A Techno-Economic Analysis of a PV-Battery System in Greece

Abstract

1. Introduction

2. Materials and Methods

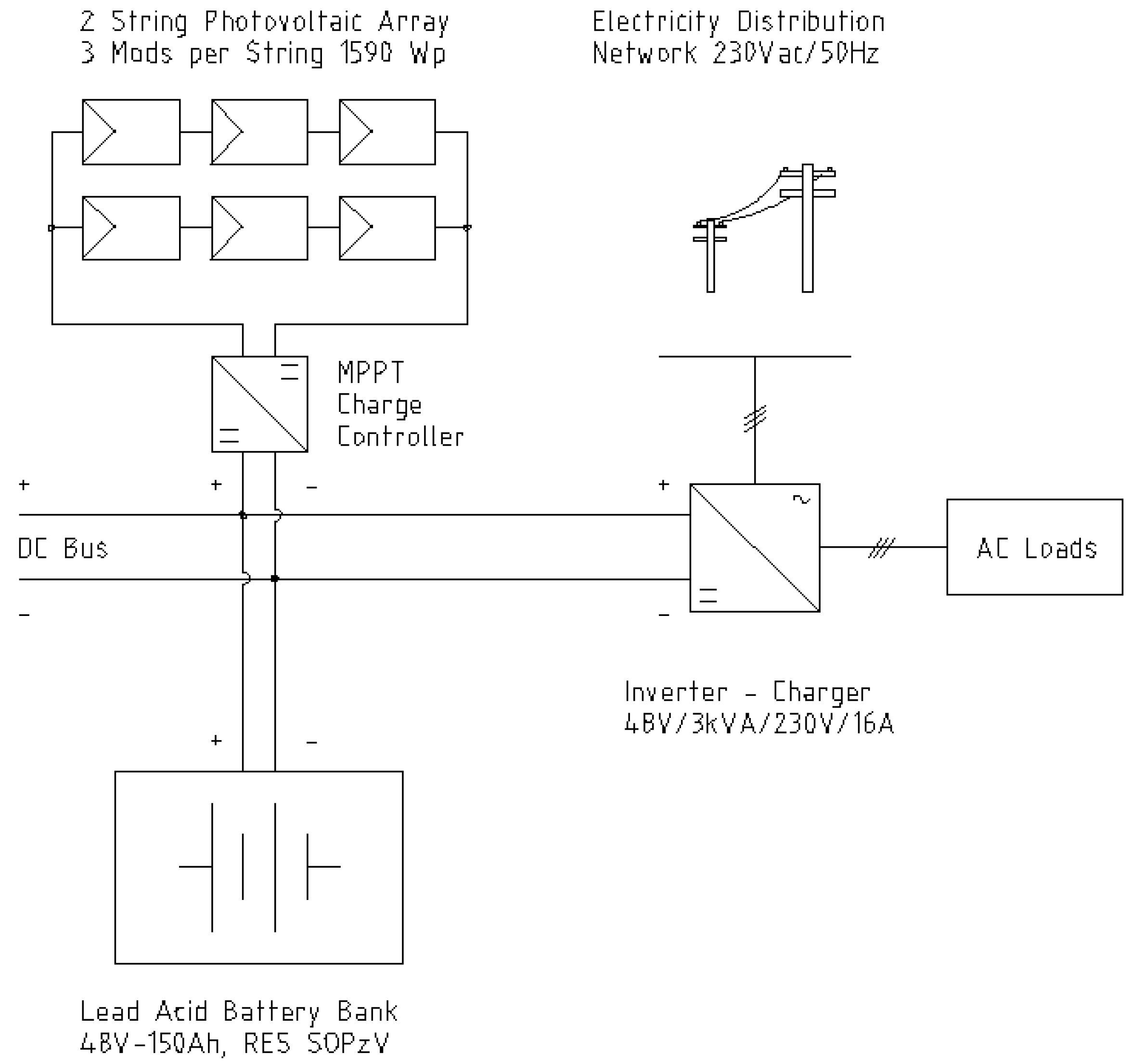

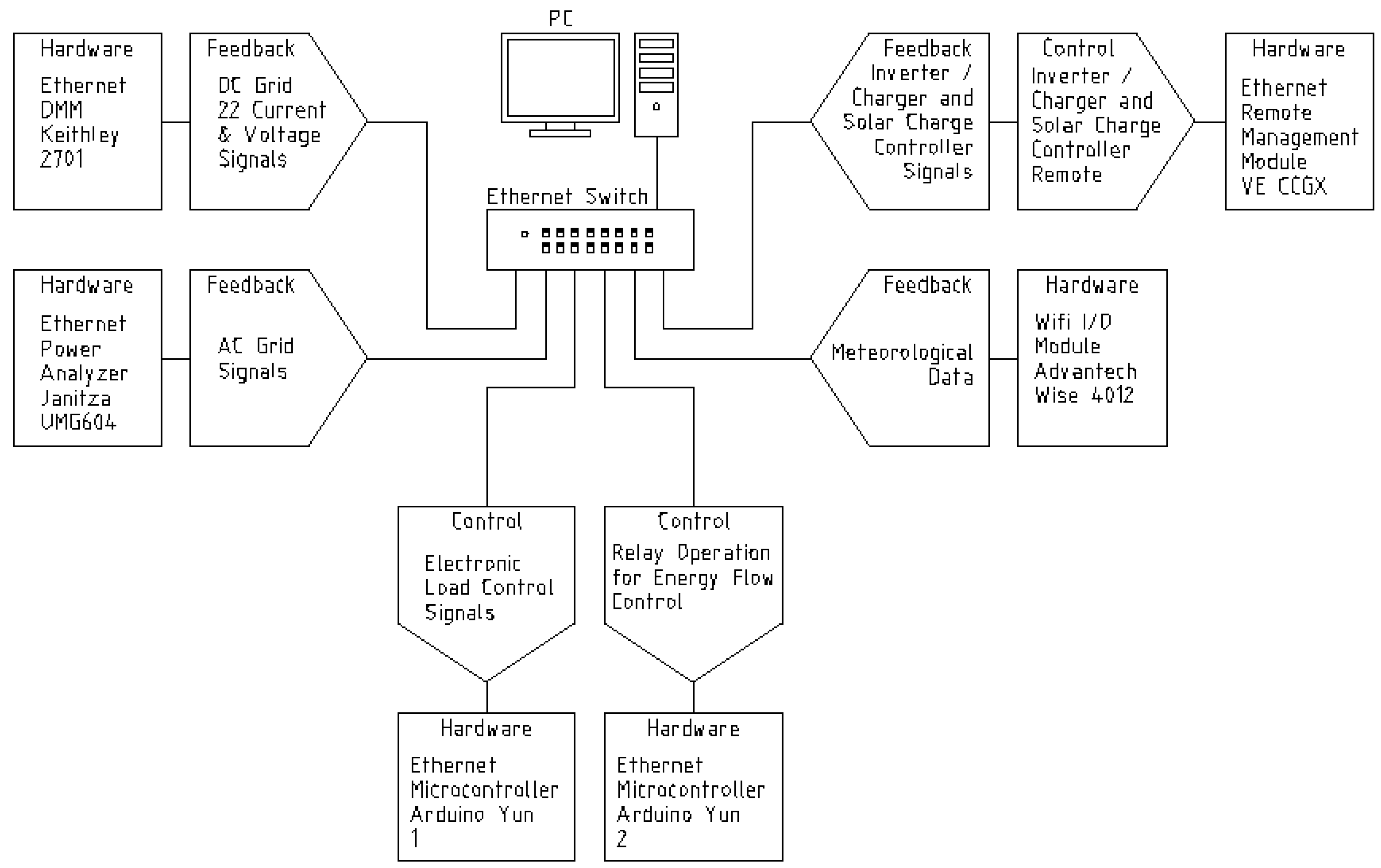

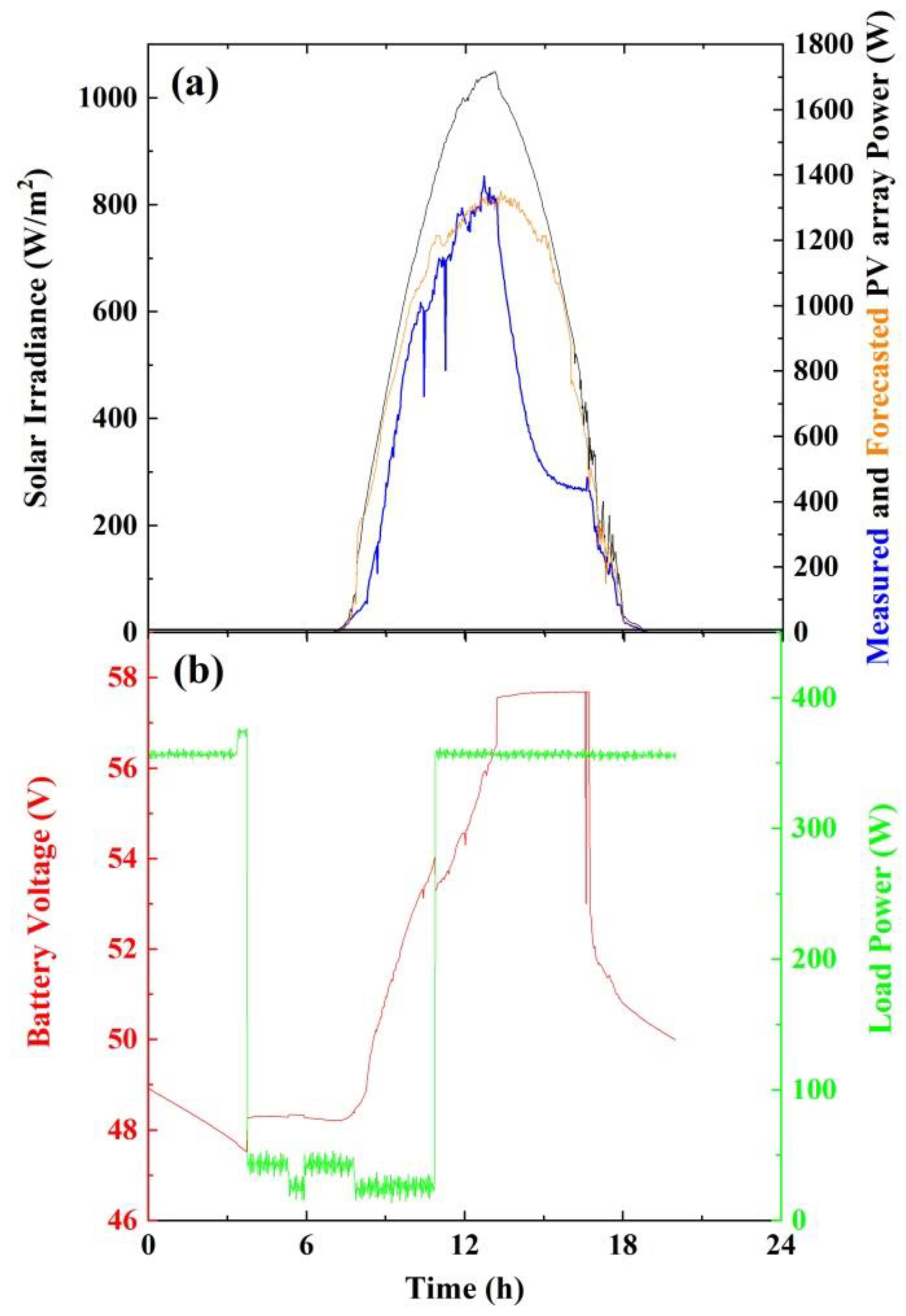

