene carbonate (PC) and dimethoxyethane (DME).

2. Materials and Methods

For the synthesis of the electrode material based on Li

4Ti

5O

12, the following materials were used as starting reagents: Lithium carbonate Li

2CO

3 (purity grade «pure», Neva-Reaktiv, Russia), as well as titanium oxide TiO

2 having the crystalline modification of rutile (purity grade «pure», Lenreaktiv, Russia,) taken in a stoichiometric ratio. The reaction mix was subjected to mechanical activation using the AGO-2 planetary ball mill activator (Novits, Russia) and was carried out in steel drums filled with steel grinding 6-mm balls, with the mass ratio to the mass of the treated reagent mix of 10:1; acetone was used as a medium for the dispersion process; and treatment was carried out for 20 min at a rotation frequency of 560 rpm. The heat treatment of the mechanically activated reaction mix was carried out in a tube furnace with a controllable (argon) atmosphere and heating trajectory, which was performed under a constant rate of 10 °C·min

−1. The synthesized product was cooled when the heating was turned off. The described synthesis approach was developed in the series of our earlier works [

7,

8,

9,

10,

11].

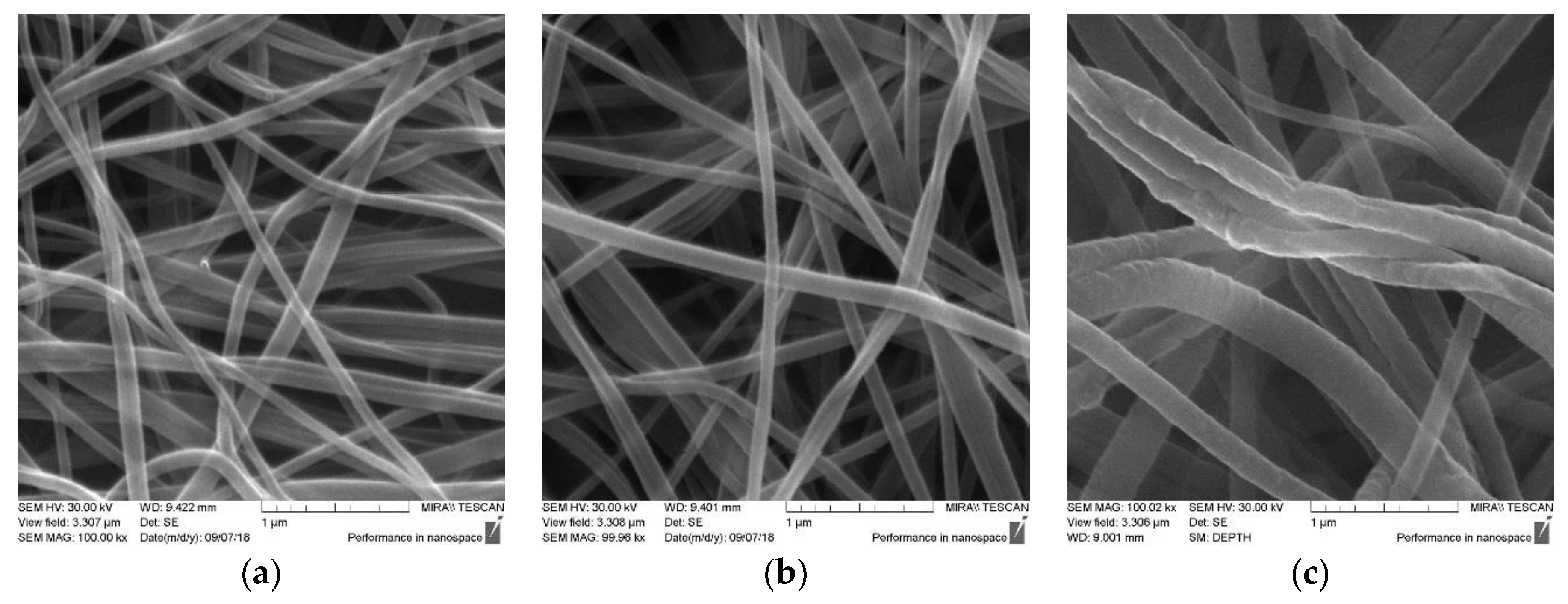

The separation material was obtained by capillary-less electrospinning from a polymer solution in a laboratory equipment (NS LAB-200, Elmarco, Liberec, Czech Republic). Samples of PVDF and PTFE were dispersed in dimethylformamide and butylacetate in a weight ratio of 1:1 with stirring for 2 h to obtain solutions with polymer concentrations from 6 to 10 wt.%. Next, the resulting solution was placed in a bath and electrospinning was performed under the following conditions: Collecting electrode was string, supply electrode was four-string electrode, the height between the electrodes was 170 mm, and electrode rotation frequency of 16 rpm. To obtain a uniform structure of the separation material, paper was used as a substrate. The operating voltage was 70 kV, current of 0.02 to 0.03 mA, and the temperature and humidity inside the NS LAB-200 unit were 25 ± 2 °C and 14 ± 2%, respectively. The thickness of the separator was determined using a thickness gauge Absolute Digimatic ID-S 543-790 (Mitutoyo Corp., Kawasaki-shi, Kanagawa, Japan). The diameter of the fibers of the separation material was determined according to scanning electron microscopy (SEM) using the equipment MIRA LMU (Tescan, Brno, Czech Republic). So, the material’ properties varied in the following intervals: Thickness—50–60 μm, surface density—15–30 g·m−2, bulk porosity—70%–85%, and fiber diameter—100–250 nm.

