Active Power Control of Hydraulic Wind Turbines during Low Voltage Ride-Through (LVRT) Based on Hierarchical Control

Abstract

1. Introduction

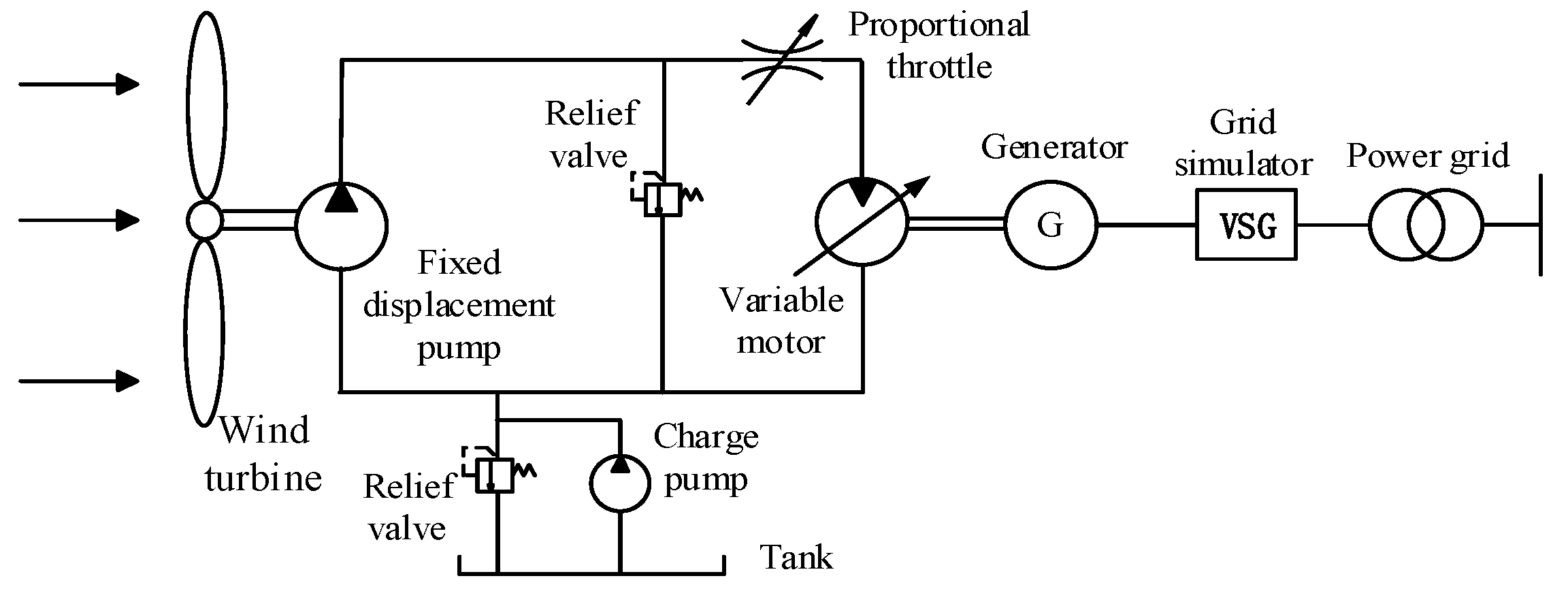

2. Mathematical Model of Hydraulic Wind Turbine

2.1. Working Principle of Hydraulic Wind Turbine

2.2. Wind Turbine Model

2.3. Pitching System Model

2.4. Hydraulic System Mathematical Model

- (1)

- Since the wind turbine is directly connected to the fixed-displacement pump, it is considered that the speed of the wind turbine is the same as the speed of the fixed-displacement pump. That is, the moment of inertia of the wind turbine is converted to the moment of inertia of the fixed-displacement pump.

- (2)

- The pipeline between the fixed-displacement pump and the variable hydraulic motor is short. Thus, the pressure loss in the pipeline is ignored.

