Behavior of Weakly Cemented Rock with Different Moisture Contents under Various Tri-Axial Loading States

Abstract

1. Introduction

2. Experimental Program

2.1. Geological Conditions and Research Area

2.2. Preparation of Rock Samples

2.3. Test Matrix

2.4. Moisture Content

2.5. Test Set-Up and Instrumentation

3. Experimental Results and Discussions

3.1. General

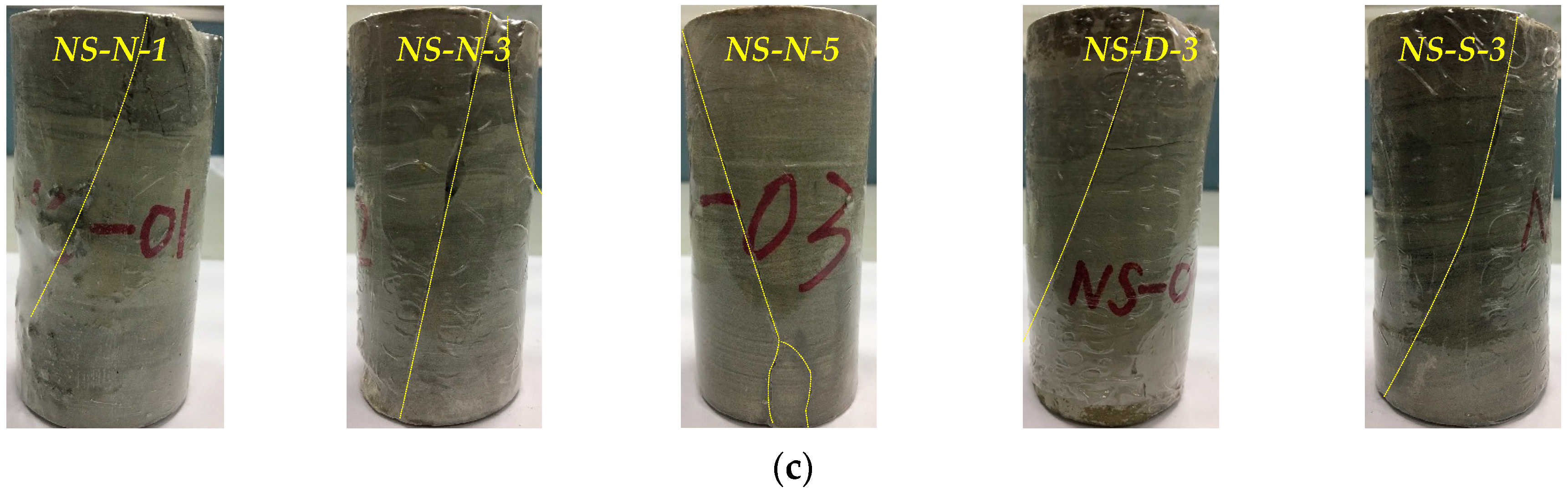

3.1.1. Failure Modes

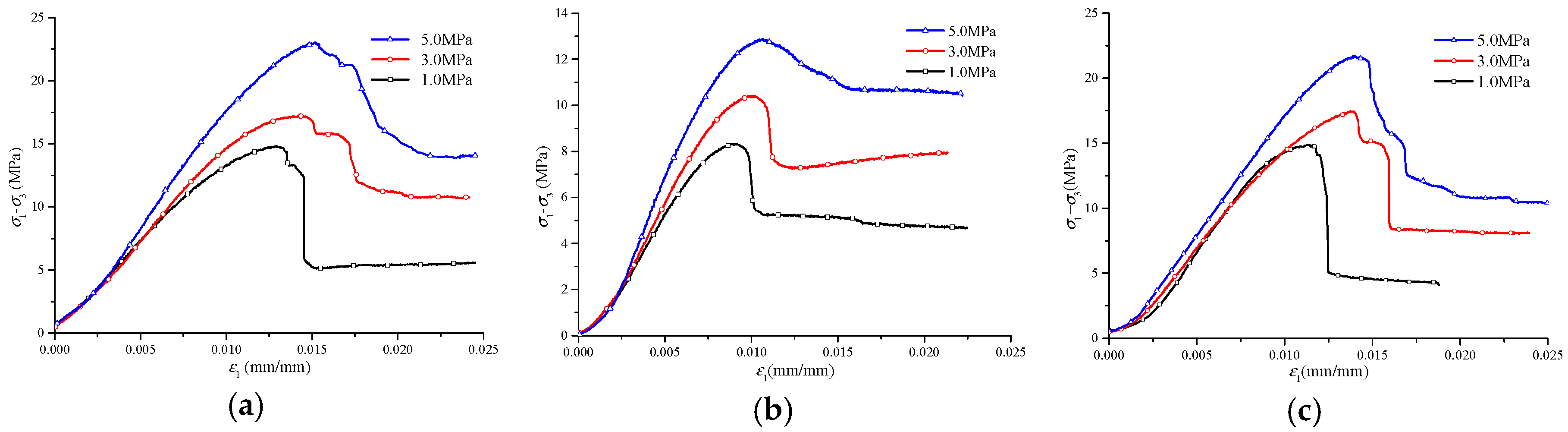

