Assessment of a Universal Reconfiguration-less Control Approach in Open-Phase Fault Operation for Multiphase Drives

Abstract

1. Introduction

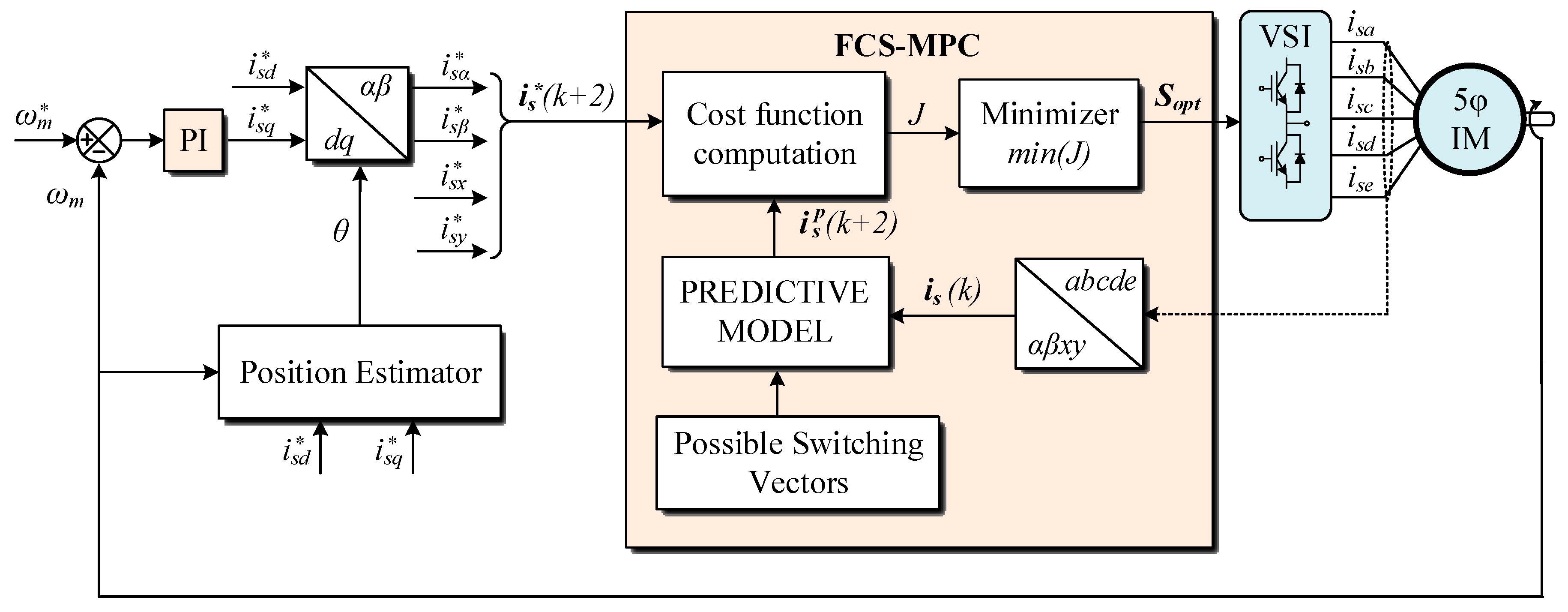

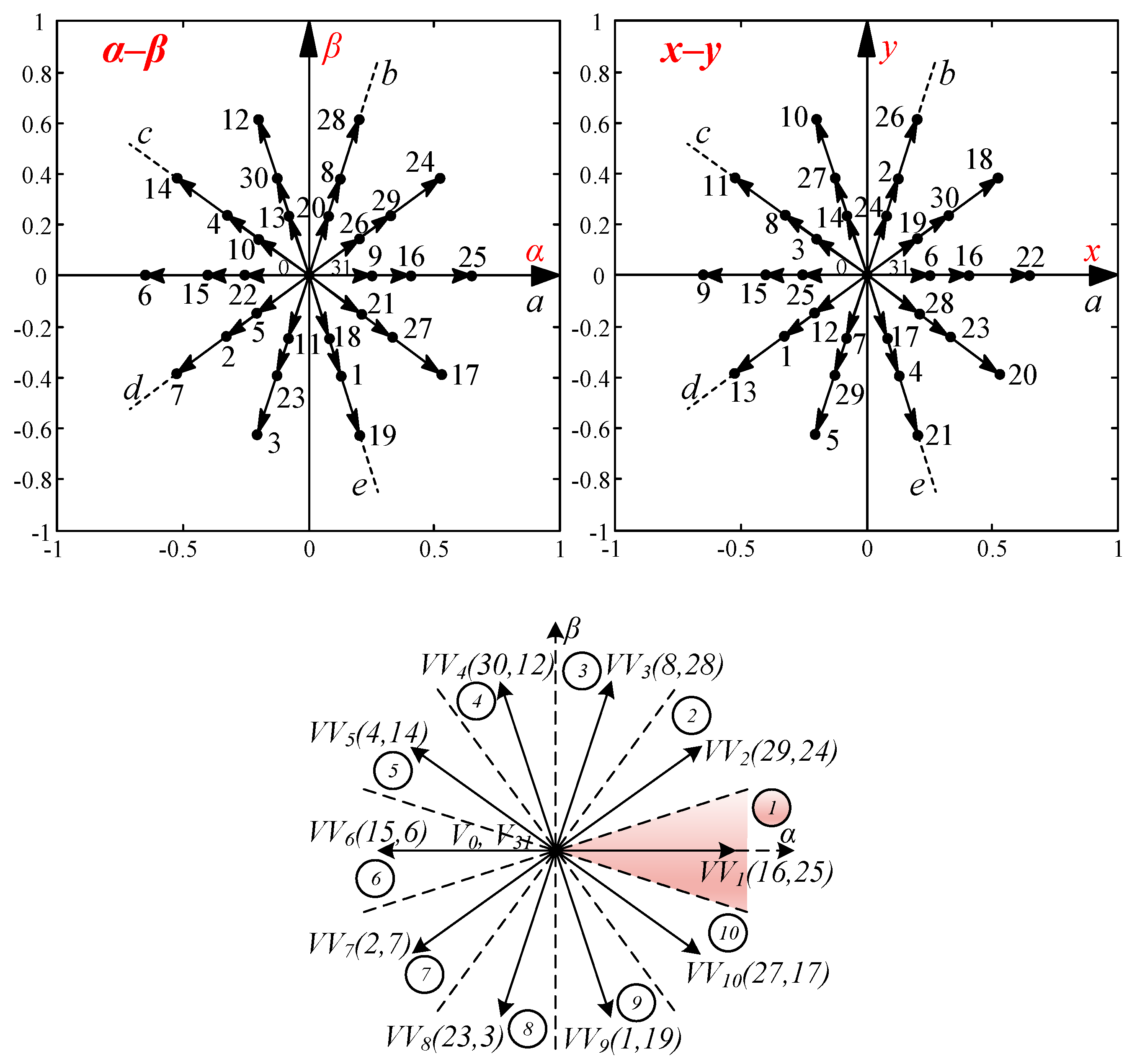

2. Basis of Natural Fault-Tolerant Controllers Using MPC

