Densification and Fuel Properties of Onion Husks

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Physicochemical Properties of the Raw Materials

2.2.2. Pressure Agglomeration Process

2.2.3. Combustion of Pellets

- —the actual compound content in the exhaust gas [%, mg·Nm−3];

- —content of the compound in the exhaust gas for the calculated concentration of oxygen [%, mg·Nm−3];

- —set oxygen content in the exhaust [%]; and

- —actual (obtained) oxygen content in the exhaust gas [%].

3. Results and Discussion

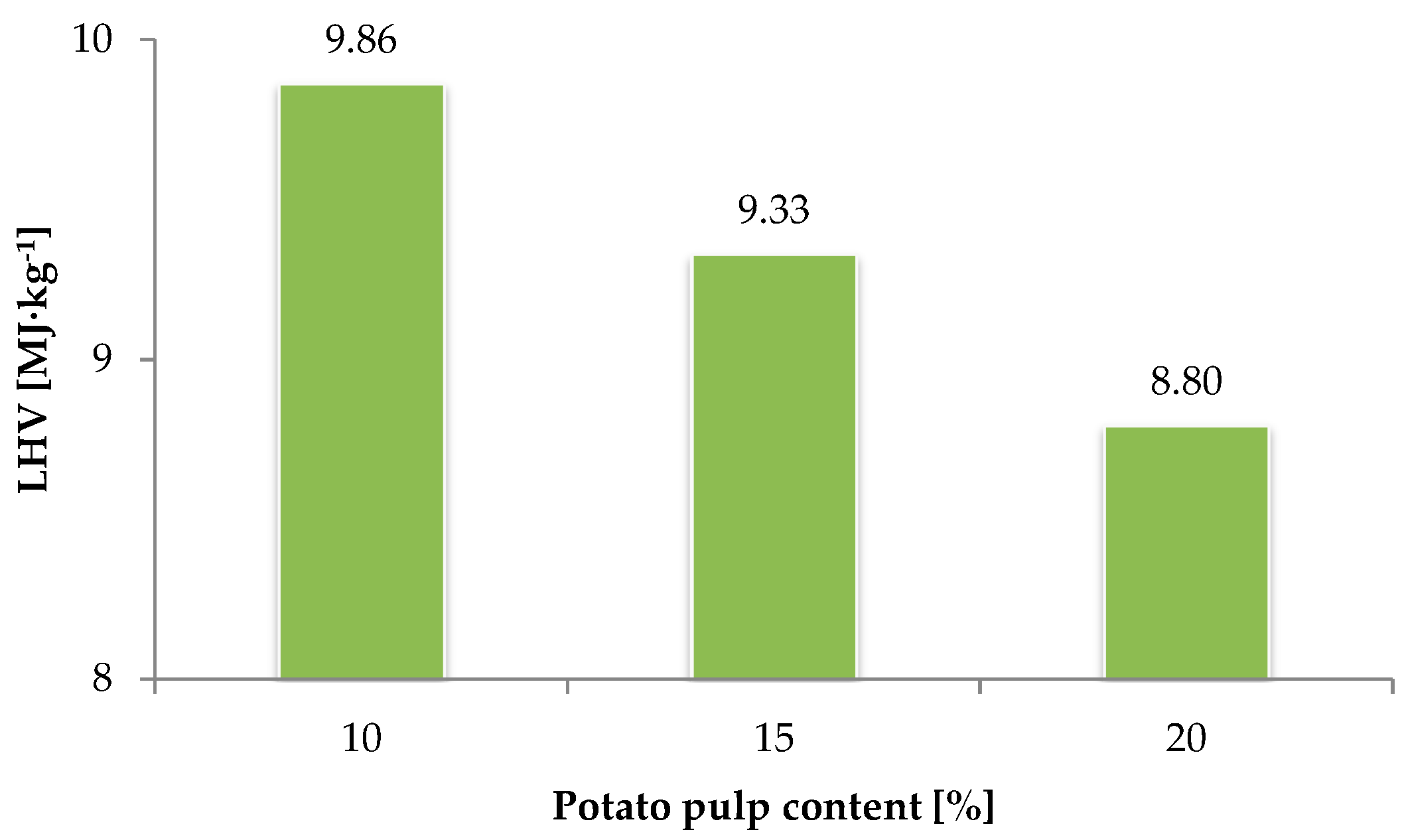

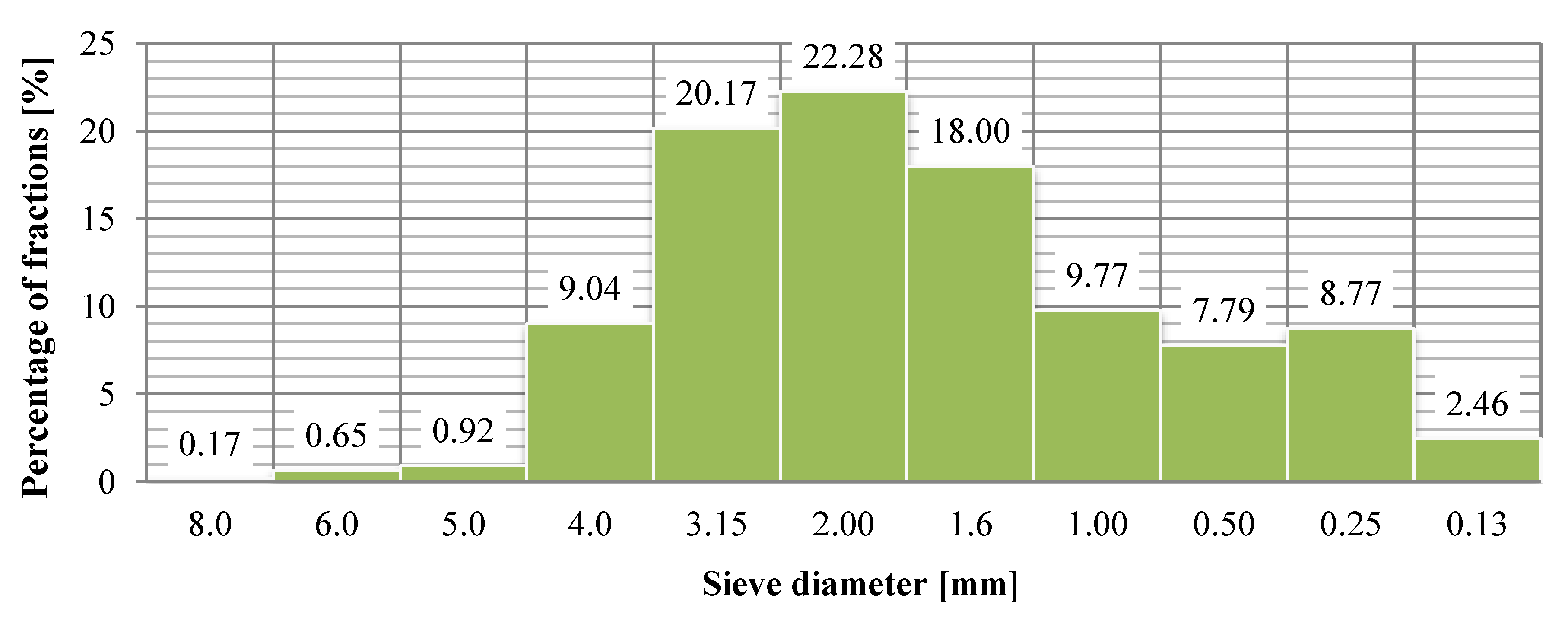

3.1. Physicochemical Properties of Raw Materials

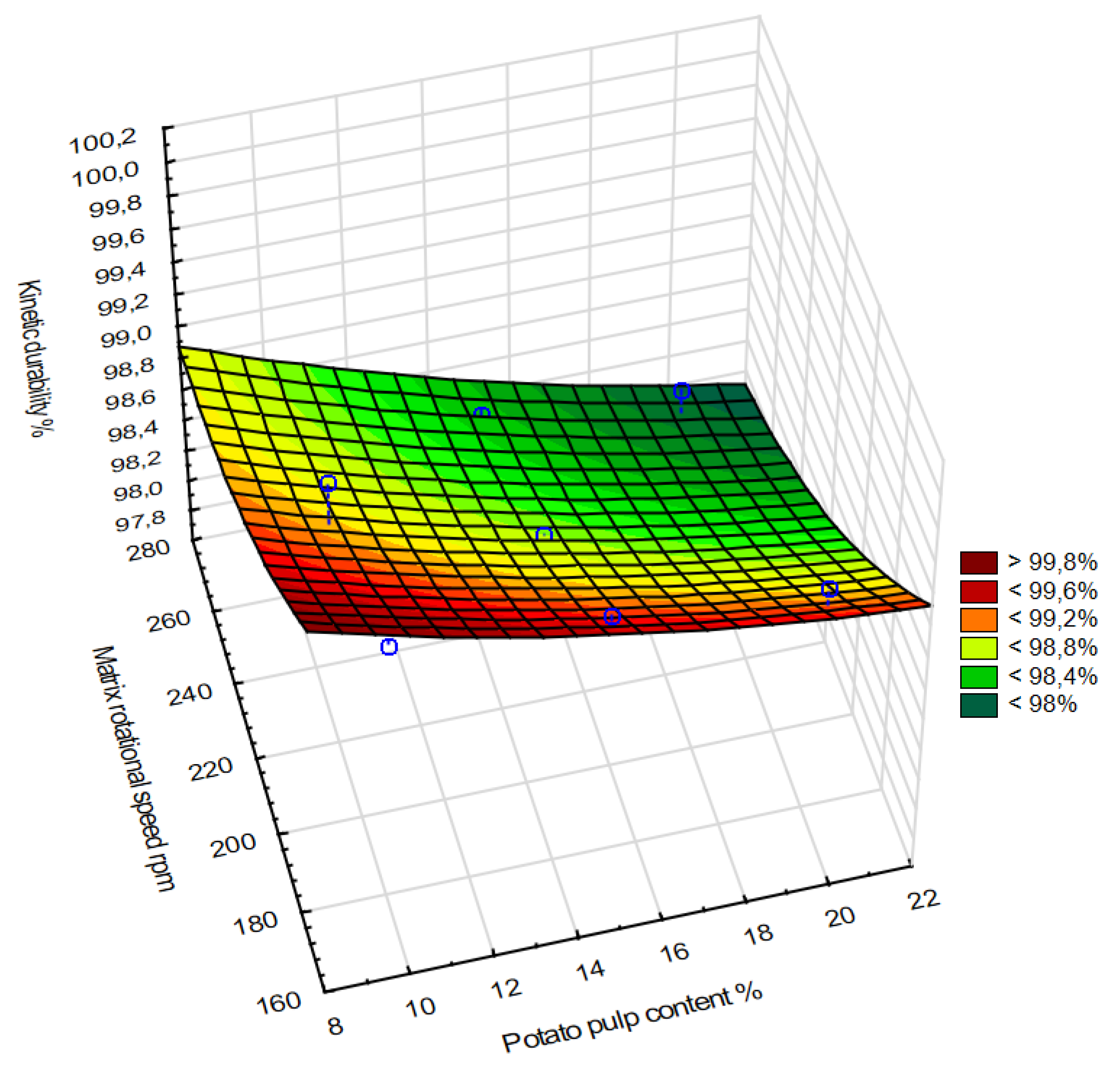

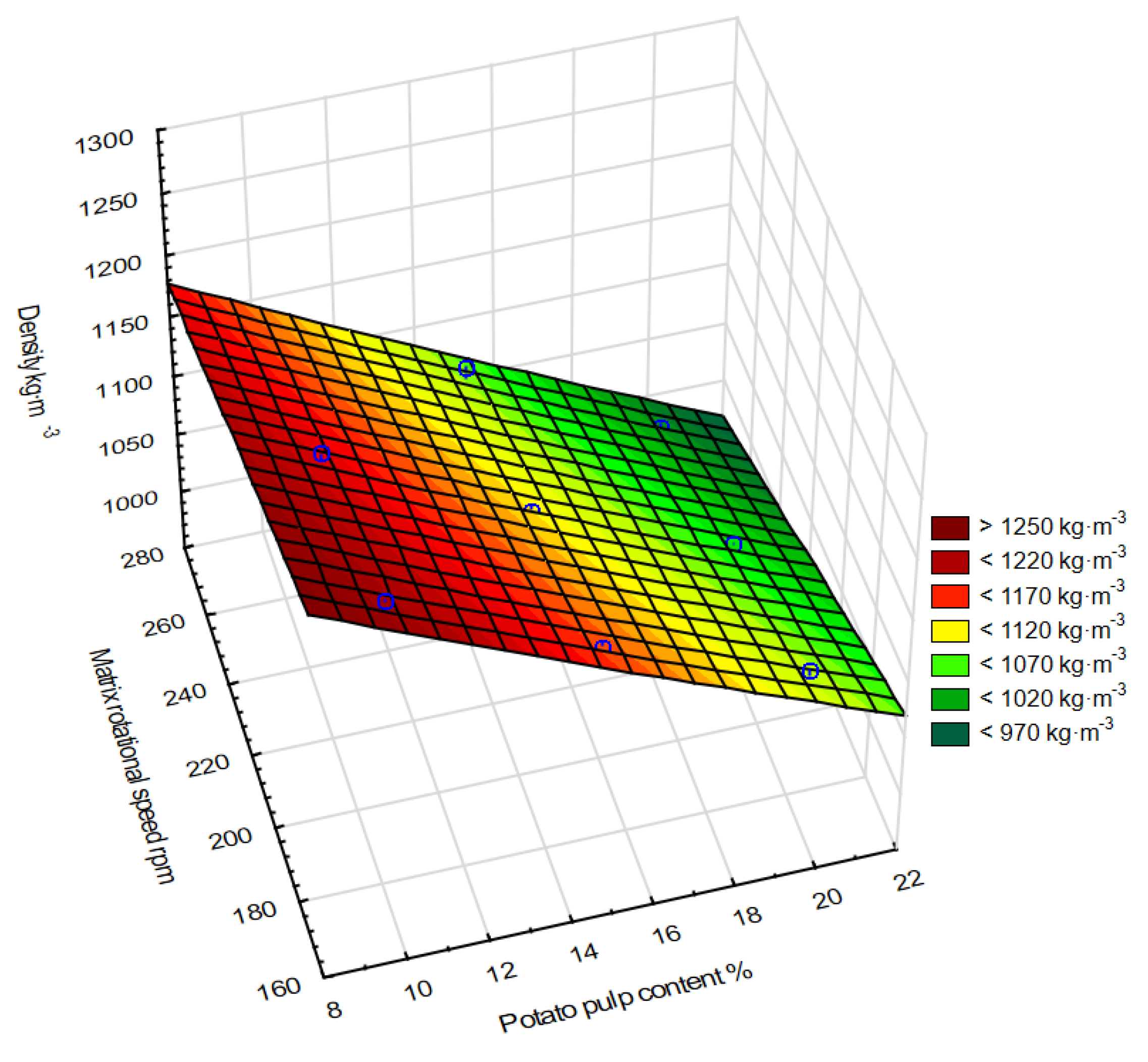

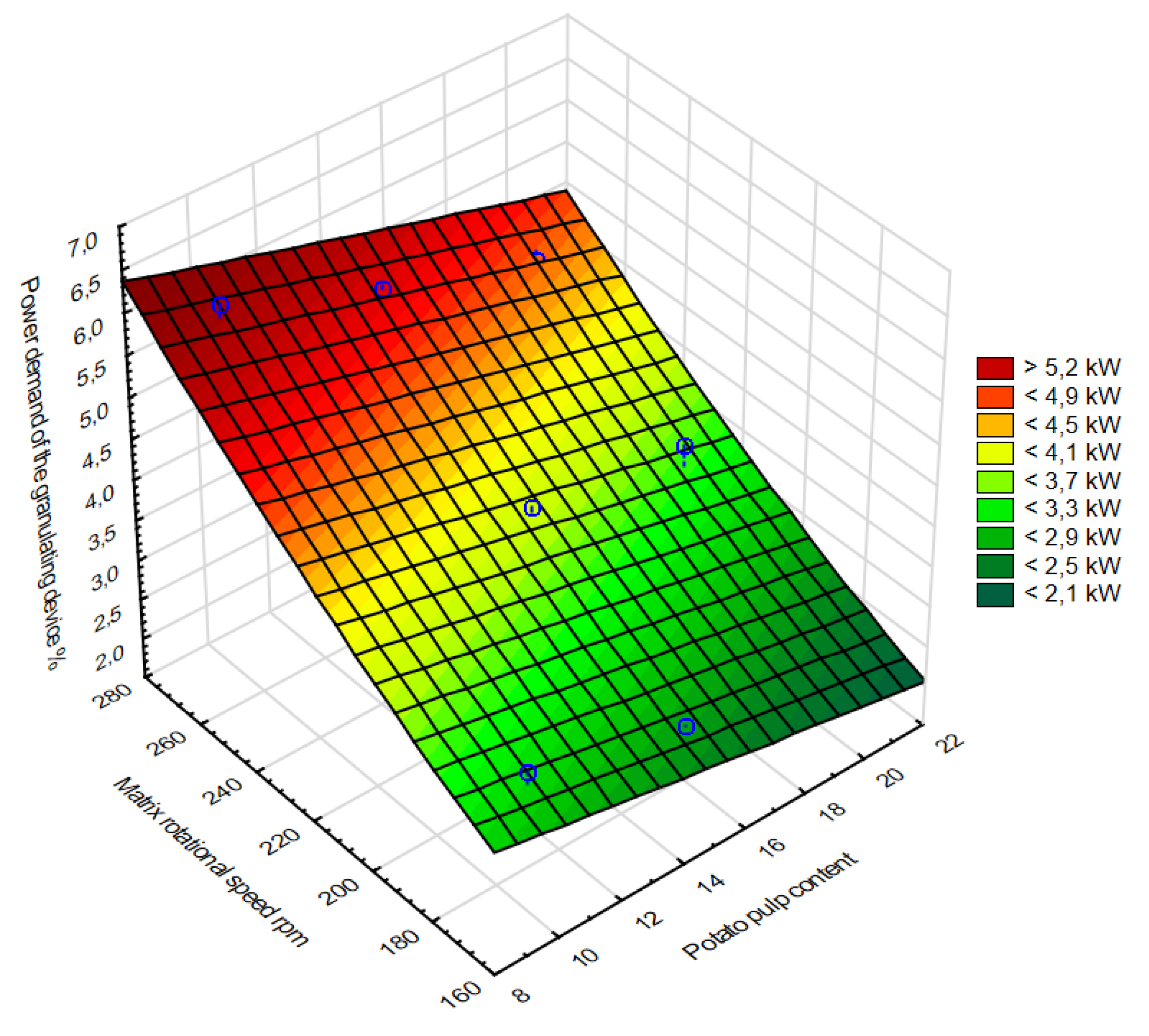

