Numerical Simulation and Experimental Investigation of Diesel Fuel Reforming over a Pt/CeO2-Al2O3 Catalyst

Abstract

:1. Introduction

2. Theory and Experiment

2.1. Reforming Kinetics of Representative Hydrocarbons

2.2. Reforming Process Evaluated

- n-Heptane was used as surrogate diesel fuel to simulate the gas phase reaction processes.

- The surface reaction mechanisms of propene were applied to investigate the reforming products over platinum catalyst.

- Pt/CeO2-Al2O3 catalyst seen in Figure 1 was chosen and its profile was measured by using a Micromeritics ASAP 2020 device. The measured parameters of the catalyst were: Pt 2.0 wt %, CeO2 49.0 wt %, Al2O3 49.0 wt %, surface area 100 m2/g, surface density 2.04 × 10−9 moles/cm2, porosity 0.8, diameter 2.2 cm and length 8.5 cm.

- Referring to the prototype diesel engine operating conditions [35], the Gas Hourly Space Velocity (GHSV; volumetric flow rate of gas per hour divided by the volume of the catalyst bed) was set to 10,000, 15,000, 20,000 and 25,000 1/h. O2/C molar ratio was set to 0.6, 0.8, 1.0 and 1.2. H2O/C molar ratio was set to 1, 1.5, 2 and 2.5. The reaction temperature was set to 400, 450, 500, and 550 °C.