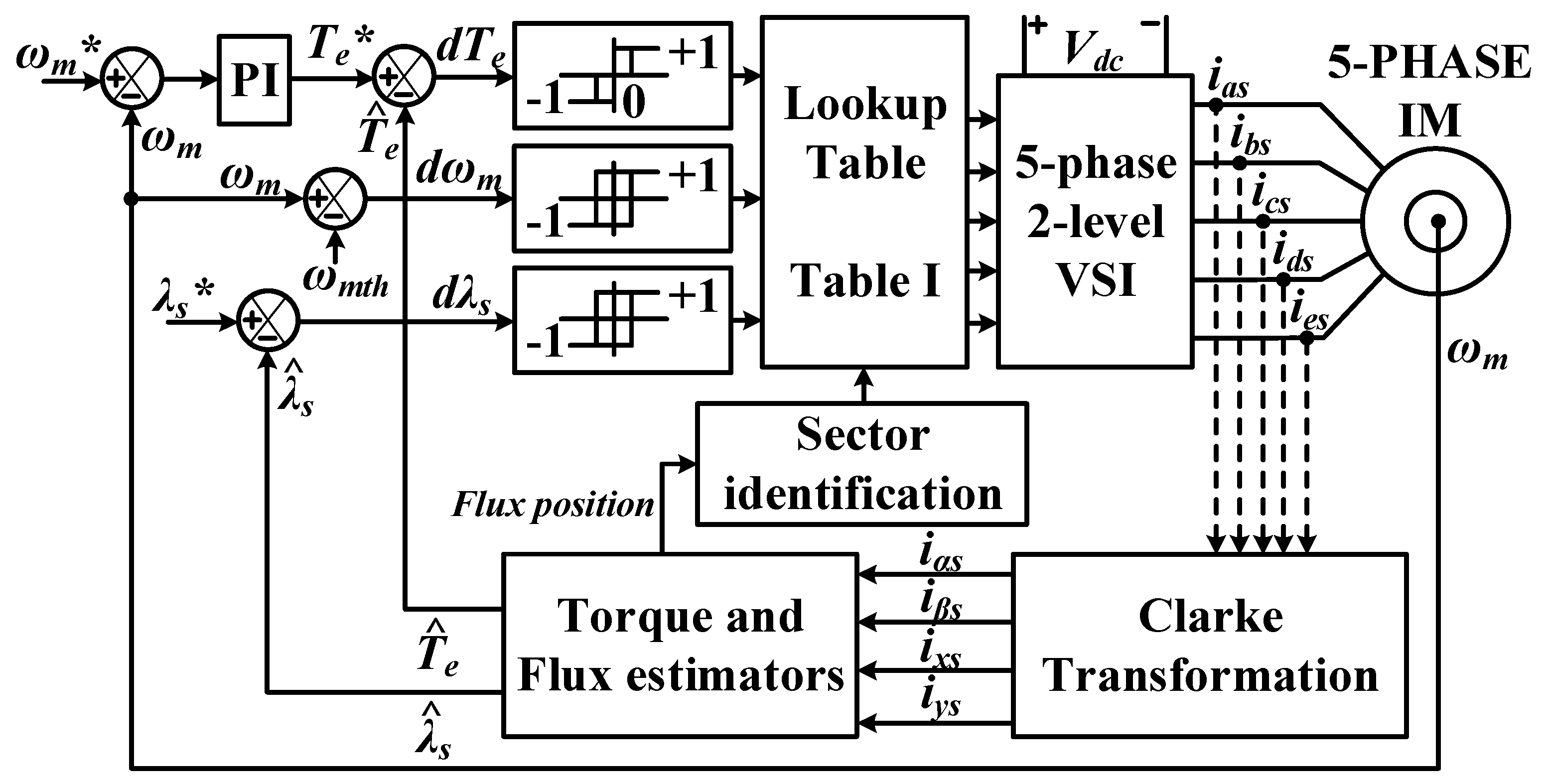

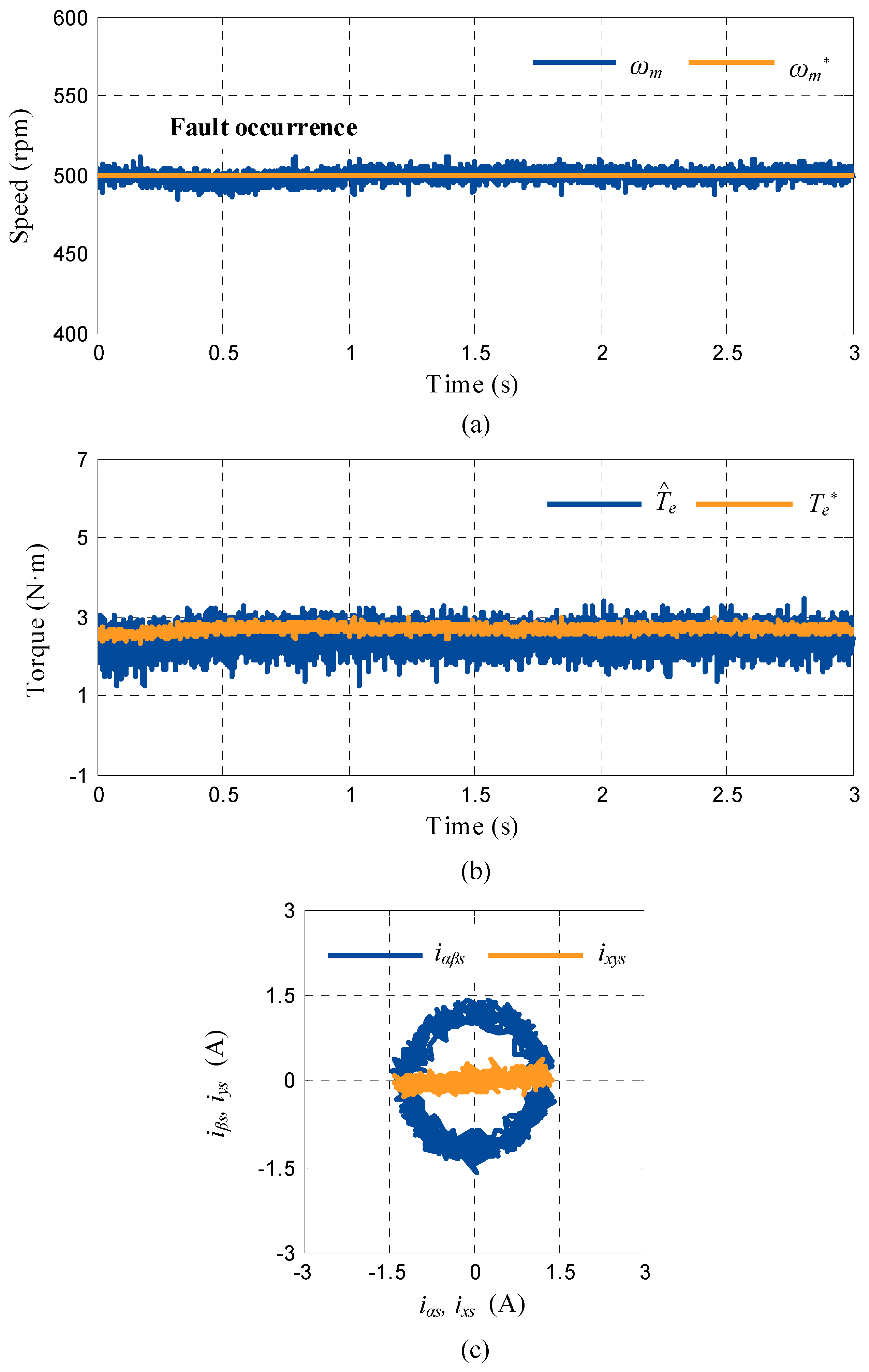

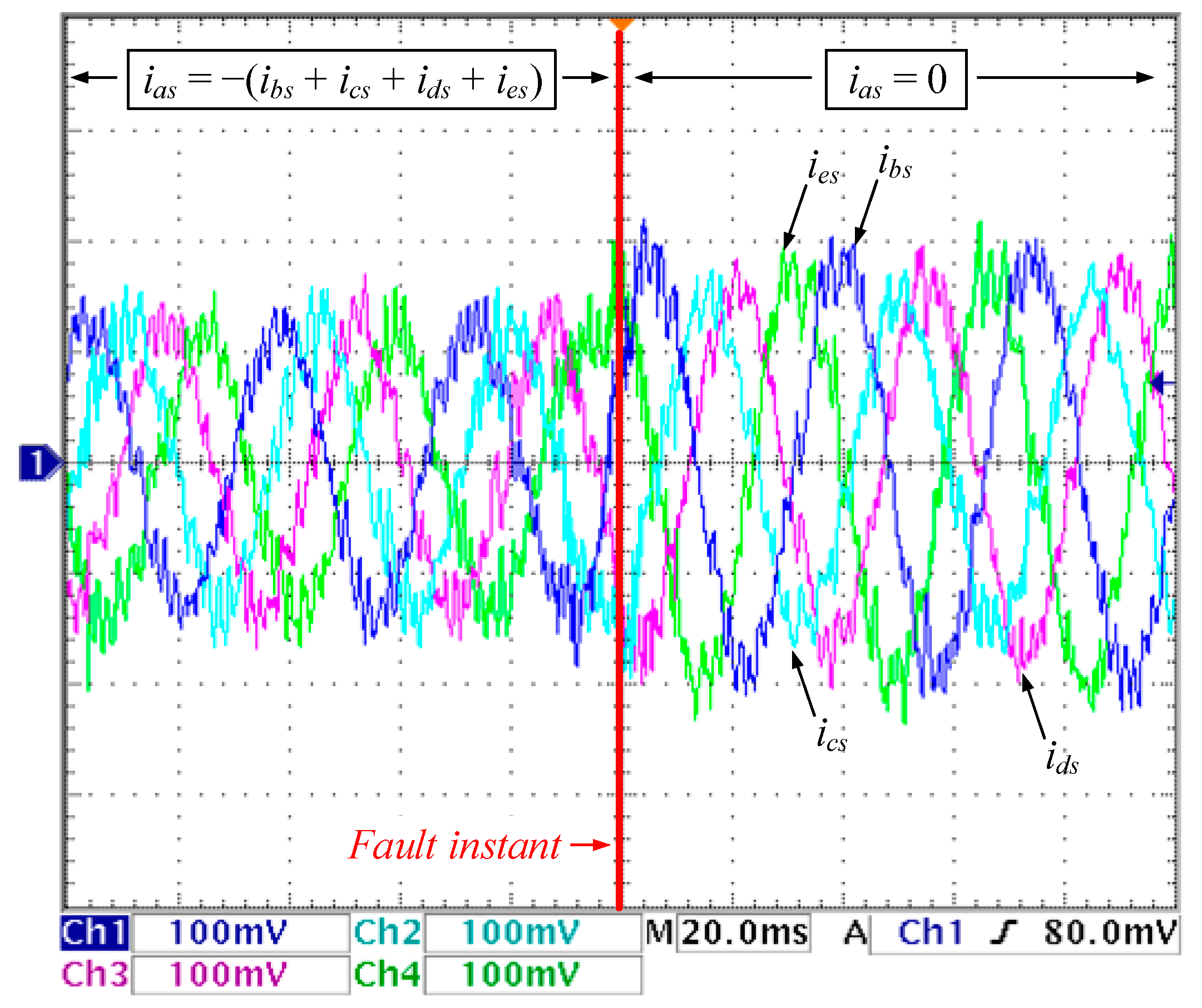

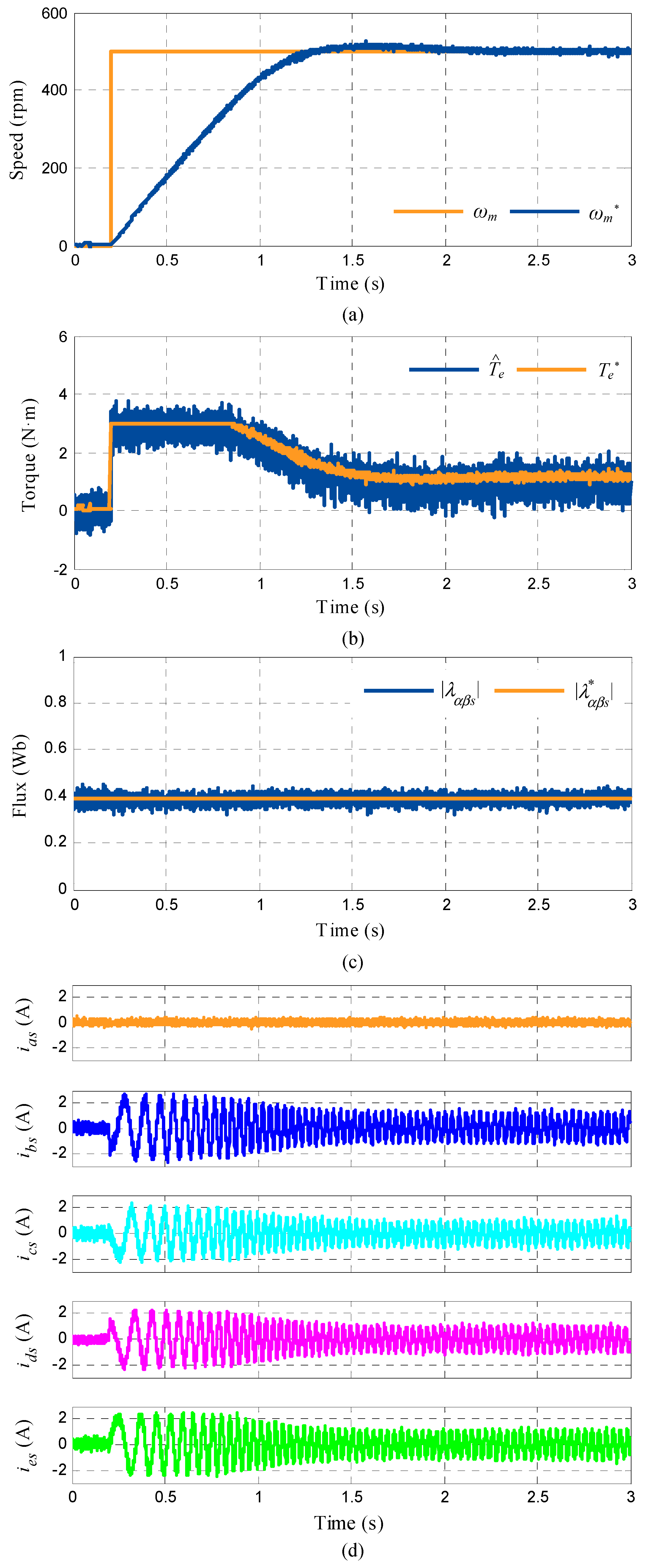

