Numerical Study on Flow Characteristics in a Francis Turbine during Load Rejection

Abstract

1. Introduction

2. Numerical Simulation Method

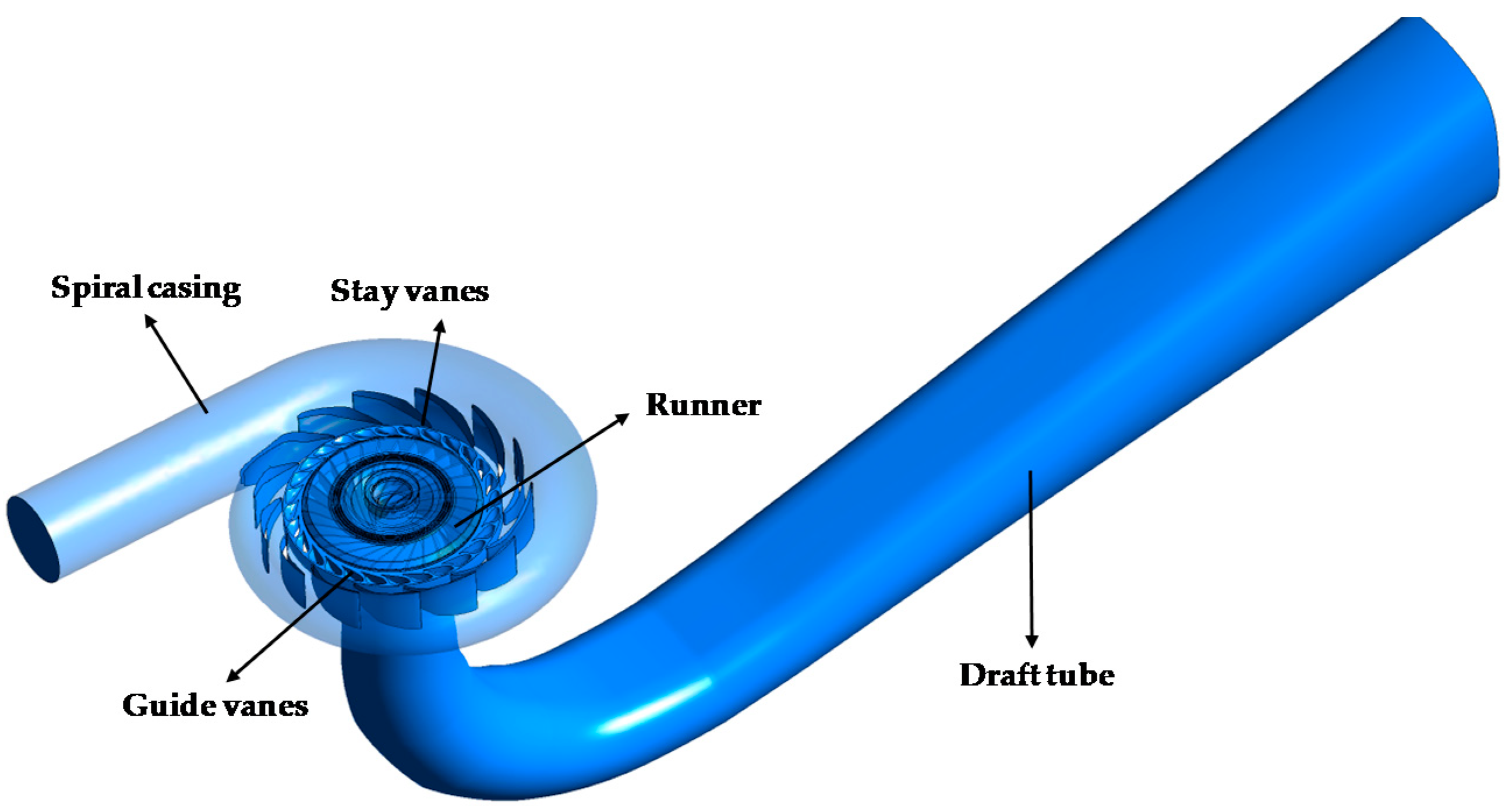