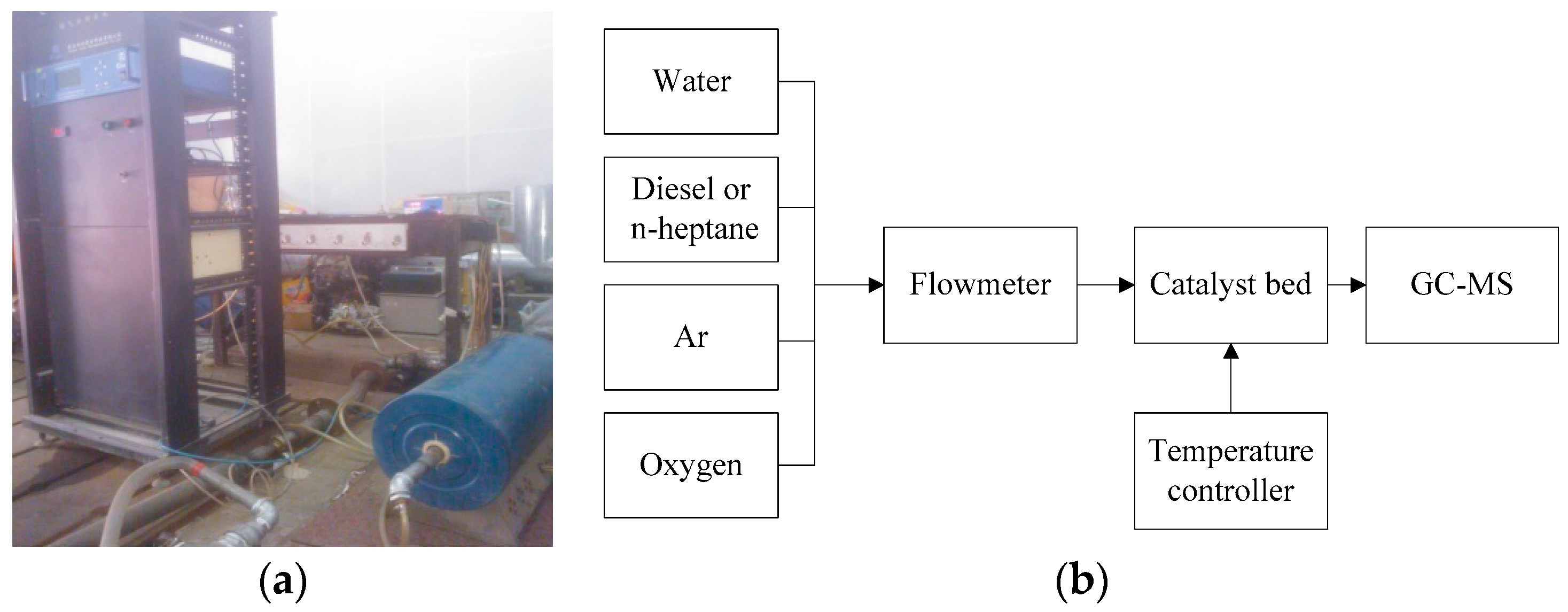

2.3. Experimental Procedure

3. Results and Discussion

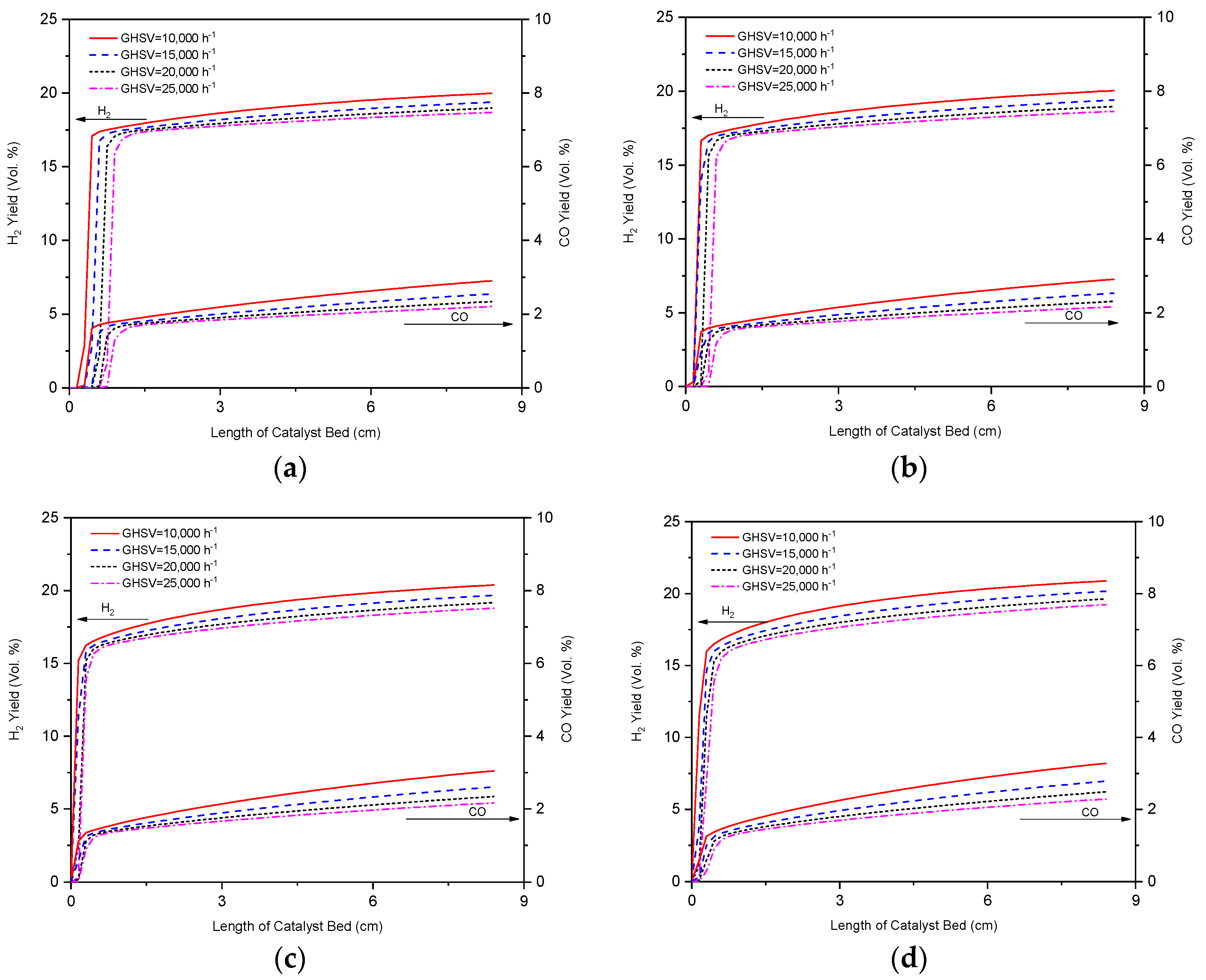

3.1. Effect of GHSV on Reformer Product

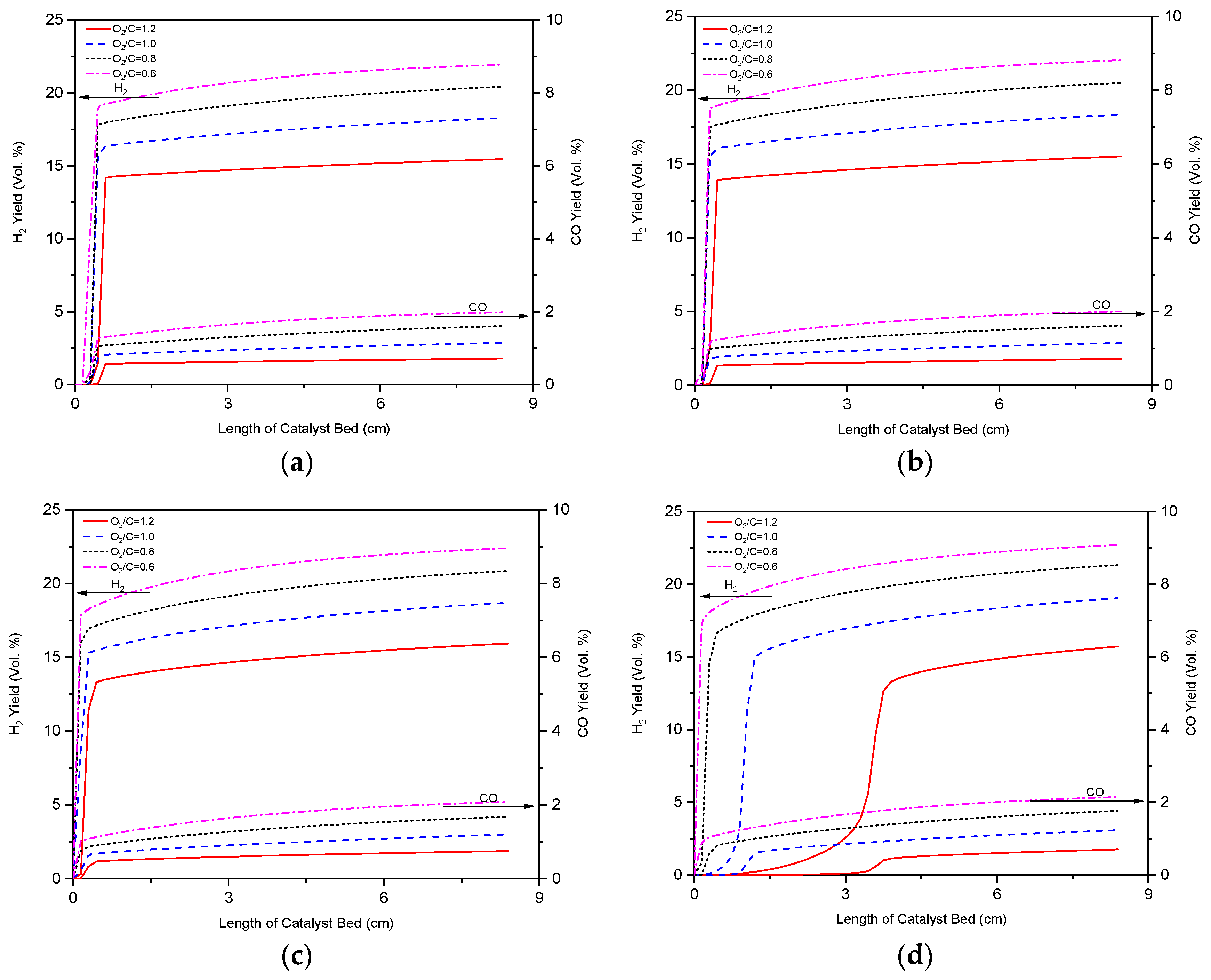

3.2. Effect of O2/C Ratio on Reformer Product

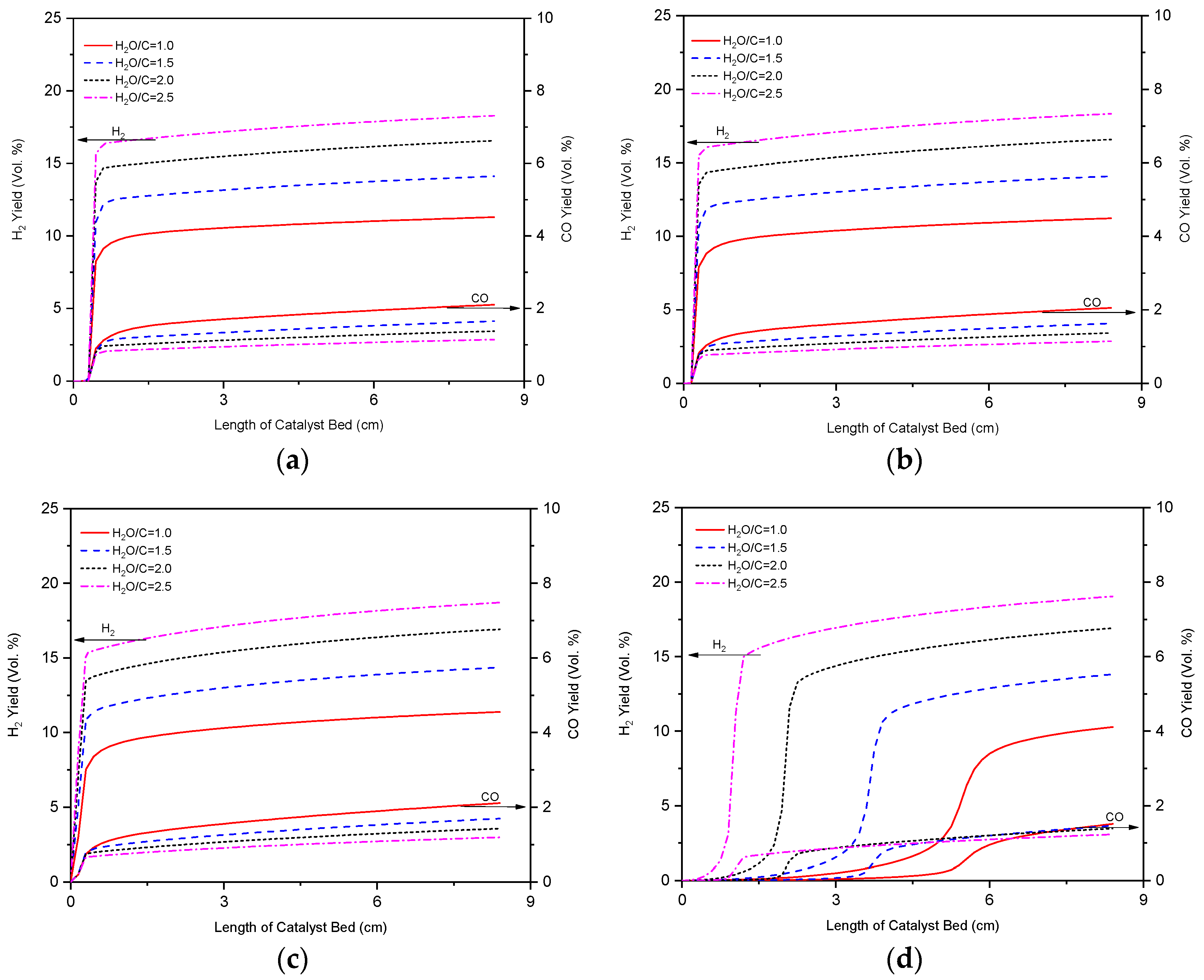

3.3. Effect of H2O/C Ratio on Reformer Product

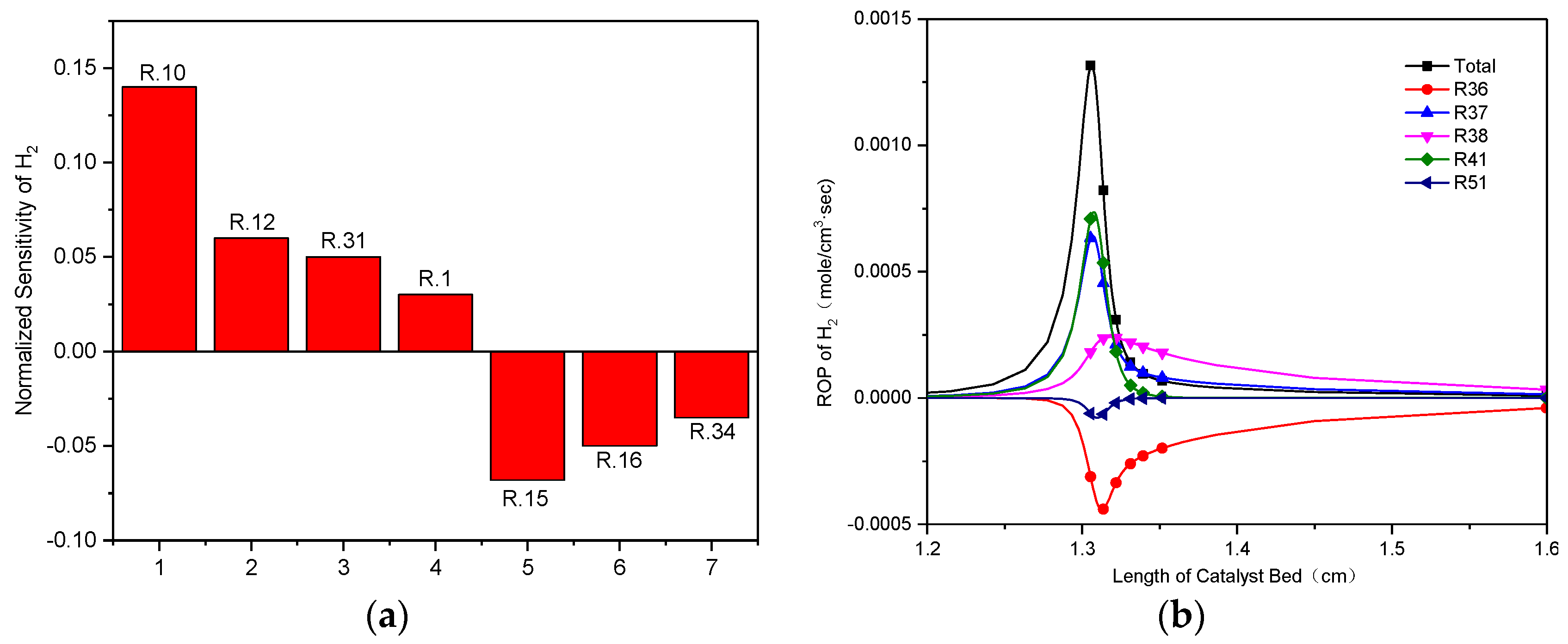

3.4. Sensitivity Analysis and ROP Analysis of the Reaction Steps Effect on H2 Production

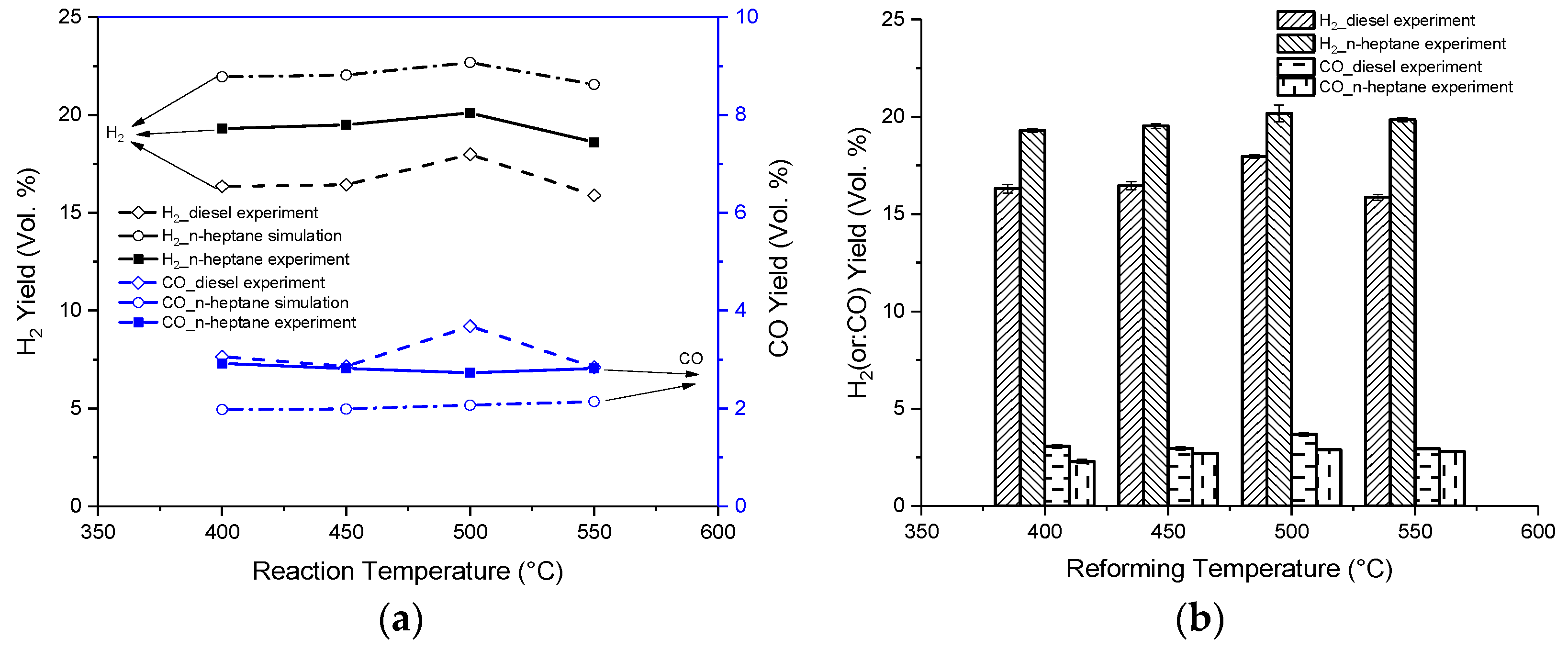

3.5. Experimental Results of H2 and CO Production

4. Conclusions

- During the n-heptane reforming simulation process, the H2 and CO yields (vol.%) increased as the GHSV decreased. In addition, the maximum H2 and CO yield moved toward unity as the GHSV decreased and the reaction temperature increased. Under lower GHSV conditions, hydrogen and carbon monoxide selectivity was much lower than under higher GHSV conditions. The H2 and CO yield (vol.%) increased as the reaction temperature increased from 400 to 500 °C. Due to occurrence of the WGSR reaction, the actual mole ratio of H2/CO for the reformer products exceeded the stoichiometric ratio of H2/CO for the one-step n-heptane SR reaction.