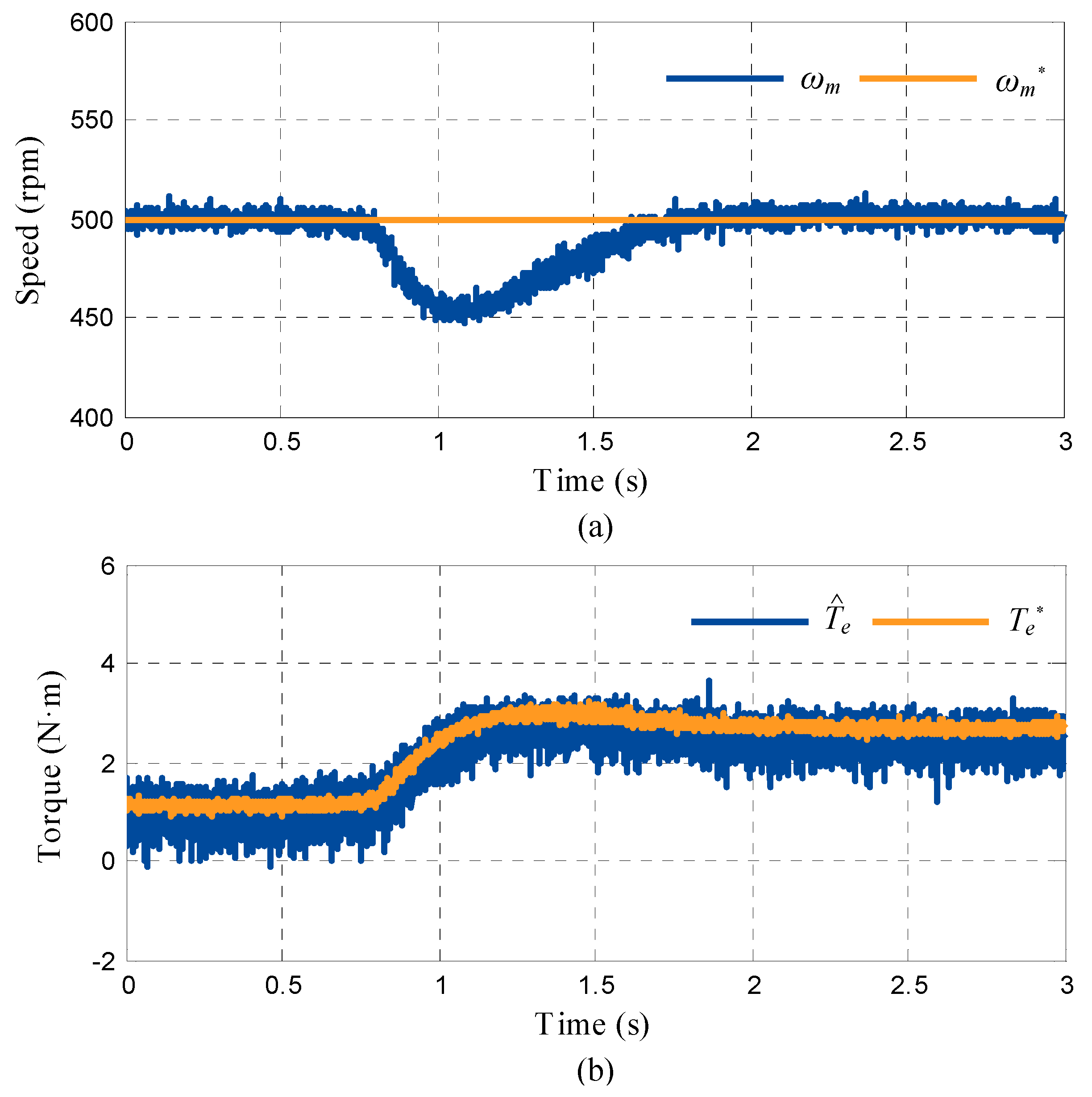

3. Extension of the Reconfiguration-less Approach to the DTC Case

