A Novel Encapsulation Method for Phase Change Materials with a AgBr Shell as a Thermal Energy Storage Material

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

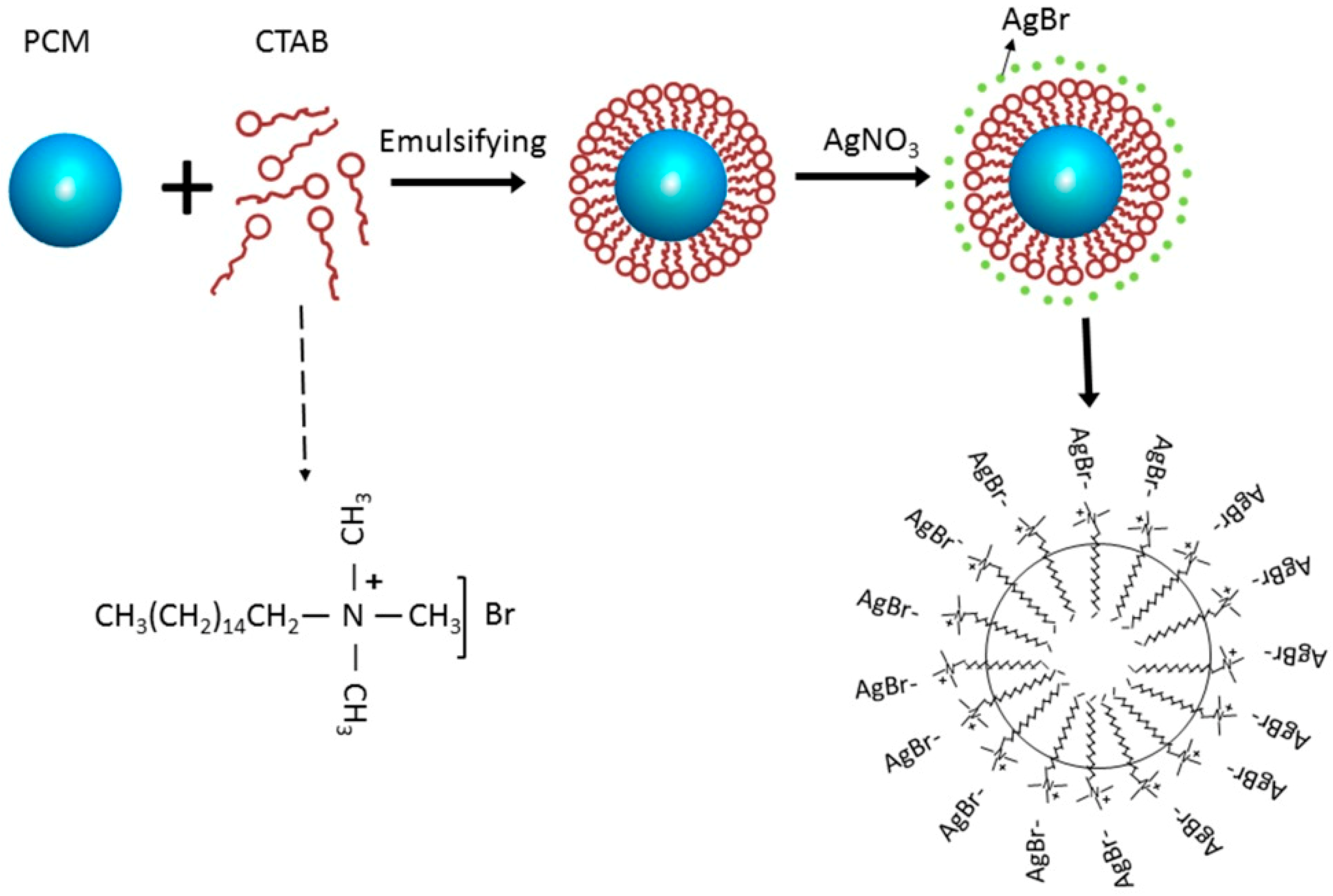

2.2. Preparation Process

2.3. Characterization

3. Results

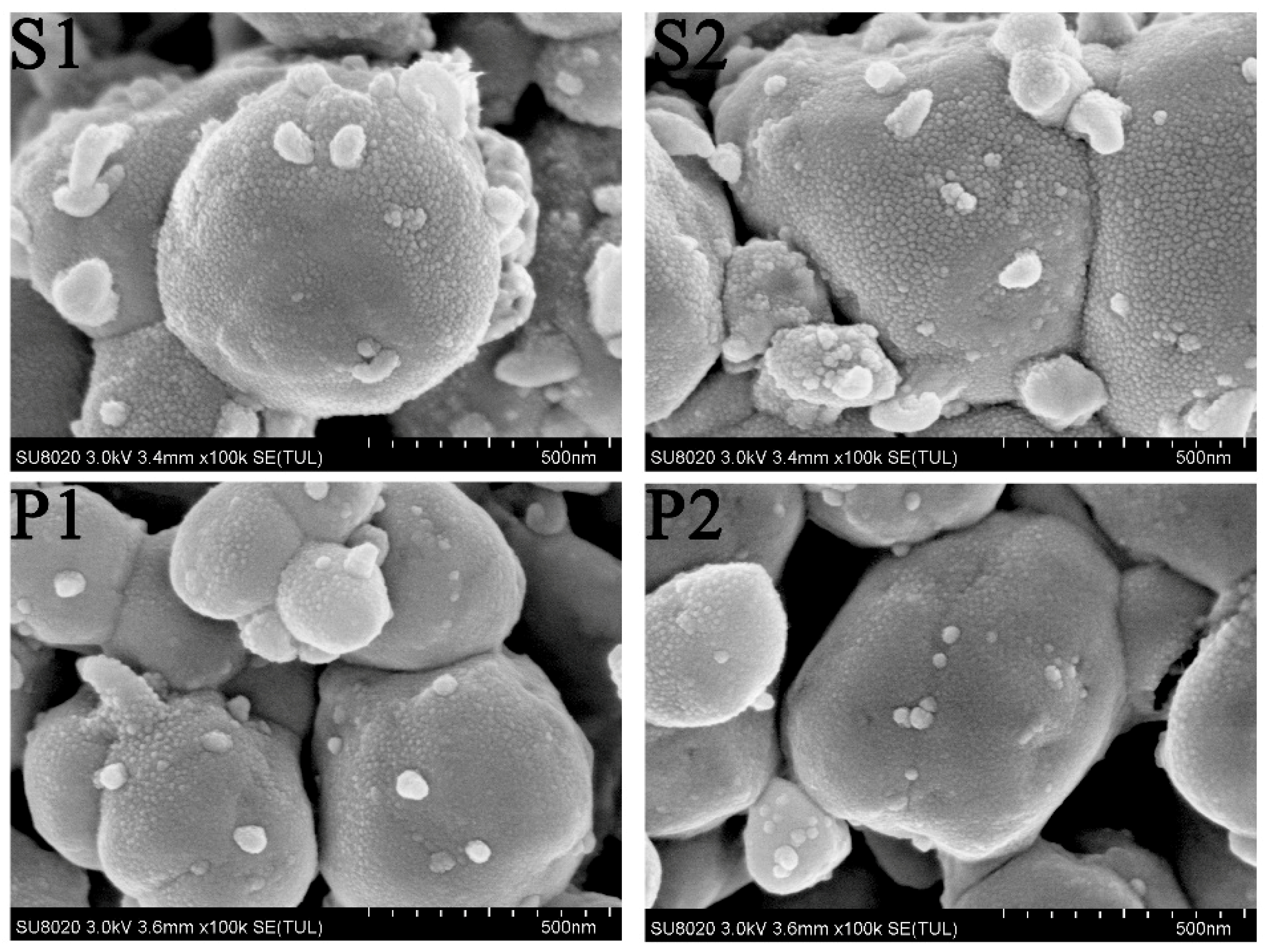

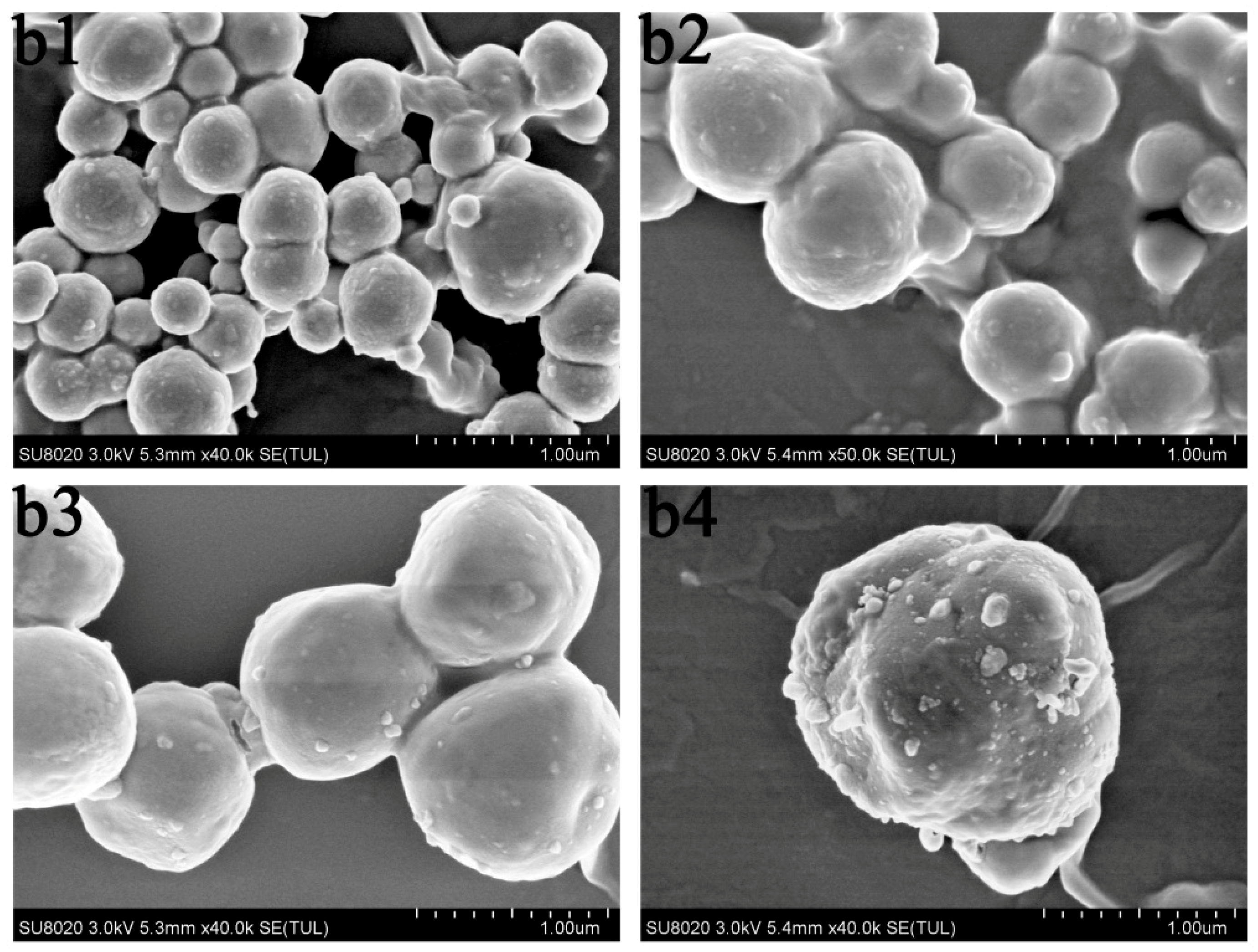