- An increase of O2/C ratio meant an increase of the quantity of oxygen reacting with hydrogen and carbon monoxide. In the n-heptane reforming simulation results, both the hydrogen and carbon monoxide mole fractions decreased with an increase of O2/C ratio. A GHSV of 10,000 1/h, O2/C ratio of 0.6 and reaction temperature of 500 °C were preferable in terms of H2 and CO productivity.

- As the water added to the reforming reactor and H2O/C ratio increased from 1.0 to 2.5, the H2 production increased but the CO content of the reformer product was reduced during the n-heptane reforming simulation process. There was a trade-off between the H2O/C ratio and the reaction temperature. Optimisation of the reforming reaction process and the catalyst to obtain further conversion of the carbon monoxide to hydrogen by the WGSR would improve the produced hydrogen levels even further.

- For the simulation of n-heptane reforming under typical diesel engine operating conditions, the reaction temperature effect was more pronounced at low reaction temperatures, e.g., from 400 °C to 500 °C, than at high reaction temperatures, e.g., from 500 °C to 550 °C.

- Through the comparison of reforming bench tests of diesel fuel and n-heptane, the change trends of H2 and CO yield (vol.%) revealed consistence, although differences between the average H2 and CO yield (vol.%) results were obvious. A reduction range of H2 yield (vol.