- (3)

- The bulk modulus of the oil in the high- and low-pressure pipelines is constant, and the pressure is equal.

- (4)

- There is no pressure shock in the pipeline, the input signal of the proportional throttle valve is small, and no saturation occurs.

2.4.1. The Model of the Fixed-Displacement Pump

2.4.2. The Model of the Variable Hydraulic Motor

2.4.3. The Model of the Proportional Throttle Valve

2.4.4. Hydraulic Piping Model

2.4.5. Hydraulic System Overall Model

3. Research on LVRT Energy Regulation

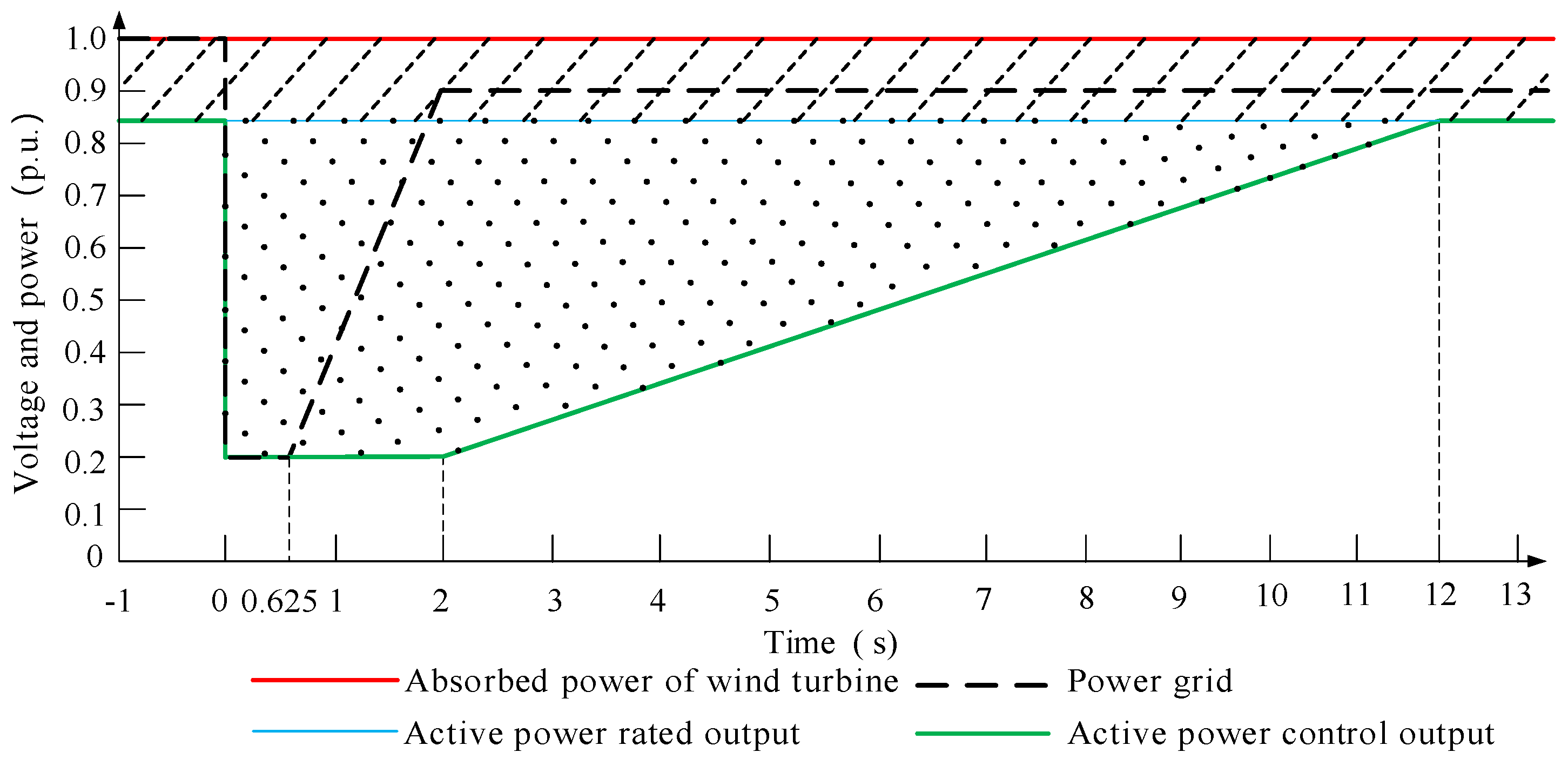

3.1. Analysis of LVRT Energy Transfer Mechanism

3.1.1. LVRT Residual Energy Generation Mechanism

3.1.2. Energy Transmission Law of LVRT

3.2. LVRT Energy Layered Control

3.2.1. Top-Level Control

3.2.2. Mid-Level Control

3.2.3. Underlying Control

3.3. Energy Stratification Control Law Planning

3.3.1. Selecting the Target of Optimization

3.3.2. Determining the Optimization Goal

3.3.3. Construction Constraints

4. Test and Simulation

4.1. Simulation Research on the Law of Residual Energy Generation of HWT

