Scaling Method of the Rotating Blade of a Wind Turbine for a Rime Ice Wind Tunnel Test

Abstract

:1. Introduction

2. Rime Ice Scaling Method and Test Verification

2.1. Identification of the Scaling Parameters

2.1.1. Geometric Scaling Requirements

2.1.2. Flow Field Scaling Requirements

2.1.3. Droplet Trajectory Scaling Requirements

2.1.4. Droplet Impinging Mass Scaling Requirements

2.1.5. Thermodynamic Scaling Requirements

2.1.6. Dynamic Pressure Scaling Requirements

2.1.7. Liquid Water Dynamic Scaling Requirement

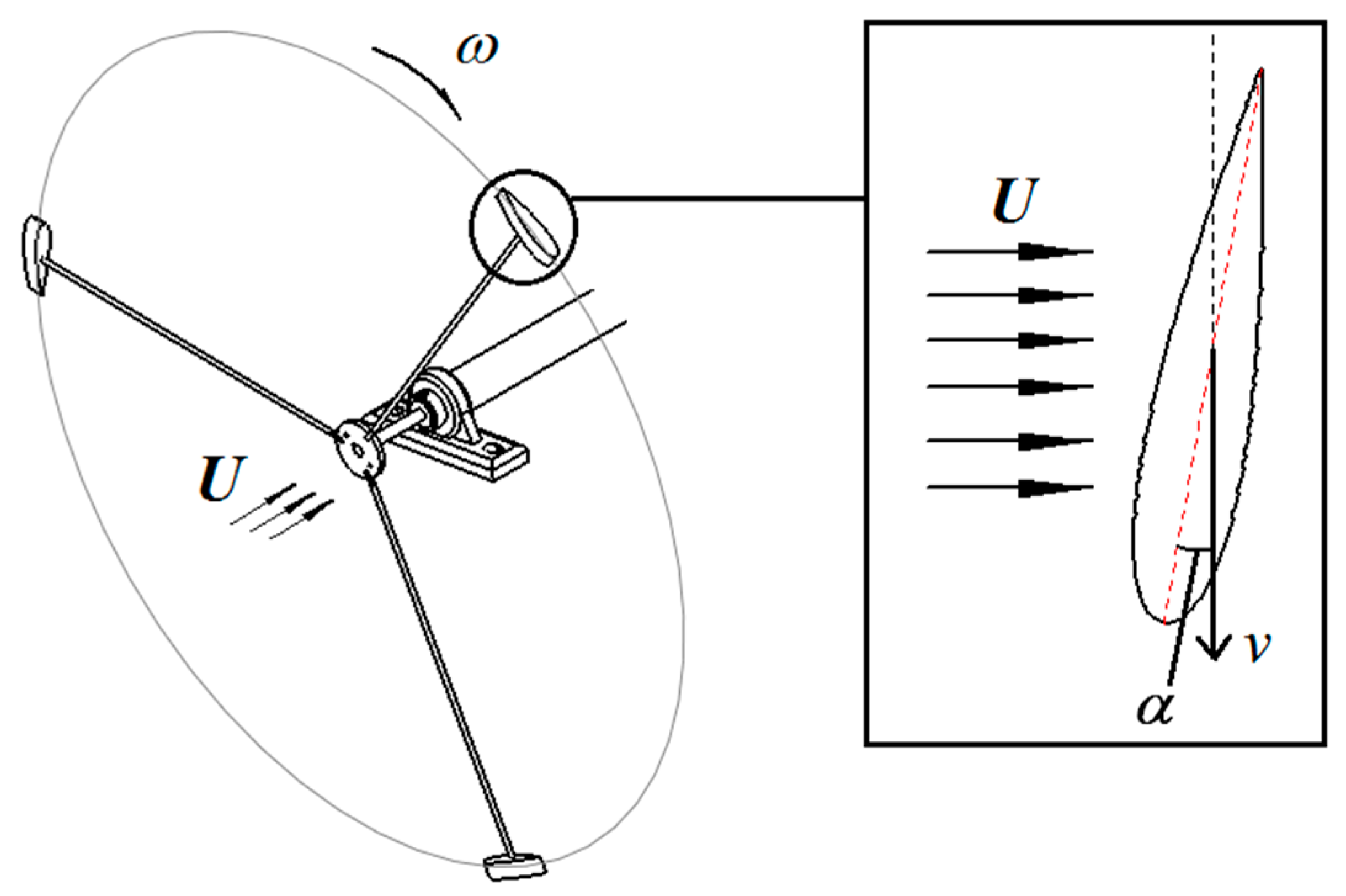