%) of diesel fuel reforming from 10.9% to 20.1% compared to n-heptane reforming experiments was achieved at typical reaction temperatures. The characteristics of n-heptane reforming could represent the H2 and CO yield (vol.%) features of diesel fuel reforming under typical reaction temperature to a certain extent.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| GHSV | gas hourly space velocity |

| SR | steam reforming |

| ATR | autothermal reforming |

| POX | partial oxidation reforming |

| WGSR | water gas shift reaction |

| LLNL | Lawrence Livermore National Laboratory |

| GC-MS | gas chromatograph-mass spectrometer |

| vol. | volume |

| ROP | rate-of-production |

| 1/h | 1/hour |

| A | pre-exponential factor |

| s−1 | second−1 |

| n | temperature index |

| E | activation energy |

| J | joule |

| mol | mole |

| cm | centimetre |

| kg | kilogram |

| wt | weight |

References

- Tsolakis, A.; Megaritis, A.; Wyszynski, M.L. Low temperature exhaust gas fuel reforming of diesel fuel. Fuel 2004, 83, 1837–1845. [Google Scholar] [CrossRef]

- Tsolakis, A.; Megaritis, A.; Wyszynski, M.L. Application of exhaust gas fuel reforming in compression ignition engines fuelled by diesel and biodiesel fuel mixtures. Energy Fuels 2003, 17, 1464–1473. [Google Scholar] [CrossRef]