3.1.2. Stress-Strain Behavior

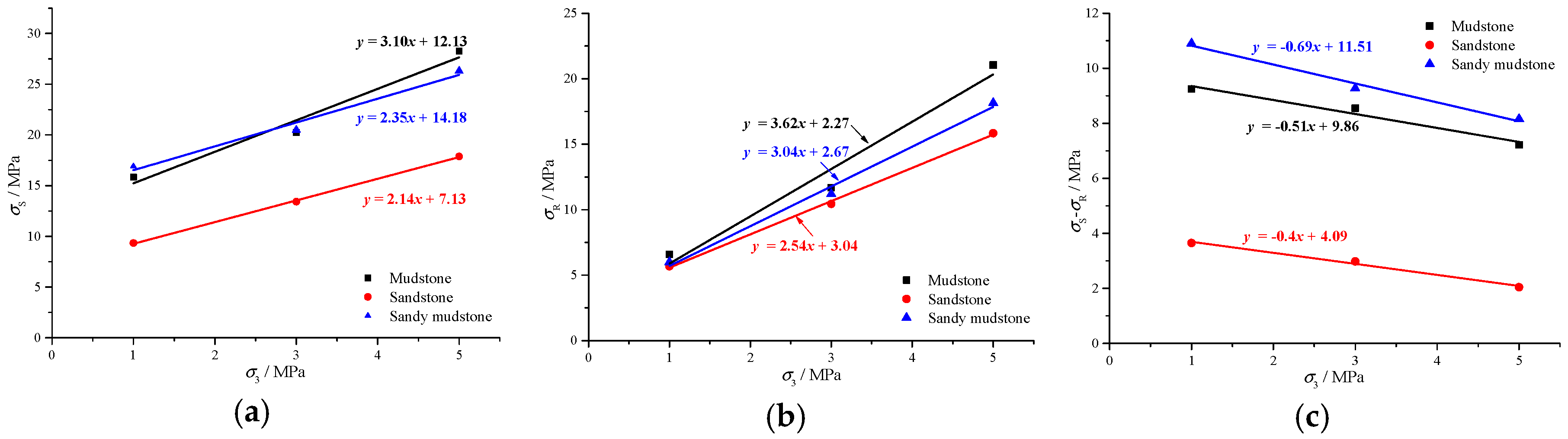

3.2. Effect of Confining Pressure

3.2.1. Sensitivity Coefficient of Confining Pressure (kc)

3.2.2. Transfer Confining Pressure (σT)

3.2.3. Comparison in Microstructures

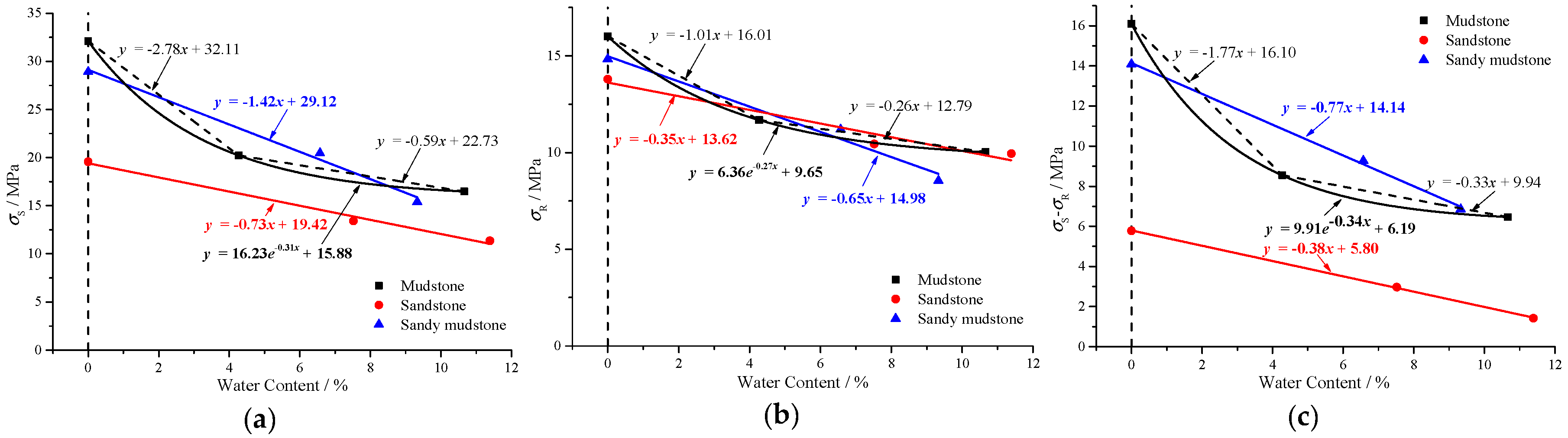

3.3. Effect of Moisture Content

3.3.1. Sensitivity Coefficient of Moisture Content (kw)

3.3.2. Moisture Migration Procedure

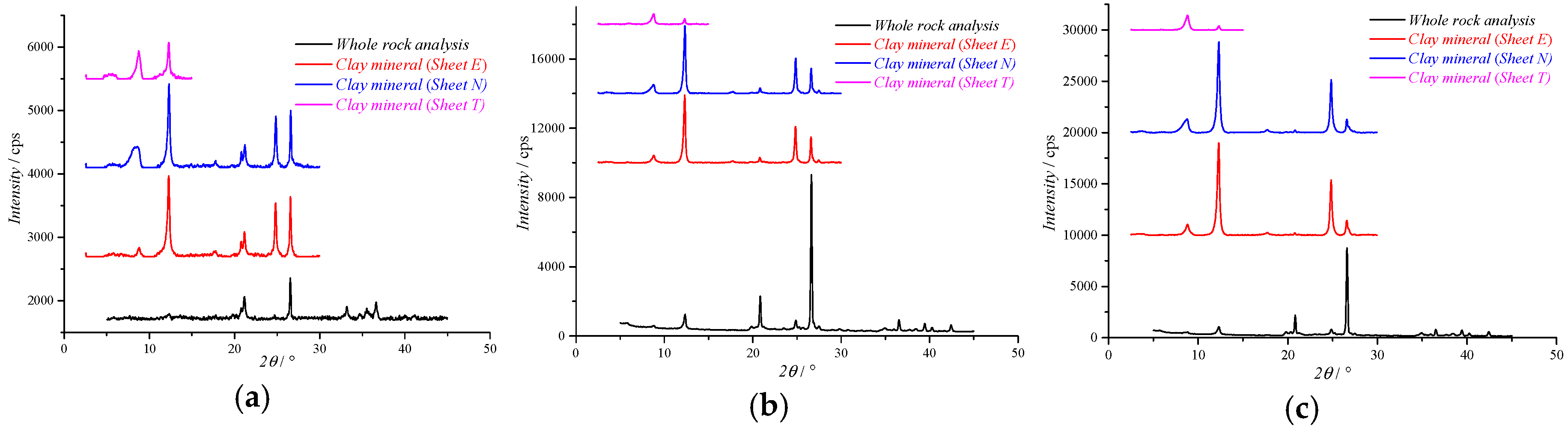

3.3.3. Comparison of Mineral Components

4. Conclusions

- The mechanical behavior of weakly cemented rock samples under tri-axial is generally correlated with confining pressure. Among them, mudstone is much more sensitive to confining pressure compared to sandstone, followed by sandy stone. It should be noted that the residual stress of weakly cemented rock is much more sensitive to confining pressure rather than the peak stress.

