Numerical Simulation on Interfacial Characteristics in Supersonic Steam–water Injector Using Particle Model Method

Abstract

:1. Introduction

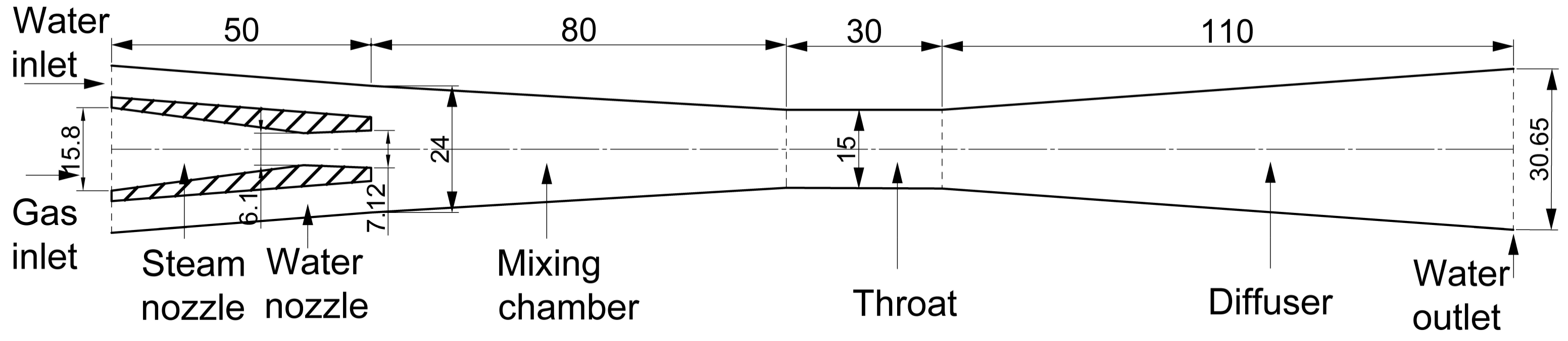

- 1.

- Steam nozzleIn steam nozzle, high-pressure steam will be accelerated to a supersonic velocity and create low pressure around the nozzle outlet which is below the pressure of suction water. If the steam inlet pressure is high enough, a converging–diverging nozzle (Laval type) should be adopted to ensure enough expansion, in case of expansion loss outside the nozzle.

- 2.

- Water nozzleThe suction water is taken in through a coaxial and annular conduit called water nozzle, whose function is to distribute the water evenly all around the steam nozzle exit.

- 3.

- Mixing chamberIn the mixing chamber, supersonic steam jet entrains water into the mixing chamber and contact directly with the suction water.

- 4.

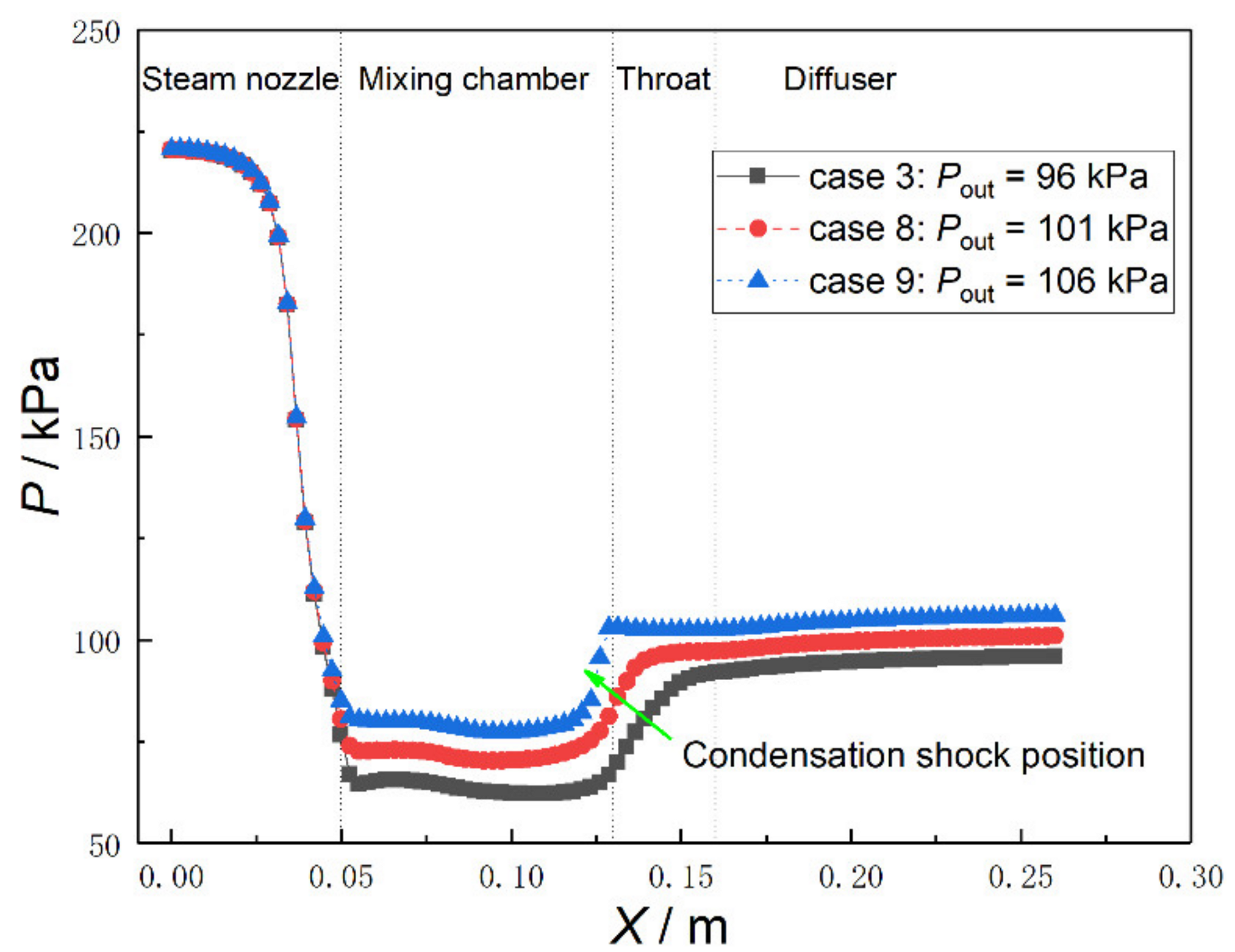

- ThroatIn most cases, steam condenses completely in the vicinity of throat. This phenomenon, called condensation shock, causes a rapid pressure rise.

- 5.

- DiffuserDiffuser is a divergent channel with a single-phase flow inside. The flow is decelerated constantly, thus leading to a further increase of static pressure.

