1. Introduction

Recently, environmental problems associated with fine dust have become increasingly important, and various technologies for the conversion of environmental pollutants into energy, as well as for the suppression of air pollutants, have been proposed [

1]. It has been reported that volatile organic compounds (VOCs), NOx, SO

2, and NH

3 exhausted to the atmosphere can act as precursors for the formation of fine dust particles. The major anthropogenic sources of VOC emissions include gasoline and diesel vehicles, solvent use, and various industries [

2]. VOCs act as precursors of fine dust, and the NOx generated in flare stacks, used in VOC treatment facilities in factories that exhaust them, can also produce fine dust. Moreover, secondary air pollutants may be generated by combustion facilities, such as those used for reducing the emission of organic solvents exhausted by car painting or printing factories. Many species of VOCs and hazardous air pollutants (HAPs) emitted by emission facilities can, in very small amounts, adversely affect health and the environment. In addition, individual VOCs can produce secondary pollutants, such as ozone or photochemical oxide, that can remain in the atmosphere for a long period of time, produce toxic and carcinogenic effects, and cause odors [

3]. Moreover, VOCs, including toluene, are carcinogenic substances that can affect the human body and have negative effects on the nervous system and olfactory function [

4].

It has been proposed that synthesis gas can be produced via a reforming reaction, thereby producing fuel for the production of heat and power through an internal combustion engine [

5,

6,

7,

8]. The production technology for synthesis gas produced by the toluene-reforming reaction proposed in this study was studied, because nitrogen oxide is exhausted during the high-temperature combustion processes used when treating chemical thinners, such as those used in painting and printing factories. Among the chemical species contained in such thinners, approximately 80% is toluene, a hydrocarbon having seven carbon atoms. Toluene can be used as a fuel in a reforming reaction that can produce hydrogen and carbon monoxide. In this study, we propose a method for reforming toluene in a catalytic reactor that can prevent carbon deposition while producing synthesis gas.

At present, thinner that is used in painting and printing factories is collected and concentrated through an adsorption process with activated carbon; subsequently, synthesis gas can be produced by reforming the recovered thinner. This study sought to produce synthesis gas for use as a fuel in an internal combustion engine by reforming toluene, a main component of thinner. For such reforming, a demonstration catalyst was prepared, and its performance evaluated.

Liquid hydrocarbons have lower binding energies in the C–C and C–H bonds than those of methane, so pyrolysis, along with the formation of carbon, easily occurs around 500 °C. Aromatic hydrocarbons in particular have a relatively low number of hydrogens compared to aliphatic hydrocarbons; thus, carbon is formed more easily during pyrolysis. When hydrocarbons are used as fuel, carbon can be deposited on the catalyst surface (depending on the operating conditions). In the case of aromatic compounds, carbon deposition can be severe. Carbon coke is a typical catalyst deactivating substance that is generally deposited on a catalyst surface, lowering its catalytic activity [

9,

10,

11]. Many researchers have attempted to suppress catalyst deactivation in a heterogeneous catalytic reaction process by using hydrocarbons as a feedstock [

12,

13,

14,

15]. In particular, since carbon nanotubes grow well on the surface of nickel, many studies have been conducted to control the steam/carbon (S/C) ratio, in order to suppress carbon deposition during the reforming reaction for liquid hydrocarbons using nickel catalysts. Nickel-based catalysts, such as Ni/Al

2O

3, Ni-CeO

2/Al

2O

3, Ni/CeO

2, Ni/olivine, and Ni/C have been studied.

For the inhibition of carbon deposition, low-acidity support materials and high-oxygen mobility promoters have also been studied. There have been many studies reporting on support materials and catalytic promoters for oxidizing and removing coke, and most researchers have attempted to design a catalyst that inhibits deactivation of the reforming catalyst and have investigated carbon deposition on the catalyst surface [

12,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22,

23,

24]. However, in the reforming reaction, carbon may be produced not only on the surface of the catalyst, but also, for various reasons that depend on the operating conditions, in other areas.

Typical reforming reaction behavior involves hydrocarbon pyrolysis. Since aromatic hydrocarbons have a smaller number of hydrogen atoms than olefinic and paraffinic hydrocarbons, the decomposition of aromatic compounds produces carbon rather than producing light hydrocarbons. In the reforming reaction, there is a high possibility that the pyrolysis reaction occurs in the high-temperature region inside the reactor, which, due to the formation of carbon, may cause problems during the reaction process. In addition, when the temperature in the catalyst bed drops, due to a high endothermic reaction during the reforming reaction, thermodynamic carbon formation may occur. Carbon may be formed when the temperature in a steam reforming reaction drops under 650 °C. In practice, a temperature drop in the catalyst layer of a laboratory-scale microreactor, resulting from an endothermic reaction, can be prevented by supplying heat from an electric furnace; thus, the reaction temperature can be kept constant. However, when the reactant supply amount is increased for device scale-up, and the heat supply to the catalyst bed is insufficient, the temperature in the catalyst bed can decrease to the carbon depositional temperature. In contrast, an auto-thermal reforming reaction can be used to prevent such a temperature drop, and can reduce energy consumption by supplying a suitable amount of oxygen, so that the endothermic and exothermic reactions can occur simultaneously during the reforming reaction. In this study, carbon deposition was shown to be more effectively prevented by auto-thermal reforming than by steam reforming. In addition, the carbon deposition inhibitory effect was confirmed, examining the results obtained from a catalyst with added catalytic promoters.

2. Experiments

2.1. Preparation of Nickel-Based Catalysts

In this study, nickel-based pellet catalysts were prepared for use in the steam and auto-thermal reforming of toluene. The nickel catalyst was prepared via the impregnation method, with 10 wt % nickel impregnated using alumina pellets as the support. Nickel nitrate (Ni(NO3)2 · 6H2O) was used as the precursor for impregnating nickel on the support. In order to prevent the sintering of nickel at high temperatures, magnesium nitrate (Mg(NO3)2 · 6H2O) was used. To reduce carbon deposition on the surface of the catalyst, cerium nitrate (Ce(NO3)2 · 6H2O) and zirconium nitrate (Ce(NO3)2 · 6H2O) were added as precursors, so that CeO2 and ZrO2 existed as complex oxides. The promoters’ contents were Mg-, Ce-, and Zr-oxides at 3 wt %, 2 wt %, and 1 wt %, respectively. The catalysts obtained by impregnation of nickel, magnesia, ceria, and zirconia on alumina pellets were dried at 150 °C for 12 h, and then calcined at 750 °C for 4 h to be used for the reforming of toluene. MgO was added to suppress the high-temperature sintering of nickel, and CeO2 was added to prevent carbon deposition on the catalyst surface. ZrO2 was also added to improve the lattice oxygen mobility of CeO2.

To investigate the optimum cerium oxide content when used as a catalytic promoter, the content of cerium oxide in the nickel-based catalysts varied within the range of 2–8 wt %. For the preparation of catalysts for assessing the effect of CeO2, the molar ratio of Ce/Zr was fixed at 2.0, and the content of alumina used as the support was decreased as the content of the additive was increased. The effect of cerium oxide in the auto-thermal toluene-reforming reaction on the nickel catalyst was investigated by fixing the nickel oxide and magnesium oxide levels and reducing the alumina content, by increasing the amounts of Ce and Zr.