2.1.8. Rotation Parameter Scaling Requirement

2.2. Principles for Selecting Test Parameters

2.3. Test Verification

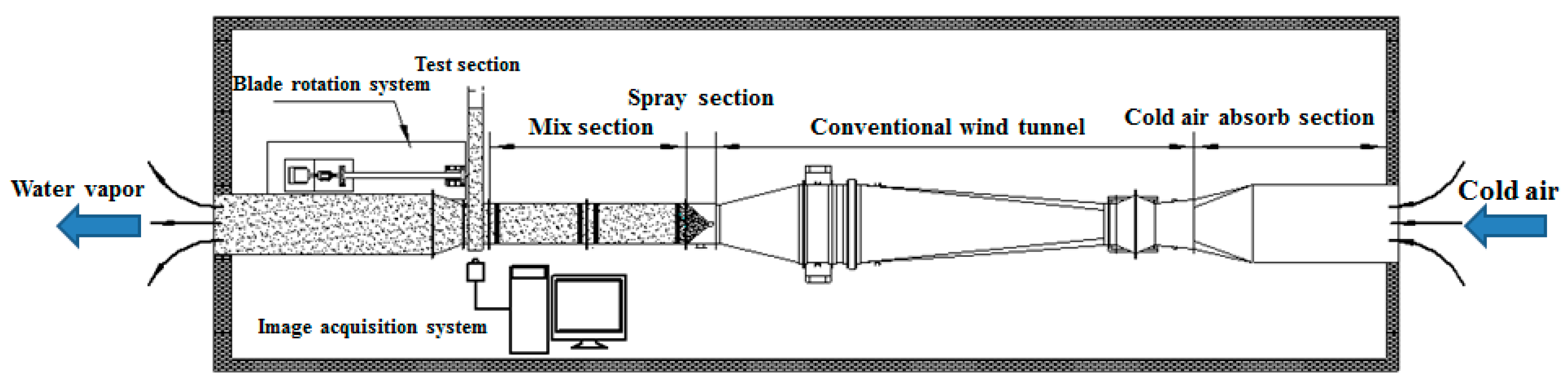

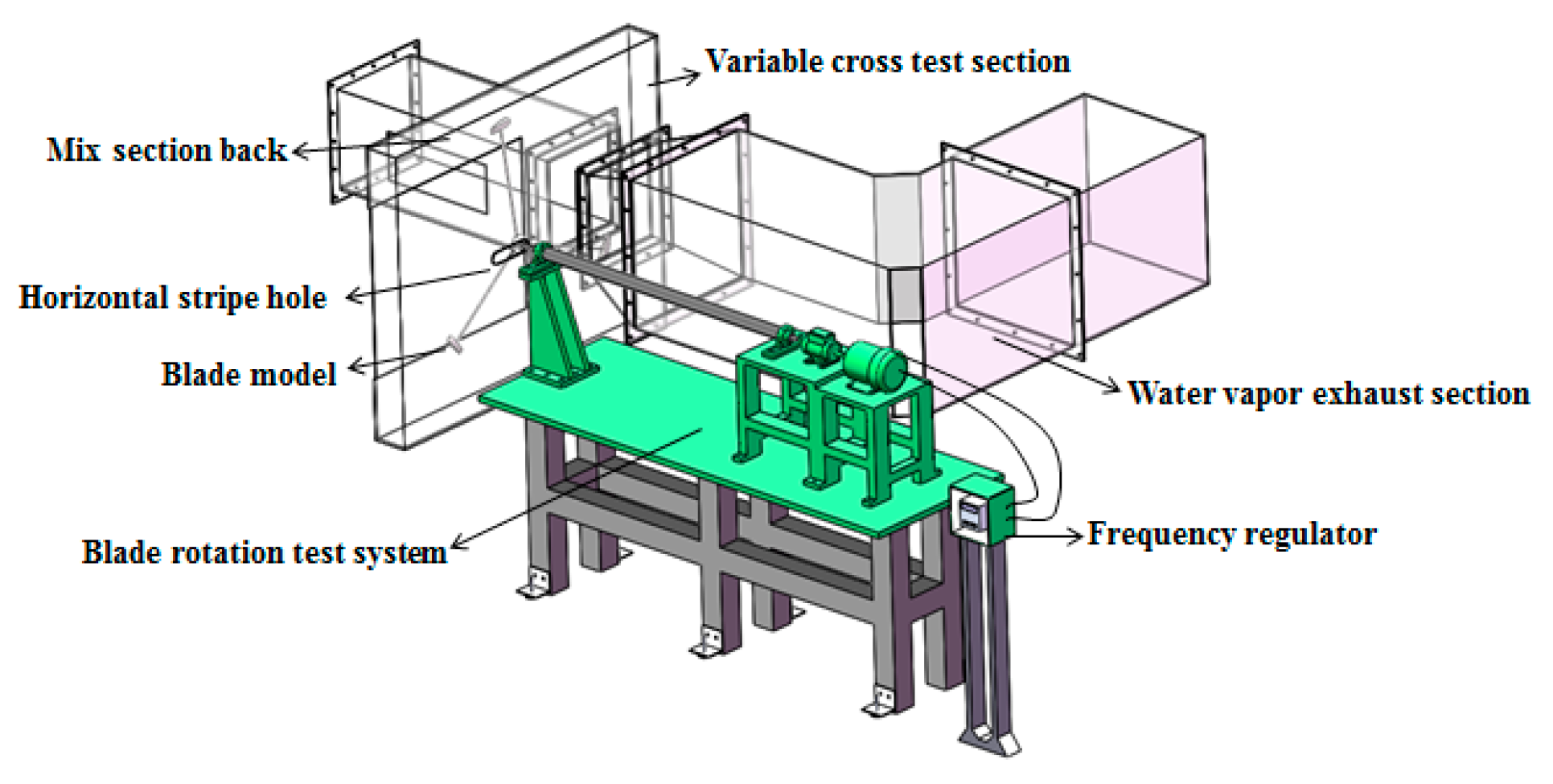

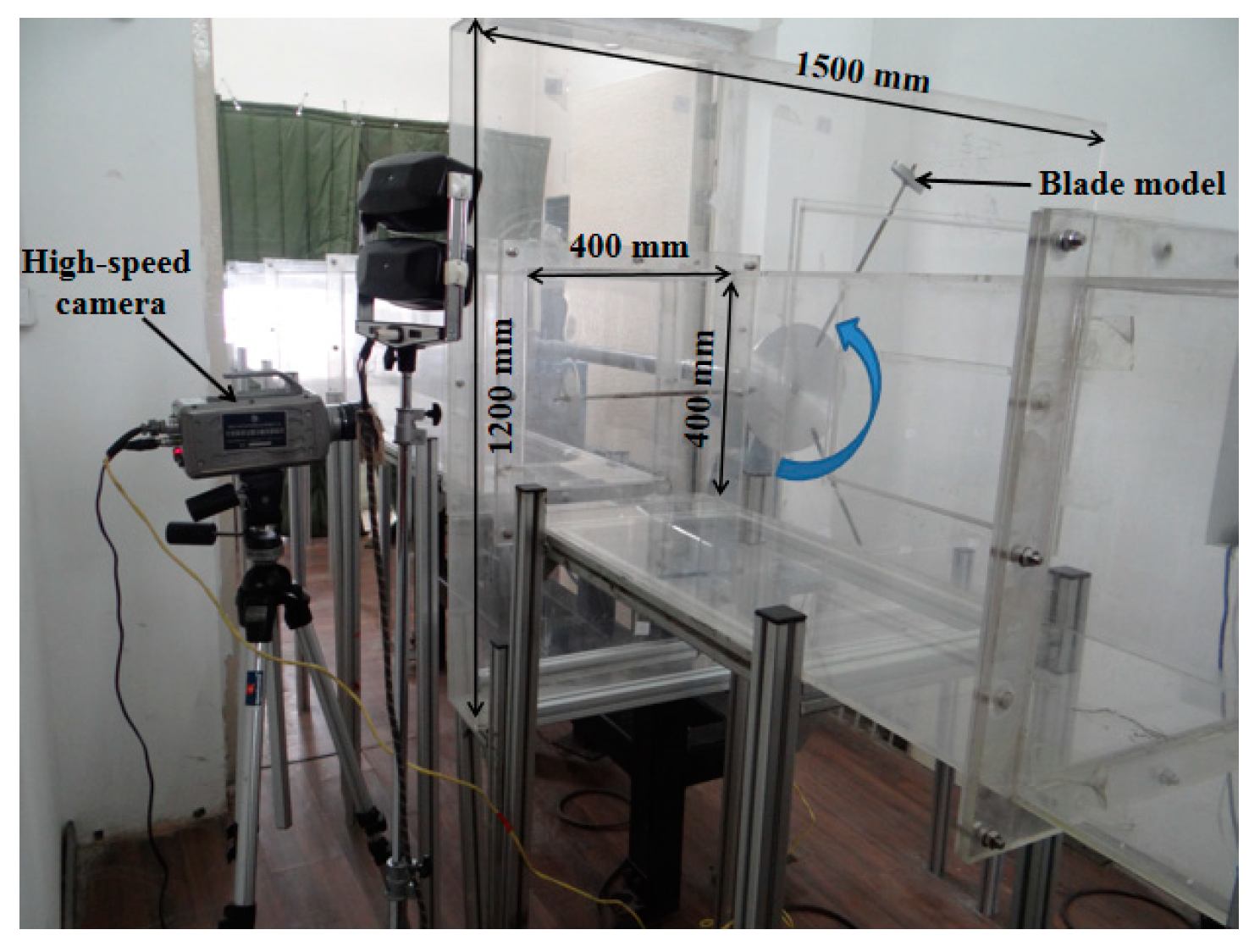

2.3.1. Test Apparatus

2.3.2. Test Plan

3. Results and Analysis

