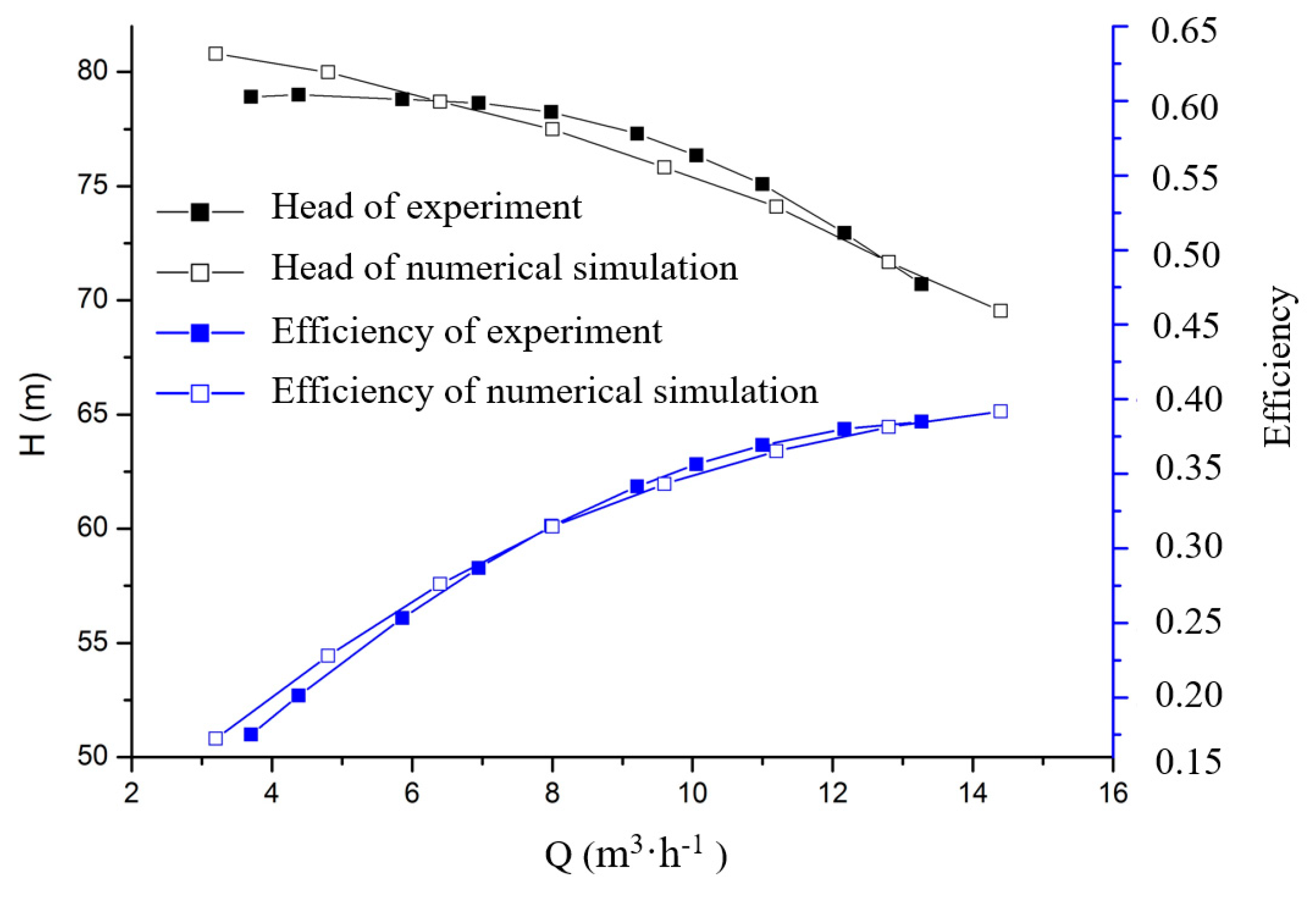

3.1. Experimental Verification

To verify the reliability of the numerical calculation, the numerical calculation results at different flow rate conditions were compared with the experimental data of the magnetic drive pump prototype. The external characteristic curves drawn by the experimental data at different flow rate conditions were compared with the ANSYS-CFX numerical simulation results, as shown in

Figure 8.

From the flow-head curve, it can be seen that the simulation calculation agrees well with the experiment near the design flow rate condition, and there are slight deviations between the numerical calculation and the experimental results under other flow rate conditions. The reason for the deviation may be that the stability of the flow field is poor and the boundary layer is separated under non-rated conditions. In this condition, if numerical simulation still uses the steady flow model, the error would occur. The simulation efficiency agrees well with the experiment efficiency near the design flow rate condition. In the flow rate range of 0.6 and 1.4 Qd, the maximum relative error of efficiency is 4.4% (at 0.6 Qd). In conclusion, the general trends of the simulation and experiment results are consistent, and the numerical simulation results of the whole flow field in the magnetic drive pump are true and credible.