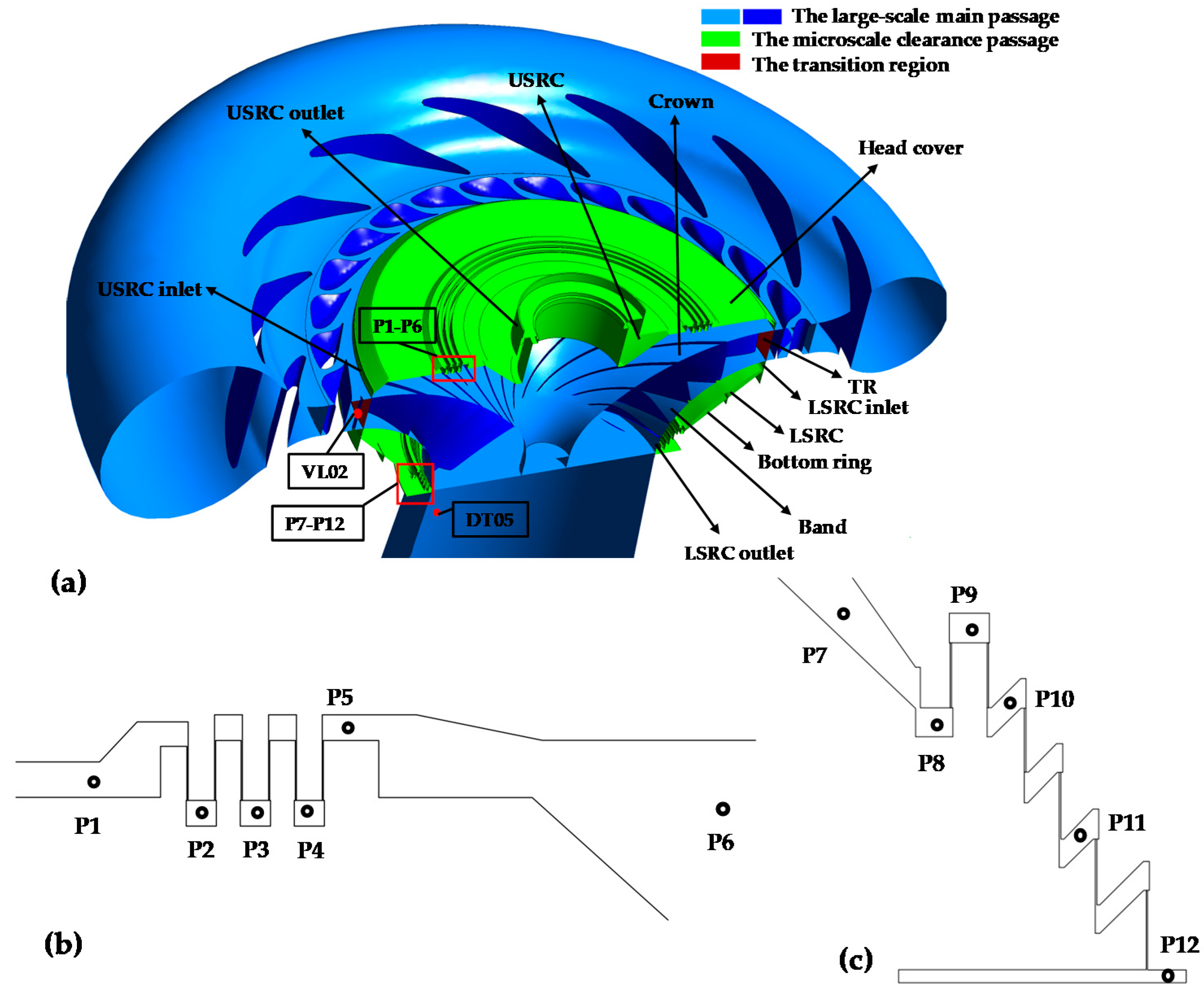

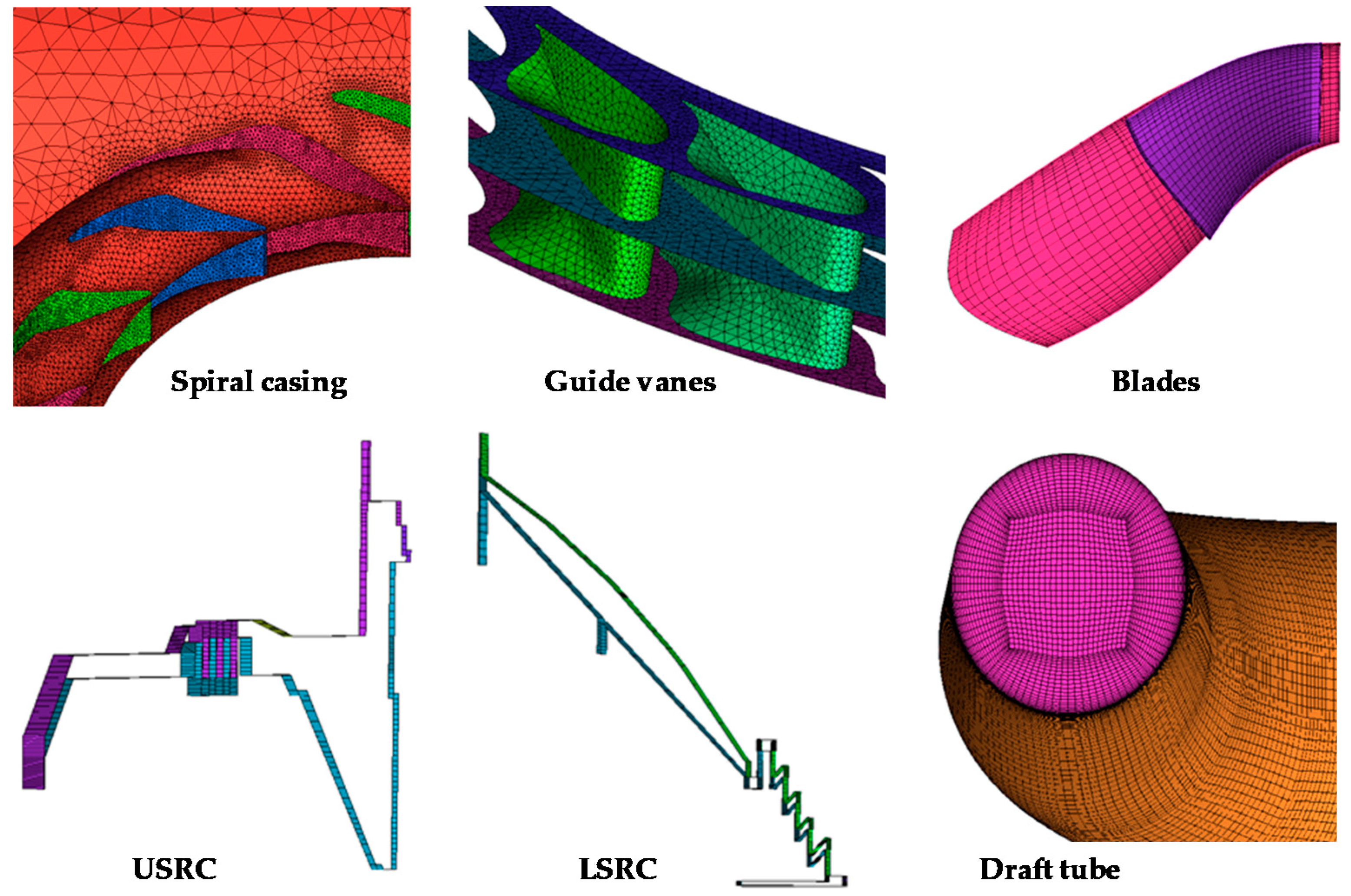

2.1. Computation Domain and Meshing Schemes

2.2. Governing Equations

2.3. Solution Method, Boundary