Combustion Analysis of Homogeneous Charge Compression Ignition in a Motorcycle Engine Using a Dual-Fuel with Exhaust Gas Recirculation

Abstract

1. Introduction

2. Experimental Methodology

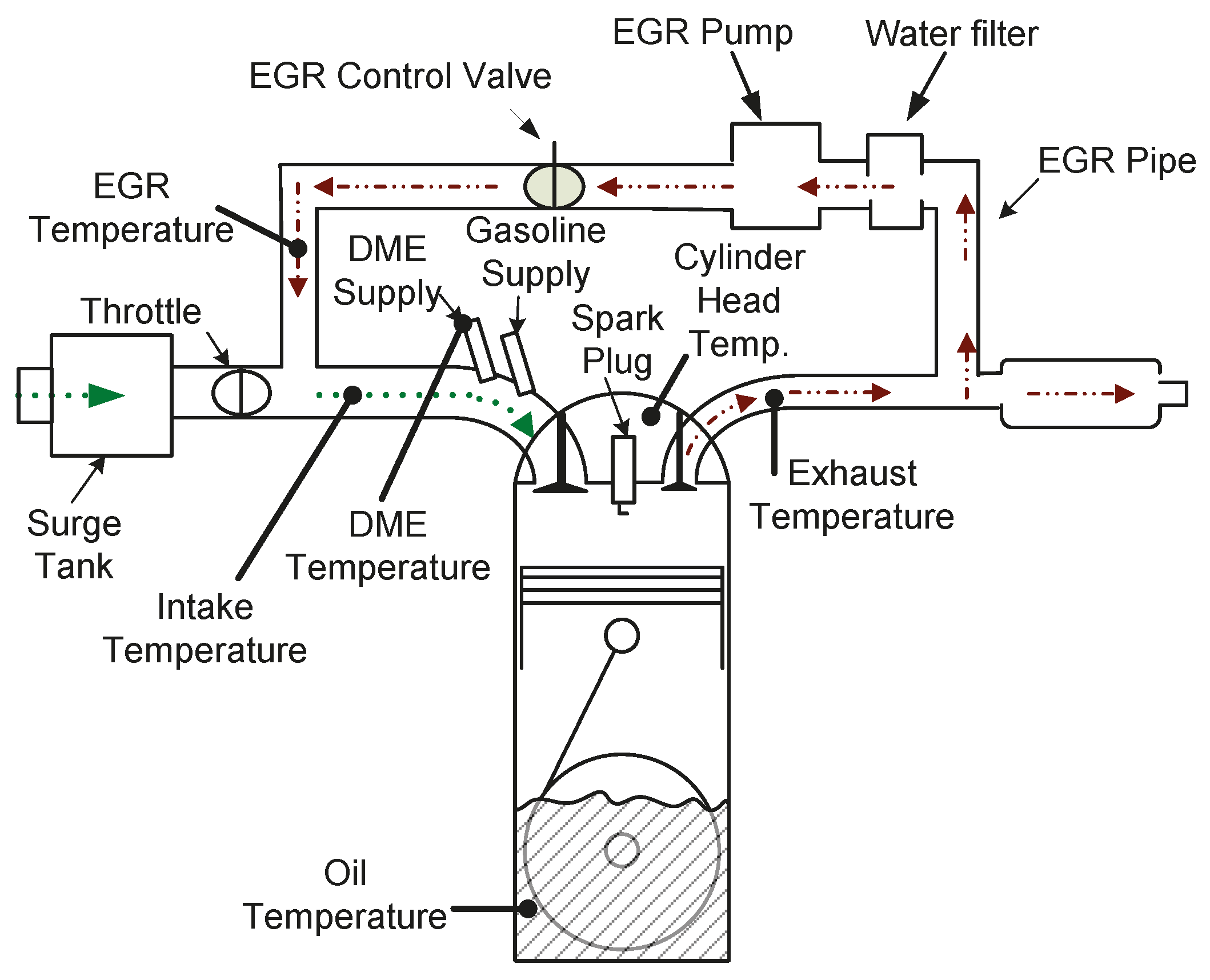

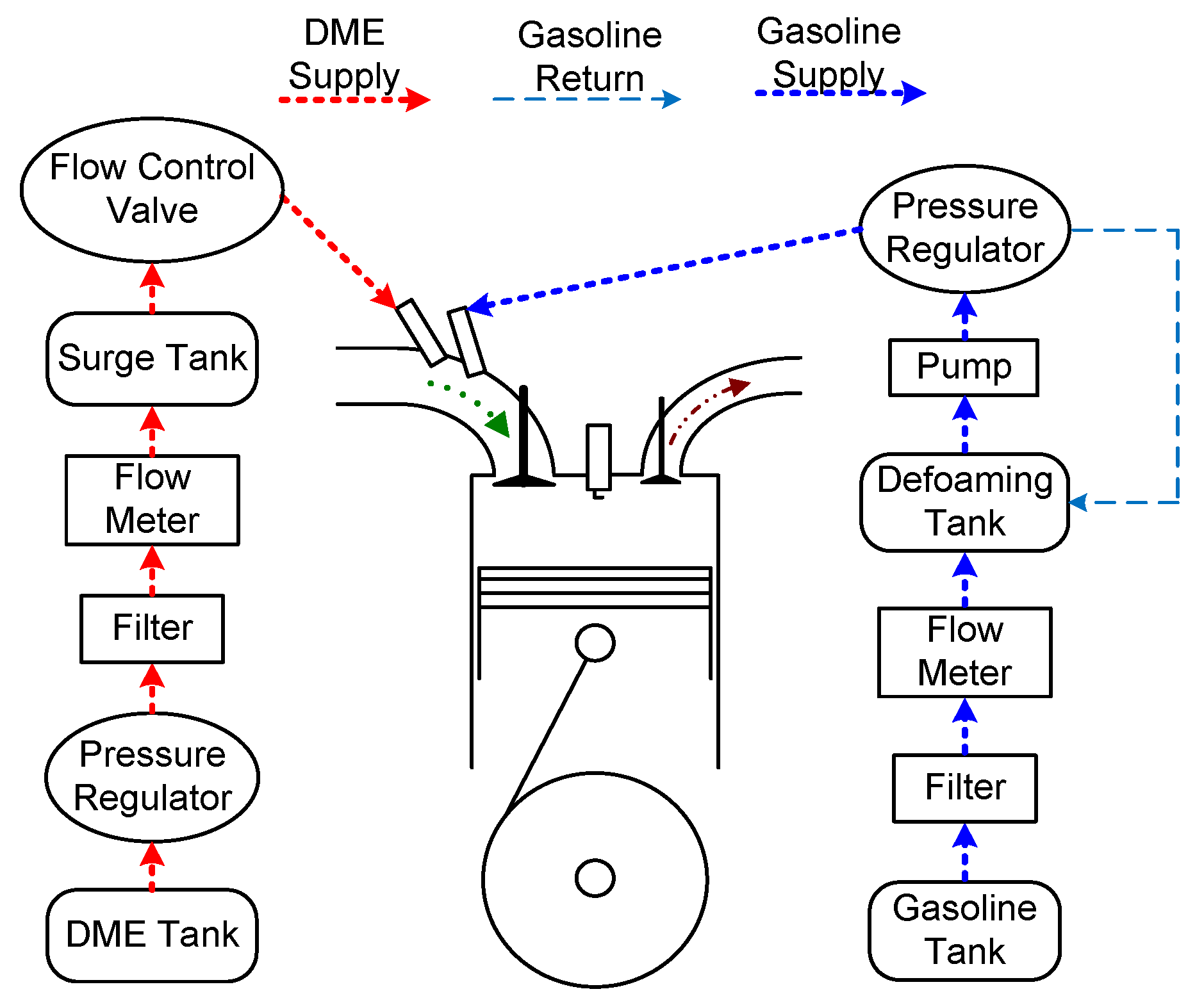

2.1. Experimental Setup

2.2. Calculation of Combustion Parameters

3. Results and Discussion

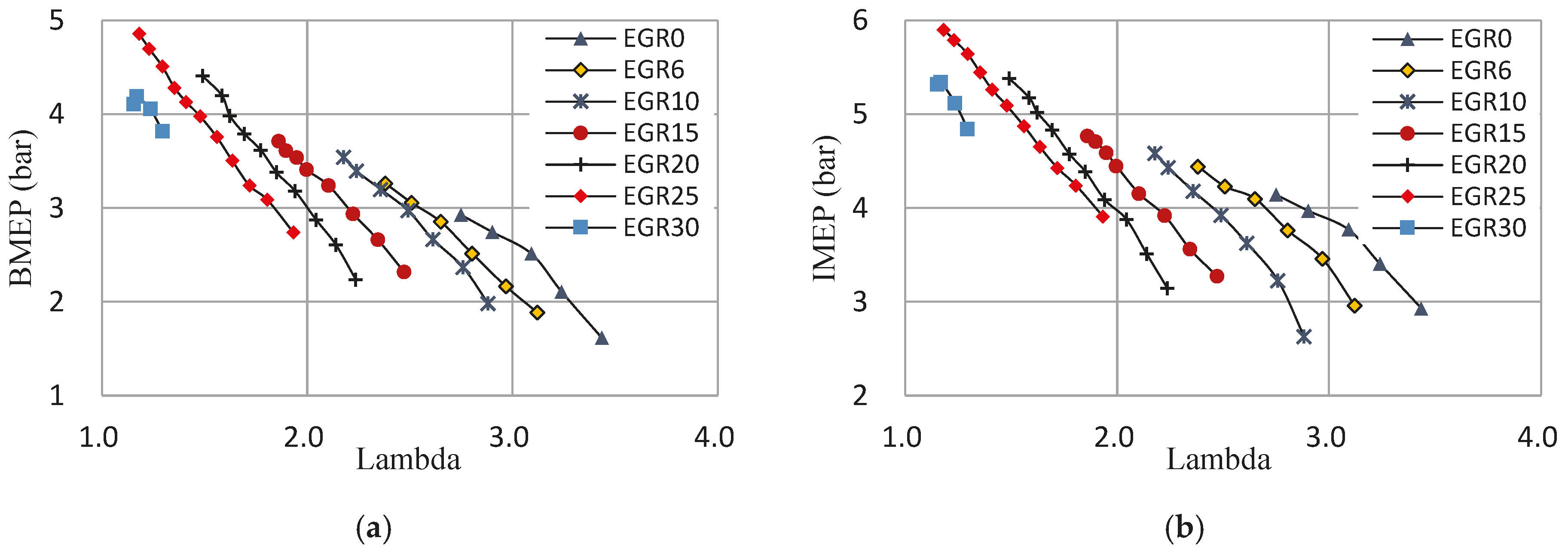

