1. Introduction

With the development of hybrid microgrid, battery energy storage systems, and uninterrupted power supplies, bidirectional DC-DC converters have been widely used in bidirectional power conversion applications [

1,

2,

3,

4,

5]. Thereinto, dual active bridge (DAB) DC-DC converter gains more and more attention due to the advantages of high power density, soft-switching ability, bidirectional power-transfer capability, and high efficiency [

6,

7,

8,

9].

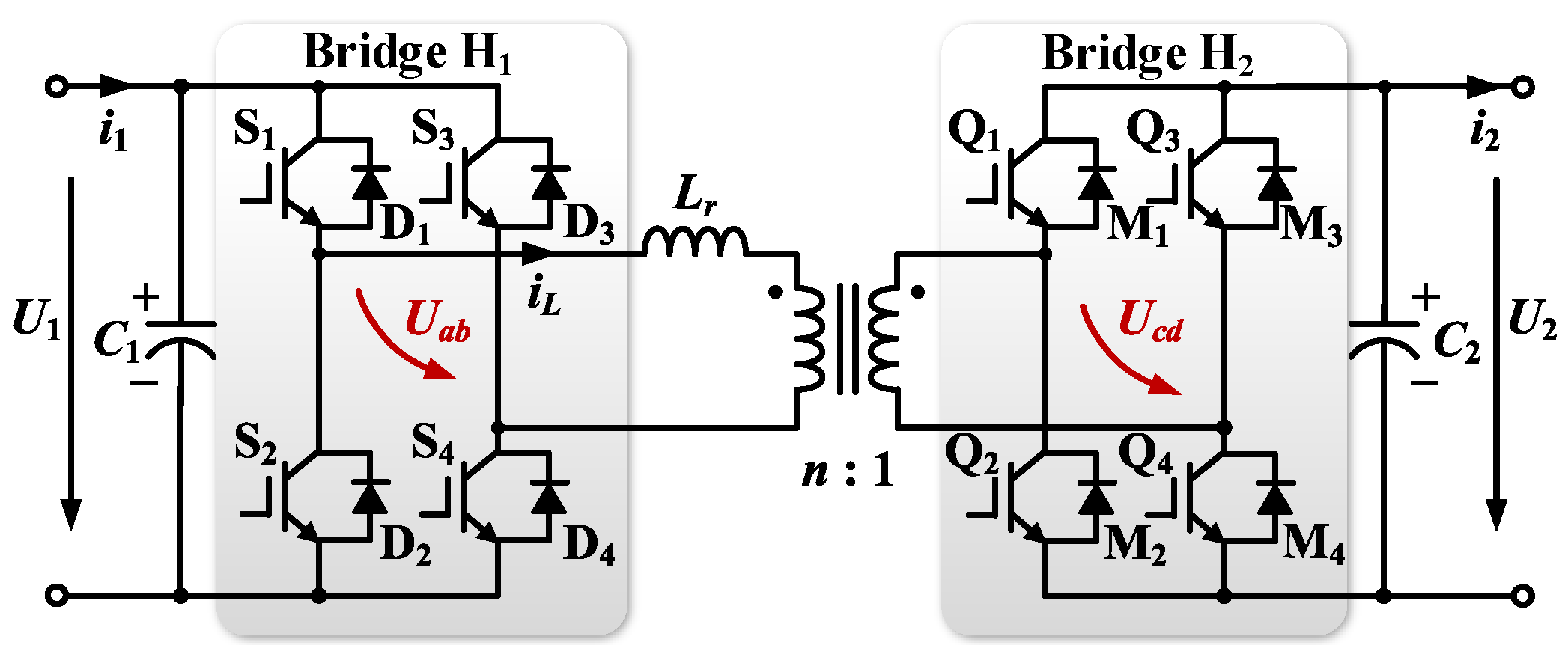

Figure 1 depicts the typical topology of DAB converter, which is constructed by two full bridges and a high-frequency isolated transformer with the turns ratio

n:1.

and

are ac output voltages of two bridges H

and H

, respectively.

is the sum of the transformer leakage inductance and the auxiliary inductor, and

is the current of

.

The basic control scheme of DAB converter is single-phase-shift (SPS) scheme, in which the direction and magnitude of the transmission power are merely determined by the outer phase-shift ratio between H

and H

. However, when the input and output voltages of the isolated transformer are mismatched, the converter will suffer from limited soft-switching range and high current stress, thus the efficiency will degrade significantly [

10]. To improve the performance of the converter, enhanced-phase-shift (EPS) scheme, double-phase-shift (DPS) scheme and triple-phase-shift (TPS) scheme are proposed, which can increase the control freedom by adding inner phase-shift ratios inside H

and H

. Compared with other phase-shift schemes, TPS scheme facilitates the most degrees of control freedom, which controls the duty ratios of H

and H

by two extra inner phase-shift ratios individually. Therefore, TPS control has become the most popular phase-shift control scheme of DAB converter in current research [

11,

12].

