Robust Speed Controller Design Using H_infinity Theory for High-Performance Sensorless Induction Motor Drives

Abstract

:1. Introduction

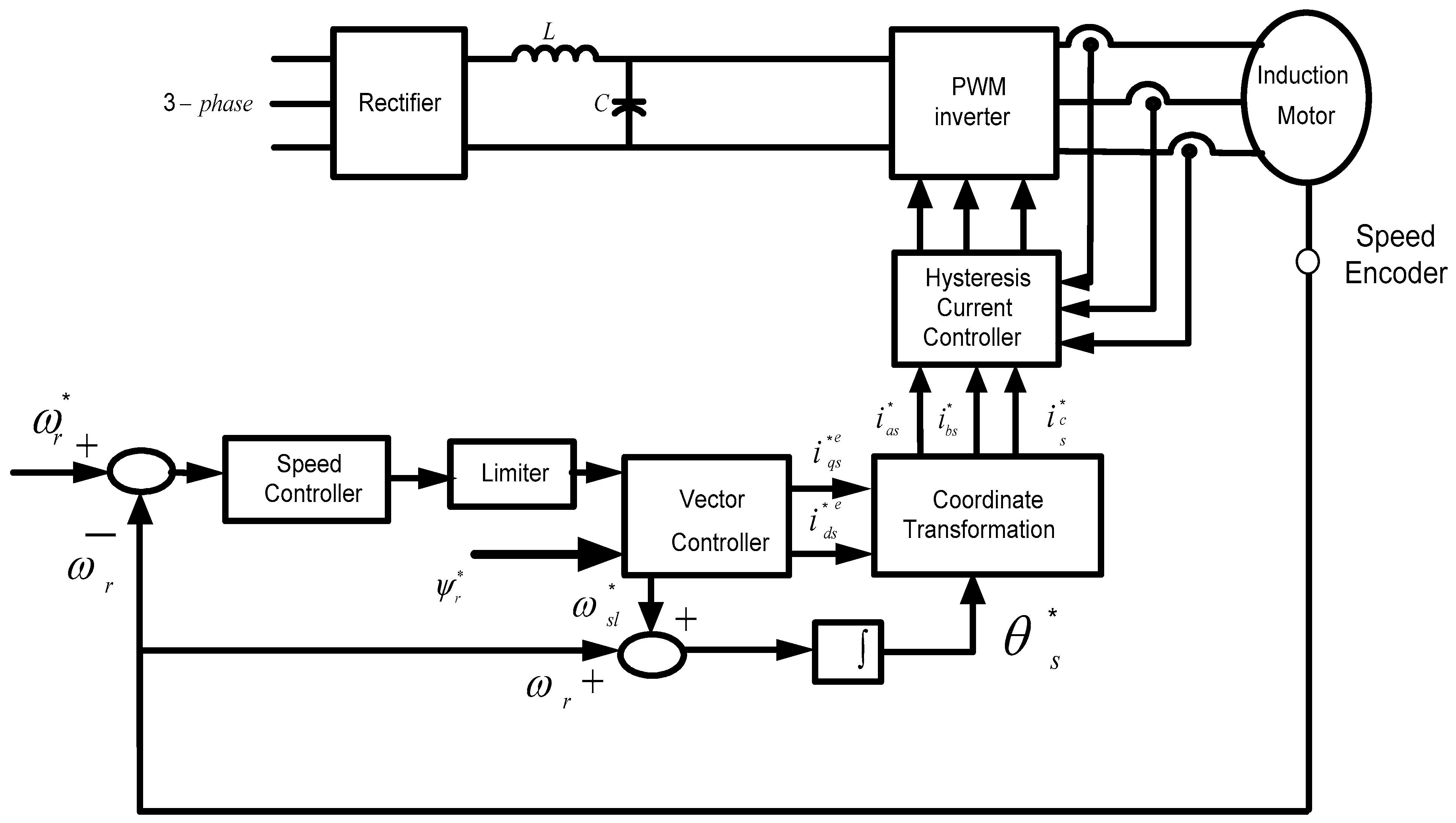

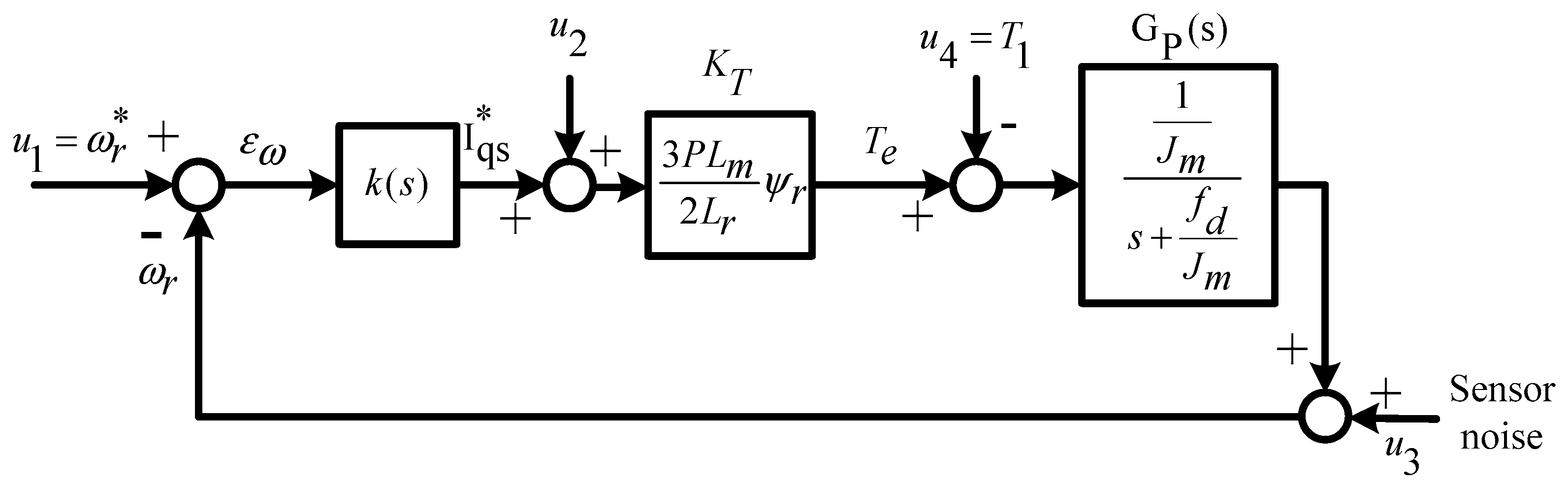

2. Mathematical Model of an Induction Motor

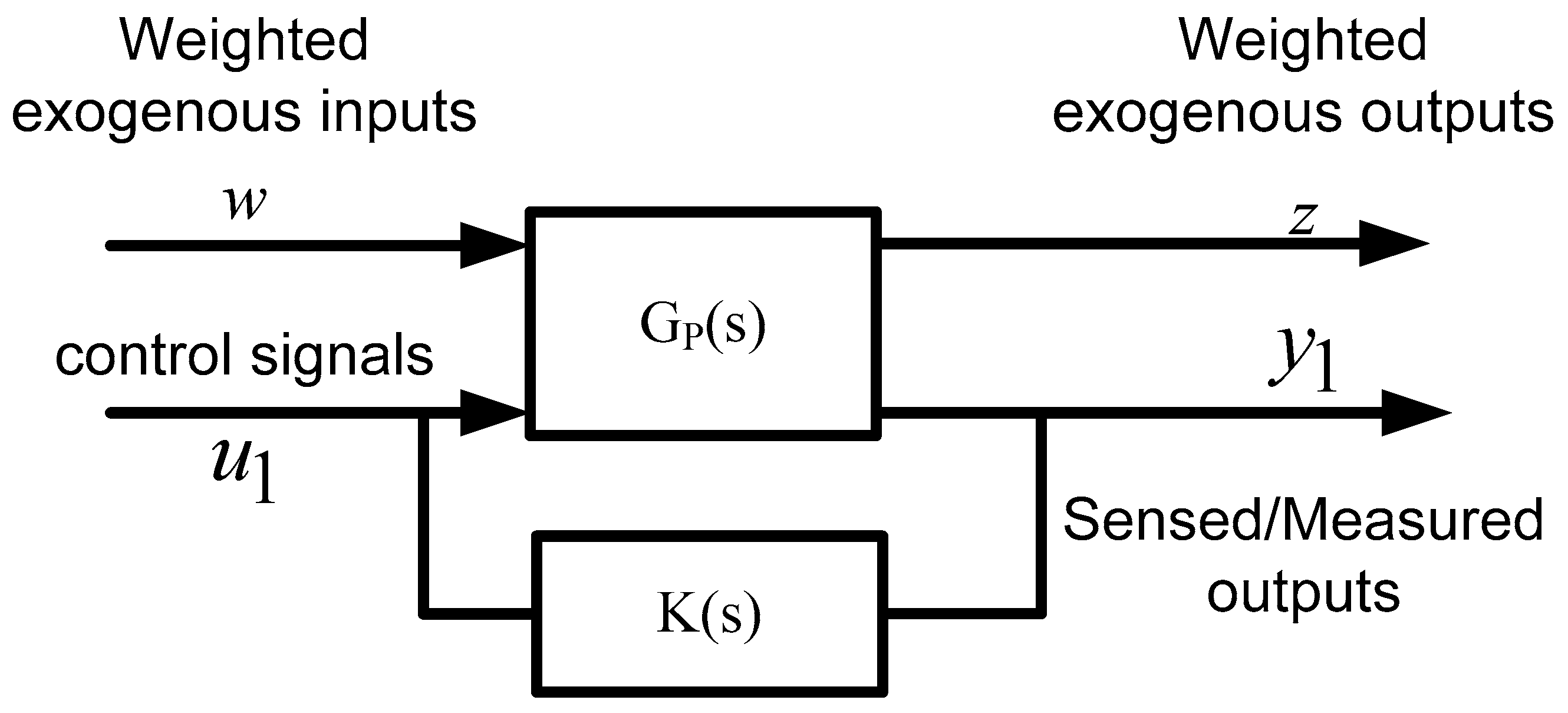

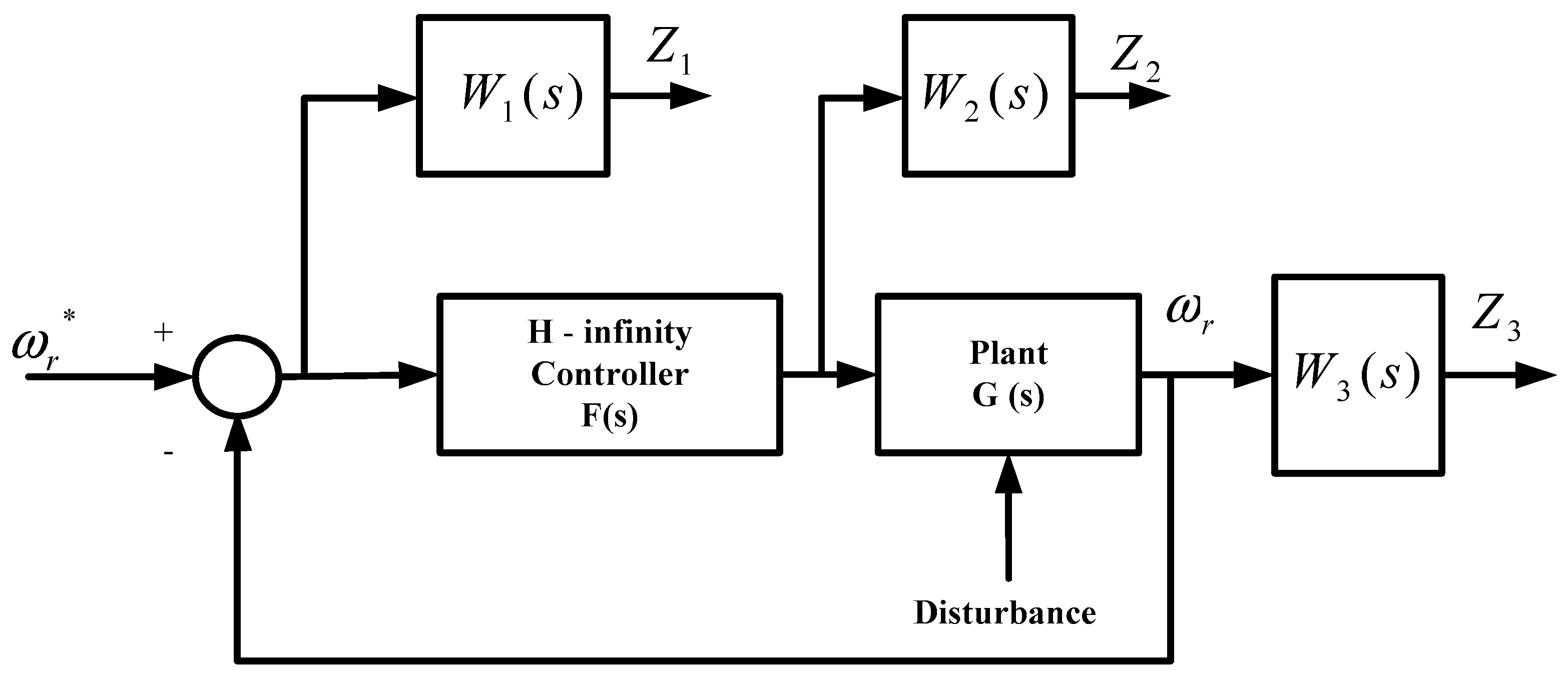

3. Design of the Proposed Controller Based on H∞ Theory

- (1)

- Minimum effect of the measurement noise at high frequency

- (2)

- Maximum bounds on closed-loop signals to prevent saturation

- (3)

- Minimum effect of load disturbance rejection, reducing the maximum speed dip

- (4)

- Asymptotic and good tracking for sudden changes in command signals, in addition to a rapid and excellent damping response

- (5)

- Survivability against system parameter variations.

- Formulation: the first stage is to select the optimal weighting functions. The proper selections of the weighting functions give the ability to improve the robustness of the system at different operation condition and varying the model parameters. Moreover, this to reject the disturbance and noises besides the parameter uncertainties.

- Solution: The transfer function of the weights has been updated to reach the optimal configuration. In this paper, the MATLAB optimization toolbox in the Simulink is used to determine the best weighting functions.