The electrolyte uptake (EU) of the separation material was measured by soaking the PVDF/PTFE and PP membranes in 0.67 M LiClO

4 solution in the mixture of PC:DME = 7:3 (by vol.), which was calculated in accordance with Equation (1) [

12]:

where

w0 and

w1 are the weight of the separators before and after soaking in the electrolyte for 1 h, respectively.

The average pore diameters of the PP and PVDF/PTFE separation materials were measured using the equipment Porometer 3 Gzh (Quantocrome Instruments, Odelzhausen, Germany) in the range of pore size values 0.013–100 μm. Measurements were carried out in the ranges of pressure 0–6 bar and flow rate 0–200 L/min. Porofil fluid was used as the wetting liquid for capillary flow porometry measurements.

The electrochemical experiment was performed in agreement with our previous work [

13]. The studied electrodes were made by blending 80 wt.% Li

4Ti

5O

12, 10 wt.% acetylene black, and 10 wt.% PVdF binder. The electrolyte was 0.67 M LiClO

4 solution in the mix of organic solvents: Propylene carbonate:dimethoxyethane (7:3, vol.). The electrode composite coated the Al-foil with a coating density of 5 mg∙cm

−2 using a «Dr. Blade» instrument. The electrochemical measurements were conducted in laboratory half coin cells and half pouch cells containing the working electrode, lithium counter electrode, and lithium reference electrode (in the pouch cells only). Coin cells were used for constant current measurements under relatively small currents (0.1–1 C), when polarization of the metallic lithium counter electrode was negligibly small. At higher currents, pouch cells with reference electrode were used. Also, pouch cells were applied in the PITT and EIS measurements, when the response of the working electrode only was recorded. Elins/P-45X potentiostat-galvanostat with FRA module (Elins, Russian Federation) and Autolab/PGSTAT302N modular high-current potentiostat/galvanostat (Metrohm Autolab B.V., Utrecht, The Netherlands) with an FRA frequency response analyzer were applied for PITT and EIS measurements. Neware/BTS10V10mA (Neware Technology Limited, Shenzhen, China) and Booster/UZR 0.03-10 (Booster, Saint-Petersburg, Russia) charge-discharge modules were used for the galvanostatic charge-discharge tests. The electrode potentials were measured versus the Li reference electrode in the same electrolyte. The ambient temperature during the measurements was 25 °C.