3.3. Range and Variance Analysis of Performance Indexes

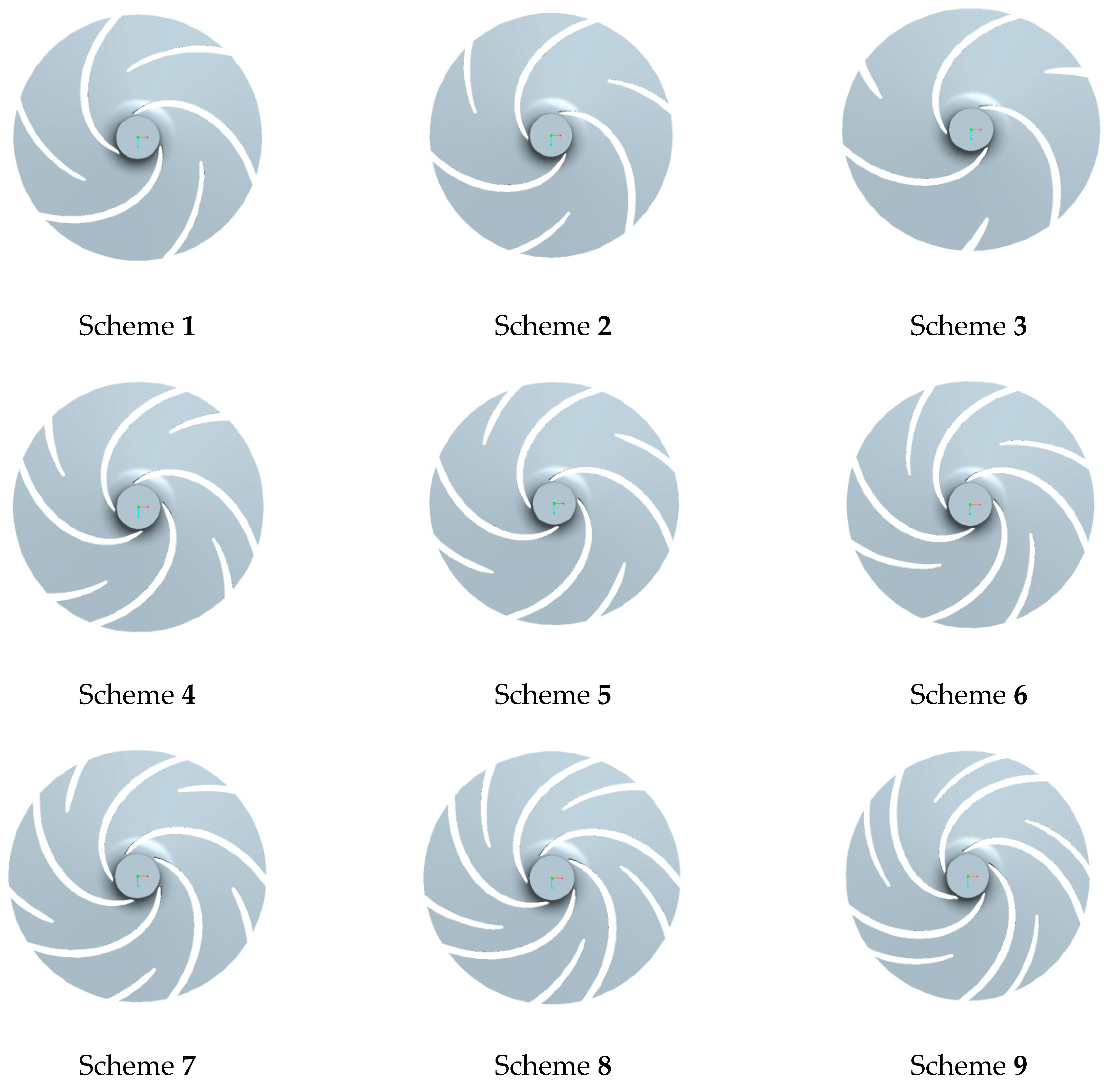

The efficiency and head of each scheme impeller obtained by numerical simulation are shown in

Table 4, in which scheme 0 corresponds to the original design impeller.

The range analysis of head and efficiency was conducted based on the orthogonal test results in

Table 5. In

Table 5, H represents the performance index of head (m), η represents the performance index of efficiency in percentage, K represents the sum of the test results at the corresponding level, k represents the average value of the test results at the corresponding level, and R represents the range value of k.

According to the principle of the orthogonal test, the influence of the factors on the result is directly proportional to the magnitude of the range. Therefore, the sequence of factors affecting the head of the magnetic drive pump is ADCB, namely, blades number, deflection angle, inlet diameter of splitter blades, and bias angle in the peripheral direction. The sequence of factors affecting the efficiency of the magnetic drive pump is ABCD, namely, blades number, bias angle in the peripheral direction, inlet diameter of splitter blades, and deflection angle. The effects of various factors on head and efficiency are shown in

Figure 10 and

Figure 11, respectively.