2.2. Steam Reforming and Auto-Thermal Reforming Tests

The steam reforming reaction for toluene was carried out in a fixed-bed catalytic reactor with a tubular reactor of 1-inch SUS316 charged with an 8 g pellet catalyst (diameter × height = 5 mm × 5 mm). The reactor was installed vertically in the center of the furnace. A preheater was installed at the front end of the reactor to vaporize the liquid hydrocarbons and water. The temperature of the preheater was maintained at 180 °C by a temperature controller. A condenser for collecting unreacted liquid hydrocarbons and water was installed at the rear end of the reactor. Liquid hydrocarbons and water were supplied via micro-pump. At the end of the condenser, a gas chromatograph (GC) with a thermal conductivity detector (TCD) was connected and used to analyze the composition of the dry gas. Gas composition was automatically analyzed over the full time-course of the reaction. Before initiating the reforming reaction, the catalyst was reduced for 4 h at 500 °C in a 50 vol % H2 (N2-balanced) atmosphere as a pretreatment, prior to activation of the nickel-based catalyst. The reforming experiments were carried out at 750 °C and 800 °C and the S/C and oxygen/carbon (O2/C) ratios were 3.0 and 0.2, respectively. Toluene and distilled water were fed at 0.5 cc/min and 1.8 cc/min, respectively, and the air was added at 705 mL/min for auto-thermal reforming. Air was not supplied in the steam reforming tests. The space velocities in the steam reforming and auto-thermal reforming reactions were fixed at 11,000 mL/g-cat·h and 15,000 mL/g-cat·h, respectively. The S/C ratio was lowered to 2.0, and the O2/C ratio was 0.2 in the experiment to investigate the carbon deposition characteristics, according to the CeO2 promoter content on the Ni catalyst in the auto-thermal reforming reaction. The flow rates of toluene and distilled water, controlled using micro-pumps, were 0.5 cc/min and 1.2 cc/min, respectively. The air inflow rate was fixed at 705 mL/min. The condensed water and liquid hydrocarbons were collected at the bottom of the condenser, and the fuel and water conversion amounts were measured. The flow rate of the dry gas vented to the downstream portion of the condenser, located at the outlet of the reactor, was measured by using a wet gas meter.

2.3. Characterization of Catalysts

To confirm the deposition of carbon on the catalyst, the surface morphology of the catalyst was observed using scanning electric microscopy (SEM; S-4100, Hitachi, Tokyo, Japan), and the deposit’s crystal structure was examined by using X-ray diffraction (XRD; Rigaku, D/MAX-2500, Tokyo, Japan). The temperature programmed oxidation (TPO) test was performed using a thermo-gravimetric analyzer/differential temperature analyzer (TGA/DTA; TA instruments SDT-Q600, Champaign, IL, USA). TPO experiments were carried out within the temperature range of room temperature to 800 °C, with the temperature rising at a rate of 5 °C/min. The sample’s weight used in the TPO tests was approximately 13 mg.

3. Results and Discussion

3.1. Catalytic Activity of Nickel-Based Catalysts

The steam reforming and auto-thermal reforming of toluene were performed over the nickel-based catalysts prepared in this study. The composition of the catalyst used in these tests was 10 wt % NiO, 3 wt % MgO, 2 wt % CeO

2, 1 wt % ZrO

2, and 84 wt % Al

2O

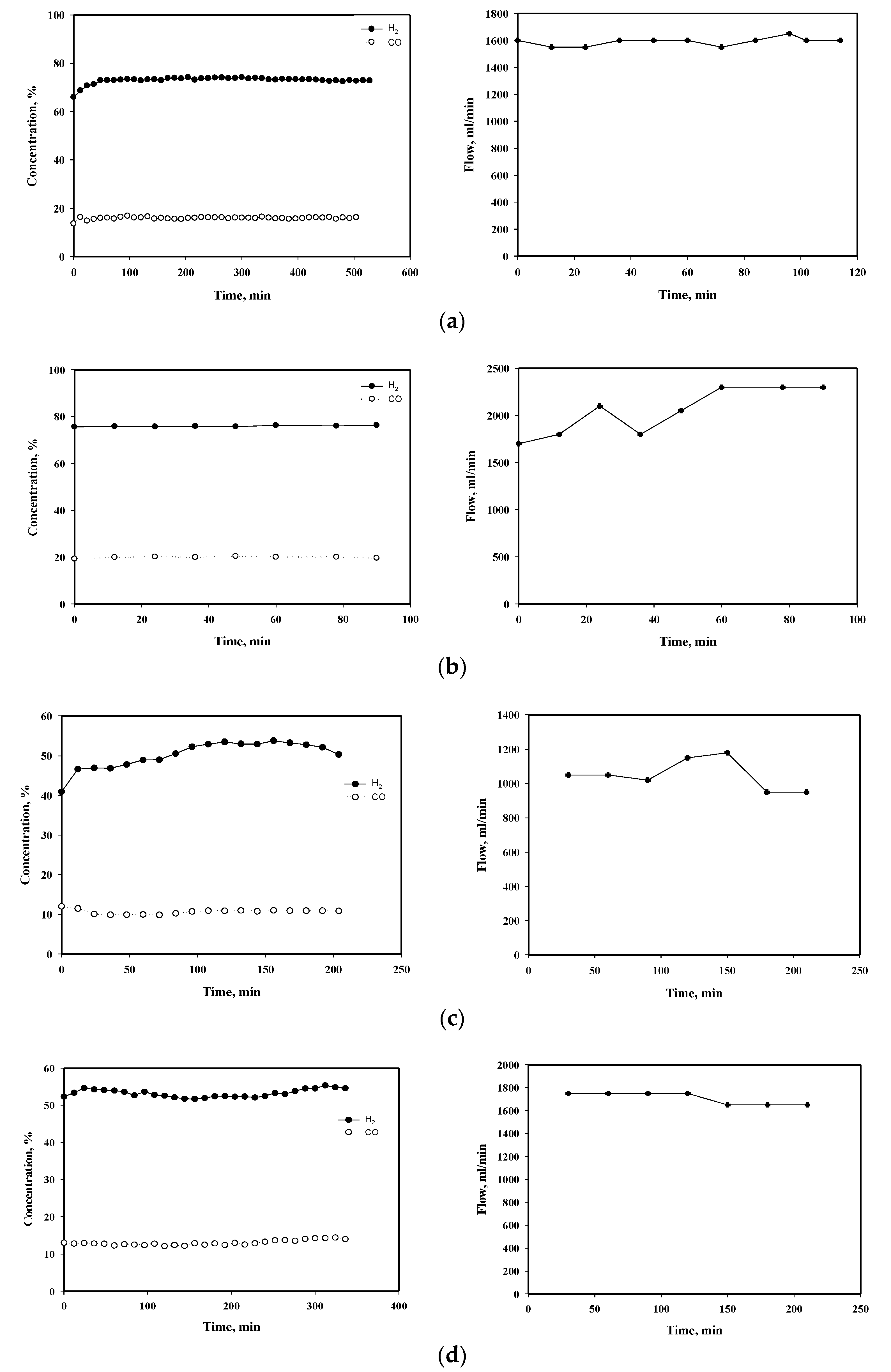

3. Hydrogen and carbon monoxide concentrations of the reformate gases were measured during the reforming reaction at 750 °C and 800° C. In the steam reforming reaction of toluene, the amounts of hydrogen and carbon monoxide differed slightly with the reaction temperature; it was 74% hydrogen and 15% carbon monoxide at 750 °C, as shown in

Figure 1a, and 75% hydrogen and 18% carbon monoxide at 800 °C, as shown in

Figure 1b. Although the hydrogen and carbon monoxide contents were similar at 750 and 800 °C, the flow rate of the drying gas at the outlet of the reactor varied considerably with the reaction temperature. When the steam reforming reaction was carried out at 750 and 800 °C, the dry gas flow rates were approximately 96 L/h and 138 L/h, respectively. The increase in the flow rate of the dry gas with the increasing temperature of the reforming reactor indicates that gaseous hydrocarbons are present in the product gas at 750 °C, even though no liquid hydrocarbon was observed in the condenser connected to the reforming reactor outlet. At 800 °C, the hydrocarbons in the gas phase were considered to have been converted to hydrogen and carbon monoxide by the reforming reaction.

