Applications of the 3T Method and the R1 Formula as Efficiency Assessment Tools for Comparing Waste-to-Energy and Landfilling

Abstract

:1. Introduction

2. Materials and Methods

2.1. Energy Efficiency Tools

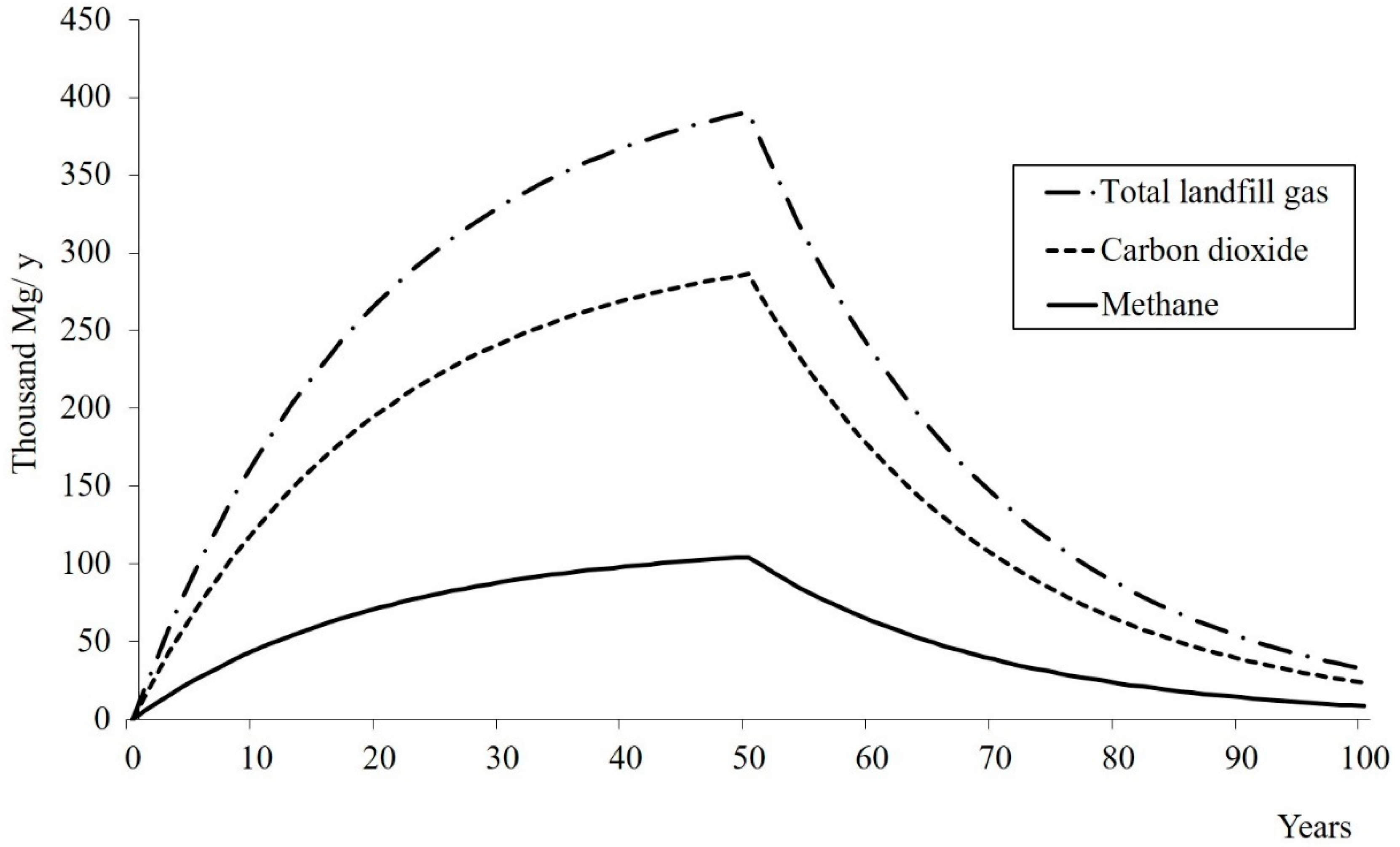

2.2. Landfill Gas Modeling and Application Parameters

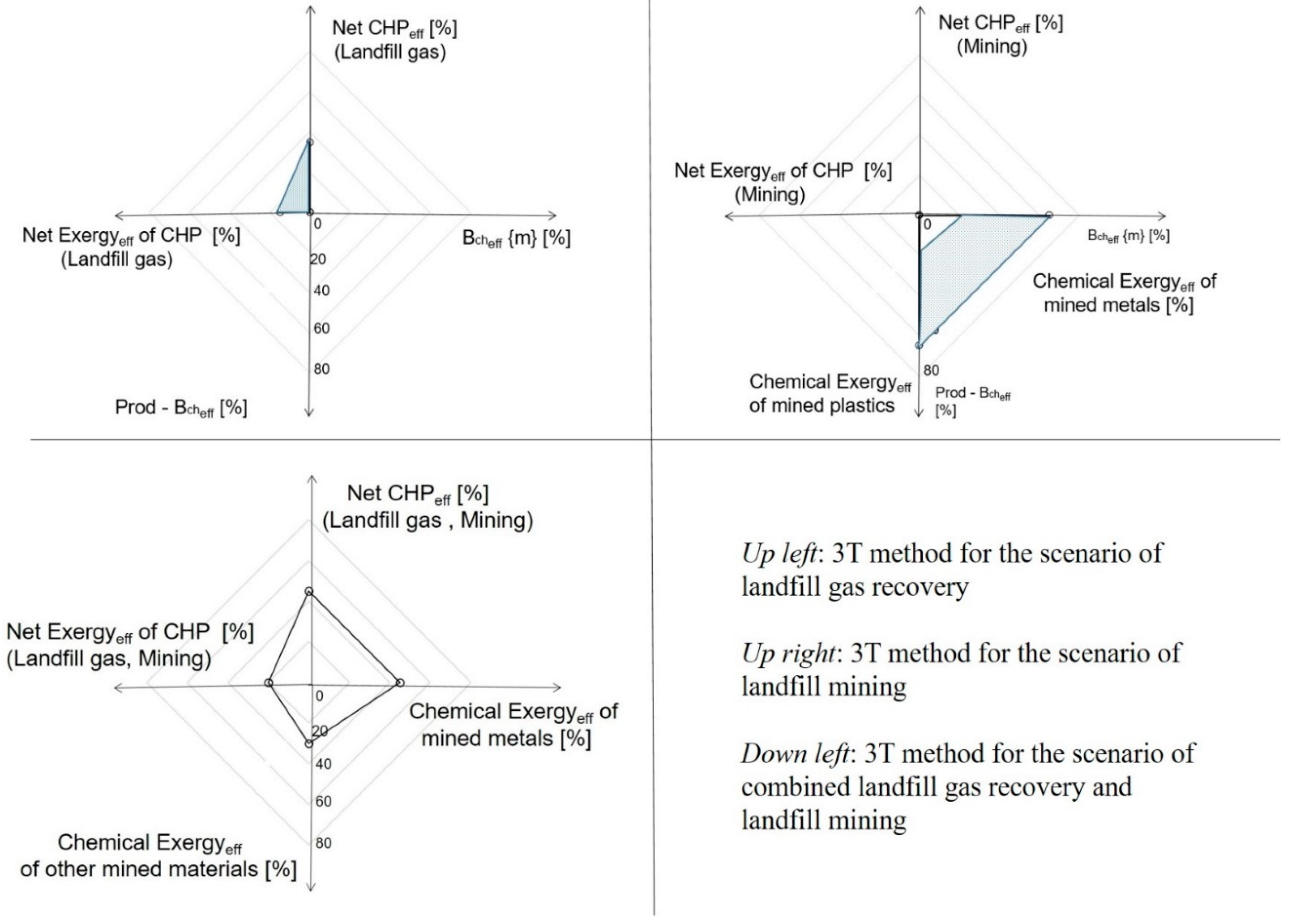