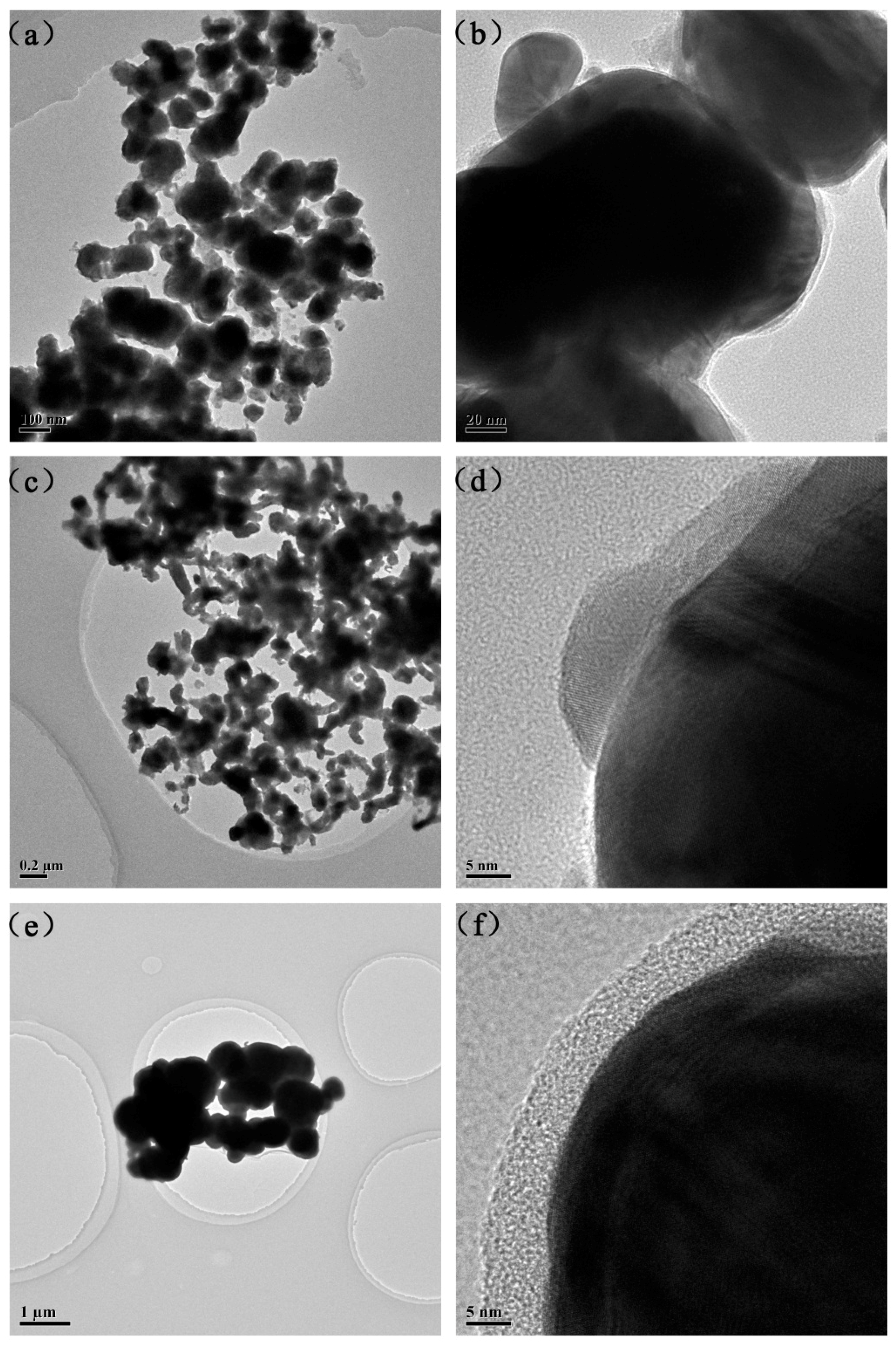

3.1. Morphologies and Particle Sizes of the Micro/Nanocapsules

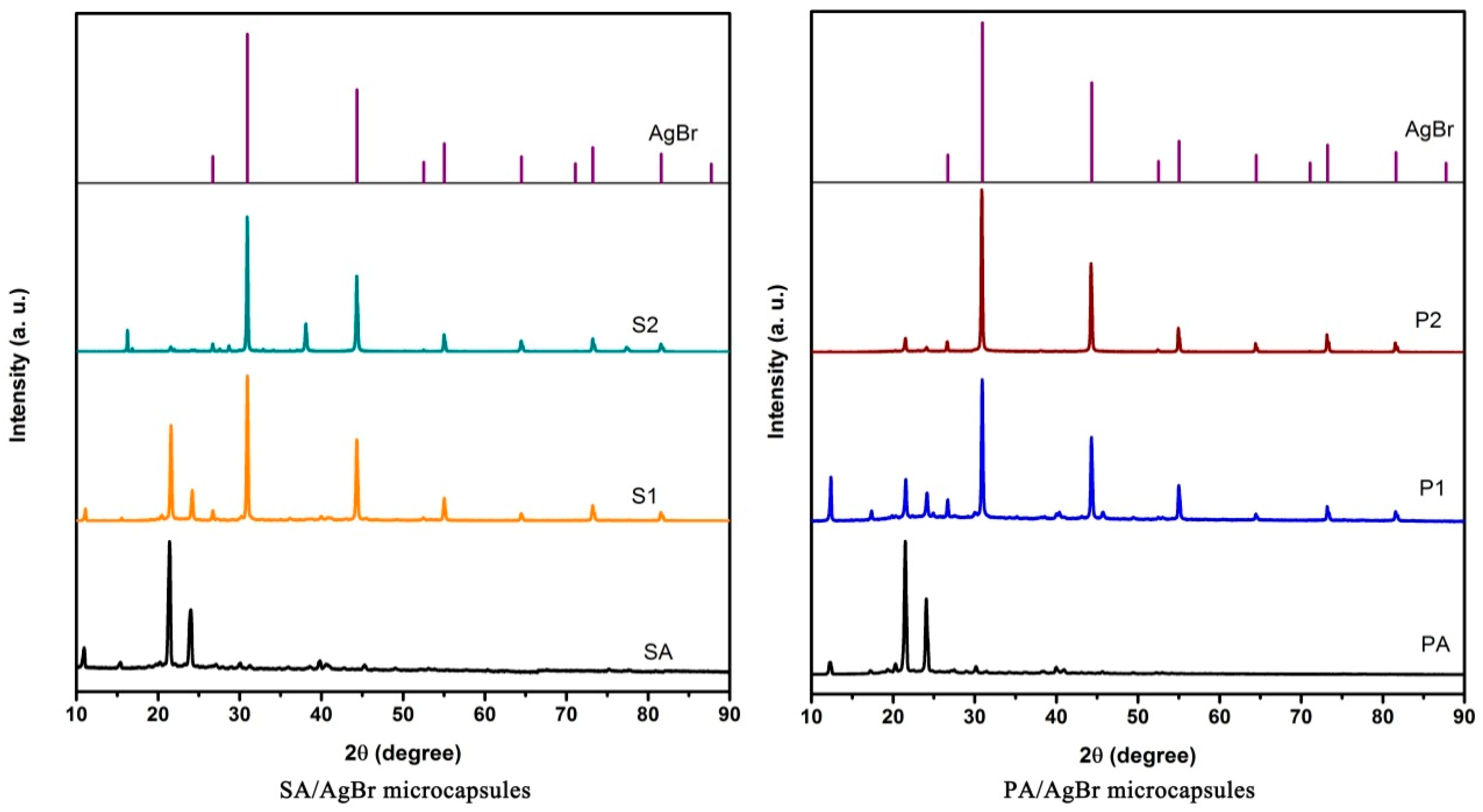

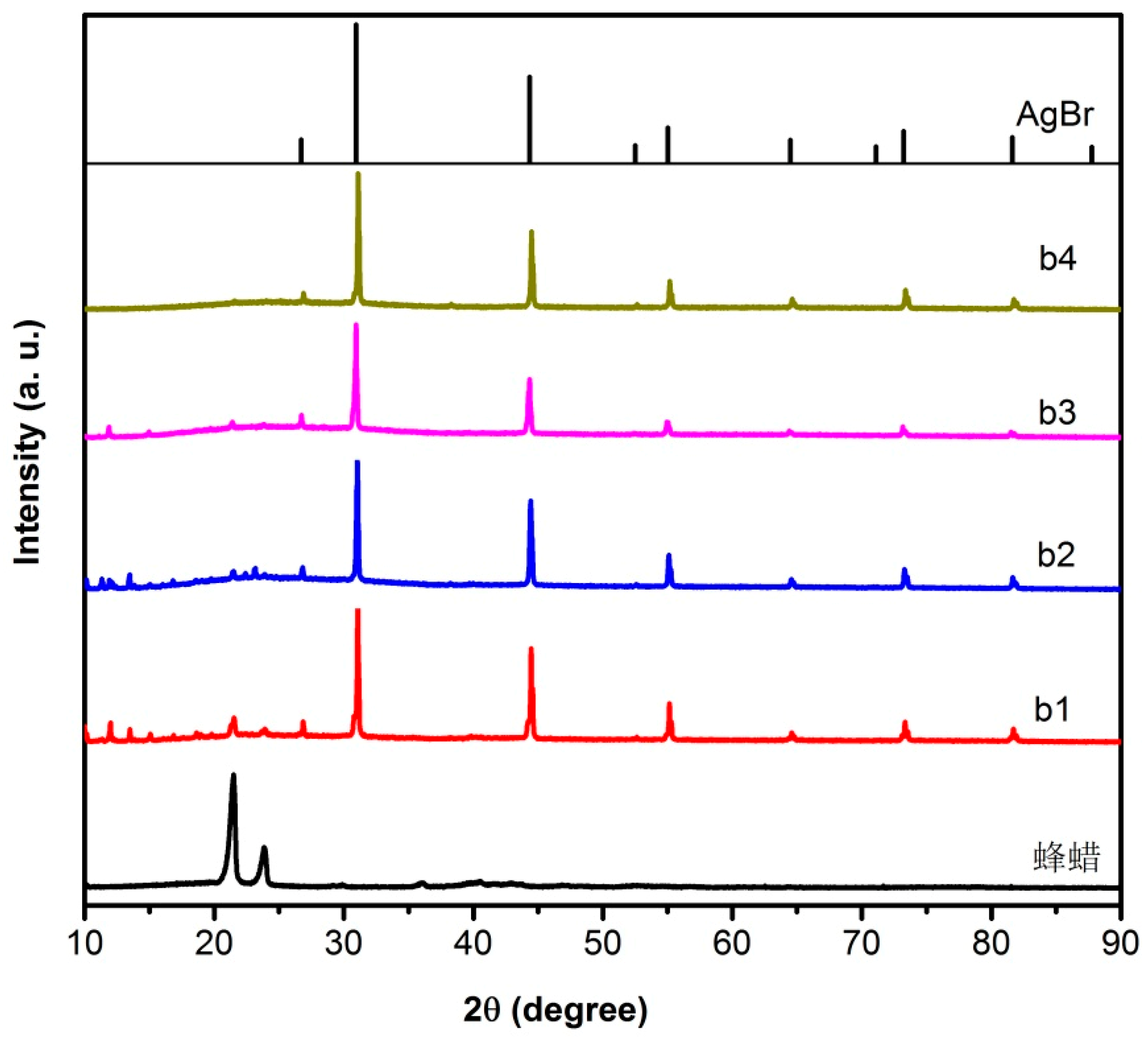

3.2. Crystalloid Phase of Microencapsulated PCMs with AgBr Shell

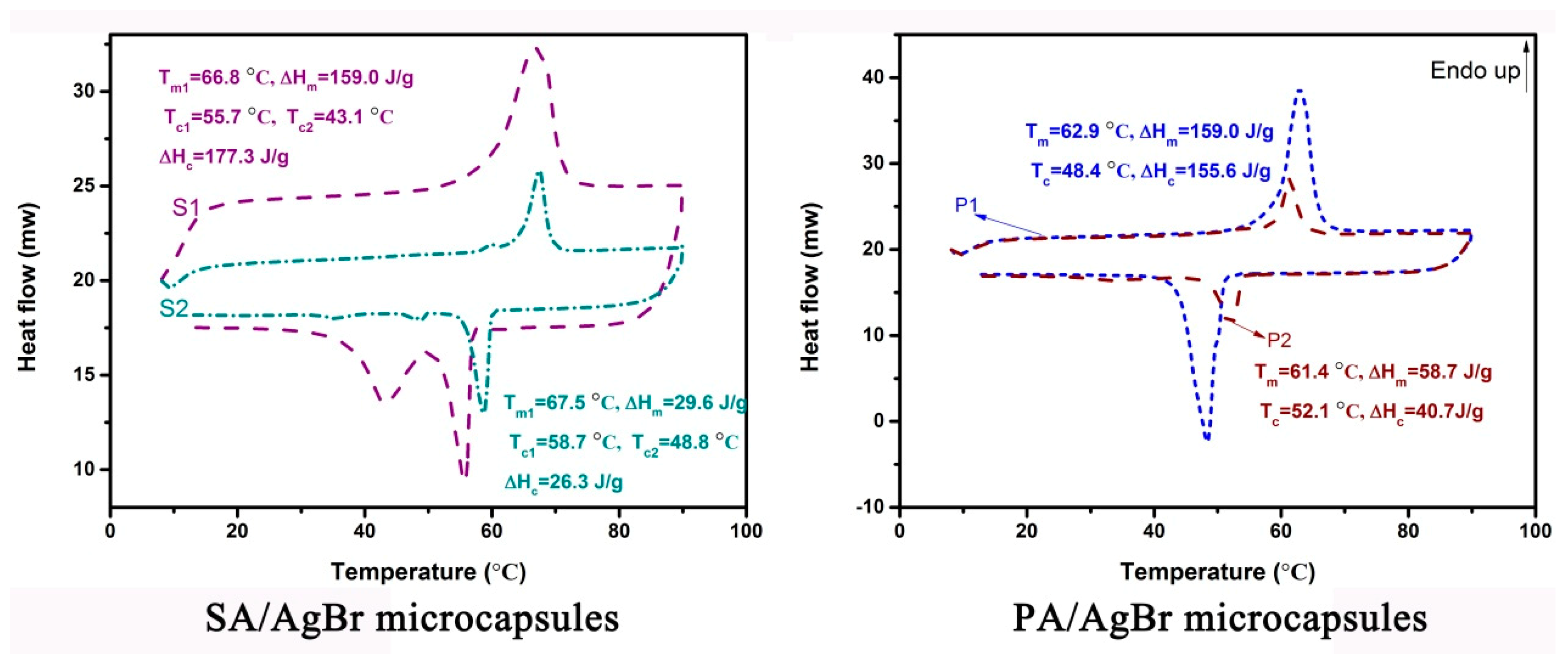

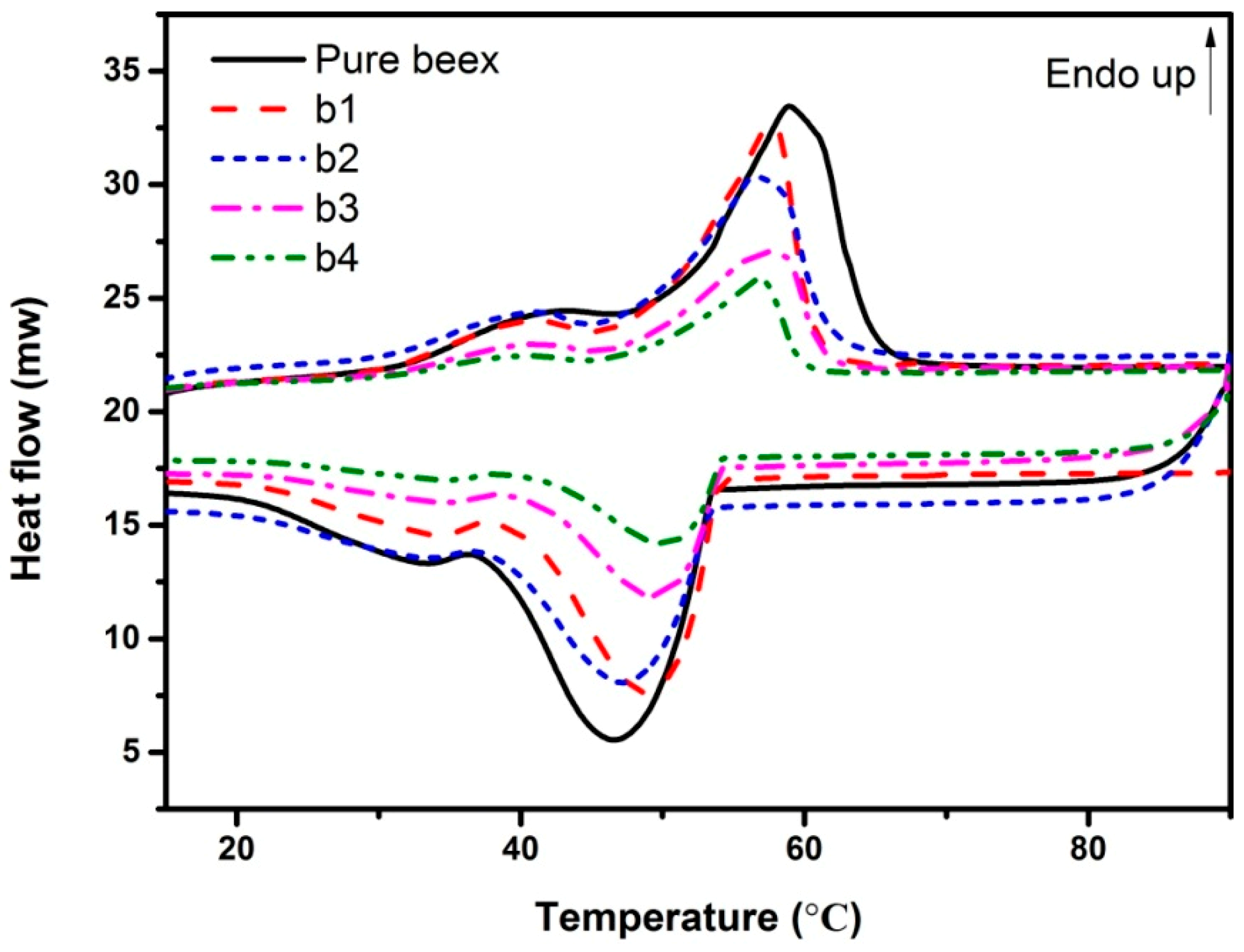

