Techno-Economic Analysis of a Cogeneration System for Post-Harvest Loss Reduction: A Case Study in Sub-Saharan Rural Community

Abstract

1. Introduction

1.1. Yam Storage

1.2. Renewable Energy Regulation in Nigeria

2. Modelling and Methodology

2.1. Case Study Area

2.2. System Design

2.3. Anaerobic Digester

2.3.1. System Modelling

2.3.2. Process Simulation

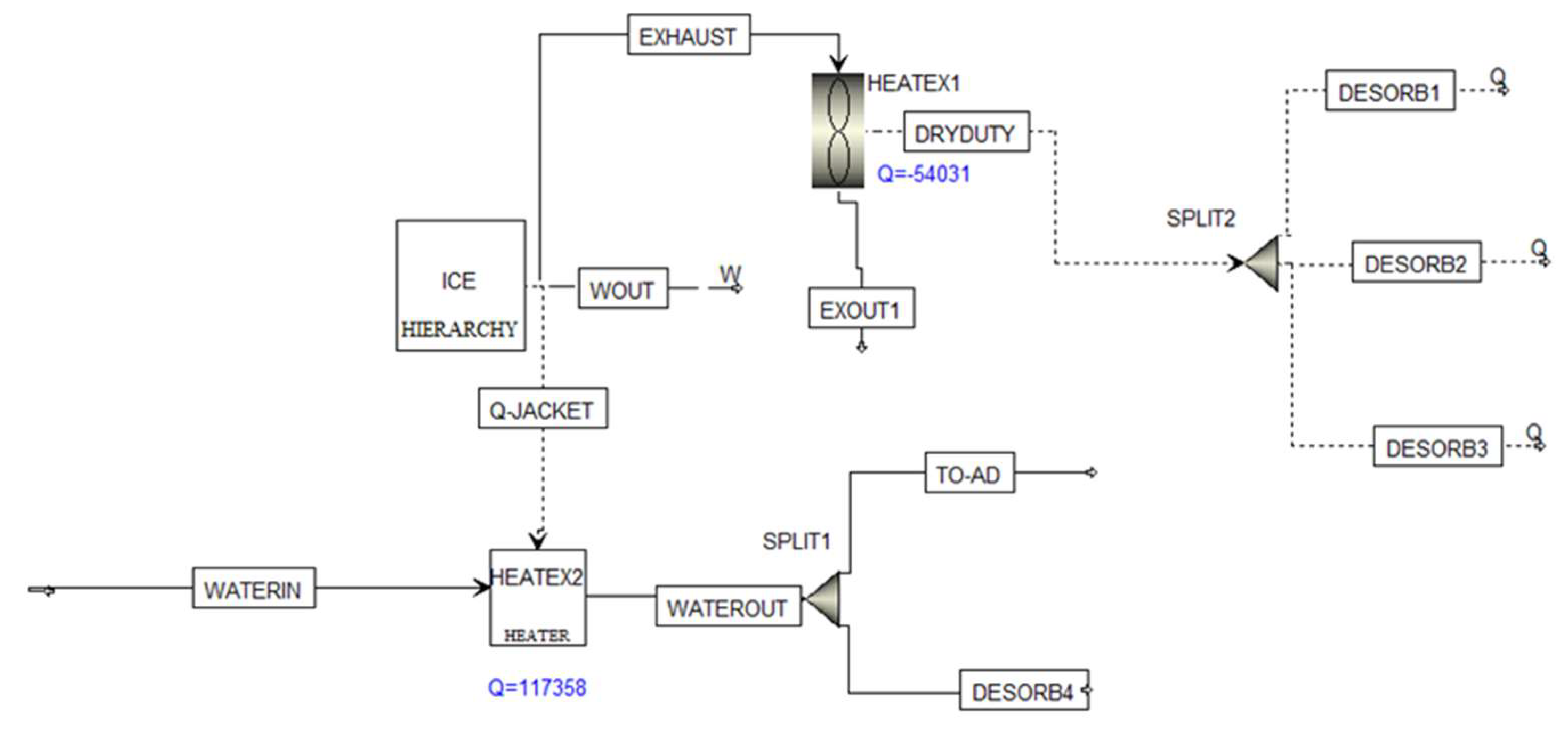

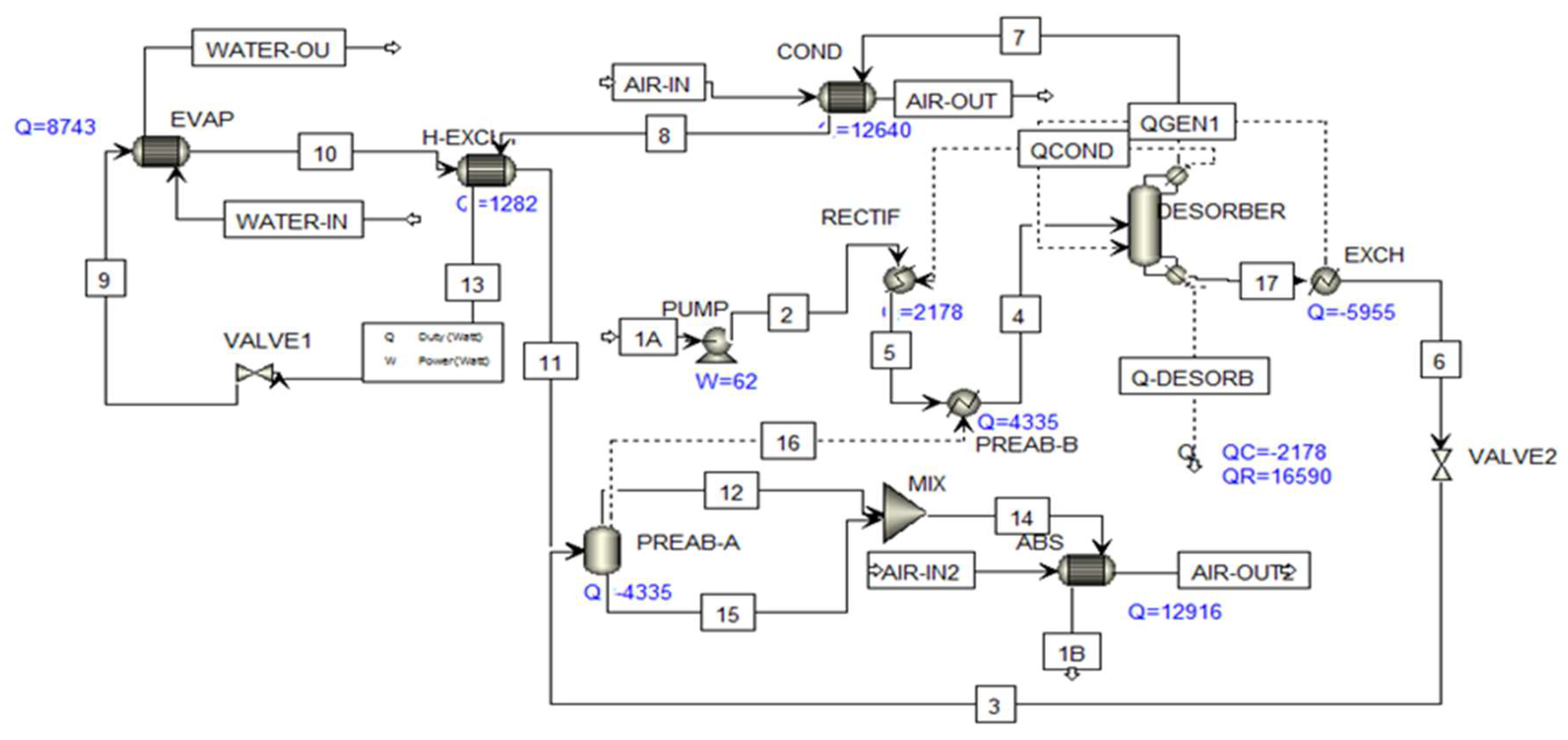

2.4. Simulation of Combined Cooling and Power Unit

2.4.1. Evaluation of Cooling Load

2.4.2. Evaluation of the Cogeneration System

2.5. Economic Evaluation

3. Results and Discussions

3.1. Heat Balance of AD System

3.2. Cooling Load

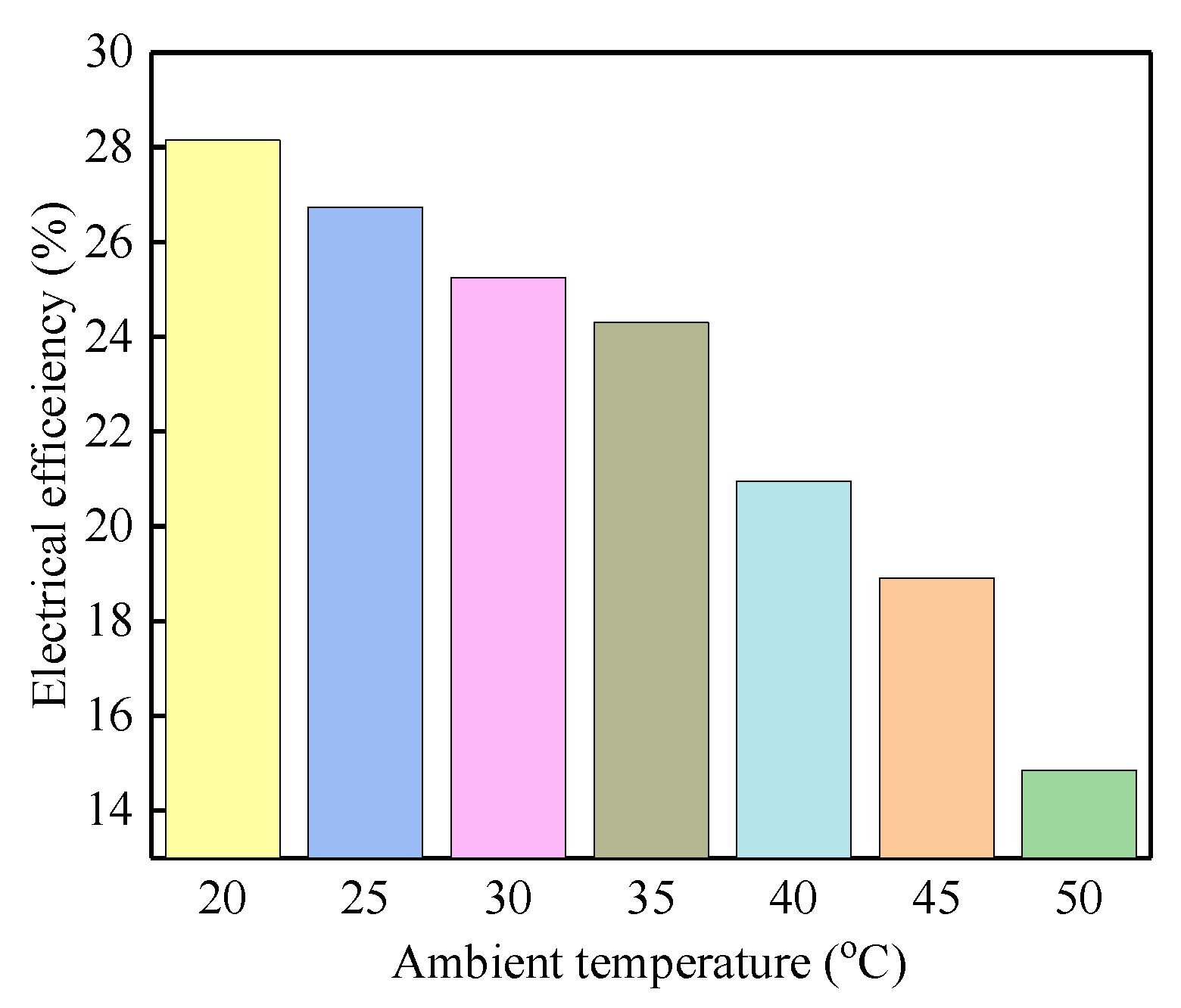

3.3. Efficiency of the System

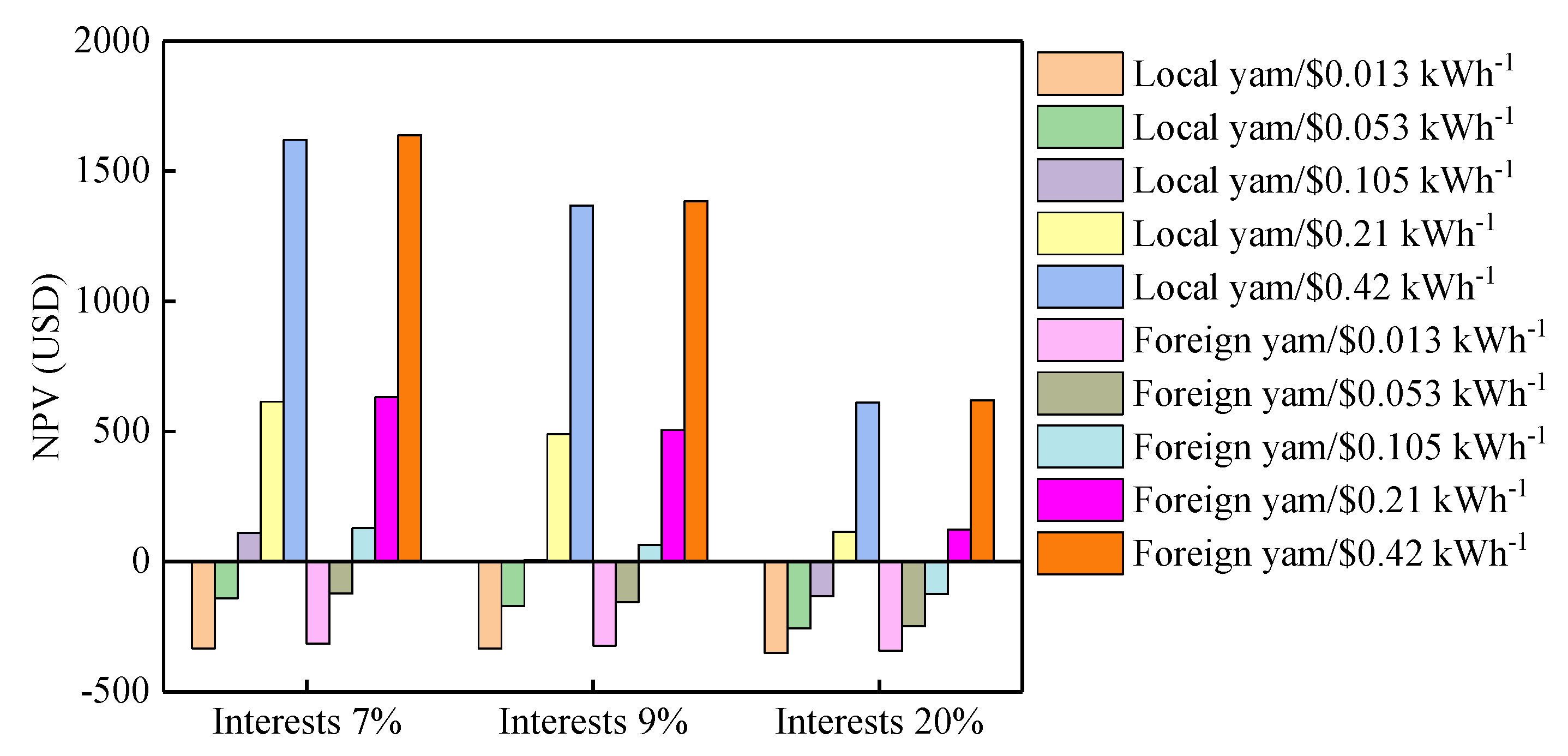

3.4. Economic Evaluation Results