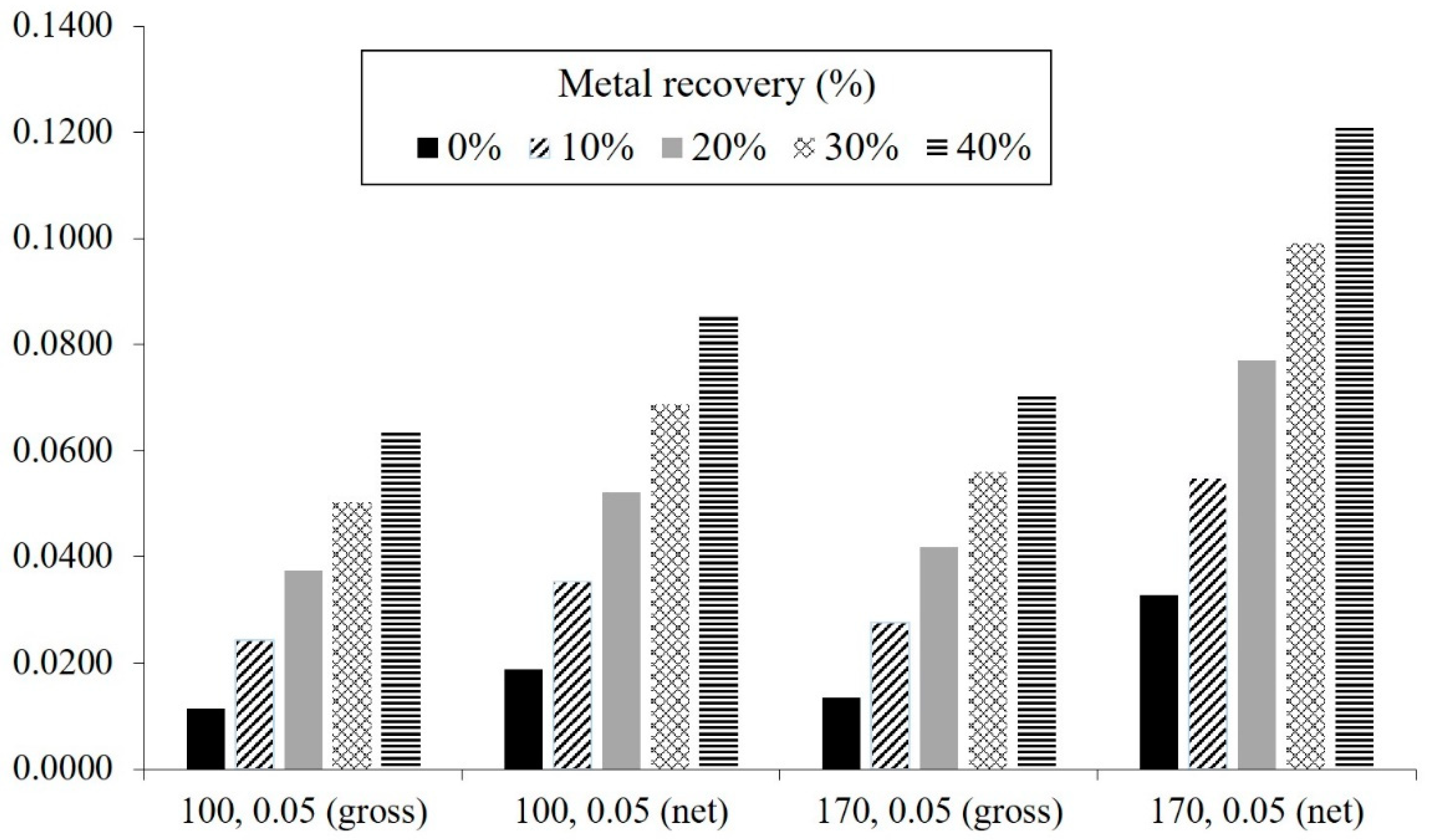

3. Results

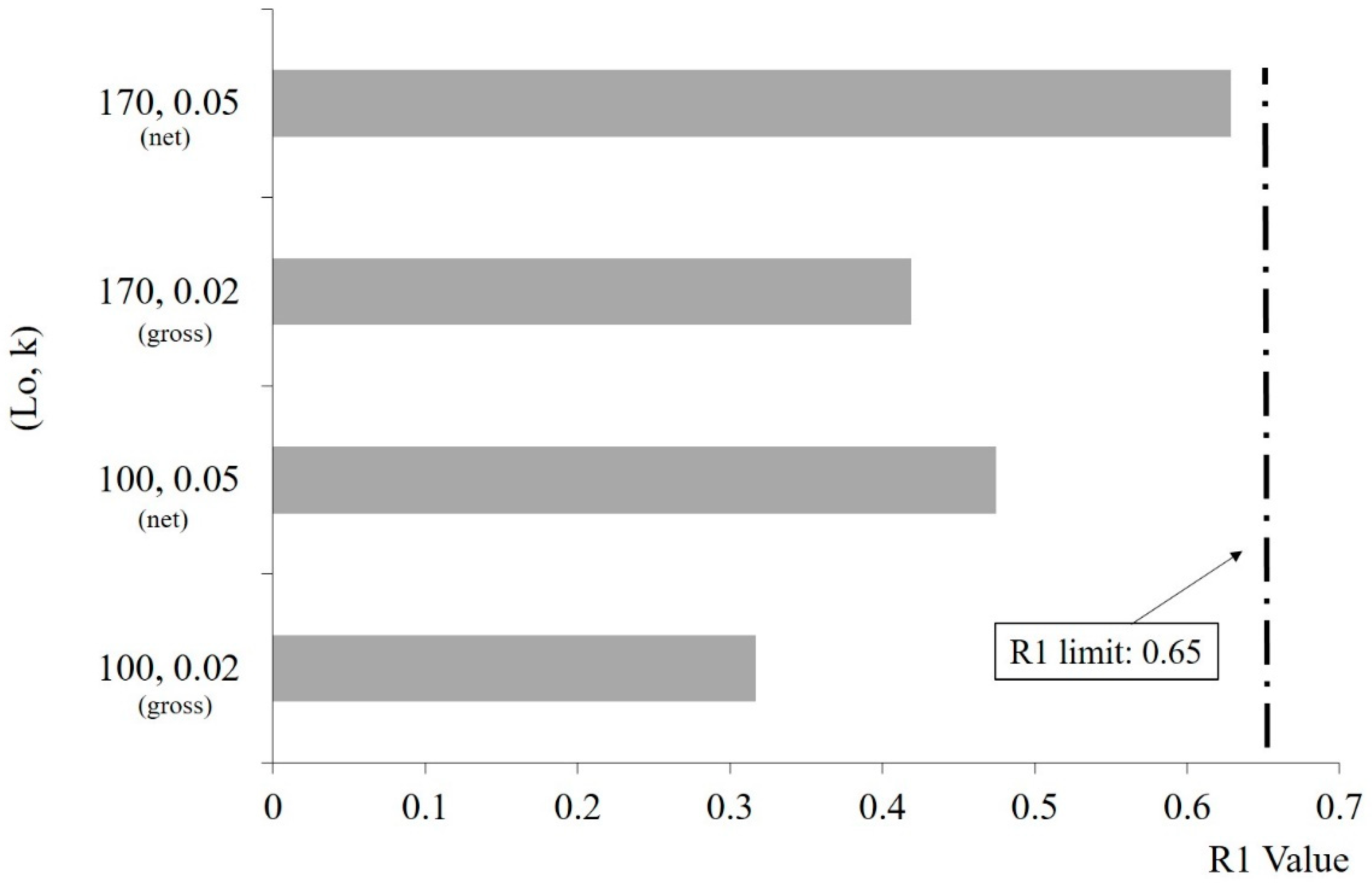

- The net energy efficiency, which is the energy produced in years 20 to 60, divided by the input waste for the years 20 to 60.

- The gross energy efficiency, which is the energy produced in years 20 to 60, divided by the input waste for the years 0 to 60.