2. Numerical Method

2.1. Two-Fluid Model

2.2. Turbulence Model

2.3 Interphase Transfer Models

2.3.1. Interfacial Area

2.3.2. Interphase Heat Transfer

2.3.3. Interphase Momentum Transfer

2.3.4. Interphase Mass Transfer

3. Mesh Solution and Model Validation

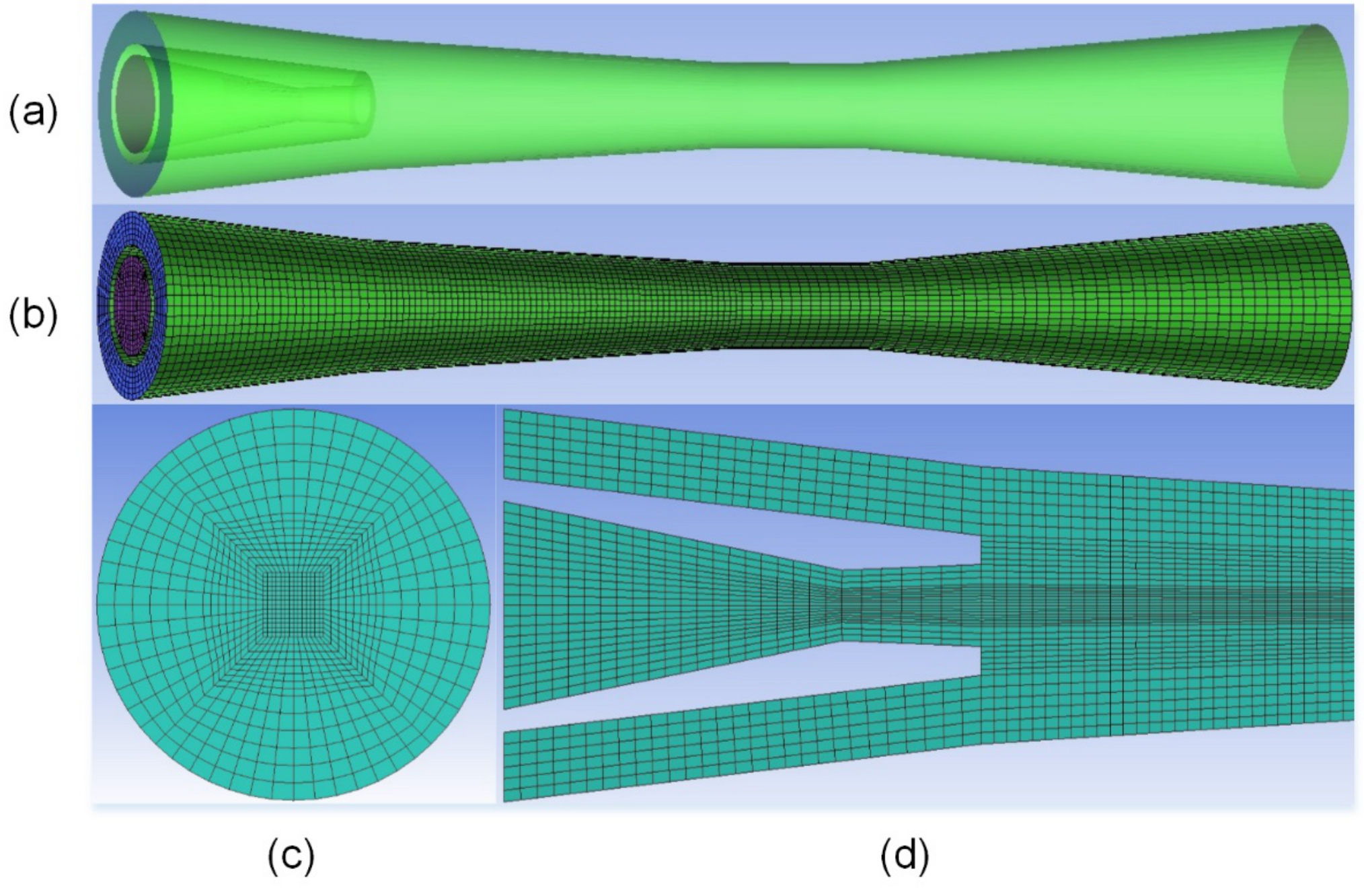

3.1. Simulation Domain and Mesh Solution