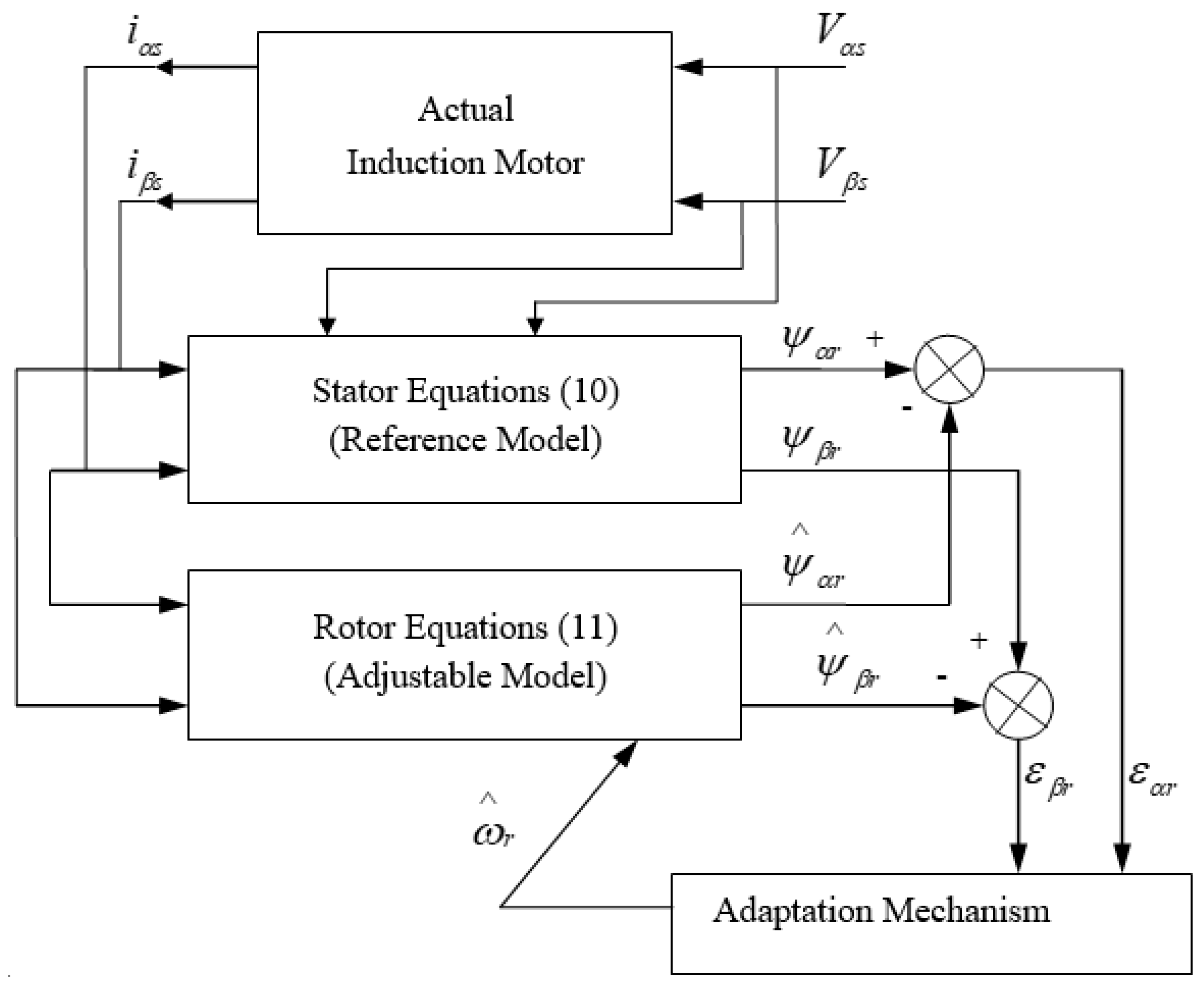

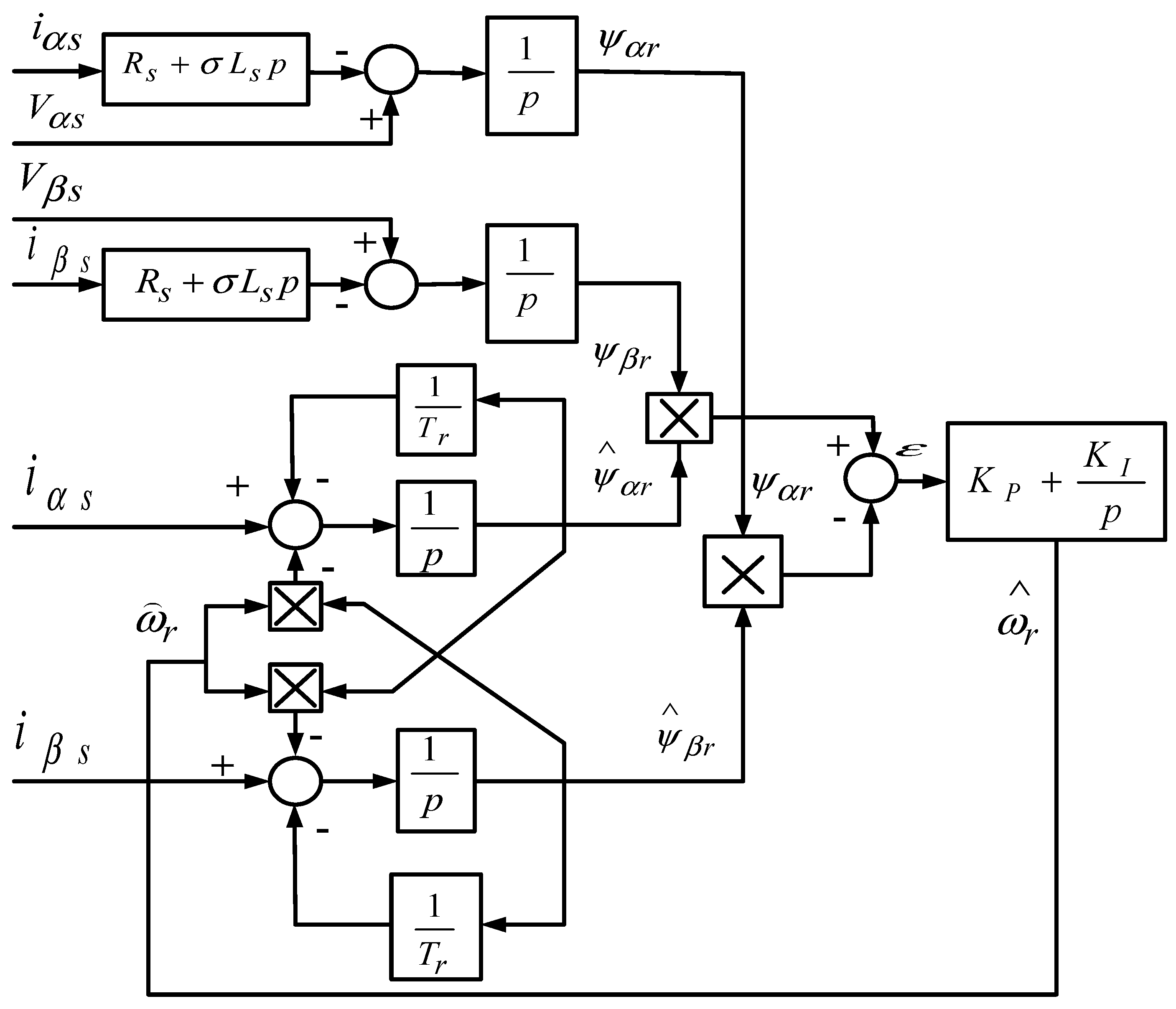

4. Robust Speed Estimation Based on MRAS Techniques for an IFO Control

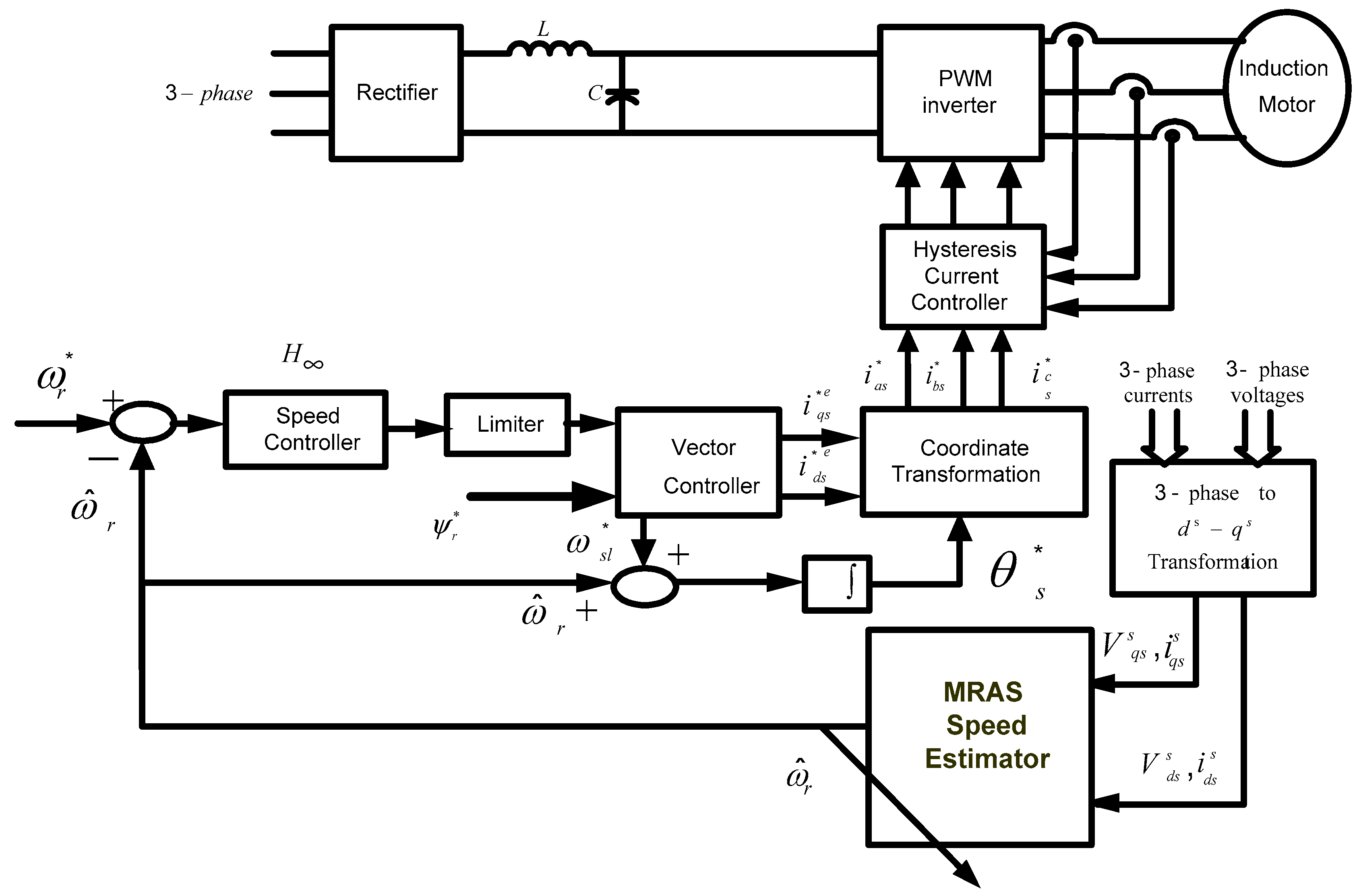

5. Proposed Sensor-Free Induction Motor Drive for High-Performance Applications

6. Simulation and Experimental Results

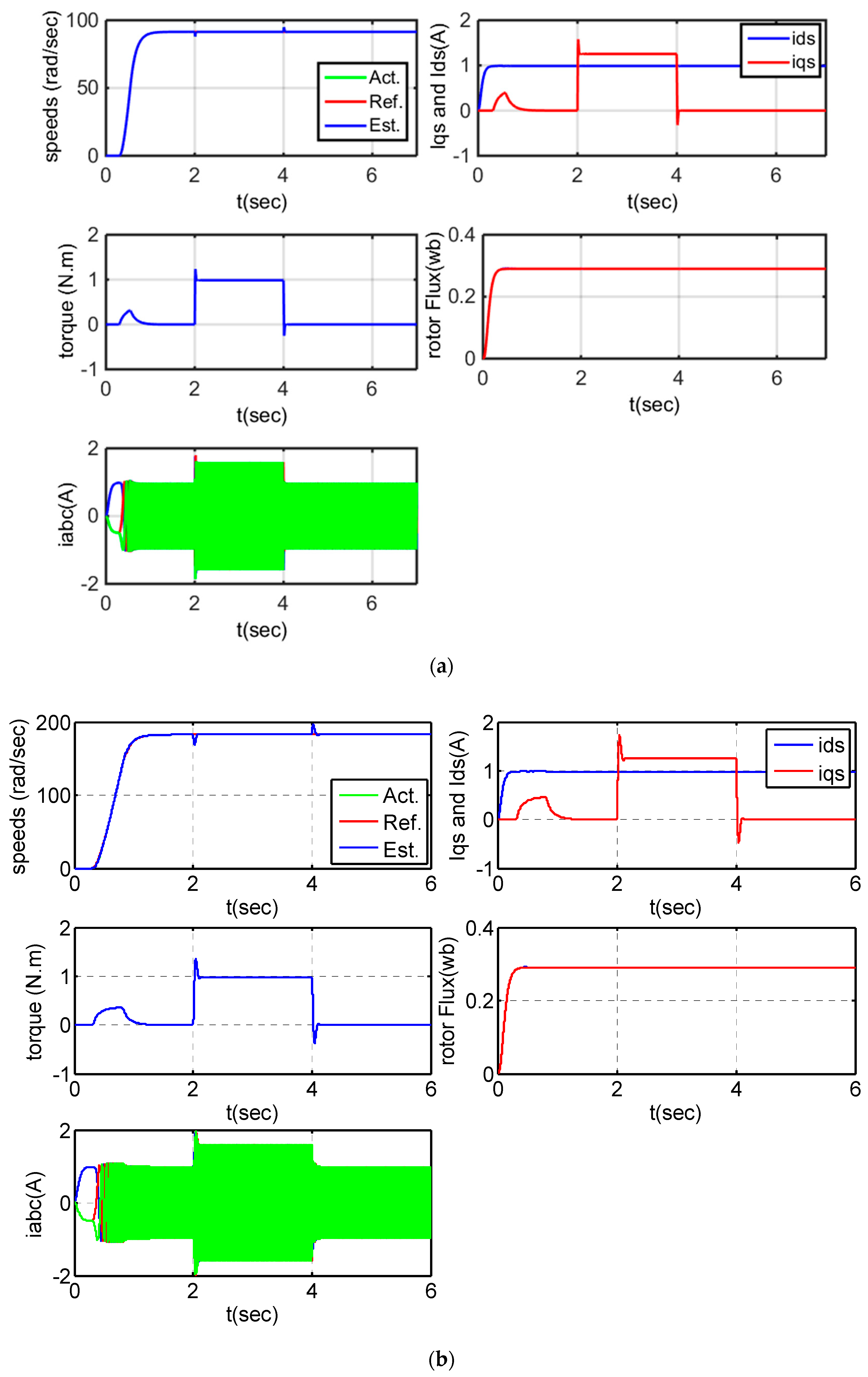

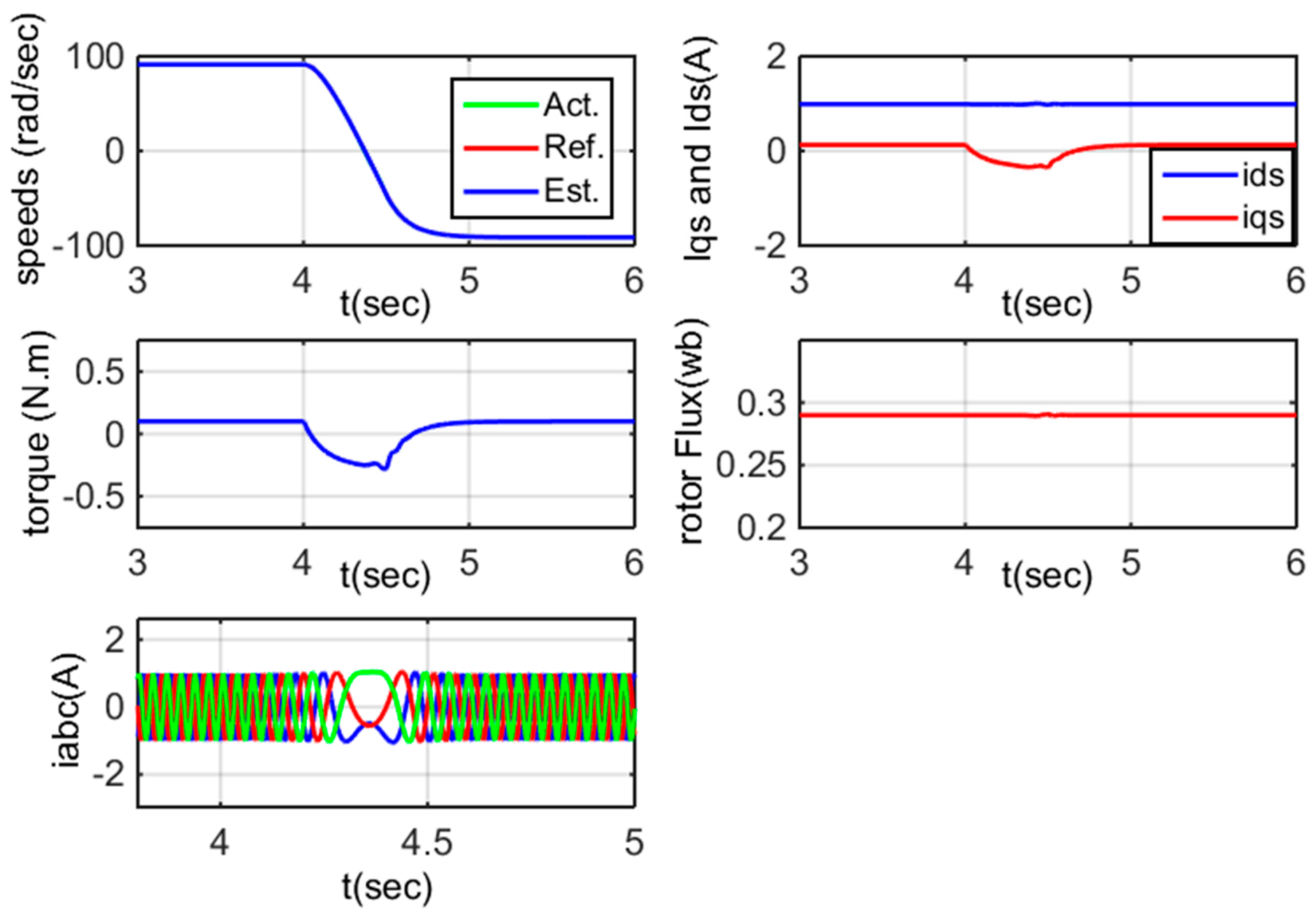

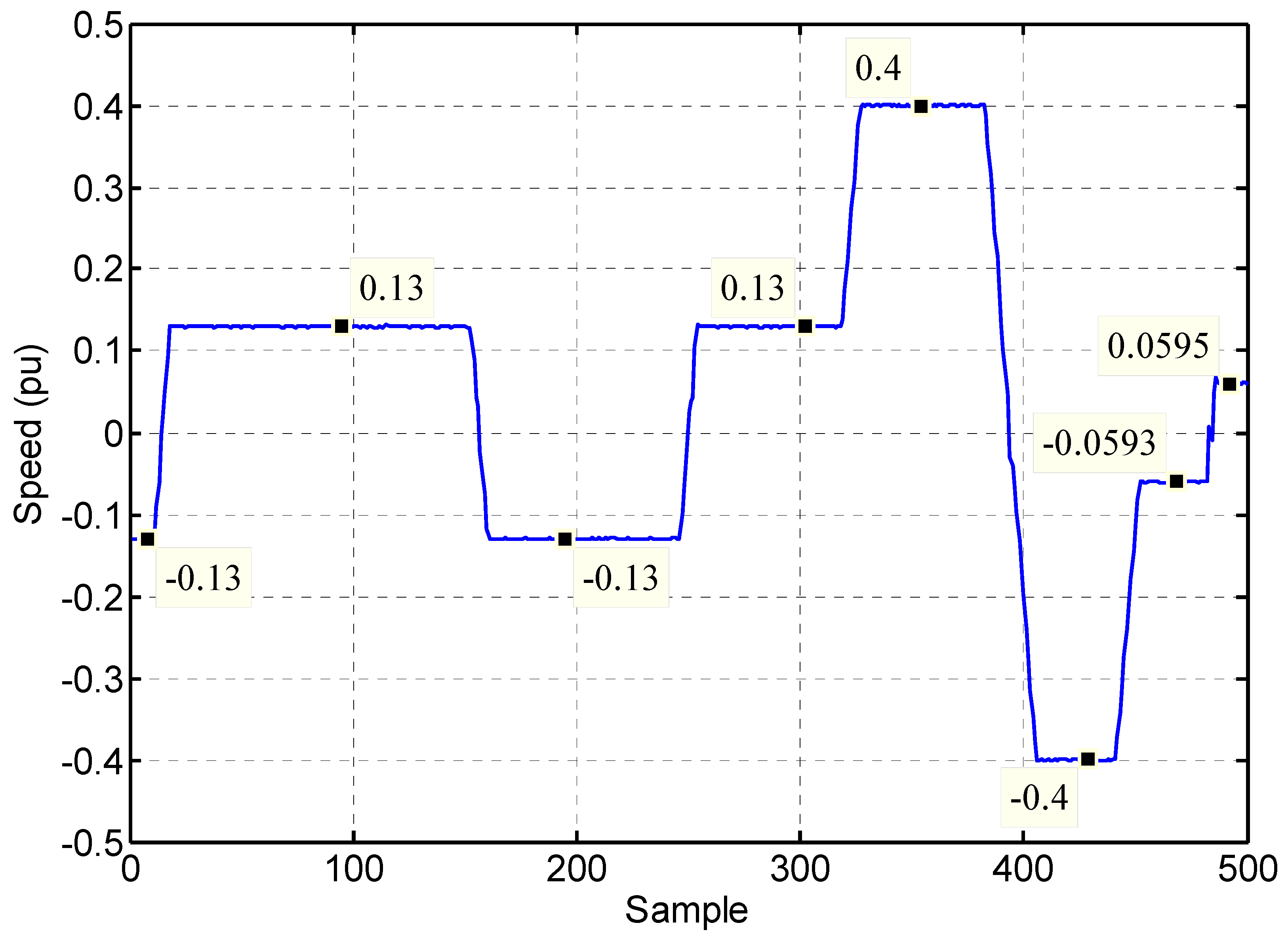