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| A | Area (m2) |

| AD | Anaerobic digestion |

| AP | Aspen Plus |

| AWAC | Ammonia-water absorption chiller |

| Cp | Specific heat capacity (kJ·kg−1·°C−1) |

| CCP | Combined cooling and power |

| CHP | Combined heat and power |

| DCI | Discounted cash inflow |

| DPP | Discounted payback period |

| f | Cash flow (USD) |

| FITs | Feed in tariffs |

| HX | Heat exchanger |

| HP | Horsepower |

| ha | Hectare |

| hr | Hour |

| I | Investment cost (USD) |

| ICE | Internal combustion engine |

| IWA | International water association |

| LCOE | Levelised cost of energy |

| M | Mass (kg) |

| NREA | Nigerian rural electrification agency |

| NPV | Net present value (USD) |

| NRTL | Non-Random two-liquid model |

| n | Period (year) |

| PHL | Postharvest loss |

| PI | Profitability Index |

| Q | Heat (kW) |

| r | Interest rate (%) |

| RCSTR | Rigorous continuous stir tank reactor |

| SSA | Sub-Saharan African region |

| T | Temperature (°C) |

| TLCC | Total life cycle cost (USD) |

| VS | Volatile solids |

| yr | Year |

Greek letters

| µ | Efficiency (%) |

| ε | Emissivity of the outer brick wall |

| ơ | Stefan-Boltzmann constant |

Subscripts

| amb | Ambient |

| bio | Biogas |

| CO2 | Carbon dioxide |

| d | Digestion |

| e | Electricity |

| gen | Generator |

| h | Heat |

| over | Overall |

| res | Respiration |

| s | Sensible |

| stor | storage |

| w | Water |

| wm | Warm |

| y | Yam |

References

- Ansah, I.G.K.; Tetteh, B.K.D.; Donkoh, S.A. Determinants and income effect of yam postharvest loss management: Evidence from the Zabzugu District of Northern Ghana. Food Secur. 2017, 9, 610–620. [Google Scholar] [CrossRef]

- FAOSTAT. Country Crop Production Data; Food Agriculture Organization: Rome, Italy, 2017. [Google Scholar]

- Newspaper, T.P. FG targets $8bn annual FX earning from yam export. The Punch Newspaper, 22 June 2017. [Google Scholar]

- Rehman, I.H.; Kar, A.; Banerjee, M.; Kumar, P.; Shardul, M.; Mohanty, J.; Hossain, I. Understanding the political economy and key drivers of energy access in addressing national energy access priorities and policies. Energy Policy 2012, 47, 27–37. [Google Scholar] [CrossRef]

- Somorin, T.O.; Adesola, S.; Kolawole, A. State-level assessment of the waste-to-energy potential (via incineration) of municipal solid wastes in Nigeria. J. Clean. Prod. 2017, 164, 804–815. [Google Scholar] [CrossRef]