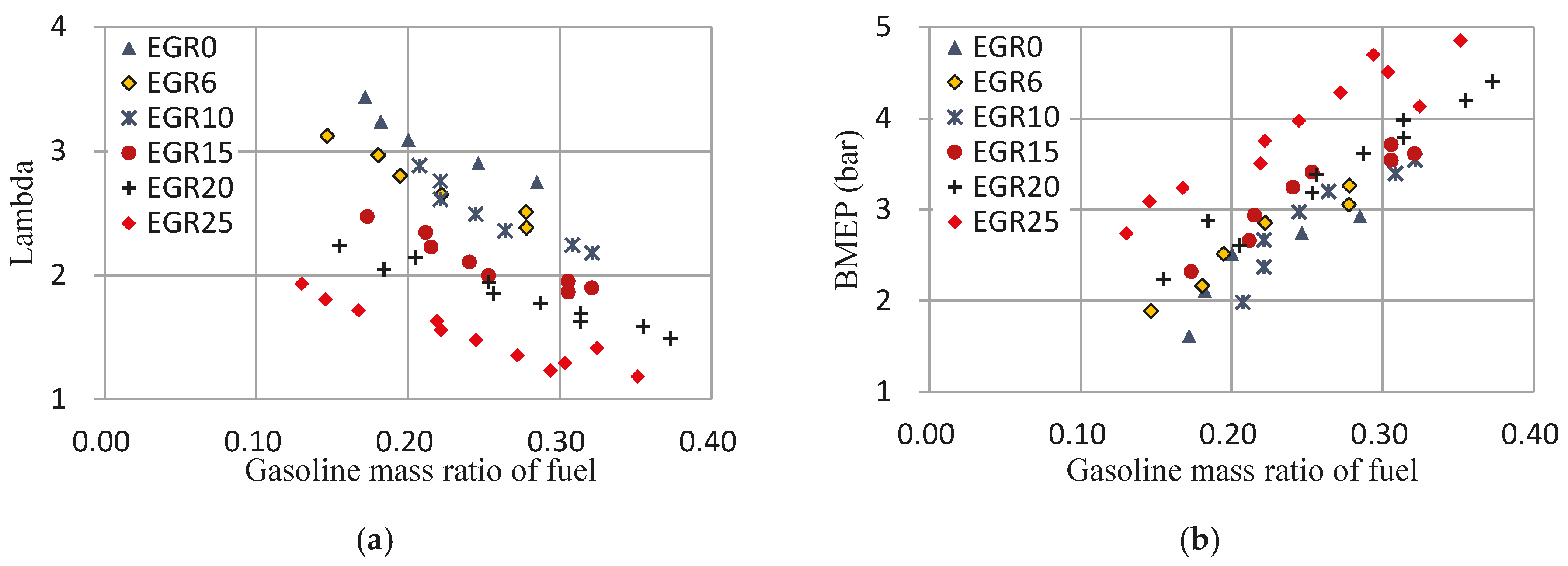

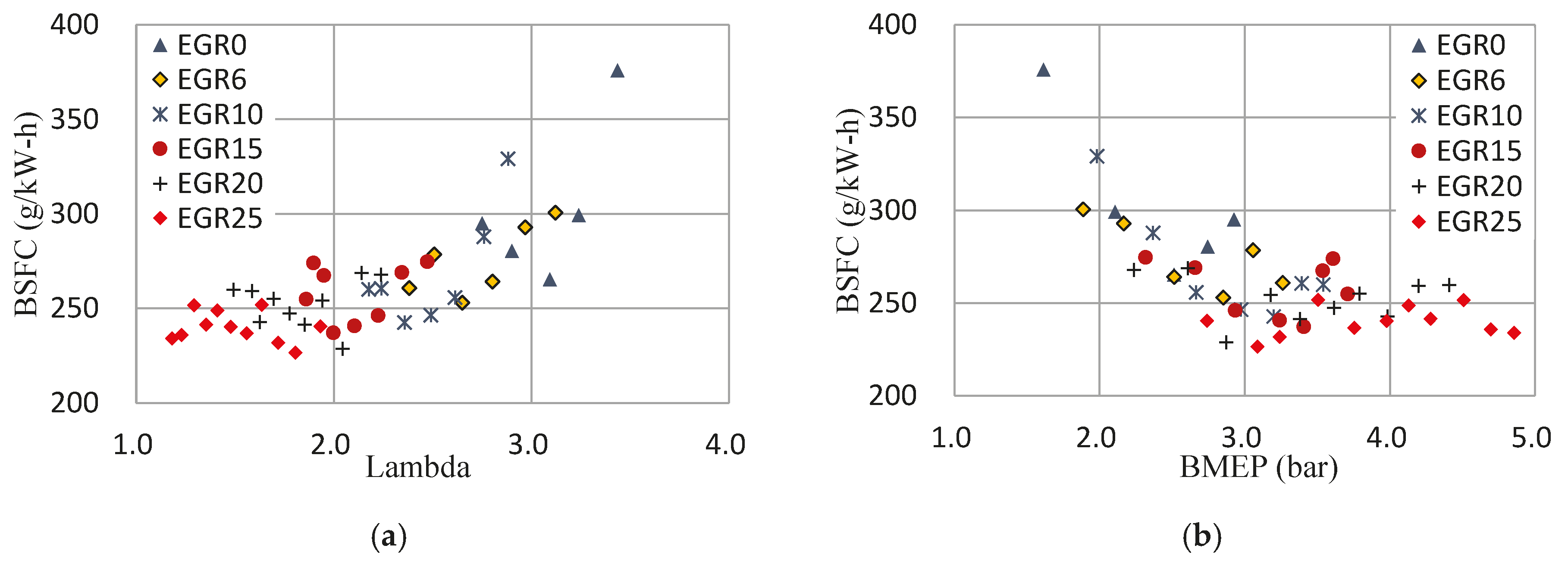

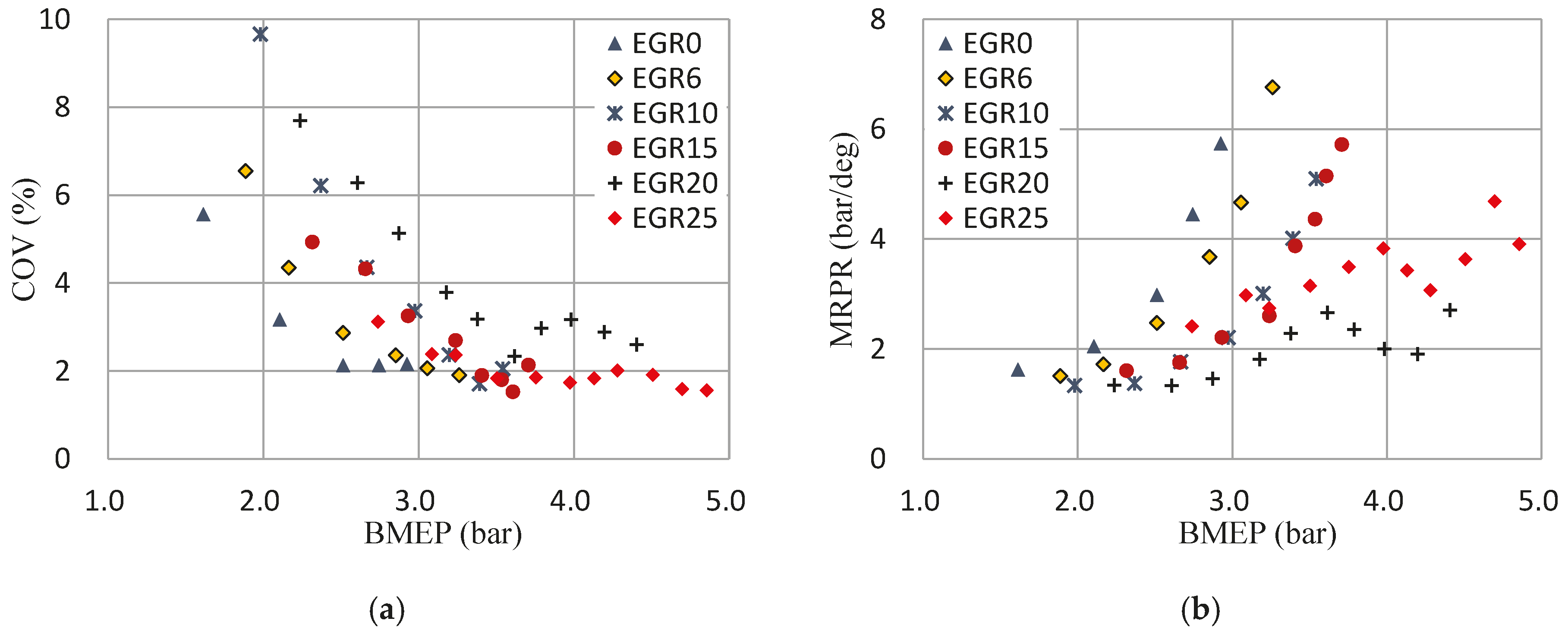

3.1. Engine Performances

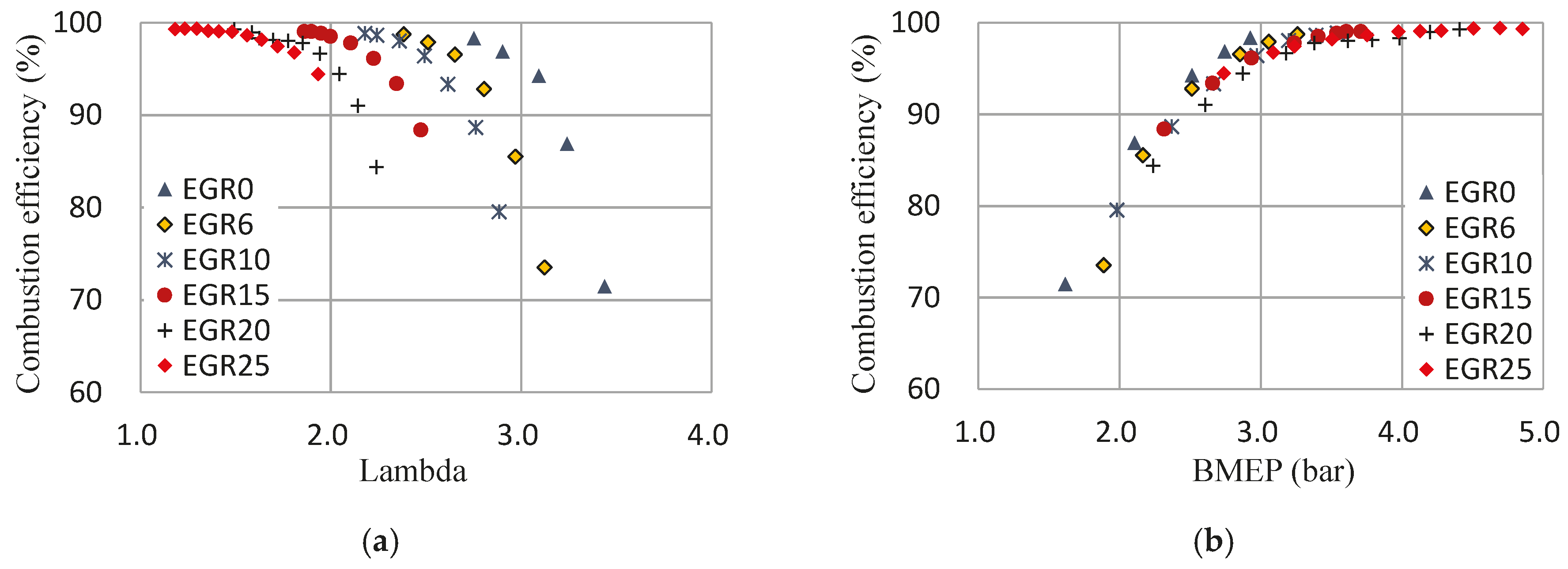

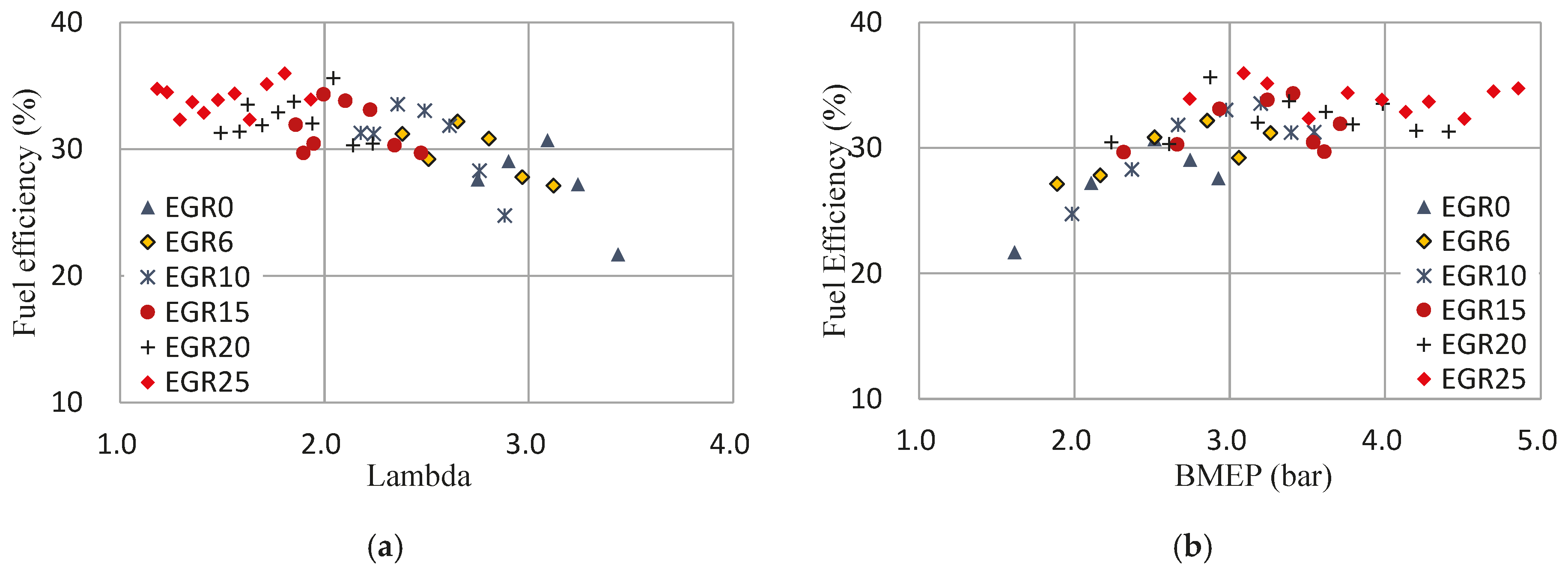

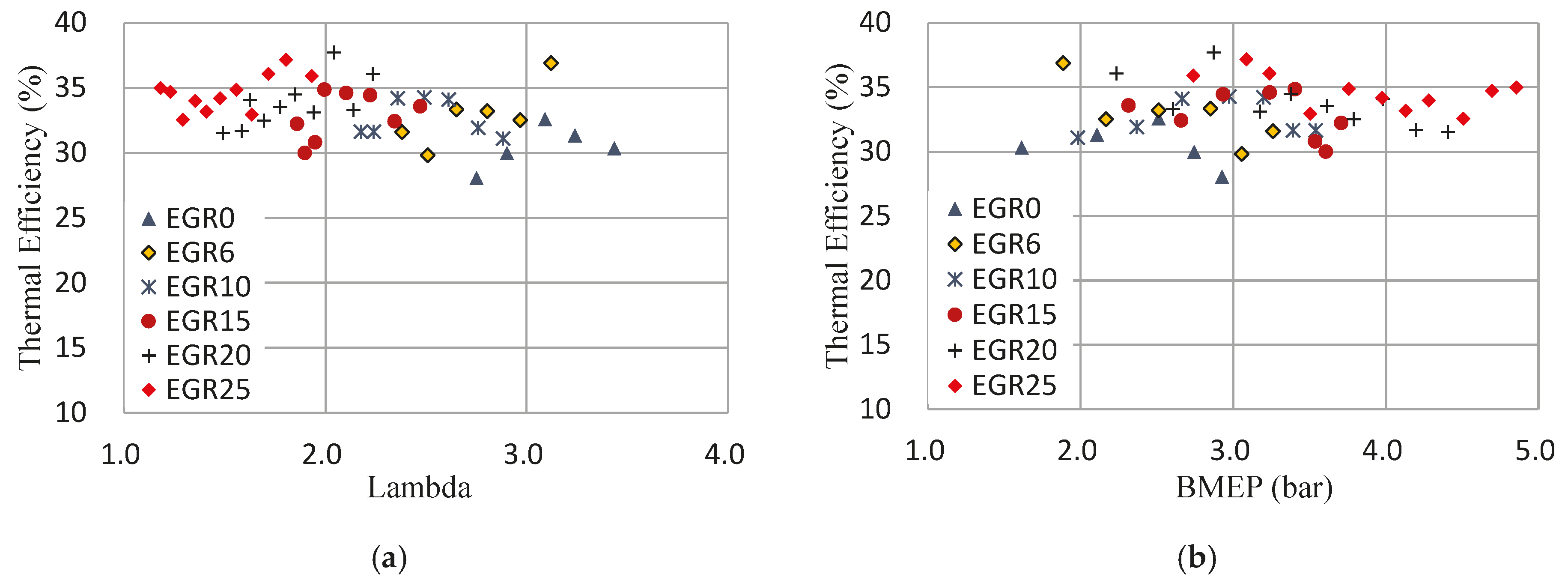

3.2. Engine Efficiencies

3.3. Exhaust Emissions

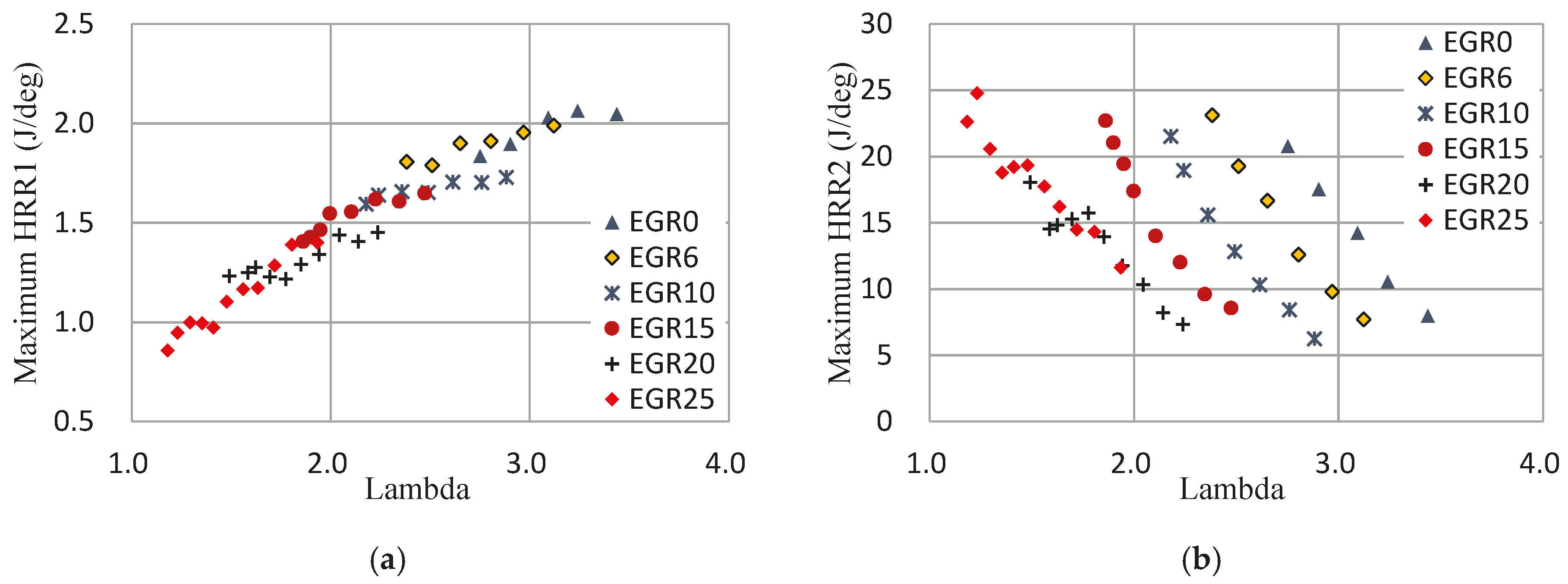

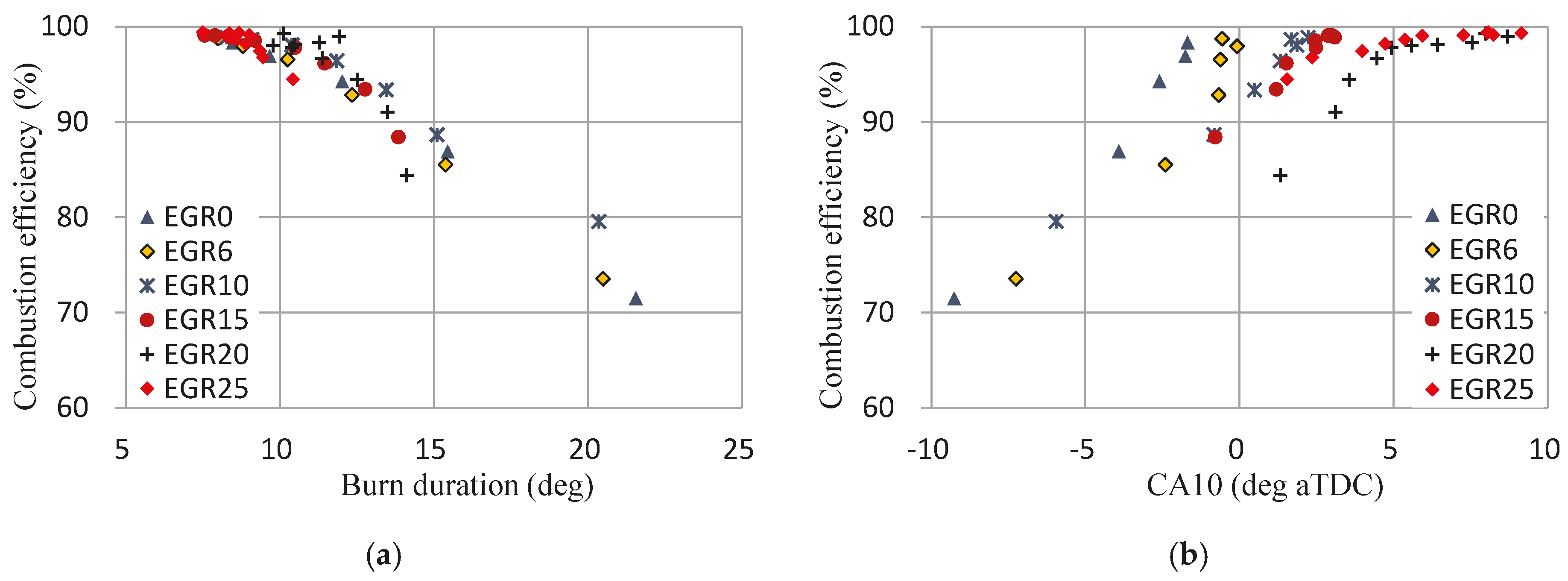