3.3. Thermal Properties of the LA/SiO2 Nanocapsules

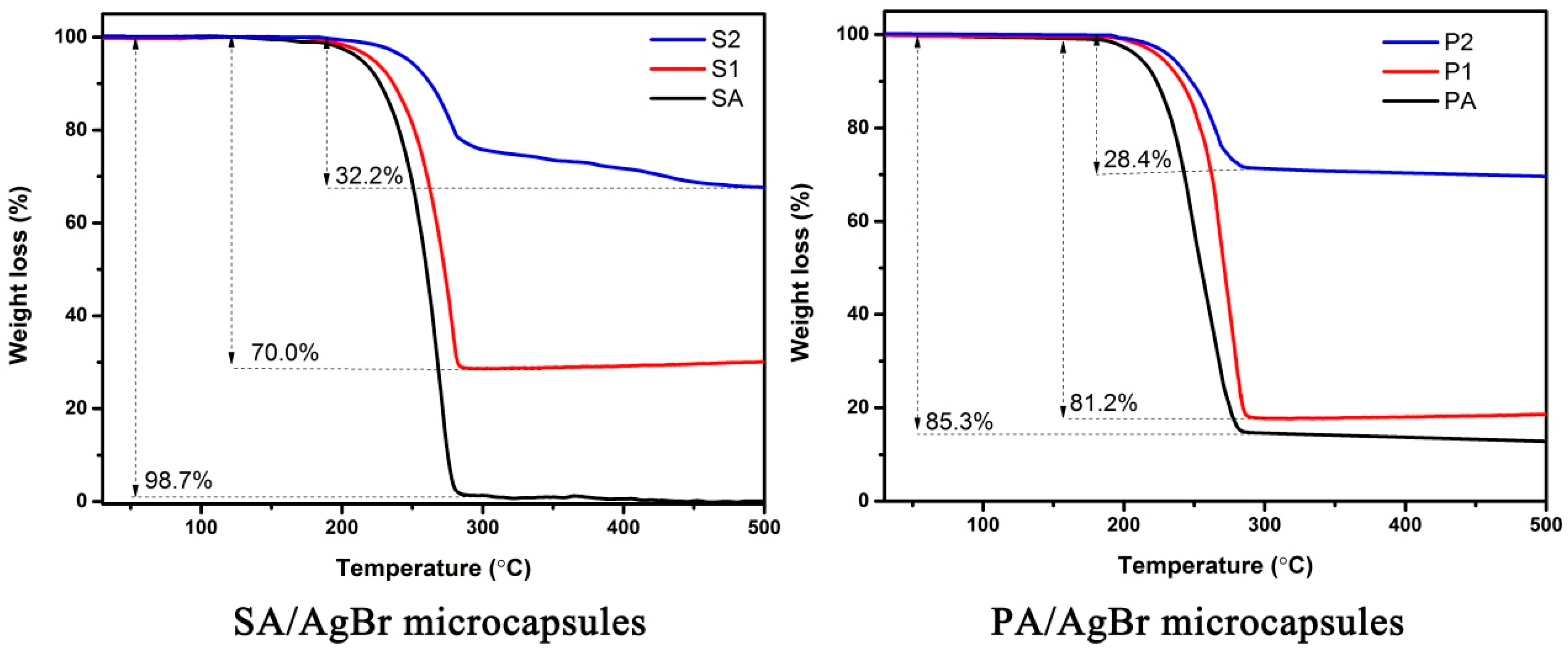

3.4. Thermal Stability of the Microcapsules

4. Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lian, Q.; Yan, L.; Sayyed, A.A.S.; Cheng, J.; Zhang, J. Facile Strategy in Designing Epoxy/Paraffin Multiple Phase Change Materials for Thermal Energy Storage Applications. ACS