Experimental Demonstration of Deterministic Chaos in a Waste Oil Biodiesel Semi-Industrial Furnace Combustion System

Abstract

:1. Introduction

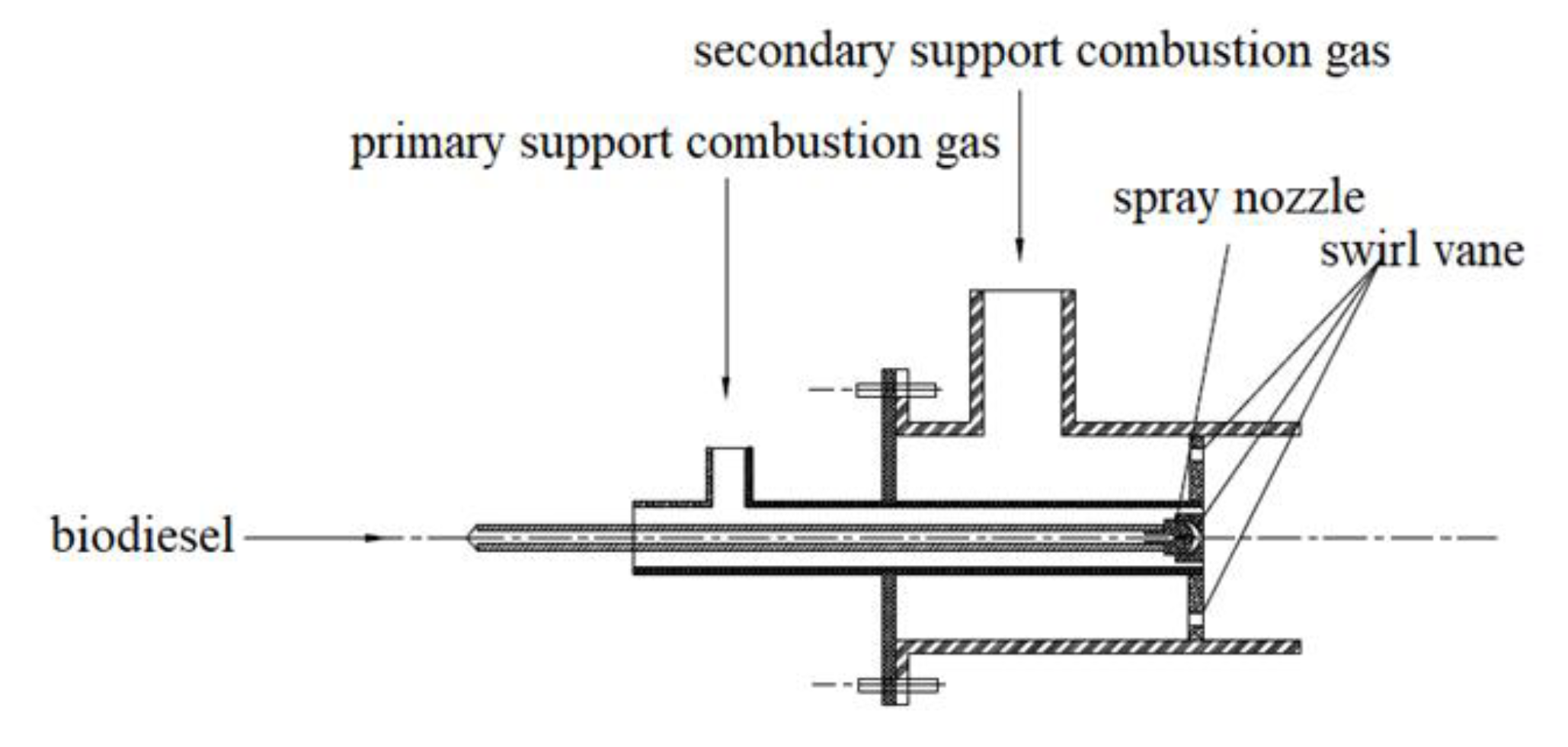

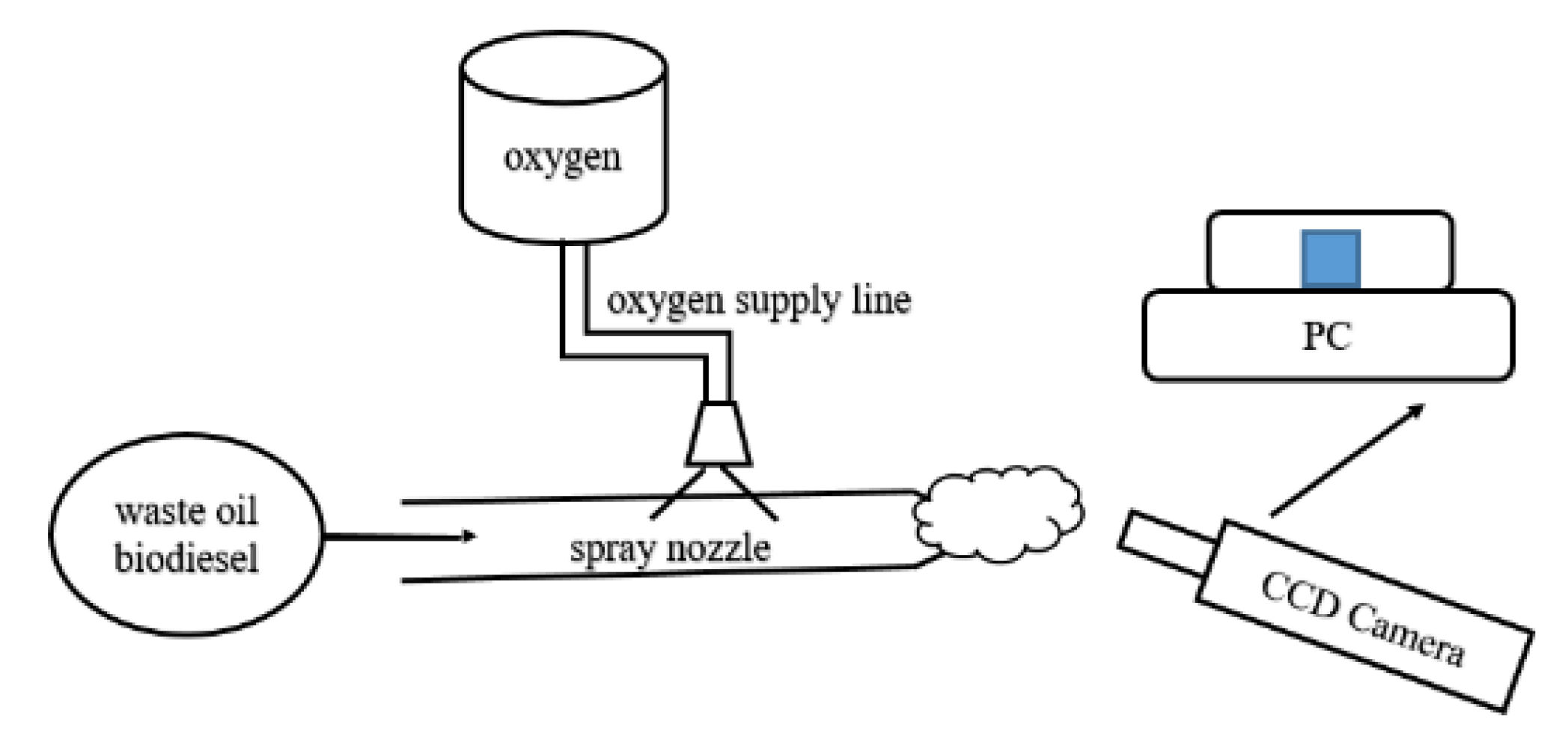

2. Experimental Apparatus, Operating Conditions

2.1. Experimental Apparatus

2.2. Operating Conditions

2.3. Image Processing and Signal Analysis

3. Diagnostic Tools

3.1. Power Spectrum Analysis of Time Series

3.2. Reconstruction Phase Space

3.3. Largest Lyapunov Exponent

3.4. The 0-1 Test Method

4. Results and Analysis