3.4. Combustion Characteristics

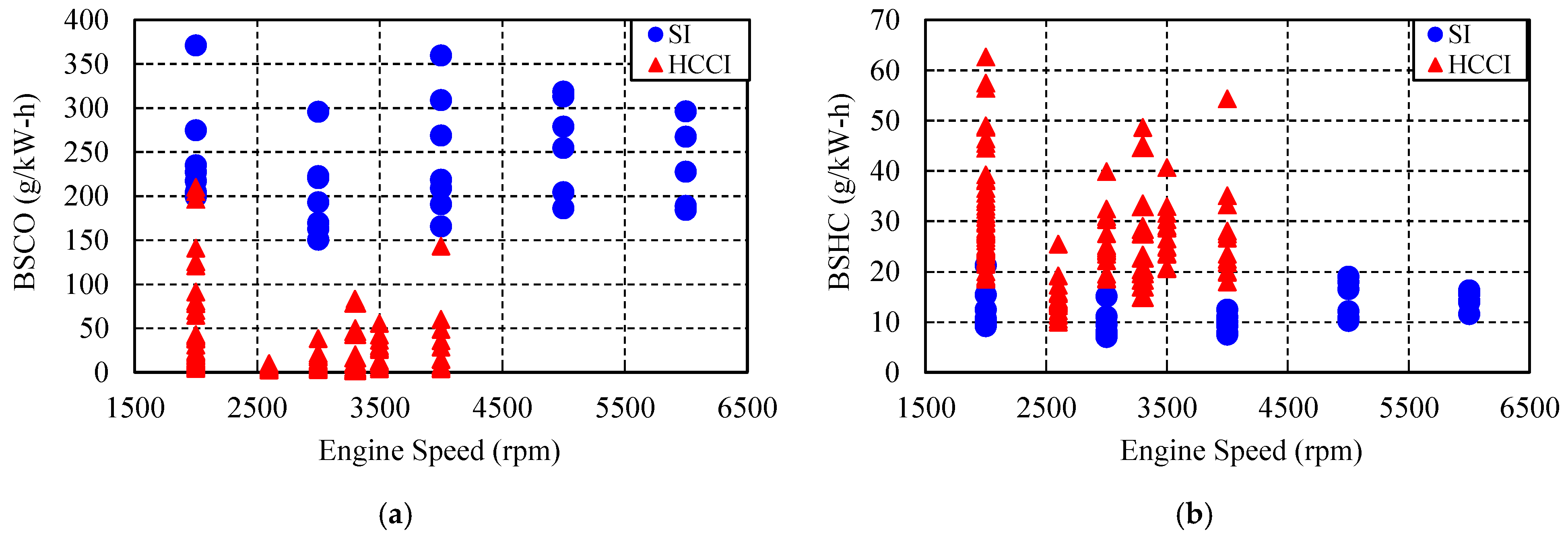

3.5. Comparison between HCCI and SI

4. Conclusions

- (1)

- To pursue both high engine output and low BSFC, the proposed HCCI system for a motorcycle engine is DME-gasoline dual-fuel with 25% EGR and λ < 2. Therefore, the design guide for HCCI engine obtaining high output and low BSFC can be led to a DME-gasoline