4. Discussion

PP-based separation material is widely used in modern LIBs. Its architecture is a compromise between electrochemical properties and mechanical characteristics that allow it to effectively withstand dendritic processes and mechanical stresses that occur during battery assembly. However, in electrochemical systems in which dendritic formation is practically impossible, for example, with medium-voltage anode materials, as in our case with Li

4Ti

5O

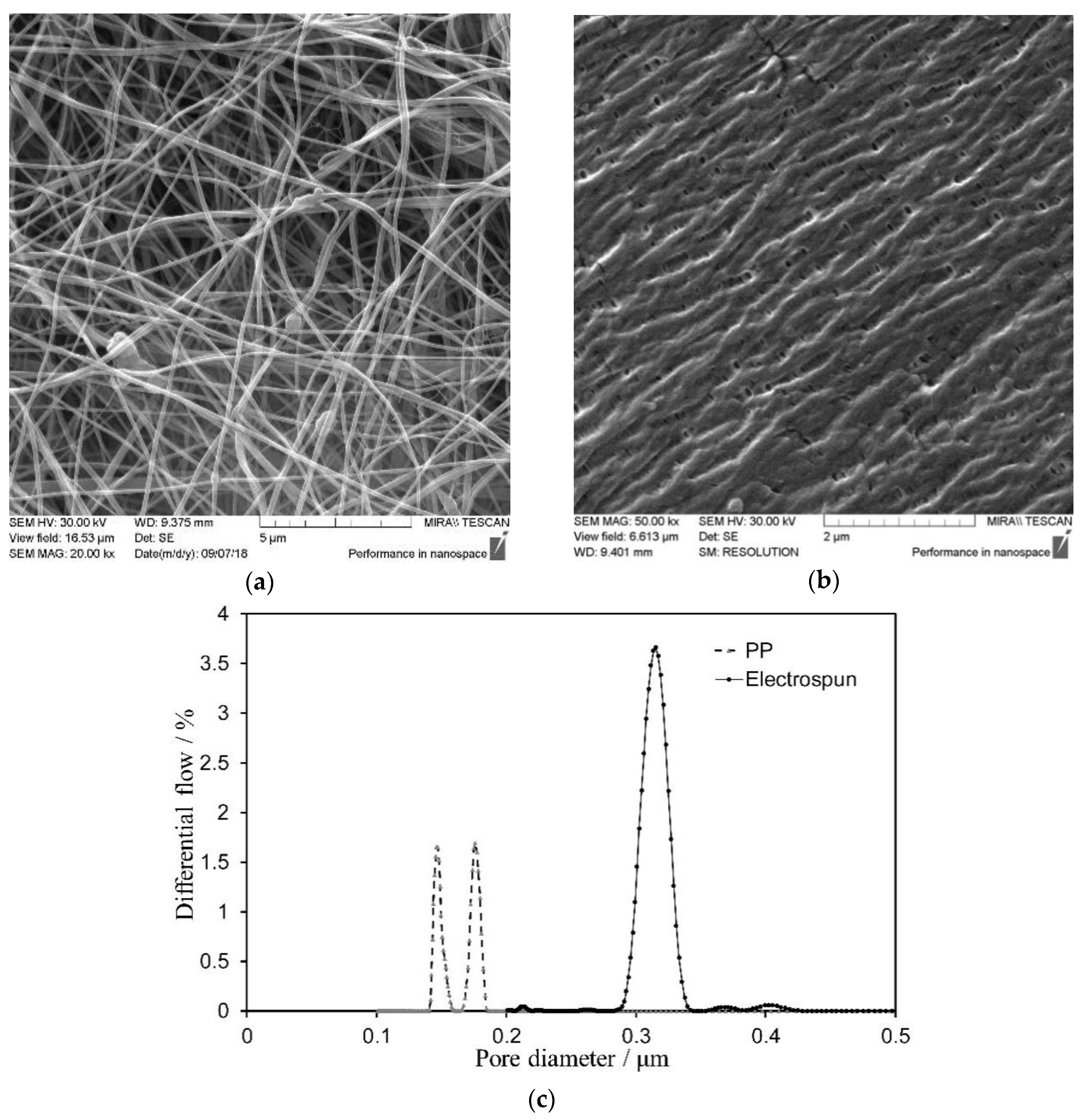

12, such mechanical characteristics are excessive, which is why the electrochemical properties are severely limited. For this reason, conventional PP-based, and considered in this paper, PVDF and PTFE mix fibers electrospun separation materials have some very different morphologies (