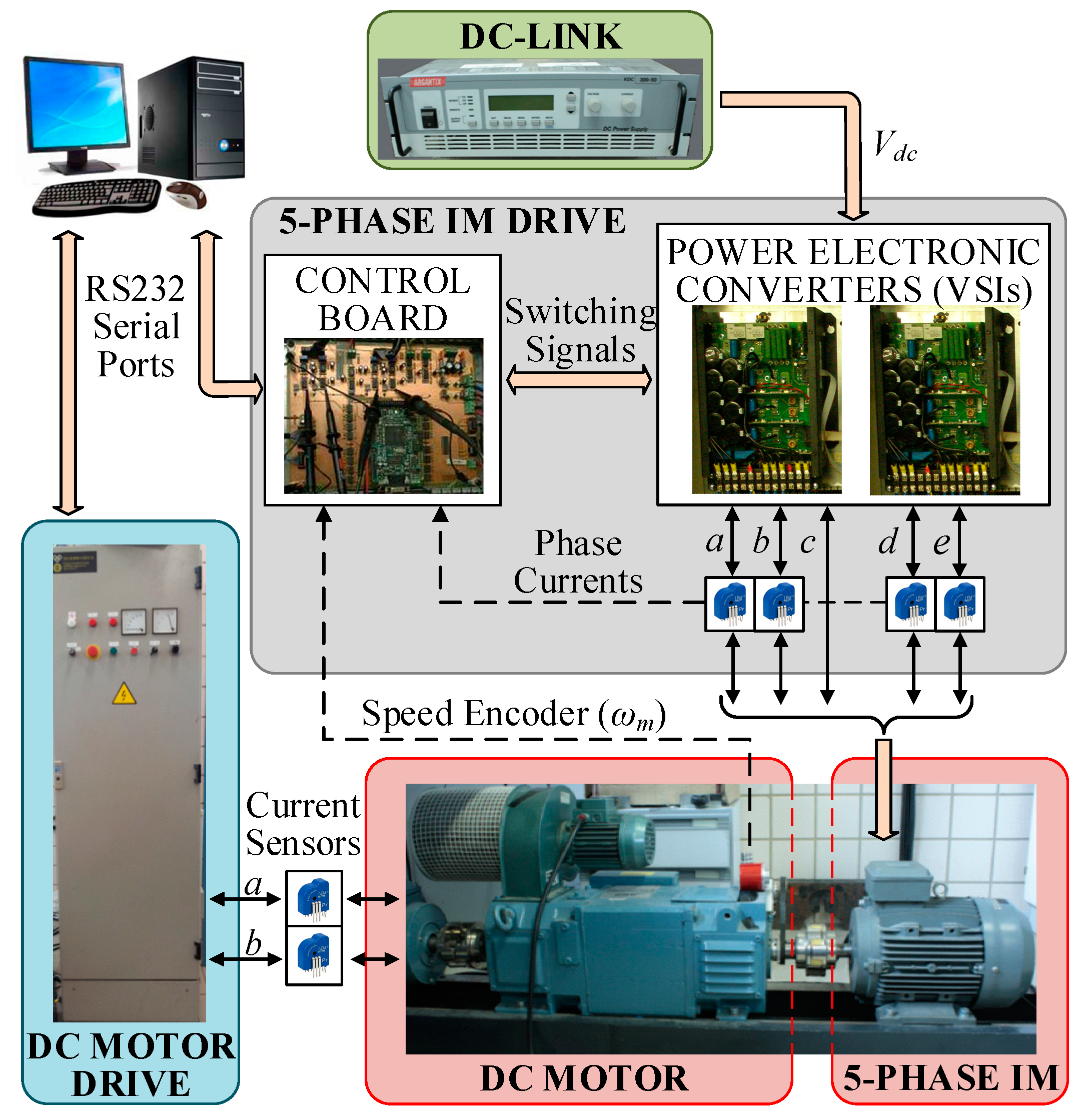

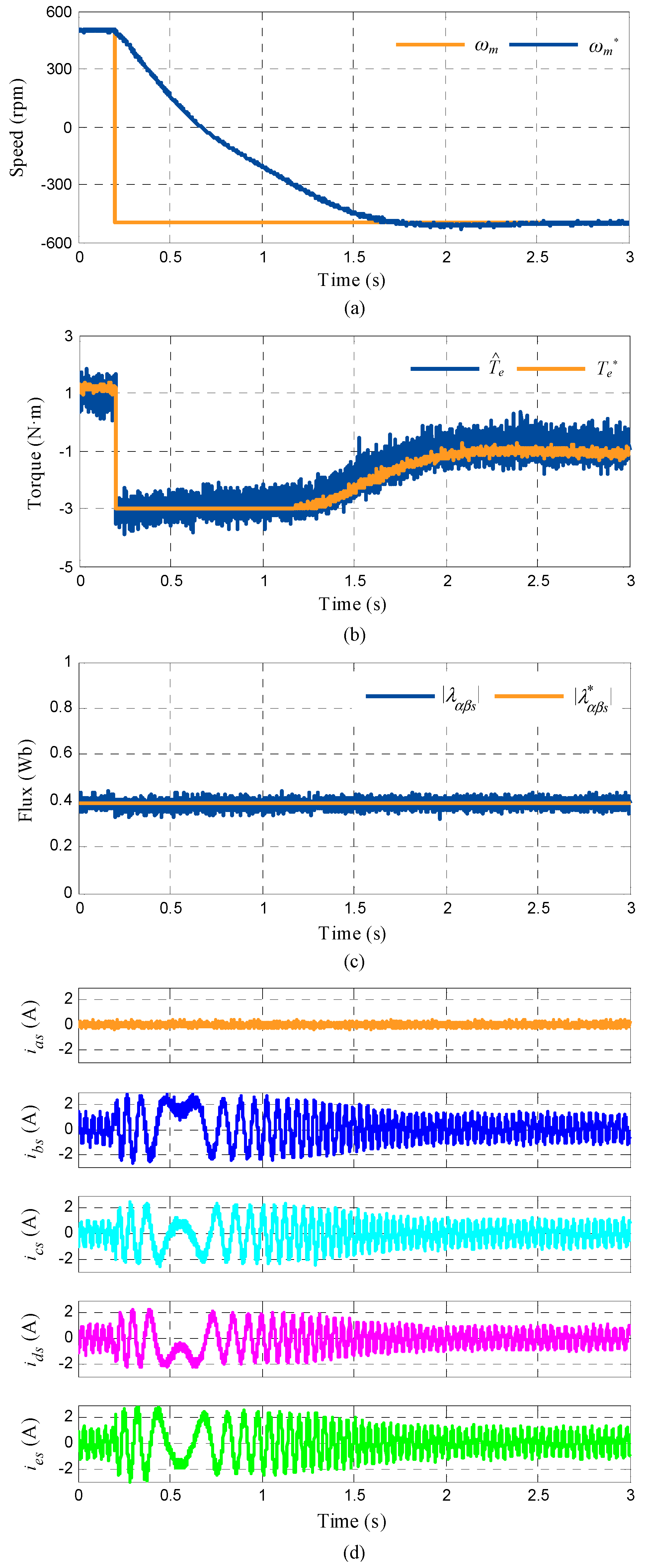

4. Experimental Work

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Levi, E.; Barrero, F.; Duran, M.J. Multiphase Machines and Drives-Revisited. IEEE Trans. Ind. Electron. 2016, 63, 429–432. [Google Scholar] [CrossRef]