4.2. Simulation Study on HWT Energy Regulation

4.2.1. Simulation Study on Top-Level Control Effect of Pitching and Abandoning Wind Power

4.2.2. Simulation Study on Mid-Level Control Effect of Adjusting Variable Motor Swash Plate Angle

4.2.3. Simulation Study on Underlying Control Effect of Adjusting the Throttle Valve Opening

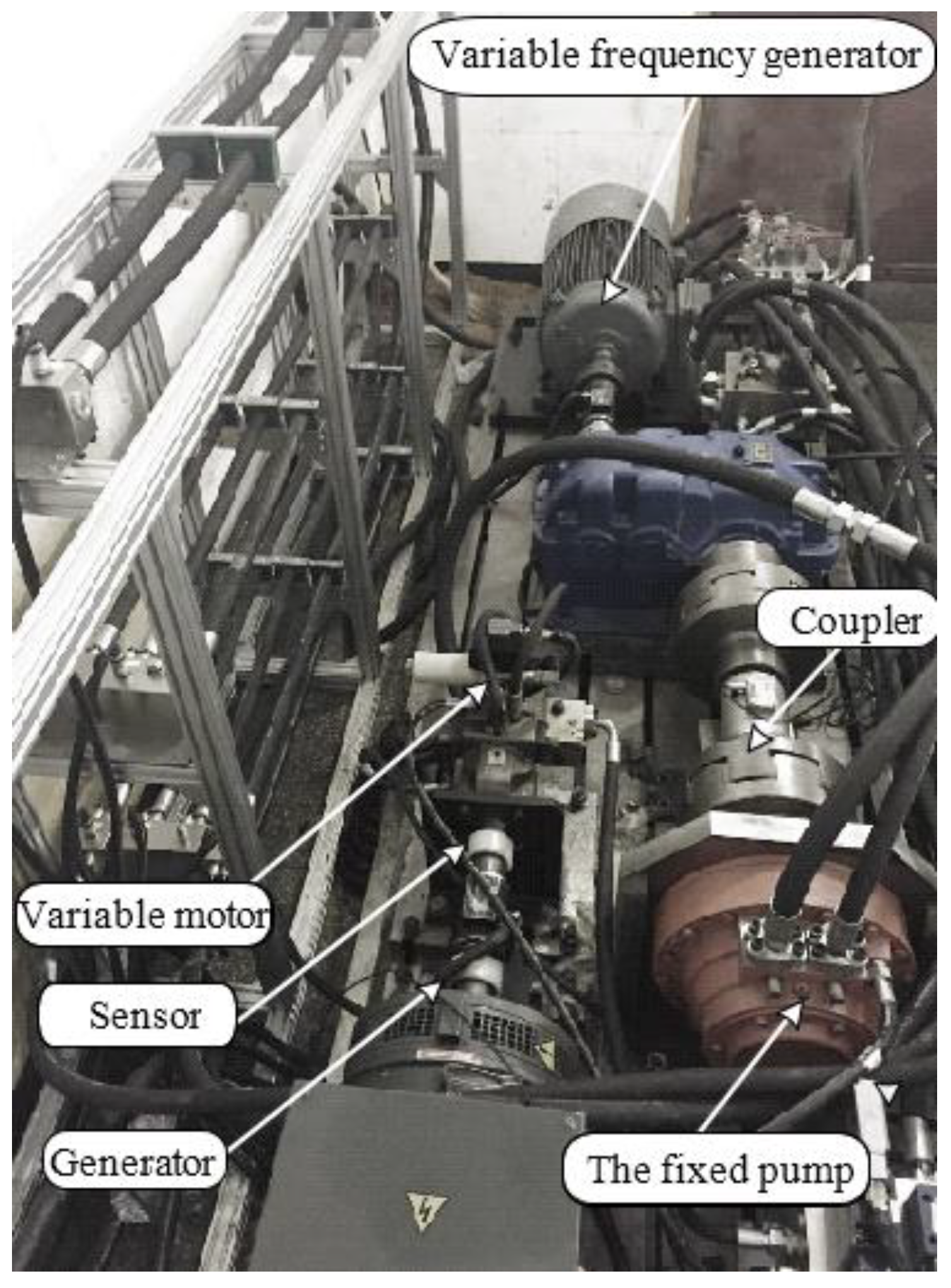

4.3. Experimental Research

4.3.1. Joint Simulation and Experiment of Three-Phase Voltage Drop of 20%

4.3.2. Joint Simulation and Experiment of Single-Phase Voltage Drop of 80%

4.3.3. Result

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- State Electricity Regulatory Commission. Technical Rule for Connecting Wind Farm to Power System: GB/T 19963-2011; Standards Press of China: Beijing, China, 2011.

- Zhang, J.; Ding, L.; Dai, C. Research of doubly-fed induction generator LVRT based on stator side new crowbar. Electr. Drive 2016, 7, 44–50. [Google Scholar]