On the other hand, after performing the auto-thermal reforming reaction on toluene with the same catalyst, the hydrogen and carbon monoxide contents in the drying gas flowing out to the outlet of the reforming reactor were slightly changed, according to the reaction temperature. As shown in

Figure 1c,d, the hydrogen content in the dry gas was approximately 54 vol % and 55 vol % at 750 °C and 800 °C, respectively, but the carbon monoxide content was 10 vol % and 13 vol %, respectively. The carbon monoxide increased by approximately 3% with the increase in temperature. That result indicates that the compositional change in the fuel gas after the auto-thermal reforming of toluene was different from that after steam reforming. The auto-thermal result is considered to be due to a partial oxidation reaction by the air supplied as a reactant in the auto-thermal reforming reaction.

Hydrogen in the synthesis gas was produced at a lower concentration in the auto-thermal reforming reaction than in the steam reforming reaction, a difference that is related to the dilution of the reformate gas concentration by the nitrogen in the air supplied for auto-thermal reforming. The increase in the concentration of carbon monoxide in the auto-thermal reforming reaction was probably due to the combination of oxygen and carbon in the air. It was observed that the concentration of the gas remained relatively stable during the steam reforming reaction, but the concentration of the gas showed a tendency to change, in the case of the auto-thermal reforming reaction. It was concluded that the change in synthesis gas concentration can cause a temperature change inside the reactor, due to the oxygen combustion reaction.

In actuality, the measured flow rate of the dry gas was half of the theoretical maximum flow rate; however, an oil component could not be confirmed in the condenser at the downstream portion of the reactor. Regardless, the results suggest that a significant amount of the incoming toluene may have been converted to carbon by pyrolysis.

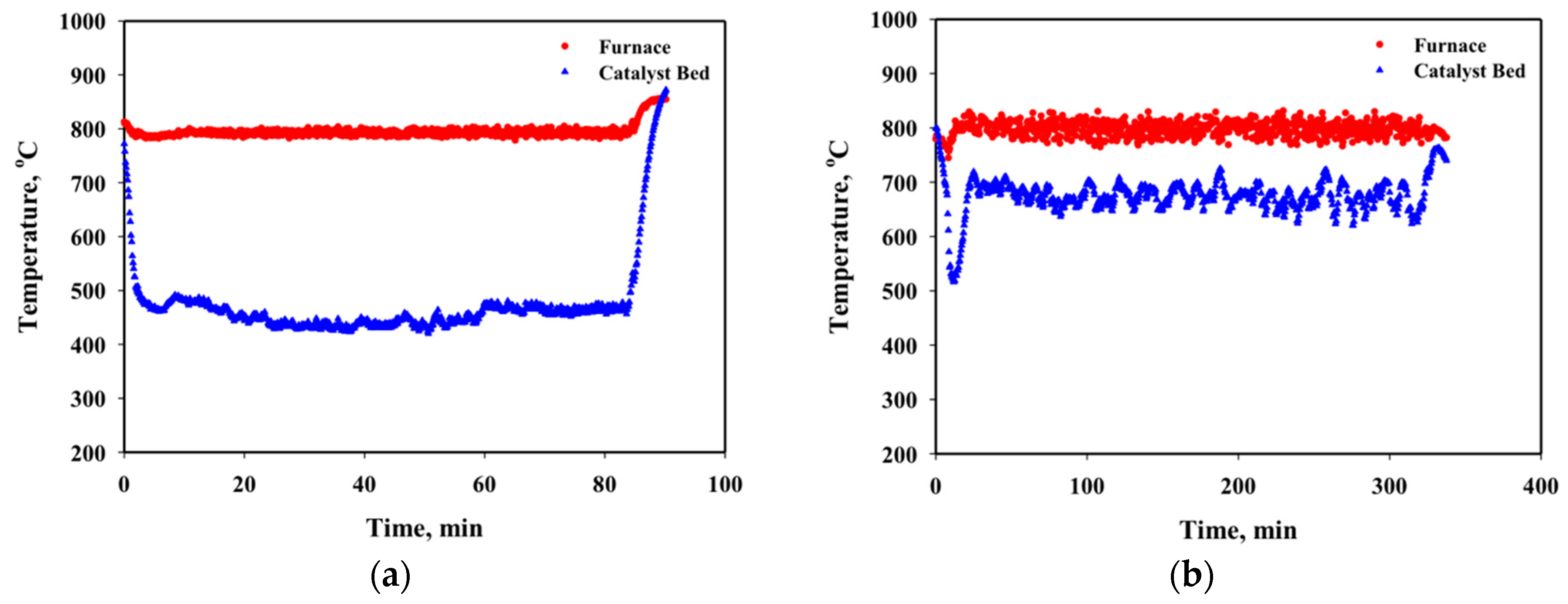

Changes in catalyst bed temperature in the reactor during the steam and auto-thermal reforming of toluene were also measured. As shown in

Figure 2, the reaction was started with the catalyst bed temperature established at 800 °C, using an electric furnace. However, when the reaction started, the temperature of the catalyst layer dropped sharply. In the case of steam reforming, the temperature dropped to approximately 450 °C, as shown in

Figure 2a. A similar temperature drop was observed in the case of auto-thermal reforming, with the temperature dropping to approximately 500 °C immediately after initiation of the reaction; subsequently, the temperature tended to rise immediately, and then be maintained at approximately 700 °C. In the auto-thermal reforming reaction, the temperature is recovered by strong endothermic and exothermic reactions. That is to say, the consumption heat and generated heat from the endothermic and exothermic reactions are balanced, and they attain an equilibrium according to the supply amount of hydrocarbon fuel, steam, and oxygen used as the reactants in an auto-thermal reforming reaction.

The drop in the temperature of the catalyst bed can have the effect of lowering catalytic activity of the catalyst in the reforming reaction, and if the thermodynamic temperature of the carbon formation is reached, it may have a catastrophic effect on the catalyst layer and the reactor’s piping. The temperature difference of approximately 250 °C between the steam reforming and auto-thermal reforming reactions is due to the presence of an exothermic reaction resulting from the supply of oxygen. If the temperature of the catalyst bed during the steam reforming reaction decreases, carbon deposition significantly increases, due to the pyrolysis reaction. In the case of the auto-thermal reforming reaction, the reaction temperature changed but was maintained at about 700 °C; as a result, the efficiency of the reforming reaction may have been lowered. Regardless, severe carbon deposition was avoided.