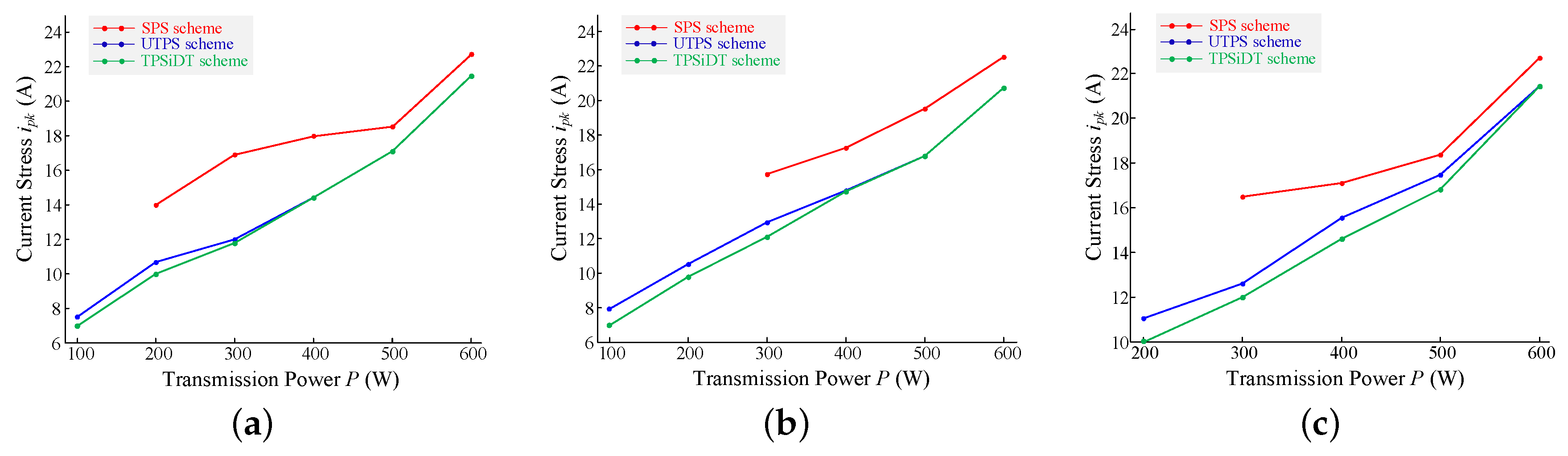

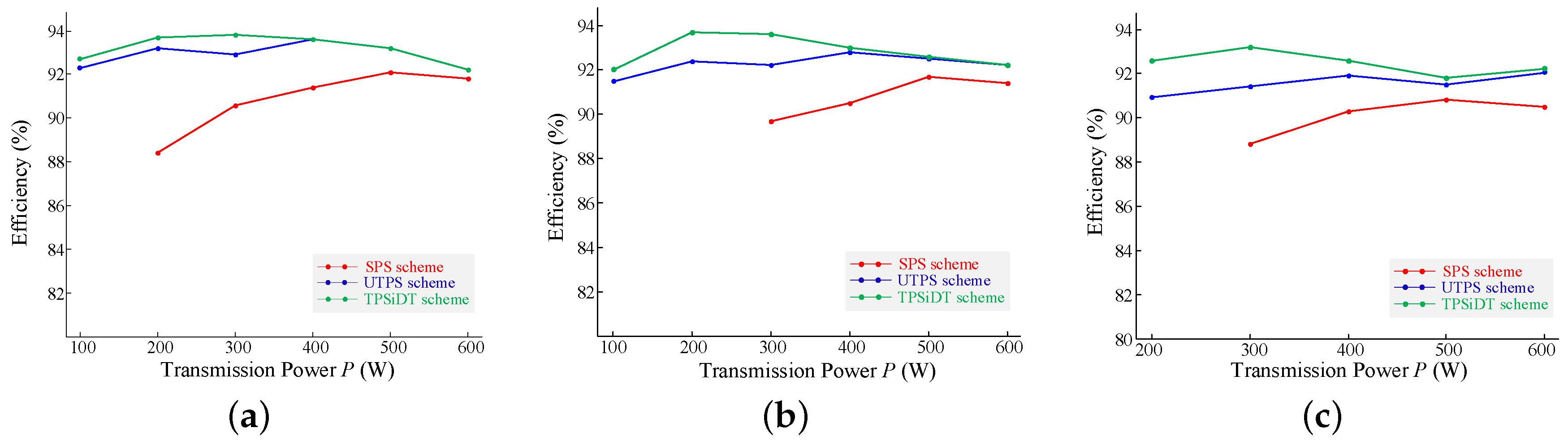

Numerous modulation strategies have been proposed to improve the performance of DAB converter. These strategies mainly focus on minimizing current stress or root-mean-square (RMS) current [

12,

13], reducing backflow power [

14,

15], and broadening soft-switching range [

16,

17]. An optimal modulation scheme for minimizing the current stress of DAB converter under TPS control is proposed in [

13]. Based on the relationship among the phase-shift ratios of the optimization algorithm, the optimal scheme can be realized without additional load-current sensor, and the complexity of the control system can be decreased. A unified triple-phase-shift (UTPS) scheme developed in [

11] operates the converter in minimum-current-stress state while satisfying soft-switching constraints over the whole operation range. Therefore, the conducting losses, as well as the switching losses can be reduced, and the system efficiency can be improved. Unfortunately, all modulation schemes mentioned before fail to consider the existence of dead time, which is necessary to guarantee the system safety in practical applications.

To avoid shoot-through phenomenon and guarantee the reliability of the converter, dead time is necessary to be inserted between the interlocked switches in the same bridge. In traditional unidirectional DC-DC converter, the dead-time effect is usually ignored due to the limited dead-time ratio and low power rating. However, in high-power high-switching-frequency DAB converter, the dead-time ratio will be relatively larger, and the switching characterization, as well as the transmission power model, will be affected by dead time apparently [

18,

19]. The external characteristics caused by dead time are analyzed in detail under SPS and DPS control in [

20,

21], including voltage polarity reversal, voltage sag, duty-cycle abnormity, etc. Due to the voltage distortions, the ideal transmission power models in traditional schemes will be inaccurate, and have apparent deviation with the actual power models. The direct impact of the inaccurate power model is the phase-shift errors, which are defined as the differences between the phase-shift ratios calculated by the power model and the actual values to realize the required transmission power [

18]. Various problems will result from phase-shift errors, such as output voltage offset, soft-switching failure, optimal scheme failure, etc. However, in previous work, researchers have paid more attention to the external characteristics of dead-time effect, and the phase-shift errors effect is seldom studied comprehensively. Actually, these problems will affect the accuracy of the traditional optimal schemes, and even invalidate the modulation schemes. Therefore, the performance of DAB converter will be degraded significantly.

In traditional inverters, dead-time compensation is a prevalent measure to deal with the voltage distortions and avoid the phase-shift errors. However, in DAB converter, the polarity of the current

is changeable during the dead time, which brings challenges for detecting the current direction. Therefore, dead-time compensation is rather difficult to be applied in DAB converter [

18]. To overcome the drawbacks of phase-shift errors caused by dead time, novel accurate power models incorporating dead time are developed in some studies. The authors of [

20] focused on building a comprehensive transmission power model with dead-time effect under all voltage conversion ratio. In [

22], a novel power model is developed over a short time scale incorporating dead time and semiconductor voltage loss. The transmission power and switching characteristics are provided in [

19] to describe the dead-time effect in three-phase DAB converter. These accurate power models provide approaches for accurate power flow computation to avoid phase-shift errors. However, these previous studies remain in building the accurate power models, and further work, such as modulation scheme incorporating dead time is seldom studied. Based on the power model proposed in [

20], an adaptive-dead-time scheme is developed to minimize the current stress in [

23]. However, the minimum safe value of dead time is not considered, making the converter insecure in practical operation. Note that all the accurate transmission power models mentioned above are merely based on SPS control, and no modulation scheme incorporating dead time under TPS control is found at present.

In view of the study situation mentioned above, this paper proposes an optimal TPS incorporating dead time (TPSiDT) scheme for DAB converter. Due to the accurate power model proposed in this paper, the phase-shift errors can be avoided, and the converter can operate in minimum-current-stress and soft-switching state in practical applications. The rest of this paper is organized as follows.