6.1. Simulation Results

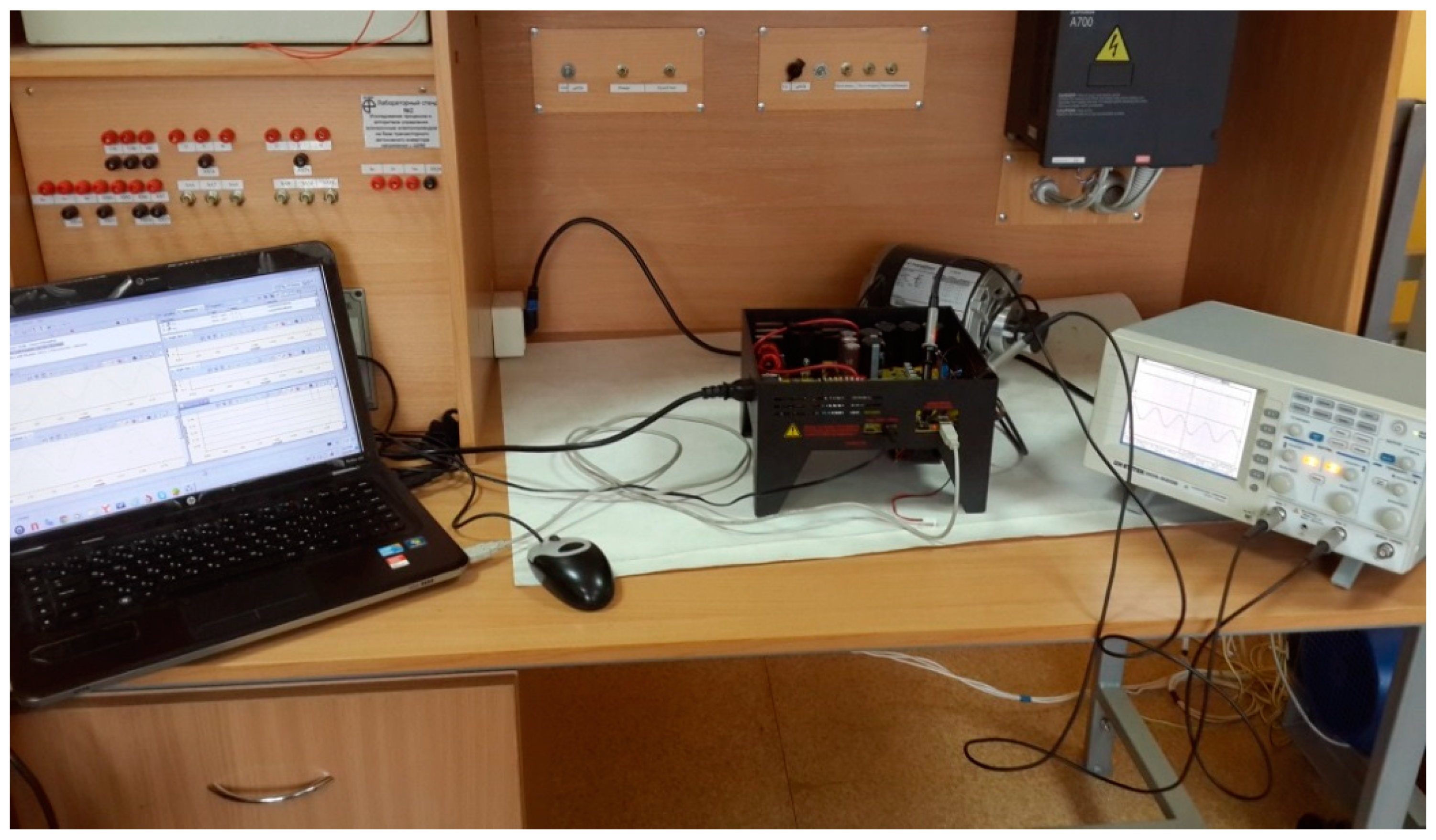

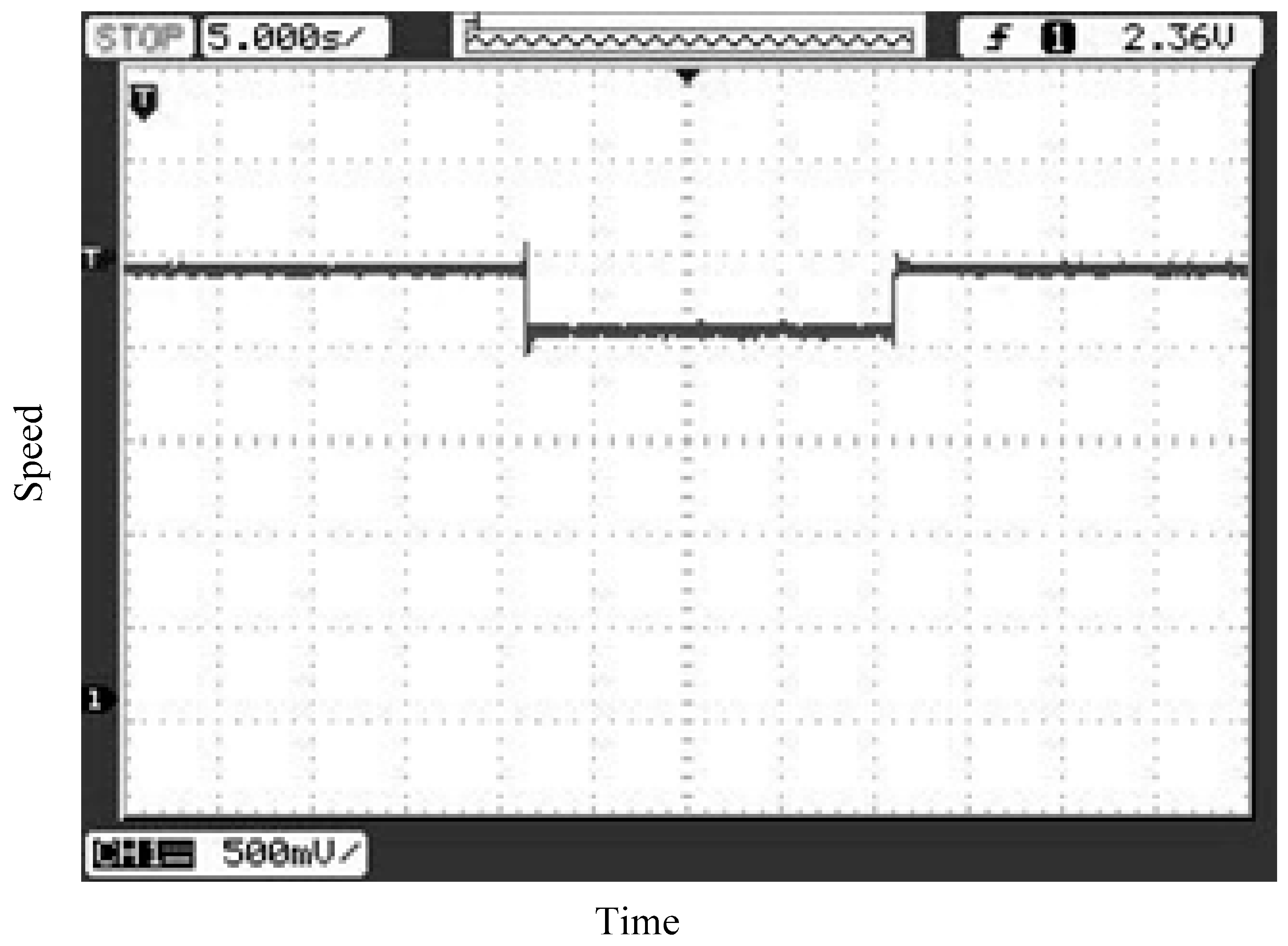

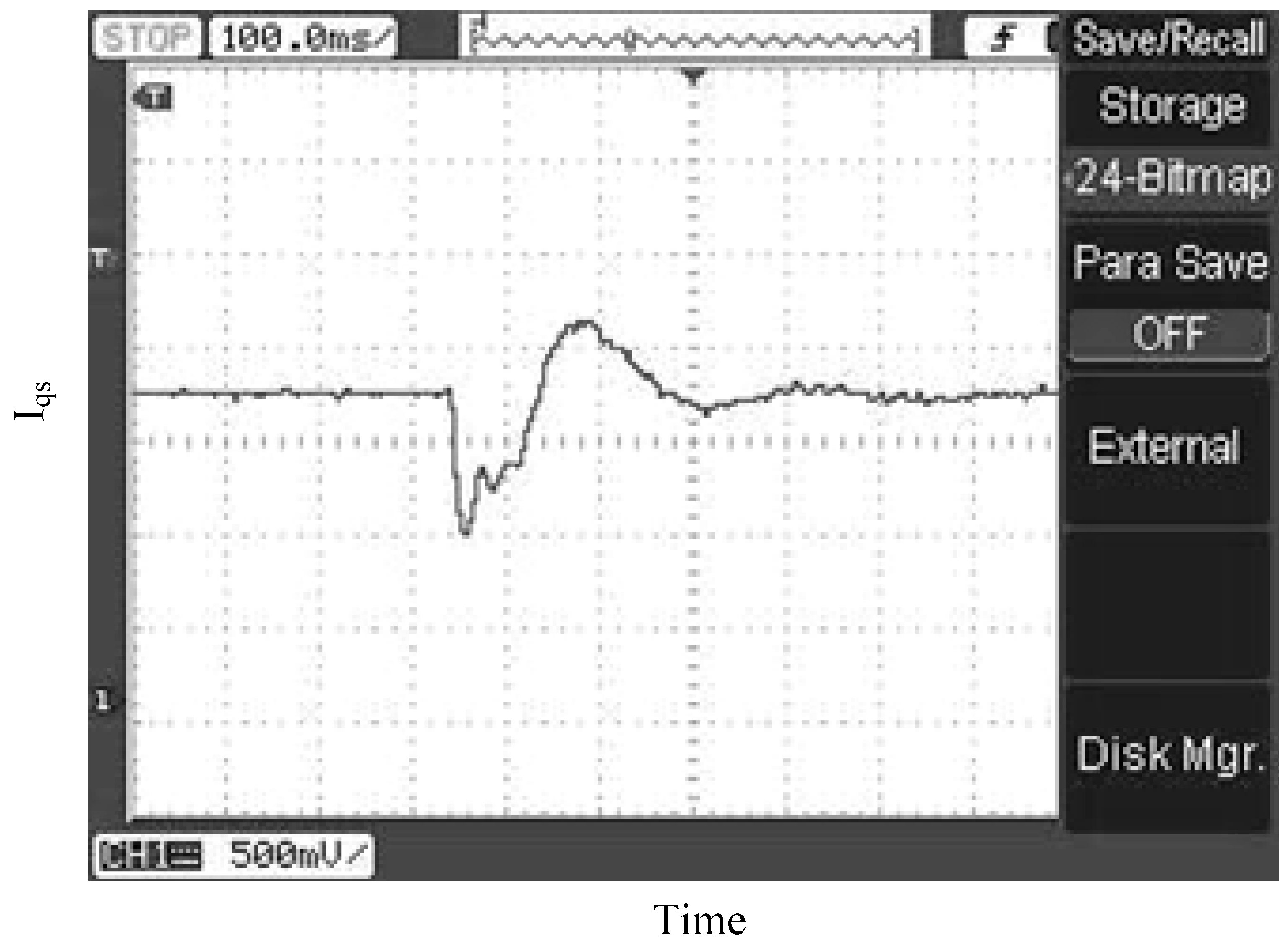

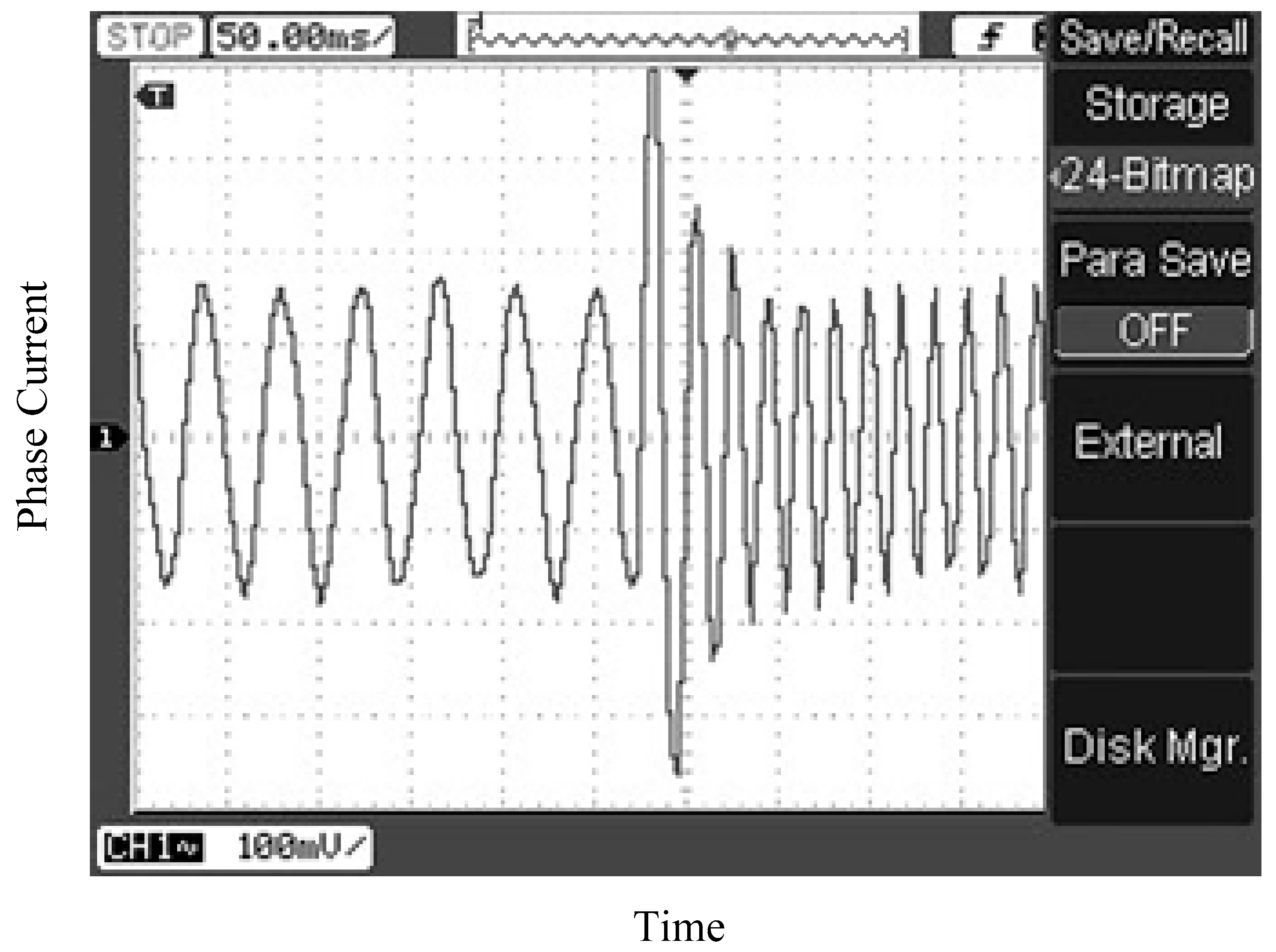

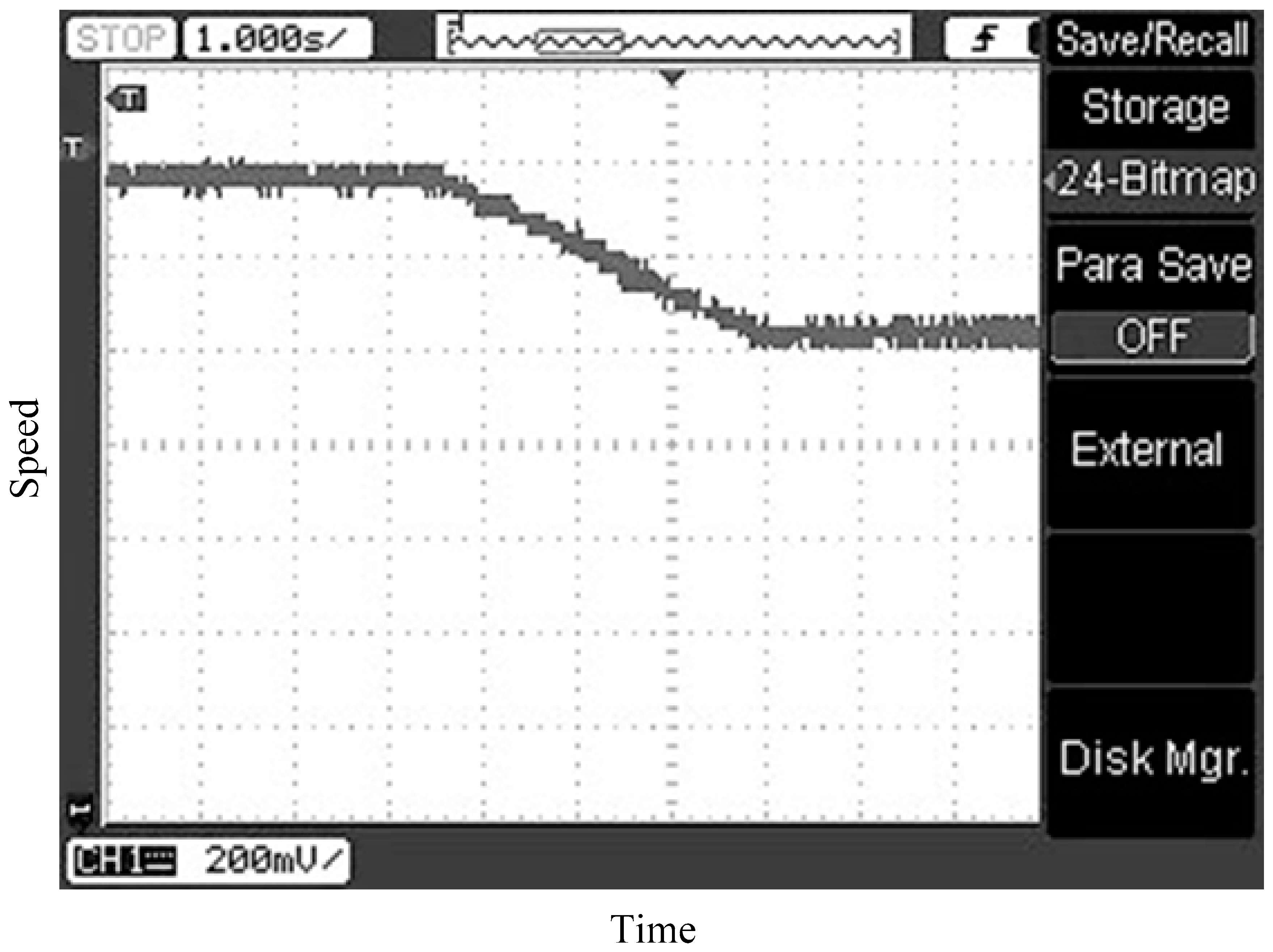

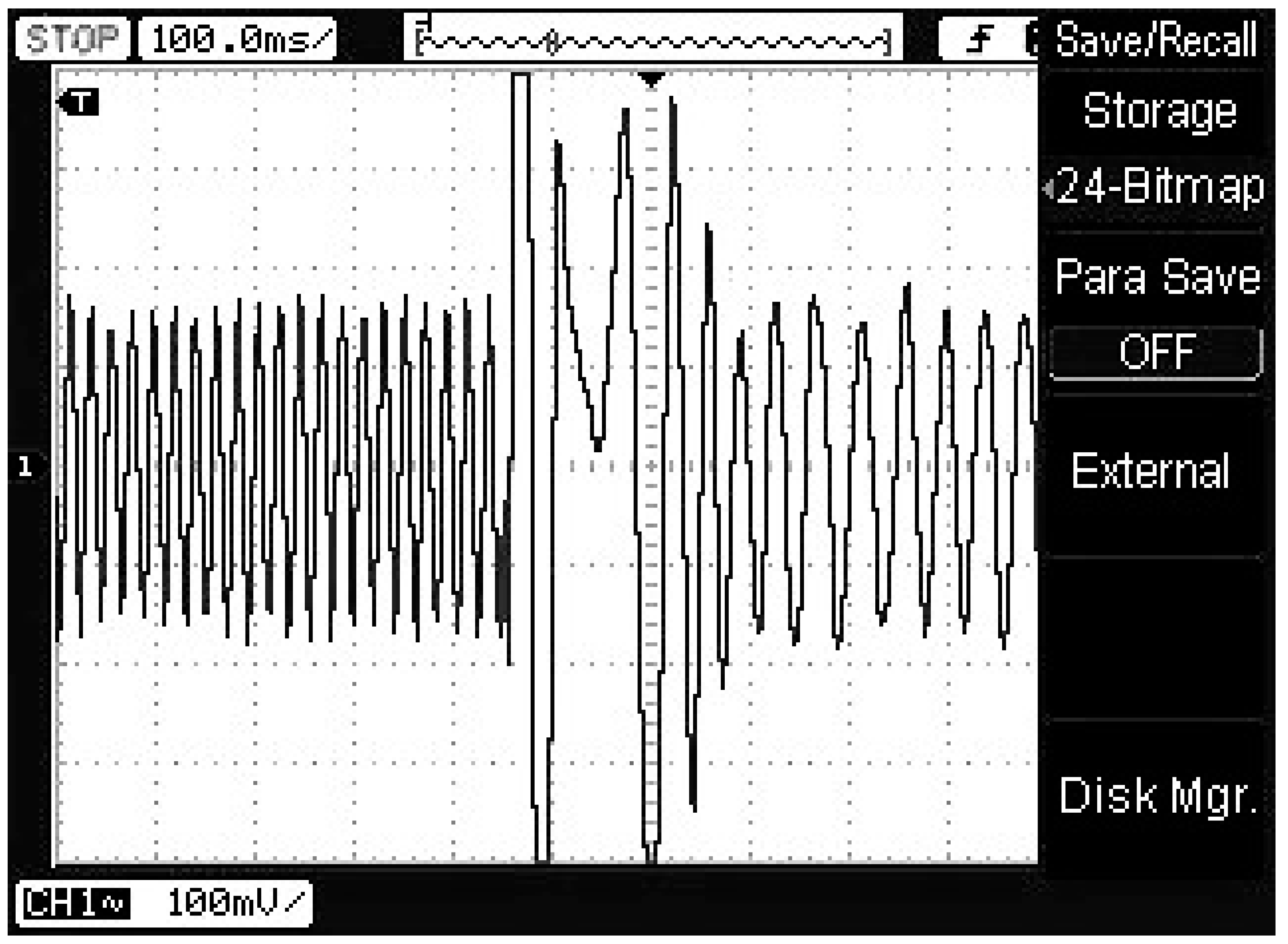

6.2. Practical Results

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Vas, P. Vector Control of AC Machines; Oxford University Press: Oxford, UK, 1990; pp. 122–215. [Google Scholar]