dual-fuel system with suitable EGR ratio and air-fuel mixture not too lean.

- (2)

- The maximum BMEP increase was from 2.93 to 4.86 bar, an increase of 65.8%, when the EGR was 0% to 25%. At 25% EGR, BMEP increased by 77.4% from 2.74 to 4.86 bar when the gasoline ratio increased from 0.13 to 0.35.

- (3)

- The BSFC was improved great as compared with the original SI engine and NO emision was too small to measure.

- (4)

- The thermal efficiency ranged from 30%–35% and had no clear relationship with λ or BMEP.

- (5)

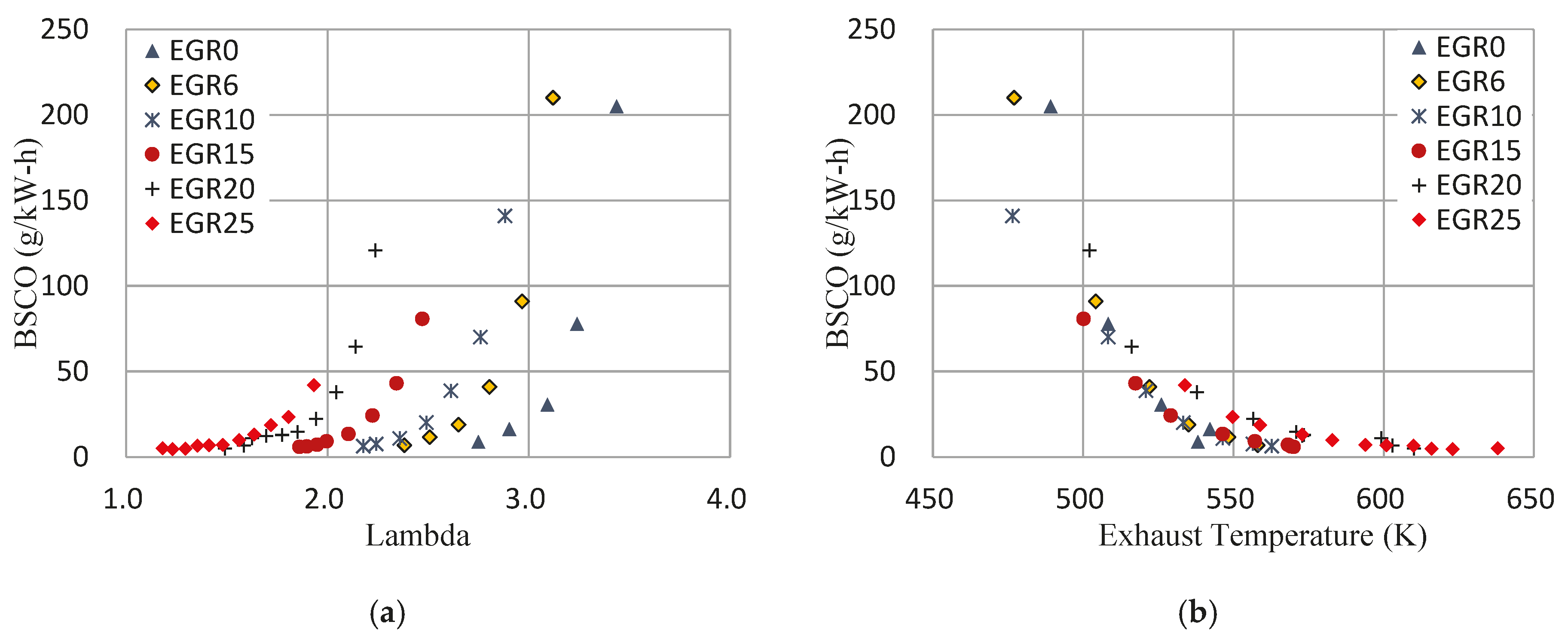

- Both BSCO and BSHC decreased when the exhaust temperature increased, whereas the exhaust temperature increased linearly with BMEP. When the exhaust temperature was > 550 K or BMEP was > 3.16 bar, the amount of CO emitted was very small.