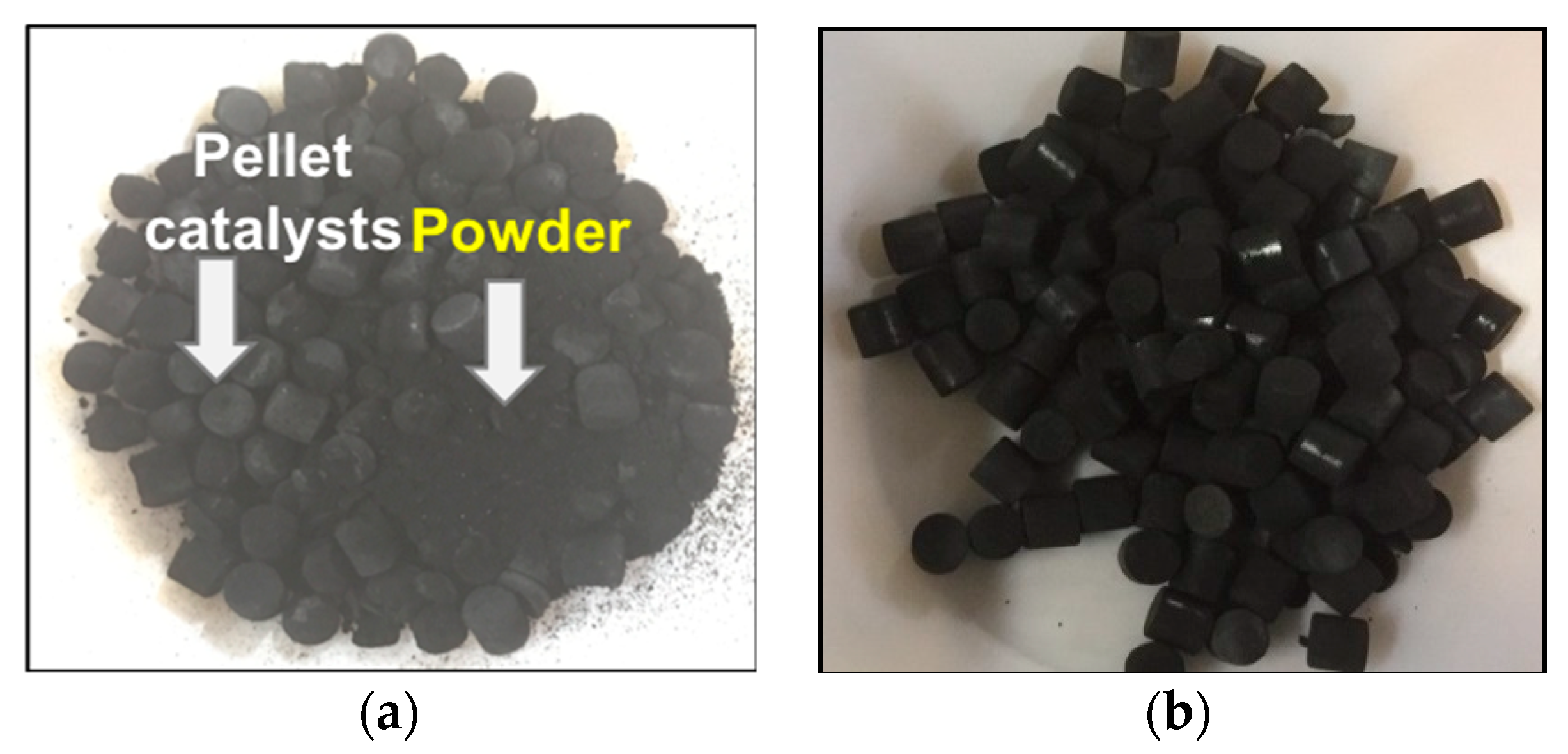

3.2. Characterization of Nickel-Based Catalyst Surface

The surfaces of the catalyst used in the steam reforming reaction and the auto-thermal reforming reaction were also analyzed. During catalyst collection, a considerable amount of powder was observed in the sample obtained from the steam reforming reaction. In order to observe the surface state of the catalyst, the crystal structure of the sample before and after the reforming reaction was analyzed by XRD. The catalysts collected after the steam reforming reaction at 800 °C are shown in

Figure 3. As shown in

Figure 3a, it was confirmed that the catalyst collected after the steam reforming reaction contained a considerable amount of powder particles, together with the pellet catalyst packed in the reactor. In contrast, as shown in

Figure 3b, no powder was detected in the catalyst samples collected after the auto-thermal reforming reaction. Generally, when carbon deposition is severe, carbon is formed in the pores of the catalyst pellet, and the catalyst can be crushed.