Section 2 analyzes the problems caused by phase-shift errors in detail. In

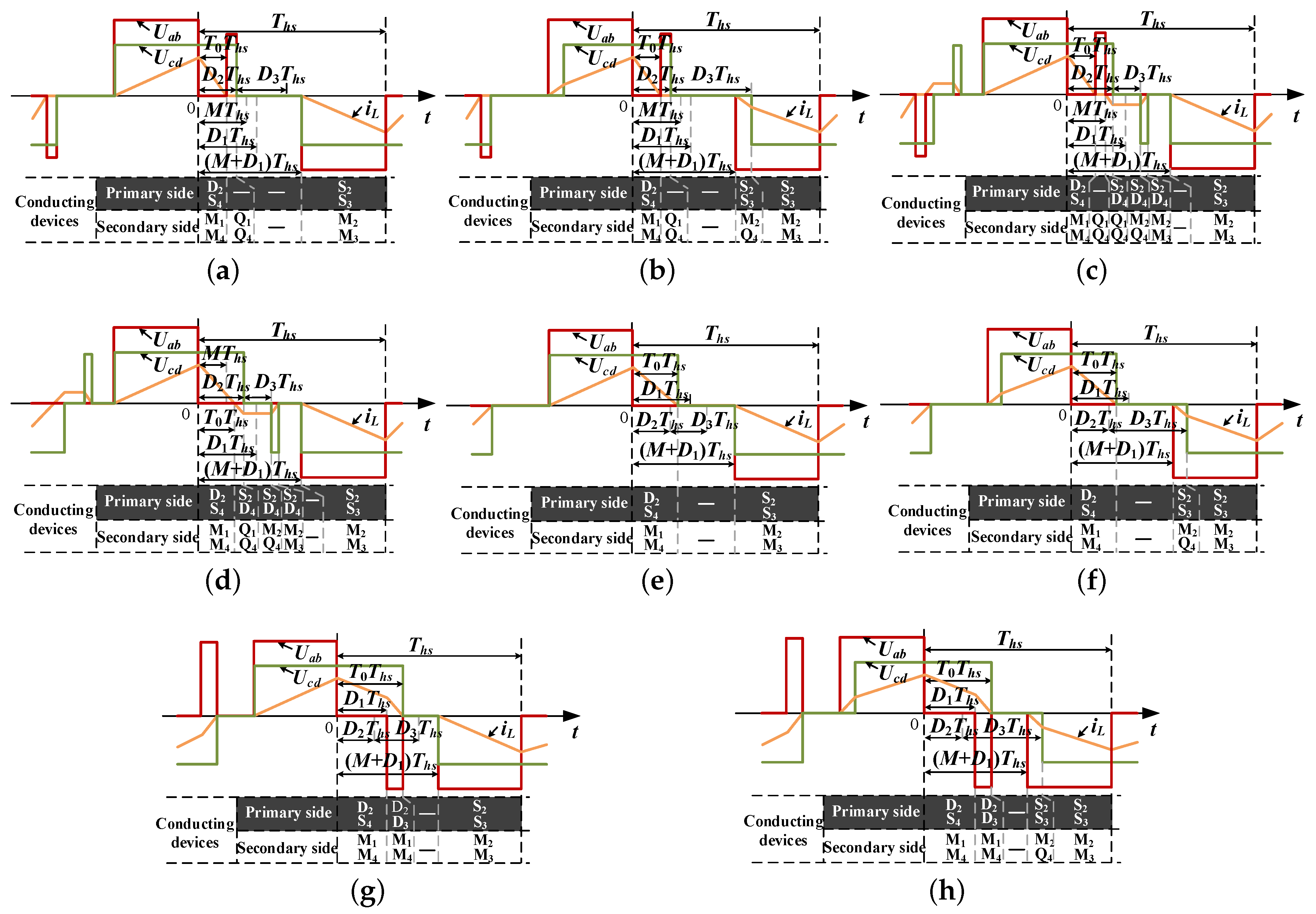

Section 3, thirteen operating modes are compartmentalized under soft-switching constraints, and then, the accurate transmission power model and current stress model incorporating dead time are built.

Section 4 presents the proposed TPSiDT scheme obtained by using Lagrange multiplier method (LMM) and Genetic Algorithm (GA). In

Section 5, the accuracy of the power model and the effectiveness of TPSiDT scheme are verified by the experimental results. The conclusion is drawn in

Section 6.