3.2. Pressure Agglomeration Process

3.3. Emissions

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Dołżyńska, M.; Obidziński, S.; Kowczyk-Sadowy, M.; Krasowska, M.; Karczewski, K.; Jóźwiak, D.; Buczyński, R. Pressure Agglomeration Process of Bakery Industry Waste. Proceedings 2019, 16, 37. [Google Scholar] [CrossRef]

- European Parliament and of the Council of 19 November 2008 on waste and repealing certain Directives, OJ L312/3-30 of 22.11.2008. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32008L0098 (accessed on 1 October 2019).

- Czekała, W.; Lewicki, A.; Pochwatka, P.; Czekała, A.; Wojcieszak, D.; Jozwiakowski, K.; Waliszewska, H. Digestate management in polish farms as an element of the nutrient cycle. J. Clean. Prod. 2020, 242, 118454. [Google Scholar] [CrossRef]

- Czekała, W. Agricultural Biogas Plants as a Chance for the Development of the Agri-Food Sector. J. Ecol. Eng. 2018, 19, 179–183. [Google Scholar] [CrossRef]

- Cengiz, N.Ü.; Yıldız, G.; Sert, M.; Gokkaya, D.S.; Saglam, M.; Yüksel, M.; Ballice, L. Hydrothermal gasification of a biodiesel by-product crude glycerol in the presence of phosphate based catalysts. Int. J. Hydrogen Energy 2015, 40, 14806–14815. [Google Scholar] [CrossRef]

- Galanakis, C.M. Recovery of high added-value components from food waste: Conventional, emerging technologies and commercialized applications. Trends Food Sci. Technol. 2012, 26, 68–87. [Google Scholar] [CrossRef]

- Laufenberg, G.; Kunz, B.; Nystroem, M. Transformation of vegetable waste into value added products: (A) the upgrading concept; (B) practical implementations. Bioresour. Technol. 2003, 87, 167–198. [Google Scholar] [CrossRef]

- Lin, C.S.K.; Pfaltzgraff, L.A.; Herro-Davilas, L.; Mubofu, E.B.; Abderrahim, S.; Clark, J.H.; Koutinas, A.A.; Kopsahelis, N.; Stamatelatou, K.; Dickson, F.; et al. Food waste as a valuable resource for the production of chemicals, materials and fuels. Current situation and global perspective. Energy Environ. Sci. 2013, 6, 426–464. [Google Scholar] [CrossRef]

- Polish Journal of Laws 2001 No. 62 item 628. Act of 27 April 2001 on waste. Available online: https://www.global-regulation.com/translation/poland/10093814/the-act-of-27-april-2001%252c-the-environmental-protection-law.html (accessed on 2 October 2019).