Sustain. Chem. Eng. 2018, 6, 3375–3384. [Google Scholar] [CrossRef]

- Liu, H.; Wang, X.; Wu, D. Fabrication of Graphene/TiO2/Paraffin Composite Phase Change Materials for Enhancement of Solar Energy Efficiency in Photocatalysis and Latent Heat Storage. ACS Sustain. Chem. Eng. 2017, 5, 4906–4915. [Google Scholar] [CrossRef]

- Zhou, Y.; Liu, X.; Sheng, D.; Lin, C.; Ji, F.; Dong, L.; Xu, S.; Wu, H.; Yang, Y. Polyurethane-based solid-solid phase change materials with in situ reduced graphene oxide for light-thermal energy conversion and storage. Chem. Eng. J. 2018, 338, 117–125. [Google Scholar] [CrossRef]

- Zhang, H.; Sun, Q.; Yuan, Y.; Zhang, Z.; Cao, X. A novel form-stable phase change composite with excellent thermal and electrical conductivities. Chem. Eng. J. 2018, 336, 342–351. [Google Scholar] [CrossRef]

- Yuan, H.; Bai, H.; Zhang, X.; Zhang, J.; Zhang, Z.; Yang, L. Synthesis and characterization of stearic acid/silicon dioxide nanoencapsules for solar energy storage. Sol. Energy 2018, 173, 42–52. [Google Scholar] [CrossRef]