- (6)

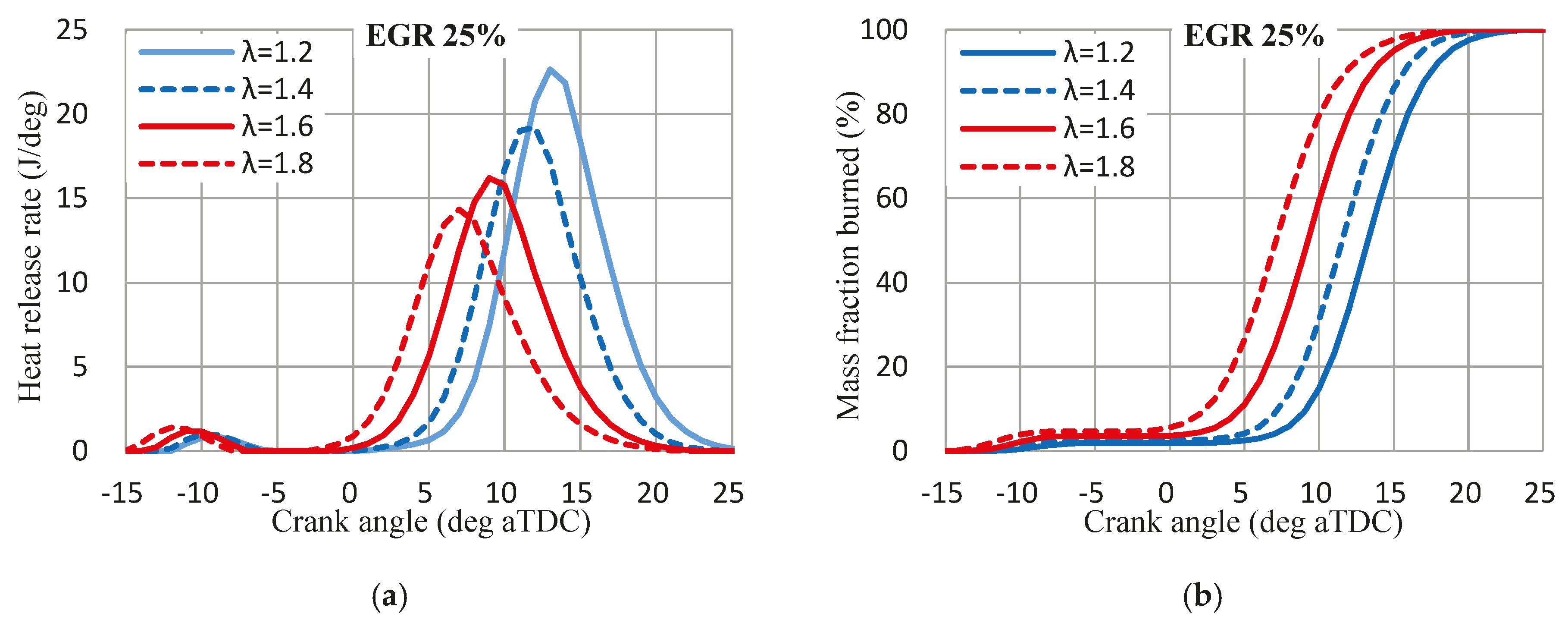

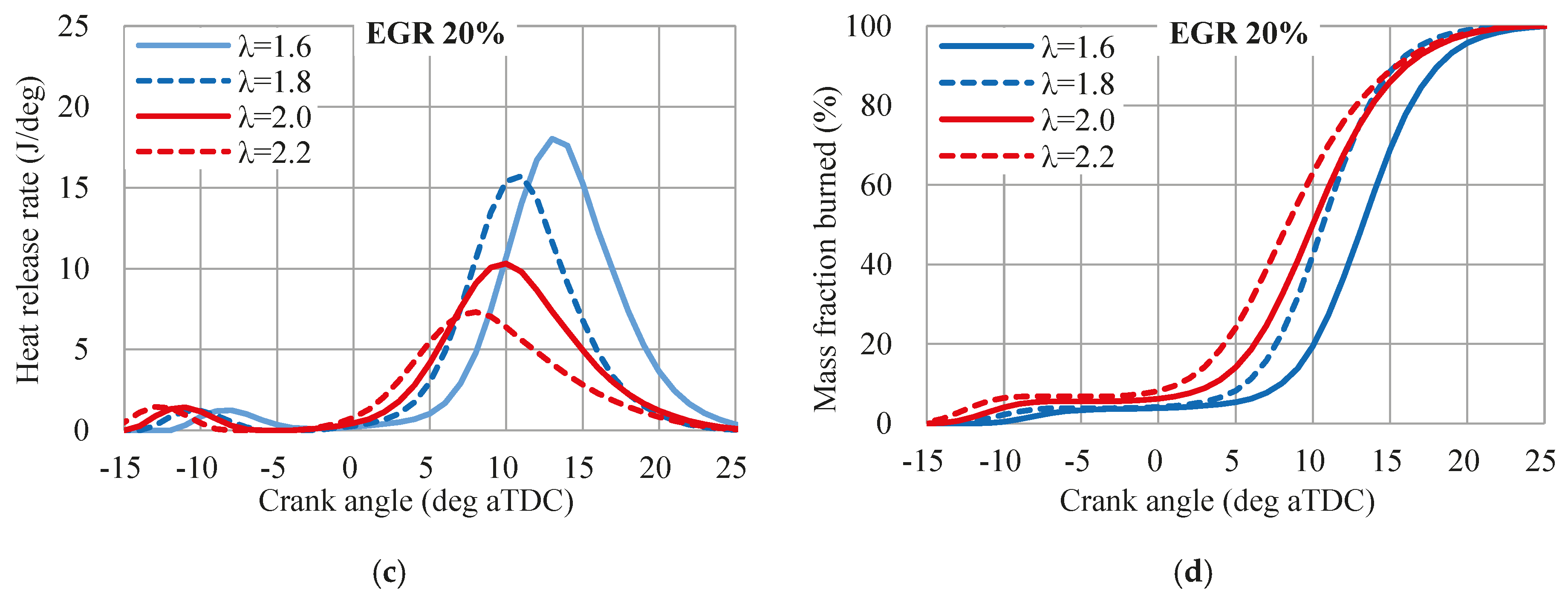

- Both CA10 and CA50 were delayed by a decrease in λ. This is caused by the addition of more gasoline fuel, which delays combustion.