Figure 1a,b). The morphological characteristics of the separation materials that are most significant for enhancing the electrochemical properties are the pore size and total porosity. PP-based material has a significantly lower average pore size (0.17 vs. 0.32 μm) (

Figure 1c) and lower total porosity (39% vs. 71.4%) compared to the PVDF and PTFE mix fibers electrospun separation material. Similar results were provided by the wettability test: Electrolyte uptake (EU) values for the PP and PVDF/PTFE separation materials were 445% and 800%, respectively. It is logical to expect that these features of the latter one significantly reduce the resistance of electrolyte retained in the pores. The development of approaches to synthesis made it possible to determine the conditions (

Table 1) for obtaining the optimal morphology separation material (

Figure 2). A rather similar morphology of the electrospun obtained materials can be observed in the literature [

16]: Materials with high total porosity and a rather large pore size are formed, which leads to a high degree of electrolyte uptake. Due to their high elasticity, such separation membranes can be used in flexible LIB designs.

The most indicative are cycling tests of electrochemical cells with separation material at elevated charge-discharge rates (

Figure 3). Electrospun separation material demonstrates a higher ability to cycle under high currents compared to PP-based separation material: With increasing current, the cell polarization decreased slower.

Table 2 shows the charge and discharge capacities as well as the averaged electrode potential for each curve, which allowed an evaluation of the electrode polarization. These data allowed a comparison of the cycling rate capability of the cells with two types of separation materials: PVDF and PTFE mix fibers electrospun-based separation material and PP-based separation material.