2. Phase-Shift Errors Effect of DAB Converter

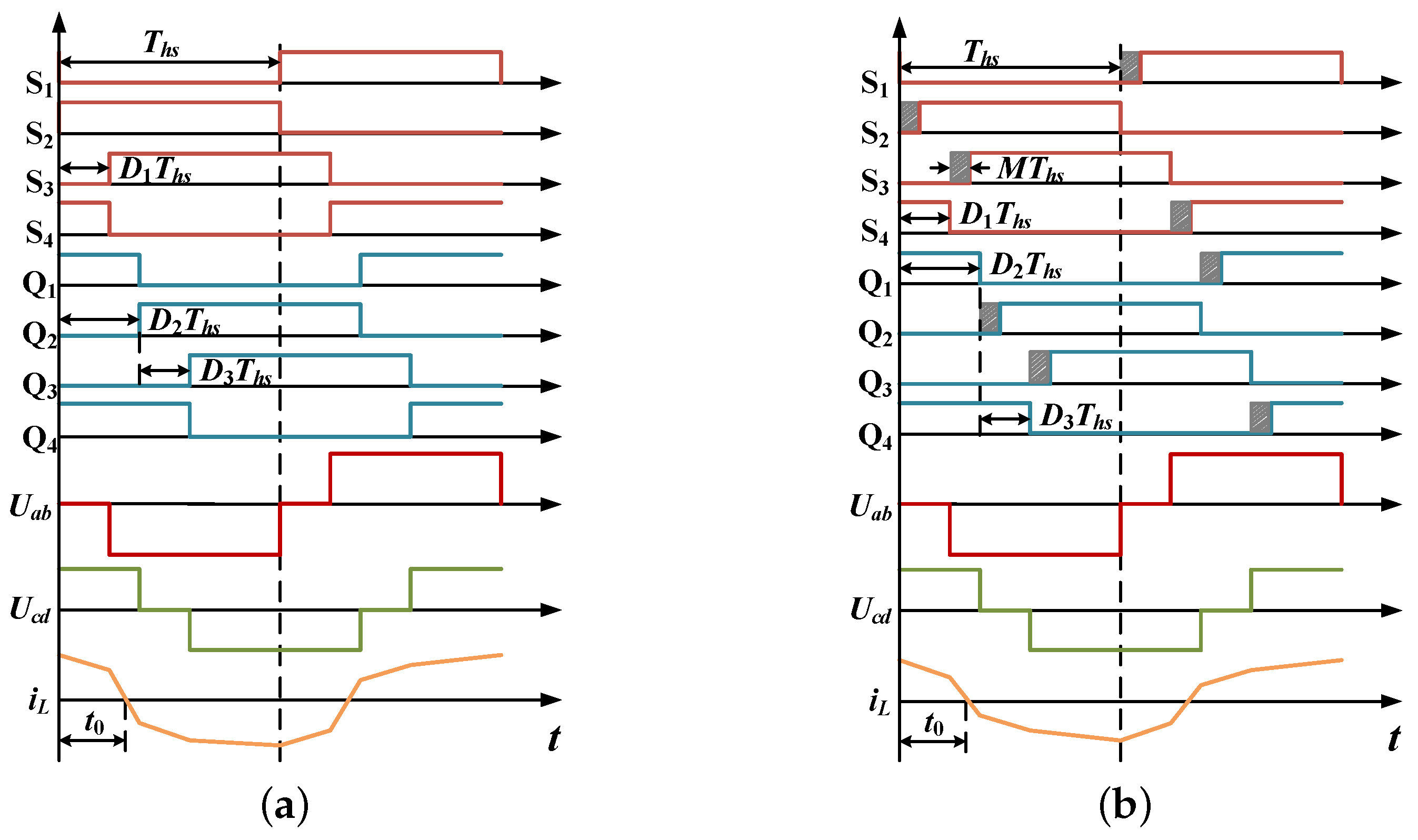

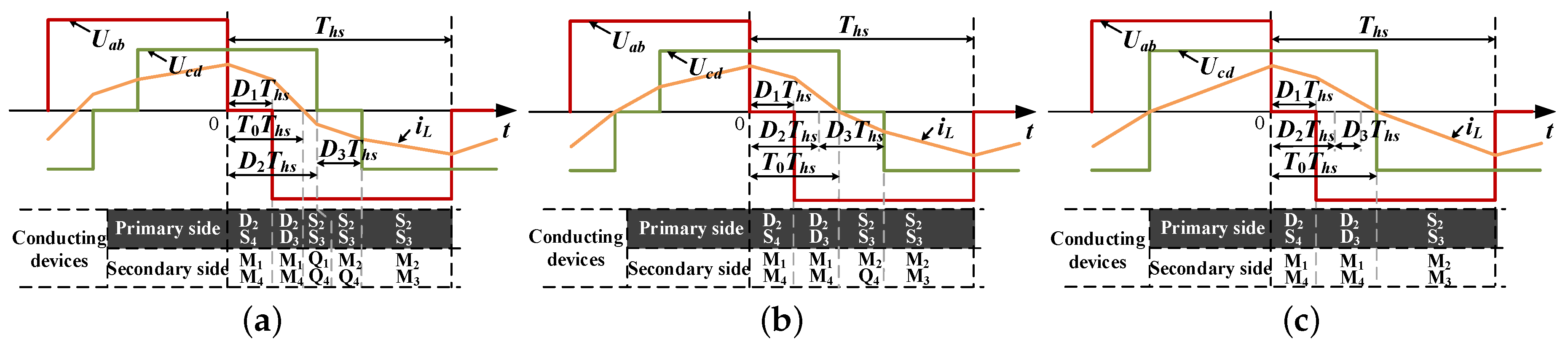

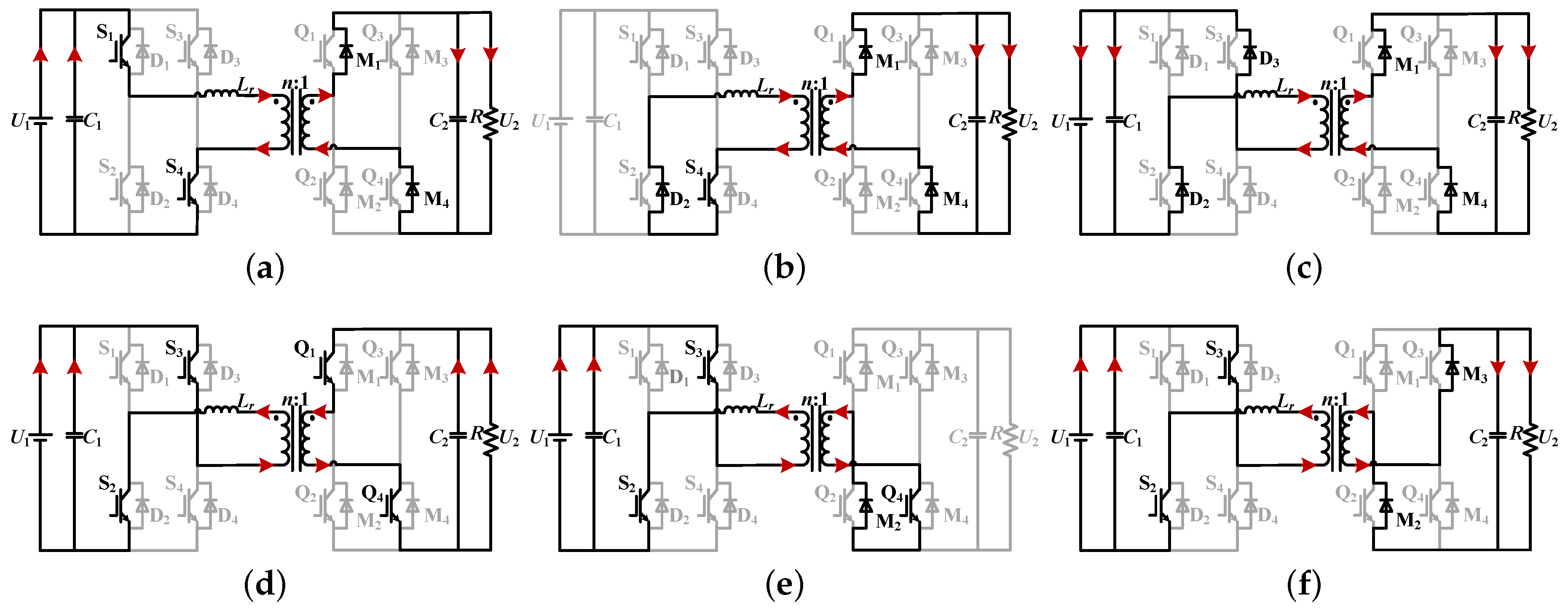

Figure 2 depicts the typical operating waveforms of DAB converter under ideal TPS control and actual TPS control, respectively. The ideal TPS control takes no account of dead time, and the magnitude of the power flow is determined by three phase-shift ratios.

is the inner phase-shift ratio between S

and Q

.

and

are outer phase-shift ratios between S

and S

, and Q

and Q

, respectively. The value ranges of three phase-shift ratios are 0

,

, amd

1. However, in actual TPS control scheme, the dead-time ratio

M becomes another factor to affect the transmission power of DAB converter, which presents the equivalent duty ratio of dead time in a half switching cycle. In

Figure 2,

presents a half switching cycle,

presents the zero-crossing point of

, and

presents the zero-crossing-point ratio of

. For convenience, the initial time of turn-off signal for S

is defined as beginning of the switching cycle.

The average transmission power of DAB converter can be calculated as

which indicates that the transmission power model is relevant to the waveforms of

and

directly. Therefore, the voltage distortions caused by dead time will affect the traditional transmission power model and make it inaccurate. The inaccurate transmission power model will result in phase-shift errors, which will mislead the power calculation and design of DAB converter. The detailed analysis of the problems caused by phase-shift errors are described as follows.

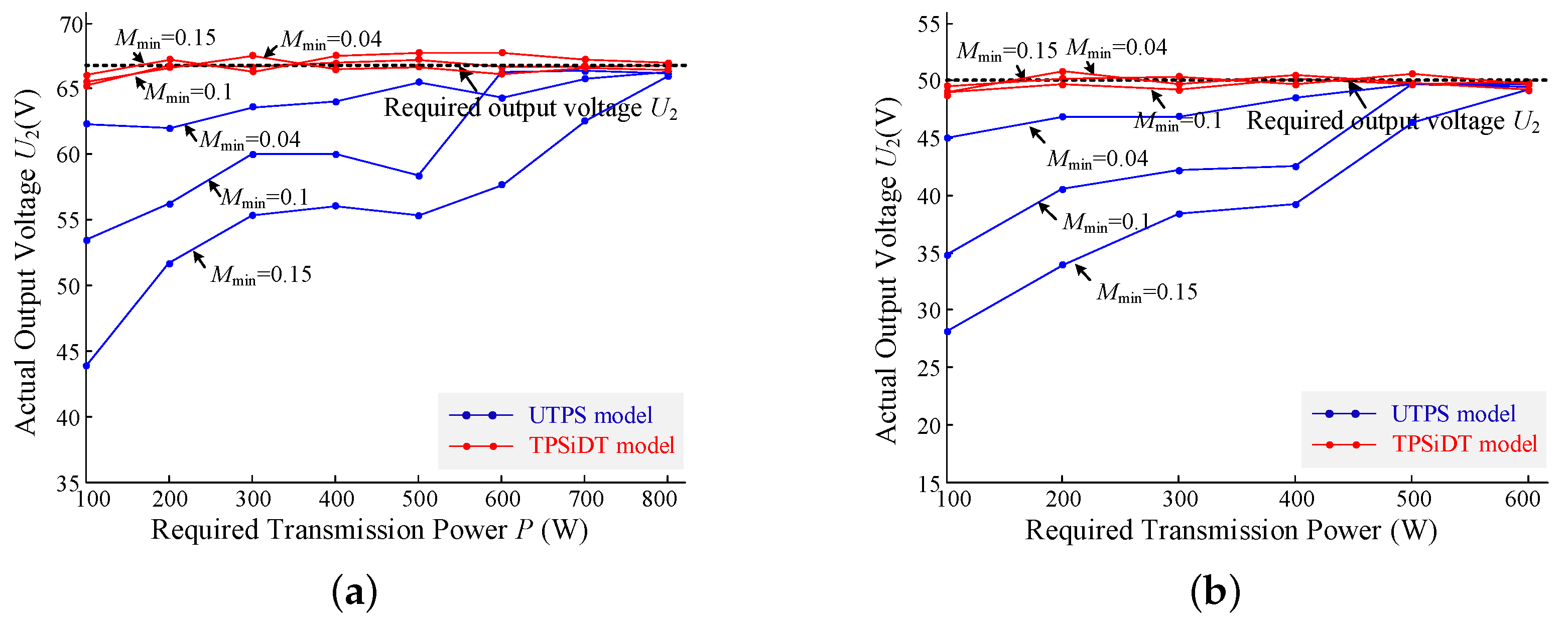

(a) Output voltage offset:

Figure 3 shows the transient waveforms switching from ideal TPS control to actual TPS control in open-loop system, in which the input voltage is 100 V, the transmission power is 125 W, the transformer turns ratio is 1, and the required output voltage is set to 50 V. From the waveform of the output voltage as shown in

Figure 3a, it can be seen that in ideal operation, the dead-time ratio

M is set to zero, and the output voltage

is 50 V, which is identical with the required value. However, when

M is set to 0.1 at 0.2 s, the output voltage falls to 37.5 V, and there is a significant offset between the two voltages. The corresponding waveform of the inductor current is shown in

Figure 3b, in which the current decreases obviously at the switching point. Thus, the transmission power will decrease when considering the dead time, which coincides with

Figure 3a. It indicates that, in practical operation, the theoretical phase-shift ratios calculated by ideal power model cannot realize the required transmission power.