- (7)

- The burn duration increased in line with λ because a leaner mixture causes slower combustion. The combustion efficiency was close to 100% when the burn duration was <10 deg CA.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| A | area of combustion chamber surface |

| BMEP | brake mean effective pressure |

| BSCO | brake-specific CO |

| BSFC | brake-specific fuel consumption |

| BSHC | brake-specific HC |

| BDC | bottom dead center |

| Cm | average piston speed |

| cp | specific heat for constant pressure |

| CA | crank angle |

| CAD | crank angle degrees |

| CA10 | crank angle at which the mass fraction burned is 10% |

| CA50 | crank angle at which the mass fraction burned is 50% |

| CA90 | crank angle at which the mass fraction burned is 90% |

| CO | carbon monoxide |

| CO2 | carbon dioxide |

| COV | coefficient of variation |

| DI | direct injection |

| DME | dimethyl ether |

| ECE | Economic Commission of Europe |

| EGR | exhaust gas recirculation |

| EPA | Environmental Protection Administration |

| FSN | filter smoke number |

| HC | hydrocarbons |

| HCCI | homogeneous charge compression ignition |

| HRR | heat release rate |

| H2O2 | hydrogen peroxide |

| h | heat transfer coefficient |

| IMEP | indicated mean effective pressure |

| IMEPavg | average IMEP |

| IMEPstd | standard deviation of IMEP |

| MFB | mass fraction burned |

| MHRR | maximum heat release rate |

| MRPR | maximum rate of pressure rise |

| NMHC | non-methane hydrocarbons |

| NO | nitric oxide |

| NOx | nitrogen oxides |

| NVO | negative valve overlap |

| OBD | on-board diagnostics |

| OH | hydroxyl radical |

| P | cylinder gas pressure (bar) |

| PFI | port fuel injection |

| PM | particulate matter |

| QLHV | low heating value of fuel |

| RON | research octane number |

| St | Stanton number |

| SCR | selective catalytic reduction |

| SI | spark ignition |

| T | cylinder gas temperature |

| TDC | top dead center |

| V | cylinder volume |

| WMTC | worldwide motorcycle test cycle |

| bhp | brake horsepower |

| mf | fuel mass supplied per cycle |

| λ | air–fuel equivalence ratio |

| θ | crank angle (degree) |

| γ | specific heat ratio |

| ηc | combustion efficiency (%) |

| ηf | fuel efficiency (%) |

| ηth | brake thermal efficiency (%) |

References

- Taiwan Ministry of Transportation and Communications (MOTC). Motor Vehicle Registration (Sept. 2018). Available online: http://stat.motc.gov.tw/mocdb/stmain.jsp?sys=100&funid=e3301 (accessed on 6 November 2018).

- Lin, C.Y.; Wu, S.Y.; Liang, H.J.; Liu, Y.C.; Ueng, T.H. Metabolomic analysis of the effects of motorcycle exhaust on rat testes and liver. Aerosol Air Qual. Res. 2014, 14, 1714–1725. [Google Scholar] [CrossRef]

- Chuang, S.C.; Chen, S.J.; Huang, K.L.; Chang-Chien, G.P.; Wang, L.C.; Huang, Y.C. Emissions of polychlorinated dibenzo-p-dioxin and polychlorinated dibenzofuran from motorcycles. Aerosol Air Qual. Res. 2010, 10, 533–539. [Google Scholar] [CrossRef]

- Taiwan Environmental Protection Administration (EPA). Air Pollutant Emission Regulations for Transportation Vehicles. Available online: https://oaout.epa.gov.tw/law/LawContent.aspx?id=FL015347 (accessed on 6 November 2018).

- Finesso, R.; Spessa, E.; Venditti, M.; Yang, Y. Offline and Real-Time Optimization of EGR ratio and Injection Timing in Diesel Engines. SAE Int. J. Engines 2015, 8, 2099–2119. [Google Scholar] [CrossRef]

- Theis, J.; Kim, J.; Cavataio, G. TWC+LNT/SCR Systems for Satisfying Tier 2, Bin 2 Emission Standards on Lean-Burn Gasoline Engines. SAE Int. J. Fuels Lubr. 2015, 8, 474–486. [Google Scholar] [CrossRef]

- De Abreu Goes, J.; Olsson, L.; Berggrund, M.; Kristoffersson, A.; Gustafson, L.; Hicks, M. Performance Studies and Correlation between Vehicle- and Rapid- Aged Commercial Lean NOx Trap Catalysts. SAE Int. J. Engines 2017, 10, 1613–1626. [Google Scholar] [CrossRef]

- Lin, Y.C.; Yang, P.M.; Chen, C.B. Reducing emissions of polycyclic aromatic hydrocarbons and greenhouse gases from engines using a novel plasma-enhanced combustion system. Aerosol Air Qual. Res. 2013, 13, 1107–1115. [Google Scholar] [CrossRef]

- Wei, M.; Nguyen, T.S.; Turkson, R.F.; Liu, J.; Guo, G. Water injection for higher engine performance and lower emissions. J. Energy Inst. 2017, 90, 285–299. [Google Scholar] [CrossRef]

- Wu, Y.Y.; Chen, B.C.; Hwang, J.J.; Chen, C.Y. Performance and emissions of motorcycle engines using water–fuel emulsions. Int. J. Veh. Des. 2009, 49, 91–110. [Google Scholar] [CrossRef]

- Hasan, M.M.; Rahman, M.M. Homogeneous charge compression ignition combustion: Advantages over compression ignition combustion, challenges and solutions. Renew. Sustain. Energy Rev. 2016, 57, 282–291. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Singh, A.P.; Maurya, R.K. Evolution, challenges and path forward for low temperature combustion engines. Prog. Energy Combust. Sci. 2017, 61, 1–56. [Google Scholar] [CrossRef]

- Jung, D.; Iida, N. Thermal and chemical effects of the in-cylinder charge at IVC on cycle-to-cycle variations of DME HCCI combustion with combustion-phasing retard by external and rebreathed EGR. Appl. Therm. Eng. 2017, 113, 132–149. [Google Scholar] [CrossRef]

- Mohebbi, M.; Reyhanian, M.; Hosseini, V.; Muhamad Said, M.F.; Aziz, A.A. The effect of diethyl ether addition on performance and emission of a reactivity controlled compression ignition engine fueled with ethanol and diesel. Energy Convers. Manag. 2018, 174, 779–792. [Google Scholar] [CrossRef]

- Hasan, M.M.; Rahman, M.M.; Kadirgama, K.; Ramasamy, D. Numerical study of engine parameters on combustion and performance characteristics in an n-heptane fueled HCCI engine. Appl. Therm. Eng. 2018, 128, 1464–1475. [Google Scholar] [CrossRef]

- Kalaskar, V.; Splitter, D.; Szybist, J. Gasoline-Like Fuel Effects on High-Load, Boosted HCCI Combustion Employing Negative Valve Overlap Strategy. SAE Int. J. Fuels Lubr. 2014, 7, 82–93. [Google Scholar] [CrossRef]

- Yun, H.; Wermuth, N.; Najt, P. Extending the High Load Operating Limit of a Naturally-Aspirated Gasoline HCCI Combustion Engine. SAE Int. J. Engines 2010, 3, 681–699. [Google Scholar] [CrossRef]

- Szybist, J.P.; Nafziger, E.; Weall, A. Load Expansion of Stoichiometric HCCI Using Spark Assist and Hydraulic Valve Actuation. SAE Int. J. Engines 2010, 3, 244–258. [Google Scholar] [CrossRef]

- Lawler, B.; Lacey, J.; Güralp, O.; Najtc, P.; Filipi, Z. HCCI combustion with an actively controlled glow plug: The effects on heat release, thermal stratification, efficiency, and emissions. Appl. Energy 2018, 211, 809–819. [Google Scholar] [CrossRef]

- Ji, C.; Dec, J.; Dernotte, J.; Cannella, W. Boosted Premixed-LTGC/HCCI Combustion of EHN-doped Gasoline for Engine Speeds Up to 2400 rpm. SAE Int. J. Engines 2016, 9, 2166–2184. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, H.; Huang, Z.; Liu, Z. Study on combustion and emission of a dimethyl ether-diesel dualfuel premixed charge compression ignition combustion engine with LPG (liquefied petroleum gas) as ignition inhibitor. Energy 2016, 96, 278–285. [Google Scholar] [CrossRef]

- Pedersen, T.D.; Schramm, J.; Yanai, T.; Sato, Y. Controlling the Heat Release in HCCI Combustion of DME with Methanol and EGR; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2010. [Google Scholar]

- Li, G.; Zhang, C.; Zhou, J. Study on the knock tendency and cyclical variations of a HCCI engine fueled with n-butanol/n-heptane blends. Energy Convers. Manag. 2017, 133, 548–557. [Google Scholar] [CrossRef]

- Khandal, S.V.; Banapurmath, N.R.; Gaitonde, V.N. Performance studies on homogeneous charge compression ignition (HCCI) engine powered with alternative fuels. Renew. Energy 2019, 132, 683–693. [Google Scholar] [CrossRef]

- Zheng, Z.; Xia, M.; Liu, H.; Wang, X.; Yao, M. Experimental study on combustion and emissions of dual fuel RCCI mode fueled with biodiesel/n-butanol, biodiesel/2,5-dimethylfuran and biodiesel/ethanol. Energy 2018, 148, 824–838. [Google Scholar] [CrossRef]