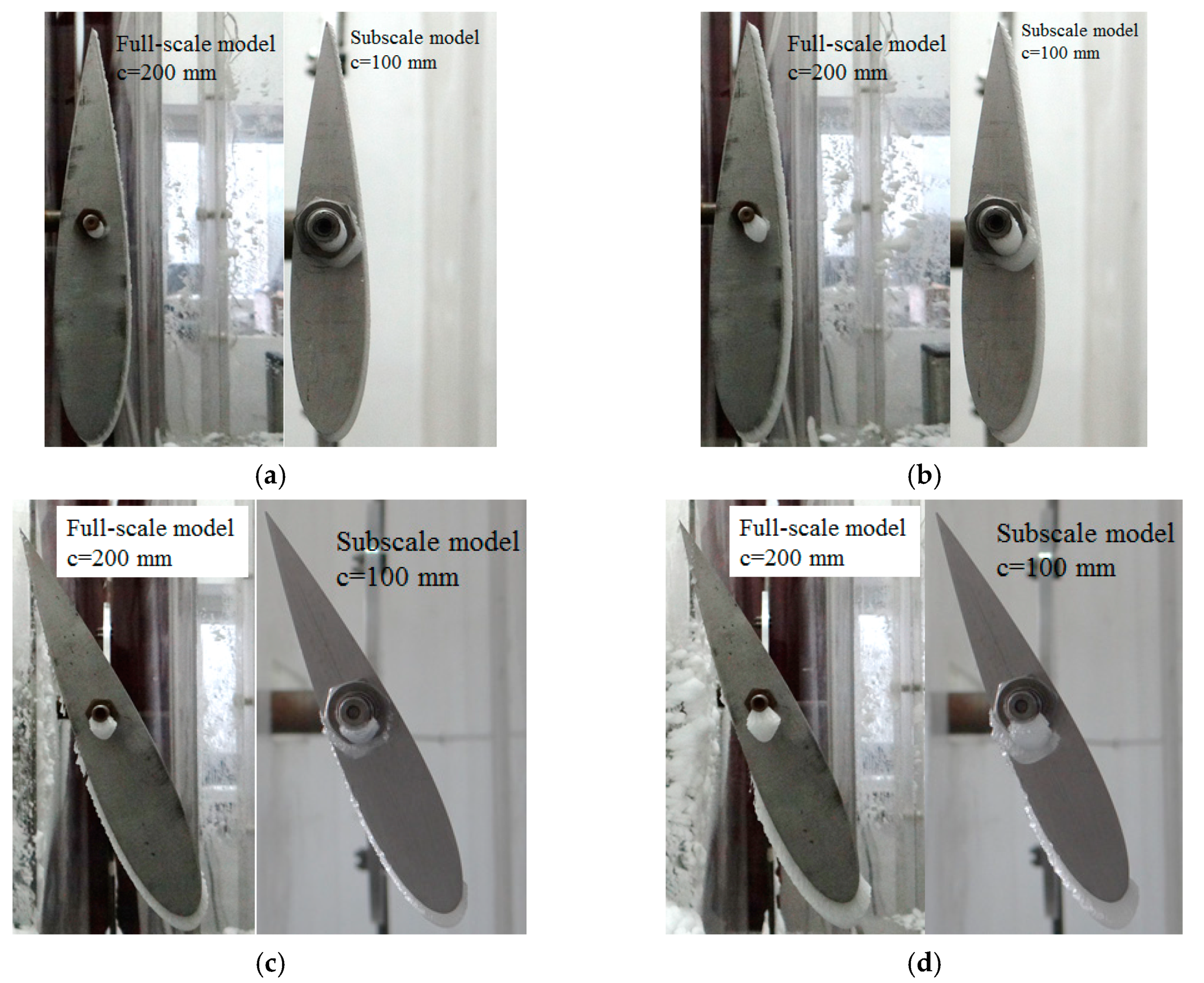

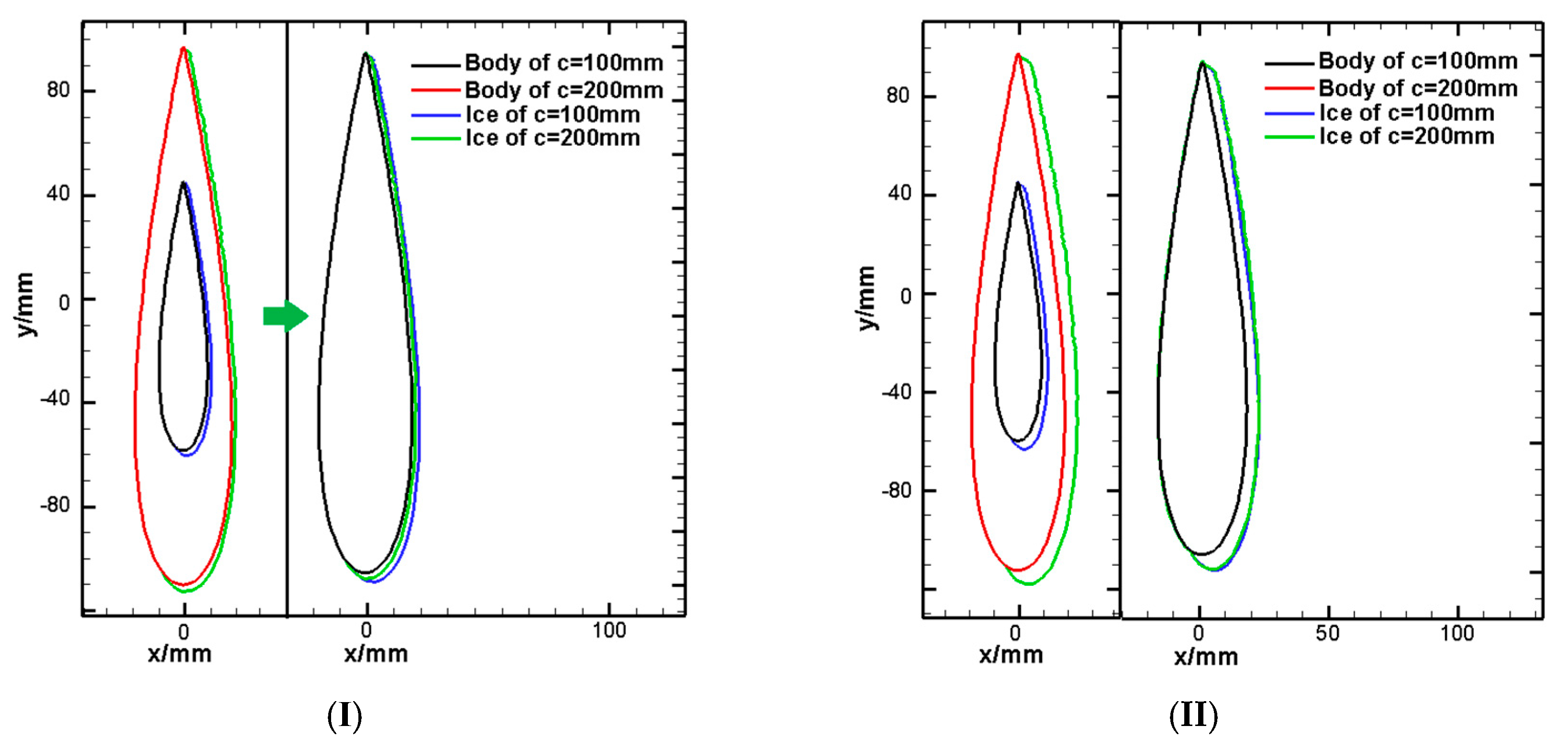

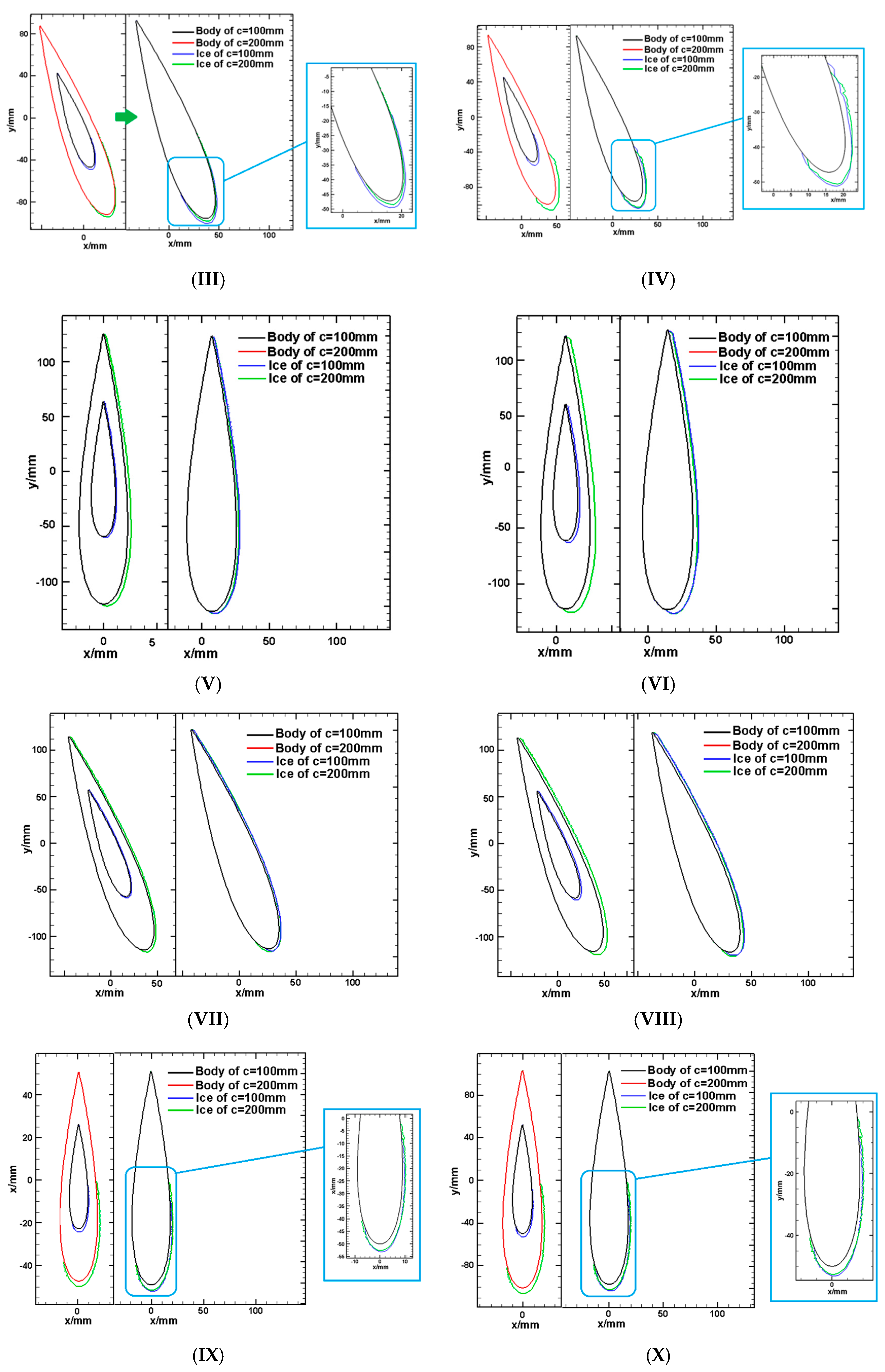

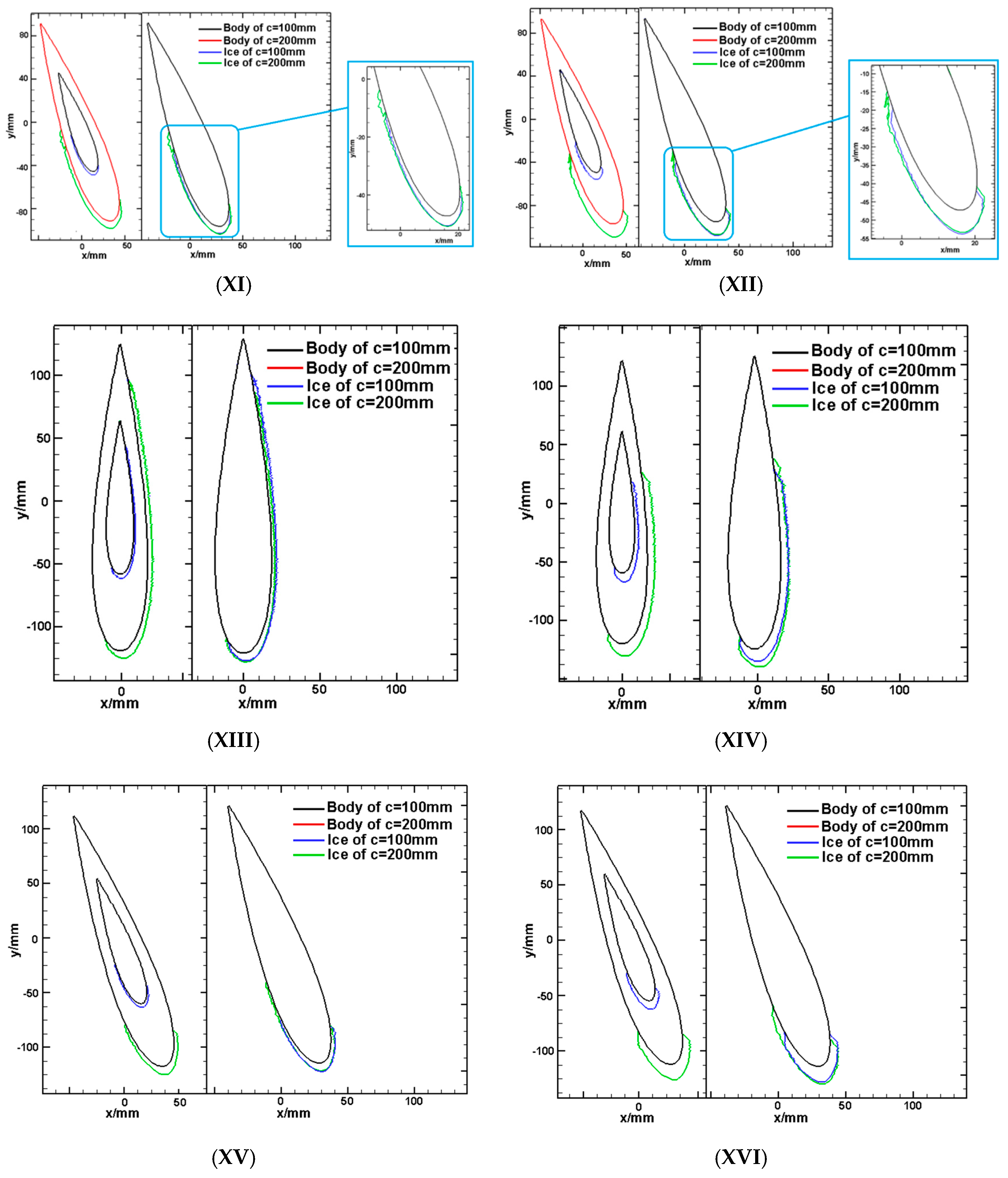

3.1. Icing Shape

3.2. Similar Icing Shape Evaluation Method

4. Conclusions

- (1)

- The rime ice scaling method has been established. The scaling parameter requirements including flow field, droplet trajectory, droplet impinging mass, thermodynamic, dynamic pressure, liquid water dynamic are defined. The rotating parameter based on the centrifugal force is added into the new rime ice scaling method.