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| β | chemical exergy factor |

| Φwaste | waste mass flow rate (kg/s) |

| B, Bph, Bch | exergy, physical exergy, chemical exergy (MJ) |

| Ep | annual energy produced as heat or electricity |

| Ef | annual energy from fuels contributing to the production of steam (GJ/year) |

| Ew | annual energy contained in the treated waste (GJ/year) |

| Ei | annual energy imported excluding Ew and Ef (GJ/Year) |

| i | 1-year time increment |

| j | 0.1-year time increment |

| k | methane generation rate (y−1) |

| L0 | potential methane generation capacity (m3 Mg−1) |

| LHV | lower heating value (MJ/kg) |

| Mi | mass of solid waste disposed in the ith year (Mg or ton) |

| n | year of the calculation—initial year of waste acceptance |

| ηel | net electric efficiency |

| ηth | net thermal efficiency |

| Pel | electric power |

| Paux | electric self-consumption of the auxiliary equipment |

| Pth | thermal power |

| QCH4 | estimated methane generation flow rate (m3 y−1) |

| S, s | entropy, specific entropy (J K−1, J K−1 kg−1) |

| T, T0 | temperature, temperature of environment (K) |

| tij | age of the jth section of waste mass disposed in the ith year |

References

- European Commission. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives; European Commission: Brussels, Belgium, 2008. [Google Scholar]

- European Commission. COMMISSION DIRECTIVE (EU) 2015/1127 (2008). 10 July 2015 Amending Annex II to Directive 2008/98/EC of the European Parliament and of the Council on Waste and Repealing Certain Directives; European Commission: Brussels, Belgium, 2015. [Google Scholar]

- Tebert, C. The Energy Efficiency Formula of ANNEX II of the Waste Framework Directive a Critical Review Formula Proposed by the EU Commission on 21st December 2005 in Waste Framework Directive COM 2005/667—ANNEX II; Technical Briefing for EEB; Ökopol GmbH, Institute for Environmental Strategies: Hamburg, Germany, 2006. [Google Scholar]

- European Commission, DG (Directorate-General) Environment. Guidelines on the Interpretation of the R1 Energy Efficiency Formula for Incineration Facilities Dedicated to the Processing of Municipal Solid Waste according to Annex II of Directive 2008/98/EC on Waste; European Commission: Brussels, Belgium, 2011. [Google Scholar]

- Vakalis, S.; Baratieri, M. State-of-the-Art of Small Scale Biomass Gasifiers in the Region of South Tyrol. Waste Biomass Valorization 2015, 6, 817–829. [Google Scholar] [CrossRef]

- Ciuta, S.; Tsiamis, D.; Castaldi, M.J. Gasification of Waste Materials: Technologies for Generating Energy, Gas, and Chemicals from Municipal Solid Waste, Biomass, Nonrecycled Plastics, Sludges, and Wet Solid Wastes, 1st ed.; Academic Press: Cambridge, MA, USA, 2017; ISBN 9780128127179. [Google Scholar]

- Castaldi, M.J.; Themelis, N.J. The Case for Increasing the Global Capacity for Waste to Energy (WTE). Waste Biomass Valorization 2010, 1, 91–105. [Google Scholar] [CrossRef]

- Vakalis, S.; Moustakas, K.; Loizidou, M. Introduction of the trapezoidal thermodynamic technique method for measuring and mapping the efficiency of waste-to-energy plants: A potential replacement to the R1 formula. Waste Manag. Res. 2018, 36, 810–817. [Google Scholar] [CrossRef]

- Intharathirat, R.; Abdul Salam, P. Valorization of MSW-to-Energy in Thailand: Status, Challenges and Prospects. Waste Biomass Valorization 2016, 7, 31–55. [Google Scholar] [CrossRef]

- Bourka, A.; Malamis, D.; Venetis, C.; Moustakas, K.; Konstantzos, G.E.; Skiadi, O.; Loizidou, M. Athens-Biowaste Model: Cost and Carbon Footprint Calculation of the Collection at Source and Treatment of Biowaste. Waste Biomass Valorization 2015, 6, 685–698. [Google Scholar] [CrossRef]