- Lee, J.; Song, S.; Chun, K.M. Study of n-C12H26 reforming over DFC catalyst in a simulated diesel exhaust. Int. J. Automot. Technol. 2012, 13, 23–31. [Google Scholar] [CrossRef]

- Xu, L.; Mi, W.; Su, Q. Hydrogen production through diesel steam reforming over rare-earth promoted Ni/γ-Al2O3 catalysts. J. Nat. Gas Chem. 2011, 20, 287–293. [Google Scholar] [CrossRef]

- Boon, J.; Van Dijk, E.; De Munck, S.; Van den Brink, R. Steam reforming of commercial ultra-low sulphur diesel. J. Power Sources 2011, 196, 5928–5935. [Google Scholar] [CrossRef]

- Achouri, I.E.; Abatzoglou, N.; Fauteux-Lefebvre, C.; Braidy, N. Diesel steam reforming: Comparison of two nickel aluminate catalysts prepared by wet-impregnation and co-precipitation. Catal. Today 2013, 207, 13–20. [Google Scholar] [CrossRef]

- Wang, P.J.; Zhou, L.; Li, G.L.; Lin, H.X.; Shao, Z.G.; Zhang, X.F.; Yi, B.L. Direct internal reforming molten carbonate fuel cell with core-shell catalyst. Int. J. Hydrogen Energy 2012, 37, 2588–2595. [Google Scholar] [CrossRef]

- Meißner, J.; Pasel, J.; Peters, R.; Samsun, R.C.; Thimm, F.; Stolten, D. Quantitative analysis of sub-ppm traces of hydrocarbons in the product gas from diesel reforming. Int. J. Hydrogen Energy 2019, 44, 4020–4030. [Google Scholar] [CrossRef]

- Kang, I.; Bae, J.; Bae, G. Performance comparison of autothermal reforming for liquid hydrocarbons, gasoline and diesel for fuel cell applications. J. Power Sources 2006, 163, 538–546. [Google Scholar] [CrossRef]

- Choi, W.Y.; Lee, J.W.; Kim, M.J.; Park, C.J.; Jeong, Y.H.; Choi, H.Y.; Park, N.K.; Lee, T.J. Durability tests of Rh/Al-Ce-Zr catalysts coated on NiCrAl metal foam for ATR of dodecane at high temperature. Int. J. Precis. Eng. Manuf.-Green Technol. 2017, 4, 183–189. [Google Scholar] [CrossRef]

- Thiyagarajan, S.; Herfatmanesh, M.R.; Geo, V.E.; Peng, Z. Experimental investigation into the effect of magnetic fuel reforming on diesel combustion and emissions running on wheat germ and pine oil. Fuel Process. Technol. 2019, 186, 116–124. [Google Scholar] [CrossRef]

- Huerta, G.V.; Jordan, J.A.; Dragon, M.; Leites, K.; Kabelac, S. Energy analysis of the diesel pre-reforming solid oxide fuel cell system with anode off-gas recycling in the SchIBZ project. Pat I: Modeling and validation. Int. J. Hydrogen Energy 2018, 43, 16684–16693. [Google Scholar] [CrossRef]

- Garcia-Diez, E.; Garcia-Labiano, F.; De, L.F.; Abad, A.; Gayan, P.; Adanez, J. Autothermal chemical looping reforming process of different fossil liquid fuels. Int. J. Hydrogen Energy 2017, 42, 13633–13640. [Google Scholar] [CrossRef]

- Lee, W.S.; Dong, G.J.; Jung, S.Y.; Lee, S.C.; Dong, S.H.; Hwang, B.W.; Jae, C.K. N-Dodecane autothermal reforming properties of Ni-Al based catalysts prepared by various methods. Top. Catal. 2017, 60, 727–734. [Google Scholar] [CrossRef]

- Ra, Y.; Reitz, R.D. A combustion model for IC engine combustion simulations with multi-component fuels. Combust. Flame 2011, 158, 69–90. [Google Scholar] [CrossRef]

- Palm, C.; Cremer, P.; Peters, R.; Stolten, D. Small-scale testing of a precious metal catalyst in the autothermal reforming of various hydrocarbon feeds. J. Power Sources 2002, 106, 231–237. [Google Scholar] [CrossRef]

- Tsolakis, A.; Megaritis, A.; Golunski, S.E. Reaction profiles during exhaust-assisted reforming of diesel engine fuels. Energy Fuels 2005, 19, 744–752. [Google Scholar] [CrossRef]

- Tsolakis, A.; Golunski, S.E. Sensitivity of process efficiency to reaction routes in exhaust-gas reforming of diesel fuel. Chem. Eng. J. 2006, 117, 131–136. [Google Scholar] [CrossRef]

- Amphlett, J.C.; Mann, R.F.; Peppley, B.A.; Roberge, P.R.; Rodrigues, A.; Salvador, J.P. Simulation of a 250kW diesel fuel processor/PEM fuel cell system. J. Power Sources 1998, 71, 179–184. [Google Scholar] [CrossRef]

- Cheekatamarla, P.K.; Finnerty, C.M. Reforming catalysts for hydrogen generation in fuel cell applications. J. Power Sources 2006, 160, 490–499. [Google Scholar] [CrossRef]

- Ghenciu, A.F. Review of fuel processing catalysts for hydrogen production in PEM fuel cell systems. Curr. Opin. Solid State Mater. Sci. 2002, 6, 389–399. [Google Scholar] [CrossRef]

- Craciun, R.; Shereck, B.; Gorte, R.J. Kinetic studies of methane steam reforming on ceria-supported Pd. Catal. Lett. 1998, 51, 149–153. [Google Scholar] [CrossRef]

- Wang, X.; Gorte, R.J. A study of steam reforming of hydrocarbon fuels on Pd/ceria. Appl. Catal. A-Gen. 2002, 224, 209–218. [Google Scholar] [CrossRef]

- Montini, T.; Melchionna, M.; Monai, M.; Fornasiero, P. Fundamentals and catalytic applications of CeO2-Based materials. Chem. Rev. 2016, 116, 5987–6041. [Google Scholar] [CrossRef] [PubMed]

- Devaiah, D.; Reddy, L.H.; Park, S.E.; Reddy, B.M. Ceria-zirconia mixed oxides: Synthetic methods and applications. Catal. Rev. 2018, 60, 177–277. [Google Scholar] [CrossRef]

- Hamoule, T.; Peyrovi, M.H.; Rashidzadeh, M.; Toosi, M.R. Catalytic reforming of n-heptane over Pt/Al-HMS catalysts. Catal. Commun. 2011, 16, 234–239. [Google Scholar] [CrossRef]