- (2)

- The icing wind tunnel verification tests were carried out. The results show that the icing shapes of subscale blade are similar to those of the full-scale blade.

- (3)

- An evaluation method for analyzing the similar degree of icing shapes on different scale blades has been proposed. The similar parameter similar degree (Sim) is proposed. The results show that the similar degree of icing shapes of subscale model and full-scale model is between 75.22% and 93.01%. The value indicates that the new rime ice scaling method is an effective method

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| c | Chord length (m) | η | Dimensionless method |

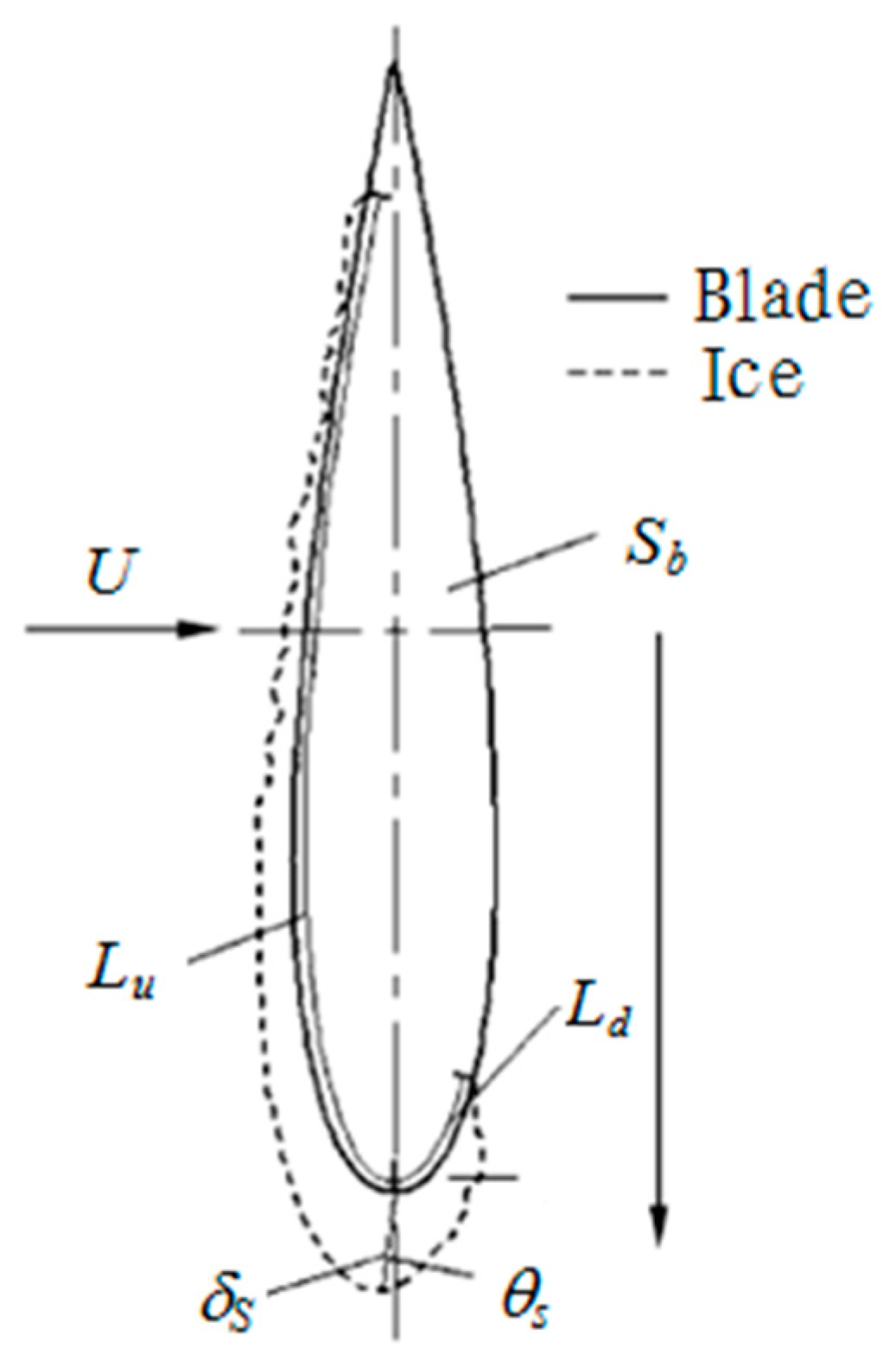

| b | Blade | δS | Stationary point thickness (mm) |

| D | Rotor diameter (m) | Ld | Downer impingement limit |

| E | Energy (J) | Lu | Upper impingement limit |

| f | Full-scale model | v | Peripheral speed (m/s) |

| L | Icing limit (mm) | αs | Deflection angle of icing |

| LWC | Liquid water content (g/m3) | θ | Rotation angle of airfoil (°) |

| MVD | Medium volume droplet diameter (μm) | cov | cover |

| m | Subscale model | Scov | Icing area (mm2) |

| Q | Quantity of heat (J) | t | Icing time (s) |

| U | Velocity of wind flows (m/s) | T | Temperature (°C) |

| Sim | Similar degree (%) | ς | Difference rate factor |

| ri | Weighting factor | HAWT | Horizontal axis wind turbine |

| Ac | accumulation parameter | mw | Water mass (g) |

| K | Inertia parameter | K0 | Modified inertia parameter |

| Re∞ | Free Reynolds number of droplets | Rerel | Relative Reynolds number of droplets |

| β | Local impingement efficiency | σc | Rotating parameters scaling requirement |

| Si | Icing area (mm2) | Sb | Blade area (mm2) |

| θs | Stationary point deflect angle (°) | α | Installed angle (°) |

References

- Li, Y.; Zhao, S.; Tagawa, K.; Feng, F. Starting performance effect of a truncated-cone-shaped wind gathering device on small-scale straight-bladed vertical axis wind turbine. Energy Convers. Manag. 2018, 167, 70–80. [Google Scholar] [CrossRef]