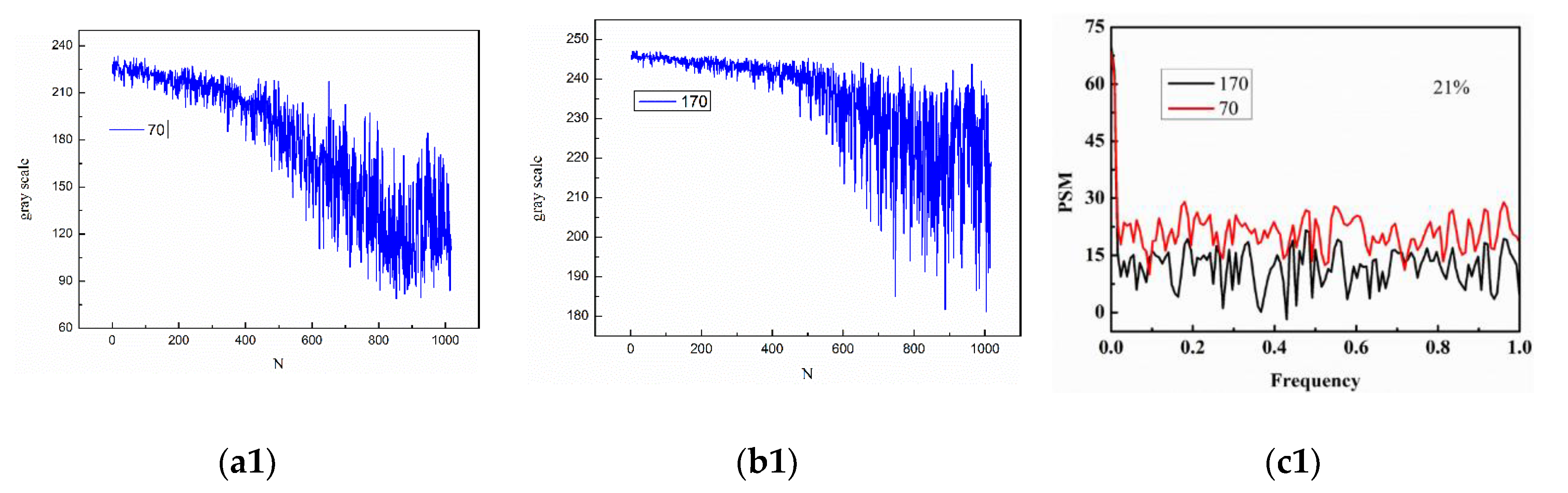

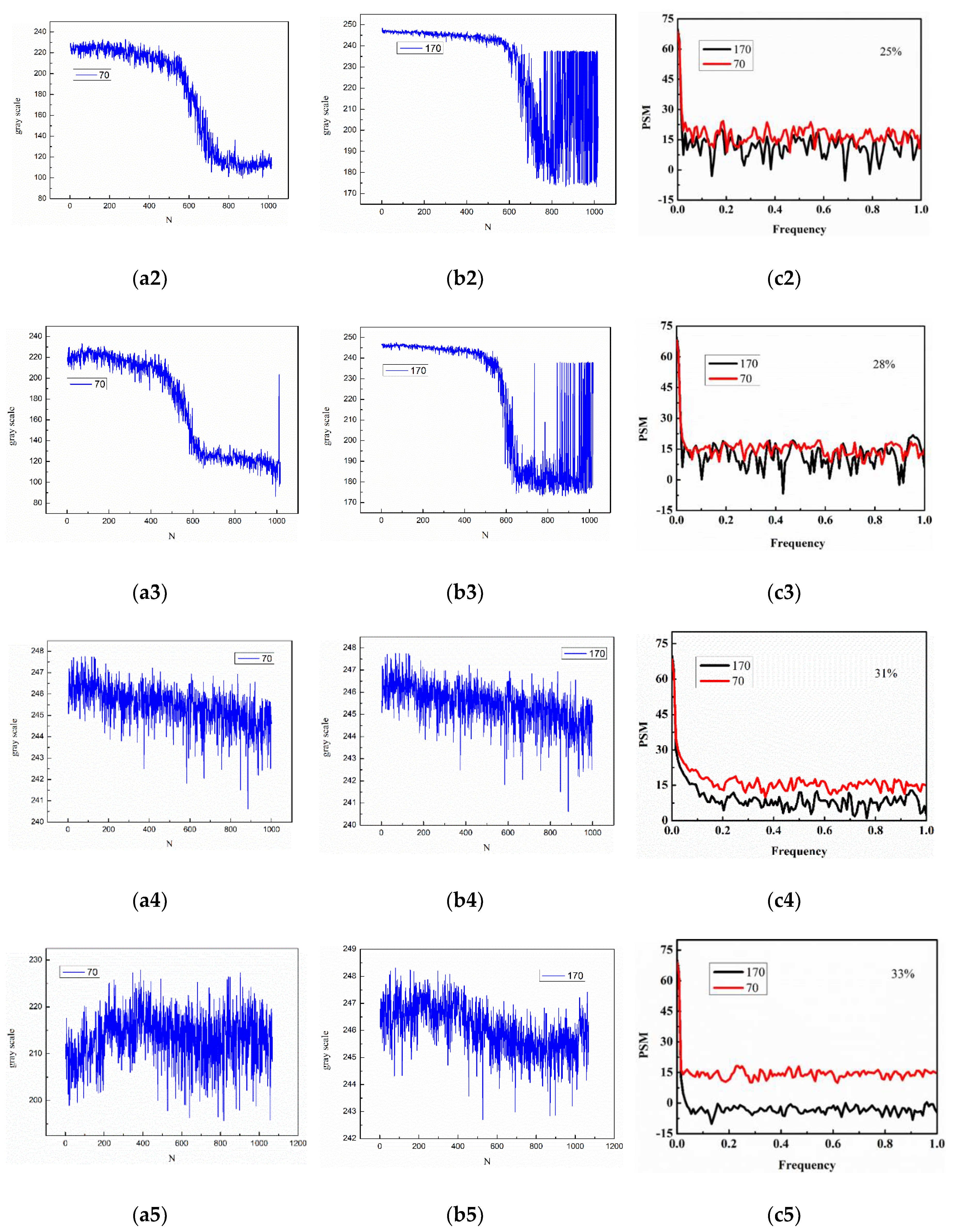

4.1. Flame Image Feature

4.2. Power Spectrum Analysis of Time Series

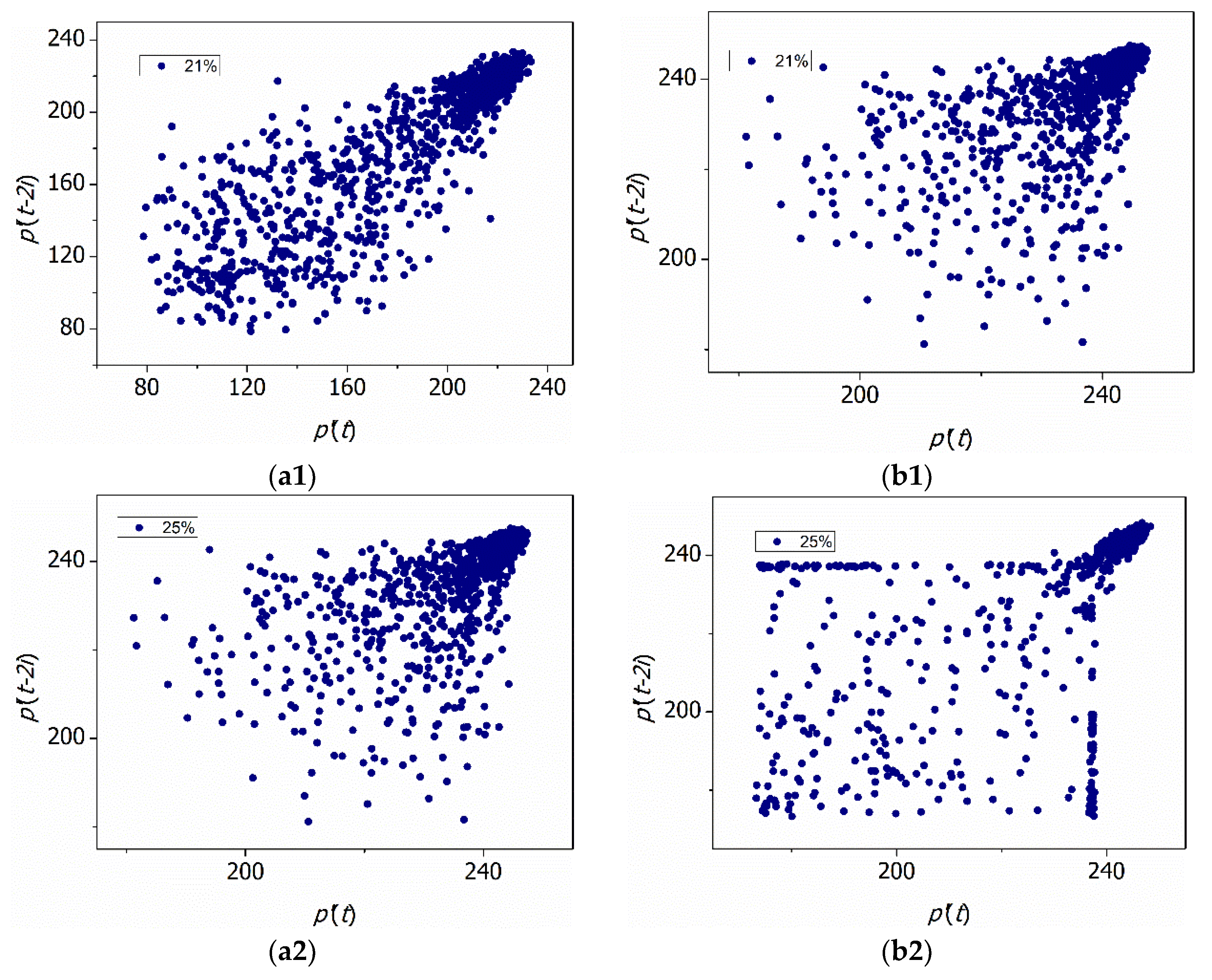

4.3. Phase Reconstruction Method

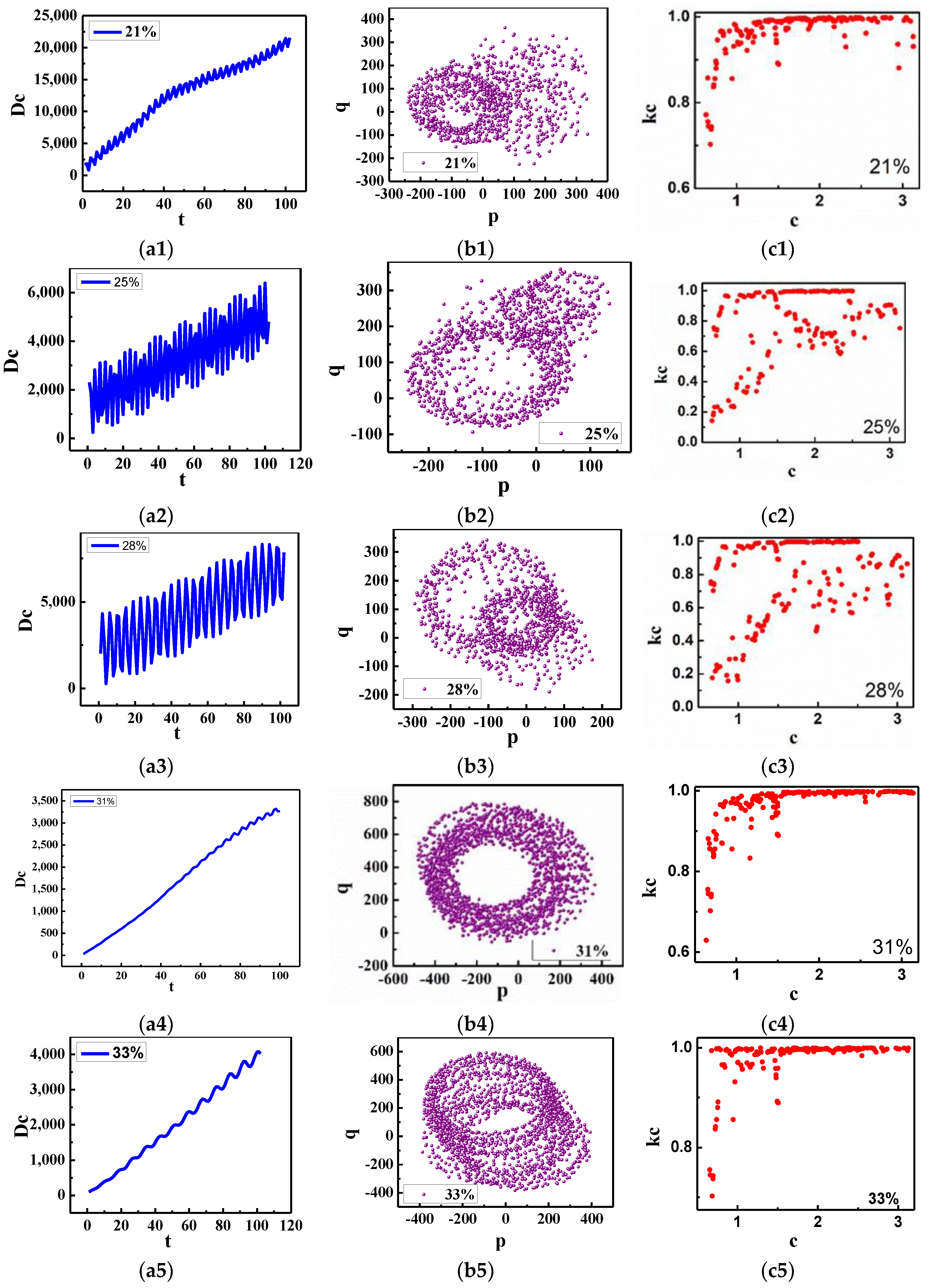

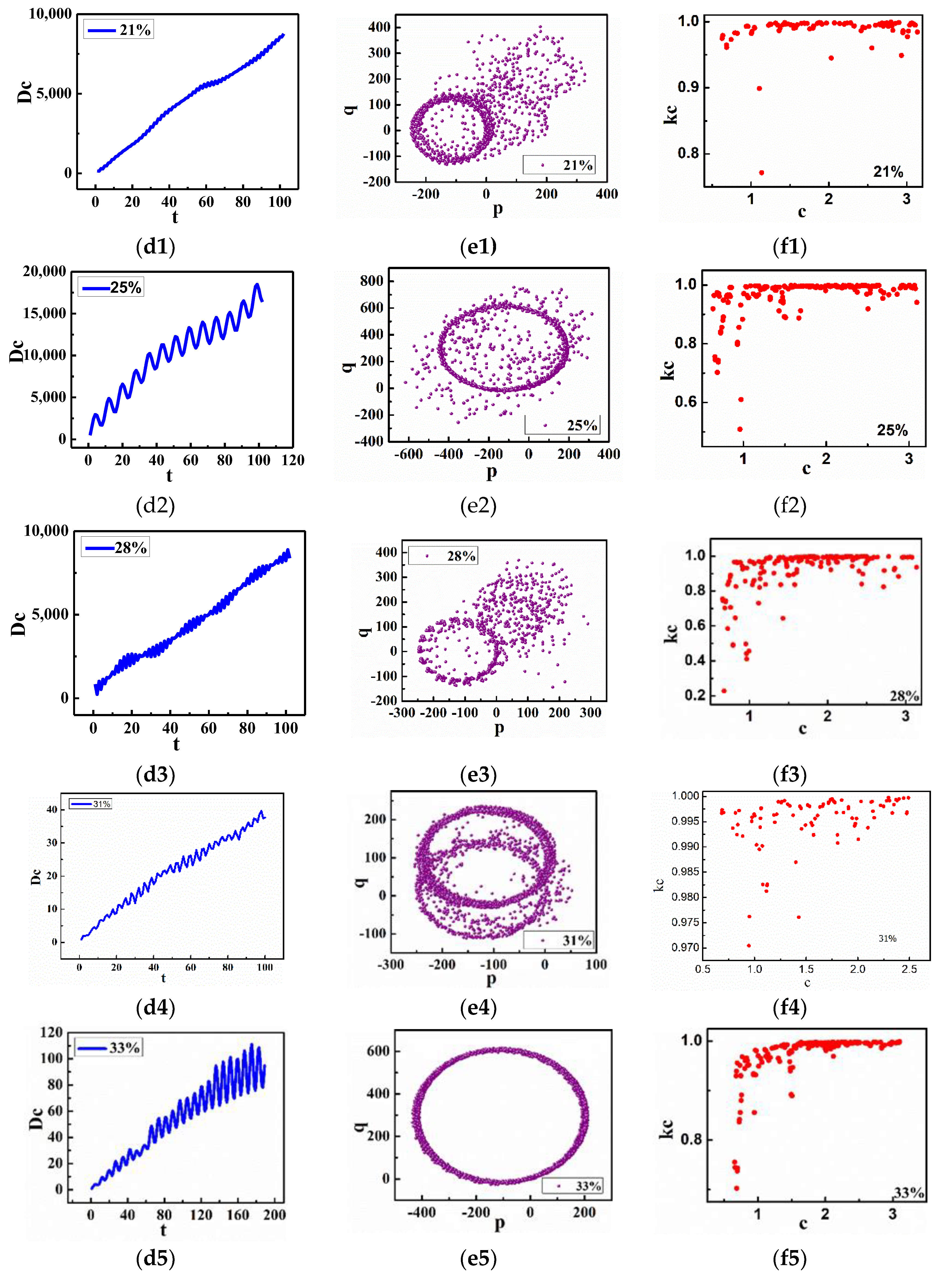

4.4. 0-1 Test Results

4.5. Calculation Results of the Largest Lyapunov Exponent

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| cov | coefficient of variation |

| LLE | largest Lyapunov exponent |

| MSD | mean square displacement |

| mean | mean value |