3.2. Boundary Conditions and Solver Settings

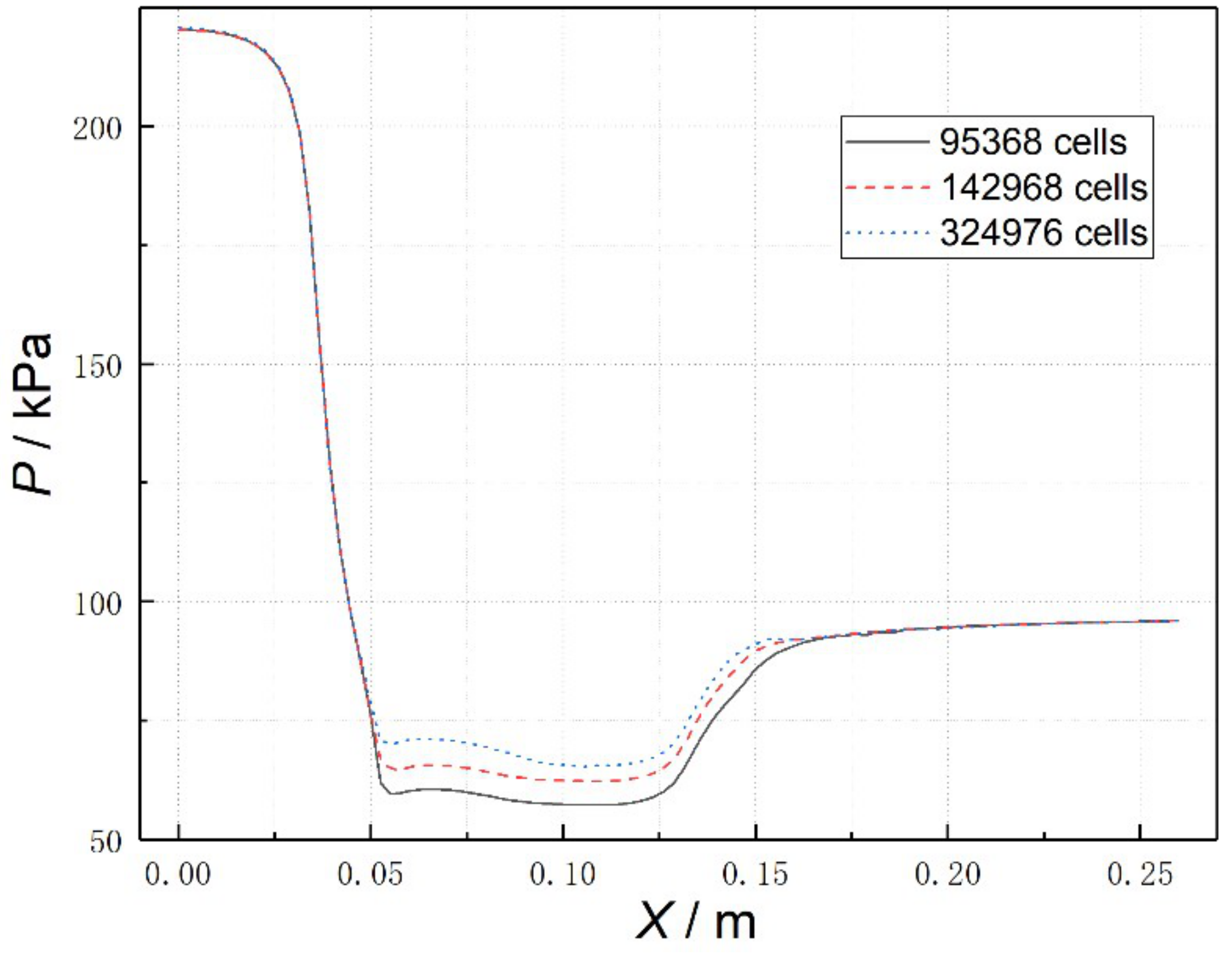

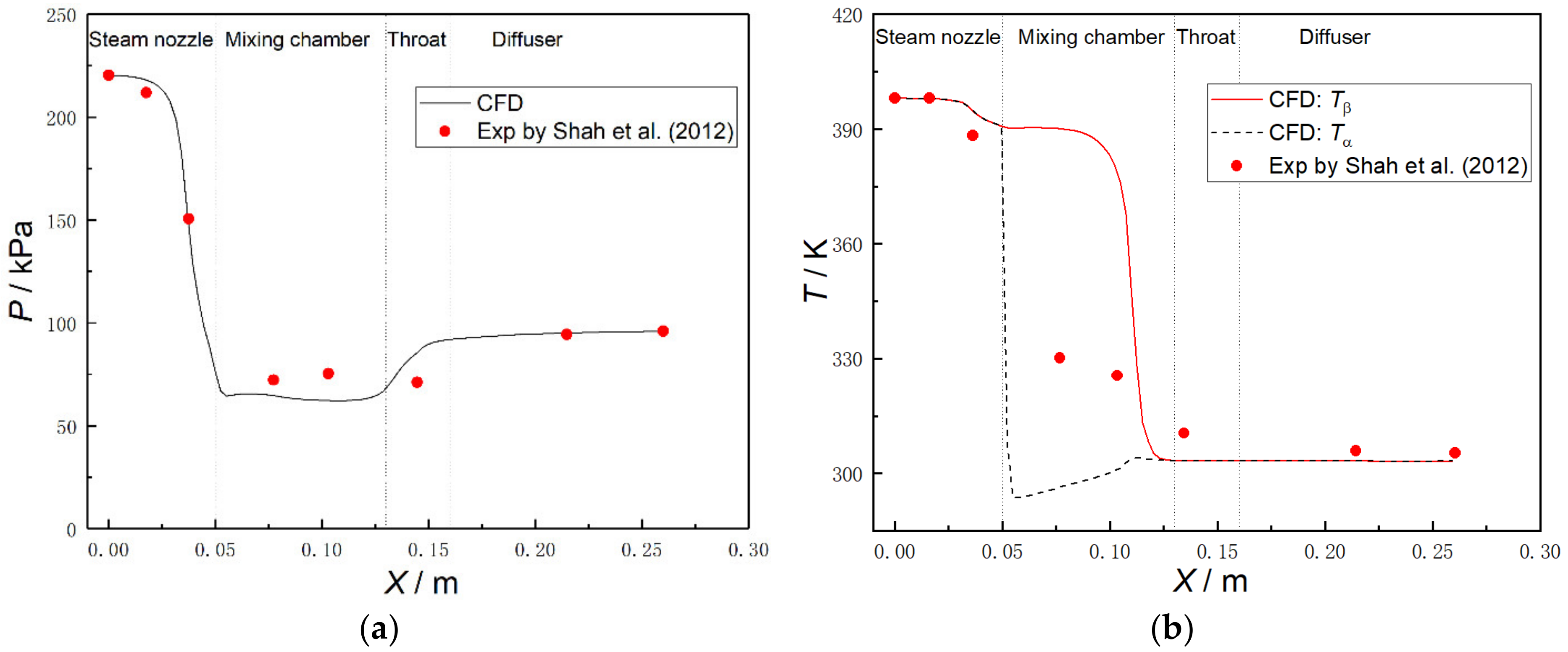

3.3. Mesh Independency Check and Model Validation

4. Results and Discussion

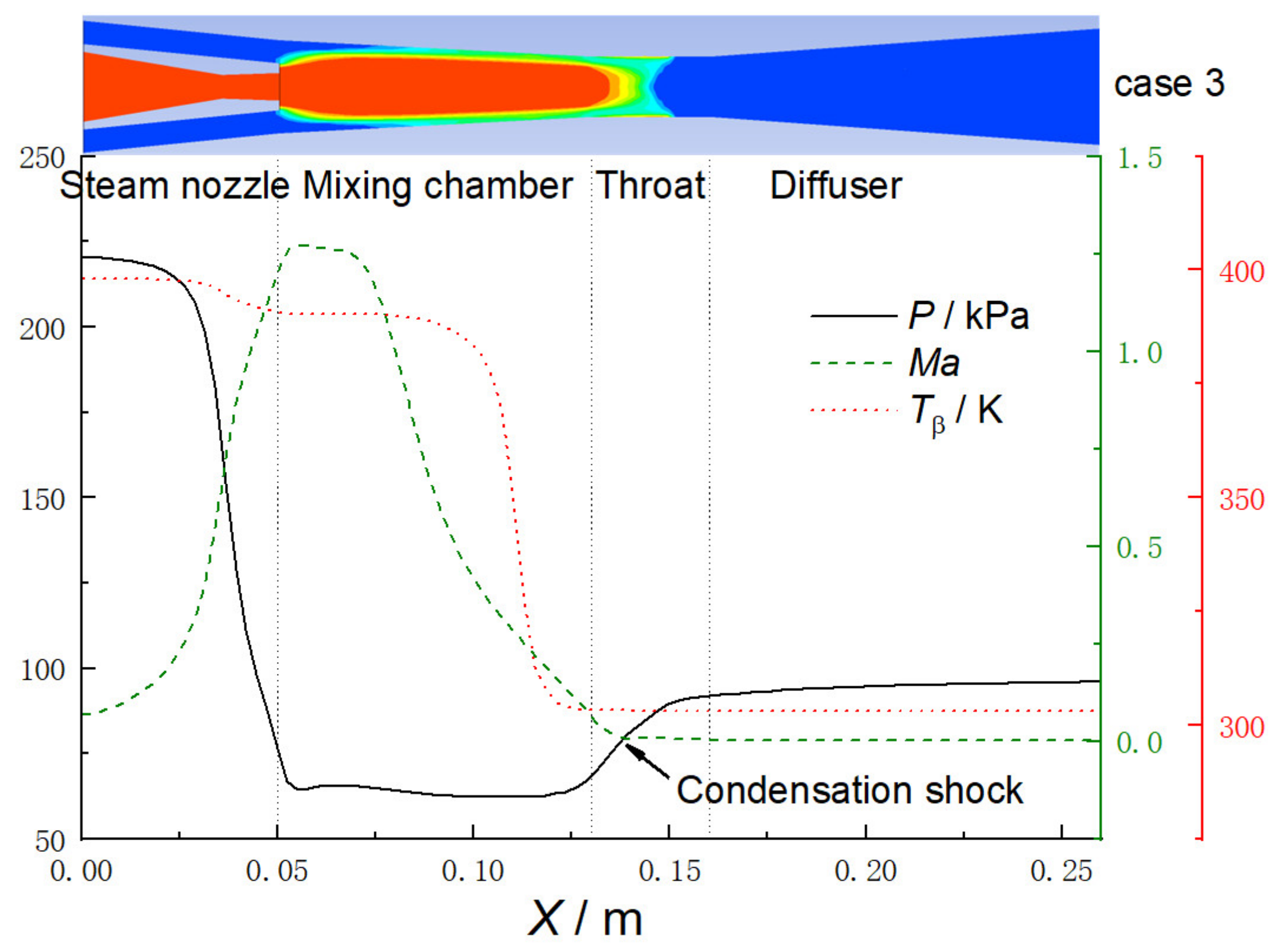

4.1. The Analysis of Axial Thermodynamic Parameters Profiles along the Centerline

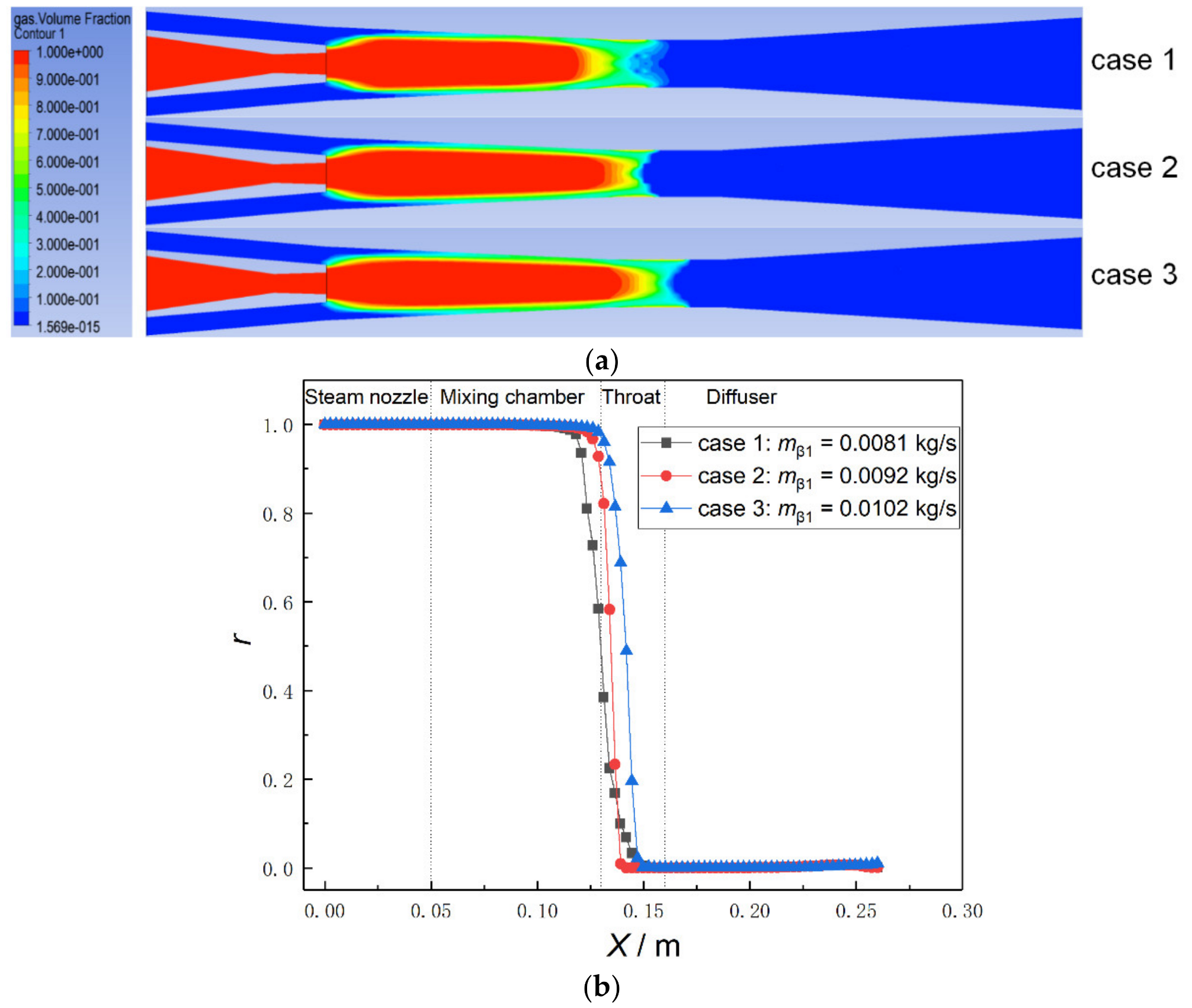