- Amigun, B.; von Blottnitz, H. Capacity-cost and location-cost analyses for biogas plants in Africa. Resour. Conserv. Recycl. 2010, 55, 63–73. [Google Scholar] [CrossRef]

- Lamidi, R.O.; Jiang, L.; Pathare, P.B.; Wang, Y.D.; Roskilly, A.P. Recent advances in sustainable drying of agricultural produce: A review. Appl. Energy 2019, 233, 367–385. [Google Scholar] [CrossRef]

- Lamidi, R.O.; Wang, Y.; Pathare, P.B.; Roskilly, A.P.; Aguilar, M.C. Biogas Tri-generation for Postharvest Processing of Agricultural Products in a Rural Community: Techno-economic Perspectives. Energy Procedia 2017, 142, 63–69. [Google Scholar] [CrossRef]

- Lamidi, R.O.; Wang, Y.D.; Pathare, P.B.; Roskily, A.P. Evaluation of CHP for Electricity and Drying of Agricultural Products in a Nigerian Rural Community. Energy Procedia 2017, 105, 47–54. [Google Scholar] [CrossRef]

- Purdy, A.; Pathare, P.B.; Wang, Y.; Roskilly, A.P.; Huang, Y. Towards sustainable farming: Feasibility study into energy recovery from bio-waste on a small-scale dairy farm. J. Clean. Prod. 2018, 174, 899–904. [Google Scholar] [CrossRef]

- Russo, V.; von Blottnitz, H. Potentialities of biogas installation in South African meat value chain for environmental impacts reduction. J. Clean. Prod. 2017, 153, 465–473. [Google Scholar] [CrossRef]

- Osunde, Z.D.; Orhevba, B.A. Effects of storage conditions and storage period on nutritional and other qualities of stored yam tubers. Afr. J. Food Agric. Nutr. Dev. 2009, 9, 678–690. [Google Scholar]

- Amponsah, S.K.; Akowuah, J.O.; Adu-kwarteng, E.; Bessah, E. Design and construction of improved yam storage structure using locally-available materials. Int. J. Res. Agric. For. 2015, 2, 1–11. [Google Scholar]

- Onwueme, I.C.; Charles, W.B. Tropical Root and Tuber Crops: Production, Perspectives and Future Prospects; Food Agriculture Organization: Rome, Italy, 1994. [Google Scholar]

- NERC-Nigeria Electricity Regulation Commission. Draft Feed-In-Tariff Regulations for Renewable Energy Sourced Electricity in Nigeria; NERC-Nigeria Electricity Regulation Commission: Abuja, Nigeria, 2015. [Google Scholar]

- Soneye, A.S.O. Farm Holdings in Northern Nigeria and Implication for Food Security: A Remote Sensing and GIS Assessment. Afr. J. Food Agric. Nutr. Dev. 2014, 14, 1–15. [Google Scholar]

- Awotide, B.A.; Karimov, A.A.; Diagne, A. Agricultural technology adoption, commercialization and smallholder rice farmers’ welfare in rural Nigeria. Agric. Food Econ. 2016, 4, 3. [Google Scholar] [CrossRef]

- Adeniyan, O.N.; Aluko, O.A.; Olanipekun, S.O.; Olasoji, J.O.; Aduramigba-Modupe, V.O. Growth and Yield Performance of Cassava/Maize Intercrop Under Different Plant Population Density of Maize. J. Agric. Sci. 2014, 6, 35–40. [Google Scholar] [CrossRef]

- Government of Benue State. Indigenous Administrative Structure and Institutions; Nigerian Benue State Minist Lands Survey, 2018.

- Simonyan, K.J.; Fasina, O. Biomass resources and bioenergy potentials in Nigeria. Afr. J. Agric. Res. 2013, 8, 4975–4989. [Google Scholar]

- Garba, N.A.; Zangina, U. Rice straw & husk as potential sources for mini-grid rural electricity in Nigeria. Int. J. Appl. Sci. Eng. Res. 2015, 4, 523–530. [Google Scholar]

- Nguyen, H.H.; Heaven, S.; Banks, C. Energy potential from the anaerobic digestion of food waste in municipal solid waste stream of urban areas in Vietnam. Int. J. Energy Environ. Eng. 2014, 5, 365–374. [Google Scholar] [CrossRef]

- Lindorfer, H.; Braun, R.; Kirchmayr, R. Self-heating of anaerobic digesters using energy crops. Water Sci. Technol. 2006, 53, 159–166. [Google Scholar] [CrossRef] [PubMed]

- Thirugnanasambandam, M.; Iniyan, S.; Goic, R. A review of solar thermal technologies. Renew. Sustain. Energy Rev. 2010, 14, 312–322. [Google Scholar] [CrossRef]

- Firdous, R.; Gilani, A.H. Changes in Chemical Composition of Sorghum as Influenced by Growth Stage and Cultivar. Asian-Australas J. Anim. Sci. 2001, 14, 935–940. [Google Scholar] [CrossRef]