(b) Soft-switching failure: In practical applications, the converter generally operates in closed-loop schemes to guarantee the system stability. For instance, in the UTPS scheme proposed in [

11],

and

are calculated by the optimization algorithm, and

is regulated by PI controller to obtain the required transmission power. To compensate the output voltage offset caused by phase-shift errors, the outer phase shift regulated by PI controller will be significantly different from the theoretical value. Therefore, soft-switching constraints of DAB converter may not be satisfied in practical operation.

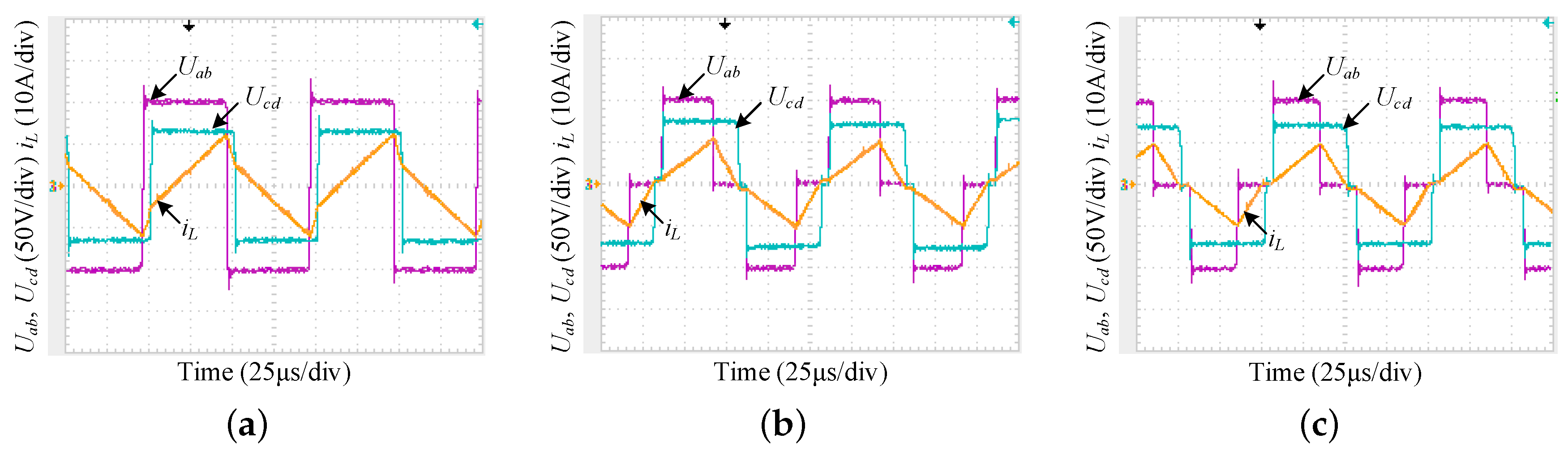

Figure 4 shows the ZVS failure phenomenon under UTPS scheme in some cases.

Figure 4a,b shows the ideal waveforms and actual waveforms, respectively. It can be seen that, compared with the ideal waveforms, the instantaneous value of

is negative at the moment S

turns on. It indicates that part of the switches of primary side will operate in hard-switching (HS) state. That is to say, phase-shift errors invalidate the soft-switching operation proposed in UTPS scheme.

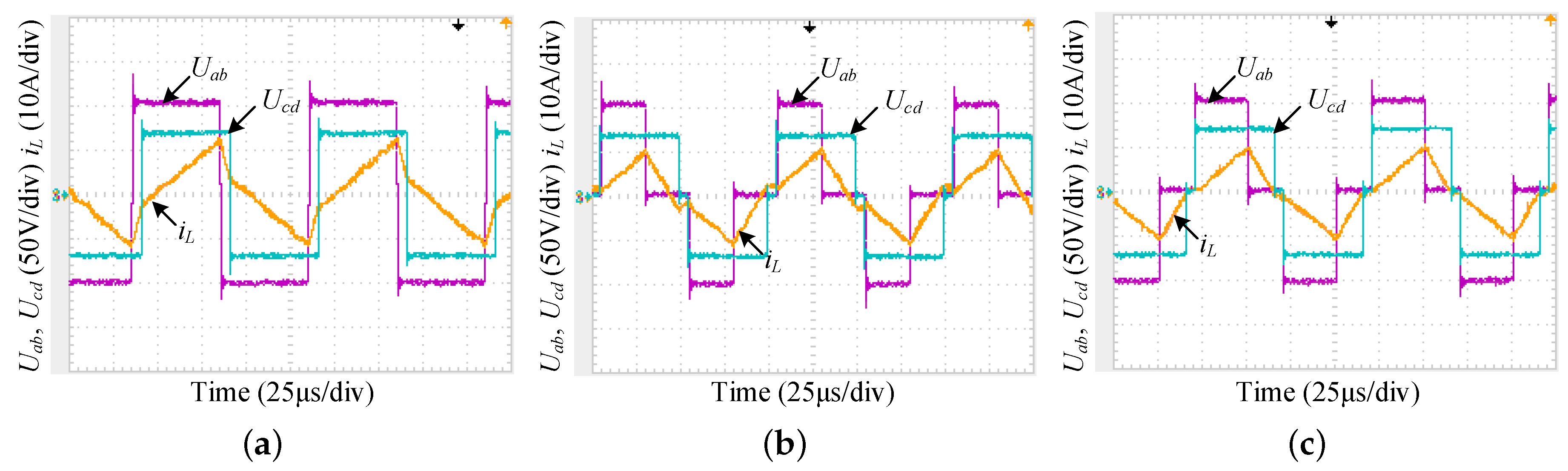

(c) Optimal scheme failure: Similar to the soft-switching failure analysis, due to the regulated phase shifts in closed-loop system, the optimization algorithm for the performance indexes, such as current stress, backflow power, etc., will be invalid.

Figure 5a gives the actual waveforms of DAB converter in UTPS scheme, in which the transmission power is 125 W, and the dead-time ratio is 0.1. It can be seen that the actual current stress is 8.8 A under the phase shifts (

and

) calculated by UTPS scheme. However, with the same required transmission power and dead time, the current stress can be reduced to 7.55 A with

and

, as shown in

Figure 5b. It indicates that the current stress cannot be minimized under the UTPS scheme when taking account of dead time, and the optimal solutions calculated by the ideal power model are not applicable in practical operation.

Due to the problems caused by phase-shift errors, the effectiveness of the traditional optimal schemes cannot be guaranteed in practical applications. As a result, the switching losses and conducting losses will increase, which degrades the performance of DAB converter significantly. From the previous analysis, it can be seen that the fundamental cause of phase-shift errors is the inaccurate power model. Thus, the following section will build an accurate transmission power model incorporating dead time to overcome the drawbacks of phase-shift errors.

4. TPSiDT Scheme of DAB Converter

From Equations (13) and (16), it can be seen that the dead-time ratio M affects the transmission power and current stress directly. For guaranteeing the optimality of the proposed algorithm, M is used as another control variable to optimize the system together with the three phase-shift ratios. However, to avoid shoot-through phenomenon, M needs to be larger than a minimum safe value. In this paper, is defined as the safe dead-time ratio, which is mainly determined by the turn-on and turn-off times of the power switches. Actually, is also the practical value of engineering applications. Therefore, the range of the dead-time ratio is 1.