2.1. Description of the PV-BAT System

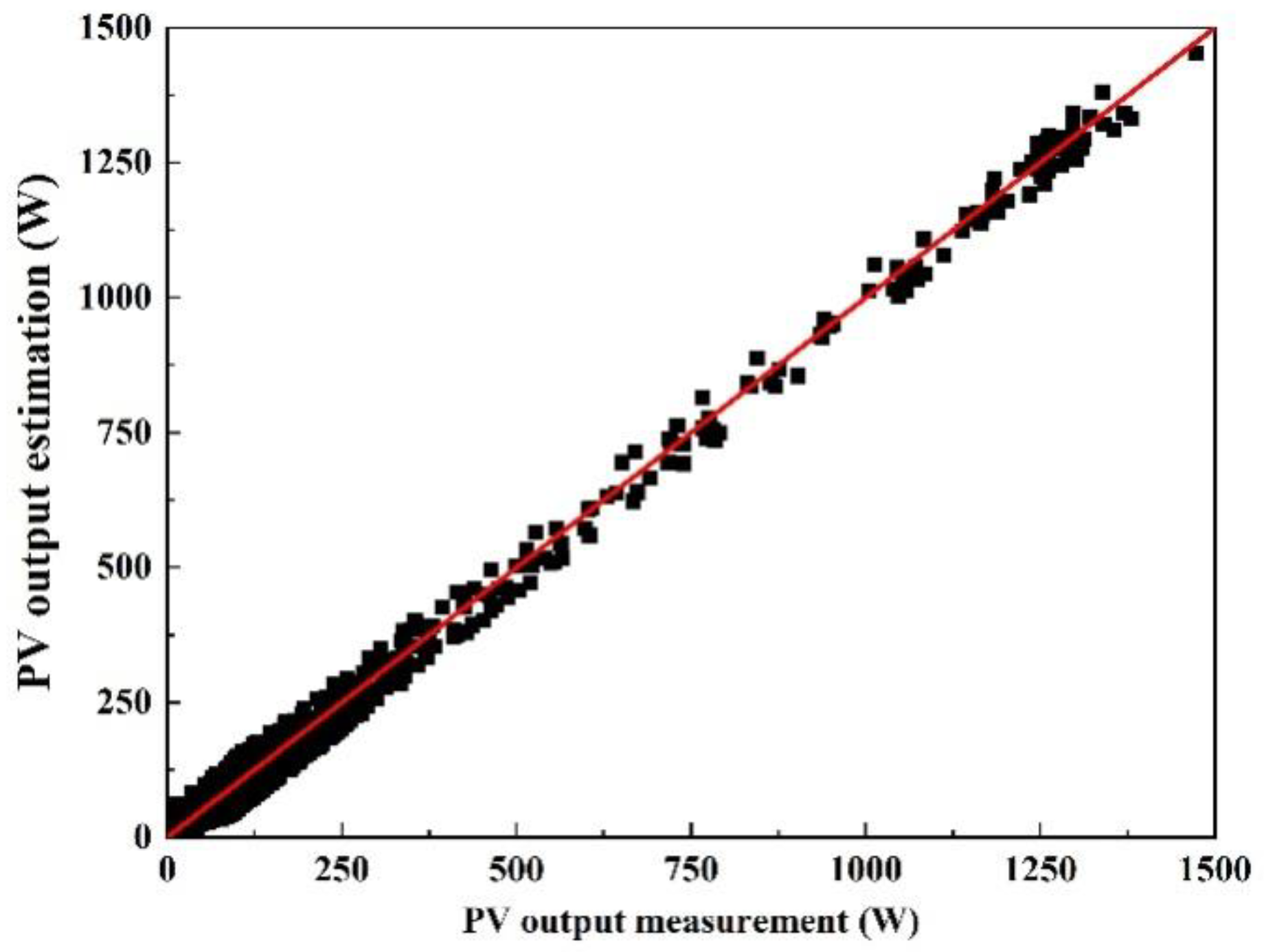

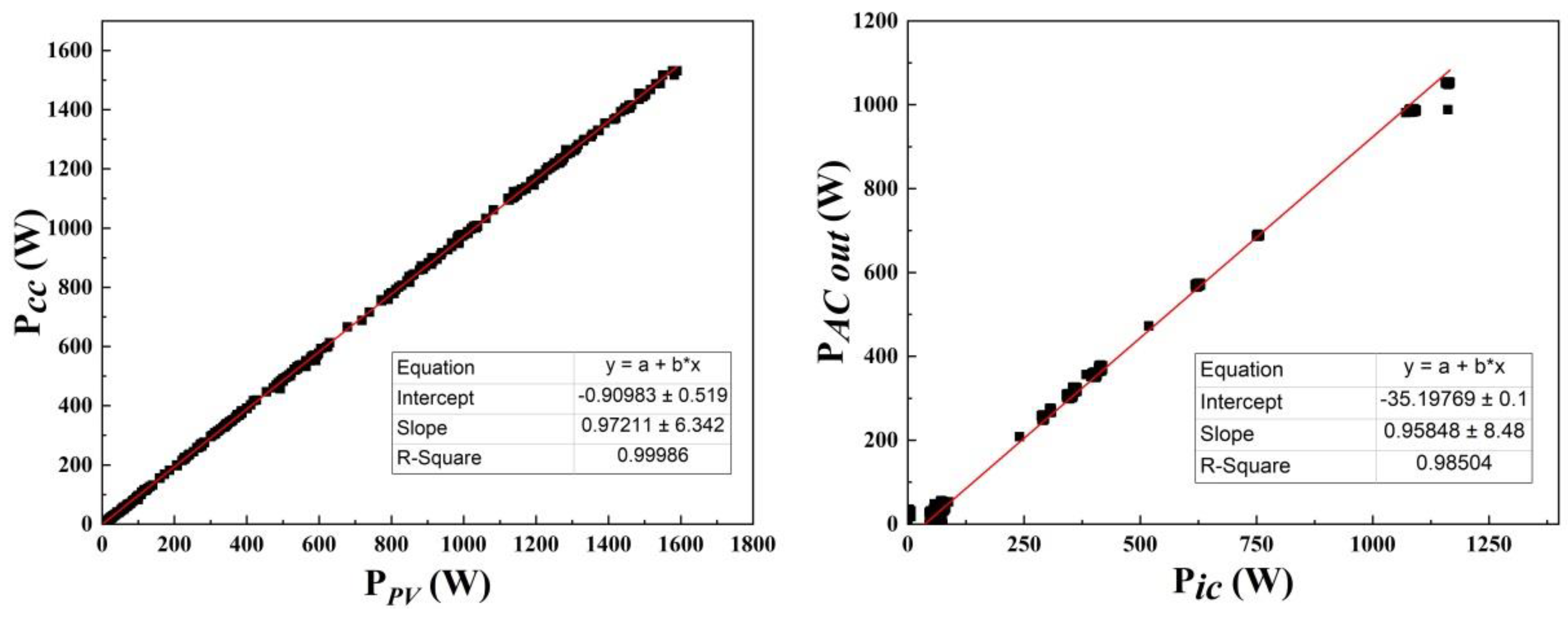

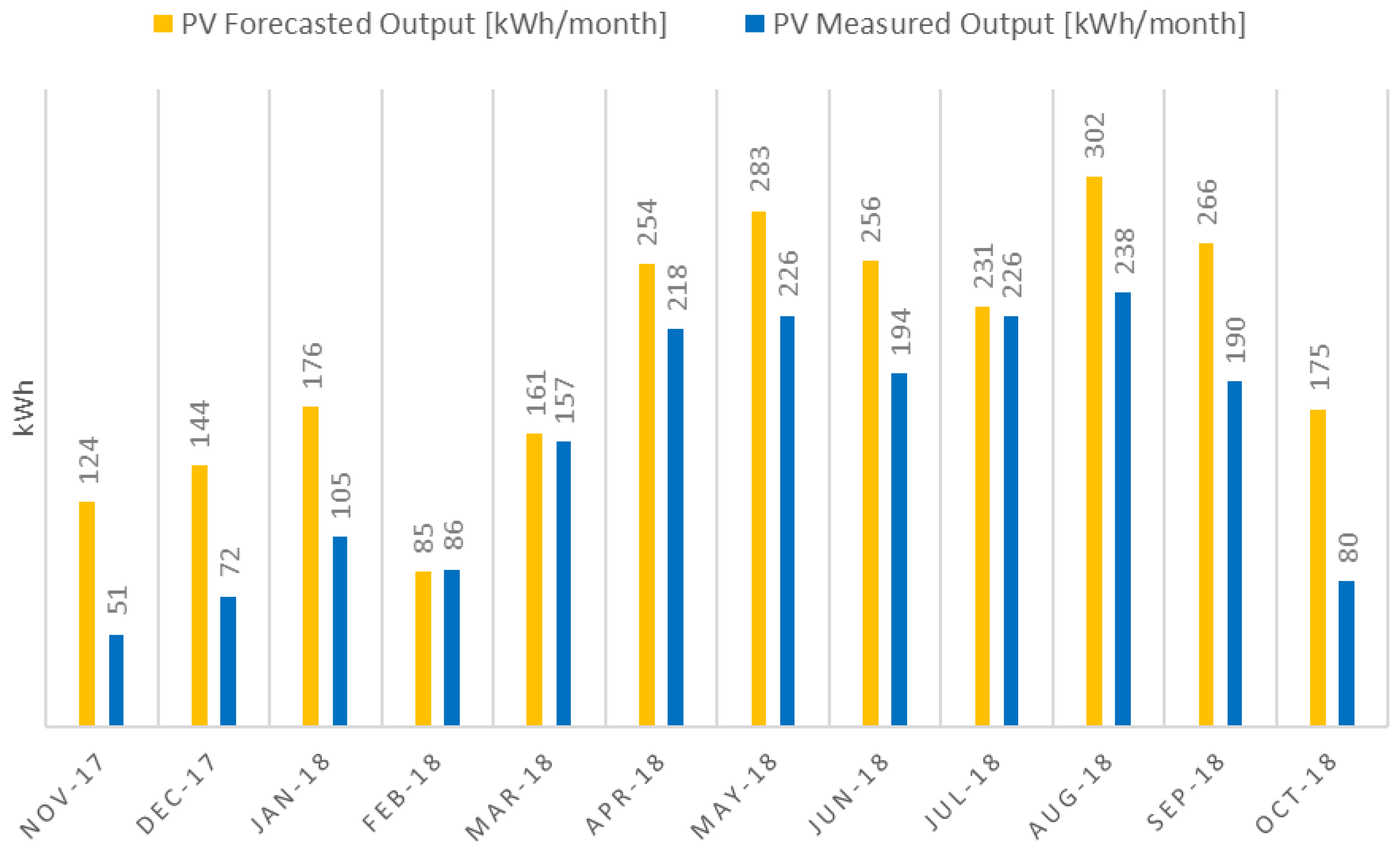

2.2. Energy Output

2.3. Energy Cost

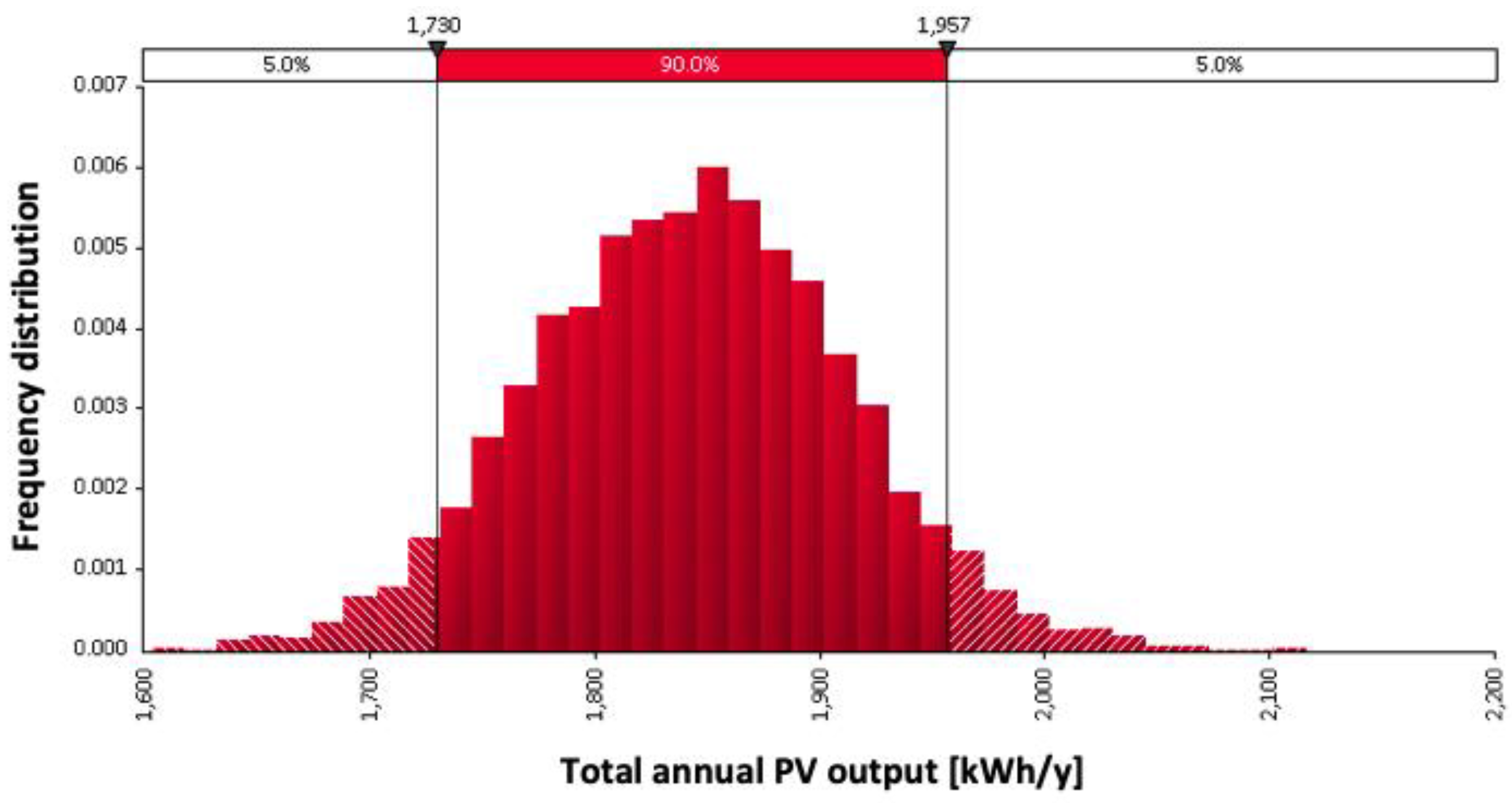

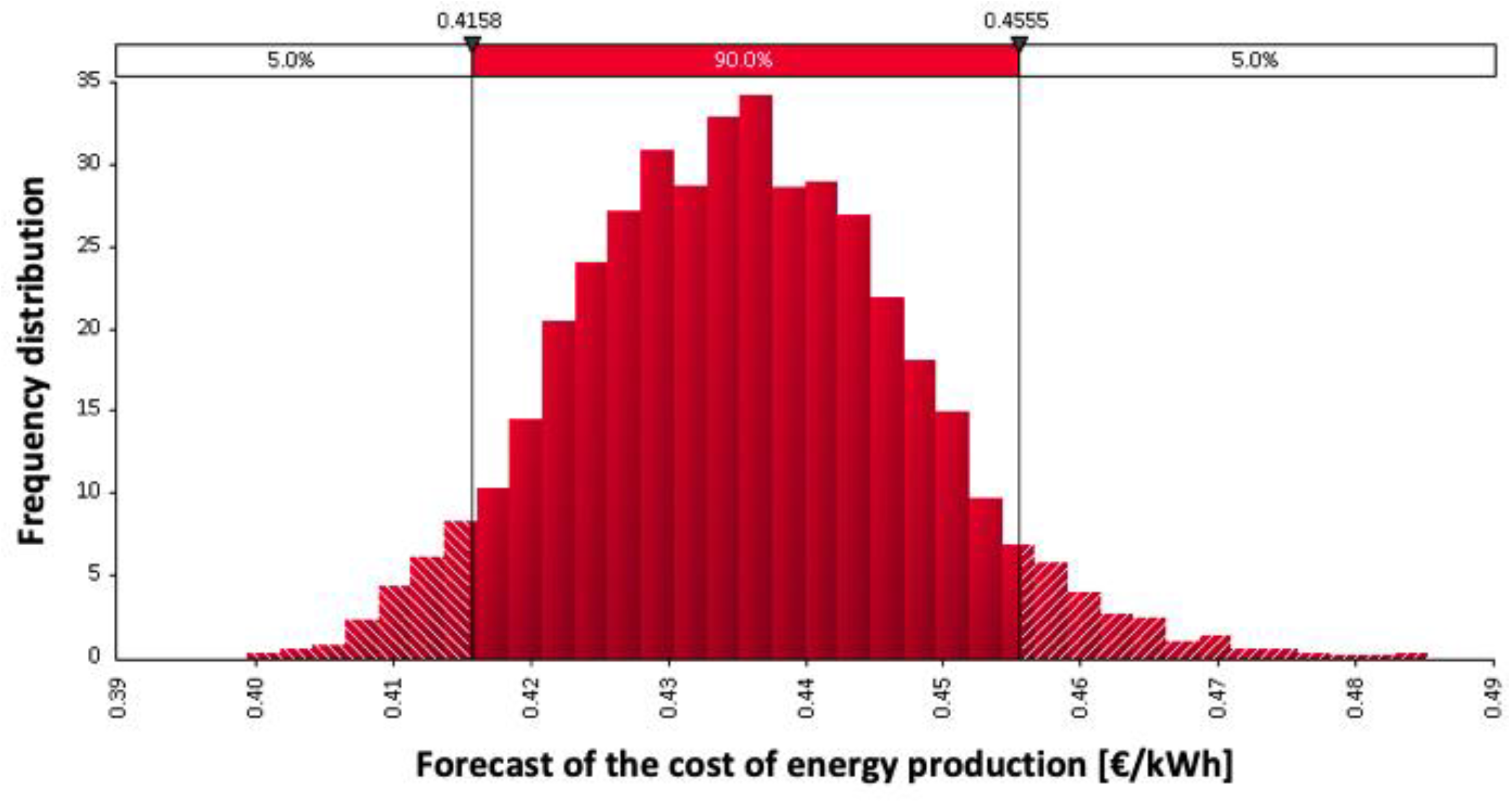

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Conti, J.; Holtberg, P.; Diefenderfer, J.; LaRose, A.; Turnure, J.T.; Westfall, L. International Energy Outlook 2016 with Projections to 2040; USDOE Energy Information Administration (EIA): Washington, DC, USA, 2016. [Google Scholar]

- Dincer, I. Renewable energy and sustainable development: A crucial review. Renew. Sustain. Energy Rev. 2000, 4, 157–175. [Google Scholar] [CrossRef]

- Kempener, R.; Borden, E. Battery Storage for Renewables: Market Status and Technology Outlook; International Renewable Energy Agency: Abu Dhabi, UAE, 2015; p. 32. Available online: https://www.irena.org/publications/2015/Jan/Battery-Storage-for-Renewables-Market-Status-and-Technology-Outlook (accessed on 29 December 2018).