- The peak stress of three types of rock samples decreases with the increase of water contents. When the moisture content decreases due to the loss of water from the rock mass, the peak stress, residual stress and residual stress of mudstone are most sensitive to the moisture content compared to sandy mudstone, followed by sandstone. While the moisture content changes from a natural state to a saturated state, the peak stress, residual stress, and residual stress of sandstone becomes to be much more sensitive to moisture content, compared to mudstone and sandy rock.

- The effect of confining pressure mainly depends on the cementation state and porosity for weakly cemented rocks. When the rock cementation state is similar, the effect of particle size will be much more significant than other parameters. However, for the specimens with a high content of clay mineral components, the effect of moisture content plays a critical role owing to the deterioration while the reaction between water and hydrophilic mineral occurs.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhang, D.S.; Liu, H.L.; Fan, G.W.; Wang, X.F. Connotation and prospection on scientific mining of large Xinjiang coal base. J. Min. Saf. Eng. 2015, 32, 1–6. [Google Scholar]

- Zhang, D.S.; Fan, G.W.; Ma, L.Q.; Wang, X.F. Aquifer protection during longwall mining of shallow coal seams: A case study in the Shendong Coalfield of China. Int. J. Coal Geol. 2011, 86, 190–196. [Google Scholar] [CrossRef]

- Zhang, D.S.; Fan, G.W.; Liu, Y.D.; Ma, L.Q. Field trials of aquifer protection in longwall mining of shallow coal seams in China. Int. J. Rock Mech. Min. Sci. 2010, 47, 908–914. [Google Scholar] [CrossRef]

- Wang, W.M.; Zhao, Z.H.; Wang, Y.J.; Gao, X. Failure Behavior and Constitutive Model of Weakly Consolidated Soft Rock. Sci. World J. 2013, 2013, 758750. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.M.; Zhao, Z.H.; Wang, L. Elastic-plastic damage analysis for weakly consolidated surrounding rock regarding stiffness and strength cracking. J. Min. Saf. Eng. 2013, 30, 679–685. [Google Scholar]

- Nguyen, V.H.; Gland, N.; Dautriat, J.; David, C.; Wassermann, J.; Guélard, J. Compaction, permeability evolution and stress path effects in unconsolidated sand and weakly consolidated sandstone. Int. J. Rock Mech. Min. Sci. 2014, 67, 226–239. [Google Scholar] [CrossRef]

- You, S.; Ji, H.G.; Wang, T.; Song, C.Y. Thermal and mechanical coupling effects on permeability of weakly cemented sandstone. Emerg. Mater. Res. 2018, 7, 100–108. [Google Scholar] [CrossRef]

- Zheng, H.; Feng, X.T.; Hao, X.J. A creep model for weakly consolidated porous sandstone including volumetric creep. Int. J. Rock Mech. Min. Sci. 2015, 78, 99–107. [Google Scholar] [CrossRef]

- Erguler, Z.A.; Ulusay, R. Water-induced variations in mechanical properties of clay-bearing rocks. Int. J. Rock Mech. Min. Sci. 2009, 46, 355–370. [Google Scholar] [CrossRef]

- Zhao, Y.C.; Yang, T.H.; Xiao, F.K.; Wang, H.; Liu, G.; Zheng, X.; Zhou, J.R.; Shen, Z.L. The variation law of plastic strain energy of western weak cemented sandstone during cyclic loading experiment. J. China Coal Soc. 2015, 40, 1813–1819. [Google Scholar]

- Meng, Q.B. Study on Structure and Mechanical Properties and Constitutive Model of Very Weakly Cemented Rock. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2014. [Google Scholar]