Naturally, various operating points (

,

,

, and

M) can realize a certain required transmission power. Thus, the minimum-current-stress problem is described as finding the optimal point (

,

,

, and

) that minimize the current stress under the required transmission power and voltage conversion ratio

k. The standard form of the optimization problem can be described as

where

= (

,

,

,

M), and

is the required transmission power.

is the assemblage of the mode-operational constraints of each sub mode.

LMM is a general optimization method to obtain the analytic solutions, which can be used for simplifying the design of the control system. The standard form of LMM can be described as

where

E (

,

) is the Lagrangian function,

is the Lagrangian Multiplier, and

= (

,

,

,

) expresses the optimal solution. The Lagrangian function of M

can be expressed as

The equations of LMM in M

can be derived as

From Equation (

20),

and

can be derived with an expression of

as

According to Equations (13) and (21), the phase-shift ratio

can be expressed with respect to

and

k, and the optimization algorithm of M

can be obtained as

To meet the mode-operational constraints of M

, the transmission power range can be deduced as

In addition, According to Equations (16) and (22), the minimum current stress

with respect to

and

k can be derived as

With the same analysis, the optimal analytic solutions, the power range and the expressions of

of other modes obtained by LMM can be obtained, as shown in

Table 2. It should be noted that, in other sub modes, the expressions of

,

,

and

with respect to

can hardly be obtained by LMM. For instance, in M

and M

, the equations of LMM are as follows:

It can be seen from Equation (

25) that there are merely two effective equations, and the relationship among

,

,

and

M can be merely derived as

, thus, the expressions with respect to

of these two modes cannot be obtained by LMM, neither.

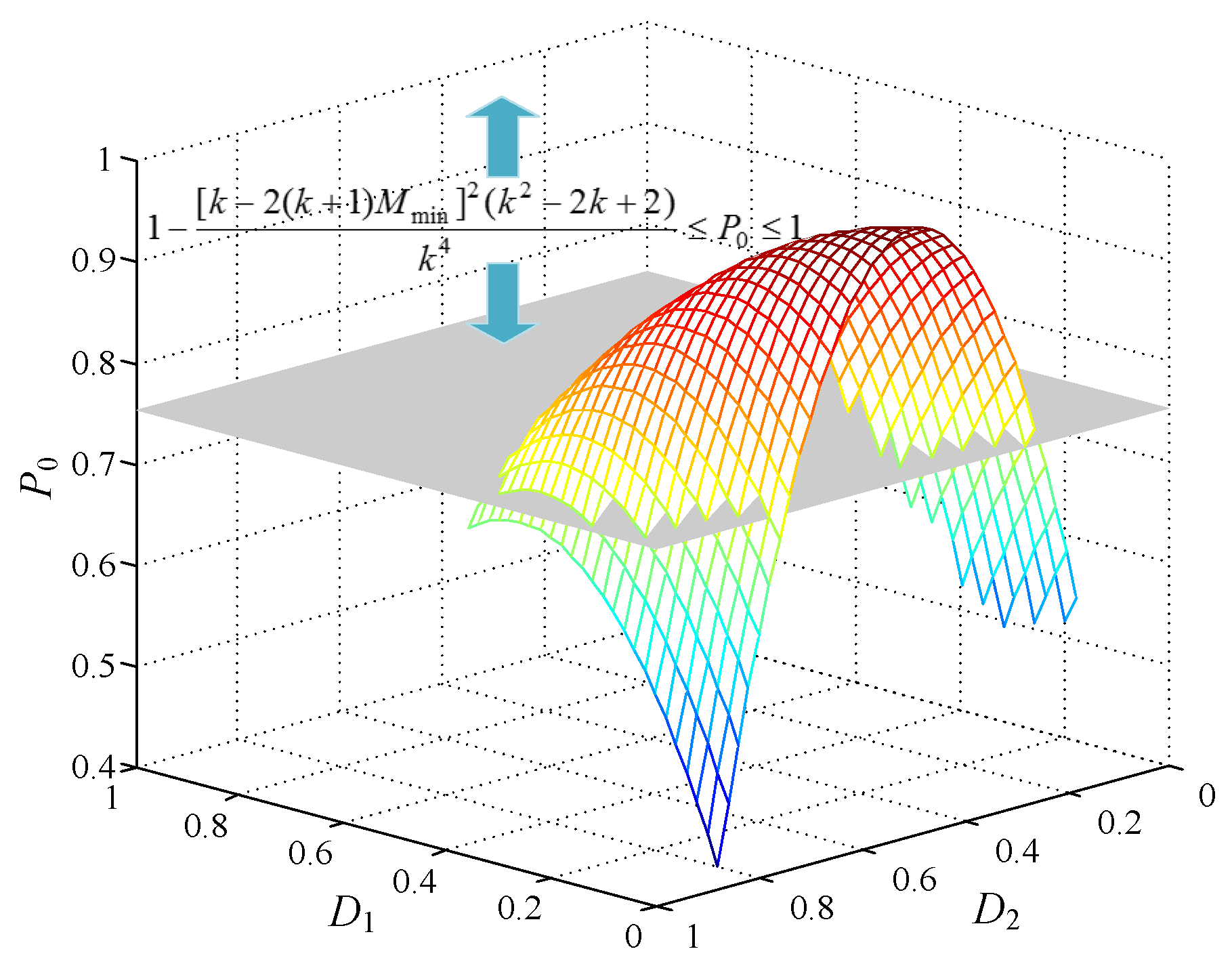

In addition, the power ranges that LMM can be used may be narrower than the whole feasible transmission power range of the sub modes. For instance,

Figure 10 gives the feasible power range of M

, in which the gray plane describes the boundary value of Equation (

23). By using LMM, the optimal solutions is effective in the power range, as shown in Equation (

23). However, from

Figure 10, it can be seen that the whole feasible region is wider than Equation (

23). Thus, LMM method can only obtain the optimal solutions in partial feasible region. Therefore, by using LMM, the control system can be simplified due to the analytic solutions; however, it cannot guarantee the comprehensiveness of the optimal solutions. In this way, GA is used to compensate the drawbacks of LMM, which can obtain the numerical solutions over the full feasible regions, and the numerical table needs to be generated in practical applications. For guaranteeing the simplicity together with the comprehensiveness of the proposed scheme, the two optimization methods are combined to solve the optimization problem in this paper.