| FFT | fast Fourier transform |

| PSD | power spectral density |

| DFT | discrete Fourier transform |

| symbols | |

| c | random value |

| Dc(n) | modified mean square displacement |

| λ | largest Lyapunov exponent |

| Mc(n) | mean square displacement |

| m | embedding dimension |

| p(n) | translation variable |

| q(n) | translation variable |

| ts | time parameter |

| t | time |

| τ | delay time |

References

- Aransiola, E.F.; Ojumu, T.V.; Oyekola, O.O.; Madzimbamuto, T.F.; Ikhu-Omoregbe, D.I.O. A review of current technology for biodiesel production: State of the art. Biomass Bioenerg. 2013, 61, 276–297. [Google Scholar] [CrossRef]

- Ashraful, A.M.; Masjuki, H.H.; Kalam, M.A.; Rizwanul Fattah, I.M.; Imtenan, S.; Shahir, S.A.; Mobarak, H.M. Production and comparison of fuel properties, engine performance, and emission characteristics of biodiesel from various non-edible vegetable oils: A review. Energy Conversi. Manag. 2014, 80, 202–228. [Google Scholar] [CrossRef]

- Reddy, V.M.; Biswas, P.; Garg, P.; Kumar, S. Combustion characteristics of biodiesel fuel in high recirculation conditions. Fuel Process. Technol. 2014, 118, 310–317. [Google Scholar] [CrossRef]