The influence of each factor level on the performance of the magnetic drive pump is as follows:

- (1)

For factor A, the head increases with the increase of the number of blades. The head increases sharply from A1 to A2, while the head increases slowly from A2 to A3. The head reaches the maximum at A3. The efficiency increases with the increase of the number of blades. Efficiency increases slowly from A1 to A2, while the efficiency curve increases sharply from A2 to A3. The efficiency at A3 is the highest. Considering the influence of factor level on head and efficiency, A3 (the number of blades Z = 5) is the best choice.

- (2)

For factor B, the change of bias angle in the peripheral direction has no obvious effect on head. The efficiency decreases gradually with the increase of bias angle in the peripheral direction. The efficiency reaches the highest when the bias angle is 0.4θ(B1). Therefore, it is reasonable to select the bias angle of 0.4θ.

- (3)

For factor C, the head is the highest at C3 (the inlet diameter of splitter blades Dsi = 0.75D2), while the efficiency is the lowest at C3. The head at C1 (the inlet diameter of splitter blades Dsi = 0.55D2) is slightly lower than that at C3, while the efficiency at C1 is the highest. If more consideration is given to head, C1 is chosen. If the head at C1 and C3 has met the design requirements, C3 is more energy-saving.

- (4)

For factor D, the variation trend of the head curve and efficiency curve is basically the same. When the deflection angle of splitter blades is 0° (D2), the head and efficiency both reaches the maximum; therefore, the best deflection angle was 0°.

The Taguchi method and ANOVA (Analysis of Variance) were applied to find the proportion of the influence of each orthogonal factor on the performance indexes. The Taguchi method is an optimal design method based on the orthogonal test, which was proposed by Dr. Taguchi of Japan. The Taguchi method can optimize the design of multiple objectives. Through the establishment of the orthogonal test table and the ANOVA of the orthogonal test results, the best combination of design parameters can be obtained with the least number of tests [

27,

28]. Analysis of variance of factors is conducted based on orthogonal test results (

Table 4 and

Table 5), and the analysis results are given in

Table 6.

As can be seen in

Table 6, factor A (73.602%) has the decisive influence on head. Factor D (13.411%) and factor C (12.941%) influence the head greatly, while factor B (0.046%) has the least influence on the head.

The results of variance analysis show that the influence proportion of each factor on efficiency are: Factor A (51.972%), factor B (20.892%), factor C (15.728%), and factor D (11.408%), respectively.

Factor A has a greater influence on both head and efficiency than other factors. For factor C, the influence ratio on efficiency (15.728%) is higher than the influence on head (12.941%).

Based on the Taguchi method, combined with the data in

Table 6 and

Table 5, two sets of optimized impeller combinations are obtained. The combination of A

3B

1C

3D

2 has the best head, while the combination of A

3B

1C

1D

2 has the best efficiency.

Table 7 lists the parameters of the two optimized impellers.

The above analysis shows that the better design schemes of split blades is A

3B

1C

3D

2 and A

3B

1C

1D

2. A

3B

1C

3D

2 is Scheme 7 of the orthogonal test. The combination scheme of A

3B

1C

1D

2 did not appeared in the test schemes, and is newly named as Scheme 10. Modeling and numerical simulation of Scheme 10 was conducted.