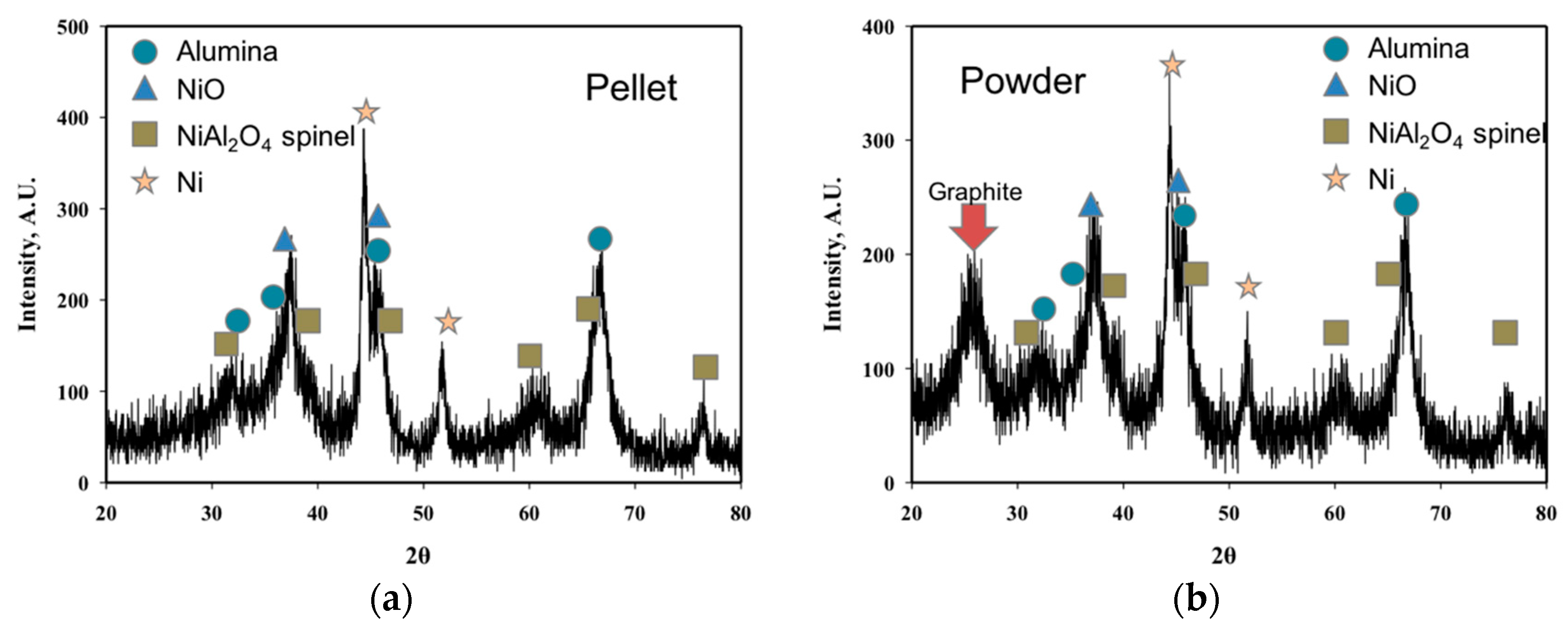

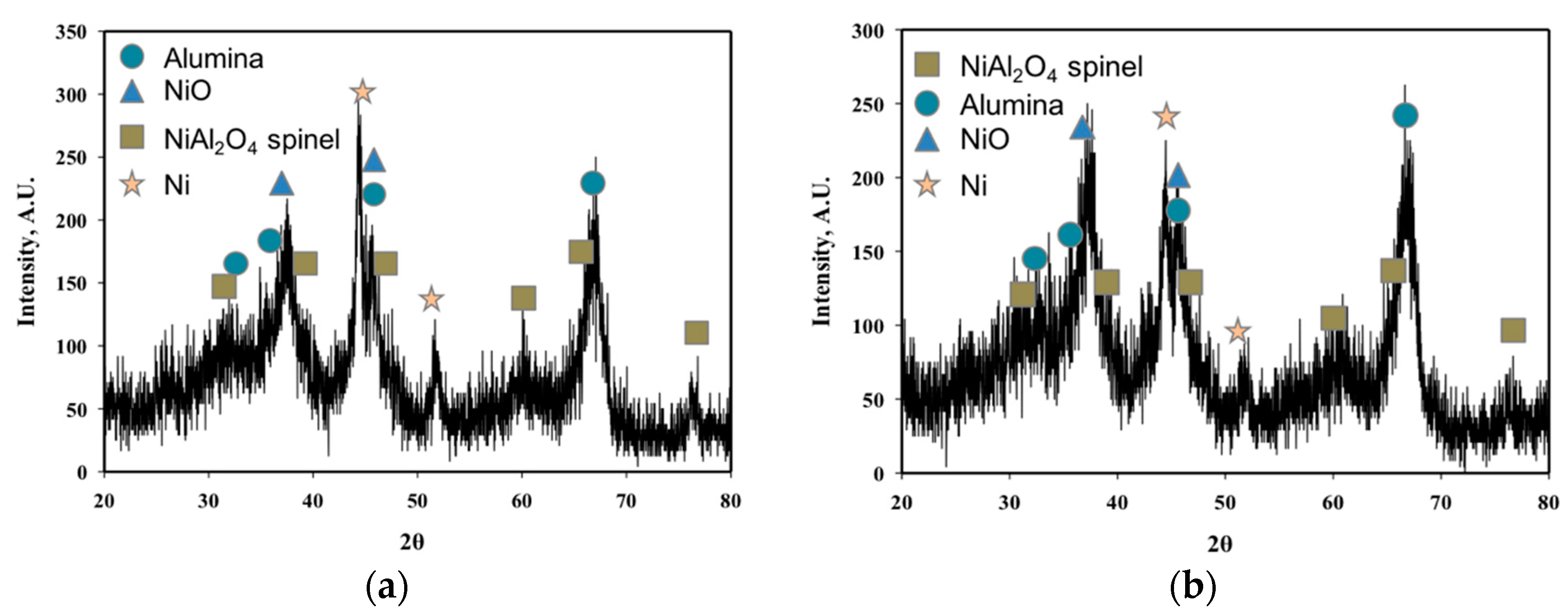

The crystal structure of the catalyst was analyzed by XRD, in order to confirm the formation of carbon on the catalyst. Ni metal, NiO, NiAl

2O

4, and alumina were identified, as shown in the XRD pattern in

Figure 4. NiO is reduced to Ni during reduction by hydrogen in the pretreatment period before the reforming reaction, in order to activate Ni-based catalysts, and the peak pattern shown by NiO indicates an incompletely reduced Ni-based catalyst. The NiAl

2O

4 spinel structure is a composite metal oxide produced by bonding between alumina as the support and NiO as the active material at high temperatures. It has been reported that the Ni metal sites on the Ni-based catalysts have a high activity for reforming hydrocarbons [

20,

21,

23,

25]. The XRD analysis of the powders collected during catalyst sampling showed carbon peaks at 2 theta = 25°, with Ni, NiO, and an NiAl

2O

4 spinel, as shown in

Figure 4b. This XRD peak (2 theta = 25° peak) is typical of carbon and is observed in graphite [

26]. Therefore, a considerable amount of carbon was formed in the toluene steam reforming reaction. Of particular note, the presence of powder particles in the steam reforming reactor means that physical cracking of the pellet-shaped catalyst due to the formation of carbon had occurred.

The XRD patterns of the catalysts obtained after auto-thermal reforming were similar to those obtained after the steam reforming reaction, but there was no clear evidence confirming the formation of carbon in the auto-thermal reaction, as shown by the XRD patterns presented in

Figure 5. This result may be due to the oxidation of carbon by the oxygen contained in the air supplied to the auto-thermal reforming, thereby converting the carbon to carbon monoxide or carbon dioxide. The catalyst samples collected after auto-thermal reforming did not contain powder, and no carbon deposition was observed in the XRD analysis. These results indicate that there is less carbon formation in the auto-thermal reforming reaction than in the steam reforming reaction. However, the peak intensity of the Ni metal in the catalyst was slightly decreased, and the peak intensity of NiO in the catalyst was slightly increased after the reforming reaction. Compared with the levels in the fresh catalyst, as shown in

Figure 5a,b. This suggests that the Ni metal active sites are partially oxidized by the oxygen supplied as a reactant in the auto-thermal reforming reaction.