- Abashar, M.E.E. Steam reforming of n-heptane for production of hydrogen and syngas. Int. J. Hydrogen Energy 2013, 38, 861–869. [Google Scholar] [CrossRef]

- Gonzalez-Marcos, M.P.; Inarra, B.; Guil, J.M.; Gutierrez-Ortiz, M.A. Development of an industrial characterisation method for naphtha reforming bimetallic Pt-Sn/Al2O3 catalysts through n-heptane reforming test reactions. Catal. Today 2005, 44, 685–692. [Google Scholar] [CrossRef]

- Koop, J.; Deutschmann, O. Detailed surface reaction mechanism for Pt-catalyzed abatement of automotive exhaust gases. Appl. Catal. B-Environ. 2009, 91, 47–58. [Google Scholar] [CrossRef]

- Zamostny, P.; Karaba, A.; Olahova, N.; Petru, J.; Patera, J.; Hajekova, E.; Bajus, M.; Belohlav, Z. Generalized model of n-heptane pyrolysis and steam cracking kinetics based on automated reaction network generation. J. Anal. Appl. Pyrol. 2014, 109, 159–167. [Google Scholar] [CrossRef]

- Chatterjee, D.; Deutschmann, O.; Warnatz, J. Detailed surface reaction mechanism in a three-way catalyst. Faraday Discuss. 2001, 119, 371–384. [Google Scholar] [CrossRef]

- Curran, H.J.; Gaffuri, P.; Pitz, W.J.; Westbrook, C.K. A comprehensive modelling study of n-heptane oxidation. Combust. Flame 1998, 114, 149–177. [Google Scholar] [CrossRef]

- Zhang, K.; Banyon, C.; Bugler, J.; Curran, H.J.; Rodriguez, A.; Herbinet, O.; Battin-Leclerc, F.; B’Chir, C.; Heufer, K.A. An updated experimental and kinetic modelling study of n-heptane oxidation. Combust. Flame 2016, 172, 116–135. [Google Scholar] [CrossRef]

- Reaction Design. Available online: http://www.reactiondesign.com/products/chemkin/chemkin-2/ (accessed on 10 January 2019).

- Chen, H.; Shen, H.; Wu, T.; Zuo, C. Numerical simulation and experimental research on combustion characteristics of compression-ignition engine under an O2/CO2 atmosphere. HKIE Trans. 2017, 24, 121–132. [Google Scholar] [CrossRef]

- Kim, D.H.; Kang, J.S.; Lee, Y.J.; Park, N.K.; Kim, Y.C.; Hong, S.I.; Moon, D.J. Steam reforming of n-hexadecane over noble metal-modified Ni-based catalysts. Catal. Today 2008, 136, 228–234. [Google Scholar] [CrossRef]

- Tsolakis, A.; Megaritis, A. Catalytic exhaust gas fuel reforming for diesel engines-effects of water addition on hydrogen production and fuel conversion efficiency. Int. J. Hydrogen Energy 2004, 29, 1409–1419. [Google Scholar] [CrossRef]

- Mariagiovanna, M. On-board fuel processor modelling for hydrogen-enriched gasoline fuelled engine. Int. J. Hydrogen Energy 2005, 30, 1483–1490. [Google Scholar]

- Dong, J.M.; Sreekumar, K.; Sang, D.L.; Lee, B.G.; Kim, H.S. Study on gasoline fuel processor system for fuel-cell powered vehicles application. Appl. Catal. A-Gen. 2001, 215, 1–9. [Google Scholar]

- Tottrup, P.B. Evaluation of intrinsic steam reforming kinetic parameters from rate measurements on full particle size. Appl. Catal. 1982, 4, 377–389. [Google Scholar] [CrossRef]

- Nah, C.Y.; Palanki, S. Analysis of heptane autothermal reformer to generate hydrogen for fuel cell applications. Int. J. Hydrogen Energy 2009, 34, 8566–8573. [Google Scholar] [CrossRef]

- Whittington, B.I.; Jiang, C.J.; Trimm, D.L. The relative importance of catalytic oxidation, steam reforming and water-gas shift reactions. Catal. Today 1995, 26, 41–45. [Google Scholar] [CrossRef]