- Peng, S.S. Longwall Mining; Society for Mining Metallurgy, and Exploration: Littleton, CO, USA, 2006. [Google Scholar]

- Xie, H.P.; Zhang, Y.T.; Gao, F.; Zhang, R.; Gao, M.Z.; Liu, J.F. Stress-fracture-seepage field behavior of coal under different mining layouts. J. China Coal Soc. 2016, 41, 2405–2417. [Google Scholar]

- ASTM D4543-01, Standard Practices for Preparing Rock Core Specimens and Determining Dimensional and Shape Tolerances; ASTM International: West Conshohocken, PA, USA, 2001.

- ASTM D4643-17, Standard Test Method for Determination of Water Content of Soil and Rock by Microwave Oven Heating; ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D7012-14e1, Standard Test Methods for Compressive Strength and Elastic Moduli of Intact Rock Core Specimens under Varying States of Stress and Temperatures; ASTM International: West Conshohocken, PA, USA, 2014.

- Yu, D.H.; Peng, J.B. Experimental study of mechanical properties of chlorite schist with water under triaxial compression. Chin. J. Rock Mech. Eng. 2009, 28, 205–211. [Google Scholar]

- Hsieh, Y.M.; Li, H.H.; Huang, T.H.; Jeng, F.S. Interpretations on how the macroscopic mechanical behavior of sandstone affected by microscopic properties—Revealed by bonded-particle model. Eng. Geol. 2008, 99, 1–10. [Google Scholar] [CrossRef]

- Atapour, H.; Mortazavi, A. The influence of mean grain size on unconfined compressive strength of weakly consolidated reservoir sandstones. J. Pet. Sci. Eng. 2018, 171, 63–70. [Google Scholar] [CrossRef]

- Zhou, Z.L.; Cai, X.; Cao, W.L.; Li, X.B.; Cheng, X. Influence of Water Content on Mechanical Properties of Rock in Both Saturation and Drying Processes. Rock Mech. Rock Eng. 2016, 49, 3009–3025. [Google Scholar] [CrossRef]

- Lindqvist, J.E.; Åkesson, U.; Malaga, K. Microstructure and functional properties of rock materials. Mater. Charact. 2007, 58, 1183–1188. [Google Scholar] [CrossRef]

- Peng, J.; Wong, L.N.Y.; Teh, C.I. Influence of grain size heterogeneity on strength and microcracking behavior of crystalline rocks. J. Geophys. Res.-Solid Earth 2017, 122, 1054–1073. [Google Scholar] [CrossRef]

- Sajid, M.; Coggan, J.; Arif, M.; Andersen, J.; Rollinson, G. Petrographic features as an effective indicator for the variation in strength of granites. Eng. Geol. 2016, 202, 44–54. [Google Scholar] [CrossRef]

- SY/T5163-2010, Analysis Method for Clay Minerals and Ordinary Non-Clay Minerals in Sedimentary Rocks by the X-Ray Diffraction; Chinese National Energy Board: Beijing, China, 2010.

| Series | Samples | Diameter/mm | Height/mm | Moisture Content/% | Confining Pressure/MPa |