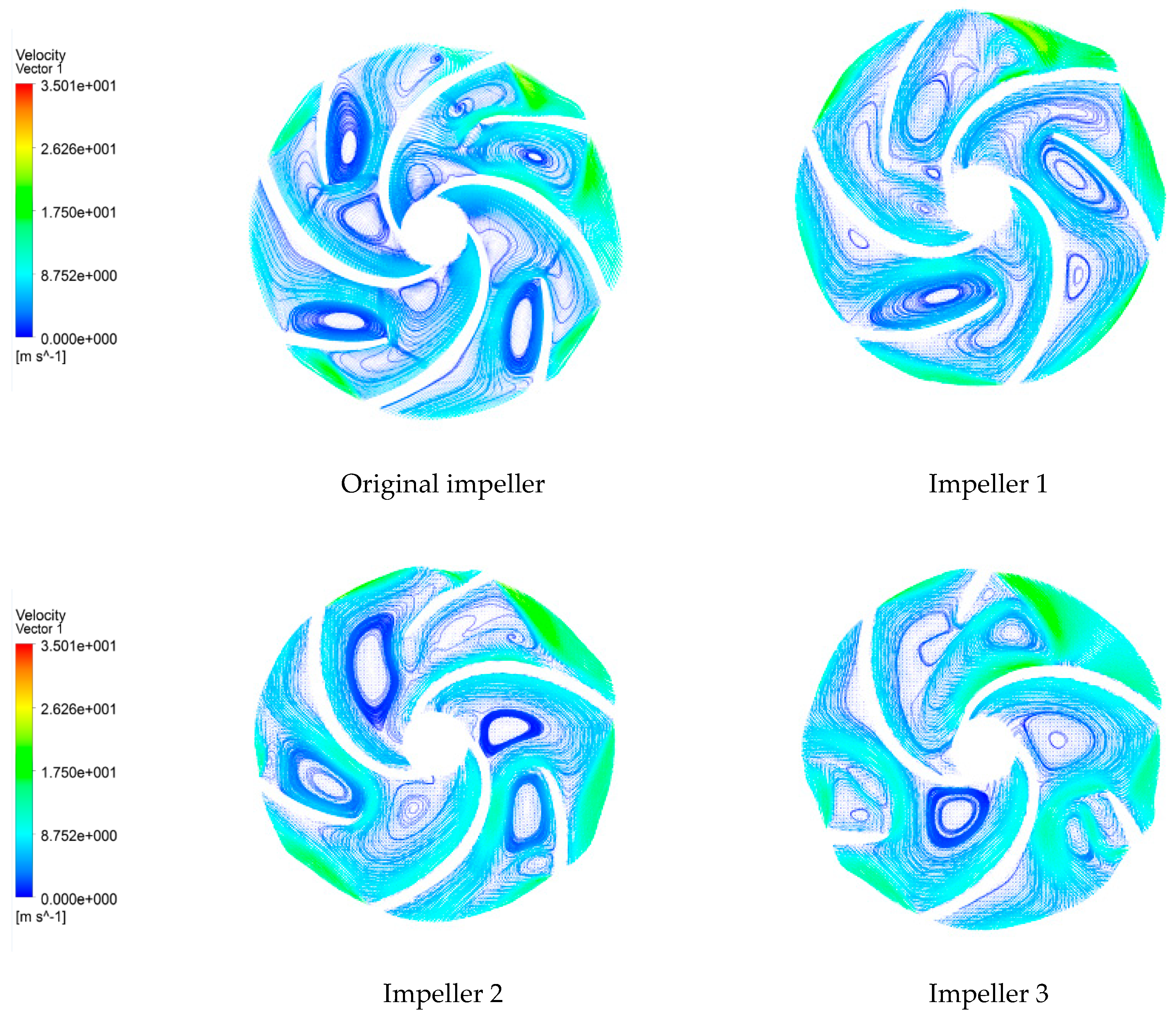

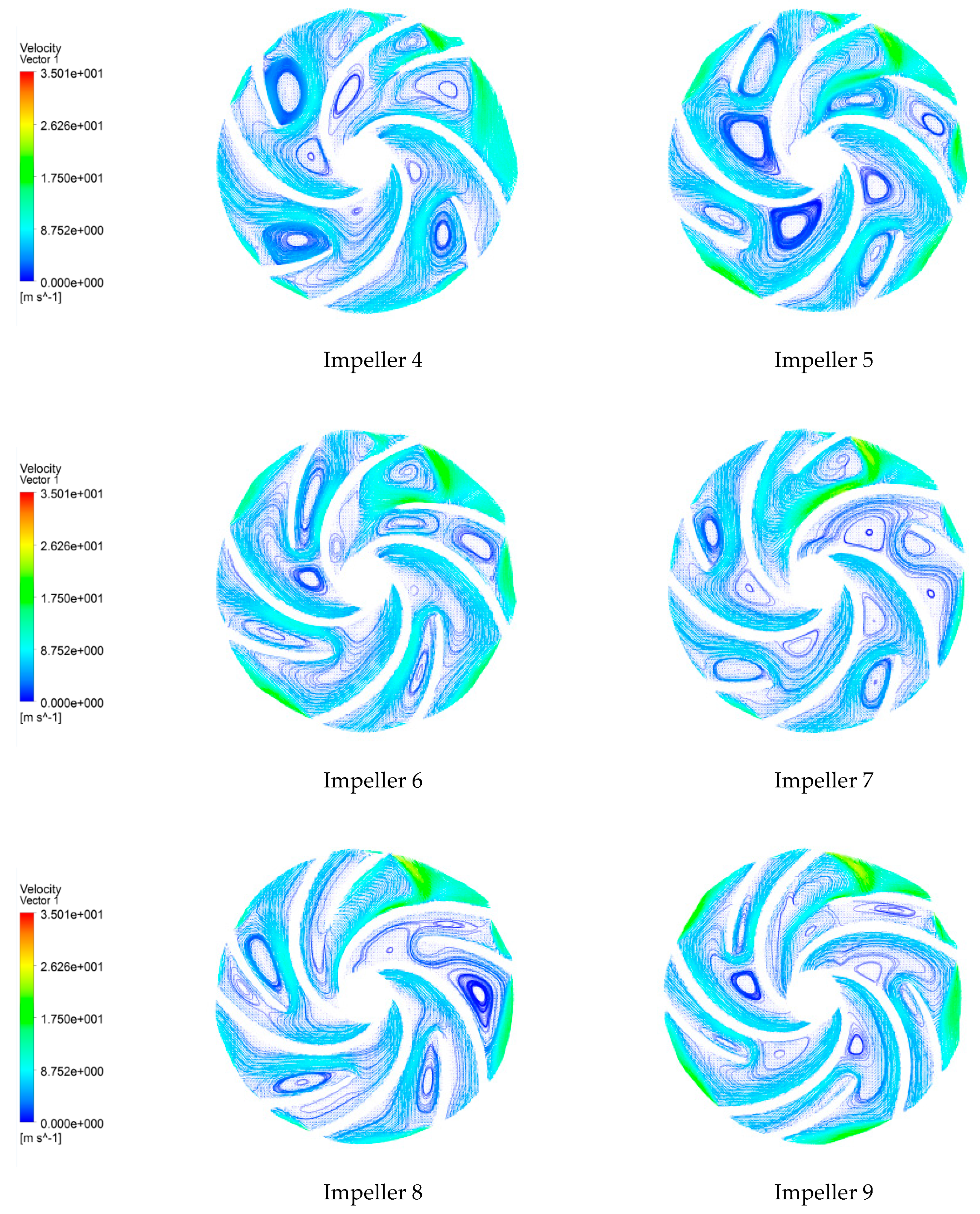

Figure 12 is the water body model of the impeller of Scheme 10, and

Figure 13 is its inner flow cloud diagram. It could be seen that the inner vortex of the impeller of Scheme 10 is less and the streamline is more stable than that of Scheme 7 (shown in

Figure 9).

Comparisons of impeller performance between Scheme 7 (

Z = 5,

θs = 0.4

θ,

Dsi = 0.75

D2,

α = 0°) and Scheme 10 (

Z = 5,

θs = 0.4

θ,

Dsi = 0.55

D2,

α = 0°) is shown in

Figure 14. The head of Scheme 10 is 77.12 m, which is lower than that of Scheme 7 (80.07 m). The efficiency of Scheme 10 is 45.59%, which is higher than that of Scheme 7 (44.15%). Scheme 7 increases the head and efficiency by 2.68% and 4.82%, respectively. Scheme 10 reduces the head by 0.33% and increases the efficiency by 8.24%. The data shows that the decrease of inlet diameter of splitter blades improves the flow condition inside the impeller, reduces the energy loss, and improves the efficiency.