- Kosmadakis, I.; Elmasides, C. Towards performance enhancement of hybrid power supply systems based on renewable energy sources. Energy Procedia 2019, 157, 977–991. [Google Scholar] [CrossRef]

- Badwawi, R.A.; Abusara, M.; Mallick, T. A review of hybrid solar PV and wind energy system. Smart Sci. 2015, 3, 127–138. [Google Scholar] [CrossRef]

- Askarzadeh, A. Optimisation of solar and wind energy systems: A survey. Int. J. Ambient Energy 2017, 38, 653–662. [Google Scholar] [CrossRef]

- Singh, S.; Singh, M.; Kaushik, S.C. A review on optimization techniques for sizing of solar-wind hybrid energy systems. Int. J. Green Energy 2016, 13, 1564–1578. [Google Scholar] [CrossRef]

- Shaw-Williams, D.; Susilawati, C.; Walker, G. Value of Residential Investment in Photovoltaics and Batteries in Networks: A Techno-Economic Analysis. Energies 2018, 11, 1022. [Google Scholar] [CrossRef]

- Shaikh, P.H.; Leghari, Z.H.; Mirjat, N.H.; Shaikh, F.; Solangi, A.R.; Jan, T.; Uqaili, M.A. Wind–PV-Based Hybrid DC Microgrid (DCMG) Development: An Experimental Investigation and Comparative Economic Analysis. Energies 2018, 11, 1295. [Google Scholar] [CrossRef]

- Alharthi, Y.Z.; Siddiki, M.K.; Chaudhry, G.M. Resource Assessment and Techno-Economic Analysis of a Grid-Connected Solar PV-Wind Hybrid System for Different Locations in Saudi Arabia. Sustainability 2018, 10, 3690. [Google Scholar] [CrossRef]

- Aderemi, B.A.; Chowdhury, S.P.D.; Olwal, T.O.; Abu-Mahfouz, A.M. Techno-Economic Feasibility of Hybrid Solar Photovoltaic and Battery Energy Storage Power System for a Mobile Cellular Base Station in Soshanguve, South Africa. Energies 2018, 11, 1572. [Google Scholar] [CrossRef]

- Waldau-Jäger, A. Pv Status Report 2016; EUR 28159 EN; European Commission, Joint Research Centre, Directorate C, Energy Efficiency and Renewables Unit: Ispra, VA, Italy, 2016. [Google Scholar] [CrossRef]

- Giannini, E.; Moropoulou, A.; Maroulis, Z.; Siouti, G. Penetration of photovoltaics in greece. Energies 2015, 8, 6497. [Google Scholar] [CrossRef]

- Energy Exchange Group DAS Monthly Report October 2018. Available online: http://www.enexgroup.gr/fileadmin/groups/EDRETH/DAS_Monthly_Reports/201810_DAS_Monthly_Report.pdf (accessed on 29 December 2018).

- Ilas, A.; Ralon, P.; Rodriguez, A.; Taylor, M. Renewable Power Generation Costs in 2017; International Renewable Energy Agency (IRENA): Abu Dhabi, UAE, 2018; 160p, Available online: www.irena.org/publications/2018/Jan/Renewable-power-generation-costs-in-2017 (accessed on 20 October 2018).

- Vieira, F.M.; Moura, P.S.; de Almeida, A.T. Energy storage system for self-consumption of photovoltaic energy in residential zero energy buildings. Renew. Energy 2017, 103, 308–320. [Google Scholar] [CrossRef]

- Nykvist, B.; Nilsson, M. Rapidly falling costs of battery packs for electric vehicles. Nat. Clim. Chang. 2015, 5, 329–332. [Google Scholar] [CrossRef]

- Comello, S.D.; Glenk, G.; Reichelstein, S. Levelized Cost of Electricity Calculator: A User Guide. Sustainable Energy Initiative, 2017. Available online: Http://stanford.Edu/dept/gsb_circle/cgi-bin/sustainableenergy/lcoe (accessed on 28 October 2018).

- Tsagarakis, K.P. Shallow geothermal energy under the microscope: Social, economic, and institutional aspects. Renew. Energy 2019, in press. [Google Scholar] [CrossRef]

- Rhodes, J.D.; King, C.; Gulen, G.; Olmstead, S.M.; Dyer, J.S.; Hebner, R.E.; Beach, F.C.; Edgar, T.F.; Webber, M.E. A geographically resolved method to estimate levelized power plant costs with environmental externalities. Energy Policy 2017, 102, 491–499. [Google Scholar] [CrossRef]

- Maxwell, E.L. A Quasi-Physical Model for Converting Hourly Global to Direct Normal Insolation. Aug. 1987 (SERI/TR-215-3087). pp. 35–46. Available online: http://rredc.nrel.gov/solar/pubs/PDFs/TR-215-3087.pdf (accessed on 21 August 2018).

- Loutzenhiser, P.G.; Manz, H.; Felsmann, C.; Strachan, P.A.; Frank, T.; Maxwell, G.M. Empirical validation of models to compute solar irradiance on inclined surfaces for building energy simulation. Sol. Energy 2007, 81, 254–267. [Google Scholar] [CrossRef]

- King, D.L.; Boyson, W.E.; Kratochvil, J.A. Photovoltaic Array Performance Model. Sandia Report 2004 (SAND2004-3535). Available online: http://www.osti.gov/servlets/purl/919131-sca5ep/ (accessed on 17 August 2018).

- De Soto, W.; Klein, S.A.; Beckman, W.A. Improvement and Validation of a Model for Photovoltaic Array Performance. Sol. Energy 2006, 80, 78–88. [Google Scholar] [CrossRef]

- Hongmei, T.; Mancilla-David, F.; Ellis, K.; Muljadi, E.; Jenkins, P. A Cell-to-Module-to-Array Detailed Model for Photovoltaic Panels. Sol. Energy 2012, 86, 2695–2706. [Google Scholar]

- Gray, J.L. The Physics of the Solar Cell; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2003; Chapter 3; pp. 62–112. ISBN 0-471-49196-9 2003. Available online: http://dx.doi.org/10.1002/9780470974704.ch3 (accessed on 21 August 2018).