|---|---|---|---|---|---|

| Mudstone | NY-N-1 | 49.7 | 99.1 | 4.27 | 1.0 |

| NY-N-3 | 49.5 | 99.8 | 4.27 | 3.0 | |

| NY-N-5 | 49.9 | 98.9 | 4.27 | 5.0 | |

| NY-D-3 | 49.3 | 100.1 | 0.00 | 3.0 | |

| NY-S-3 | 50.1 | 100.3 | 10.66 | 3.0 | |

| Sandstone | SY-N-1 | 50.0 | 100.0 | 7.52 | 1.0 |

| SY-N-3 | 49.6 | 100.0 | 7.52 | 3.0 | |

| SY-N-5 | 48.7 | 98.9 | 7.52 | 5.0 | |

| SY-D-3 | 50.0 | 101.2 | 0.00 | 3.0 | |

| SY-S-3 | 50.1 | 101.5 | 11.39 | 3.0 | |

| Sandy mudstone | NS-N-1 | 49.4 | 100.3 | 6.57 | 1.0 |

| NS-N-3 | 49.9 | 100.5 | 6.57 | 3.0 | |

| NS-N-5 | 49.7 | 99.5 | 6.57 | 5.0 | |

| NS-D-3 | 49.5 | 99.8 | 0.00 | 3.0 | |

| NS-S-3 | 49.8 | 98.9 | 9.33 | 3.0 |

| Lithology | Specimens | Peak Stress/MPa | Residual Stress/MPa | Peak Strain/% | Elastic Modulus/GPa | kC/kCS, kCR, kC (SR) | kW/kWS, kWR, kW (SR) |

|---|---|---|---|---|---|---|---|

| Mudstone | NY-N-1 | 15.84 | 6.59 | 1.29 | 1.44 | 3.10, 3.62, −0.51 | −5.03e−0.31x −1.72e−0.27x −3.37e−0.34x (0 ≤ x ≤ 10.66) |

| NY-N-3 | 20.23 | 11.68 | 1.44 | 1.67 | |||

| NY-N-5 | 28.26 | 21.04 | 1.53 | 2.03 | |||

| NY-D-3 | 32.11 | 16.01 | 1.71 | 2.01 | |||

| NY-S-3 | 16.48 | 10.02 | 1.41 | 1.28 | |||

| Sandstone | SY-N-1 | 9.33 | 5.77 | 0.91 | 1.32 | 2.14, 2.54, −0.40 | −0.74, −0.35, −0.38 |

| SY-N-3 | 13.42 | 10.91 | 1.01 | 1.42 | |||

| SY-N-5 | 17.88 | 15.64 | 1.12 | 1.81 | |||

| SY-D-3 | 19.58 | 13.80 | 1.53 | 1.52 | |||

| SY-S-3 | 11.36 | 9.94 | 0.94 | 1.45 | |||

| Sandy mudstone | NS-N-1 | 15.91 | 5.14 | 1.13 | 1.68 | 2.35, 3.04, −0.69 | −1.42, −0.65, −0.77 |

| NS-N-3 | 20.47 | 11.28 | 1.38 | 1.72 | |||

| NS-N-5 | 26.70 | 17.84 | 1.39 | 1.94 | |||

| NS-D-3 | 28.92 | 14.83 | 1.72 | 1.87 | |||

| NS-S-3 | 15.41 | 8.55 | 1.16 | 1.48 |

| Lithology | Content of Minerals (%) | Relative Content of Clay Minerals (%) | ||||

|---|---|---|---|---|---|---|

| Quartz | Potash Feldspar | Clay Minerals | Illite (It) | Kaolinite (K) | Illite-Smectite Mixed-Layer (I/S) | |

| Mudstone | 29 | 0 | 71 | 8 | 43 | 49 |

| Sandstone | 70 | 5 | 25 | 13 | 69 | 18 |

| Sandy mudstone | 60 | 4 | 36 | 12 | 69 | 19 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Zhang, D.; Zhao, H.; Chi, M.; Yu, W. Behavior of Weakly Cemented Rock with Different Moisture Contents under Various Tri-Axial Loading States. Energies 2019, 12, 1563. https://doi.org/10.3390/en12081563

Liu H, Zhang D, Zhao H, Chi M, Yu W. Behavior of Weakly Cemented Rock with Different Moisture Contents under Various Tri-Axial Loading States. Energies. 2019; 12(8):1563. https://doi.org/10.3390/en12081563

Chicago/Turabian StyleLiu, Honglin, Dongsheng Zhang, Hongchao Zhao, Mingbo Chi, and Wei Yu. 2019. "Behavior of Weakly Cemented Rock with Different Moisture Contents under Various Tri-Axial Loading States" Energies 12, no. 8: 1563. https://doi.org/10.3390/en12081563

APA StyleLiu, H., Zhang, D., Zhao, H., Chi, M., & Yu, W. (2019). Behavior of Weakly Cemented Rock with Different Moisture Contents under Various Tri-Axial Loading States. Energies, 12(8), 1563. https://doi.org/10.3390/en12081563