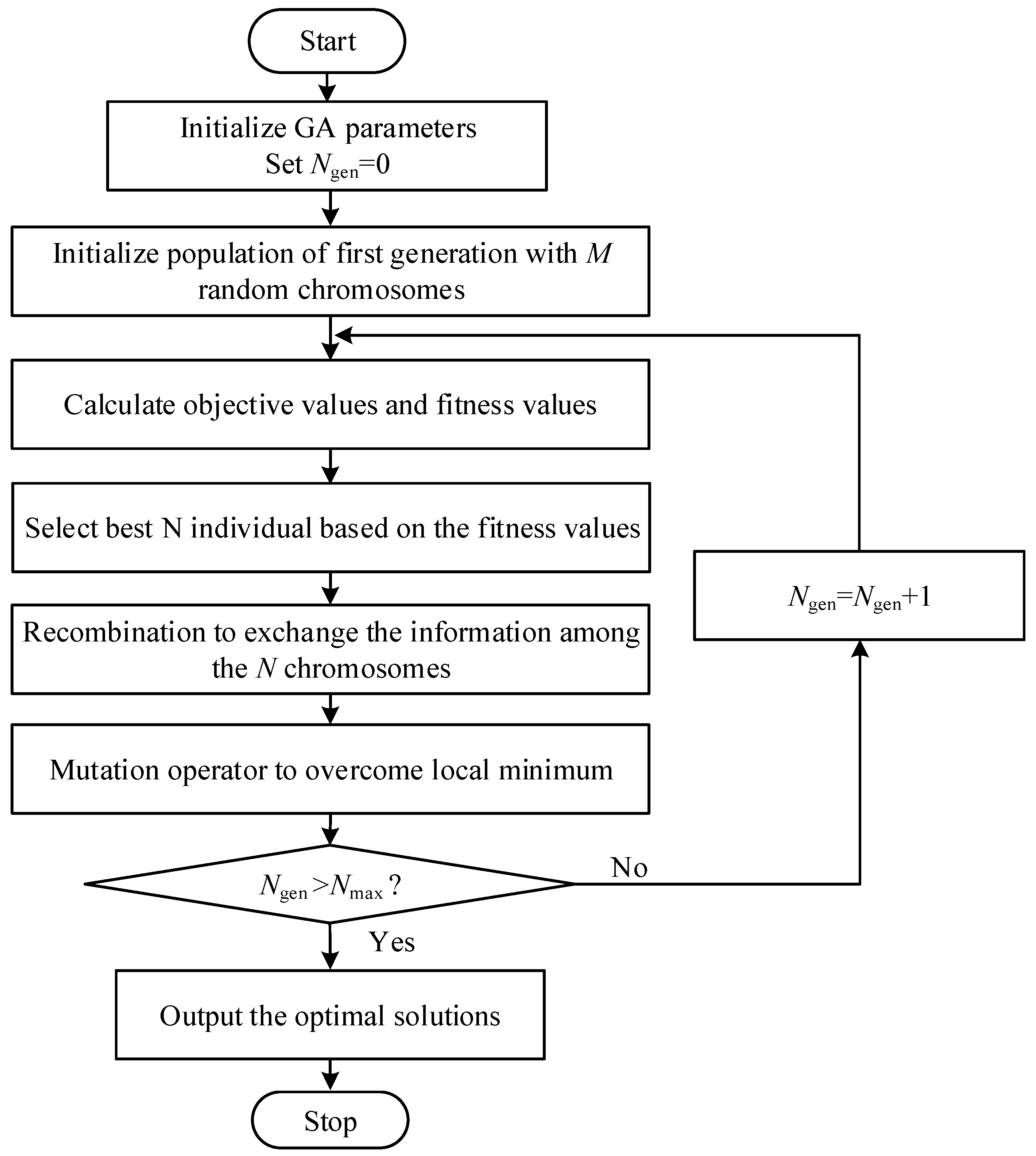

GA is a popular global optimization method due to the advantages of better robustness and parallel characteristics [

24]. For the optimization problem, as shown in Equation (

17), the GA procedure for acquiring the optimal solutions is shown in

Figure 11, in which

is the iteration number, and

is the maximum iteration number. The optimization procedure is operated in the MATLAB R2014a/Optimization Tool, where the current stress model is the fitness function, the reference transmission power and operational-mode constraints are the various constraints. The main parameters of GA such as initial population size and mutation probability are also set in the Optimization Tool.

The relation curves of the minimum current stress

in each mode with respect to

and

k by GA are shown in

Figure 12. It should be noted that the feasible power range of M

is too narrow to be considered. In

Figure 12, the boundary values of the transmission power obtained by

Table 2 are expressed by the dotted lines, which are defined as

However, the boundary values in M

are not marked in

Figure 12. That is because, when

k is close to 1, the transmission power range of M

is pretty narrow, and, when

k increases, the power range broadens gradually, but the minimum current stress

is not the least compared with that of other modes. Therefore, M

can be ignored in the optimal scheme. In

Figure 12, it can be seen that the power gap between

and

becomes wider and wider along with the increase of the safe dead-time ratio

. When

approaches to 0, the power gap between

and

will disappear, and the optimal scheme will be identical with the traditional ideal scheme. Some information for acquiring the global optimization algorithm can be extracted from

Figure 12, which is summarized as follows.

(a) At low power level (

): In

Figure 12, it can be seen that the feasible power range of M

is pretty narrow, especially when

is relatively large. The values of the minimum current stress of M

are not less than those of the sub modes under M

. In addition, the optimal solutions of M

cannot expressed by analytic solutions, which will bring more inconvenience in practical applications. Therefore, although M

has the ability to make all of the power switches operate at ZVS, it is more meaningful to choose the sub modes under M

during this power range. As can be seen in

Table 2, the minimum current stress

of M

, M

, M

, M

, M

and M

is identical, and the value is less than that of any other mode. Thus, the analytic solutions of M

, M

, M

, M

, M

and M

by LMM are the global optimization algorithm during

. Compared with other modes, the voltage distortions will not emerge in M

, which can be seen in the waveforms of

Figure 8e. Therefore, the electromagnetic interference (EMI) and other issues will not be brought by frequent variation of voltage. In addition, as is seen in

Table 2, in the optimization algorithm of M

, the dead-time ratio

M can be set to

constantly at low power level, which reduces the complexity of the control system. Therefore, it is meaningful to choose the optimal solutions of M

as the optimization algorithm at low power level. Under the operational-mode constraints of M

, there are various choices of the expressions of

and

. Assuming that

and

, the mode-operational constraints can be easily satisfied. Actually, when choosing the expressions of

and

that satisfy

, the converter actually operates at the boundary of M

and M

. Therefore, the optimization algorithm at low power range can be derived as

(b) At high power level (

): With the same analysis of low power level, the analytic solutions of M

calculated by LMM are the global optimization algorithm during this power level. From previous analysis, dead time has no effect on the waveforms of M