- Benitéz, V.; Molla, E.; Martin-Cabrejas, M.A.; Aguilera, Y.; Lopez-Andreu, F.J.; Cools, K.; Terry, L.A.; Esteban, R.M. Characterization of industrial onion wastes (Allium cepa L): Dietary fiber and bioactive compounds. Plant Foods Hum. Nutr. 2011, 66, 48–57. [Google Scholar] [CrossRef]

- Waldron, K.W. Useful ingredients from onion waste. Food Sci. Technol. 2001, 15, 38–41. [Google Scholar]

- Ly, T.; Hazama, C.; Shimoyamada, M.; Ando, H.; Kato, K.; Yamauchi, R. Antioxidative compounds from the outer scales of onion. J. Agric. Food Chem. 2005, 53, 8183–8189. [Google Scholar] [CrossRef]

- Roldan, E.; Sanchez-Moreno, C.; Ancos, B.; Cano, M. Characterization of onion (Allium cepa L.) products as food ingredients with antioxidant and antibrowning properties. Food Chem. 2008, 108, 907–916. [Google Scholar] [CrossRef] [PubMed]

- Albishi, T.; John, J.; Al-Khalifa, A.; Shahidi, F. Antioxidative phenolic constituents of skin of onion varieties and their activities. J. Funct. Foods 2013, 5, 1191–1203. [Google Scholar] [CrossRef]

- Obidziński, S.; Hejft, R.; Dołżyńska, M. Badanie procesu granulowania odpadów zbożowych/Research on granulation of cereal waste. Przemysł Chem. 2017, 96, 2360–2363. [Google Scholar]

- Dołżyńska, M.; Obidziński, S.; Kowczyk-Sadowy, M.; Krasowska, M. Densification and Combustion of Cherry Stones. Energies 2019, 12, 3042. [Google Scholar] [CrossRef]

- Ohman, M.; Boman, C.; Hedman, H.; Eklund, R. Residential combustion performance of pelletized hydrolysis residue from lignocellulosic ethanol production. Energy Fuels 2006, 20, 298–304. [Google Scholar] [CrossRef]

- Miranda, T.; Arranz, J.I.; Montero, I.; Román, S.; Rojas, C.V.; Nogales, S. Characterization and combustion of olive pomace and forest residue pellets. Fuel Process. Technol. 2012, 103, 91–96. [Google Scholar] [CrossRef]

- Chou, C.S.; Lin, S.H.; Lu, W.C. Preparation and characterization of solid biomass fuel made from rice straw and rice bran. Fuel Process. Technol. 2009, 90, 980–987. [Google Scholar] [CrossRef]

- Chou, C.S.; Lin, S.H.; Peng, C.C.; Lu, W.C. The optimum conditions for preparing solid fuel briquette of rice straw by a piston-mold process using the Taguchi method. Fuel Process. Technol. 2009, 90, 1041–1046. [Google Scholar] [CrossRef]

- Celma, A.R.; Cuadros, F.; López-Rodríguez, F. Characterization of pellets from industrial tomato residues. Food Bioprod. Process. 2012, 90, 700–706. [Google Scholar] [CrossRef]

- Stahl, M.; Berghel, J. Energy efficient pilot-scale production of wood fuel pellets made from a raw material mix including sawdust and rapeseed cake. Biomass Bioenergy 2011, 35, 4849–4854. [Google Scholar] [CrossRef]

- Sotannde, O.A.; Oluyege, A.O.; Abah, G.B. Physical and combustion properties of charcoal briquettes from neem wood residues. Int. Agrophisics 2010, 24, 189–194. [Google Scholar]

- Chachułowa, J. Pasze/Feed; Wydawnictwo Fundacja Rozwój SGGW: Warszawa, Poland, 1997. [Google Scholar]

- Obidziński, S. Analysis of usability of potato pulp as solid fuel. Fuel Process. Technol. 2012, 94, 67–74. [Google Scholar] [CrossRef]

- Obidziński, S. Pelletization of biomass waste with potato pulp content. Int. Agrophys. 2014, 28, 85–91. [Google Scholar] [CrossRef][Green Version]

- Obidziński, S. Utilization of post-production waste of potato pulp and buckwheat hulls in the form of pellets. Pol. J. Environ. Stud. 2014, 23, 1391–1395. [Google Scholar]

- Obidziński, S.; Joka, M.; Bieńczak, A.; Jadwisieńczak, K. Tests of the process of post-production onion waste pelleting. J. Res. Appl. Agric. Eng. 2017, 62, 89–92. [Google Scholar]

- Obidziński, S.; Hejft, R. The influence of potato pulp addition to the oat bran on the energy consumption of the pelletisation process and pellets quality. J. Res. Appl. Agric. Eng. 2013, 58, 133–138. [Google Scholar]