- Jiang, Z.; Yang, W.; He, F.; Xie, C.; Fan, J.; Wu, J.; Zhang, K. Modified Phase Change Microcapsules with Calcium Carbonate and Graphene Oxide Shells for Enhanced Energy Storage and Leakage Prevention. ACS Sustain. Chem. Eng. 2018, 6, 5182–5191. [Google Scholar] [CrossRef]

- Zhang, T.; Chen, M.; Zhang, Y.; Wang, Y. Microencapsulation of stearic acid with polymethylmethacrylate using iron (III) chloride as photo-initiator for thermal energy storage. Chem. Eng. J. 2017, 25, 1524–1532. [Google Scholar] [CrossRef]

- Siyabi, I.A.; Khanna, S.; Mallick, T.; Sundaram, S. Multiple Phase Change Material (PCM) Configuration for PCM-Based Heat Sinks—An Experimental Study. Energies 2018, 11, 1629. [Google Scholar] [CrossRef]

- Li, S.; Yu, C.; Sun, Z. Numerical Simulation and Optimization of the Melting Process of Phase Change Material inside Horizontal Annulus. Energies 2017, 10, 1249. [Google Scholar]

- Akeiber, H.J.; Hosseini, S.E.; Wahid, M.A.; Mohammad, A.T. Phase Change Materials-Assisted Heat Flux Reduction: Experiment and Numerical Analysis. Energies 2016, 9, 30. [Google Scholar] [CrossRef]

- Pielichowska, K.; Pielichowski, K. Phase change materials for thermal energy storage. Prog. Mater. Sci. 2014, 65, 67–123. [Google Scholar] [CrossRef]

- Fang, Y.; Zou, T.; Liang, X.; Wang, S.; Liu, X.; Gao, X.; Zhang, Z. Self-assembly Synthesis and Properties of Microencapsulated n-Tetradecane Phase Change Materials with a Calcium Carbonate Shell for Cold Energy Storage. ACS Sustain. Chem. Eng. 2017, 5, 3074–3080. [Google Scholar] [CrossRef]

- Jamekhorshid, A.; Sadrameli, S.M.; Farid, M. A review of microencapsulation methods of phase change materials (PCMs) as a thermal energy storage (TES) medium. Renew. Sustain. Energy Rev. 2014, 31, 531–542. [Google Scholar] [CrossRef]

- Farid, M.M.; Khudhair, A.M.; Razack, S.; Al-Hallaj, S. A review on phase change energy storage: Materials and applications. Energy 2004, 45, 1597–1615. [Google Scholar] [CrossRef]

- Teixeira, M.I.; Andrade, L.R.; Farina, M.; Rocha-Leao, M.M. Characterization of short chain fatty acid microcapsules produced by spray drying. Mater. Sci. Eng. C 2004, 24, 653–658. [Google Scholar] [CrossRef]

- Fang, Y.; Liu, X.; Liang, X.; Liu, H.; Gao, X.; Zhang, Z. Ultrasonic synthesis and characterization of polystyrene/n-dotriacontane composite nanoencapsulated phase change material for thermal energy storage. Appl. Energy 2014, 132, 551–556. [Google Scholar] [CrossRef]

- Liang, S.; Li, Q.; Zhu, Y.; Chen, K.; Tian, C.; Wang, J.; Bai, R. Nanoencapsulation of n-octadecane phase change material with silica shell through interfacial hydrolysis and polycondensation in miniemulsion. Energy 2015, 93, 1684–1692. [Google Scholar] [CrossRef]

- Chen, Z.H.; Yu, F.; Zeng, X.R.; Zhang, Z.G. Preparation, characterization and thermal properties of nanocapsules containing phase change material n-dodecanol by miniemulsion polymerization with polymerizable emulsifier. Appl Energy 2012, 91, 7–12. [Google Scholar] [CrossRef]

- Li, W.; Song, G.L.; Tang, G.Y.; Chu, X.D.; Ma, S.D.; Liu, C.F. Morphology, structure and thermal stability of microencapsulated phase change material with copolymer shell. Energy 2011, 36, 785–791. [Google Scholar] [CrossRef]

- Bao, Y.; Pan, W.; Wang, T.; Wang, Z.; Wei, F.; Xiao, F. Microencapsulation of fatty acid as phase change material for latent heat storage. J. Energy Eng. 2011, 137, 214–219. [Google Scholar] [CrossRef]

- Hu, X.; Huang, Z.; Zhang, Y. Preparation of CMC-modified melamine resin spherical nano-phase change energy storage materials. Carbohyd. Polym. 2014, 101, 83–88. [Google Scholar] [CrossRef]

- Fang, G.Y.; Chen, Z.; Li, H. Synthesis and properties of microencapsulated paraffin composites with SiO2 shell as thermal energy storage materials. Chem. Eng. J. 2010, 163, 154–159. [Google Scholar] [CrossRef]

- Latibari, S.T.; Mehrali, M.; Mehrali, M.; Mahlia, T.M.I.; Metselaar, H.S.C. Synthesis, characterization and thermal properties of nanoencapsulated phase change materials via sol-gel method. Energy 2013, 61, 664–672. [Google Scholar] [CrossRef]

- Latibari, S.T.; Mehrali, M.; Mehrali, M.; Afifi, A.B.M.; Mahlia, T.M.I.; Akhiani, A.R.; Metselaar, H.S.C. Facile synthesis and thermal performances of stearic acid/titania core/shell nanocapsules by sol–gel method. Energy 2015, 85, 635–644. [Google Scholar] [CrossRef]

- Zhu, Y.; Liang, S.; Wang, H.; Zhang, K.; Jia, X.; Tian, C.; Zhou, Y.; Wang, J. Morphological control and thermal properties of nanoencapsulated n-octadecane phase change material with organosilica shell materials. Energy Convers. Manag. 2016, 119, 151–162. [Google Scholar] [CrossRef]

- Ahmad, K.; Ho, C.C.; Fong, W.K.; Toji, D. Properties of palm oil-in-water emulsions stabilized by nonionic emulsifiers. J. Colloid Interf. Sci. 1996, 181, 595–604. [Google Scholar] [CrossRef]