Conditions and Simulation Conditions

3. Numerical Results and Analysis

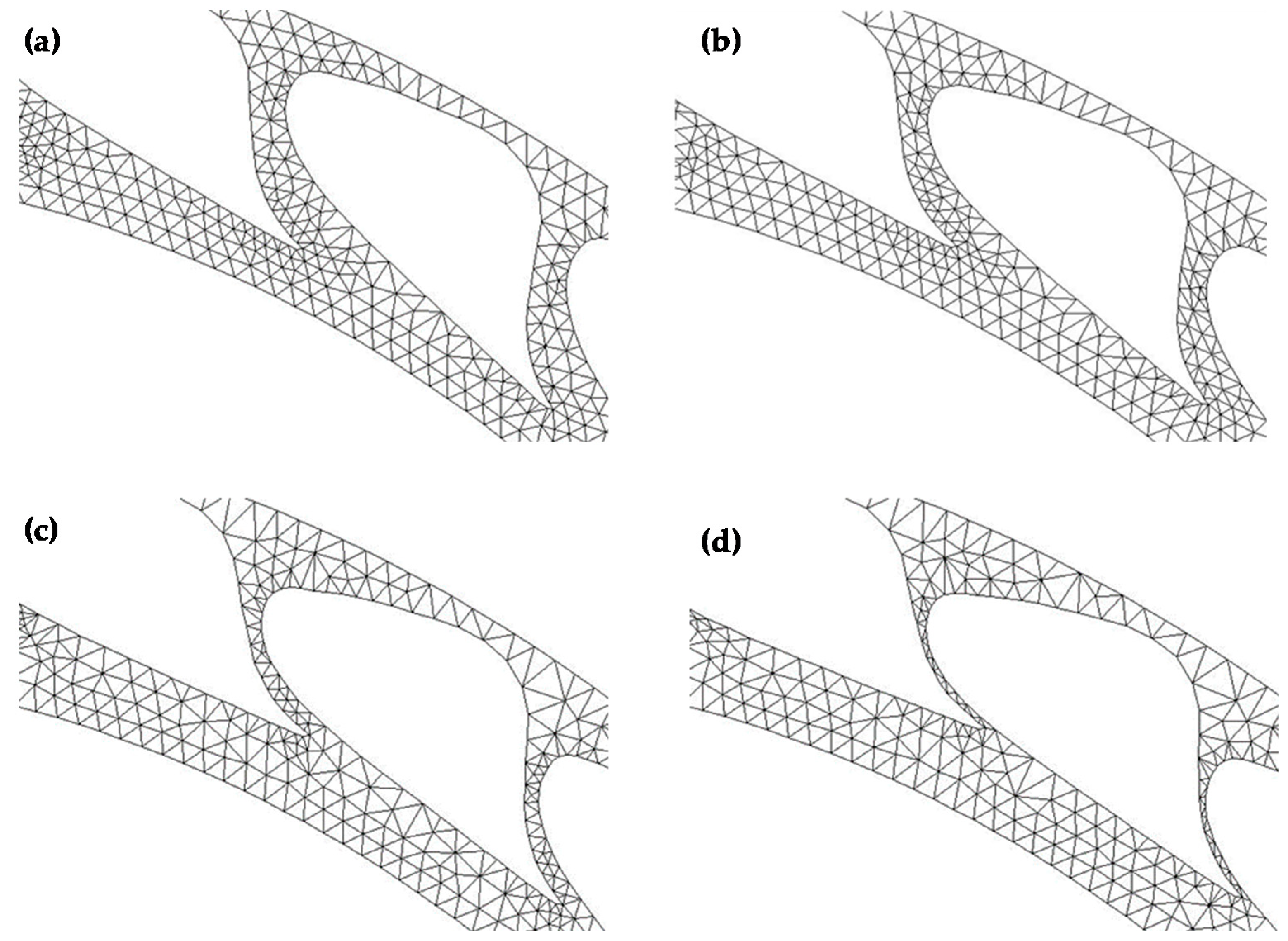

3.1. Mesh and Time Step Dependency Analysis

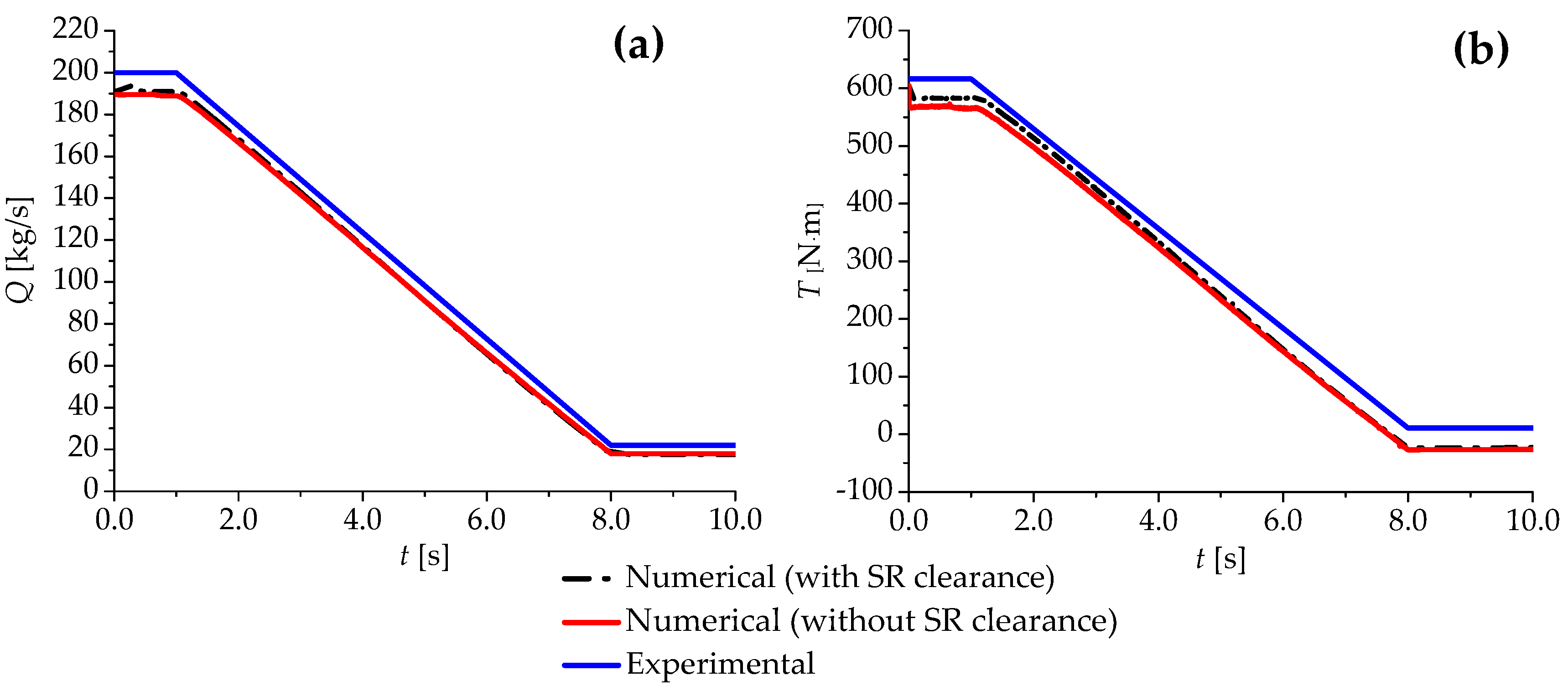