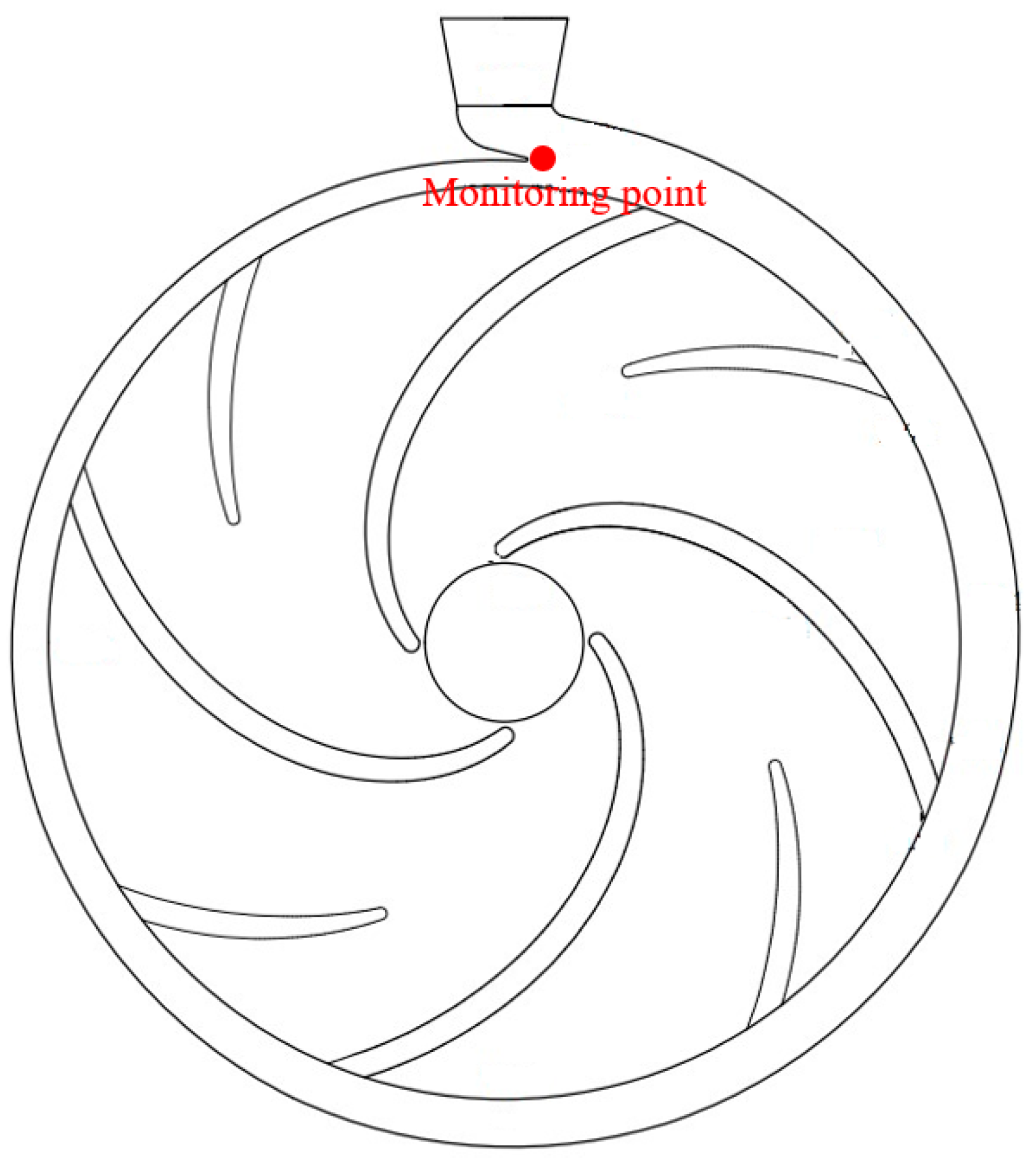

3.4. Analysis of Pressure Fluctuation

Pressure fluctuation is the main factor affecting the stable operation of the pump. The transient numerical calculation of the whole flow field of the magnetic drive pump was carried out. A pressure fluctuation monitoring point was set at the volute tongue. The location of the monitoring point is shown in

Figure 15. The steady calculation results were taken as the initial condition of transient calculation. Because the rated speed of the impeller is 2900 r/min, considering the economy of calculation, the final time step was 1.7241 × 10

−4 s, namely, the impeller rotated 3° per time step.