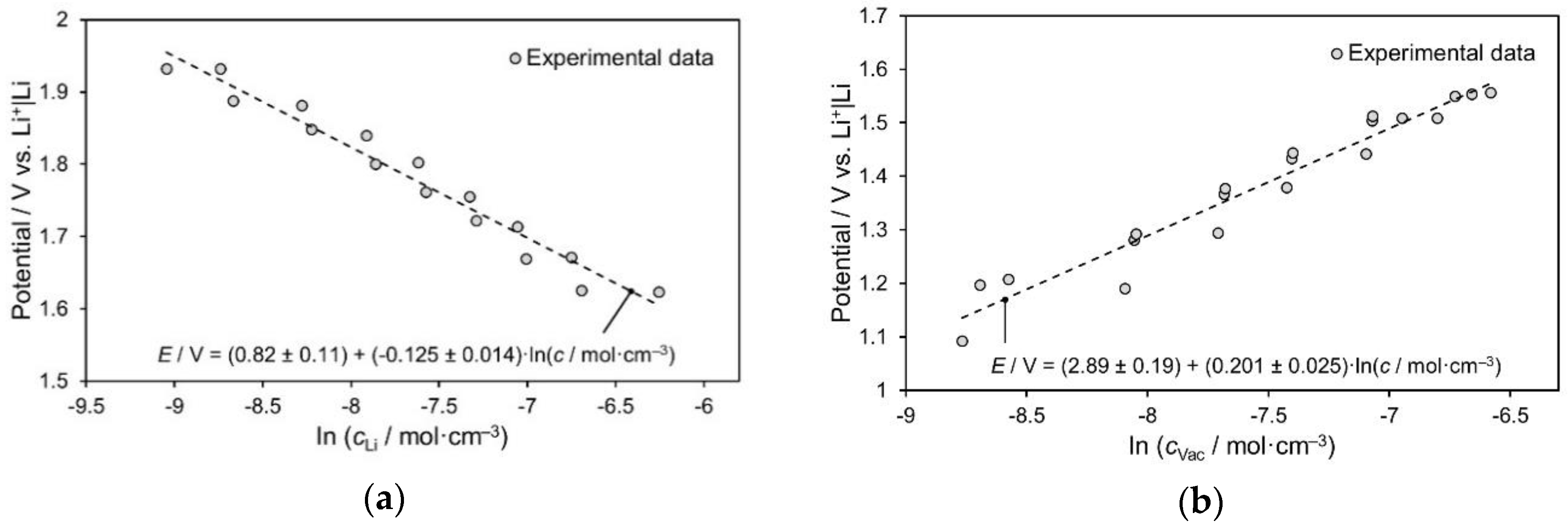

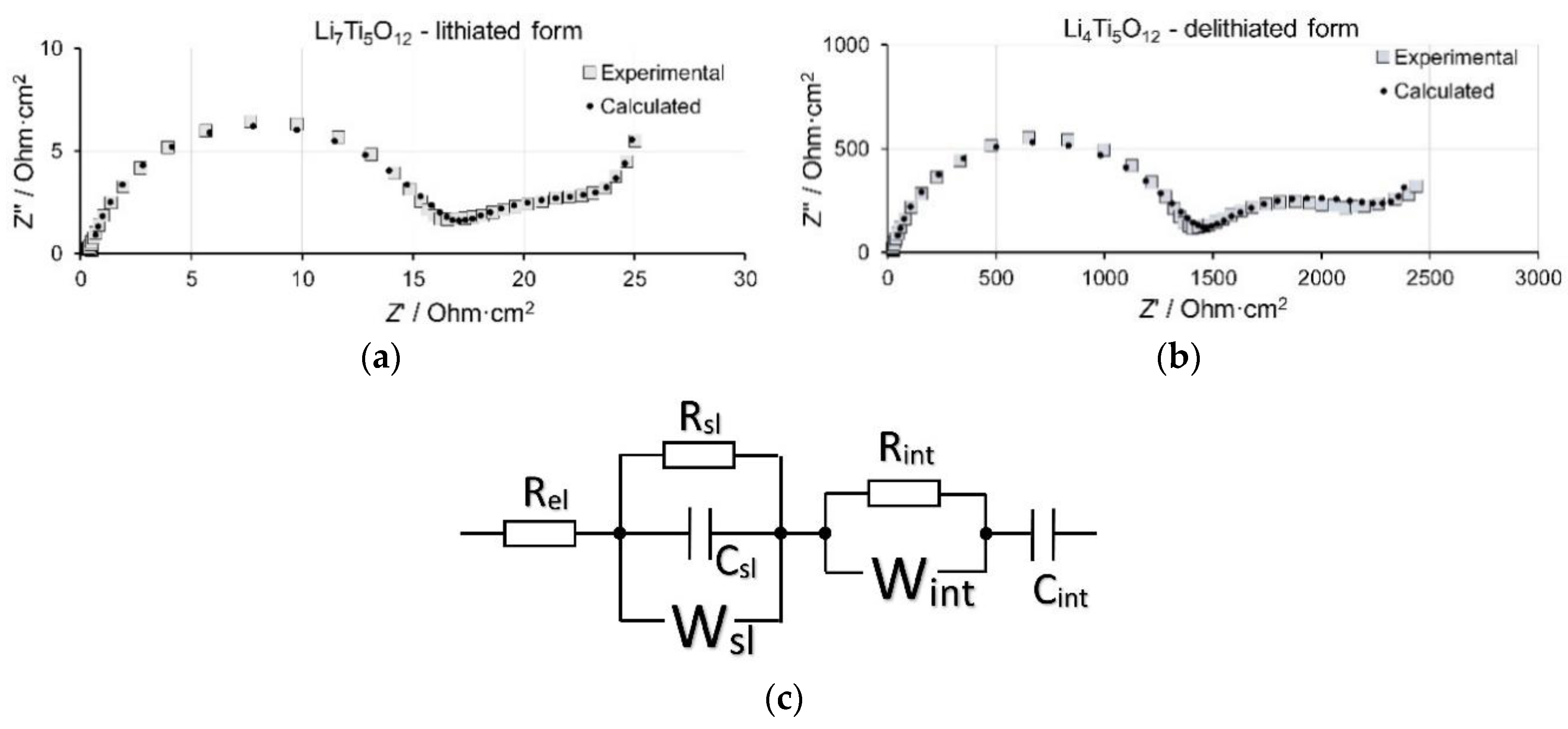

It is of interest to find out how high-speed cycling conditions affect the kinetic characteristics of the electrode material. For these purposes, we used the EIS method, as the most informative and sufficiently rapid method of electrochemical analysis. Model approaches for the analysis of EIS data were developed by us in a number of our earlier works [