| Reaction Step | Elementary-Step Reaction | A | n | E |

|---|---|---|---|---|

| R.1 | C7H16 + O2 = C7H15 + HO2 | 2.8 × 1014 | 0.0 | 47,180.0 |

| R.2 | C7H16 + H = C7H15 + H2 | 5.6 × 107 | 2.0 | 7667.0 |

| R.3 | C7H16 = C7H15 + H | 3.972 × 1019 | −0.95 | 103,200.0 |

| R.4 | C7H16 + OH = C7H15 + H2O | 8.600 × 109 | 1.1 | 1815.0 |

| R.5 | C7H16 + HO2 = C7H15 + H2O2 | 8.000 × 1012 | 0.0 | 19,300.0 |

| R.6 | C7H15 + O2 = C7H15O2 | 2.000 × 1012 | 0.0 | 0.0 |

| R.7 | C5H11CO = C5H11 + CO | 1.000 × 1011 | 0.0 | 9600.0 |

| R.8 | C7H15O2 = C7H14O2H | 6.000 × 1011 | 0.0 | 20,380.0 |

| R.9 | C7H16 = C4H9 + C3H7 | 2.000 × 1016 | 0.0 | 80,710.0 |

| R.10 | C7H14O2H + O2 = C7H14O2HO2 | 2.34 × 1011 | 0.0 | 0.0 |

| R.11 | C7H14O2HO2 = C7H14O3 + OH | 2.965 × 1013 | 0.0 | 26,700.0 |

| R.12 | C7H14O3 = C5H11CO + CH2O + OH | 1.000 × 1016 | 0.0 | 42,400.0 |

| R.13 | C5H11CO = C2H5 + C3H6 + CO | 1.000 × 1011 | 0.0 | 9600.0 |

| R.14 | C5H11 = C2H5 + C3H6 | 3.200 × 1013 | 0.0 | 28,300.0 |

| R.15 | C7H15 = CH3 + 2C3H6 | 3.000 × 1013 | 0.0 | 29,800.0 |

| R.16 | C7H15 = C2H5 + C2H4 + C3H6 | 1.200 × 1013 | 0.0 | 28,300.0 |

| R.17 | C3H6 + OH = CH3CHO + CH3 | 3.500 × 1011 | 0.0 | 0.0 |

| R.18 | CH3CHO + OH = CH3 + CO + H2O | 1.000 × 1013 | 0.0 | 0.0 |

| R.19 | C4H9 = C2H5 + C2H4 | 2.500 × 1013 | 0.0 | 28,810.0 |

| R.20 | C3H7 = C2H4 + CH3 | 9.600 × 1013 | 0.0 | 30,950.0 |

| R.21 | C3H6 = C2H3 + CH3 | 6.150 × 1015 | 0.0 | 85,500.0 |

| R.22 | CH3 + HO2 = CH2O + H + OH | 4.300 × 1013 | 0.0 | 0.0 |

| R.23 | CO + OH = CO2 + H | 3.510 × 107 | 1.3 | −758.0 |

| R.24 | O + OH = O2 + H | 4.000 × 1014 | −0.5 | 0.0 |

| R.25 | H + O2 + M = HO2 + M | 2.800 × 1018 | −0.86 | 0.0 |

| R.26 | HO2 + HO2 = H2O2 + O2 | 2.000 × 1012 | 0.0 | 0.0 |

| R.27 | OH + OH (+M) = H2O2 (+M) | 7.600 × 1013 | −0.37 | 0.0 |

| R.28 | CH2O + OH = HCO + H2O | 2.430 × 1010 | 1.18 | −447.0 |

| R.29 | CH2O + HO2 = HCO + H2O2 | 3.000 × 1012 | 0.0 | 8000.0 |

| R.30 | HCO + O2 = HO2 + CO | 3.300 × 1013 | −0.4 | 0.0 |

| R.31 | CH4 + O = CH3 + OH | 1.020 × 1019 | 1.5 | 8604.0 |

| R.32 | CH4 + HO2 = CH3 + H2O2 | 1.000 × 1013 | 0.0 | 18,700.0 |

| R.33 | C2H4 + OH = CH2O + CH3 | 6.000 × 1013 | 0.0 | 960.0 |

| R.34 | H + O2 + N2 = HO2 + N2 | 2.600 × 1019 | −1.24 | 0.0 |

| R.35 | C2H5 + O2 = C2H4 + HO2 | 2.000 × 1010 | 0.0 | −2200.0 |

| R.36 | CH4 + 2H2O = CO2 + 4H2 | 2.290 × 1012 | 0.0 | 20,000.0 |

| R.37 | CO + H2O = CO2 + H2 | 6.200 × 1015 | 0.0 | 20,000.0 |

| R.38 | C3H6 + 3H2O ⇒ 3CO + 6H2 | 9.49 × 1020 | 0.0 | 10,000.0 |

| R.39 | C3H5+3H2O ⇒ 3CO + 5.5H2 | 9.49 × 1015 | 0.0 | 67,800.0 |

| R.40 | C2H5 + 2H2O ⇒ 2CO + 4.5H2 | 9.49 × 1015 | 0.0 | 10,000.0 |

| R.41 | C2H4 + 2H2O ⇒ 2CO + 4H2 | 9.49 × 1020 | 0.0 | 18,000.0 |

| R.42 | CH3 + H2O ⇒ CO + 2.5H2 | 9.49 × 1016 | 0.0 | 67,800.0 |

| R.43 | H + C2H5 ⇒ H2 + C2H4 | 2.000 × 1012 | 0.0 | 0.0 |

| R.44 | C2H4 + H = C2H3 + H2 | 5.670 × 1019 | 0.0 | 62,900.0 |

| R.45 | C2H6 + H = C2H5 + H2 | 1.400 × 1019 | 0.0 | 31,000.0 |

| R.46 | C2H5 = C2H4 + H | 1.020 × 1043 | −9.1 | 22,400.0 |

| R.47 | H2 + CO(+M) ⇔ CH2O(+M) | 4.300 × 107 | 1.5 | 79,600.0 |

| R.48 | 2O + M ⇔ O2 + M | 1.200 × 1017 | −1.0 | 0.0 |

| R.49 | H + HO2 ⇔ O2 + H2 | 4.480 × 1013 | 0.0 | 1068.0 |

| R.50 | H + CH4 ⇔ CH3 + H2 | 6.600 × 1013 | 1.620 | 10,840.0 |

| R.51 | H + HCO ⇔ H2 + CO | 7.340 × 1013 | 0.0 | 0.0 |

| R.52 | H + CH2O ⇔ HCO + H2 | 5.740 × 1017 | 1.900 | 2742.0 |

| R.53 | 2H + M ⇔ H2 + M | 1.000 × 1018 | 1.0 | 0.0 |

| R.54 | 2H + H2 ⇔ 2H2 | 9.000 × 1016 | −0.6 | 0.0 |

| R.55 | 2H + H2O ⇔ H2 + H2O | 6.000 × 1019 | −1.25 | 0.0 |

| R.56 | 2H + CO2 ⇔ H2 + CO2 | 5.500 × 1020 | −2.0 | 0.0 |

| R.57 | O2 + CO ⇔ O + CO2 | 2.500 × 1012 | 0.0 | 47,800.0 |

| R.58 | O + CO(+M) ⇔ CO2(+M) | 1.800 × 1010 | 0.0 | 2385.0 |

| Reaction Step | Elementary-Step Reaction | A | n | E |

|---|---|---|---|---|

| R.1 | CO2 + Pt(S) ⇒ CO2(S) | 5.000 × 10−3 | 0.0 | 0.0 |

| R.2 | O + Pt(S) +Pt(S) ⇒ O(S) + O(S) | 7.000 × 10−2 | 0.0 | 0.0 |