- PN-R-64798: 2009. Feed - Determination of fragmentation; Polish Committee for Standardization: Warsaw, Poland, 2009. [Google Scholar]

- PN-EN 14774-1: 2010. Solid biofuels - Determination of moisture content - Drying method - Part 1: Total moisture - Reference method; Polish Committee for Standardization: Warsaw, Poland, 2010. [Google Scholar]

- PN-EN ISO 17828:2016. Solid biofuels - Determination of bulk density; Polish Committee for Standardization: Warsaw, Poland, 2016. [Google Scholar]

- PN-EN ISO 16948:2016. Solid biofuels - Determination of total carbon, hydrogen and nitrogen content; Polish Committee for Standardization: Warsaw, Poland, 2016. [Google Scholar]

- PN-EN ISO 16994:2016. Solid biofuels - Determination of total sulfur and chlorine content; Polish Committee for Standardization: Warsaw, Poland, 2016. [Google Scholar]

- PN-EN ISO 18123:2017. Solid biofuels - Determination of volatile matter; Polish Committee for Standardization: Warsaw, Poland, 2017. [Google Scholar]

- PN-EN ISO 18134:2017. Solid biofuels - Determination of moisture content - Drying method - Part 3: Moisture in the sample for general analysis; Polish Committee for Standardization: Warsaw, Poland, 2017. [Google Scholar]

- PN-EN ISO 18122:2017. Solid biofuels - Determination of ash content; Polish Committee for Standardization: Warsaw, Poland, 2017. [Google Scholar]

- PN-ISO 1928:2002. Solid fuels - Determination of heat of combustion by calorimetric bomb method and calorific value calculation; Polish Committee for Standardization: Warsaw, Poland, 2002. [Google Scholar]

- PN-R-64834:1998. Feed - Test for the kinetic strength of granules; Polish Committee for Standardization: Warsaw, Poland, 1998. [Google Scholar]

- Dołżyńska, M.; Obidziński, S.; Simiński, P. Ocena granulatów z odpadów konopi siewnej jako biopaliwa/Evaluation of granulates from hemp waste as a biofuel. Przemysł Chem. 2018, 97, 686–688. [Google Scholar]

- Frączek, J.; Kurpaska, S.; Łapczyńska-Kordon, B. Thermal Conversion of Biomass; Polskie Towarzystwo Inżynierii Rolniczej: Kraków, Poland, 2011. [Google Scholar]

- Szatyłowicz, E.; Skoczko, I. Evaluation of the PAH Content in Soot from Solid Fuels Combustion in Low Power Boilers. Energies 2019, 12, 4254. [Google Scholar] [CrossRef]

- Demirbaş, A. Combustion characteristics of different biomass fuels. Prog. Energy Combust. Sci. 2004, 30, 219–230. [Google Scholar] [CrossRef]

- Dołżyńska, M.; Obidziński, S. Wpływ dodatku zużytego oleju spożywczego na efekty spalania osadów ściekowych/Impact of used cooking oil addition on the effects of burning sewage sludge. Przemysł Chem. 2017, 96, 1848–1851. [Google Scholar]

- Stępień, J.C.; Salij, A.; Psuj, K. Analiza techniczna i elementarna wybranych rodzajów biomasy oraz węgla kamiennego/Technical and elemental analysis of selected types of biomass and hard coal. Rynek Energii 2018, 3, 65–69. [Google Scholar]

- Lewandowski, W.M.; Ryms, M. Biopaliwa: Proekologiczne Odnawialne Źródła Energii/Biofuels: Pro-Ecological Renewable Energy Sources; Wydawnictwo WNT: Warszawa, Poland, 2013. [Google Scholar]

- Obernberger, I.; Brunner, T.; Barnthaler, G. Chemical properties of solid biofuels—Significance and impact. Biomass Bioenergy 2006, 30, 973–982. [Google Scholar] [CrossRef]

- Saidur, R.; Abdelaziz, E.A.; Demirbaş, A.; Hossaina, M.S.; Mekhilef, S. A review on biomass as a fuel for boilers. Renew. Sustain. Energy Rev. 2011, 15, 2262–2289. [Google Scholar] [CrossRef]

- Kriżan, M.; Kristof, K.; Angelović, M.; Jobbagy, J.; Urbanovićova, O. Energy potential of densified biomass from maize straw in form of pellets and briquettes. Agron. Res. 2018, 16, 474–482. [Google Scholar]

- Zając, G.; Szyszlak-Bargłowicz, J. Wpływdodatkuotrąbżytnichnawłasnościenergetycznepeletów z biomasyślazowcapensylwańskiego/The influence of rye bran additive on energy properties of pellets from syllab of Columbian mallow. Autobusy Tech. Eksploat. Syst. Transp. 2011, 10, 459–464. [Google Scholar]

- Obidzinski, S.; Piekut, J.; Dec, D. The influence of potato pulp content on the properties of pellets from buckwheat hulls. Renew. Energy 2016, 87, 289–297. [Google Scholar] [CrossRef]

- Zwiślak, K.; Sobczak, P.; Panasiewicz, M.; Mazur, J.; Nadulski, R.; Starek, A. Wpływ wielkości frakcji otrąb pszennych na jakość granulatu. Inżynieria Przetwórstwa Spożywczego 2014, 3, 25–28. [Google Scholar]