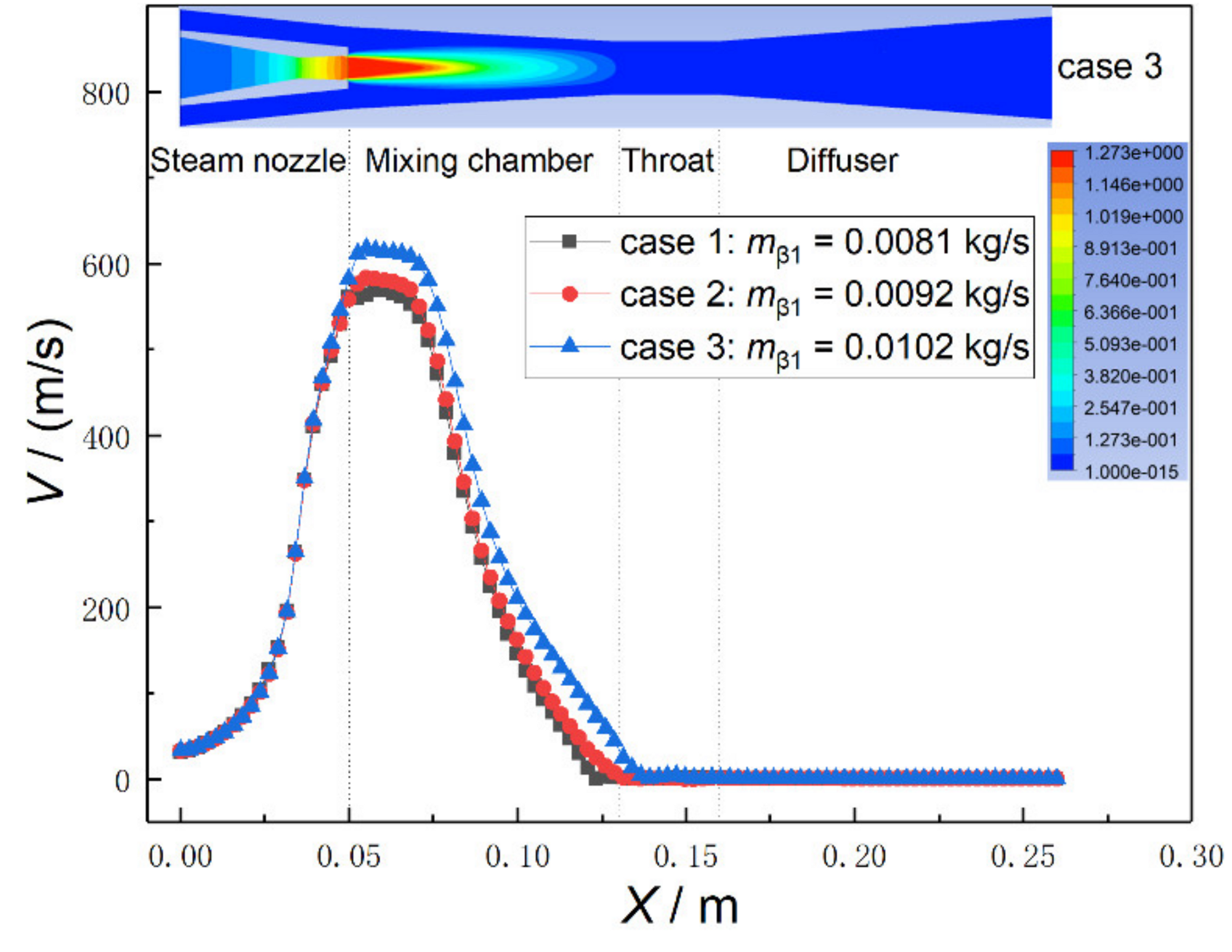

4.2. Effect of Steam Inlet Mass Flow rate on Steam Volume Fraction and Mach Number Profiles

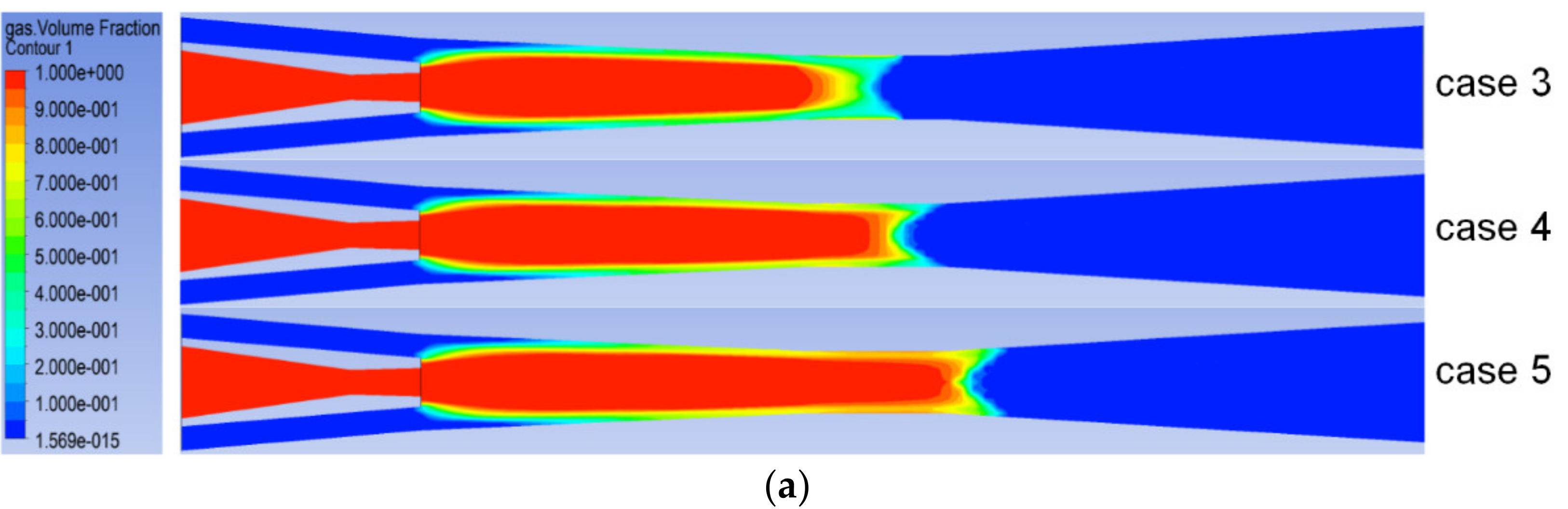

4.3. Effect of Water Inlet Temperature on Steam Volume Fraction

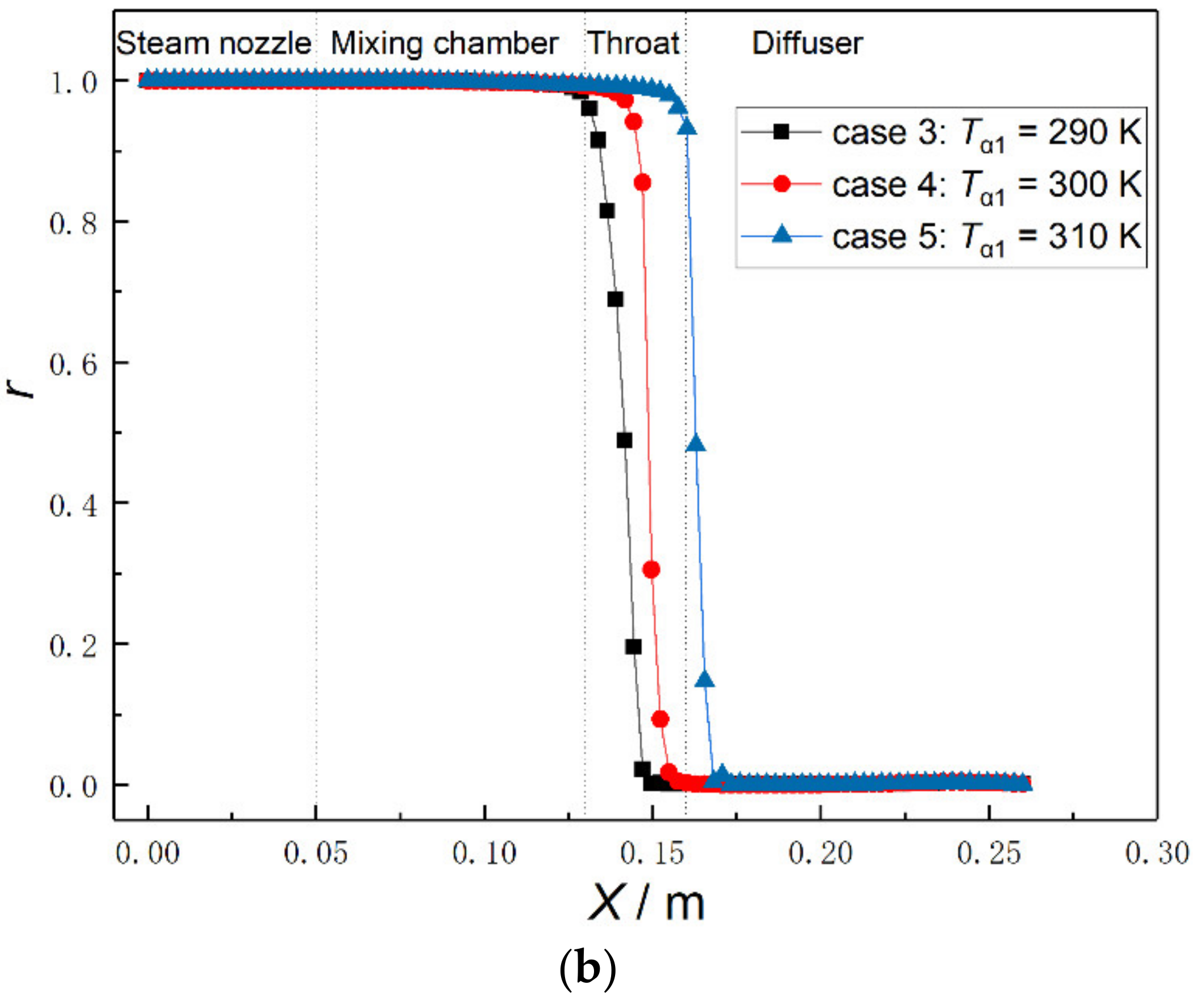

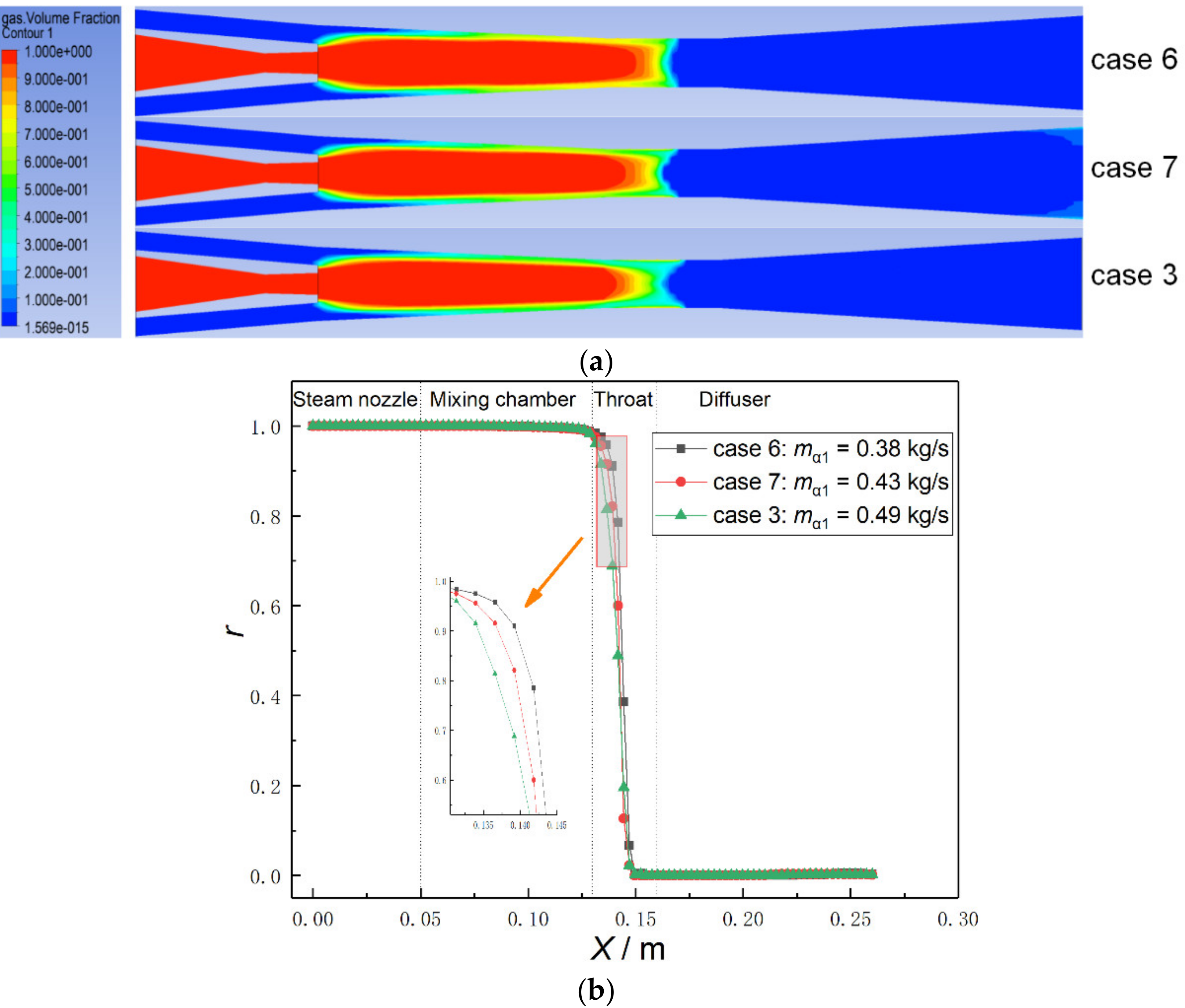