- Stein, J.S. The Photovoltaic Performance Modeling Collaborative (PVPMC). In Proceedings of the 2012 38th IEEE Photovoltaic Specialists Conference, Austin, TX, USA, 3–8 June 2012; pp. 3048–3052. [Google Scholar]

- Stein, J.S.; Holmgren, W.F.; Forbess, J.; Hansen, C.W.H. PVLIB: Open Source Photovoltaic Performance Modeling Functions for Matlab and Python. In Proceedings of the IEEE 44th Photovoltaic Specialist Conference, Portland, OR, USA, 5–10 June 2017; pp. 3425–3430. [Google Scholar]

- Andrews, R.W.; Stein, J.S.; Hansen, C.W.H.; Riley, D. Introduction to the Open Source PV LIB for Python Photovoltaic System Modelling Package. In Proceedings of the IEEE 40th Photovoltaic Specialist Conference, Denver, CO, USA, 8–13 June 2014; pp. 170–174. [Google Scholar]

- Holmgren, W.F.; Groenendyk, D.G. An Open Source Solar Power Forecasting Tool Using PVLIB-Python. In Proceedings of the IEEE 43rd Photovoltaic Specialists Conference, Portland, OR, USA, 5–10 June 2016; pp. 972–975. [Google Scholar]

- Creedy, J.; Passi, H. Public sector discount rates: A comparison of alternative approaches. Aust. Econ. Rev. 2018, 51, 139–157. [Google Scholar] [CrossRef]

- Tsagarakis, K.P.; Papadogiannis, C. Technical and economic evaluation of the biogas utilization for energy production at iraklio municipality, greece. Energy Convers. Manag. 2006, 47, 844–857. [Google Scholar] [CrossRef]

- Tsagarakis, K.P. Optimal number of energy generators for biogas utilization in wastewater treatment facility. Energy Convers. Manag. 2007, 48, 2694–2698. [Google Scholar] [CrossRef]

- Walraven, D.; Laenen, B.; D’haeseleer, W. Minimizing the levelized cost of electricity production from low-temperature geothermal heat sources with orcs: Water or air cooled? Appl. Energy 2015, 142, 144–153. [Google Scholar] [CrossRef]

- Usman, M.; Imran, M.; Yang, Y.; Lee, D.H.; Park, B.-S. Thermo-economic comparison of air-cooled and cooling tower based organic rankine cycle (ORC) with R245FA and R1233ZDE as candidate working fluids for different geographical climate conditions. Energy 2017, 123, 353–366. [Google Scholar] [CrossRef]

- Commission Delegated Regulation (EU) No 480/2014 of Supplementing Regulation (EU) No 1303/2013 of the European Parliament and of the Council Laying Down Common Provisions on the European Regional Development Fund, the European Social Fund, the Cohesion Fund, the European Agricultural Fund for Rural Development and the European Maritime and Fisheries Fund and Laying Down General Provisions on the European Regional Development Fund, the European Social Fund, the Cohesion Fund and the European Maritime and Fisheries Fund. OJ L 138, 13.5.2014, p. 5–44.

- Kost, C.; Shammugam, S.; Jűlch, V.; Nguyen, H.; Schlegel, T. Levelized Cost of Electricity—Renewable Energy Technologies; Fraunhofer ISE: Freiburg, Germany, 2013. [Google Scholar]

- Cucchiella, F.; D’Adamo, I.; Gastaldi, M.; Stornelli, V. Solar Photovoltaic Panels Combined with Energy Storage in a Residential Building: An Economic Analysis. Sustainability 2018, 10, 3117. [Google Scholar] [CrossRef]

- IEA-PVPS. Technical Assumptions Used in PV Financial Models. Review of Current Practices and Recommendations. International Energy Agency - Photovoltaic Power Systems Programme, Report IEA-PVPS T13-08:2017. Available online: http://www.iea-pvps.org/index.php?id=426&eID=dam_frontend_push&docID=3822 (accessed on 17 August 2018).

- Weiss, M.; Junginger, M.; Patel, M.K.; Blok, K. A review of experience curve analyses for energy demand technologies. Technol. Forecast. Soc. Chang. 2010, 77, 411–428. [Google Scholar] [CrossRef]

- Wei, M.; Smith, S.J.; Sohn, M.D. Experience curve development and cost reduction disaggregation for fuel cell markets in Japan and the US. Appl. Energy 2017, 191, 346–357. [Google Scholar] [CrossRef]

- Shum, K.L.; Watanabe, C. Towards a local learning (innovation) model of solar photovoltaic deployment. Energy Policy 2008, 36, 508–521. [Google Scholar] [CrossRef]

- Winskel, M.; Markusson, N.; Jeffrey, H.; Candelise, C.; Dutton, G.; Howarth, P.; Jablonski, S.; Kalyvas, C.; Ward, D. Learning pathways for energy supply technologies: Bridging between innovation studies and learning rates. Technol. Forecast. Soc. Chang. 2014, 81, 96–114. [Google Scholar] [CrossRef]

- Ferioli, F.; Schoots, K.; van der Zwaan, B.C.C. Use and limitations of learning curves for energy technology policy: A component-learning hypothesis. Energy Policy 2009, 37, 2525–2535. [Google Scholar] [CrossRef]