- Fezzani, B.; Cheikh, R.B. Implementation of IWA anaerobic digestion model No. 1 (ADM1) for simulating the thermophilic anaerobic co-digestion of olive mill wastewater with olive mill solid waste in a semi-continuous tubular digester. Chem. Eng. J. 2008, 141, 75–88. [Google Scholar] [CrossRef]

- Mansouri, R.; Boukholda, I.; Bourouis, M.; Bellagi, A. Modelling and testing the performance of a commercial ammonia/water absorption chiller using Aspen-Plus platform. Energy 2015, 93, 2374–2383. [Google Scholar] [CrossRef]

- Njie, D.N.; Rumsey, T.R.; Singh, R.P. Thermal properties of cassava, yam and platain. J. Food Eng. 1998, 37, 63–76. [Google Scholar] [CrossRef]

- Peiris, K.H.S.; Mallon, J.L.; Kays, S.J. Respiratory rate and vital heat of some specialty vegetables at various storage temperatures. Horttechnology 1997, 7, 46–49. [Google Scholar] [CrossRef]

- Tampio, E.; Marttinen, S.; Rintala, J. Liquid fertilizer products from anaerobic digestion of food waste: Mass, nutrient and energy balance of four digestate liquid treatment systems. J. Clean. Prod. 2016, 125, 22–32. [Google Scholar] [CrossRef]

| World (Million Tonnes) | 68.132 |

|---|---|

| Nigeria | 45 |

| Ghana | 7.119 |

| Cote d’Ivoire | 5.809 |

| Benin | 3.221 |

| Ethiopia | 1.449 |

| Togo | 0.786 |

| Cameroon | 0.579 |

| Central African Republic | 0.479 |

| Haiti | 0.477 |

| Chad | 0.444 |

| Crop Residue | Rice | Sorghum | Soybean | |||

|---|---|---|---|---|---|---|

| Yield (kg·ha−1) | 2175.2 | 1239.8 | 944 | |||

| Planted/household (ha·yr−1) | 1 | 1.5 | 1.5 | |||

| Household production (kg·yr−1) | 2175.2 | 1859.7 | 1410 | |||

| Residue type | Straw | Husk | Straw | Husk | Straw | pod |

| Moisture content (%) | 12.71 | 2.37 | 15 | 15 | 15 | 15 |

| Residue grain ratio (%) | 1.757 | 0.20 | 1.25 | 0.20 | 2.5 | 1.0 |

| Residue availability (%) | 83.5 | 100 | 83.5 | 100 | 70 | 100 |

| Residue/household (kg·yr−1) | 3191.25 | 435.04 | 1941.06 | 371.94 | 2467.5 | 1410 |

| Type | Unit | Energy Demand (kWh·d−1) | Currently Used |

|---|---|---|---|

| Households | 200 | 3.5·households−1 | None |

| Commercial | 4 | 300 | 4 × 10 HP generator |

| Health centre | 1 | 180 | 10 HP × 1 |

| Primary school | 1 | Unknown | None |

| Crop | Moisture Content (WB) | Crude Protein (%) | Volatile Solids (%) | Crude Fibre (%) | Ether Extracts (%) | Ash (%) |