- Castellano, J.M.; Gómez, M.; Fernández, M.; Esteban, L.S.; Carrasco, J.E. Study on the effects of raw materials composition and pelletization conditions on the quality and properties of pellets obtained from different woody and non woody biomasses. Fuel 2015, 139, 629–636. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Natural binders and solid bridge type binding mechanisms in briquettes and pellets made from corn stover and switchgrass. Bioresour. Technol. 2010, 101, 1082–1090. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Factors affecting strength and durability of densified biomass products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Alakangas, E.; Paju, P. Wood Pellets in Finland—Technology, Economy and Market; OPET Report 5; VTT Processes: Jyvaskyla, Finland, 2002. [Google Scholar]

- Obidziński, S. Doctoral dissertation. In Pelleting of Plant Materials in an Annular Granulator Working System; Bialystok University of Technology: Białystok, Poland, 2005. [Google Scholar]

- Hejft, R. Ciśnieniowa Aglomeracja Materiałów Roślinnych/Pressure Agglomeration of Plant Materials; Biblioteka Problemów Eksploatacji, Radom: Białystok, Poland, 2002. [Google Scholar]

- Jiang, L.; Liang, J.; Yuan, X.; Li, H.; Li, C.; Xiao, Z. Co-pelletization of sewage sludge and biomass: The density and hardness of pellet. Bioresour. Technol. 2014, 166, 435–443. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Jiang, L.B.; Li, C.Z.; Liang, J.; Yuan, X.Z.; Xiao, Z.H. Co-pelletization of sewage sludge and biomass: The energy input and properties of pellets. Fuel Process. Technol. 2015, 132, 55–61. [Google Scholar] [CrossRef]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. Effects of compressive force, particle size and moisture content on mechanical properties of biomass pellets from grasses. Biomass Bioenergy 2006, 30, 648–654. [Google Scholar] [CrossRef]

- Brunerová, A.; Roubík, H.; Brožek, M.; Herák, D.; Šleger, V.M. Potential of Tropical Fruit Waste Biomass for Production of Bio-Briquette Fuel: Using Indonesia as an Example. Energies 2017, 10, 2119. [Google Scholar] [CrossRef]

- Cui, X.; Yang, J.; Shi, X.; Lei, W.; Huang, T.; Bai, C. Experimental Investigation on the Energy Consumption, Physical, and Thermal Properties of a Novel Pellet Fuel Made from Wood Residues with Microalgae as a Binder. Energies 2019, 12, 3425. [Google Scholar] [CrossRef]

- Shaw, M.D.; Tabil, L.G. Compression and relaxation characteristics of selected biomass grinds. In Proceedings of the ASAE Annual International Meeting, Minneapolis, MN, USA, 17–20 June 2007; ASAE Paper No. 076183; ASAE: St. Joseph, MI, USA, 2007. [Google Scholar]

- Mediavilla, I.; Esteban, L.S.; Fernández, M.J. Optimisation of pelletisation conditions for poplar energy crop. Fuel Process. Technol. 2012, 104, 7–15. [Google Scholar] [CrossRef]

- Obidziński, S.; Joka, M.; Fijoł, O. Two-stage agglomeration of fine-grained herbal waste of nettle. Int. Agrophisics 2017, 31, 515–523. [Google Scholar] [CrossRef]

- PN EN-303-5: 2012. Boilers - Part 5: Boilers for solid fuels with manual and automatic fuel feed with a nominal power of up to 500 kW - Terminology, requirements, testing and marking; Polish Committee for Standardization: Warsaw, Poland, 2012. [Google Scholar]

- Nussbaumer, T. Combustion and co-combustion of biomass. In Proceedings of the 12th European Biomass Conference, Amsterdam, The Netherlands, 17–21 June 2002. [Google Scholar]

- Glarborg, P.; Miller, J.A.; Ruscic, B.; Klippenstein, S.J. Modeling nitrogen chemistry in combustion. Prog. Energy Combust. Sci. 2018, 67, 31–68. [Google Scholar] [CrossRef]

- Mladenović, M.; Paprika, M.; Marinković, A. Denitrification techniques for biomass combustion. Renew. Sustain. Energy Rev. 2018, 82, 3350–3364. [Google Scholar] [CrossRef]

- Pudlik, W. Termiczna Przeróbka Odpadów. Podstawy teoretyczne/Thermal Waste Treatment. Theoretical Basics; WydawnictwoPolitechniki: Gdańskiej, Poland, 2014. [Google Scholar]

- Obernberger, I. Physical characteristics and chemical composition of solid biomass fuels. Thermochemical Biomass Conversion; Script for the Lecture; Eindhofen University of Technology, Department for Mechanical Engineering, Section Process Technology: Eindhofen, The Netherlands, 2003. [Google Scholar]

- Spiegel, M. Corrosion in molten salts. Mater. Sci. Mater. Eng. 2010, 1, 316–330. [Google Scholar]

- Obernberger, I. Nutzung fester Biomasse in VerbrennungsanlagenunterbesondererBerücksichtigung des Verhaltensaschebildender Elemente; Schriftenreihe Thermische Biomassenutzung, Band 1; Osterreichdbv-Verlag der Technischen Universitat Graz: Graz, Austria, 1997. [Google Scholar]

- Król, D.; Borsukiewicz-Gozdur, A. Energy from sawmill and agricultural waste biomass. ArchiwumGospodarkiOdpadamiiOchronyŚrodowiska 2014, 16, 87–94. [Google Scholar]