- Clausen, A.; Pretz, T. The Relevance of Framework Conditions for Modelling GHG Emissions from rMSW Treatment Systems in EU. Waste Biomass Valorization 2016, 6, 175–191. [Google Scholar] [CrossRef]

- Grando, R.L.; De Souza Antune, A.M.; Da Fonseca, F.V.; Sánchez, A.; Barrena, R.; Font, X. Technology overview of biogas production in anaerobic digestion plants: A European evaluation of research and development. Renew. Sustain. Energy Rev. 2017, 80, 44–53. [Google Scholar] [CrossRef]

- Vakalis, S. Applications of the 3T Method as an efficiency assessment tool for Waste-to-Energy facilities and numerical comparisons with the R1 Formula. In Proceedings of the 2018 EEC/WTERT Bi-Annual Conference, New York, NY, USA, 4–5 October 2018. [Google Scholar]

- Sues, A.; Jurascık, M.; Ptasinski, K. Exergetic evaluation of 5 biowastes-to-biofuels routes via gasification. Energy 2010, 35, 996–1007. [Google Scholar] [CrossRef]

- Vakalis, S.; Prando, D.; Patuzzi, F.; Baratieri, M. Measuring the performance of biomass small-scale gasification plants by implementing mass and energy balances. In Proceedings of the 4th Central European Biomass Conference, Graz, Austria, 15–18 January 2014. [Google Scholar]

- Jurascık, M.; Sues, A.; Ptasinski, K. Exergy analysis of synthetic natural gas production method from biomass. Energy 2010, 35, 880–888. [Google Scholar]

- Dewulf, J.; Van Langenhove, H. Thermodynamic optimization of the life cycle of plastics by exergy analysis. Int. J. Energy Res. 2004, 28, 969–976. [Google Scholar] [CrossRef]

- Vakalis, S.; Patuzzi, F.; Baratieri, M. Introduction of an energy efficiency tool for small-scale biomass gasifiers- a thermodynamic approach. Energy Convers. Manag. 2017, 131, 1–9. [Google Scholar] [CrossRef]

- Reimann, D. CEWEP Energy Report III (Status 2007–2010). Results of Specific Data for Energy, R1 Plant Efficiency Factor and NCV of 314 European Waste-to-Energy (WtE) Plants; Technical Report; Confederation of European Waste-to-Energy Plants: Brussels, Belgium, 2012. [Google Scholar]

- Kamalan, H.; Sabour, M.; Shariatmadari, N. A Review on Available Landfill Gas Models. Environ. Sci. Technol. 2011, 4, 79–92. [Google Scholar] [CrossRef]

- Alexander, A.; Burklin, C.; Singleton, A. Landfill Gas Emissions Model (LandGEM) Version 3.02 User’s Guide (Eastern Research Group, Purchase Order No. 3C-R127-NALX); U.S. Environmental Protection Agency, Office of Research and Development: Washington, DC, USA, 2005. Available online: https://www3.epa.gov/ttn/catc/dir1/landgem-v302-guide.pdf (accessed on 22 September 2018).

- Chacartegui, R.; Carvalho, M.; Abrahão, R.; Becerra, J. Analysis of a CHP plant in a municipal solid waste landfill in the South of Spain. Appl. Therm. Eng. 2015, 91, 706–717. [Google Scholar] [CrossRef]

- Fallahizadeh, S.; Rahmatinia, M.; Mohammadi, Z.; Vaezzadeh, M.; Tajamiri, A.; Soleimani, H. Estimation of methane gas by LandGEM model from Yasuj municipal solid waste landfill, Iran. MethodsX 2019. [Google Scholar] [CrossRef]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; Towards a Circular Economy: A Zero Waste Programme for Europe. Act. Communication (2014) 398 Final; European Commission: Brussels, Belgium, 2014. [Google Scholar]

- Eriksson, O.; Finnveden, G. Energy Recovery from Waste Incineration—The Importance of Technology Data and System Boundaries on CO2 Emissions. Energies 2017, 10, 539. [Google Scholar] [CrossRef]

- Di Matteo, U.; Nastasi, B.; Albo, A.; Garcia, D.A. Energy Contribution of OFMSW (Organic Fraction of Municipal Solid Waste) to Energy-Environmental Sustainability in Urban Areas at Small Scale. Energies 2017, 10, 229. [Google Scholar] [CrossRef]