- Sun, L.; Wang, Y.A. Comprehensive Control Strategy for Low Voltage Ride Through of Doubly-Fed Fan Based on Crowbar Series Capacitor. Grid Technol. 2018, 42, 2089–2095. [Google Scholar]

- Zhou, B.; Dong, S.; Liu, S.; Li, S. Optimization of Low Voltage Ride Through Capability of Doubly-Fed Fan Based on Rotor String Resistor Capacity. Electr. Meas. Instrum. 2018, 55, 108–115. [Google Scholar]

- Ye, Y.; Wang, Q.; Jiang, N.; Pu, C. Analysis of Low Voltage Ride Through Characteristics of Doubly-Fed Fan Based on DIgSILENT. J. Nanjing Norm. Univ. 2016, 16, 9–15. [Google Scholar]

- Jiang, H.; Li, T.; Wu, Y. Integrated low voltage ride-through strategy for doubly-fed wind turbines. High Volt. Technol. 2017, 43, 2062–2068. [Google Scholar]

- Zhou, S.; Wang, Q.; Lv, X.; Ni, Y.; Xu, M. Low Voltage Ride Through Control Strategy for Doubly-Fed Wind Turbines with Stator Crowbar Circuit Mode Switching. Power Syst. Prot. Control 2017, 45, 33–39. [Google Scholar]

- Jiang, H.; Fan, Z.; Chen, J.A. Low Voltage Ride Through Method for Dynamically Adjusting the Resistance of Rotor Bars. Autom. Electr. Power Syst. 2018, 42, 125–131. [Google Scholar]