| AA | Cost Component | Pieces | €/Piece | Total Price |

|---|---|---|---|---|

| 1 | Solar Charge Controller | 1 | 225.00 € | 225.00 € |

| 2 | PV Module | 6 | 200.70 € | 1204.20 € |

| 3 | Inverter / Charger | 1 | 1212.00 € | 1212.00 € |

| 4 | Battery Bank (w. 35mm2 cabling 6m) | 24 | 51.81 € | 1243.44 € |

| 5 | Battery Rack | 1 | 125.00 € | 125.00 € |

| 6 | Circuit breaker for photovoltaics (DC) | 1 | 87.49 € | 87.49 € |

| 7 | Miniature Circuit Breaker (for AC/DC circuits) | 1 | 24.90 € | 24.90 € |

| 8 | Miniature Circuit Breaker (for AC/DC circuits) | 3 | 9.70 € | 29.10 € |

| 11 | AC indoor installation cabling | 15 | 0.80 € | 12.00 € |

| 12 | Din Rail Enclosure (40W x 60H x 18D cm) | 1 | 56.93 € | 56.93 € |

| 13 | DC Cable (4 mm2, 10 mm2) | 20 | 2.50 € | 50.00 € |

| 9 | Roof Solar Installation (incl. Wiring) | 450.00 € | ||

| 10 | Indoor Electrical Installation | 200.00 € | ||

| 14 | Additional costs for residential installation | 400.00 € | ||

| 15 | Miscellaneous | 69.49 € | ||

| Sum | 5,389.55 € |

| Scenario | Capital Cost | O&M cost | kWh/yr | TAEC | €/kWh |

|---|---|---|---|---|---|

| 1 | 5389.55 € | 270 € | 2456.35 | 1068.66 | 0.44 |

| 2 | 5389.55 € | 270 € | 1843.26 | 1068.66 | 0.58 |

| Statistics | Forecasted | Measured |

|---|---|---|

| Values | 5000 | 5000 |

| Mean | 2456.36 | 1843.26 |

| Standard Deviation | 68.26 | 68.87 |

| Median | 2455.76 | 1844.05 |

| Minimum | 2202.03 | 1603.69 |

| 25% Percentile | 2410.29 | 1795.62 |

| 50% Percentile | 2455.76 | 1844.05 |

| 75% Percentile | 2503.09 | 1889.92 |

| Maximum | 2675.22 | 2116.13 |

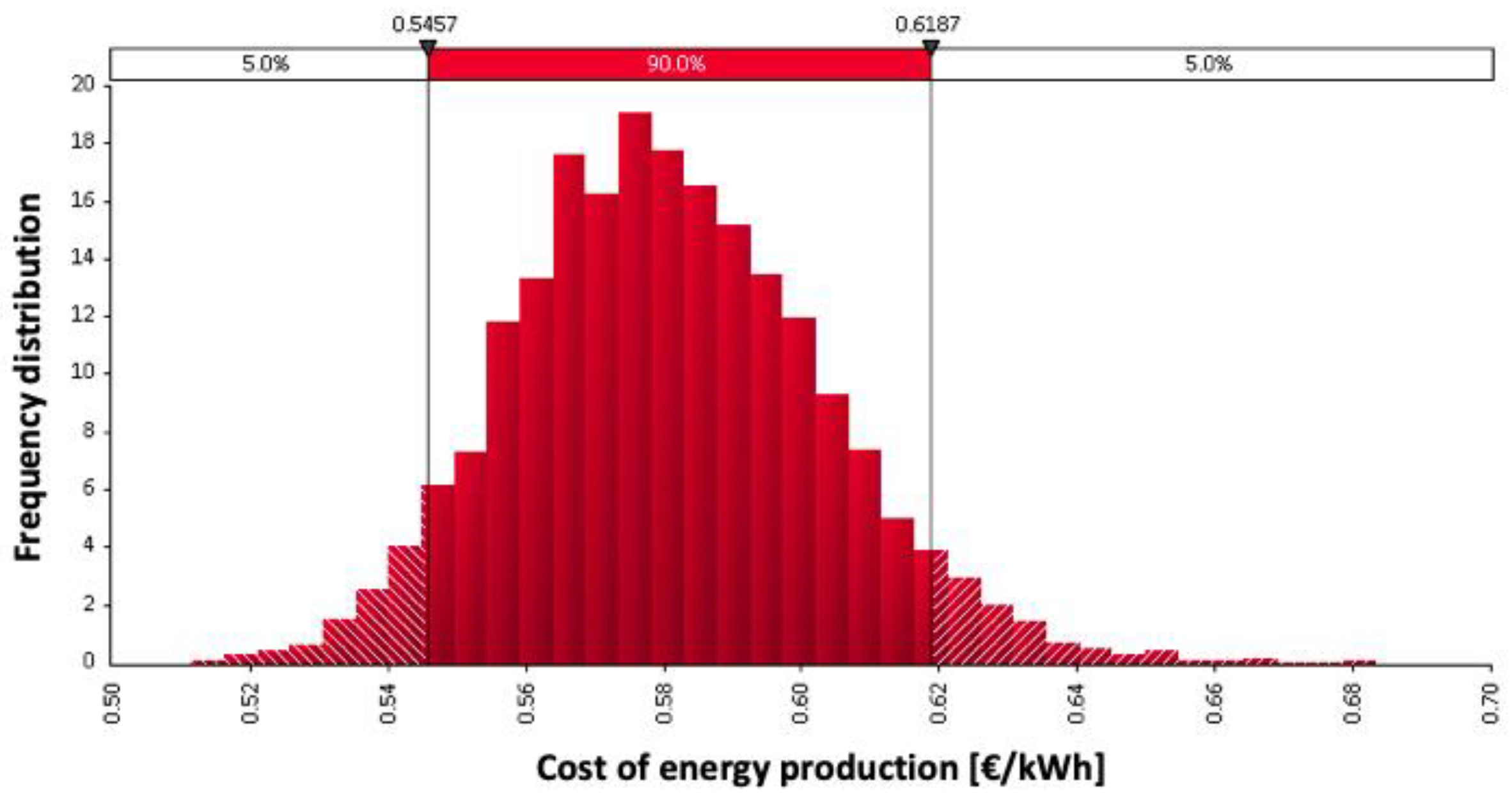

| Statistics | Forecasted | Measured |

|---|---|---|

| Values | 5000 | 5000 |

| Mean | 0.44 | 0.58 |

| Standard Deviation | 0.01 | 0.02 |

| Median | 0.44 | 0.58 |

| Minimum | 0.40 | 0.51 |

| 25% Percentile | 0.43 | 0.57 |

| 50% Percentile | 0.44 | 0.58 |

| 75% Percentile | 0.44 | 0.60 |

| Maximum | 0.49 | 0.68 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kosmadakis, I.E.; Elmasides, C.; Eleftheriou, D.; Tsagarakis, K.P. A Techno-Economic Analysis of a PV-Battery System in Greece. Energies 2019, 12, 1357. https://doi.org/10.3390/en12071357

Kosmadakis IE, Elmasides C, Eleftheriou D, Tsagarakis KP. A Techno-Economic Analysis of a PV-Battery System in Greece. Energies. 2019; 12(7):1357. https://doi.org/10.3390/en12071357

Chicago/Turabian StyleKosmadakis, Ioannis E., Costas Elmasides, Dimitrios Eleftheriou, and Konstantinos P. Tsagarakis. 2019. "A Techno-Economic Analysis of a PV-Battery System in Greece" Energies 12, no. 7: 1357. https://doi.org/10.3390/en12071357

APA StyleKosmadakis, I. E., Elmasides, C., Eleftheriou, D., & Tsagarakis, K. P. (2019). A Techno-Economic Analysis of a PV-Battery System in Greece. Energies, 12(7), 1357. https://doi.org/10.3390/en12071357