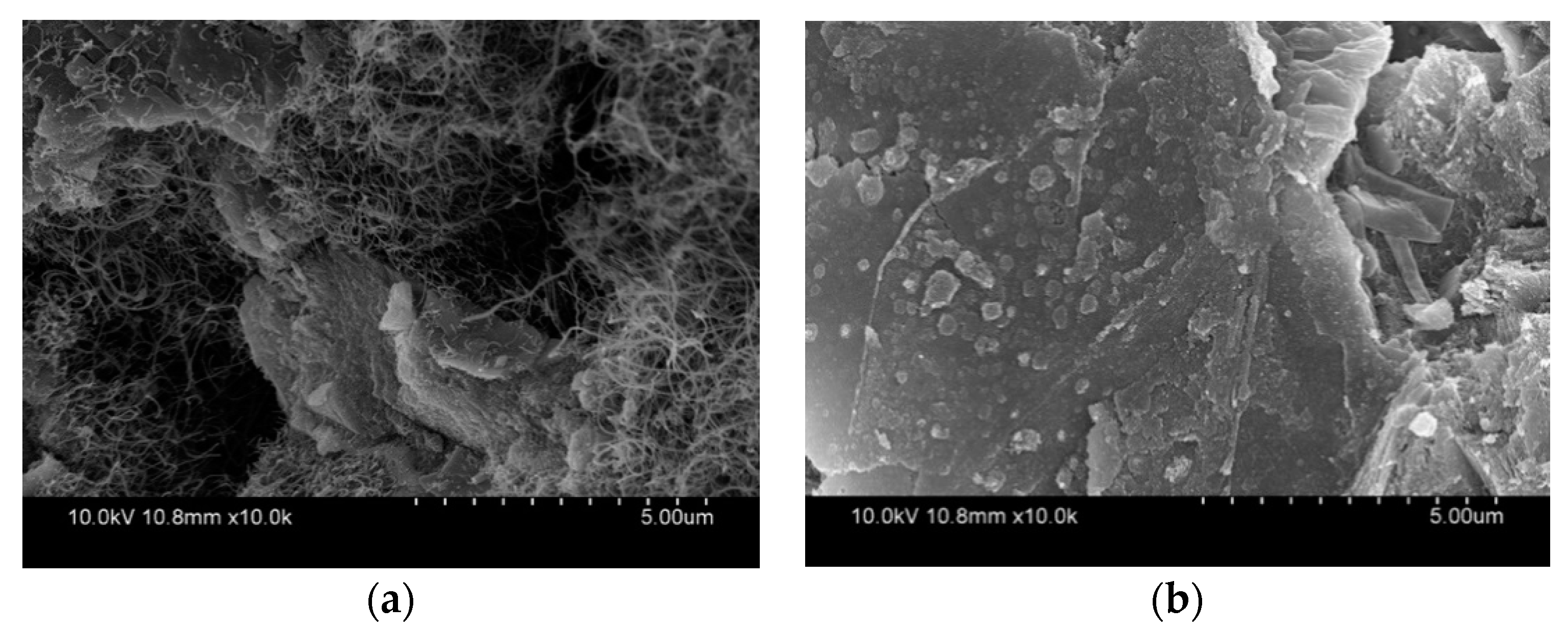

Observations with a scanning electron microscope to confirm carbon deposition on the surface of the catalyst showed the presence of fibrous carbon after the steam reforming reaction, as shown in

Figure 6a. In contrast, carbon deposition was not observed on the surface of the catalyst after the auto-thermal reforming reaction, as shown in

Figure 6b. The fibrous carbon grew on metal catalyst sites, such as the Ni metal site, and had a different morphology from the spherical-type carbon particles formed by the pyrolysis of hydrocarbons [

27,

28]. The catalysts used in the experiments included a promoter like CeO

2 to inhibit carbon formation; regardless, the formation of fibrous carbon was clearly observed after the steam reforming of toluene. Thus, it was confirmed that the use of a catalytic promoter cannot inhibit carbon deposition. These results mean that a small amount of oxygen must be supplied for effective carbon deposition inhibition by the redox property of a promoter, such as CeO

2.

3.3. Effect of Ce–Zr-Based Additives

In this study, it was confirmed that a significant amount of carbon can be produced during a toluene-reforming reaction. Development of a catalyst that has resistance to carbon formation is very important, because carbon deposition on the surface of the catalyst can be the main cause of deactivation of the catalyst. In the auto-thermal reforming, the carbon deposition over the surface of the catalyst could not be confirmed, and it was concluded that the generated carbon had reacted with oxygen and was removed as carbon monoxide or carbon dioxide. In order to oxidize and remove carbon on the surface of the catalyst, it is advantageous if a catalytic promoter capable of providing oxygen to the surface of the catalyst is present. Therefore, in this study, CeO2, which has redox properties, was added to the Ni-based catalysts to act as a promoter. To investigate the effect of increasing the content of CeO2 in the catalyst, the CeO2 impregnation amount was varied (2, 4, 6, and 8 wt %). In addition, the S/C ratio in the reaction was lowered to 2.0, while the O2/C ratio was maintained at 0.2 to confirm resistance to carbon deposition. In this experiment, the reaction temperature was fixed at 800 °C.

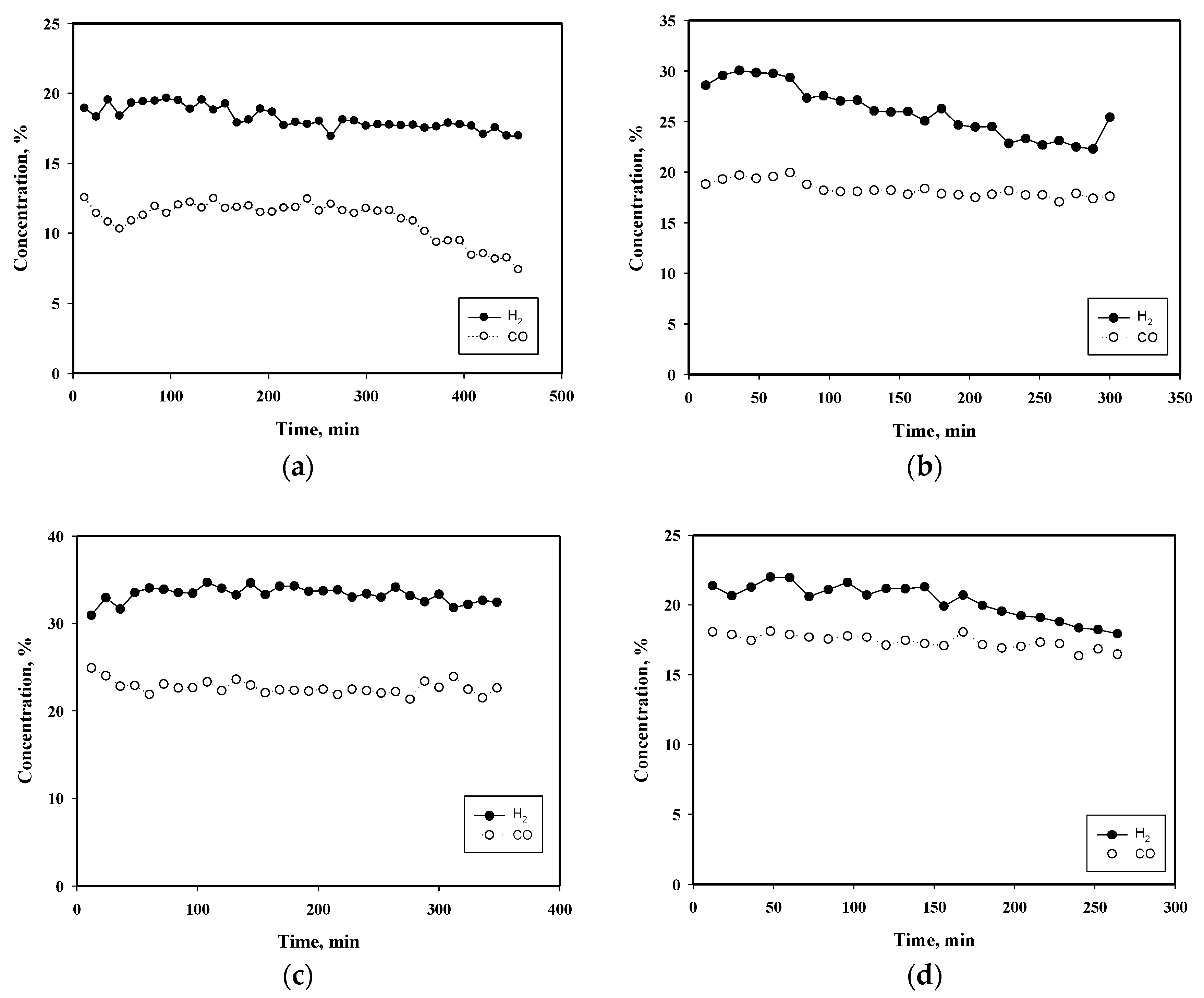

As shown in

Figure 7, the hydrogen and carbon monoxide content in the synthesis gas produced by the auto-thermal reforming changed with the CeO