- Putrasari, Y.; Jamsran, N.; Lim, O. An investigation on the DME HCCI autoignition under EGR and boosted operation. Fuel 2017, 200, 447–457. [Google Scholar] [CrossRef]

- Ito, S.; Ikeda, H.; Jung, D.W.; Iida, N. Potential of Stratification Charge for Reducing Pressure-Rise Rate in HCCI Engines Based on Multi-Zone Modeling and Experiments by Using RCM; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- Jamsran, N.; Lim, O.; Iida, N. An Investigation on DME HCCI Engine about Combustion Phase Control Using EGR Stratification by Numerical Analysis; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2012. [Google Scholar]

- Nishi, M.; Kanehara, M.; Iida, N. Assessment for innovative combustion on HCCI engine by controlling EGR ratio and engine speed. Appl. Therm. Eng. 2016, 99, 42–60. [Google Scholar] [CrossRef]

- Lee, C.; Chung, J.; Lee, K. Emission Characteristics for a Homogeneous Charged Compression Ignition Diesel Engine with Exhaust Gas Recirculation Using Split Injection Methodology. Energies 2017, 10, 2146. [Google Scholar] [CrossRef]

- Lee, K.; Cho, S.; Kim, N.; Min, K. A study on combustion control and operating range expansion of gasoline HCCI. Energy 2015, 91, 1038–1048. [Google Scholar] [CrossRef]

- Szybist, J.P.; Edwards, K.D.; Foster, M.; Confer, K.; Moore, W. Characterization of Engine Control Authority on HCCI Combustion as the High Load Limit is Approached; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- Wu, Y.Y.; Chen, B.C.; Hsieh, F.C. Heat transfer model for small-scale air-cooled spark ignition four-stroke engines. Int. J. Heat Mass Transf. 2006, 49, 3895–3905. [Google Scholar] [CrossRef]

- Wu, Y.Y.; Chen, B.C.; Wang, J.H. Experimental study on HCCI combustion in a small engine with various fuels and EGR. Aerosol Air Qual. Res. 2016, 16, 3338–3348. [Google Scholar] [CrossRef]

- Mack, J.H.; Flowers, D.L.; Buchholz, B.A.; Dibble, R.W. Investigation of HCCI combustion of diethyl ether and ethanol mixtures using carbon 14 tracing and numerical simulations. Proc. Combust. Inst. 2005, 30, 2693–2700. [Google Scholar] [CrossRef]

- Wu, Y.Y.; Jang, C.T.; Chen, B.L. Combustion characteristics of HCCI in motorcycle engine. J. Eng. Gas Turbines Power-Trans. ASME 2010, 132. [Google Scholar] [CrossRef]

- Yao, M.; Chen, Z.; Zheng, Z.; Zhang, B.; Xing, Y. Study on the controlling strategies of homogeneous charge compression ignition combustion with fuel of dimethyl ether and methanol. Fuel 2006, 85, 2046–2056. [Google Scholar] [CrossRef]

- Holman, J.P. Experimental Methods for Engineers, 5th ed.; McGraw-Hill: New York, NY, USA, 1989; ISBN 9780070296220. [Google Scholar]

- Ceviz, M.A.; Kaymaz, I. Temperature and air-fuel ratio dependent specific heat ratio functions for lean burned and unburned mixture. Energy Convers. Manag. 2005, 46, 2387–2404. [Google Scholar] [CrossRef]

- Sun, R.; Thomas, R.; Gray, C.L., Jr. An HCCI Engine: Power Plant for a Hybrid Vehicle; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2004. [Google Scholar]

- Fathi, M.; Saray, R.K.; Checkel, M.D. The Influence of Exhaust Gas Recirculation (EGR) on Combustion and Emissions of n-heptane/Natural Gas Fuelled Homogeneous Charge Compression Ignition (HCCI) Engines. Appl. Energy 2011, 88, 4719–4724. [Google Scholar] [CrossRef]

- Wu, Y.Y.; Chen, B.C.; Wang, J.H. Application of HCCI Engine in Motorcycle for Emission Reduction and Energy Saving. Aerosol Air Qual. Res. 2015, 15, 2140–2149. [Google Scholar] [CrossRef]

- Turns, S.R. An Introduction to Combustion, 3rd ed.; McGraw-Hill: Singapore, 2012; p. 172. ISBN 978-007-108687-5. [Google Scholar]

- Sjöberg, M.; Dec, J.E. An investigation into lowest acceptable combustion temperatures for hydrocarbon fuels in HCCI engines. Proc. Combust. Inst. 2005, 30, 2719–2726. [Google Scholar] [CrossRef]

- Machrafi, H.; Cavadias, S.; Amouroux, J. A parametric study on the emissions from an HCCI alternative combustion engine resulting from the auto-ignition of primary reference fuels. Appl. Energy 2008, 85, 755–764. [Google Scholar] [CrossRef]

- Kelly-Zion, P.L.; Dec, J.E. A computational study of the effect of fuel type on ignition time in homogeneous charge compression ignition engines. Proc. Combust. Inst. 2000, 28, 1187–1194. [Google Scholar] [CrossRef]

| Stage (Implemented Date) | Maxi. Speed (km/h) | CO (mg/km) | HC (mg/km) | NMHC (mg/km) | NOx (mg/km) | PM 1 (mg/km) |

|---|---|---|---|---|---|---|

| 6th stage (1 Jan. 2017) | <130 | 1140 | 380 | - | 70 | - |

| ≥130 | 1140 | 170 | - | 90 | - | |

| 7th stage (1 Jan. 2021) | - | 1000 | 100 | 68 | 60 | 4.5 |

| Items | Specifications | Units |

|---|---|---|

| Engine type | 4-stroke, 1-cylinder, SI | - |

| Valve system | 4-valve, overhead cam | - |

| Cooling system | Forced air cooling | - |

| Displacement | 150 | cc |

| Bore × stroke | 57.4 × 57.8 | mm |

| Compression ratio | 10.5 changed to 12.4 | - |

| Fuel system | Electronic port fuel injection | - |

| Intake valve open 1 | 10° bTDC | CA |

| Intake valve close 1 | 20° aBDC | CA |

| Exhaust valve open 1 | 30° bBDC | CA |

| Exhaust valve close 1 | 10° aTDC | CA |

| Properties | DME | Gasoline |

|---|---|---|

| Chemical structure | C2H6O | - |

| Lower heating value (MJ/kg) | 28.9 | 44.0 |

| Octane number | 35 | 92 |

| Cetane number | 60 | 5–12 |

| Autoignition temperature 1 (K) | 508 | 553–729 |

| Stoichiometric air-fuel ratio | 9.0 | 14.7 |

| Viscosity at 20 °C (cP) | 0.224 | 0.74 |

| Item | Maximum Error (± %) |

|---|---|

| Engine Speed | 0.68 |

| Engine Torque | 1.75 |

| IMEP | 1.92 |

| Fuel Rate | 5.57 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.-Y.; Jang, C.-T. Combustion Analysis of Homogeneous Charge Compression Ignition in a Motorcycle Engine Using a Dual-Fuel with Exhaust Gas Recirculation. Energies 2019, 12, 847. https://doi.org/10.3390/en12050847

Wu Y-Y, Jang C-T. Combustion Analysis of Homogeneous Charge Compression Ignition in a Motorcycle Engine Using a Dual-Fuel with Exhaust Gas Recirculation. Energies. 2019; 12(5):847. https://doi.org/10.3390/en12050847

Chicago/Turabian StyleWu, Yuh-Yih, and Ching-Tzan Jang. 2019. "Combustion Analysis of Homogeneous Charge Compression Ignition in a Motorcycle Engine Using a Dual-Fuel with Exhaust Gas Recirculation" Energies 12, no. 5: 847. https://doi.org/10.3390/en12050847

APA StyleWu, Y.-Y., & Jang, C.-T. (2019). Combustion Analysis of Homogeneous Charge Compression Ignition in a Motorcycle Engine Using a Dual-Fuel with Exhaust Gas Recirculation. Energies, 12(5), 847. https://doi.org/10.3390/en12050847