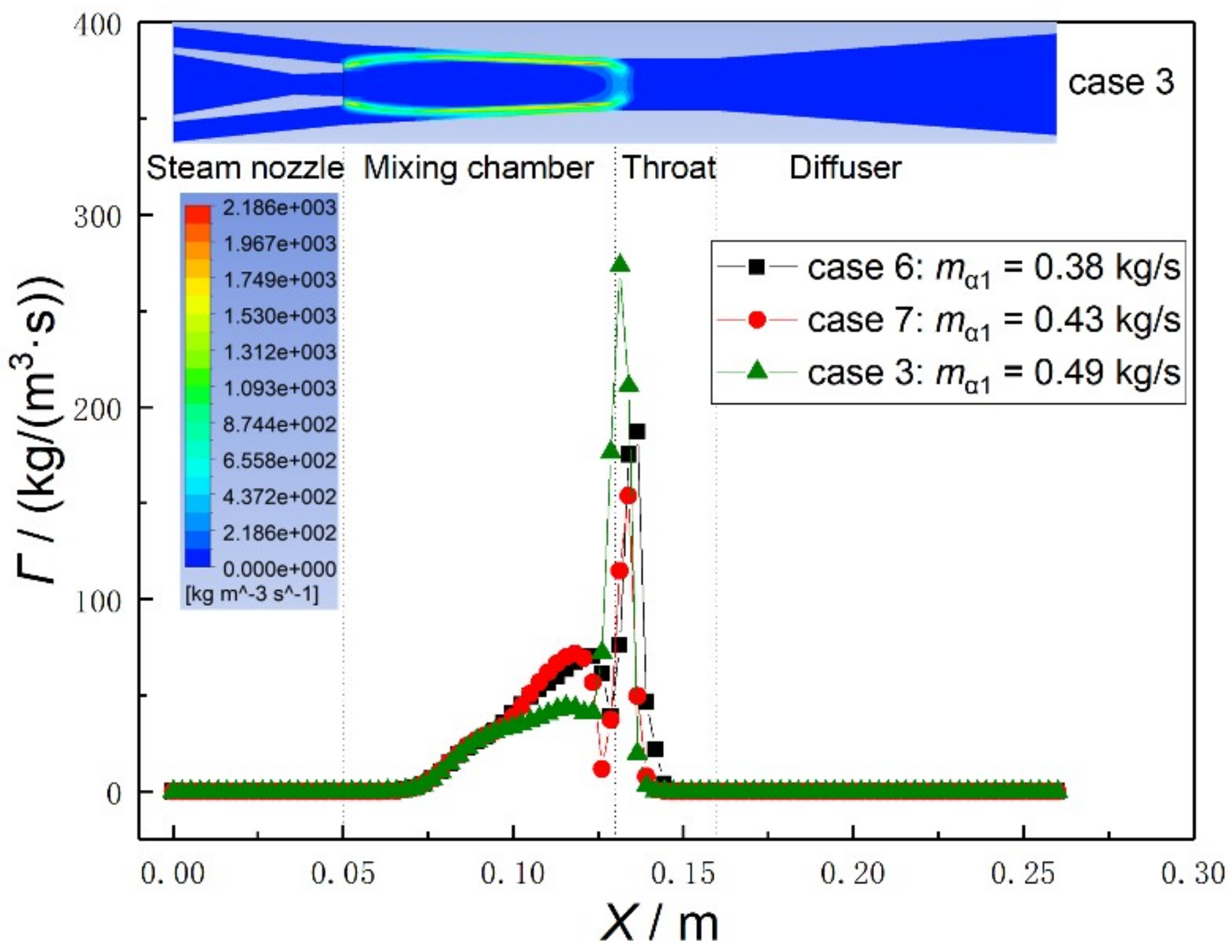

4.4. Effect of Water Inlet Mass Flow Rate on Steam Volume Fraction

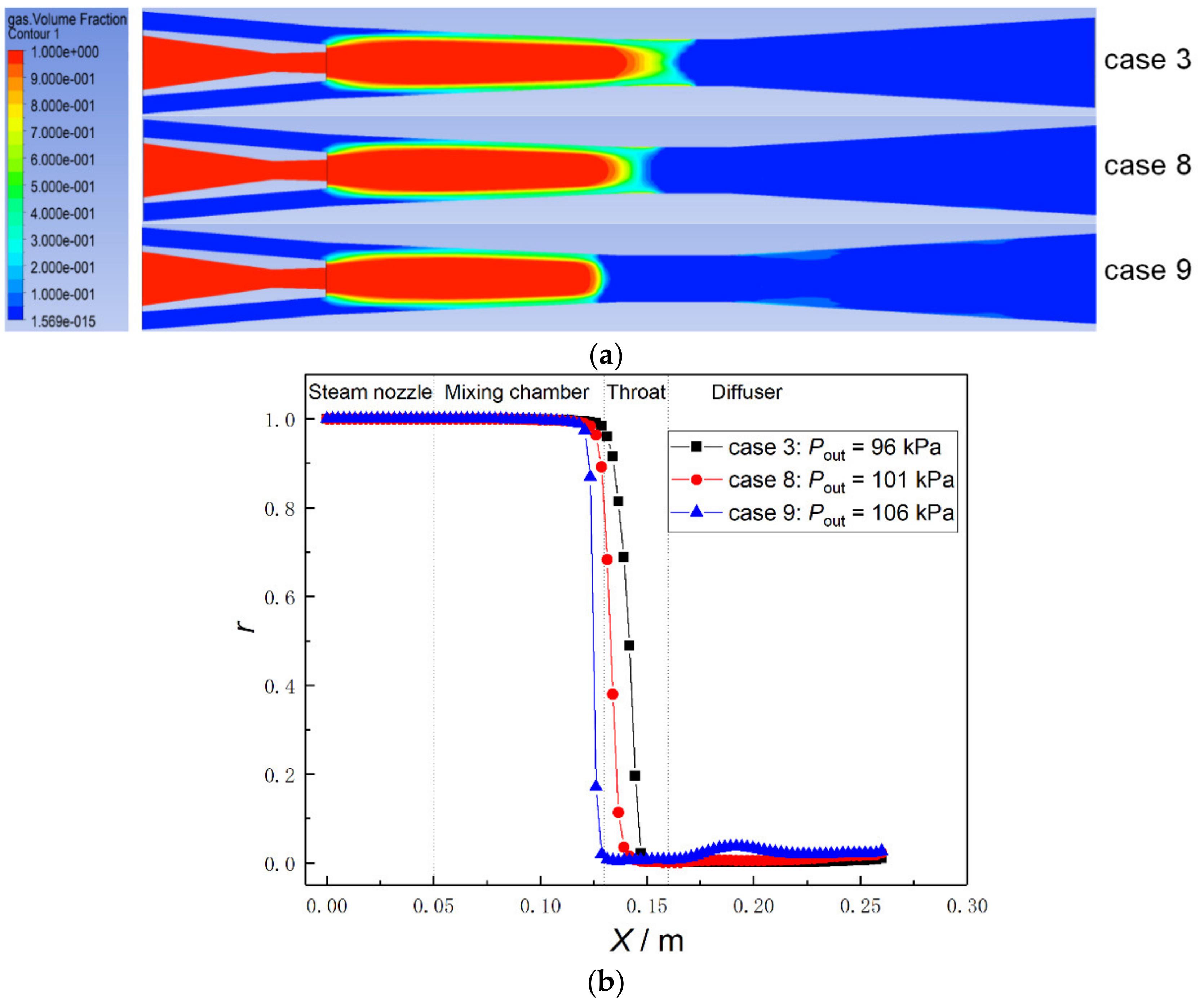

4.5. Effect of Backpressure on Steam Volume Fraction and Condensation Shock Position

5. Conclusions

- (1)

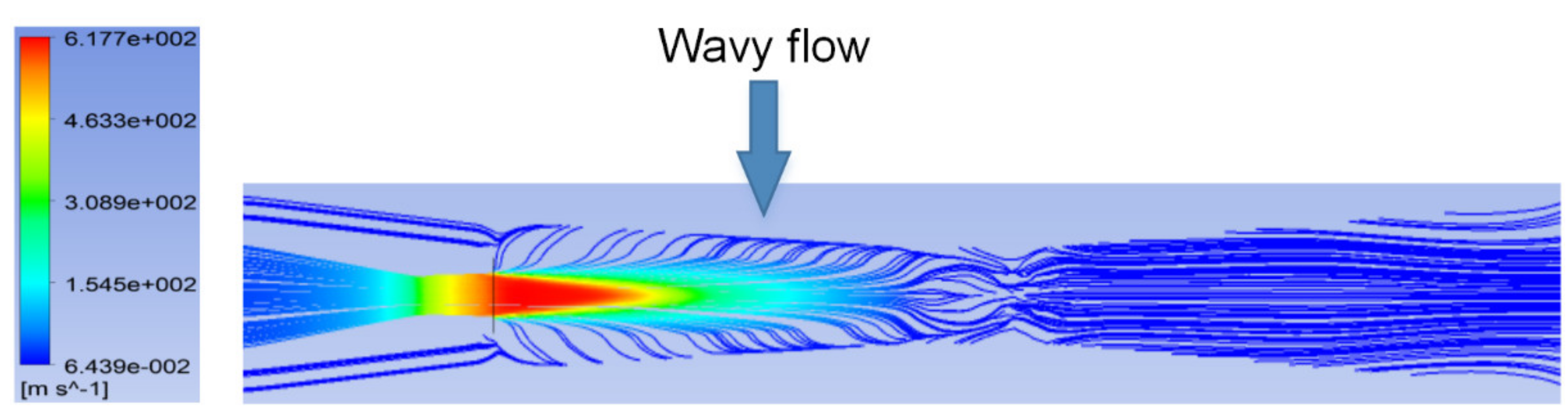

- The axial thermodynamic parameters along SI centerline including static pressure, Mach number, and temperature are used to analyze the overall physical process of SI. The maximum Mach number achieved at the Laval nozzle outlet rises with steam inlet mass flow rate increasing and the interphase momentum transfer is enhanced by the wavy flow across the steam–water interface according to the streamline.