- Wang, C.; Liu, T.; Xing, Y. Research on LVRT Ability of Double-fed Wind Farms and Its Coordination with Low Voltage Protection. Water Res. Power 2018, 36, 208–212. [Google Scholar]

- Yang, S.; Zhou, T.; Sun, D. A SCR crowbar commutated with power converter for DFIG-based wind turbines. Int. J. Electr. Power Energy Syst. 2016, 81, 87–103. [Google Scholar] [CrossRef]

- Ananth Duggirala, V.N.; Nagesh, K.G.V. Improved LVRT for grid connected DFIG using enhanced field oriented control technique with super capacitor as external energy storage system. Eng. Sci. Technol. Int. J. 2016, 19, 1742–1752. [Google Scholar] [CrossRef]

- Wang, Z. Research on Low Voltage Ride Through Control Method of Constant Frequency Doubly-Fed Wind Power Unit. Sci. Bull. 2018, 34, 189–192. [Google Scholar]

- Liu, Z.; Liu, C.; Li, G. Coordinated power control method for improving low voltage ride through capability of wind turbines with permanent magnet synchronous generators. Autom. Electr. Power Syst. 2015, 3, 23–29. [Google Scholar]

- Huang, H.; Qin, B.; Shi, M. Research on Low Voltage Ride Coordination Control of Direct Drive Permanent Magnet Wind Power System. Electr. Electr. 2018, 4, 10–13. [Google Scholar]

- Cheng, Z.; Lai, W.; Yan, G. Low Voltage Ride-through Scheme of the PMSG Wind Power System Based on Coordinated Instantaneous Active Power Control. Energies 2017, 7, 995. [Google Scholar] [CrossRef]

- Xu, L.; Lin, R.; Ding, L. Enhancing the LVRT Capability of PMSG-Based Wind Turbines Based on R-SFCL. Mater. Sci. Eng. Conf. Ser. 2018, 322, 072044. [Google Scholar] [CrossRef]

- Shen, M. Study on Key Technologies of Low Voltage Ride Through of Permanent Magnet Direct Drive Wind Turbine. Electr. Energy Effic. Manag. Technol. 2018, 12, 61–66. [Google Scholar]

- Cheng, Q.; Huang, W.; Cheng, Y. LVRT of permanent magnet wind generation based on two stage matrix converter and system stability analysis. Power Syst. Technol. 2016, 7, 2059–2066. [Google Scholar]

- Rajkumar, S.; Suganthi, S.T. A Hybrid Control Scheme for Fault Ride-Through Capability using Line-Side Converter and an Energy Storage System for PMSG Wind Turbine Systems. Int. Electr. Eng. J. 2014, 5, 1305–1312. [Google Scholar]

- He, A.; Hou, K.; Wang, X.; Jiang, Y.; Liu, J.; Lu, F.A. Low Voltage Ride Through Control Technology for Energy Storage Virtual Synchronous Generator under Asymmetric Conditions. Autom. Electr. Power Syst. 2018, 42, 122–127. [Google Scholar]

- Hu, W.; Wu, Z.; Dou, X.; Hu, M. Load virtual synchronous machine and its low voltage fault ride through control. Autom. Electr. Power Syst. 2018, 42, 100–107. [Google Scholar]

- Kim, K.H.; Jeung, Y.C.; Lee, D.C. LVRT Scheme of PMSG Wind Power Systems Based on Feedback Linearization. IEEE Trans. Power Electr. 2012, 27, 2376–2384. [Google Scholar] [CrossRef]

- Wang, J. Research on the low-voltage ride-through capability of wind synchronous generator with hydro-dynamically controlled gearbox. Electr. Drive Autom. 2016, 3, 1–8. [Google Scholar]

- Chapple, P.; Niss, M. A Method and System for Connecting a Wind Turbine System to an Electric Grid. EP2481915A1, 1 August 2012. [Google Scholar]