- Docquier, N.; Sébastien, C. Combustion control and sensors: A review. Prog. Energy Combust. Sci. 2002, 28, 107–150. [Google Scholar] [CrossRef]

- Ballester, J.; Tatiana, G.-A. Diagnostic techniques for the monitoring and control of practical flames. Prog. Energy Combust. Sci. 2010, 36, 375–411. [Google Scholar] [CrossRef]

- Zhang, C. Study on Combustion Characteristics of Biodiesel in Furnace; Central South University: Hunan, China, 2012. [Google Scholar] [CrossRef]

- Wang, C. Study on the Influence of Air Preheating Temperature on Combustion Characteristics of Biodiesel; Central South University: Hunan, China, 2013. [Google Scholar] [CrossRef]

- Jiang, Y.; Jiang, S.; Huang, L.; Chen, L.; Zhong, W. Experimental Study on Temperature Field of Biodiesel Combustion Flame. J. Cent. South Univ. (Nat. Sci. Ed.) 2015, 46, 540–3545. [Google Scholar] [CrossRef]

- Jiang, S.; Zhong, W.; Zhang, C.; Wang, C. Study on Flame Characteristics of Biodiesel in Furnace Based on Image Processing Technology. J. Agric. Mach. 2013, 44, 24–29. [Google Scholar] [CrossRef]

- Ibrahim, A. Performance and combustion characteristics of a diesel engine fuelled by butanol–biodiesel–diesel blends. Appl. Therm. Eng. 2016, 103, 651–659. [Google Scholar] [CrossRef]

- Calder, J.; Roy, M.M.; Wang, W. Performance and emissions of a diesel engine fueled by biodiesel-diesel blends with recycled expanded polystyrene and fuel stabilizing additive. Energy 2018, 149, 204–212. [Google Scholar] [CrossRef]

- Qubeissi, A.M. Predictions of droplet heating and evaporation: An application to biodiesel, diesel, gasoline and blended fuels. Appl. Therm. Eng. 2018, 136, 260–267. [Google Scholar] [CrossRef]