2 content in the Ni-based catalyst. When the content of CeO

2 on the catalyst was 2.0 wt %, the concentration of hydrogen in the dry gas at the outlet of the reactor was approximately 18 vol %, and the concentration of carbon monoxide was approximately 13 vol %. When the content of CeO

2 increased to 4.0 wt % under the same conditions, the concentration of hydrogen in the dry gas was initially about 30 vol % and then decreased to 22 vol % over time. However, the concentration of carbon monoxide was maintained at about 18 vol %. When the content of CeO

2 was 6.0 wt %, the hydrogen concentration in the dry gas was maintained at approximately 34 vol %, and the concentration of carbon monoxide was maintained at approximately 22 vol %. Thus, the concentrations of hydrogen and carbon monoxide tended to increase as the content of CeO

2 increased on the nickel catalyst in auto-thermal reforming of toluene. On the other hand, when the content of CeO

2 on the catalyst was 8.0 wt %, the concentrations of hydrogen and carbon monoxide in the dry gas decreased. At the beginning of the reforming reaction with 8.0 wt % CeO

2, the hydrogen concentration was maintained at about 22 vol % and decreased to almost the same level as that of carbon monoxide. However, the concentration of carbon monoxide remained unchanged at about 18 vol %. The increase in hydrogen content in these experiments means that the partial oxidation reaction of toluene is promoted by the redox property of CeO

2. However, the increase in the concentration of carbon monoxide can be considered a result of the formation of carbon by the pyrolysis of toluene and the oxidation of carbon by oxygen. Nevertheless, when the content of CeO

2 increased, the activity of the reforming reaction of the nickel catalyst lowered, and the oxidation reaction of carbon produced from the pyrolysis of toluene was presumed to have been maintained.

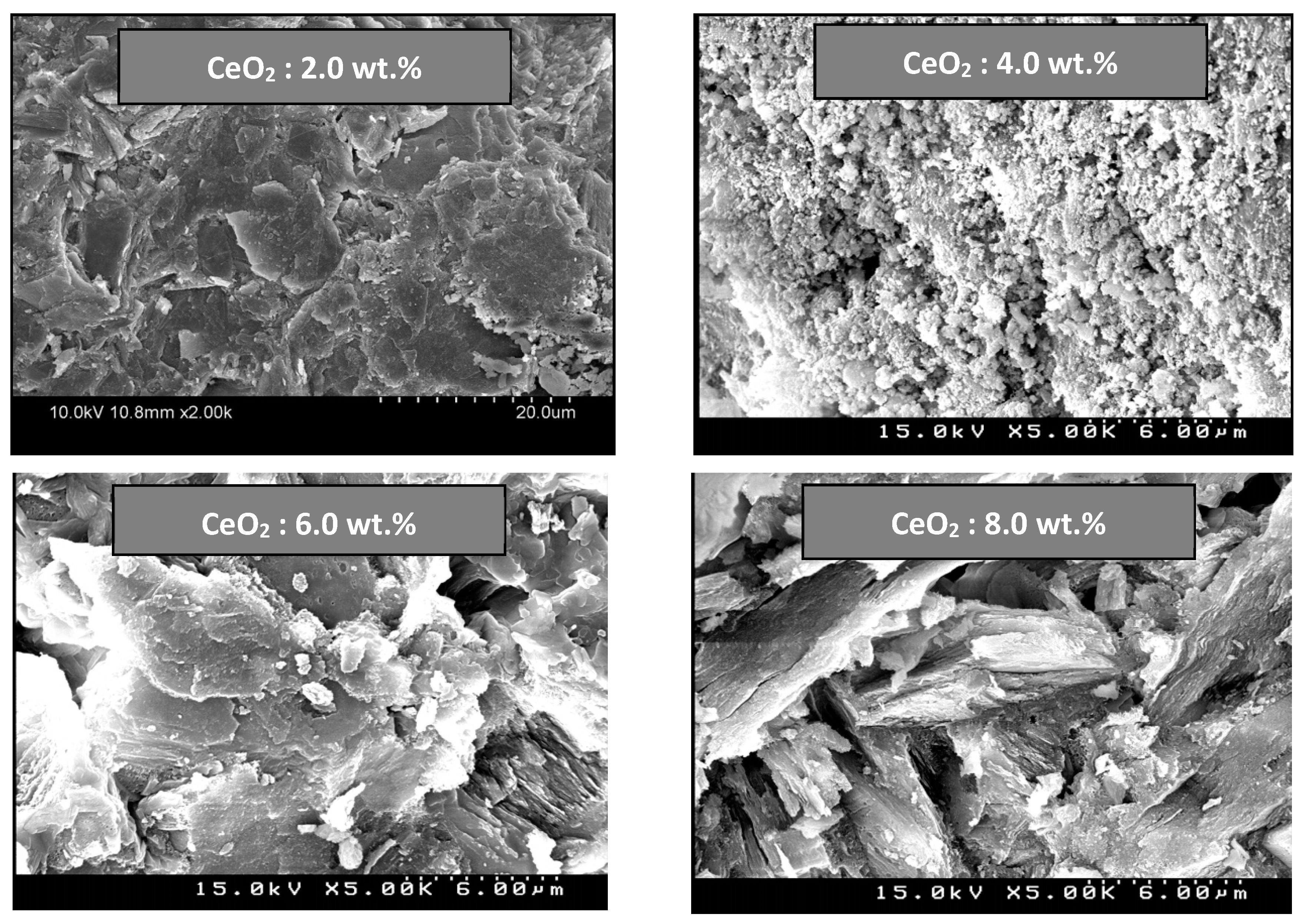

As shown in

Figure 8, the formation of filament-type carbon observed in the steam reforming reaction was not observed on the surface of the catalyst after the auto-thermal reforming on the catalyst that contained CeO

2. It is believed that this is due to the strong catalysis of CeO

2, resulting in carbon oxidation. As the content of CeO

2 increased, the surface morphology of the catalyst changed; thus, it was concluded that the added CeO

2 does cover the nickel surface. Based on the results, the content of CeO

2 in the catalyst for effective suppression of carbon deposition on the Ni catalyst surface should be maintained at 6 wt %.