- Kourkoumpas, D.S.; Karellas, S.; Kouloumoundras, S.; Koufodimos, G.; Grammelis, P.; Kakaras, E. Comparison of Waste-to-Energy Processes by Means of Life Cycle Analysis Principles regarding the Global Warming Potential Impact: Applied Case Studies in Greece, France and Germany. Waste Biomass Valorization 2015, 6, 605–621. [Google Scholar] [CrossRef]

- Thanopoulos, S.; Karellas, S.; Kavrakos, M.; Konstantellos, G.; Tzempelikos, D.; Kourkoumpas, D. Analysis of Alternative MSW Treatment Technologies with the Aim of Energy Recovery in the Municipality of Vari-Voula-Vouliagmeni. Waste Biomass Valorization 2018. [Google Scholar] [CrossRef]

- Ramos, A.; Teixeira, C.A.; Rouboa, A. Environmental Analysis of Waste-to-Energy—A Portuguese Case Study. Energies 2018, 11, 548. [Google Scholar] [CrossRef]

- Saidani, M.; Yannou, B.; Leroy, Y.; Cluzel, F. Alissa Kendall, A taxonomy of circular economy indicators. J. Clean. Prod. 2019, 207, 542–559. [Google Scholar] [CrossRef]

| Waste –to-Energy Plant | (Landfill) Lo = 100/k = 0.05 | (Landfill) Lo = 170/k = 0.05 | |

|---|---|---|---|

| Electrical efficiency (%) | 17 | 40.8 | 40.8 |

| Thermal efficiency (%) | 55 | 41.7 | 41.7 |

| Temperature of output heat (°C) | 85 | 90 | 90 |

| Exergy efficiency of metals (%) | 0%–60% | 0%–40% | 0%–40% |

| Parameters of Analysis | Lo = 100 | Lo = 170 |

|---|---|---|

| Total energy input (waste, PJ) | 12,000 | 12,000 |

| Energy input years 20–60 (waste, PJ) | 4800 | 4800 |

| Energy in landfill Gas Years (Y) 20–60 (PJ) | 1455.01 | 1926.37 |

| Recovered energy in Landfill Gas (LG) (total) (%) | 22.99 | 24.67 |

| Recovered energy in LG (Y 20–60) (%) | 12.13 | 16.05 |

| Gross recovered energy in LG Y 0–60 (%) | 20.21 | 26.76 |

| Net recovered energy in LG Y 20–60 (%) | 30.31 | 40.13 |

| Net/gross electrical efficiency (%) | 12.37/8.25 | 16.37/10.92 |

| Net/gross thermal efficiency (%) | 12.64/8.43 | 16.74/11.16 |

| Net/gross Combined Heat and Power efficiency (%) | 25.01/16.67 | 33.11/22.07 |

| Total exergy efficiency net/gross (%) | 14.63/11.23 | 19.37/14.87 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vakalis, S.; Moustakas, K. Applications of the 3T Method and the R1 Formula as Efficiency Assessment Tools for Comparing Waste-to-Energy and Landfilling. Energies 2019, 12, 1066. https://doi.org/10.3390/en12061066

Vakalis S, Moustakas K. Applications of the 3T Method and the R1 Formula as Efficiency Assessment Tools for Comparing Waste-to-Energy and Landfilling. Energies. 2019; 12(6):1066. https://doi.org/10.3390/en12061066

Chicago/Turabian StyleVakalis, Stergios, and Konstantinos Moustakas. 2019. "Applications of the 3T Method and the R1 Formula as Efficiency Assessment Tools for Comparing Waste-to-Energy and Landfilling" Energies 12, no. 6: 1066. https://doi.org/10.3390/en12061066

APA StyleVakalis, S., & Moustakas, K. (2019). Applications of the 3T Method and the R1 Formula as Efficiency Assessment Tools for Comparing Waste-to-Energy and Landfilling. Energies, 12(6), 1066. https://doi.org/10.3390/en12061066