|---|---|---|---|---|---|---|

| Rice | 12.71 | 5 | 80 | 40 | 3 | 20 |

| Sorghum | 15 | 4 | 96 | 35 | 3 | 5 |

| Soybeans | 15 | 12 | 95 | 46 | 7 | 5 |

| Items | Parameters | Amount |

|---|---|---|

| Internal combustion engine | Power (kW) | 72 |

| Fuel consumption (Nm3·h−1) | 42.2 | |

| Ambient air temperature (°C) | 25 | |

| Jacket water temperature (°C) | 99 | |

| Compression ratio | 10.5:1 | |

| Combustion air flow rate (m3·h−1) | 292 | |

| Displacement (L) | 10.5 | |

| Exhaust stack temperature (°C) | 581 | |

| Exhaust gas flow rate (m3·h−1) | 324 | |

| Heat rejection to jacket water (kW) | 99 | |

| Heat rejection to lubricant oil (kW) | 16 | |

| Absorption chiller | Power (kW) | 17.5 |

| Nominal water flow rate (m3·h−1) | 2.77 | |

| Temperature change (ΔT) (°C) | 5.5 | |

| Water capacity pressure loss (kPa) | 29 | |

| Ambient operating temperature (°C) | 0–45 | |

| Thermal input (kW) | 25 | |

| Electric power (kW) | 0.84 |

| Parameters | Amount |

|---|---|

| Capital cost (AD + ICE system) (USD·kW−1) | 2900 |

| Capital cost (cold storage)a (USD·unit−1) | 2000 |

| Capital cost (chiller)b (USD·unit−1) | 35,508.18 |

| Fixed O&M (AD + ICE system) (USD·kW−1·yr−1) | 53.5 |

| Variable O&M (AD + ICE) (USD·MWh−1) | 0.95 |

| Variable O&M (cold storage) (USD·MWh−1) | 0.15 |

| Fuel cost (USD·MWh−1) | 5 |

| Parasitic load (%) | 10 |

| Life Span (Yr) | 20 |

| Interest rates (%) | 7, 9, 20 |

| Capacity (kW) | 72 |

| Availability (%) | 90 |

| Exchange rate (USD·#−1) | 305 |

| Price of yam tuber (fresh) (USD·tuber−1) | 0.82 |

| Price of yam tuber (off-season) (USD·tuber−1) | 1.64 |

| Price of yam tuber (export) (USD·tuber−1) | 3.25 |

| Electricity price (rural grid) (USD·kWh−1) | 0.013 |

| Electricity price (Self-generated) (USD·kWh−1) | 0.75 |

| Electricity price (REA) (USD·kWh−1) | 0.42 |

| FITs Biomass (N·MWh−1) | 37,357 |

| Replacement (60000h) (USD·kW−1) | 1389.77 |

| Total project cost | 357,324.50 |

| Items | Mesophilic Process | Thermophilic Process |

|---|---|---|

| Operating temperature (°C) | 35 | 55 |

| Percentage methane (%) | 64.80 | 58.20 |

| Specific biogas production (L·kgVS−1·day−1) | 256.16 | 293.56 |

| Specific methane production (g·kgVS−1·day−1) | 190.26 | 196.80 |

| Composition | Percentage (Dry Basis) | Molar Mass (g·mole−1) | Daily Flow (kg·day−1) | (kJ·mole−1) | Enthalpy Heat (kW) |