- Zhao, Z.Z.; Qian, S.Y.; Zheng, Y.; Wang, R.X.; Zeng, G.S. Enhancement approaches of aerodynamics performance of lift type vertical axis wind turbine considering small angle of attack. J. Drain. Irrig. Mach. Eng. (JDIME) 2018, 36, 146–153. (In Chinese) [Google Scholar]

- Li, Y.; Zheng, Y.F.; Zhao, S.Y.; Feng, F.; Li, J.Y.; Wang, N.X.; Bai, R.B. A review on aerodynamic characteristics of straight-bladed vertical axis wind turbine. Acta Aerodyn. Sin. 2017, 35, 368–382. (In Chinese) [Google Scholar]

- Zhang, Y.; Tang, N.; Niu, Y.; Du, X. Wind energy rejection in China: Current status, reasons and perspectives. Renew. Sustain. Energy Rev. 2016, 66, 322–344. [Google Scholar] [CrossRef]

- Li, Y.; Tagawa, K.; Feng, F.; Li, Q.; He, Q. A wind tunnel experimental study of icing on wind turbine blade airfoil. Energy Convers. Manag. 2014, 85, 591–595. [Google Scholar] [CrossRef]

- Xian, Y.; Kaichun, W.; Honglin, M.; Guolin, Z. 3-D numerical simulation of droplet collection efficiency in large-scale wind turbine icing. Acta Aerodyn. Sin. 2013, 31, 745–751. (In Chinese) [Google Scholar]

- Shu, L.; Li, H.; Hu, Q.; Jiang, X.; Qiu, G.; He, G.; Liu, Y. 3D numerical simulation of aerodynamic performance of iced contaminated wind turbine rotors. Cold Reg. Sci. Technol. 2018, 148, 50–62. [Google Scholar] [CrossRef]

- Li, Y.; Wang, S.; Sun, C.; Yi, X.; Guo, W.; Zhou, Z.; Feng, F. Icing distribution of rotating blade of horizontal axis wind turbine based on Quasi-3D numerical simulation. Therm. Sci. 2018, 22, 1191–1201. [Google Scholar] [CrossRef]

- Wang, S. Numerical Simulation and Icing Wind Tunnel Test Study on Icing Distribution on Rotating Blade of Horizontal Axis Wind Turbine. Ph.D. Thesis, Northeast Agricultural University, Harbin, China, 2017. [Google Scholar]

- Hu, L.; Zhu, X.; Chen, J.; Shen, X.; Du, Z. Numerical simulation of rime ice on NREL Phase VI blade. J. Wind Eng. Ind. Aerodyn. 2018, 178, 57–68. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, K.; Xian, H.; Du, X. A review of methods for vortex identification in hydroturbines. Renew. Sustain. Energy Rev. 2018, 81 Pt 1, 1269–1285. [Google Scholar] [CrossRef]

- Li, Y.; Wang, S.; Liu, Q.; Feng, F.; Tagawa, K. Characteristics of ice accretions on blade of the straight-bladed vertical axis wind turbine rotating at low tip speed ratio. Cold Reg. Sci. Technol. 2018, 145, 1229–1236. [Google Scholar] [CrossRef]

- Zeng, J.; Song, B. Research on experiment and numerical simulation of ultrasonic de-icing for wind turbine blades. Renew. Energy 2017, 113, 706–712. [Google Scholar] [CrossRef]

- Gao, L.; Liu, Y.; Zhou, W.; Hu, H. An experimental study on the aerodynamic performance degradation of a wind turbine blade model induced by ice accretion process. Renew. Energy 2019, 133, 663–675. [Google Scholar] [CrossRef]

- Jolin, N.; Bolduc, D.; Swytink-Binnema, N.; Rosso, G.; Godreau, C. Wind turbine blade ice accretion: A correlation with nacelle ice accretion. Cold Reg. Sci. Technol. 2019, 157, 235–241. [Google Scholar] [CrossRef]

- Taylor, G.L. Notes on Possible Equipment and Technique for Experiments on Icing on Aircraft; R&M, No. 2024; HM Stationery Office: Richmond, UK, January 1940. [Google Scholar]

- Langmuir, I.; Blodgett, K.B. A Mathematical Investigation of Water Droplet Trajectories; Army Air Forces Technical Report No. 5418 (Contract No. W-33-038-ac-9151); Army Air Forces Headquarters, Air Technical Service Command: San Antonio, TX, USA, February 1946. [Google Scholar]

- Wang, Z.X. Numerical Simulation of Droplet Impact Characteristic about Aircraft Icing and Study on Icing Scaling Law. Ph.D. Thesis, China Aerodynamics Research and Development Center Graduate School, Mianyang, China, 2008. [Google Scholar]

- Hauger, H.H.; Englar, K.G. Analysis of Model Testing in an Icing Wind Tunnel; Report No.SM14933; Douglas Aircraft Company, Inc.: Santa Monica, CA, USA, 1954. [Google Scholar]

- Jackson, E.T. Development Study: The Use of Scale Models in an Icing Tunnel to Determine the Ice Catch on a Prototype Aircraft with Particular Reference to Concorde; SST/B75T/TMMcK/242; British Aircraft Corp. (Operating) Ltd., Filton Division: London, UK, July 1967. [Google Scholar]

- Ormsbee, A.I.; Vragg, M.B. Trajectory Scaling Laws for a Particle Injected into the Wake of an Aircraft; Report ARL-1; University of Illinois, Aviation Research Laboratory: Chicago, IL, USA, June 1978. [Google Scholar]

- Armand, C. Techniques and Facilities Used at the OneraModane Centre for Icing Tests; AGARD-AF-127; North Atlantic Traty Organization Advisory Group for Aerospace Research and Development: Neuilly sur Seine, France, November 1978. [Google Scholar]

- Ruff, G.A. Analysis and Verification of the Icing Scaling Equations; AEDC-TR-85-30, Vol 1 (Rev); NASA: Washington, DC, USA, March 1989.