- Shinoda, K.; Saito, H. The stability of O/W type emulsions as functions of temperature and the HLB of emulsifiers: The emulsification by PIT-method. J. Colloid Interf. Sci. 1969, 30, 258–263. [Google Scholar] [CrossRef]

- Kamel, B.S. Emulsifiers. In Food Additive User’s Handbook; Springer: Boston, MA, USA, 1991; pp. 169–201. [Google Scholar]

- Cortazar, M.G.; Rodriguez, R. Thermal Storage Nanocapsules by Miniemulsion Polymerization. J. Appl. Polym. Sci. 2013, 127, 5059–5064. [Google Scholar] [CrossRef]

- Park, S.; Lee, Y.; Kim, Y.S.; Lee, H.M.; Kim, J.H.; Cheong, I.W.; Koh, W.G. Magnetic nanoparticle-embedded PCM nanocapsules based on paraffin core and polyurea shell. Colloid. Surf. A 2014, 450, 46–51. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Y.; Xia, T.D.; Zhao, W.J.; Yang, W.H. Effects of fabricated technology on particle size distribution and thermal properties of stearic–eicosanoic acid/polymethylmethacrylate nanocapsules. Sol. Energy Mater. Sol. Cells 2014, 120, 481–490. [Google Scholar] [CrossRef]

- Yuan, H.; Bai, H.; Lu, X.; Zhang, X.; Zhang, J.; Zhang, Z.; Yang, L. Size controlled lauric acid/silicon dioxide nanocapsules for thermal energy storage. Solar Energy Mater. Solar Cells 2019, 191, 243–257. [Google Scholar] [CrossRef]

| PCM (g) | Samples | CKBr (mM) | |

|---|---|---|---|

| SA | S1 | 18 | 80 |

| S2 | 54 | 240 | |

| PA | P1 | 18 | 80 |

| P2 | 54 | 240 | |

| Beewax | b1 | 18 | 80 |

| b2 | 36 | 160 | |

| b3 | 54 | 240 | |

| b4 | 72 | 400 |

| Samples | Melting | Solidifying | Encapsulation Ratio R (%) | Encapsulation Efficiency E (%) | ||

|---|---|---|---|---|---|---|

| Tm (°C) | ΔHm (J/g) | Tc (°C) | ΔHc (J/g) | |||

| Pure SA | 67.0 | 238.7 | 62.5 | 244.1 | 100 | 100 |

| S1 | 66.8 | 159.0 | 55.7 | 177.3 | 66.6 | 69.6 |

| S2 | 67.5 | 29.6 | 58.7 | 26.3 | 28.2 | 11.6 |

| Pure PA | 60.4 | 172.1 | 50.1 | 174.4 | 3.7 | 100 |

| P1 | 62.9 | 159.0 | 48.4 | 155.6 | 92.4 | 65.2 |

| P2 | 61.4 | 58.7 | 52.1 | 40.7 | 34.1 | 20.6 |

| Samples | Melting | Solidifying | Encapsulation Ratio R (%) | Encapsulation Efficiency E (%) | ||

|---|---|---|---|---|---|---|

| Tm (°C) | ΔHm (J/g) | Tc (°C) | ΔHc (J/g) | |||

| beeswax | 58.9 | 119.3 | 46.5 | 128.6 | 100.0 | 100.0 |

| b1 | 57.9 | 99 | 49 | 107.3 | 83.0 | 83.2 |

| b2 | 56.3 | 73 | 47.2 | 77.2 | 61.2 | 60.6 |

| b3 | 56.9 | 65.2 | 50.4 | 69.9 | 54.7 | 54.5 |

| b4 | 57.1 | 45.3 | 49.4 | 47.2 | 38.0 | 37.3 |

| Materials | Preparation Methods | R (%) | Reference |

|---|---|---|---|

| Paraffin/ PMMA | Mini-emulsion polymerization | 60.7 | [29] |

| Paraffin/polyurea | Interfacial polymerization | 66.6 | [30] |

| EA-SA/PMMA | Emulsion polymerization | 65.2 | [31] |

| n-dotriacontane/PS | Mini-emulsion polymerization | 61.2 | [16] |

| SA/ titania | Sol-gel | 64.8 | [24] |

| PA/SiO2 | Sol-gel | 90.0 | [23] |

| n-octadecane / PSDB | Interfacial polymerization on | 66.5 | [19] |

| LA/MF | In situ polymerization | 46.2 | [20] |

| Paraffin/CMC-MF | In situ polymerization | 63.1 | [21] |

| Beeswax/AgBr | New method | 83.0 | This work |

| PA/AgBr | New method | 92.4 | This work |

| SA/AgBr | New method | 66.6 | This work |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, H.; Bai, H.; Chi, M.; Zhang, X.; Zhang, J.; Zhang, Z.; Yang, L. A Novel Encapsulation Method for Phase Change Materials with a AgBr Shell as a Thermal Energy Storage Material. Energies 2019, 12, 717. https://doi.org/10.3390/en12040717

Yuan H, Bai H, Chi M, Zhang X, Zhang J, Zhang Z, Yang L. A Novel Encapsulation Method for Phase Change Materials with a AgBr Shell as a Thermal Energy Storage Material. Energies. 2019; 12(4):717. https://doi.org/10.3390/en12040717

Chicago/Turabian StyleYuan, Huanmei, Hao Bai, Minghui Chi, Xu Zhang, Jian Zhang, Zefei Zhang, and Liyun Yang. 2019. "A Novel Encapsulation Method for Phase Change Materials with a AgBr Shell as a Thermal Energy Storage Material" Energies 12, no. 4: 717. https://doi.org/10.3390/en12040717

APA StyleYuan, H., Bai, H., Chi, M., Zhang, X., Zhang, J., Zhang, Z., & Yang, L. (2019). A Novel Encapsulation Method for Phase Change Materials with a AgBr Shell as a Thermal Energy Storage Material. Energies, 12(4), 717. https://doi.org/10.3390/en12040717