- (2)

- Based on the equilibrium of steam supply and its condensation, interfacial characteristics including the variation of steam plume penetration length and the steam–water interface have been discussed under different operating conditions. The simulation results show that steam plume penetration lengthens and the steam–water interface expands with steam inlet mass flow rate and water inlet temperature increasing, while steam plume penetration shortens and the interface contracts with the increase of water inlet mass flow rate and backpressure.

- (3)

- Combined with the contour of steam volume fraction, the condensation shock position moves upstream with the backpressure increasing, changing simultaneously with corresponding condensation terminus.

Author Contributions

Funding

Conflicts of Interest

Nomenclatures

| Aαβ | interfacial area per unit volume (1/m) |

| dβ | gas bubble diameter (mm) |

| D | kinematic diffusion coefficient |

| e | internal energy (J) |

| h | heat transfer coefficient (W/(m2·K)) |

| k | turbulent kinetic energy (J) |

| Hs | saturation enthalpy of liquid phase at interfacial temperature (J/kg) |

| Hβ | saturation enthalpy of gas phase (J/kg) |

| m | mass flow rate (kg/s) |

| Mα | source term due to momentum transfer |

| Nu | Nusselt number |

| P | static pressure (kPa) |

| Pr | Prandtl number |

| Qα | sensible heat flux from interface to liquid phase (W/m2) |

| Qβ | sensible heat flux from gas to interface (W/m2) |

| r | steam volume fraction |

| Re | Reynolds number |

| Sc | Schmidt number |

| SMα | source term from external body force |

| T | static temperature (K) |

| Tsat | saturated steam temperature at local pressure (K) |

| w | mass fraction |

| X | axial location from nozzle inlet (m) |

| Subscript | |

| α | liquid phase |

| β | gas phase |

| t | Laval nozzle throat |

| out | steam–water injector outlet |

| 1 | steam nozzle or water nozzle inlet |

| Greek symbols | |

| μ | dynamic viscosity (Pa·s) |

| ρ | volume-averaged density (kg/m3) |

| Γ | interphase mass transfer (kg/(m3·s)) |

| κ | adiabatic index |

| Acronyms | |

| SI | steam–water injector |

| DCC | direct contact condensation |

References

- Yan, J.-J.; Shao, S.-F.; Liu, J.-P.; Zhang, Z. Experiment and analysis on performance of steam-driven jet injector for district-heating system. Appl. Therm. Eng. 2005, 25, 1153–1167. [Google Scholar] [CrossRef]

- Trela, M.; Kwidziński, R.; Głuch, J.; Butrymowicz, D. Analysis of application of feed-water injector heaters to steam power plants. Pol. Marit. Res. 2009, 16, 64–70. [Google Scholar] [CrossRef]

- Beithou, N.; Aybar, H.S. A mathematical model for steam-driven jet pump. Int. J. Multiph. Flow 2000, 26, 1609–1619. [Google Scholar] [CrossRef]

- Cattadori, G.; Galbiati, L.; Mazzocchi, L.; Vanini, P. A single-stage high pressure steam injector for next generation reactors: Test results and analysis. Int. J. Multiph. Flow 1995, 21, 591–606. [Google Scholar] [CrossRef]

- Deberne, N.; Leone, J.F.; Duque, A.; Lallemand, A. A model for calculation of steam injector performance. Int. J. Multiph. Flow 1999, 25, 841–855. [Google Scholar] [CrossRef]

- Deberne, N.; Leone, J.-F.; Lallemand, A. Local measurements in the flow of a steam injector and visualisation. Int. J. Therm. Sci. 2000, 39, 1056–1065. [Google Scholar] [CrossRef]

- Dumaz, P.; Geffraye, G.; Kalitvianski, V.; Verloo, E.; Valisi, M.; Méloni, P.; Achilli, A.; Schilling, R.; Malacka, M.; Trela, M. The DEEPSSI project, design, testing and modeling of steam injectors. Nucl. Eng. Des. 2005, 235, 233–251. [Google Scholar] [CrossRef]

- Narabayashi, T.; Mizumachi, W.; Mori, M. Study on two-phase flow dynamics in steam injectors. Nucl. Eng. Des. 1997, 175, 147–156. [Google Scholar] [CrossRef]

- Narabayashi, T.; Mori, M.; Nakamaru, M.; Ohmori, S. Study on two-phase flow dynamics in steam injectors: II. High-pressure tests using scale-models. Nucl. Eng. Des. 2000, 200, 261–271. [Google Scholar] [CrossRef]

- Shah, A.; Chughtai, I.R.; Inayat, M.H. Experimental and numerical analysis of steam jet pump. Int. J. Multiph. Flow 2011, 37, 1305–1314. [Google Scholar] [CrossRef]

- Shah, A.; Chughtai, I.R.; Inayat, M.H. Experimental and numerical investigation of the effect of mixing section length on direct-contact condensation in steam jet pump. Int. J. Heat Mass Trans. 2014, 72, 430–439. [Google Scholar] [CrossRef]

- Yan, J.; Wu, X.; Chong, D.; Liu, J. Experimental Research on Performance of Supersonic Steam-Driven Jet Injector and Pressure of Supersonic Steam Jet in Water. Heat Trans. Eng. 2011, 32, 988–995. [Google Scholar] [CrossRef]

- Trela, M.; Kwidzinski, R.; Butrymowicz, D.; Karwacki, J. Exergy analysis of two-phase steam–water injector. Appl. Therm. Eng. 2010, 30, 340–346. [Google Scholar] [CrossRef]

- Kwidzinski, R. Experimental investigation of condensation wave structure in steam–water injector. Int. J. Heat Mass Trans. 2015, 91, 594–601. [Google Scholar] [CrossRef]

- Shah, A. Thermal Hydraulic Analysis of Steam Jet Pump. Ph.D. Thesis, Pakistan Institute of Engineering and Applied Sciences, Islamabad, Pakistan, 2012. [Google Scholar]

- Kähler, G.; Bonelli, F.; Gonnella, G.; Lamura, A. Cavitation inception of a van der Waals fluid at a sack-wall obstacle. Phys. Fluids 2015, 27, 123307(1)–123307(26). [Google Scholar] [CrossRef]

- Vinuesa, R.; Fick, L.; Negi, P.; Marin, O.; Merzari, E.; Schlatter, P. Turbulence Statistics in a Spectral Element Code: A Toolbox for High-Fidelity Simulations; Argonne National Lab.: Argonne, IL, USA, 2017; 14p. [Google Scholar]

- Rezaeiravesh, S.; Vinuesa, R.; Liefvendahl, M.; Schlatter, P. Assessment of uncertainties in hot-wire anemometry and oil-film interferometry measurements for wall-bounded turbulent flows. Eur. J. Mech. Fluids 2018, 72, 57–73. [Google Scholar] [CrossRef]

- Dahikar, S.K.; Sathe, M.J.; Joshi, J.B. Investigation of flow and temperature patterns in direct contact condensation using PIV, PLIF and CFD. Chem. Eng. Sci. 2010, 65, 4606–4620. [Google Scholar] [CrossRef]

- Gulawani, S.S.; Dahikar, S.K.; Mathpati, C.S.; Joshi, J.B.; Shah, M.S.; RamaPrasad, C.S.; Shukla, D.S. Analysis of flow pattern and heat transfer in direct contact condensation. Chem. Eng. Sci. 2009, 64, 1719–1738. [Google Scholar] [CrossRef]

- Gulawani, S.S.; Joshi, J.B.; Shah, M.S.; RamaPrasad, C.S.; Shukla, D.S. CFD analysis of flow pattern and heat transfer in direct contact steam condensation. Chem. Eng. Sci. 2006, 61, 5204–5220. [Google Scholar] [CrossRef]

- Heinze, D.; Schulenberg, T.; Behnke, L. A physically based, one-dimensional three-fluid model for direct contact condensation of steam jets in flowing water. Int. J. Heat Mass Trans. 2017, 106, 1041–1050. [Google Scholar] [CrossRef]

- Norman, T.L.; Revankar, S.T. Jet-plume condensation of steam–air mixtures in subcooled water, Part 1: Experiments. Nucl. Eng. Des. 2010, 240, 524–532. [Google Scholar] [CrossRef]