|---|---|---|---|---|---|

| Carbohydrates | 64.44 | 180 | 3466.87 | −138.50 | −30.87 |

| Protein | 7.00 | 89 | 376.6 | +198.50 | +9.72 |

| Lipids | 4.33 | 300 | 232.95 | +544.50 | +4.89 |

| Total heat of enthalpy | −16.26 | ||||

| Required Load (kW) | Mesophilic (35 °C) | Thermophilic (55 °C) |

|---|---|---|

| Substrate warming up | +62.72 | +188.16 |

| Biochemical heat of reaction | −16.26 | −16.26 |

| Heat loss through insulation | +0.88 | +2.64 |

| Heat loss by radiation | +0.0386 | +0.312 |

| Total heat load required | 47.38 | 174.85 |

| Particulars | Required Load (kW) |

|---|---|

| Sensible cooling load required | 34.83 |

| Respiratory heat generated | 7.43 × 10−2 |

| Heat loss through insulation | 5.93 × 10−1 |

| Heat loss by radiation | 1.43 × 10−3 |

| Total cooling load required | 35.50 |

| S/N | Gas | Methane | CO2 |

|---|---|---|---|

| 1 | Base | 0.705 | 0.295 |

| 2 | Bio80 | 0.800 | 0.200 |

| 3 | Bio70 | 0.700 | 0.300 |

| 4 | Bio60 | 0.600 | 0.400 |

| 5 | Bio50 | 0.500 | 0.500 |

| 6 | Bio40 | 0.400 | 0.600 |

| Interest Rate (%) | Local (USD·kWh−1) | Foreign (USD·kWh−1) |

|---|---|---|

| 7 | 0.115 | 0.111 |

| 9 | 0.124 | 0.120 |

| 20 | 0.276 | 0.272 |

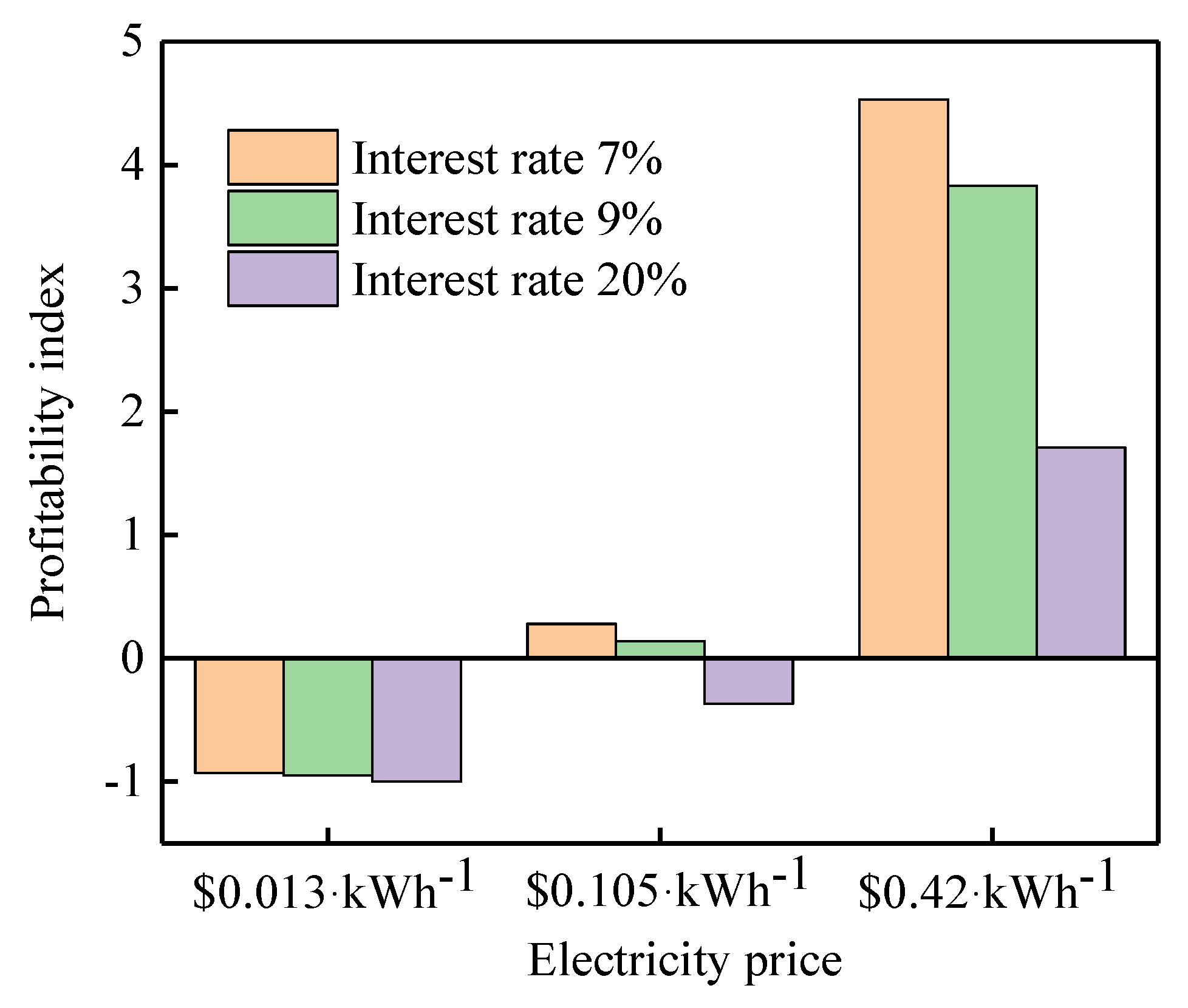

| Interest Rates | USD0.013·kWh−1 | USD0.105·kWh−1 | USD0.420·kWh−1 |

|---|---|---|---|

| 7% | negative | 11.5 | 2.01 |

| 9% | negative | 18.6 | 2.48 |

| 20% | negative | negative | 4.70 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lamidi, R.O.; Jiang, L.; Wang, Y.; Pathare, P.B.; Aguilar, M.C.; Wang, R.; Eshoul, N.M.; Roskilly, A.P. Techno-Economic Analysis of a Cogeneration System for Post-Harvest Loss Reduction: A Case Study in Sub-Saharan Rural Community. Energies 2019, 12, 872. https://doi.org/10.3390/en12050872

Lamidi RO, Jiang L, Wang Y, Pathare PB, Aguilar MC, Wang R, Eshoul NM, Roskilly AP. Techno-Economic Analysis of a Cogeneration System for Post-Harvest Loss Reduction: A Case Study in Sub-Saharan Rural Community. Energies. 2019; 12(5):872. https://doi.org/10.3390/en12050872

Chicago/Turabian StyleLamidi, Rasaq O, Long Jiang, Yaodong Wang, Pankaj B Pathare, Marcelo Calispa Aguilar, Ruiqi Wang, Nuri Mohamed Eshoul, and Anthony Paul Roskilly. 2019. "Techno-Economic Analysis of a Cogeneration System for Post-Harvest Loss Reduction: A Case Study in Sub-Saharan Rural Community" Energies 12, no. 5: 872. https://doi.org/10.3390/en12050872

APA StyleLamidi, R. O., Jiang, L., Wang, Y., Pathare, P. B., Aguilar, M. C., Wang, R., Eshoul, N. M., & Roskilly, A. P. (2019). Techno-Economic Analysis of a Cogeneration System for Post-Harvest Loss Reduction: A Case Study in Sub-Saharan Rural Community. Energies, 12(5), 872. https://doi.org/10.3390/en12050872