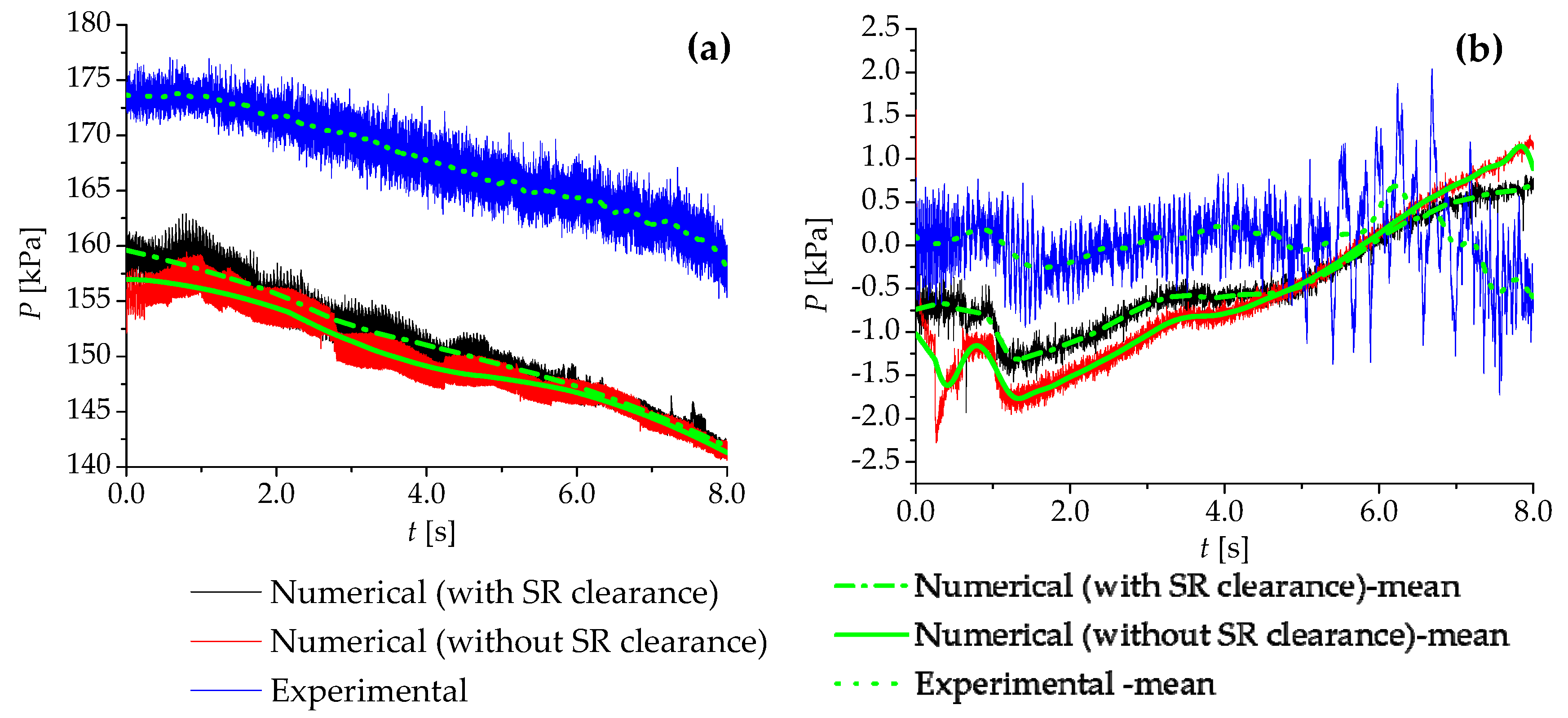

3.2. Analysis of Flow Characteristics and Forces in the Main Passage

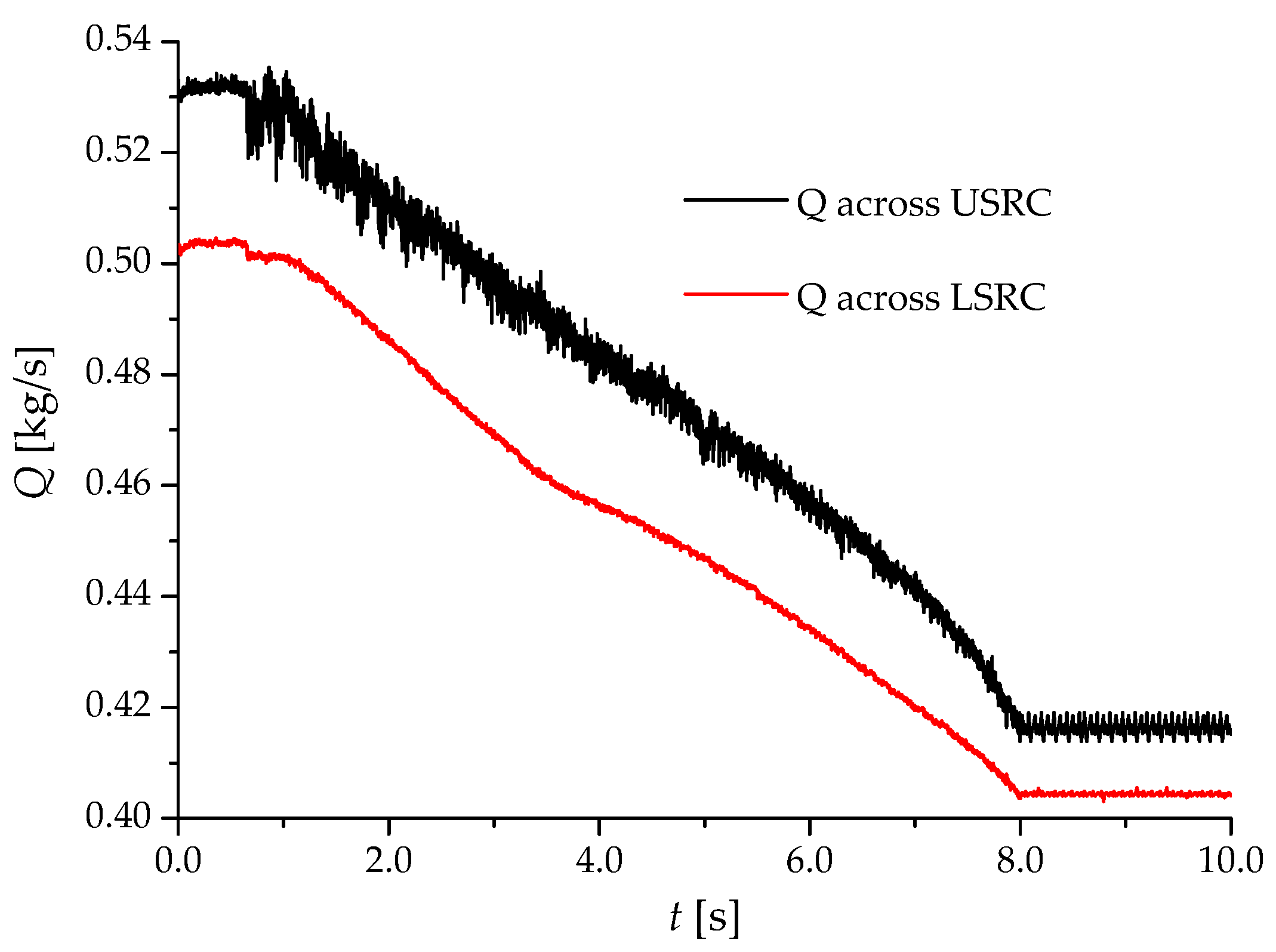

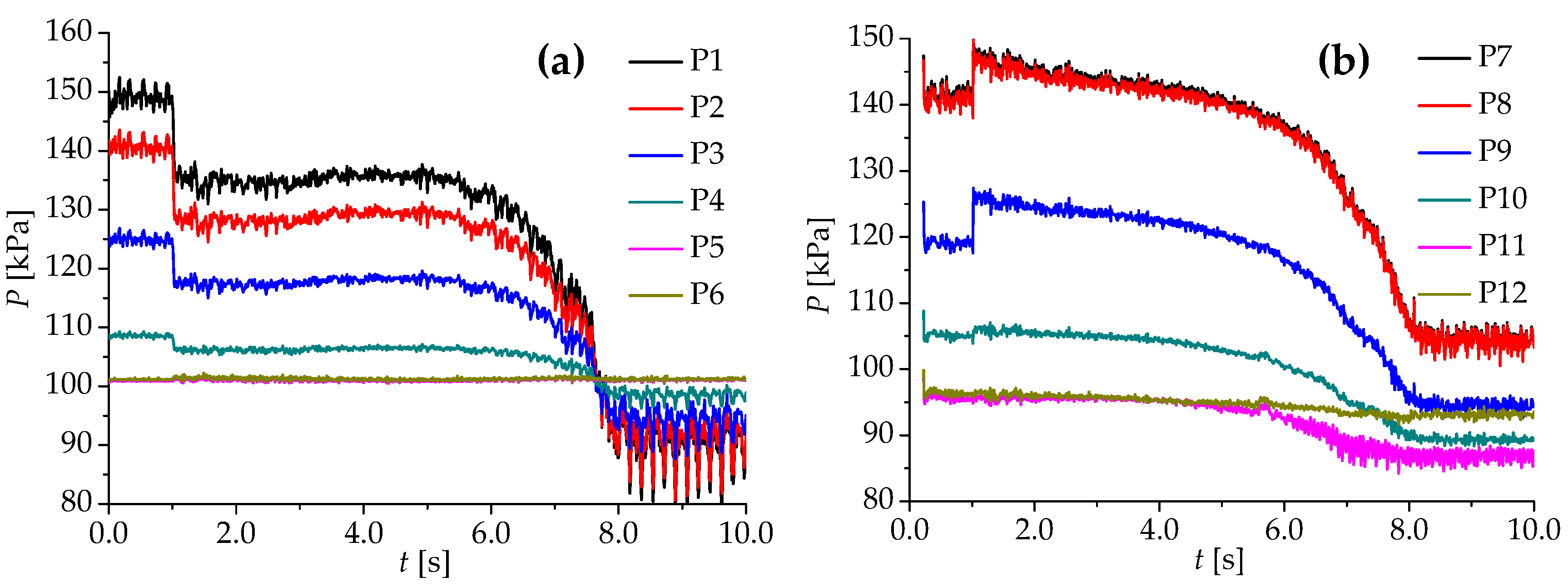

3.3. Analysis of Flow Characteristics and Forces in the Clearance Passage

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| C | Boundary moving velocity | m/s |

| Infinitesimal area | m2 | |

| D1 | Diameter of the model runner inlet | m |

| Dp1 | Diameter of the prototype runner inlet | m |

| Ff | Mixing function | - |

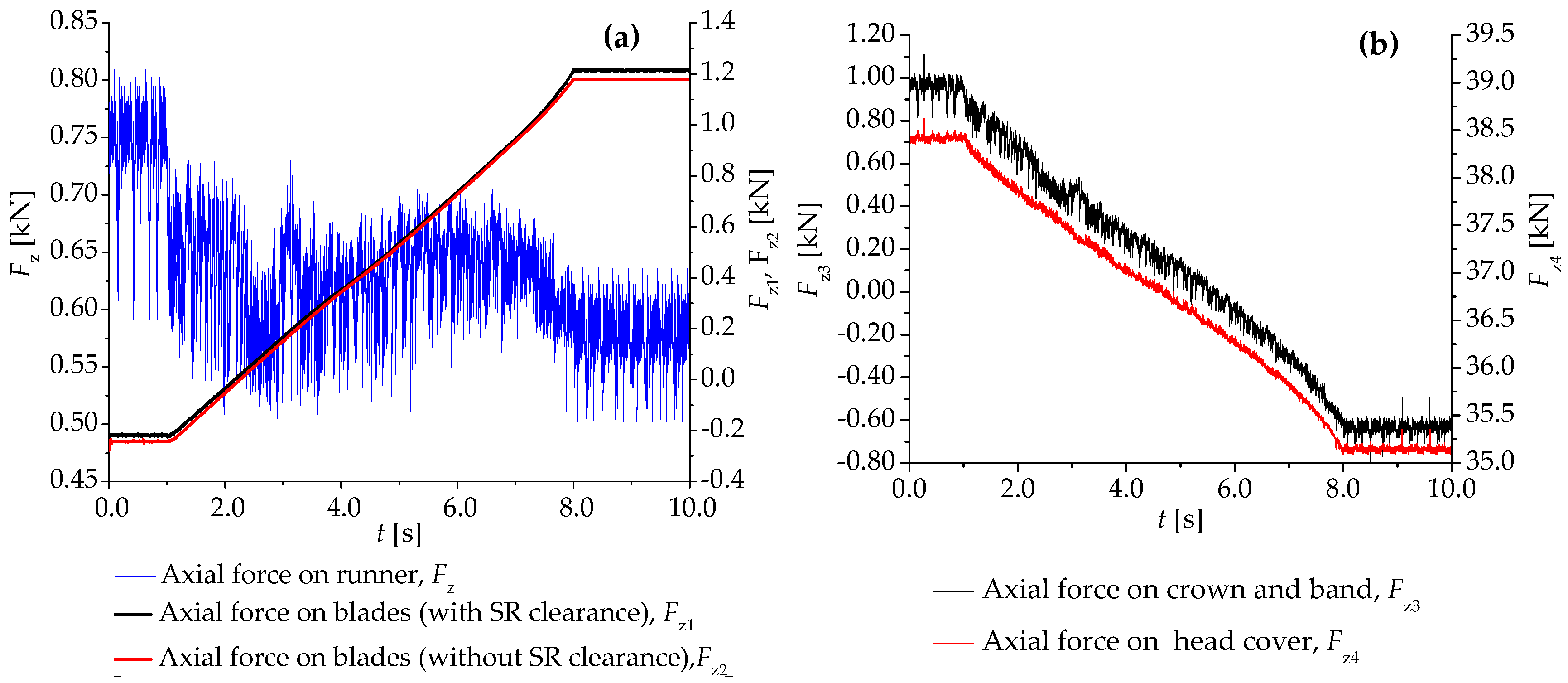

| Fz | Axial force of the runner | kN |

| Fz1 | Axial force of the blades (with SR clearance) | kN |

| Fz2 | Axial force of the blades (without SR clearance) | kN |

| Fz3 | Axial force of the crown and band | kN |

| Fz4 | Axial force of the head cover | kN |

| Vector of accelerations acting on the continuum | m/s2 | |

| Hr | Net head of the model turbine | m |

| Hpr | Net head of the prototype turbine | m |

| N | Number of mesh cells | - |

| P | Static pressure | Pa |

| Pk | Terms for generating turbulence | - |

| Terms for generating turbulence | - | |

| Q | Mass flow rate of the turbine | kg/s |

| Qr | Rated mass flow rate of the model turbine | kg/s |

| Qpr | Rated mass flow rate of the prototype turbine | kg/s |

| T | Torque of the runner | N·m |

| t | Time | s |

| V | Volume of control body | m3 |

| ηM | Efficiency of the turbine | % |

| Kinetic energy of the turbulence | J | |

| Rate of dissipation in | - | |

| Turbulence frequency | Hz | |

| Fluid velocity vector | m/s | |

| Mesh movement velocity vector | m/s | |

| ρ | Density of fluid | kg/m3 |

| Time step size | s | |

| Hamilton operator | - | |

| Laplacian operator | - | |

| μ | Fluid viscosity | Pa·s |

| Turbulent eddy viscosity | Pa·s | |

| Boundary of control volume | - | |

| Empirical coefficients | - | |

| Empirical coefficients | - | |

| Empirical coefficients | - | |

| Empirical coefficients | - |

Abbreviations

| 1D | One dimensional |

| 3D | Three dimensional |

| ALE | Arbitrary Lagrangian Eulerian |

| CFD | Computational fluid dynamics |

| DL | Design load |

| LSRC | Lower seal ring clearance |

| ML | Minimal load |

| MOC | Method of characteristics |

| SIMPLEC | Semi-Implicit method for pressure linked equations-consistent |

| SR | Seal ring |

| SST k-ω | Shear stress transport k-ω |

| USRC | Upper seal ring clearance |

References

- Paish, O. Micro-hydropower: Status and prospects. Proc. Inst. Mech. Eng. Part. A J. Power Energy 2002, 216, 31–40. [Google Scholar] [CrossRef]

- Spanhoff, B. Current status and future prospects of hydropower in Saxony (Germany) compared to trends in Germany, the European Union and the World. Renew. Sustain. Energy Rev. 2014, 30, 518–525. [Google Scholar] [CrossRef]

- Okot, D.K. Review of small hydropower technology. Renew. Sustain. Energy Rev. 2013, 26, 515–520. [Google Scholar] [CrossRef]

- Perez-Sanchez, M.; Sanchez-Romero, F.J.; Ramos, H.M.; Lopez-Jimenez, P.A. Energy Recovery in Existing Water Networks: Towards Greater Sustainability. Water 2017, 9, 97. [Google Scholar] [CrossRef]

- Zhou, D.; Chen, H.; Yang, C. A highly efficient Francis turbine designed for energy recovery in cooling towers. Adv. Mech. Eng. 2015, 7. [Google Scholar] [CrossRef]

- Wang, W.; Su, S.; Yan, Y. Study on comb labyrinth seals of Francis turbine at different Reynolds number. Appl. Mech. Mater. 2014, 444–445, 423–426. [Google Scholar] [CrossRef]

- Bouderlique, R.; Guibault, F.; Garon, A.; Vu, T. A computational model for hydraulic labyrinth seals. In Proceedings of the ASME 2010 3rd Joint US-European Fluids Engineering Summer Meeting collocated with 8th International Conference on Nanochannels, Microchannels, and Minichannels, Montreal, QC, Canada, 1–5 August 2010; pp. 23–31. [Google Scholar]

- Thapa, B.S.; Dahlhaug, G.; Thapa, B. Velocity and pressure measurements in guide vane clearance gap of a low specific speed Francis turbine. In Proceedings of the 28th IAHR Symposium on Hydraulic Machinery and Systems, Grenoble, France, 4–8 July 2016. [Google Scholar]

- Trivedi, C.; Cervantes, M.J.; Gandhi, B.K.; Ole Dahlhaug, G. Experimental investigations of transient pressure variations in a high head model Francis turbine during start-up and shutdown. J. Hydrodyn. 2014, 26, 277–290. [Google Scholar] [CrossRef]

- Trivedi, C.; Cervantes, M.J.; Gandhi, B.K. Investigation of a High Head Francis Turbine at Runaway Operating Conditions. Energies 2016, 9, 149. [Google Scholar] [CrossRef]

- Fu, X.; Li, D.; Wang, H.; Zhang, G.; Li, Z.; Wei, X. Analysis of transient flow in a pump-turbine during the load rejection process. J. Mech. Sci. Technol. 2018, 32, 2069–2078. [Google Scholar] [CrossRef]

- You, G. Characteristics of Pump Turbine in Tianhuangping Pumped Storage Power Station. In Proceedings of the Technology Construction and Management in Zhejiang Tianhuangping Pumped Storage Power Station, Hangzhou, China, 1 August 2003. [Google Scholar]

- Casartelli, E.; Cimmino, D.; Staubli, T.; Gentner, C. Interaction of Leakage Flow with the Main Runner-outflow in a Francis Turbine. Available online: https://www.researchgate.net/publication/242193073_Interaction_of_leakage_flow_with_the_main_runner-outflow_in_a_Francis_turbine (accessed on 20 January 2019).

- Celic, D.; Ondracka, H. The influence of disc friction losses and labyrinth losses on efficiency of high head Francis turbine. In Francis-99 Workshop 1: Steady Operation of Francis Turbines; Cervantes, M.J., Trivedi, C., Dahlhaug, O.G., Nielsen, T., Eds.; IOP Publishing Ltd.: Bristol, UK, 2015. [Google Scholar]

- Koirala, R.; Zhu, B.; Neopane, H.P. Effect of Guide Vane Clearance Gap on Francis Turbine Performance. Energies 2016, 9, 275. [Google Scholar] [CrossRef]

- Schiffer, J.; Benigni, H.; Jaberg, H. Numerical simulation of the flow in a Francis turbine including the runner seals on crown and band side. In Advancing Policy and Practice; Aqua~ Media International Ltd.: Bordeaux, France, 2015. [Google Scholar]

- Goyal, R.; Trivedi, C.; Gandhi, B.K.; Cervantes, M.J.; Dahlhaug, O.G. Transient pressure measurements at part load operating condition of a high head model Francis turbine. Proc. Eng. Sci. 2016, 41, 1311–1320. [Google Scholar]

- Hasmatuchi, V.; Farhat, M.; Roth, S.; Botero, F.; Avellan, F. Experimental Evidence of Rotating Stall in a Pump-Turbine at Off-Design Conditions in Generating Mode. J. Fluids Eng.-ASME 2011, 133. [Google Scholar] [CrossRef]

- Trivedi, C.; Gandhi, B.K.; Cervantes, M.J.; Dahlhaug, O.G. Experimental investigations of a model Francis turbine during shutdown at synchronous speed. Renew. Energy 2015, 83, 828–836. [Google Scholar] [CrossRef]

- Trivedi, C.; Gogstad, P.J.; Dahlhaug, O.G. Investigation of the unsteady pressure pulsations in the prototype Francis turbines during load variation and startup. J. Renew. Sustain. Energy 2017, 9. [Google Scholar] [CrossRef]

- Trivedi, C.; Agnalt, E.; Dahlhaug, O.G. Experimental Investigation of a Francis Turbine during Exigent Ramping and Transition into Total Load Rejection. J. Hydraul. Eng.-ASCE 2018, 144. [Google Scholar] [CrossRef]

- Ghidaoui, M.S.; Zhao, M.; McInnis, D.A.; Axworthy, D.H. A Review of Water Hammer Theory and Practice. Appl. Mech. Rev. 2005, 58, 49–76. [Google Scholar] [CrossRef]

- Afshar, M.H.; Rohani, M.; Taheri, R. Simulation of transient flow in pipeline systems due to load rejection and load acceptance by hydroelectric power plants. Int. J. Mech. Sci. 2010, 52, 103–115. [Google Scholar] [CrossRef]

- Wan, W.Y.; Huang, W.R. Investigation on complete characteristics and hydraulic transient of centrifugal pump. J. Mech. Sci. Technol. 2011, 25, 2583–2590. [Google Scholar] [CrossRef]

- Zhou, J.; Xu, Y.; Zheng, Y.; Zhang, Y. Optimization of Guide Vane Closing Schemes of Pumped Storage Hydro Unit Using an Enhanced Multi-Objective Gravitational Search Algorithm. Energies 2017, 10, 911. [Google Scholar] [CrossRef]

- Zhou, D.; Chen, H.; Zhang, L. Investigation of Pumped Storage Hydropower Power-Off Transient Process Using 3D Numerical Simulation Based on SP-VOF Hybrid Model. Energies 2018, 11, 1020. [Google Scholar] [CrossRef]

- Mossinger, P.; Jung, A. Transient two-phase CFD simulation of overload operating conditions and load rejection in a prototype sized Francis turbine. In Proceedings of the 28th IAHR Symposium on Hydraulic Machinery and Systems, Grenoble, France, 4–8 July 2016. [Google Scholar]

- Pavesi, G.; Cavazzini, G.; Ardizzon, G. Numerical Simulation of a Pump-Turbine Transient Load Following Process in Pump Mode. J. Fluids Eng.-Trans. ASME 2018, 140. [Google Scholar] [CrossRef]

- Li, D.; Wang, H.; Li, Z.; Nielsen, T.K.; Goyal, R.; Wei, X.; Qin, D. Transient characteristics during the closure of guide vanes in a pump turbine in pump mode. Renew. Energy 2018, 118, 973–983. [Google Scholar] [CrossRef]

- Fu, X.; Li, D.; Wang, H.; Zhang, G.; Li, Z.; Wei, X.; Qin, D. Energy Analysis in a Pump-Turbine During the Load Rejection Process. J. Fluids Eng.-Trans. ASME 2018, 140. [Google Scholar] [CrossRef]

- Fu, X.; Li, D.; Wang, H.; Zhang, G.; Li, Z.; Wei, X. Dynamic instability of a pump-turbine in load rejection transient process. Sci. China Technolo. Sci. 2018, 61, 1765–1775. [Google Scholar] [CrossRef]

- Fu, X.; Li, D.Y.; Wang, H.; Zhang, G.; Li, Z.; Wei, X. Influence of the clearance flow on the load rejection process in a pump-turbine. Renew. Energy 2018, 127, 310–321. [Google Scholar] [CrossRef]

- Dörfler, P.; Sick, M.; Coutu, A. Flow-induced Pulsation and Vibration in Hydroelectric Machinery, 1st ed.; Springer: London, UK, 2013. [Google Scholar]

- Test Case. Available online: https://www.ltu.se/research/subjects/Stromningslara/Konferenser/Francis-99 (accessed on 20 November 2013).

- Kan, K.; Zheng, Y.; Chen, Y.; Xie, Z.; Yang, G.; Yang, C. Numerical study on the internal flow characteristics of an axial-flow pump under stall conditions. J. Mech. Sci. Technol. 2018, 32, 4683–4695. [Google Scholar] [CrossRef]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Menter, F.R.; Kuntz, M.; Langtry, R. Ten years of industrial experience with the SST turbulence model. Turbul. Heat Mass Transf. 2003, 4, 625–632. [Google Scholar]

| Conditions | DL | ML | |

|---|---|---|---|

| Parameters | |||

| Guide vane angle (°) | 9.84 | 0.8 | |

| Net head (m) | 11.94 | 12.14 | |

| Discharge (kg/s) | 200 | 22 | |

| Torque to the generator (N·m) | 616.13 | 11.16 | |

| Runner angular speed (rpm) | 332.59 | 332.8 | |

| Hydraulic efficiency (%) | 92.39 | 20.94 | |

| Scheme Number | 1 | 2 | 3 | 4 | Test * |

|---|---|---|---|---|---|

| Number of mesh cells N (×104) | 353 | 487 | 660 | 887 | - |

| Hydraulic efficiency ηM (%) | 94.3 | 92.6 | 91.8 | 91.9 | 92.4 |

| Time Step Δt (s) | 0.01 | 0.005 | 0.002 | 0.001 | Test * |

|---|---|---|---|---|---|

| Mass flow rate Q (kg/s) | 188.3 | 190.1 | 192.7 | 193.2 | 200.0 |

| Runner torque T (N·m) | 488.1 | 523.2 | 585.8 | 590.1 | 616.1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, D.; Chen, H.; Zhang, J.; Jiang, S.; Gui, J.; Yang, C.; Yu, A. Numerical Study on Flow Characteristics in a Francis Turbine during Load Rejection. Energies 2019, 12, 716. https://doi.org/10.3390/en12040716

Zhou D, Chen H, Zhang J, Jiang S, Gui J, Yang C, Yu A. Numerical Study on Flow Characteristics in a Francis Turbine during Load Rejection. Energies. 2019; 12(4):716. https://doi.org/10.3390/en12040716

Chicago/Turabian StyleZhou, Daqing, Huixiang Chen, Jie Zhang, Shengwen Jiang, Jia Gui, Chunxia Yang, and An Yu. 2019. "Numerical Study on Flow Characteristics in a Francis Turbine during Load Rejection" Energies 12, no. 4: 716. https://doi.org/10.3390/en12040716

APA StyleZhou, D., Chen, H., Zhang, J., Jiang, S., Gui, J., Yang, C., & Yu, A. (2019). Numerical Study on Flow Characteristics in a Francis Turbine during Load Rejection. Energies, 12(4), 716. https://doi.org/10.3390/en12040716