| R.3 | C3H6 + Pt(S) + Pt(S) ⇒ C3H6(S) | 9.800 × 10−1 | 0.0 | 0.0 |

| R.4 | C3H6 + O(S) + Pt(S) ⇒ C3H5(S) + OH(S) | 5.000 × 10−2 | 0.0 | 0.0 |

| R.5 | H2O + Pt(S) ⇒ H2O(S) | 4.600 × 10−2 | 0.0 | 0.0 |

| R.6 | CO + Pt(S) ⇒ CO(S) | 8.400 × 10−1 | 0.0 | 0.0 |

| R.7 | H2 + Pt(S) + Pt(S) ⇒ H(S) + H(S) | 4.600 × 10−2 | 0.0 | 0.0 |

| R.8 | O(S) + O(S) ⇒ Pt(S) + Pt(S) + O2 | 3.700 × 1021 | 0.0 | 232.2 |

| R.9 | C3H6(S) ⇒ C3H6 + Pt(S) + Pt(S) | 1.000 × 1013 | 0.0 | 72.7 |

| R.10 | C3H5(S) + OH(S) ⇒ C3H6 O(S) + Pt(S) | 3.700 × 1021 | 0.0 | 31.0 |

| R.11 | H(S) + H(S) ⇒ H2 + Pt(S) + Pt(S) | 3.700 × 1021 | 0.0 | 67.4 |

| R.12 | H2O(S) ⇒ Pt(S) + H2O | 1.000 × 1013 | 0.0 | 40.3 |

| R.13 | CO(S) ⇒ CO + Pt(S) | 1.000 × 1013 | 0.0 | 136.4 |

| R.14 | CO2(S) ⇒ CO2 + Pt(S) | 1.000 × 1013 | 0.0 | 27.1 |

| R.15 | C3H5(S) + 5O(S) + 2Pt(S) ⇒ 5OH(S) + 3C(S) | 3.700 × 1021 | 0.0 | 95.0 |

| R.16 | C3H6(S) ⇒ CC2H5(S) + H(S) | 1.000 × 1013 | 0.0 | 75.4 |

| R.17 | CC2H5(S) + H(S) ⇒ C3H6(S) | 3.700 × 1021 | 0.0 | 48.8 |

| R.18 | CC2H5(S) + Pt(S) ⇒ C2H3(S) + CH2(S) | 3.700 × 1021 | 0.0 | 108.2 |

| R.19 | C2H3(S) + CH2(S) ⇒ CC2H5(S) + Pt(S) | 3.700 × 1021 | 0.0 | 3.2 |

| R.20 | C2H3(S) + Pt(S) ⇒ CH3(S) + C(S) | 3.700 × 1021 | 0.0 | 46.0 |

| R.21 | CH3(S) + C(S) ⇒ C2H3(S) + Pt(S) | 3.700 × 1021 | 0.0 | 46.9 |

| R.22 | CH3(S) + Pt(S) ⇒ CH2(S) + H(S) | 1.260 × 1021 | 0.0 | 70.4 |

| R.23 | CH2(S) + H(S) ⇒ CH3(S) + Pt(S) | 3.090 × 1021 | 0.0 | 0.0 |

| R.24 | CH2(S) + Pt(S) ⇒ CH(S) + H(S) | 7.000 × 1021 | 0.0 | 59.2 |

| R.25 | CH(S) + H(S) ⇒ CH2(S) + Pt(S) | 3.090 × 1021 | 0.0 | 0.0 |

| R.26 | CH(S) + Pt(S) ⇒ C(S) + H(S) | 3.090 × 1021 | 0.0 | 0.0 |

| R.27 | C(S) + H(S) ⇒ CH(S) + Pt(S) | 1.250 × 1021 | 0.0 | 138.0 |

| R.28 | C2H3(S) + O(S) ⇒ Pt(S) + CH3CO(S) | 3.700 × 1019 | 0.0 | 62.3 |

| R.29 | CH3CO(S) + Pt(S) ⇒ C2H3(S) + O(S) | 3.700 × 1021 | 0.0 | 196.7 |

| R.30 | CH3(S) + CO(S) ⇒ Pt(S) + CH3CO(S) | 3.700 × 1021 | 0.0 | 82.9 |

| R.31 | CH3CO(S) + Pt(S) ⇒ CH3(S) + CO(S) | 3.700 × 1021 | 0.0 | 0.0 |

| R.32 | CH3(S) + O(S) ⇒ CH2(S) + OH(S) | 3.700 × 1021 | 0.0 | 36.6 |

| R.33 | CH2(S) + OH(S) ⇒ CH3(S) + O(S) | 3.700 × 1021 | 0.0 | 25.1 |

| R.34 | CH2(S) + O(S) ⇒ CH(S) + OH(S) | 3.700 × 1021 | 0.0 | 25.1 |

| R.35 | CH(S) + OH(S) ⇒ CH2(S) + O(S) | 3.700 × 1021 | 0.0 | 25.2 |

| R.36 | CH(S) + O(S) ⇒ C(S) + OH(S) | 3.700 × 1021 | 0.0 | 25.1 |

| R.37 | C(S) + OH(S) ⇒ CH(S) + O(S) | 3.700 × 1021 | 0.0 | 224.8 |

| R.38 | O(S) + H(S) ⇒ OH(S) + Pt(S) | 3.700 × 1021 | 0.0 | 11.5 |

| R.39 | OH(S) + Pt(S) ⇒ O(S) + H(S) | 5.770 × 1022 | 0.0 | 74.9 |

| R.40 | H(S) + OH(S) ⇒ H2O(S) + Pt(S) | 3.700 × 1021 | 0.0 | 17.4 |

| R.41 | H2O(S) + Pt(S) ⇒ H(S) + OH(S) | 3.660 × 1021 | 0.0 | 73.6 |

| R.42 | OH(S) + OH(S) ⇒ H2O(S) + O(S) | 3.700 × 1021 | 0.0 | 48.2 |

| R.43 | H2O(S) + O(S) ⇒ OH(S) + OH(S) | 2.350 × 1021 | 0.0 | 41.0 |

| R.44 | CO2(S) + Pt(S) ⇒ CO(S) + O(S) | 3.700 × 1021 | 0.0 | 165.1 |

| R.45 | OH + Pt(S) ⇒ OH(S) | 1.000 | 0.0 | 0.0 |

| R.46 | OH(S) ⇒ OH + Pt(S) | 1.000 × 1013 | 0.0 | 192.8 |

| R.47 | CH4 + 2Pt(S) ⇒ CH3(S) + H(S) | 4.6334 × 1020 | 0.5 | 0.0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, H.; Wang, X.; Pan, Z.; Xu, H. Numerical Simulation and Experimental Investigation of Diesel Fuel Reforming over a Pt/CeO2-Al2O3 Catalyst. Energies 2019, 12, 1056. https://doi.org/10.3390/en12061056

Chen H, Wang X, Pan Z, Xu H. Numerical Simulation and Experimental Investigation of Diesel Fuel Reforming over a Pt/CeO2-Al2O3 Catalyst. Energies. 2019; 12(6):1056. https://doi.org/10.3390/en12061056

Chicago/Turabian StyleChen, Hanyu, Xi Wang, Zhixiang Pan, and Hongming Xu. 2019. "Numerical Simulation and Experimental Investigation of Diesel Fuel Reforming over a Pt/CeO2-Al2O3 Catalyst" Energies 12, no. 6: 1056. https://doi.org/10.3390/en12061056

APA StyleChen, H., Wang, X., Pan, Z., & Xu, H. (2019). Numerical Simulation and Experimental Investigation of Diesel Fuel Reforming over a Pt/CeO2-Al2O3 Catalyst. Energies, 12(6), 1056. https://doi.org/10.3390/en12061056