- Bilanin, A.J. Proposed Modifications to the Ice Accretion/Icing Scaling Theory, AIAA Paper AIAA-88-0203; AIAA: Reston, VA, USA, January 1988.

- Bilanin, A.J.; Anderson, D.N. Ice Accretion with Varying Surface Tension, AIAA 95-0538 and NASA TM10682; NASA: Washington, DC, USA, January 1995.

- Anderson, D.M. Rime-, Mixed- and Glaze-Ice Evaluations of Three Scaling Laws, AIAA 94-0718; AIAA: Reston, VA, USA, January 1994.

- Xian, Y. Numerical Computation of Aircraft Icing and Study on Icing Test Scaling Law. Ph.D. Thesis, China Aerodynamics Research and Development Center Graduate School, Mianyang, China, 2007. [Google Scholar]

- Han, Y.; Palacios, J.; Schmitz, S. Scaled ice accretion experiments on rotating wind turbine blade. J. Wind Eng. Ind. Aerodyn. 2012, 109, 55–67. [Google Scholar] [CrossRef]

- Li, Y.; Sun, C.; Guo, W.F.; Wang, S.L.; Feng, F.; Jiang, Y. Design of Icing Wind Tunnel Experiment System for Rotating Blades by Using Natural Low Temperature. J. Exp. Fluid Mech. 2018, 32, 40–47. (In Chinese) [Google Scholar]

- Li, Y.; Sun, C.; Jiang, Y.; Yi, X.; Xu, Z.; Guo, W. Temperature effect on icing distribution near blade tip of large-scale horizontal-axis wind turbine by numerical simulation. Adv. Mech. Eng. 2018, 10, 1–13. [Google Scholar] [CrossRef]

| Condition | V/m×s−1 | T/°C | MVD/μm | LWC/g×m−3 | P/Pa | n/rpm | α/° | t/s | |

|---|---|---|---|---|---|---|---|---|---|

| Subscale Model | Full-Scale Model | ||||||||

| 1 | 6 | −15 | 50 | 0.58 | 101,325 | 200 | 0 | 78 | 156 |

| 2 | 6 | −15 | 50 | 0.58 | 101,325 | 200 | 0 | 156 | 312 |

| 3 | 6 | −15 | 50 | 0.58 | 101,325 | 200 | 20 | 78 | 156 |

| 4 | 6 | −15 | 50 | 0.58 | 101,325 | 200 | 20 | 156 | 312 |

| 5 | 10 | −15 | 50 | 0.58 | 101,325 | 200 | 0 | 78 | 156 |

| 6 | 10 | −15 | 50 | 0.58 | 101,325 | 200 | 0 | 156 | 312 |

| 7 | 10 | −15 | 50 | 0.58 | 101,325 | 200 | 20 | 78 | 156 |

| 8 | 10 | −15 | 50 | 0.58 | 101,325 | 600 | 20 | 156 | 312 |

| 9 | 6 | −15 | 50 | 0.58 | 101,325 | 600 | 0 | 78 | 156 |

| 10 | 6 | −15 | 50 | 0.58 | 101,325 | 600 | 0 | 156 | 312 |

| 11 | 6 | −15 | 50 | 0.58 | 101,325 | 600 | 20 | 78 | 156 |

| 12 | 6 | −15 | 50 | 0.58 | 101,325 | 600 | 20 | 156 | 312 |

| 13 | 10 | −15 | 50 | 0.58 | 101,325 | 600 | 0 | 78 | 156 |

| 14 | 10 | −15 | 50 | 0.58 | 101,325 | 600 | 0 | 156 | 312 |

| 15 | 10 | −15 | 50 | 0.58 | 101,325 | 600 | 20 | 78 | 156 |

| 16 | 10 | −15 | 50 | 0.58 | 101,325 | 600 | 20 | 156 | 312 |

| Condition | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| Sim | 80.78% | 89.18% | 86.08% | 90.34% | 75.22% | 86.10% | 93.01% | 85.93% |

| Condition | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| Sim | 78.45% | 79.30% | 88.83% | 81.49% | 81.30% | 90.36% | 77.31% | 81.23% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Sun, C.; Jiang, Y.; Feng, F. Scaling Method of the Rotating Blade of a Wind Turbine for a Rime Ice Wind Tunnel Test. Energies 2019, 12, 627. https://doi.org/10.3390/en12040627

Li Y, Sun C, Jiang Y, Feng F. Scaling Method of the Rotating Blade of a Wind Turbine for a Rime Ice Wind Tunnel Test. Energies. 2019; 12(4):627. https://doi.org/10.3390/en12040627

Chicago/Turabian StyleLi, Yan, Ce Sun, Yu Jiang, and Fang Feng. 2019. "Scaling Method of the Rotating Blade of a Wind Turbine for a Rime Ice Wind Tunnel Test" Energies 12, no. 4: 627. https://doi.org/10.3390/en12040627

APA StyleLi, Y., Sun, C., Jiang, Y., & Feng, F. (2019). Scaling Method of the Rotating Blade of a Wind Turbine for a Rime Ice Wind Tunnel Test. Energies, 12(4), 627. https://doi.org/10.3390/en12040627