- Krishnan, R.; Doran, F.C. Study of parameter Sensitivity in High Performance Inverter Fed Induction Motor Drive Systems. IEEE Trans. Ind. Appl. 1987, IA-23, 623–635. [Google Scholar] [CrossRef]

- Vas, P. Parameter Estimation, Condition Monitoring, and Diagnosis of Electrical Machines; Oxford Science Publications: Oxford, UK, 1993. [Google Scholar]

- Toliyat, H.A.; Levi, E.; Raina, M. A Review of RFO Induction Motor Parameter Estimation Techniques. IEEE Trans. Energy Convers. 2003, 18, 271–283. [Google Scholar] [CrossRef]

- Minami, K.; Veles-Reyes, M.; Elten, D.; Verghese, G.C.; Filbert, D. Multi-Stage Speed and Parameter Estimation for Induction Machines. In Proceedings of the Record 22nd Annual IEEE Power Electronics Specialists Conference (IEEE PESC’91), Cambridge, MA, USA, 24–27 June 1991; pp. 596–604. [Google Scholar]

- Roncero-Sánchez, P.L.; García-Cerrada, A.; Feliú, V. Rotor-Resistance Estimation for Induction Machines with Indirect-Field Orientation. Control Eng. Pract. 2007, 15, 1119–1133. [Google Scholar] [CrossRef]

- Karayaka, H.B.; Marwali, M.N.; Keyhani, A. Induction Machines Parameter Tracking from Test Data Via PWM Inverters. In Proceedings of the Record of the 1997 IEEE Industry Applications Conference Thirty-Second IAS Annual Meeting, New Orleans, LA, USA, 5–9 October 1997; pp. 227–233. [Google Scholar]