- Kilic, G.; Sungur, B.; Topaloglu, B.; Ozcan, H. Experimental analysis on the performance and emissions of diesel/butanol/biodiesel blended fuels in a flame tube boiler. Appl. Therm. Eng. 2018, 130, 195–202. [Google Scholar] [CrossRef]

- Jeon, J.; Park, S. Effect of injection pressure on soot formation/oxidation characteristics using a two-color photometric method in a compression-ignition engine fueled with biodiesel blend (B20). Appl. Therm. Eng. 2018, 131, 284–294. [Google Scholar] [CrossRef]

- Lei, S.; Turan, A. Nonlinear/Chaotic Modeling and Control of Combustion Instabilities. Int. J. Bifurc. Chaos 2010, 20, 1245–1254. [Google Scholar] [CrossRef]

- Margolis, S.B. Chaotic combustion of solids and high-density fluids near points of strong resonance. Proceedings of the Royal Society A: Mathematical. Phys. Eng. Sci. 1991, 433, 131–150. [Google Scholar] [CrossRef]

- Lei, S.; Turan, A. Chaotic modelling and control of combustion instabilities due to vaporization. Int. J. Heat Mass Transf. 2010, 53, 4482–4494. [Google Scholar] [CrossRef]

- Ferrante, L.; Miccio, M.; Miccio, F.; Solimene, R. Fluidized Bed Combustion of Liquid Biofuels: Application of Integrated Diagnostics for Micro-explosions Characterization. Energy Fuels 2008, 22, 4213–4222. [Google Scholar] [CrossRef]

- Kuzmych, O.; Aitouche, A.; El Hajjaji, A.; Bosche, J. Nonlinear control for a diesel engine: A CLF-based approach. Int. J. Appl. Math. Comput. Sci. 2014, 24, 821–835. [Google Scholar] [CrossRef]

- Wang, L.Y.; Yang, L.P.; Ma, X.Z.; Li, J. Analysis of chaos combustion process in spark ignition natural gas engine. J. Beijing Univ. Technol. 2012, 38, 689–964. [Google Scholar]

- Lorenz, E.N. Deterministic nonperiodic flow. J. Atmos. Sci. 2004, 20, 130–141. [Google Scholar] [CrossRef]

- Rand, D.A.; Young, L.S. Dynamical systems and turbulence, Warwick 1980; Springer: New York, NY, USA, 1981. [Google Scholar] [CrossRef]

- Grassberger, P.; Procaccia, I. Characterization of Strange Attractors. Phys. Rev. Lett. 1983, 50, 346–349. [Google Scholar] [CrossRef]

- Packard, N.H.; Crutchfield, J.P.; Farmer, J.D.; Shaw, R.S. Geometry from a time series. Phys. Rev. Lett. 2008, 45, 712. [Google Scholar] [CrossRef]

- Wolf, A.; Swift, J.B.; Swinney, H.L.; Vastano, J.A. Determining Lyapunov exponents from a time series. Phys. D Nonlinear Phenom. 1985, 16, 285–317. [Google Scholar] [CrossRef]

- Sano, M.; Sawada, Y. Measurement of the Lyapunov Spectrum from a Chaotic Time Series. Phys. Rev. Lett. 1985, 55, 1082–1085. [Google Scholar] [CrossRef]

- Cheng, M.-Y.; Prayogo, D.; Ju, Y.-H.; Wu, Y.-W.; Sutanto, S. Optimizing Mixture Properties of Biodiesel Production Using Genetic Algorithm-Based Evolutionary Support Vector Machine. Int. J. Green Energy 2016, 13, 1599–1607. [Google Scholar] [CrossRef]

- Saurabh, A.; Kabiraj, L.; Wahi, P.; Sujith, R.I. Route to chaos for combustion instability in ducted laminar premixed flames. Chaos Interdiscip. J. Nonlinear Sci. 2012, 22, 23129. [Google Scholar]

- Maheshwari, N.; Balaji, C.; Ramesh, A. A nonlinear regression based multi-objective optimization of parameters based on experimental data from an IC engine fueled with biodiesel blends. Biomass-Bioenergy 2011, 35, 2171–2183. [Google Scholar] [CrossRef]

- Davies, M.L.; