Improving Energy Efficiency in a Synchronized Road-Transportation System by Using a TFMC (Transportation Fleet-Management Control) in Finland

Abstract

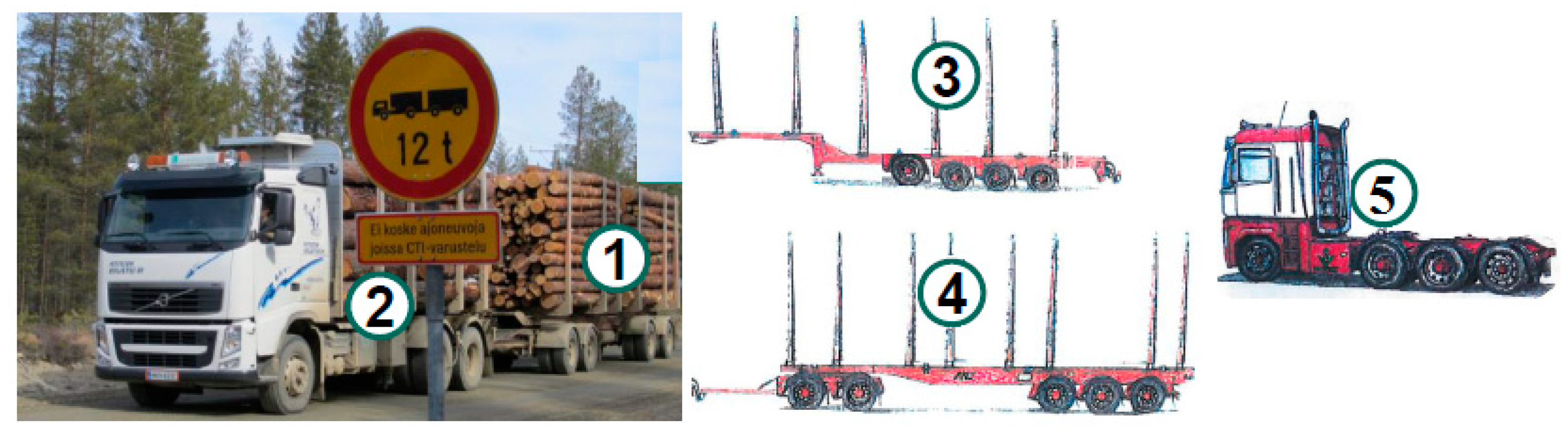

1. Introduction

- investigate the extent to which HCT configurations are insufficiently loaded during timber transportation;

- determine the impacts that HCT have on the energy efficiency of the STS in respect to the EURO-VI diesel engines; and

- recommend most effective options of TFMC to enable HCT to carry their maximum weights.

- data collection and method description regarding the energy efficiency of road-freight transportation in the STS;

- results and discussion based on the potentiality of TFMC to increase the energy efficiency.

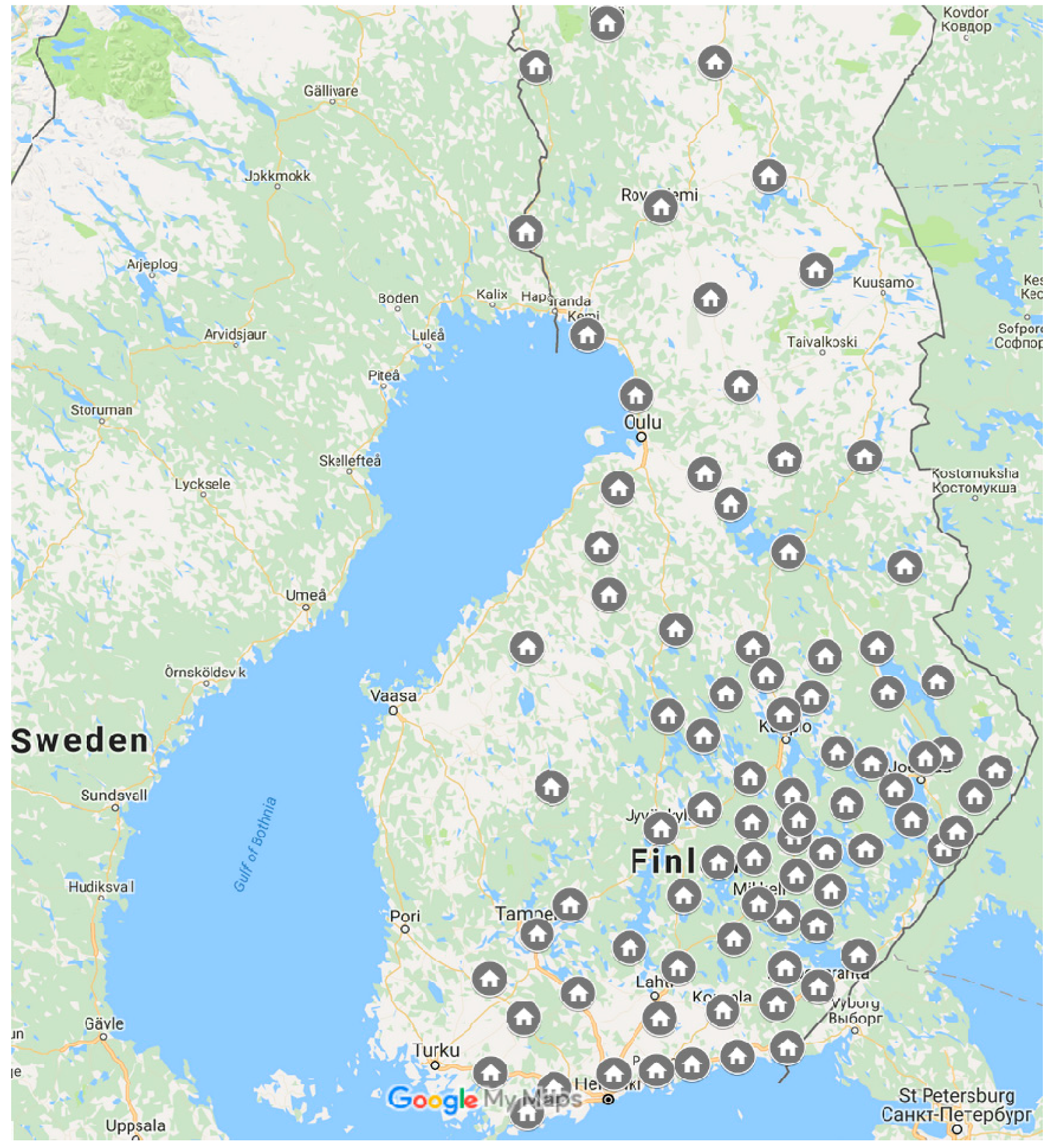

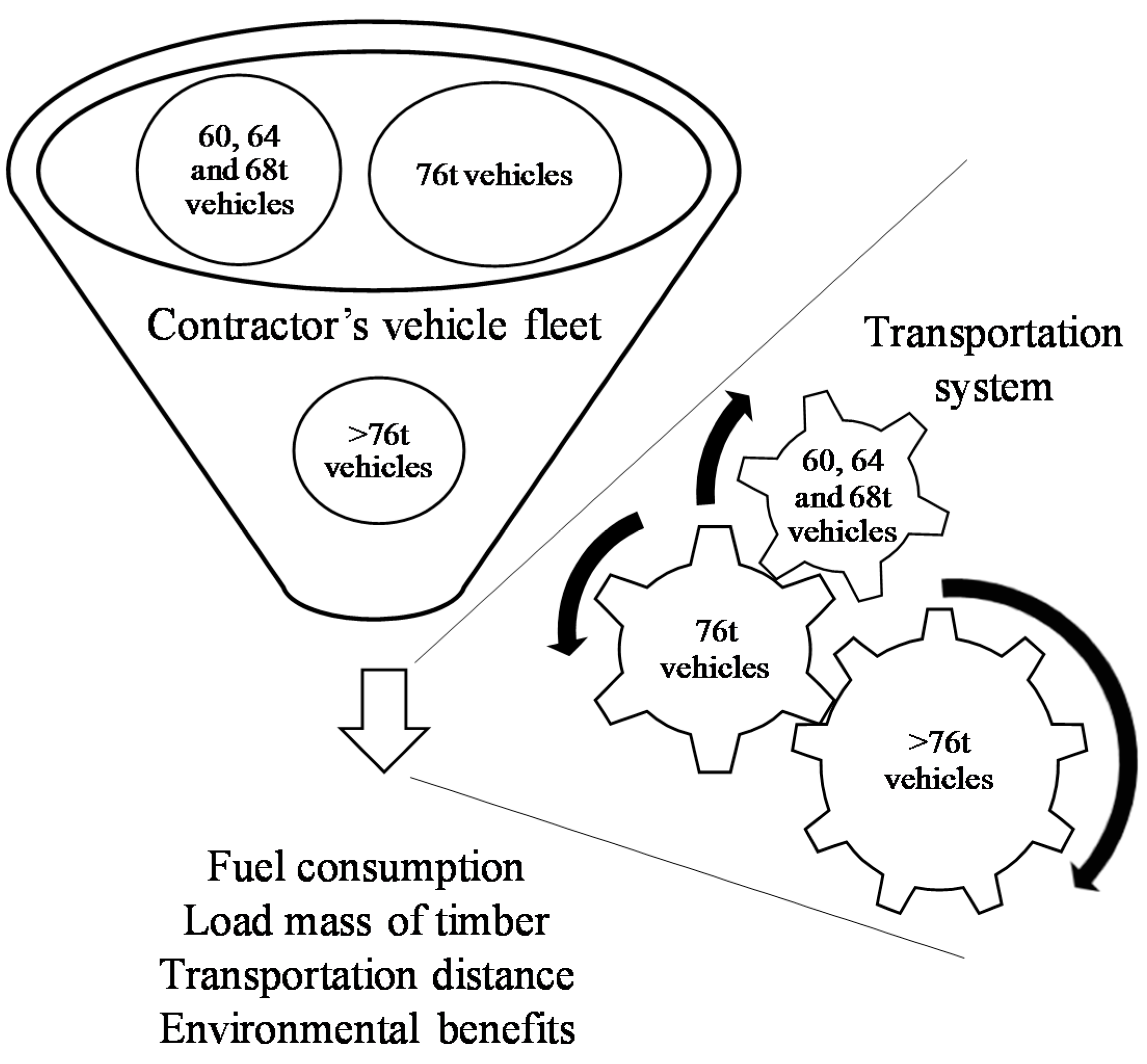

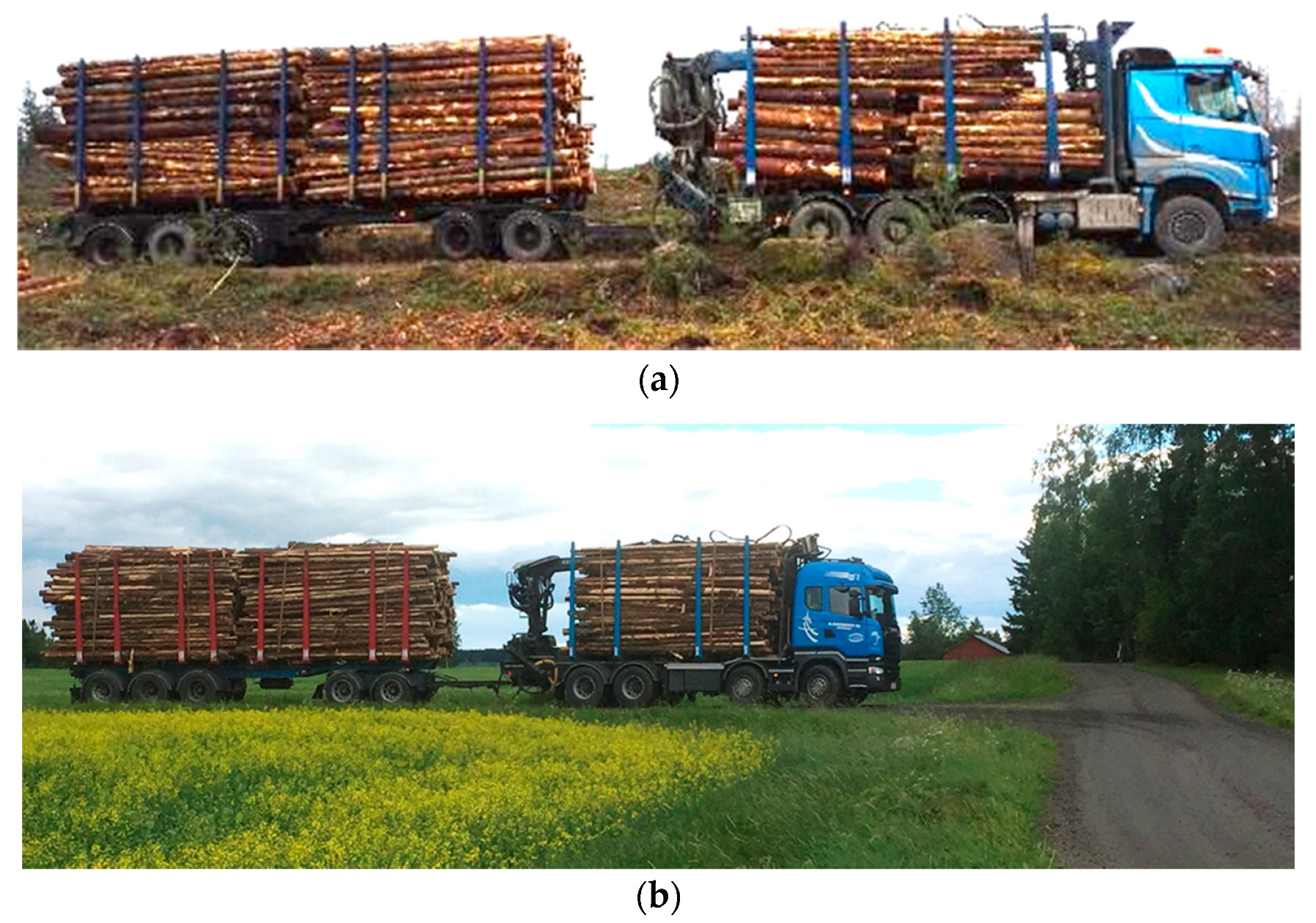

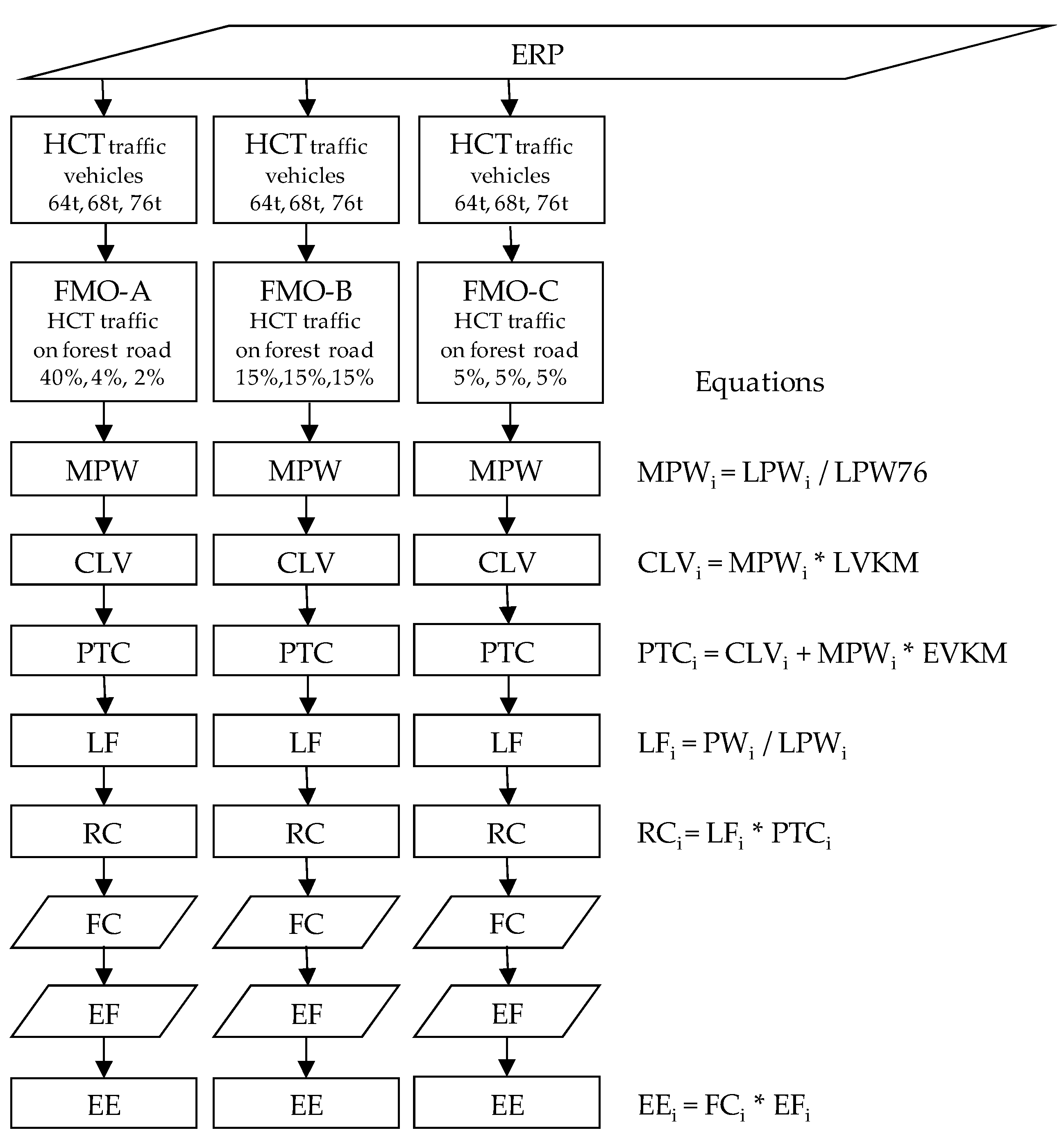

2. Material and Methods

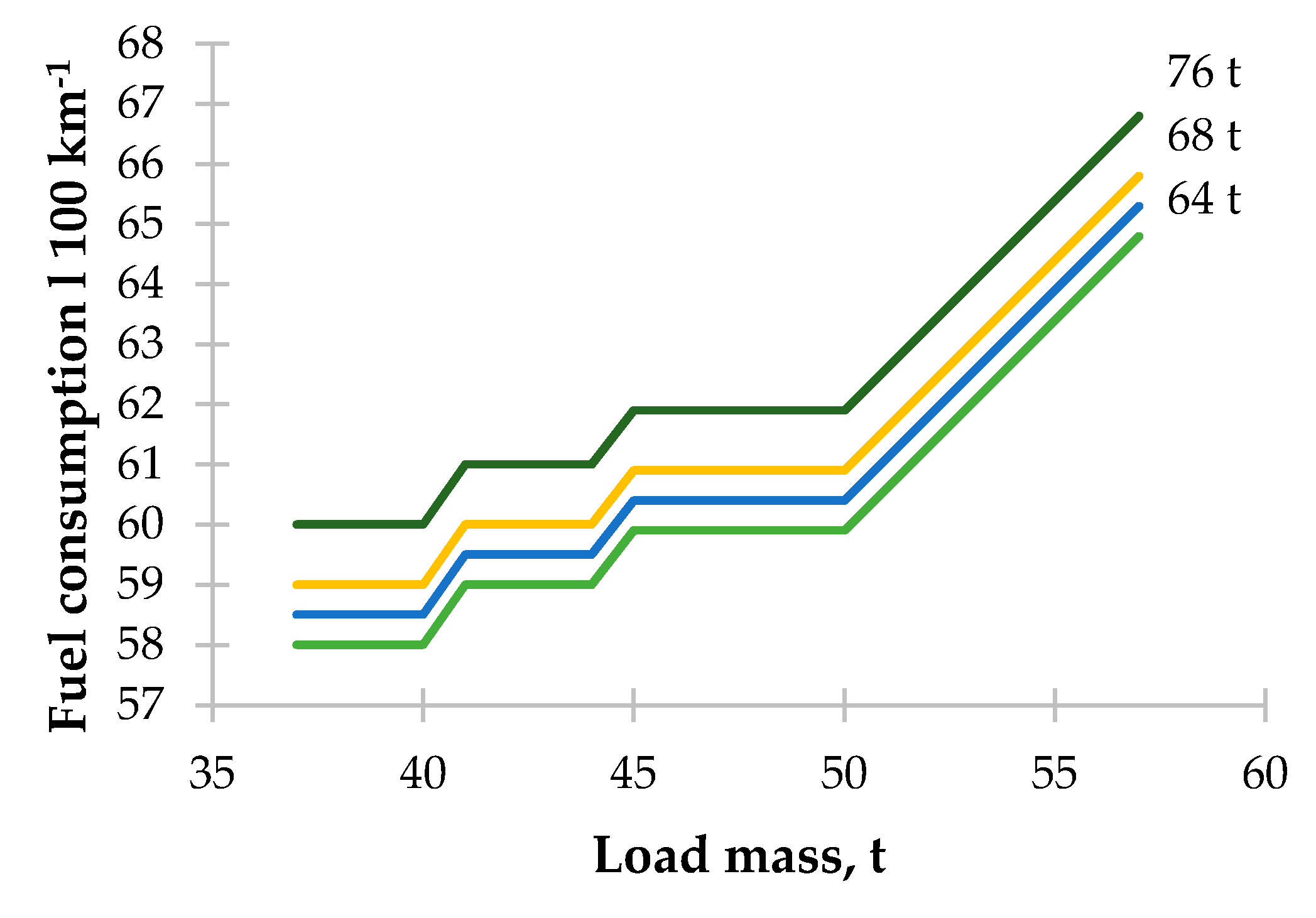

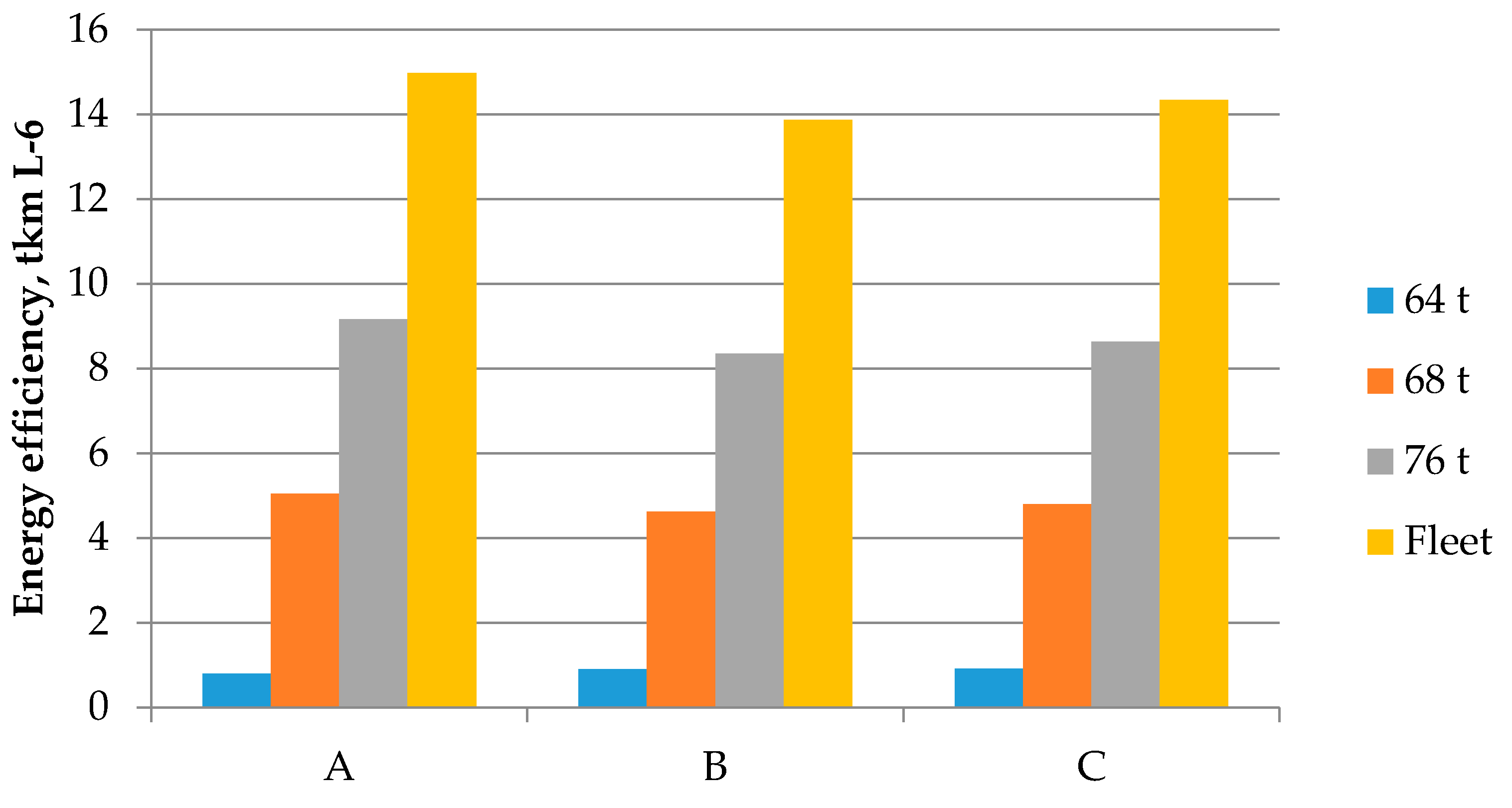

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- EUR-Lex. A Roadmap for Moving to a Competitive Low Carbon Economy in 2050. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A52011AE1389 (accessed on 22 November 2018).

- EUR-Lex. A Policy Framework for Climate and Energy in the Period from 2020 to 2030. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52014DC0015&from=EN (accessed on 22 November 2018).

- Korzhenevych, A.; Dehnen, N.; Bröcker, J.; Holtkamp, M.; Meier, H.; Gibson, G.; Varma, A.; Cox, V. Update of the Handbook on External Costs of Transport; European Commission, DG Mobility and Transport: Ispra, Italy, 2014. [Google Scholar]

- OECD. Moving Freight with Better Trucks: Improving Safety, Productivity and Sustainability. 2011. Available online: http://www.oecd-ilibrary.org/transport/ (accessed on 22 November 2018).

- Palander, T.; Kärhä, K. Characteristics of energy performance measures for 100% carbon-neutral wood procurement of forest industry. In New Trends in Nanotechnology, Material and Environmental Sciences; Zhu, J., Jin, A., Zhu, D., Eds.; AV AkademikerVerlag: Berlin, Germany, 2018; pp. 304–332. [Google Scholar]

- Palander, T.; Haavikko, H.; Kärhä, K. Towards sustainable wood procurement in forest industry—The energy efficiency of larger and heavier vehicles in Finland. Renew. Sustain. Energy Rev. 2018, 96, 100–118. [Google Scholar] [CrossRef]

- Korhonen, J. Four ecosystem principles for an industrial ecosystem. J. Clean. Prod. 2001, 9, 253–259. [Google Scholar] [CrossRef]

- Korhonen, J. A material and energy flow model for co-production of heat and power. J. Clean. Prod. 2002, 10, 537–544. [Google Scholar] [CrossRef]

- Ghose, A.; Chinga-Carrasco, G. Environmental aspects of Norwegian production of pulp fibres and printing paper. J. Clean. Prod. 2013, 57, 293–301. [Google Scholar] [CrossRef]

- Palander, T. The environmental emission efficiency of larger and heavier vehicles—A case study of road transportation in Finnish forest industry. J. Clean. Prod. 2017, 155, 57–62. [Google Scholar] [CrossRef]

- McKinnon, A. The economic and environmental benefits of increasing maximum truck weight: The British experience. Transp. Res. Part D Transp. Environ. 2005, 10, 77–95. [Google Scholar] [CrossRef]

- McKinnon, A.C.; Piecyk, M. Measurement of CO2 emissions from road freight transport: A Review of UK Experience. Energy Policy 2009, 37, 3733–3742. [Google Scholar] [CrossRef]

- Handler, R.M.; Shonnard, D.R.; Lautala, P.; Abbas, D.; Strivastava, A. Environmental impacts of roundwood supply chain options in Michigan: Life-cycle assessment of harvest and transport stages. J. Clean. Prod. 2014, 76, 64–73. [Google Scholar] [CrossRef]

- Sonne, E. Greenhouse gas emissions from forestry operations: A lifecycle assessment. J. Environ. Qual. 2006, 35, 1439–1450. [Google Scholar] [CrossRef]

- Palander, T. Environmental benefits from improving transportation efficiency in wood procurement systems. Transp. Res. Part D Transp. Environ. 2016, 44, 211–218. [Google Scholar] [CrossRef]

- Lijewski, P.; Merkisz, J.; Fuć, P.; Ziółkowski, A.; Rymaniak, L.; Kusiak, W. Fuel consumption and exhaust emissions in the process of mechanized timber extraction and transport. Eur. J. For. Res. 2017, 136, 153–160. [Google Scholar] [CrossRef]

- Commission Regulations (EU). No 582/2011. 2011. Available online: http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2011:167:0001:0168:EN:PDF (accessed on 22 November 2018).

- Mårtensson, L. Emissions from Volvo’s Trucks. Volvo Truck Corporation, 2018. Available online: https://www.volvotrucks.com/content/dam/volvo/volvo-trucks/markets/global/pdf/our-trucks/Emis_eng_10110_14001.pdf (accessed on 22 November 2018).

- Traffic Emissions Database. Road Traffic Emissions and Energy Consumption in Finland. 2017. Helsinki. Available online: http://www.lipasto.vtt.fi/ (accessed on 22 November 2018).

- Stora Enso. Stora Enso’s Policy for Energy and Carbon. 2017. Available online: https://www.storaenso.com/download-centre/ (accessed on 22 November 2018).

- Stora Enso. Stora Enso Sustainability Report 2016. 2017. Available online: https://www.storaenso.com/download-centre/ (accessed on 22 November 2018).

- Stora Enso. Progress Book. Part of Stora Enso’s Annual Report 2017. 2018. Available online: https://www.storaenso.com/download-centre/ (accessed on 22 November 2018).

- Hope, K. Annual Report on European SMEs 2016/2017, Focus on Self-Employment. SME Performance Review 2016/2017; Final Report; European Commission, Internal Market, Industry, Entrepreneurship and SMEs: Ispra, Italy, 2017. [Google Scholar]

- Haavikko, H.; Kärhä, K.; Hourula, M.; Palander, T. Attitudes of Small and Medium-Sized Enterprises towards Energy Efficiency in Wood Procurement: A Case Study of Stora Enso in Finland. Croat. J. For. Eng. 2019, 40, 107–123. [Google Scholar]

- Palander, T.; Väätäinen, J. Impacts of inter-enterprise collaboration and backhauling on wood procurement in Finland. Scand. J. For. Res. 2005, 20, 177–183. [Google Scholar] [CrossRef]

- Palander, T.; Vainikka, M.; Yletyinen, A. Potential mechanisms for co-operation between transportation entrepreneurs and customers: A case study of regional entrepreneurship in Finland. Croat. J. For. Eng. 2012, 33, 89–103. [Google Scholar]

- Marttila, V.; Granholm, H.; Laanikari, J.; Yrjölä, T.; Aalto, A.; Heikinheimo, P.; Honkatuki, J.; Järvinen, H.; Liski, J.; Merivirta, R.; et al. National strategy for Adapting Climate Change; Report 1; The Ministry of Agriculture and Forestry: Helsinki, Finland, 2005.

- Saarelainen, S.; Makkonen, L. Adaptation to Climate Change in Road Maintenance, Preliminary Report; Report 4; Finnish Road Administration: Helsinki, Finland, 2007.

- Tiehallinto. The Affect of Climate Change to Road Maintenance; Report 8; Finnish Road Administration: Helsinki, Finland, 2009.

- Holzleitner, F.; Kanzian, C.; Stampfer, K. Analyzing time and fuel consumption in road transport of round wood with an onboard fleet manager. Eur. J. For. Res. 2011, 130, 293–301. [Google Scholar] [CrossRef]

- Svenson, G.; Fjeld, D. The impact of road geometry, surface roughness and truck weight on operating speed of logging trucks. Scand. J. For. Res. 2017, 32, 515–527. [Google Scholar] [CrossRef]

- Liimatainen, H.; Pöllänen, M. Trends of energy efficiency in Finnish road freight transport 1995–2009 and forecast to 2016. Energy Policy 2010, 38, 7676–7686. [Google Scholar] [CrossRef]

- Thollander, P.; Backlund, S.; Trianni, A.; Cagno, E. Beyond barriers—A case study on driving forces for improved energy efficiency in the foundry industries in Finland, France, Germany, Italy, Poland, Spain, and Sweden. Appl. Energy 2013, 111, 636–643. [Google Scholar] [CrossRef]

- del Río González, P. Analysing the factors influencing clean technology adoption: A study of the Spanish pulp and paper industry. Bus. Strategy Environ. 2005, 14, 20–37. [Google Scholar] [CrossRef]

- Thollander, P.; Ottosson, M. An energy efficient Swedish pulp and paper industry—Exploring barriers to and driving forces for cost-effective energy efficiency investment. Energy Effic. 2008, 1, 21–34. [Google Scholar] [CrossRef]

- Thollander, P.; Danestig, M.; Rohdin, P. Energy policies for increased industrial energy efficiency: Evaluation of a local energy programme for manufacturing SMEs. Energy Policy 2007, 35, 5774–5783. [Google Scholar] [CrossRef]

- Fleiter, T.; Fehrenbach, D.; Worrell, E.; Eichhammer, W. Energy efficiency in the German pulp and paper industry—A model-based assessment of saving potentials. Energy 2012, 40, 84–99. [Google Scholar] [CrossRef]

- Fracaro, G.; Vakkilainen, E.; Hamaguchi, M.; de Souza, S.N.M. Energy efficiency in the Brazilian pulp and paper industry. Energies 2012, 5, 3550–3572. [Google Scholar] [CrossRef]

- Martin, N.; Angliani, N.; Einstein, D.; Khrushch, M.; Worrell, E.; Price, L.K. Opportunities to Improve Energy Efficiency and Reduce Greenhouse Gas Emissions in the U.S. Pulp and Paper Industry; Ernest Orlando Lawrence Berkeley National Laboratory LBNL 46141; Ernest Orlando Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2000.

- Peng, L.; Zeng, X.; Wang, Y.; Hong, G.-B. Analysis of energy efficiency and carbon dioxide reduction in the Chinese pulp and paper industry. Energy Policy 2015, 80, 65–75. [Google Scholar] [CrossRef]

- Hämäläinen, E.; Hilmola, O.P. Energy efficiency at the paper mill—Dilemma of improvement. Energy Effic. 2017, 10, 809–821. [Google Scholar] [CrossRef]

- Joelsson, J.M.; Gustavsson, L. CO2 emission and oil use reduction through black liquor gasification and energy efficiency in pulp and paper industry. Resour. Conserv. Recyc. 2008, 52, 747–763. [Google Scholar] [CrossRef]

- Kilponen, L.; Ahtila, P.; Parpala, J.; Pihko, M. Improvement of pulp mill energy efficiency in an integrated pulp and paper mill. In Proceedings of the 2001 ACEEE Summer Study on Energy Efficiency in Industry “Increasing Productivity through Energy Efficiency”, Hilton Tarrytown, Tarrytown, NY, USA, 24–27 July 2001; pp. 363–374. [Google Scholar]

- Berg, S.; Lindholm, E.L. Energy use and environmental impacts of forest operations in Sweden. J. Clean. Prod. 2003, 13, 33–42. [Google Scholar] [CrossRef]

- Gonzales-Garcia, S.; Moreira, M.T.; Dias, A.C.; Mola-Yudego, B. Cradle-to-gate Life Cycle Assessment of forest operations in Europe: Environmental and energy profiles. J. Clean. Prod. 2014, 66, 188–198. [Google Scholar] [CrossRef]

- Han, H.-S.; Oneil, E.; Bergman, R.D.; Eastin, I.L. Cradle-to-gate life cycle impacts of redwood forest resource harvesting in northern California. J. Clean. Prod. 2015, 99, 217–229. [Google Scholar] [CrossRef]

- Tikkanen, L.; Ovaskainen, H.; Palander, T.; Vesa, L. TimberLink as a tool for measuring the fuel consumption of a harvester. In The Nordic-Baltic Conference on Forest Operations—Copenhagen; Suadicani, K., Talbot, B., Eds.; Forest & Landscape Working Papers 30; Forest & Landscape: Aalborg, Denmark, 2008; pp. 70–71. [Google Scholar]

- Fan, Y.V.; Perry, S.; Klemeš, J.J.; Lee, C.T. A review on air emissions assessment: Transportation. J. Clean. Prod. 2018, 194, 673–684. [Google Scholar] [CrossRef]

- Rodrigue, J.P. The Geography of Transport Systems, 3rd ed.; Routledge: New York, NY, USA, 2013; p. 416. [Google Scholar]

- Royne, F.; Penaloza, D.; Sandin, G.; Berlin, J. Climate impact assessment in life cycle assessments of forest products: Implications of method choice for results and decision-making. J. Clean. Prod. 2016, 116, 90–99. [Google Scholar] [CrossRef]

- Finlex 407/2013. Valtioneuvoston Asetus Ajoneuvojen Käytöstä Tiellä Annetun Asetuksen Muuttamisesta. 2013. Available online: https://www.finlex.fi/fi/laki/alkup/2013/20130407 (accessed on 22 November 2018).

- Ministry of Transport and Communications. Better Competitiveness through New Masses and Dimensions for Heavy Goods Vehicles; Ministry of Transport and Communications: Helsinki, Finland, 2013. Available online: https://vayla.fi/web/en/-/mintc-better-competitiveness-through-new-masses-and-dimensions-for-heavy-goods-vehicles (accessed on 22 November 2018).

- Korhonen, J.; Pätäri, S.; Toppinen, A.; Tuppura, A. The role of environmental regulation in the future competitiveness of the pulp and paper industry: The case of the sulfur emissions directive in Northern Europe. J. Clean. Prod. 2016, 108, 864–872. [Google Scholar] [CrossRef]

- Finnish Transport Safety Agency (TRAFI). Finnish Road Statistics 2018. Helsinki; 2018. Available online: http://www.trafi.fi/tieliikenne/luvat_ja_hyvaksynnat/hct-rekat (accessed on 22 November 2018).

- EUR-Lex. Decision No 1692/96/EC of the European Parliament and of the Council of 23 July 1996 on Community Guidelines for the Development of the Trans-European Transport Network. 1996. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A31996D1692 (accessed on 22 November 2018).