- Hardy, T.; Kordylewski, W.; Mościcki, K. Zagrożenie korozją chlorkową w wyniku spalania i współspalania biomasy w kotłach. ArchiwumSpalania 2009, 9, 181–195. [Google Scholar]

- Ren, X.; Sun, R.; Chi, H.-H.; Meng, X.; Li, Y.; Levendis, Y.A. Hydrogen chloride emissions from combustion of raw and torrefiedbiomass. Fuel 2017, 200, 37–46. [Google Scholar] [CrossRef]

- Williams, A.; Jones, J.M.; Ma, L.; Pourkashanian, M. Pollutants from the combustion of solid biomass fuels. Prog. Energy Combust. Sci. 2012, 38, 113–137. [Google Scholar] [CrossRef]

- Rabacal, M.; Fernandes, U.; Costa, M. Combustion and emission characteristics of a domestic boiler fired with pellets of pine, industrial wood wastes and peach Stones. Renew. Energy 2013, 51, 220–226. [Google Scholar] [CrossRef]

- Wandrasz, J.W.; Wandrasz, A.J. Paliwa Formowane Biopaliwai Paliwa z Odpadów w Procesach Termicznych/Fuels Formed by Biofuels and Fuels from Waste in Thermal Processes; Wyd. Seidel-Przywecki: Warszawa, Poland, 2006. [Google Scholar]

- Szyszlak-Bargłowicz, J.; Zając, G.; Słowik, T. Badanie emisji wybranych zanieczyszczeń gazowych podczas spalania peletów z agro biomasy w kotle małej mocy. RocznikOchronaŚrodowiska 2017, 19, 715–730. [Google Scholar]

- Zając, G.; Szyszlak-Bargłowicz, J.; Gołębiowski, W.; Szczepanik, M. Chemical Characteristics of Biomass Ashes. Energies 2018, 11, 2885. [Google Scholar] [CrossRef]

- Sornek, K.; Filipowicz, M.; Kurcz, L.; Szubel, M.; Rosół, M.; Rzepka, K.; Ręka, J. Sterowaniepracąpiecokominka a emisjatlenkuwęgla do atmosfery/Controlling the operation of the fireplace stove and the emission of carbon monoxide into the atmosphere. InżynieriaiOchronaŚrodowiska 2015, 18, 497–512. [Google Scholar]

| Property | Onion Husks | Potato Pulp |

|---|---|---|

| Moisture [%] wb | 9.45 ± 0.26 | 90.11 ± 0.12 |

| Bulk density [kg·m−3] wb | 159.40 ± 7.34 | 521.24 ± 1.87 |

| Volative matter [%] db | 62.11 ± 0.42 | 68.44 ± 0.55 |

| Ash [%] db | 19.80 ± 0.38 | 12.19 ± 0.24 |

| Carbon [%] db | 30.60 ± 0.46 | 41.27 ± 0.56 |

| Hydrogen [%] db | 3.85 ± 0.01 | 5.36 ± 0.02 |

| Nitrogen [%] db | 1.00 ± 0.00 | 0.88 ± 0.00 |

| Sulphur [%] db | 0.499 ± 0.001 | 0.441 ± 0.002 |

| Chlorine [%] db | 0.025 | 0.013 |

| Oxygen 1 [%] db | 64.03 | 47.96 |

| HHV [MJ·kg−1] wb | 12.077 ± 0.10 | 2.503 ± 0.059 2 |

| LHV [MJ·kg−1] wb | 10.491 | 0.242 |

| Parameter | Value | |

|---|---|---|

| Onion Husks + Potato Pulp | Cherry Stones + Rye Bran [16] | |

| CO2 [%] | 7.27 | 7.20 |

| CO [mg·Nm−3] | 703.98 | 432.45 |

| SO2 [mg·Nm−3] | 216.47 | 38.62 |

| NO [mg·Nm−3] | 307.14 | 264.69 |

| HCl [mg·Nm−3] | 36.63 | 4.38 |

| The actual oxygen concentration in the exhaust [%] | 14.78 | 10.96 |

| λ [-] | 3.20 | 2.04 |

| Average flue gas temperature in the boiler outlet [°C] | 120 | 170 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Obidziński, S.; Dołżyńska, M.; Kowczyk-Sadowy, M.; Jadwisieńczak, K.; Sobczak, P. Densification and Fuel Properties of Onion Husks. Energies 2019, 12, 4687. https://doi.org/10.3390/en12244687

Obidziński S, Dołżyńska M, Kowczyk-Sadowy M, Jadwisieńczak K, Sobczak P. Densification and Fuel Properties of Onion Husks. Energies. 2019; 12(24):4687. https://doi.org/10.3390/en12244687

Chicago/Turabian StyleObidziński, Sławomir, Magdalena Dołżyńska, Małgorzata Kowczyk-Sadowy, Krzysztof Jadwisieńczak, and Paweł Sobczak. 2019. "Densification and Fuel Properties of Onion Husks" Energies 12, no. 24: 4687. https://doi.org/10.3390/en12244687

APA StyleObidziński, S., Dołżyńska, M., Kowczyk-Sadowy, M., Jadwisieńczak, K., & Sobczak, P. (2019). Densification and Fuel Properties of Onion Husks. Energies, 12(24), 4687. https://doi.org/10.3390/en12244687