- Duran, M.J.; Levi, E.; Barrero, F. Multiphase Electric Drives: Introduction. In Wiley Encyclopedia of Electrical and Electronics Engineering; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Mohammadpour, A.; Parsa, L. A Unified Fault-Tolerant Current Control Approach for Five-Phase PM Motors with Trapezoidal Back EMF under Different Stator Winding Connections. IEEE Trans. Power Electron. 2013, 28, 3517–3527. [Google Scholar] [CrossRef]

- Mohammadpour, A.; Sadeghi, S.; Parsa, L. A Generalized Fault-Tolerant Control Strategy for Five-Phase PM Motor Drives Considering Star, Pentagon, and Pentacle Connections of Stator Windings. IEEE Trans. Ind. Electron. 2014, 61, 63–75. [Google Scholar] [CrossRef]

- Duran, M.J.; Barrero, F. Recent Advances in the Design, Modeling and Control of Multiphase Machines-Part 2. IEEE Trans. Ind. Electron. 2016, 63, 459–468. [Google Scholar] [CrossRef]

- Sadeghi, S.; Guo, L.; Toliyat, H.A.; Parsa, L. Wide Operational Speed Range of Five-Phase Permanent Magnet Machines by Using Different Stator Winding Configurations. IEEE Trans. Ind. Electron. 2012, 59, 2621–2631. [Google Scholar] [CrossRef]

- Mercorelli, P.; Kubasiak, N.; Liu, S. Multilevel Bridge Governor by using Model Predictive Control in Wavelet Packets for Tracking Trajectories. In Proceedings of the IEEE International Conference on Robotics and Automation, New Orleans, LA, USA, 26 April–1 May 2004; Volume 4, pp. 4079–4084. [Google Scholar]

- Barrero, F.; Duran, M.J. Recent Advances in the Design, Modeling and Control of Multiphase Machines-Part 1. IEEE Trans. Ind. Electron. 2016, 63, 449–458. [Google Scholar] [CrossRef]

- Barcaro, M.; Bianchi, N.; Magnussen, F. Faulty Operations of a PM Fractional-Slot Machine with a Dual Three-Phase Winding. IEEE Trans. Ind. Electron. 2011, 58, 3825–3832. [Google Scholar] [CrossRef]

- Nguyen, N.K.; Meinguet, F.; Semail, E.; Kestelyn, X. Fault-Tolerant Operation of an Open-End Winding Five-Phase PMSM Drive with Short-Circuit Inverter Fault. IEEE Trans. Ind. Electron. 2016, 63, 595–605. [Google Scholar] [CrossRef]

- Zarri, L.; Mengoni, M.; Gritli, Y.; Tani, A.; Filippetti, F.; Serra, G.; Casadei, D. Detection and Localization of Stator Resistance Dissymmetry Based on Multiple Reference Frame Controllers in Multiphase Induction Motor Drives. IEEE Trans. Ind. Electron. 2013, 60, 3506–3518. [Google Scholar] [CrossRef]

- Abdel-Khalik, A.S.; Masoud, M.I.; Ahmed, S.; Massoud, A. Calculation of Derating Factors based on Steady-State Unbalanced Multiphase Induction Machine Model under Open Phase(s) and Optimal Winding Currents. Electr. Power Syst. Res. 2014, 106, 214–225. [Google Scholar] [CrossRef]

- Guzman, H.; Barrero, F.; Duran, M.J. IGBT-Gating Failure Effect on a Fault-Tolerant Predictive Current-Controlled Five-Phase Induction Motor Drive. IEEE Trans. Ind. Electron. 2015, 62, 15–20. [Google Scholar] [CrossRef]

- Dwari, S.; Parsa, L. An Optimal Control Technique for Multiphase PM Machines under Open-Circuit Faults. IEEE Trans. Ind. Electron. 2008, 55, 1988–1995. [Google Scholar] [CrossRef]

- Gonzalez-Prieto, I.; Duran, M.J.; Aciego, J.J.; Martin, C.; Barrero, F. Model Predictive Control of Six-Phase Induction Motor Drives using Virtual Voltage Vectors. IEEE Trans. Ind. Electron. 2018, 65, 27–37. [Google Scholar] [CrossRef]

- Gonzalez-Prieto, I.; Duran, M.J.; Bermúdez, M.; Barrero, F.; Martín, C. Assessment of Virtual-Voltage-based Model Predictive Controllers in Six-phase Drives under Open-Phase Faults. IEEE J. Emerg. Sel. Top. Power Electron. 2019, 1. [Google Scholar] [CrossRef]

- Jahns, T.M. Improved Reliability in Solid-State AC Drives by means of Multiple Independent Phase Drive Units. IEEE Trans. Ind. Appl. 1980, 16, 321–331. [Google Scholar] [CrossRef]