9,

13,

15]. For the correct determination of the main kinetic characteristic, the diffusion coefficient of lithium, it is necessary to correctly determine the relationship between the potential and the lithium ion concentration in the solid intercalation electrode. This was done by us (

Figure 4) using a previously developed approach [

11]. The EIS spectra show an excellent fit to the model calculations (

Figure 5). It should be noted that the separation material influences only the electrolyte conductivity, but does not influence the state of the electrode. In contrary, the EIS spectrum contains mainly electrode characteristics, and only a high frequency cutoff on the

Z’ axis relates to the electrolyte. The purpose of the EIS study of the system was to determine the influence of the current mode on the electrode state in order to define possible factors influencing the high current cycling except the separation material used.

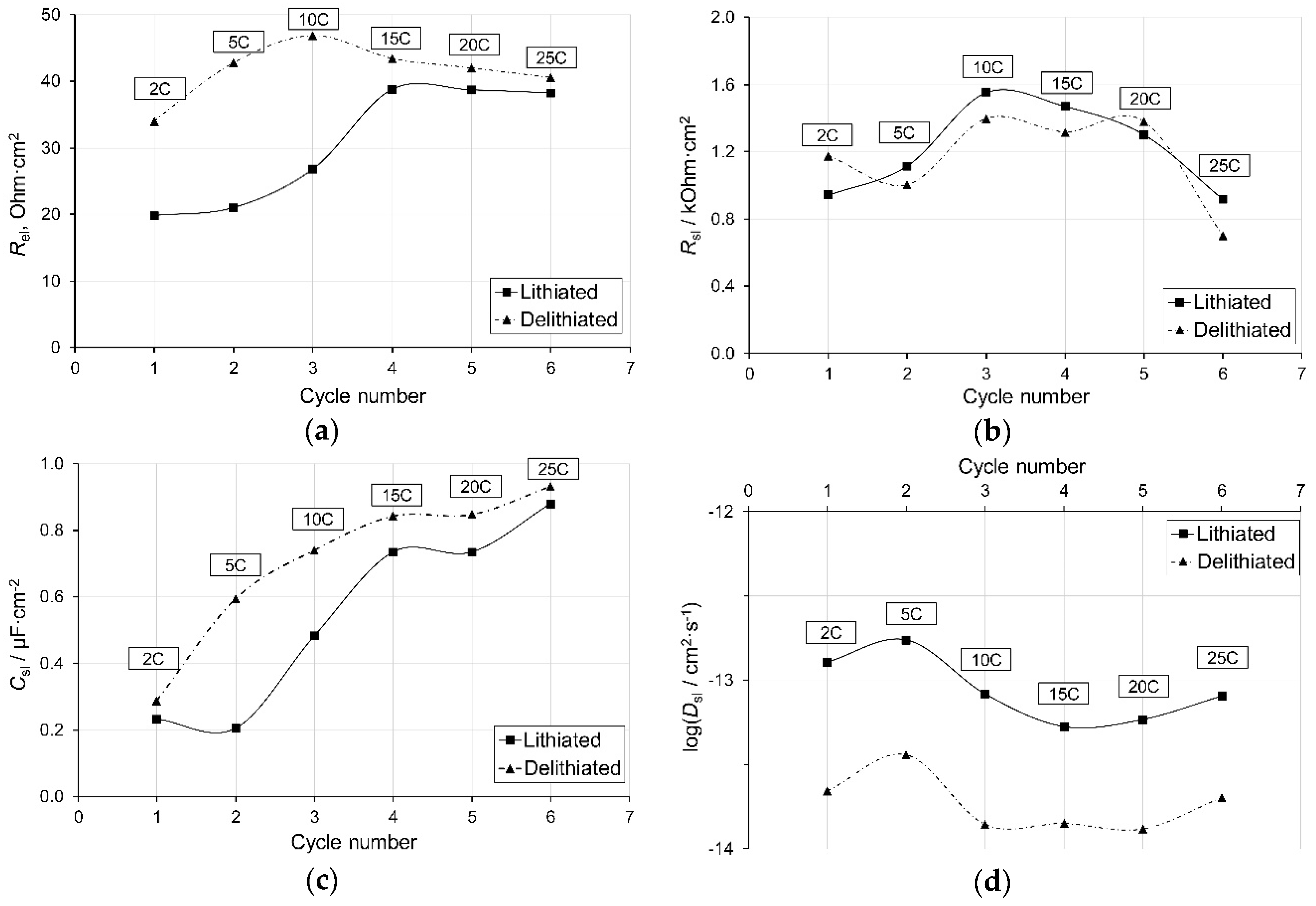

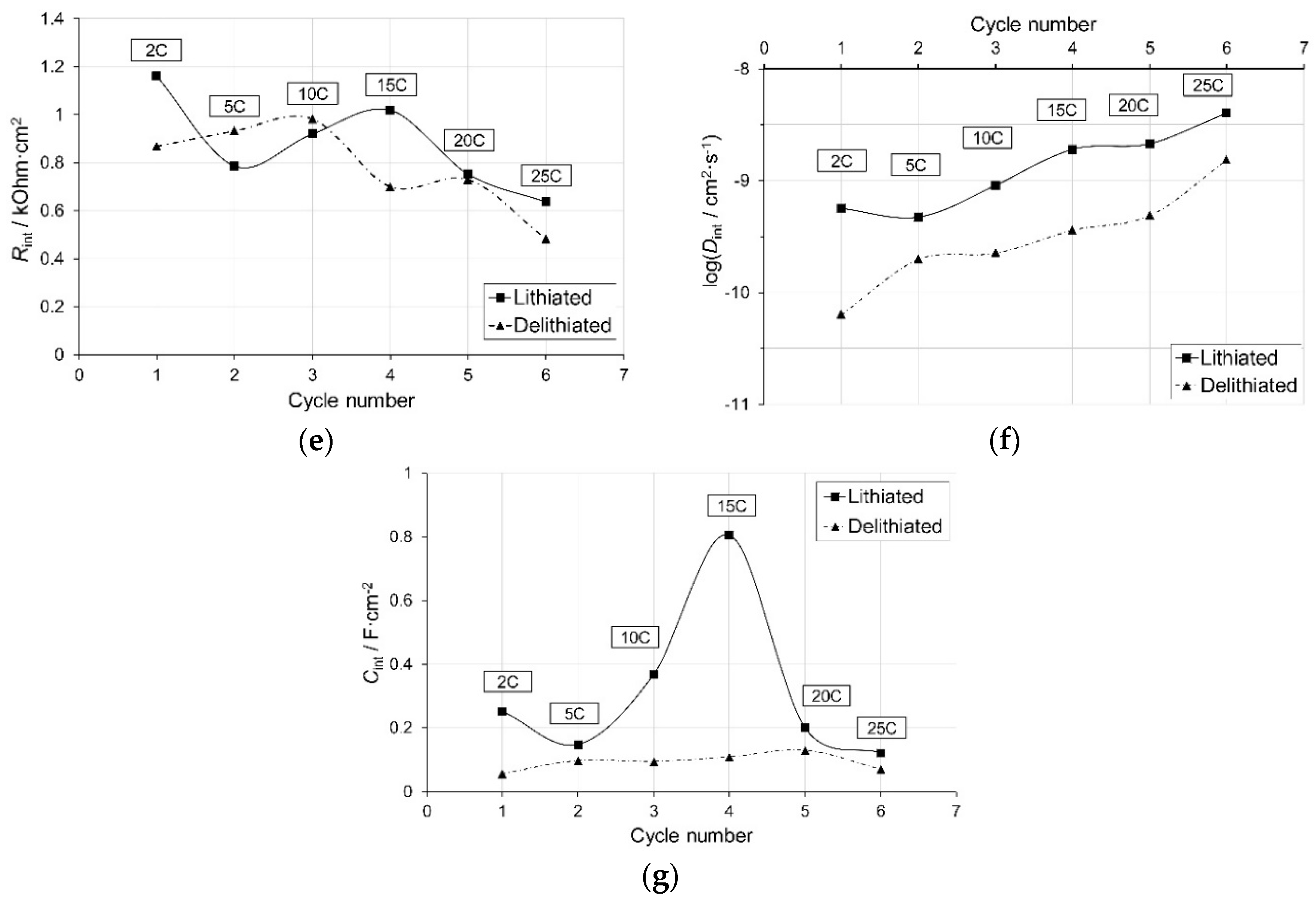

It is of interest to consider the dependence of the parameters of the electric equivalent circuit on the number of charge-discharge cycles in various current modes (