3.4. Temperature Programmed Oxidation Tests for Carbon Deposition on Catalysts

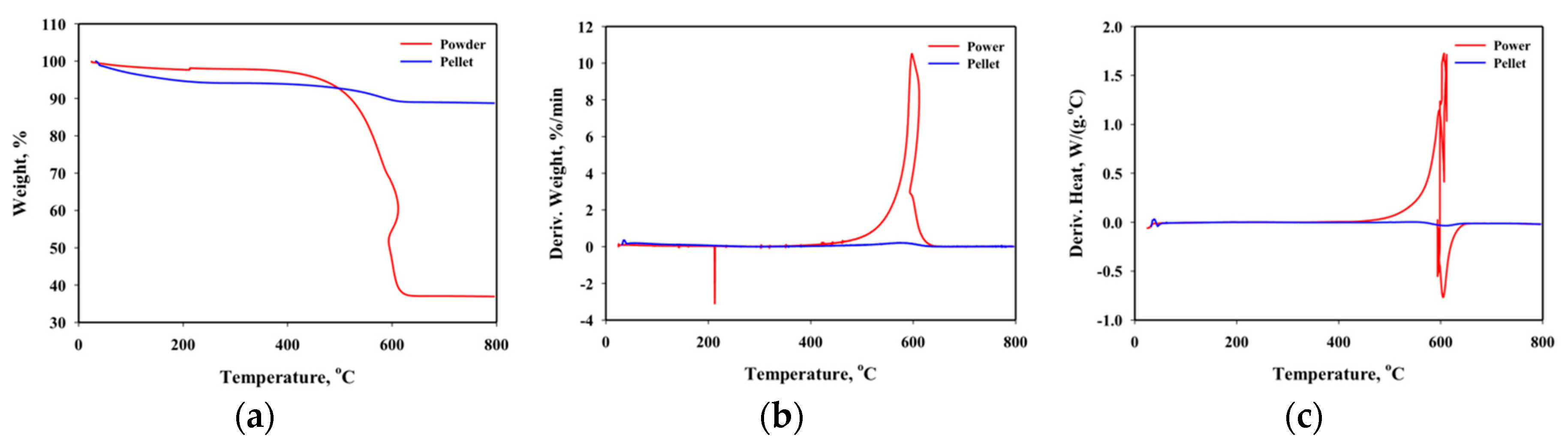

The temperature programmed oxidation (TPO) test was conducted to confirm the presence of carbon deposition on the catalyst samples obtained after the steam reforming reaction. As shown in

Figure 9, the powder particles and the pellet catalyst sampled after the steam reforming reaction were placed in an alumina dish for TGA testing, and the sample was then oxidized under an air atmosphere. The decreasing weight indicated in the thermo-gravity graph suggests the desorption of adsorbed moisture and volatile organic compounds, as well as the oxidation of the deposited carbon. As shown in

Figure 9a,b, the weight of the powder sample decreased at 450 °C, but the weight decreased rapidly above 500 °C. The weight was maintained at about 30% of the initial weight at temperatures above 600 °C. On the other hand, weight decreases in the pelletized catalyst samples were observed in the range of 500 °C to 600 °C, decreased by about 5% compared to the sample’s initial weight. A slight change in weight was observed within the temperature range of room temperature to 200 °C, and that change was concluded to be due to the desorption of adsorbed moisture. The TPO experimental results suggest that the powder samples were comprised of carbon particles produced by the pyrolysis of toluene, indicating that carbon deposition occurs in the steam reforming reaction even under the S/C = 3.0 conditions. As shown in

Figure 9c, endothermic and exothermic behaviors were observed at about 600 °C, with exothermic behavior occurring after the endothermic process. The exothermic behavior is indicative of reaction heat, due to the oxidation of the deposited carbon, while the endothermic behavior is due to a decomposition reaction.

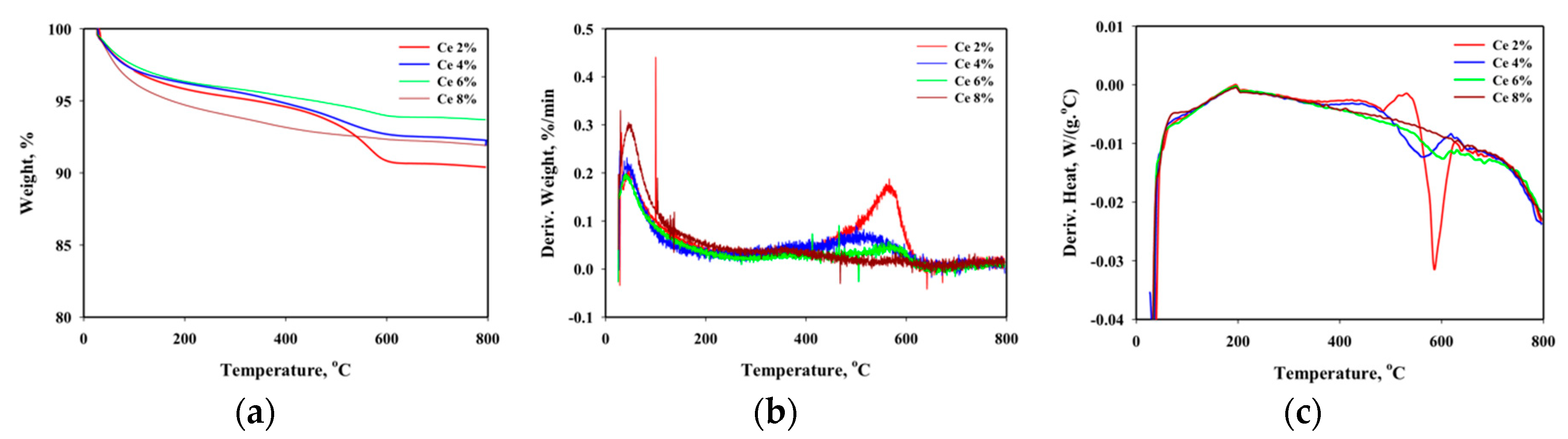

In addition, TPO tests of the catalysts prepared with varying CeO

2 content (2, 4, 6, and 8 wt %) on the Ni–Mg–Ce–Zr/Al

2O

3 catalyst for the purpose of carbon deposition inhibition were performed. As shown in

Figure 10, a slight weight decrease was observed at approximately 600 °C, and the degree of weight decrease was reduced as the amount of CeO

2 impregnated on the catalyst increased. These results indicate that CeO

2 used as a promoter in the auto-thermal reforming reaction does perform a carbon deposition inhibitory function. This may explain why other authors have applied auto-thermal reforming reactions for the reforming of liquid hydrocarbons. The results of the TPO test showed that the endothermic and exothermic behaviors at 600 °C were similar to those of the deposited carbon obtained through the steam reforming reaction.

4. Conclusions

In this study, SEM, XRD, and TPO analyses showed that carbon deposition behavior occurred over nickel-based catalysts containing CeO2 in both steam reforming and auto-thermal reforming of toluene. In toluene-reforming reactions, carbon deposition has been a serious problem. In our study, the steam reforming reaction of toluene produced a large amount of carbon deposition, but no carbon deposition was observed in the toluene auto-thermal reforming reaction. The significant amount of carbon deposition in the steam reforming reaction is attributed to the temperature drop of the catalyst bed due to a strong endothermic reaction. In the auto-thermal reforming reaction, the temperature of the catalyst bed also dropped; however, since the endothermic and exothermic reactions occur simultaneously, the temperature drop was less marked than that associated with the steam reforming reaction. Since carbon can be thermodynamically formed at a temperature below 600 °C, a significant temperature drop in the reforming reaction must be inhibited when a nickel-based catalyst is used. Many previous studies have used various catalytic promoters to inhibit carbon deposition, and it has been reported that such promoters can have a significant effect. In this study, it was confirmed that a CeO2 promoter can inhibit carbon deposition on the catalyst surface. However, it was concluded that the catalytic promotive activity of ceria inhibited the deposition of carbon more effectively in the auto-thermal reforming reaction than in the steam reforming reaction. Although carbon deposition can be prevented by adding catalytic promoters to catalysts, temperature maintenance inside the catalytic reactor is very important, because the formation of carbon cannot be prevented in the presence of a catalytic promoter when there is a significant and prolonged temperature drop in the reaction.