. Therefore, to simplify the control system, the dead-time ratio

M is set to

during this power range, and the optimization algorithm in Equation (

22) can be rewritten as

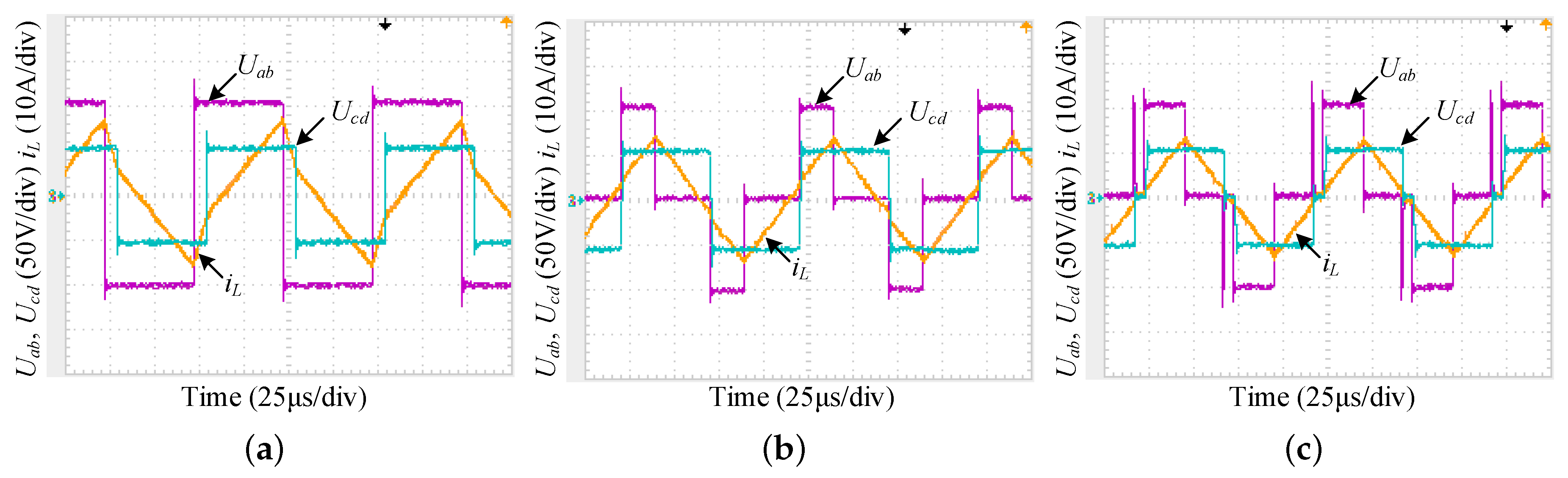

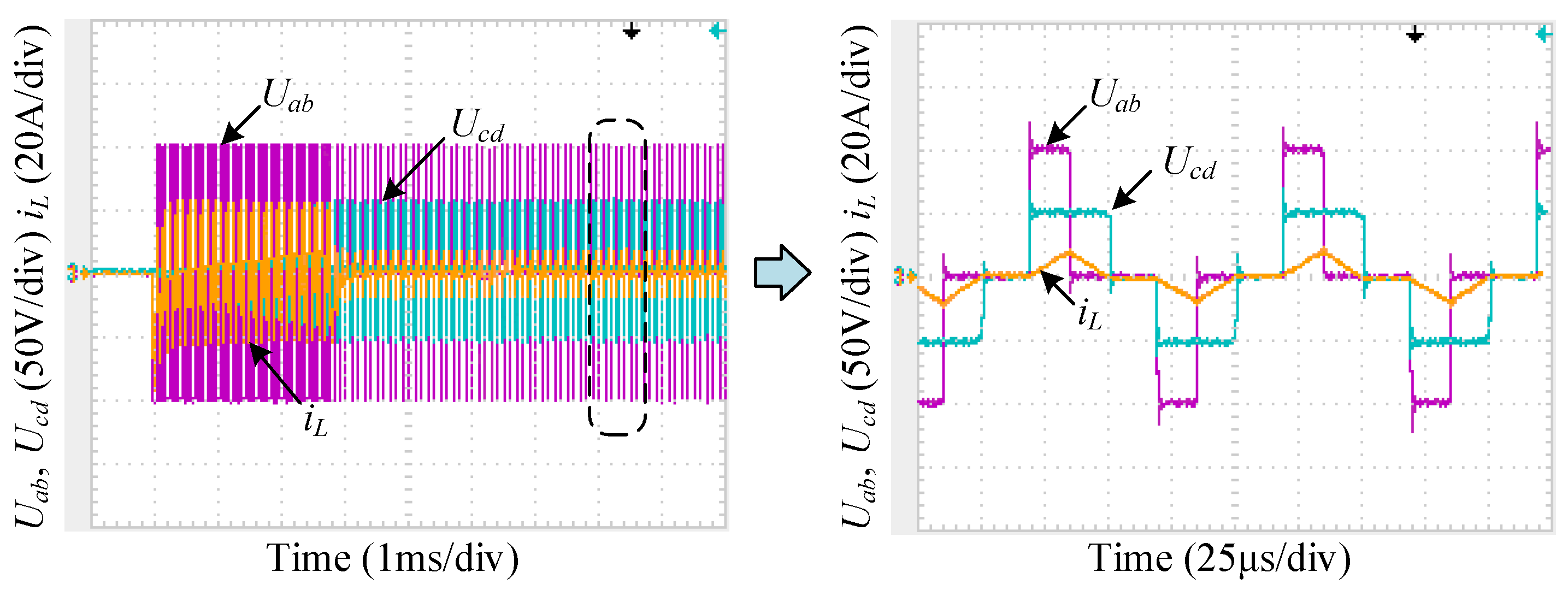

(c) At middle power level (): The global optimization algorithm is acquired by GA during this power level. For the required transmission power and voltage conversion ratio, the minimum current stress of each mode can be obtained. Comparing all the of each mode, the least value is the optimal current stress, and the control variables realizing the optimal value are the optimal solutions under the required and k. The optimization algorithm at middle power level cannot be expressed in analytic solutions, therefore, the optimal phase-shift ratios and dead-time ratio require the off-line calculation. Then, the calculated results can be stored in a form of memory of microcontroller, which can be applicable in practical application.

Overall, the optimization algorithm can be expressed in

Table 3. As shown in

Table 3, at low and high power levels, the dead-time ratio

M can be set to

constantly, and, at middle power level,

M can be adaptive in the optimization algorithm.

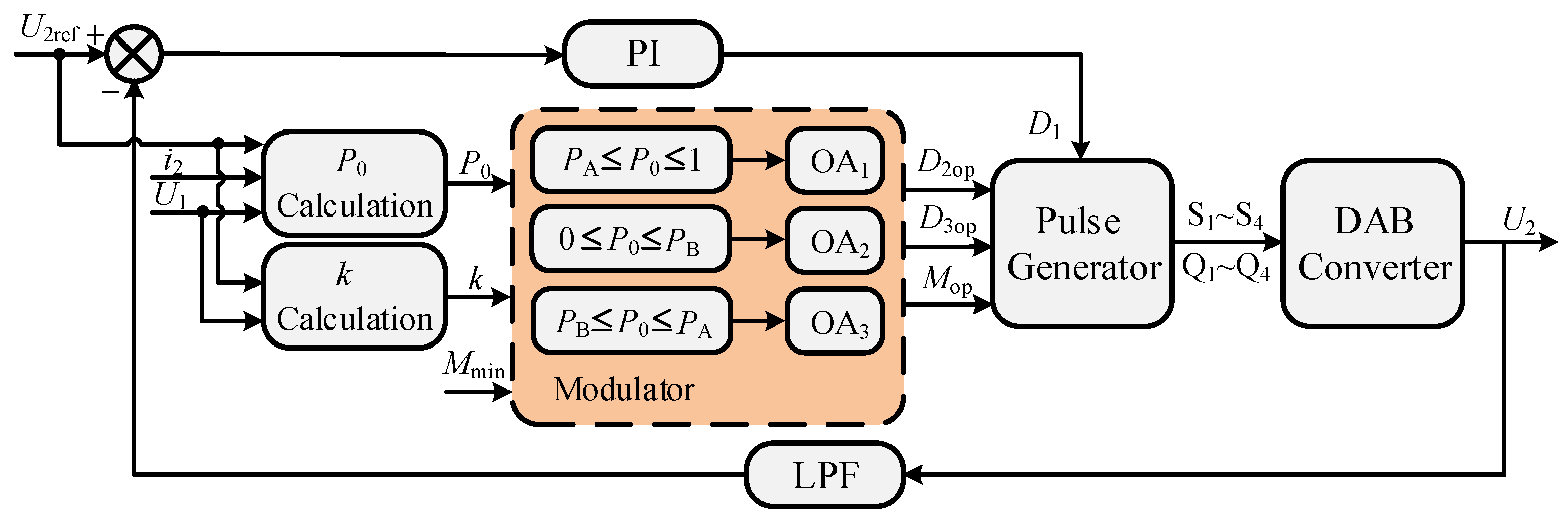

The control diagram of the proposed TPSiDT scheme is shown in

Figure 13, in which OA

, OA

and OA

are defined as the optimization algorithm at high power level, low power level, and middle power level, respectively, and

is the reference output voltage. In the control diagram, the control system detects the input voltage

, output voltage

, and output current

, and then, the real-time values of the normalized transmission power

and the voltage conversion ratio

k can be calculated. To avoid that the voltage conversion ratio

k goes to infinity at the start-up stage,

is adopted to replace

in

k calculation. The safe dead-time ratio

can be decided by the characteristics of the power devices. Thus, the power boundary values

and

can be obtained by Equation (

26). Based on the relationships among

,

and

, the power level as well as the optimal solutions can be decided. Thereinto,

,

, and

can be determined by the optimization algorithm shown in

Table 3, while

is regulated by PI controller to realize the required output voltage and transmission power.