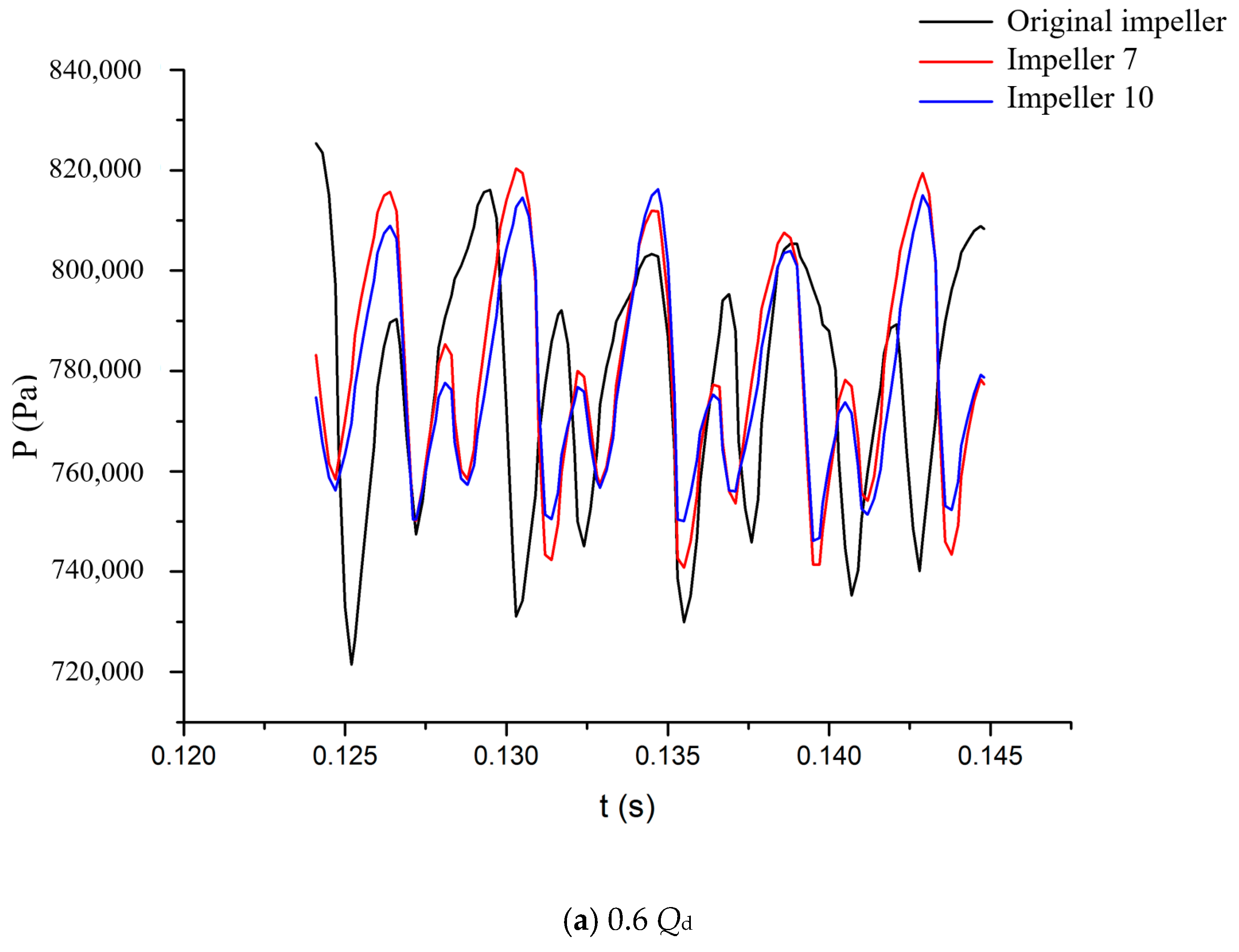

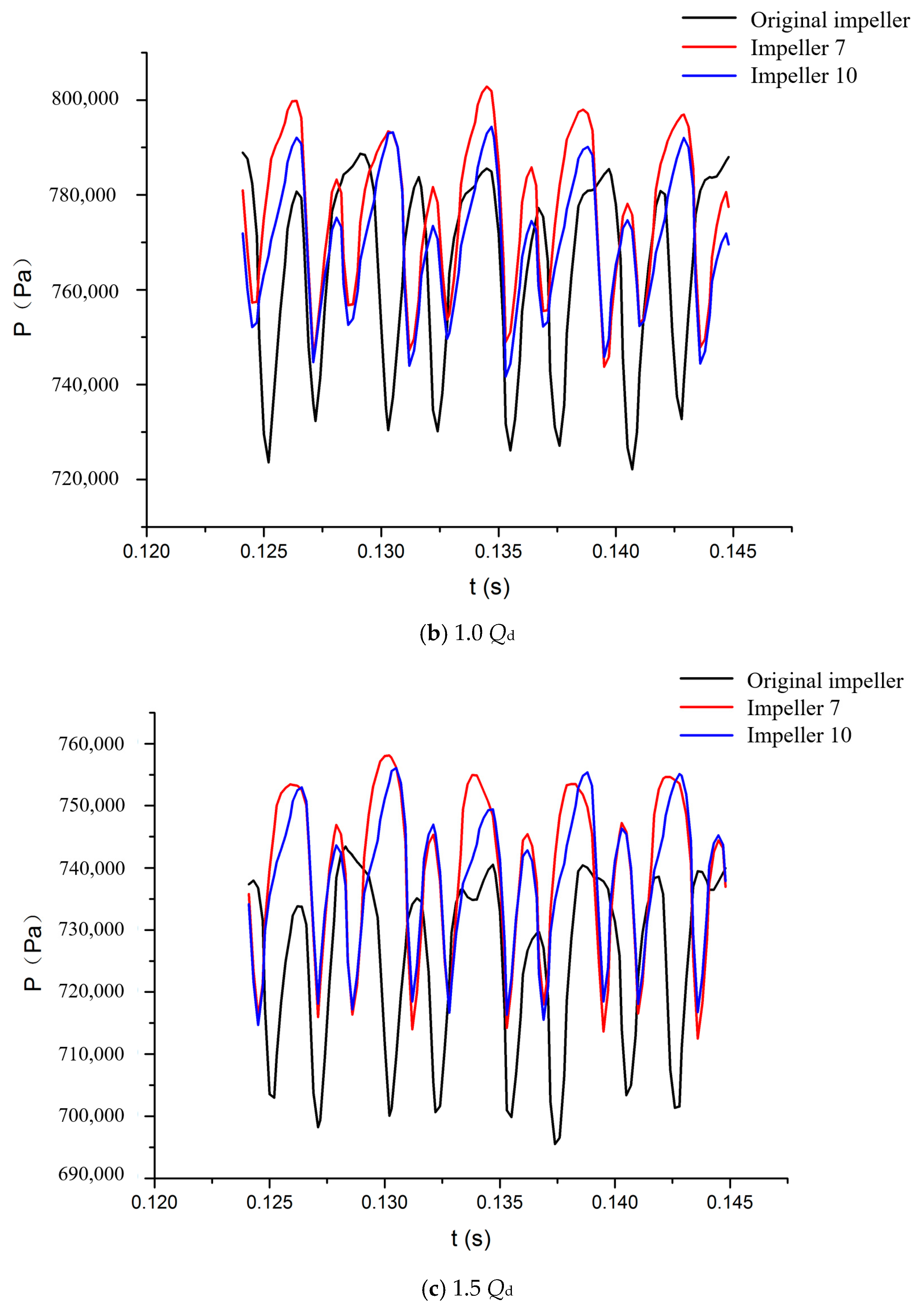

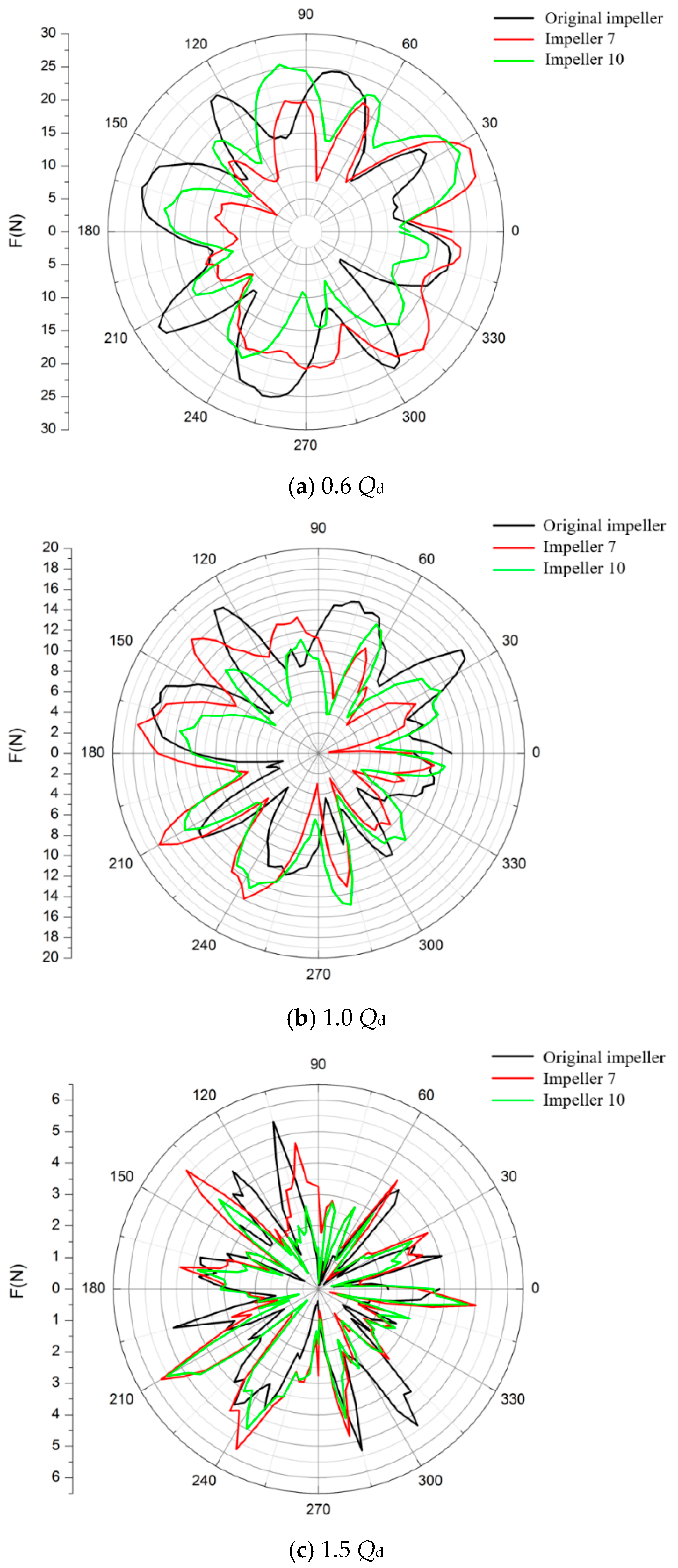

The pressure fluctuation of the original impeller, impeller 7, and impeller 10 at different flow rate conditions (0.6

Qd, 1.0

Qd and 1.5

Qd) in one period is presented in

Figure 16. It can be seen from

Figure 16 that the instantaneous low pressure appears in the original impeller, and the pressure fluctuation of the original impeller is the most disordered. The peak-to-peak values of pressure fluctuation of impellers 7 and 10 are smaller than those of the original impeller.

At small flow rate condition (0.6 Qd), the pressure fluctuation amplitudes of the three impellers are close. The pressure fluctuation of impellers 7 and 10 are more stable than those of the original impeller at design and large flow rate conditions, and the average pressure values of impellers 7 and 10 are higher than those of the original impeller. The pressures of impellers 7 and 10 are higher than those of the original impeller, which bring higher heads to the magnetic drive pump.

Comparing the pressure fluctuation of impellers 7 and 10 further, the peak-to-peak value of impeller 10 is slightly smaller than that of impeller 7 at small flow rate condition (0.6 Qd), and the pressure fluctuation performance of impeller 10 is more stable. At design flow rate condition (1.0 Qd), the average pressure amplitude of impeller 10 is slightly smaller than that of impeller 7, which is consistent with the conclusion of the higher head of impeller 7 mentioned above. At large flow rate condition (1.5 Qd), the pressure fluctuation of impeller 7 is the most consistent with that of impeller 10, and the fluctuation amplitude, maximum peak value, and minimum peak value are close to each other.