- Yousefi-Talouki, A.; Gholamian, S.A.; Yousefi-Talouki, M.; Ilka, R.; Radan, A. Harmonic Elimination in Switching Table-based Direct Torque Control of Five-Phase PMSM using Matrix Converter. IEEE Symp. Humanit. Sci. Eng. Res. Kuala Lumpur 2012, 777–782. [Google Scholar]

- Zheng, L.; Fletcher, J.E.; Williams, B.W.; He, X. A Novel Direct Torque Control Scheme for a Sensorless Five-Phase Induction Motor Drive. IEEE Trans. Ind. Electron. 2011, 58, 503–513. [Google Scholar] [CrossRef]

- Gao, L.; Fletcher, J.E.; Zheng, L. Low speed control improvements for a 2-level 5-phase inverter-fed induction machine using classic direct torque control. IEEE Trans. Ind. Electron. 2011, 58, 2744–2754. [Google Scholar] [CrossRef]

- Bermudez, M.; Gonzalez-Prieto, I.; Barrero, F.; Guzman, H.; Duran, M.J.; Kestelyn, X. Open-phase fault-tolerant direct torque control technique for five-phase induction motor drives. IEEE Trans. Ind. Electron. 2016, 64, 902–911. [Google Scholar] [CrossRef]

- Riveros, J.A.; Barrero, F.; Levi, E.; Duran, M.; Toral, S.; Jones, M. Variable-speed five-phase induction motor drive based on predictive torque control. IEEE Trans. Ind. Electron. 2013, 60, 2957–2968. [Google Scholar] [CrossRef]

- Fu, J.R.; Lipo, T.A. Disturbance-free operation of a multiphase current-regulated motor drive with an opened phase. IEEE Trans. Ind. Appl. 1994, 30, 1267–1274. [Google Scholar]

| Position of Stator Flux (Sector) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |||

| +1 | +1 | +1 | VV3 | VV4 | VV5 | VV6 | VV7 | VV8 | VV9 | VV10 | VV1 | VV2 |

| −1 | VV2 | VV3 | VV4 | VV5 | VV6 | VV7 | VV8 | VV9 | VV10 | VV1 | ||

| −1 | +1 | VV9 | VV10 | VV1 | VV2 | VV3 | VV4 | VV5 | VV6 | VV7 | VV8 | |

| −1 | VV10 | VV1 | VV2 | VV3 | VV4 | VV5 | VV6 | VV7 | VV8 | VV9 | ||

| 0 | +1 | V0 | V31 | V0 | V31 | V0 | V31 | V0 | V31 | V0 | V31 | |

| −1 | V0 | V31 | V0 | V31 | V0 | V31 | V0 | V31 | V0 | V31 | ||

| −1 | +1 | +1 | VV4 | VV5 | VV6 | VV7 | VV8 | VV9 | VV10 | VV1 | VV2 | VV3 |

| −1 | VV5 | VV6 | VV7 | VV8 | VV9 | VV10 | VV1 | VV2 | VV3 | VV4 | ||

| −1 | +1 | VV8 | VV9 | VV10 | VV1 | VV2 | VV3 | VV4 | VV5 | VV6 | VV7 | |

| −1 | VV7 | VV8 | VV9 | VV10 | VV1 | VV2 | VV3 | VV4 | VV5 | VV6 | ||

| 0 | +1 | V31 | V0 | V31 | V0 | V31 | V0 | V31 | V0 | V31 | V0 | |

| −1 | V31 | V0 | V31 | V0 | V31 | V0 | V31 | V0 | V31 | V0 | ||

| Parameter | Value | Unit |

|---|---|---|

| Stator resistance, Rs | 12.85 | Ω |

| Rotor resistance, Rr | 4.80 | Ω |

| Stator leakage inductance, Lls | 79.93 | mH |

| Rotor leakage inductance, Llr | 79.93 | mH |

| Mutual inductance, Lm | 681.7 | mH |

| Moment of inertia, J | 0.02 | kg·m2 |

| Number of pole pairs, p | 3 | - |

| Rated torque, Tn | 4.70 | N·m |

| Rated stator flux, λs* | 0.389 | Wb |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barrero, F.; Bermudez, M.; Duran, M.J.; Salas, P.; Gonzalez-Prieto, I. Assessment of a Universal Reconfiguration-less Control Approach in Open-Phase Fault Operation for Multiphase Drives. Energies 2019, 12, 4698. https://doi.org/10.3390/en12244698

Barrero F, Bermudez M, Duran MJ, Salas P, Gonzalez-Prieto I. Assessment of a Universal Reconfiguration-less Control Approach in Open-Phase Fault Operation for Multiphase Drives. Energies. 2019; 12(24):4698. https://doi.org/10.3390/en12244698

Chicago/Turabian StyleBarrero, Federico, Mario Bermudez, Mario J. Duran, Pedro Salas, and Ignacio Gonzalez-Prieto. 2019. "Assessment of a Universal Reconfiguration-less Control Approach in Open-Phase Fault Operation for Multiphase Drives" Energies 12, no. 24: 4698. https://doi.org/10.3390/en12244698

APA StyleBarrero, F., Bermudez, M., Duran, M. J., Salas, P., & Gonzalez-Prieto, I. (2019). Assessment of a Universal Reconfiguration-less Control Approach in Open-Phase Fault Operation for Multiphase Drives. Energies, 12(24), 4698. https://doi.org/10.3390/en12244698