- Farahani, N.Z.; Noble, J.S.; Klein, C.M.; Enayati, M. A decision support tool for energy efficient synchromodal supply chains. J. Clean. Prod. 2018, 186, 682–702. [Google Scholar] [CrossRef]

- EMSs, European Modular Systems. EU Directive 96/53/EC. 2013. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52013SC0108&from=EN (accessed on 22 November 2018).

| Old Mass Limit | New Mass Limit | Axles | New Payload | Payload Increase (%) | Decree of Change |

|---|---|---|---|---|---|

| 60 | 60 (64) | 7 | 44 | 10 | Temporary |

| 60 | 68 | 8 | 47 | 18 | Permanent |

| 60 | 76 | 9 | 54 | 35 | Permanent |

| 60 | 90 | 12 | 65 | 63 | Temporary (* |

| 60 | 104 | 13 | 72 | 80 | Temporary (* |

| Maximum Mass Limit (kg) | Quantity | Empty Running | Load Factor | Trips | Vehicle | Truck | Trailer | ||

|---|---|---|---|---|---|---|---|---|---|

| (tkm/1000) | (km) | (%) | (t) | (%) | (kg) | ||||

| 64,000 | 32,168 | +16,116 | +7.5 | +1860 | +4.5 | 19,800 | 19,788 | 12,319 | 7469 |

| 68,000 | 173,112 | +46,939 | +0.5 | +1343 | +2.9 | 70,800 | 20,459 | 12,165 | 8294 |

| 76,000 | 441,079 | −235,160 | −1.5 | −1352 | −2.7 | 121,600 | 21,730 | 13,330 | 8400 |

| Maximum Mass Limit (t) | A | B | C | |||

|---|---|---|---|---|---|---|

| F | H | F | H | F | H | |

| 64 | 241,952 | 362,928 | 90,732 | 514,148 | 30,244 | 574,636 |

| 68 | 129,542 | 3,109,004 | 485,782 | 2,752,764 | 161,927 | 3,076,619 |

| 76 | 120,528 | 5,905,853 | 903,957 | 5,122,423 | 301,319 | 5,725,061 |

| Total mass (t) | 492,022 | 9,377,785 | 1,480,471 | 8,389,336 | 493,490 | 9,376,317 |

| Emissions | A | B | C | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 64 | 68 | 76 | 64 | 68 | 76 | 64 | 68 | 76 | |

| EURO-0 (kg) | |||||||||

| CO2 | 1,949,199 | 8,270,408 | 15,803,284 | 1,715,119 | 9,018,890 | 17,352,526 | 1,708,395 | 8,690,605 | 1,6776,675 |

| SO2 | 29 | 125 | 236 | 26 | 135 | 259 | 26 | 130 | 251 |

| NOx | 20,440 | 86,727 | 165,720 | 17,986 | 94,576 | 181,966 | 17,915 | 91,134 | 175,928 |

| PM | 11,527 | 48,910 | 93,459 | 10,143 | 53,337 | 102,621 | 10,103 | 51,396 | 99,216 |

| CO | 2289 | 9716 | 18,565 | 2015 | 10,595 | 20,384 | 2007 | 10,209 | 19,708 |

| HC | 3919 | 16,630 | 31,776 | 3449 | 18,135 | 34,891 | 3435 | 17,475 | 33,733 |

| H2O | 58 | 247 | 473 | 51 | 270 | 519 | 51 | 260 | 502 |

| CH4 | 131 | 1304 | 2491 | 116 | 1422 | 2735 | 269 | 1370 | 2645 |

| EURO-VI (kg) | |||||||||

| CO2 | 1,948,773 | 8,268,598 | 15,799,826 | 1,714,744 | 9,016,916 | 17,348,728 | 1,708,021 | 8,688,703 | 16,773,003 |

| SO2 | 0.6 | 2.4 | 4.6 | 0.5 | 2.6 | 5.1 | 0.5 | 2.5 | 4.9 |

| NOx | 663.8 | 2816.7 | 5382.2 | 584.1 | 3071.6 | 5909.9 | 581.8 | 2959.8 | 5713.7 |

| PM | 95.9 | 406.9 | 777.4 | 84.4 | 443.7 | 853.6 | 84.0 | 427.5 | 825.3 |

| CO | 7.4 | 31.3 | 59.8 | 6.5 | 34.1 | 65.7 | 6.5 | 32.9 | 63.4 |

| HC | 44.3 | 187.8 | 358.8 | 38.9 | 204.8 | 394.0 | 38.8 | 197.3 | 380.9 |

| H2O | 0.6 | 2.4 | 4.6 | 0.5 | 2.6 | 5.1 | 0.5 | 2.5 | 4.9 |

| CH4 | 0.6 | 2.4 | 4.6 | 0.5 | 2.6 | 5.1 | 0.5 | 2.5 | 4.9 |

| Fuel (L) | 737,613 | 3,129,674 | 5,980,252 | 649,033 | 3,412,913 | 6,566,513 | 646,488 | 3,288,684 | 6,348,601 |

| Distance (km) | 973,140 | 4,875,981 | 9,093,960 | 973,140 | 4,875,981 | 9,093,960 | 973,140 | 4,875,981 | 9,093,960 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palander, T.; Kärhä, K. Improving Energy Efficiency in a Synchronized Road-Transportation System by Using a TFMC (Transportation Fleet-Management Control) in Finland. Energies 2019, 12, 670. https://doi.org/10.3390/en12040670

Palander T, Kärhä K. Improving Energy Efficiency in a Synchronized Road-Transportation System by Using a TFMC (Transportation Fleet-Management Control) in Finland. Energies. 2019; 12(4):670. https://doi.org/10.3390/en12040670

Chicago/Turabian StylePalander, Teijo, and Kalle Kärhä. 2019. "Improving Energy Efficiency in a Synchronized Road-Transportation System by Using a TFMC (Transportation Fleet-Management Control) in Finland" Energies 12, no. 4: 670. https://doi.org/10.3390/en12040670

APA StylePalander, T., & Kärhä, K. (2019). Improving Energy Efficiency in a Synchronized Road-Transportation System by Using a TFMC (Transportation Fleet-Management Control) in Finland. Energies, 12(4), 670. https://doi.org/10.3390/en12040670