Figure 6). In absolute terms, the values of all parameters of the lithium ions intercalated and deintercalated forms of the Li

4Ti

5O

12 electrode noticeably vary, but the nature of their dependences is quite similar. The electrolyte resistance shows a noticeable increase with an increasing number of cycles and an increasing charge-discharge rate (

Figure 6a). There are two main possible reasons, which can cause the variation of the electrolyte resistance: (i) The electrolyte resistance cannot be completely separated from the surface layer resistance by the analysis of the EIS spectra, which means its variation manner follows the variation of surface layer resistance; and (ii) the electrolyte resistance varies due to changes in the local conditions, like the formation of micro cracks on the surface layer to be filled with electrolyte. In the real situation, it can be a sum of both reasons. Alongside the increase of the current we observed, the electrolyte resistance values measured on lithiated and delithiated electrodes were closer, which means that under higher currents, the surface layer state becomes more stable. This also changes in a similar way (

Figure 6b). Since the value of the surface layer resistance is many times greater than the value of the electrolyte resistance, their symbiotic change can be partially explained by the insufficiently accurate separation of both these resistances. The values of the surface layer resistance measured for lithiated and delithiated forms of the electrode are very close to each other, and their dependences on the current are in a similar manner. First, they rise while the current increases up to 10 C, and after that they decrease. Here, we can observe two effects: In the first region of currents, the surface layer thickness rises and its resistance increases. After that, the concentration of defects in the surface layer increases, which causes a decrease of its resistance. When the second effect prevails over the first one, we observe a maximum on the dependences. The geometric capacity of the surface layer monotonically increases with an increasing number of cycles (

Figure 6c). Perhaps this is due to the development of the surface of the layer as a result of the intensive insertion of lithium ions into the surface layer. The resistance of the intercalation layer varies with a weakly expressed maximum (

Figure 6e). This is possibly due to the increasing electronic resistance of the contacts between the particles of the electrode material and the electrically conductive additive at the first stage, and subsequently, the increasing number of defects in the surface layer reduces this resistance. The diffusion coefficients of lithium ions in the surface and intercalation layers differ by several orders of magnitude (

Figure 6d,f). They also have the opposite course of dependencies on the cycle number. In the first case, this is due to the growing imperfection of the surface layer, and in the second case, by the development of intercalation paths in the structure of the electrode material. The intercalation capacity varies symbiotically with the resistance of the intercalation layer, which is obviously due to the changing energy of interparticle interactions in the structure with a change in the number of electrons supplied to the particles of the material.

5. Conclusions

Thus, the PVDF and PTFE mix fibers electrospun separation material can be considered as an acceptable alternative for conventional PP-based separation material, since the proposed separation material has a twice higher electrolyte uptake parameter (800% vs. 445%) compared to those for PP-based separation material, so cell polarization with this material at a high rate of cycling is 20% lower, and consequently, its capacity is 20% higher. It is expected that PVDF and PTFE mix fibers electrospun separation material will be slightly inferior in mechanical strength to conventional PP-based separation material; however, this is not critical for medium-voltage LIB anode materials, such as the Li4Ti5O12 considered in this article, since the probability of dendrite formation on such an electrode is almost equal to zero. At the same time, such electrode materials demonstrate extremely high characteristics of lithium intercalation (the found values of the diffusion coefficient of lithium ions of 10−10 to 10−9 cm2·s−1 are several orders of magnitude higher than those for many widely used electrode materials, LIB). Therefore, a dense separator with a low pore size and porosity can be a limiting factor for systems with such electrodes.

Future works will be devoted to the study of prolonged cycling experiments with proposed and conventional types of separation materials. Specific attention will be given to the physicochemical and electrochemical characteristics’ evolution of separation and electrode materials. The structural and morphological characteristics will be studied for the materials before and after the electrochemical experiment.