- Chen, G.; Ai, C.; Zhang, L. Low Voltage Operation Characteristics of Hydraulic Wind Turbine. Chin. Hydraul. Pneum. 2017, 7, 33–42. [Google Scholar]

- Ai, C.; Chen, L.; Kong, X.; Zhang, L.; Yan, G. Study on low-voltage traversing bivariate coordinated control of hydraulic wind turbines. Acta Energ. Sin. 2018, 39, 1408–1417. [Google Scholar]

- Yan, G. Research on Low Voltage Ride through of the Hydraulic Wind Turbine; Yanshan University: Qinhuangdao, China, 2015. [Google Scholar]

- Kong, X.; Ai, C.; Yan, G. Research on control method of low voltage ride through for hydraulic wind turbine. China Mech. Eng. 2014, 25, 2137–2143. [Google Scholar]

- Thomsen, K.E.; Dahlhaug, O.G.; Niss, M.O.K. Technological Advances in Hydraulic Drive Trains for Wind Turbines. Energy Procedia 2012, 24, 76–82. [Google Scholar] [CrossRef]

- Kong, X.; Ai, C.; Wang, J. A summary on the control system of hydrostatic drive train for wind turbines. Chin. Hydraul. Pneum. 2013, 1, 1–7. [Google Scholar]

- Heier, S. Grid Integration of Wind Energy Convertion Systems, 2nd ed.; Kassel University: Kassel, Germany, 2002; pp. 43–44. [Google Scholar]

- Borowy, B.S.; Salameh, Z.M. Dynamic Response of a Stand-Alone Wind Energy Conversion System with Battery Energy Storage to a Wind Gust. IEEE Trans. Energy Convers. 1997, 12, 73–78. [Google Scholar] [CrossRef]

| Name | Numerical Value |

|---|---|

| Variable motor displacement gradient | 40 |

| Variable motor viscous damping coefficient | 0.0345 |

| Variable motor and generator converted into total inertia | 0.462 |

| Oil volume elastic modulus | 743 × 106 |

| Proportional throttle valve flow gain factor | 1.166 × 10−4 |

| Proportional throttle flow-pressure system | 4 × 10−12 |

| Quantitative pump viscous damping coefficient | 0.4 |

| Quantitative pump displacement | 63 |

| Quantitative pump and wind turbine | 400 |

| Quantitative pump leakage coefficient | 1.6 × 10−11 |

| Variable motor leakage coefficient | 1.2 × 10−11 |

| Three-phase rated power | 313000 |

| Rated line voltage RMS | 400 |

| Rated frequency | 50 |

| Generator stator resistance | 0.04186 |

| Generator excitation winding resistance | 0.02306 |

| Excitation leakage reactance | 0.1381 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ai, C.; Zhou, G.; Wang, Y.; Gao, W.; Kong, X. Active Power Control of Hydraulic Wind Turbines during Low Voltage Ride-Through (LVRT) Based on Hierarchical Control. Energies 2019, 12, 1224. https://doi.org/10.3390/en12071224

Ai C, Zhou G, Wang Y, Gao W, Kong X. Active Power Control of Hydraulic Wind Turbines during Low Voltage Ride-Through (LVRT) Based on Hierarchical Control. Energies. 2019; 12(7):1224. https://doi.org/10.3390/en12071224

Chicago/Turabian StyleAi, Chao, Guangling Zhou, Yalun Wang, Wei Gao, and Xiangdong Kong. 2019. "Active Power Control of Hydraulic Wind Turbines during Low Voltage Ride-Through (LVRT) Based on Hierarchical Control" Energies 12, no. 7: 1224. https://doi.org/10.3390/en12071224

APA StyleAi, C., Zhou, G., Wang, Y., Gao, W., & Kong, X. (2019). Active Power Control of Hydraulic Wind Turbines during Low Voltage Ride-Through (LVRT) Based on Hierarchical Control. Energies, 12(7), 1224. https://doi.org/10.3390/en12071224