- Godoy, M.; Bose, B.K.; Spiegel, R.J. Design and performance evaluation of a fuzzy-logic-based variable-speed wind generation system. IEEE Trans. Energy Convers. 1997, 33, 956–964. [Google Scholar]

- Munteau, I.; Cutululis, N.A.; Bratcu, A.I.; Ceanga, E. Optimization of variable speed wind power systems based on a LQG approach. In Proceedings of the IFAC Workshop on Control Applications of Optimisation—CAO’03 Visegrad, Visegrad, Hungary, 30 June–2 July 2003. [Google Scholar]

- Hassan, A.A.; Mohamed, Y.S.; Yousef, A.M.; Kassem, A.M. Robust control of a wind driven induction generator connected to the utility grid. Bull. Fac. Eng. Assiut Univ. 2006, 34, 107–121. [Google Scholar]

- Attaiaence, C.; Perfetto, A.; Tomasso, G. Robust postion control of DC drives by means of H∞ controllers. Proc. IEE Electr. Power Appl. 1999, 146, 391–396. [Google Scholar] [CrossRef]

- Naim, R.; Weiss, G.; Ben-Yakakov, S. H∞ control applied to boost power converters. IEEE Trans. Power Electron. 1997, 12, 677–683. [Google Scholar] [CrossRef]

- Lin, F.-J.; Lee, T.; Lin, C. Robust H∞ controller design with recurrent neural network for linear synchronous motor drive. IEEE Trans. Ind. Electron. 2003, 50, 456–470. [Google Scholar]

- Pohl, L.; Vesely, I. Speed Control of Induction Motor Using H∞ Linear Parameter Varying Controller. IFAC-PapersOnLine 2016, 49, 74–79. [Google Scholar] [CrossRef]

- Kao, Y.-T.; Liu, C.-H. Analysis and design of microprocessor-based vector-controlled induction motor drives. IEEE Trans. Ind. Electron. 1992, 39, 46–54. [Google Scholar] [CrossRef]

- Prempain, E.; Postlethwaite, I.; Benchaib, A. A linear parameter variant H∞ control design for an induction motor. Control Eng. Pract. 2002, 10, 633–644. [Google Scholar] [CrossRef]

- Rigatos, G.; Siano, P.; Wira, P.; Profumo, F. Nonlinear H-infinity feedback control for asynchronous motors of electric trains. Intell. Ind. Syst. 2015, 1, 85–98. [Google Scholar] [CrossRef]

- Riberiro, L.A.D.; Lima, A.M.N. Parameter Estimation of Induction Machines Under Sinusoidal PWM Excitation. IEEE Trans. Energy Convers. 1999, 14, 1218–1223. [Google Scholar] [CrossRef]

- Moonl, S.; Keyhani, A. Estimation of Induction Machines Parameters from Standstill Time-Domain Data. IEEE Trans. Ind. Appl. 1994, 30, 1609–1615. [Google Scholar] [CrossRef]

- Lima, A.M.N.; Jacobina, C.B.; Filho, E.B.D. Nonlinear Parameter Estimation of Steady-state Induction Machine Models. IEEE Trans. Ind. Electron. 1997, 44, 390–397. [Google Scholar] [CrossRef]

- Yang, G.; Chin, T.H. Adaptive-Speed Identification Scheme for a Vector-Controlled Speed Sensorless Inverter-Induction Motor Drive. IEEE Trans. Ind. Appl. 1993, 29, 820–825. [Google Scholar] [CrossRef]

- Kubota, H.; Matsuse, K. Speed Sensorless Field-Oriented Control of Induction Motor with Rotor Resistance Adaptation. IEEE Trans. Ind. Appl. 1994, 30, 1219–1224. [Google Scholar] [CrossRef]

- Suwankawin, S.; Sangwongwanich, S. Design Strategy of an Adaptive Full Order Observer for Speed Sensorless Induction Motor Drives Tracking Performance and Stabilization. IEEE Trans. Ind. Electron. 2006, 53, 96–119. [Google Scholar] [CrossRef]

- Al-Tayie, J.; Acarnley, P. Estimation of Speed, Stator Temperature and Rotor Temperature in Cage Induction Motor Drive Using the Extended Kalman Filter Algorithm. Proc. IEE Electr. Power Appl. 1997, 144, 301–309. [Google Scholar] [CrossRef]

- Barut, M.; Bogosyan, O.S.; Gokasan, M. Switching EKF Technique for Rotor and Stator Resistance Estimation in Speed Sensorless Control of Induction Motors. Energy Convers. Manag. 2007, 48, 3120–3134. [Google Scholar] [CrossRef]

- Jingchuan, L.; Longya, X.; Zhang, Z. An Adaptive Sliding-Mode Observer for Induction Motor sensorless Speed Control. IEEE Trans. Ind. Appl. 2005, 41, 1039–1046. [Google Scholar]

- Rashed, M.; Stronach, A.F. A Stable Back-EMF MRAS-Based Sensorless Low Speed Induction Motor Drive Insensitive to Stator Resistance Variation. IEE Proc. Electr. Power Appl. 2004, 151, 685–693. [Google Scholar] [CrossRef]

- Mohamed, Y.S.; El-Sawy, A.M.; Zaki, A.A. Rotor Resistance Identification for Speed Sensorless Vector Controlled Induction Motor Drives Taking Saturation Into Account. J. Eng. Sci. Assiut Univ. 2009, 37, 393–412. [Google Scholar]

- Middeton, R.H.; Goodwin, G.C. Digital Control and Estimation, 1st ed.; Prentice-Hall, Inc.: Englewood Cliffs, NJ, USA, 1990; Volume 1. [Google Scholar]

- Blasco-Gimenez, R.; Asher, G.; Summer, M.; Bradley, K. Dynamic Performance Limitations for MRAS Based Sensorless Induction Motor Drives. Part 1: Stability Analysis for the Closed Loop Drive. Proc. IEE-Electr. Power Appl. 1996, 143, 113–122. [Google Scholar] [CrossRef]

- Diab, A.A.; Khaled, A.; Elwany, M.A.; Hassaneen, B.M. Parallel estimation of rotor resistance and speed for sensorless vector controlled induction motor drive. In Proceedings of the 2016 17th International Conference of Young Specialists on Micro/Nanotechnologies and Electron Devices (EDM), Erlagol, Russia, 30 June–4 July 2016. [Google Scholar]

- Diab, A.A. Real-Time Implementation of Full-Order Observer for Speed Sensorless Vector Control of Induction Motor Drive. J. Control Autom. Electr. Syst. 2014, 25, 639–648. [Google Scholar] [CrossRef]

- Diab, A.A.Z. Implementation of a novel full-order observer for speed sensorless vector control of induction motor drives. Electr. Eng. 2016, 99, 907–921. [Google Scholar] [CrossRef]

- Diab, A.A.Z. Novel robust simultaneous estimation of stator and rotor resistances and rotor speed to improve induction motor efficiency. Int. J. Power Electron. 2017, 8, 267–287. [Google Scholar] [CrossRef]

- Texas Instruments C2000 Systems and Applications Team. High Voltage Motor Control and PFC (R1.1) Kit Hardware Reference Guide, v. 2. 2012. Available online: http://www.ti.com/tool/TMDSHVMTRPFCKIT (accessed on 31 January 2019).

| Rated Power (W) | 180 | Rated Voltage (V) | 220 |

|---|---|---|---|

| Rated current (A) | 1.3–1.4 | Rated frequency (Hz) | 60 |

| Rs (Ω) | 11.29 | Rr (Ω) | 6.11 |

| Ls (H) | 0.021 | Lr (H) | 0.021 |

| Lm (H) | 0.29 | Rated rotor flux, (wb) | 0.3 |

| J (kg.m2) | 0.00940 | Rated speed (rpm) | 1750 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Diab, A.A.Z.; El-Sayed, A.-H.M.; Abbas, H.H.; Sattar, M.A.E. Robust Speed Controller Design Using H_infinity Theory for High-Performance Sensorless Induction Motor Drives. Energies 2019, 12, 961. https://doi.org/10.3390/en12050961

Diab AAZ, El-Sayed A-HM, Abbas HH, Sattar MAE. Robust Speed Controller Design Using H_infinity Theory for High-Performance Sensorless Induction Motor Drives. Energies. 2019; 12(5):961. https://doi.org/10.3390/en12050961

Chicago/Turabian StyleDiab, Ahmed A. Zaki, Abou-Hashema M. El-Sayed, Hossam Hefnawy Abbas, and Montaser Abd El Sattar. 2019. "Robust Speed Controller Design Using H_infinity Theory for High-Performance Sensorless Induction Motor Drives" Energies 12, no. 5: 961. https://doi.org/10.3390/en12050961

APA StyleDiab, A. A. Z., El-Sayed, A.-H. M., Abbas, H. H., & Sattar, M. A. E. (2019). Robust Speed Controller Design Using H_infinity Theory for High-Performance Sensorless Induction Motor Drives. Energies, 12(5), 961. https://doi.org/10.3390/en12050961