- Choo, Y.J.; Song, C.-H. PIV measurements of turbulent jet and pool mixing produced by a steam jet discharge in a subcooled water pool. Nucl. Eng. Des. 2010, 240, 2215–2224. [Google Scholar] [CrossRef]

- Wu, X.-Z.; Yan, J.-J.; Li, W.-J.; Pan, D.-D.; Chong, D.-T. Experimental study on sonic steam jet condensation in quiescent subcooled water. Chem. Eng. Sci. 2009, 64, 5002–5012. [Google Scholar] [CrossRef]

- Zong, X.; Liu, J.-P.; Liu, J.; Yang, X.-P.; Yan, J.-J. Experimental study on the interfacial behavior of stable steam jet condensation in a rectangular mix chamber. Int. J. Heat Mass Trans. 2017, 114, 458–468. [Google Scholar] [CrossRef]

- Zong, X.; Liu, J.-P.; Yan, J.-J. Experimental study on the interfacial wave and local heat transfer coefficient of stable steam jet condensation in a rectangular mix chamber. Int. J. Heat Mass Trans. 2018, 127, 1096–1101. [Google Scholar] [CrossRef]

- Zong, X.; Liu, J.-P.; Yang, X.-P.; Yan, J.-J. Experimental study on the direct contact condensation of steam jet in subcooled water flow in a rectangular mix chamber. Int. J. Heat Mass Trans. 2015, 80, 448–457. [Google Scholar] [CrossRef]

- Shah, A.; Chughtai, I.R.; Inayat, M.H. Experimental study of the characteristics of steam jet pump and effect of mixing section length on direct-contact condensation. Int. J. Heat Mass Trans. 2013, 58, 62–69. [Google Scholar] [CrossRef]

- Ishii, M.; Hibiki, T. Thermo-Fluid Dynamics of Two-Phase Flow; Springer US: New York, USA, 2006; pp. 119–128. [Google Scholar]

- ANSYS®. Academic Research, Release 150, Help System, ANSYS CFX-Solver Theory Guide; ANSYS Inc: Canonsburg, PA, USA, 2013. [Google Scholar]

- Bonelli, F.; Viggiano, A.; Magi, V. A Numerical Analysis of Hydrogen Underexpanded Jets Under Real Gas Assumption. J. Fluids Eng. 2013, 135, 121101. [Google Scholar] [CrossRef]

- Sarkar, S.; Balakrishnan, L. Application of a Reynolds-Stress Turbulence Model to the Compressible Shear Layer. AIAA J. 1991, 29, 743–749. [Google Scholar] [CrossRef]

- Shah, A.; Chughtai, I.R.; Inayat, M.H. Numerical Simulation of Direct-contact Condensation from a Supersonic Steam Jet in Subcooled Water. Chin. J. Chem. Eng. 2010, 18, 577–587. [Google Scholar] [CrossRef]

- Zhou, L.; Chong, D.; Liu, J.; Yan, J. Numerical study on flow pattern of sonic steam jet condensed into subcooled water. Ann. Nucl. Energy 2017, 99, 206–215. [Google Scholar] [CrossRef]

- Qu, X.-H.; Sui, H.; Tian, M.-C. CFD simulation of steam–air jet condensation. Nucl. Eng. Des. 2016, 297, 44–53. [Google Scholar] [CrossRef]

- Qu, X.-H.; Tian, M.-C.; Zhang, G.-M.; Leng, X.-L. Experimental and numerical investigations on the air–steam mixture bubble condensation characteristics in stagnant cool water. Nucl. Eng. Des. 2015, 285, 188–196. [Google Scholar] [CrossRef]

- Maurice, J.Z.; Joe, D.H. Gas Dynamics; Wiley: Hoboken, NJ, USA, 1976; Volume 1. [Google Scholar]

- Qiu, B.; Yan, J.; Liu, J.; Chong, D.; Zhao, Q.; Wu, X. Experimental investigation on the second dominant frequency of pressure oscillation for sonic steam jet in subcooled water. Exp. Therm. Fluid Sci. 2014, 58, 131–138. [Google Scholar] [CrossRef]

- Cho, S.; Song, C.H.; Park, C.K.; Yang, S.K.; Chung, M.K. Experimental study on dynamic pressure pulse in direct contact condation of steam jets discharging into subcooled water. In Proceedings of the 1st Korea-Japan Symposium on Nuclear Thermal Hydraulics and Safety, Pusan, Korea, 21–24 October 1998. [Google Scholar]

- Qiu, B.; Tang, S.; Yan, J.; Liu, J.; Chong, D.; Wu, X. Experimental investigation on pressure oscillations caused by direct contact condensation of sonic steam jet. Exp. Therm. Fluid Sci. 2014, 52, 270–277. [Google Scholar] [CrossRef]

- Qiu, B.; Yan, J.; Liu, J.; Chong, D. Experimental investigation on pressure oscillation frequency for submerged sonic/supersonic steam jet. Ann. Nucl. Energy 2015, 75, 388–394. [Google Scholar] [CrossRef]

- Xu, Q.; Guo, L.; Zou, S.; Chen, J.; Zhang, X. Experimental study on direct contact condensation of stable steam jet in water flow in a vertical pipe. Int. J. Heat Mass Trans. 2013, 66, 808–817. [Google Scholar] [CrossRef]

- Xu, Q.; Guo, L.; Chang, L.; Wang, Y. Velocity field characteristics of the turbulent jet induced by direct contact condensation of steam jet in crossflow of water in a vertical pipe. Int. J. Heat Mass Trans. 2016, 103, 305–318. [Google Scholar] [CrossRef]

| Variable | Method |

|---|---|

| Advection scheme | Upwind |

| Turbulence numerics | First order |

| Pressure interpolation type | Linear-linear |

| Velocity interpolation type | Linear-linear |

| Velocity pressure coupling | Second-order |

| mβ1 (kg/s) | Pβ1 in Exp. (kPa) | Pβ1 by gas dynamics (kPa) | Pβ1 in CFX-Post (kPa) |

|---|---|---|---|

| 0.0081 | 180 | 181 | 179 |

| 0.0092 | 200 | 206 | 198 |

| 0.0102 | 220 | 222 | 221 |

| Case No. | mβ1 (kg/s) | Tβ1 (K) | mα1 (kg/s) | Tα1 (K) | Pout (kPa) |

|---|---|---|---|---|---|

| case 1 | 0.0081 | 390 | 0.49 | 290 | 96 |

| case 2 | 0.0092 | 394 | 0.49 | 290 | 96 |

| case 3 | 0.0102 | 398 | 0.49 | 290 | 96 |

| case 4 | 0.0102 | 398 | 0.49 | 300 | 96 |

| case 5 | 0.0102 | 398 | 0.49 | 310 | 96 |

| case 6 | 0.0102 | 398 | 0.38 | 290 | 96 |

| case 7 | 0.0102 | 398 | 0.43 | 290 | 96 |

| case 8 | 0.0102 | 398 | 0.49 | 290 | 101 |

| case 9 | 0.0102 | 398 | 0.49 | 290 | 106 |

| Case No. | mβ1 (kg/s) | Mamax |

|---|---|---|

| case 1 | 0.0081 | 1.184 |

| case 2 | 0.0092 | 1.203 |

| case 3 | 0.0102 | 1.273 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Tian, M.; Zhang, G.; Liu, H. Numerical Simulation on Interfacial Characteristics in Supersonic Steam–water Injector Using Particle Model Method. Energies 2019, 12, 1108. https://doi.org/10.3390/en12061108

Chen X, Tian M, Zhang G, Liu H. Numerical Simulation on Interfacial Characteristics in Supersonic Steam–water Injector Using Particle Model Method. Energies. 2019; 12(6):1108. https://doi.org/10.3390/en12061108

Chicago/Turabian StyleChen, Xianbing, Maocheng Tian, Guanmin Zhang, and Houke Liu. 2019. "Numerical Simulation on Interfacial Characteristics in Supersonic Steam–water Injector Using Particle Model Method" Energies 12, no. 6: 1108. https://doi.org/10.3390/en12061108

APA StyleChen, X., Tian, M., Zhang, G., & Liu, H. (2019). Numerical Simulation on Interfacial Characteristics in Supersonic Steam–water Injector Using Particle Model Method. Energies, 12(6), 1108. https://doi.org/10.3390/en12061108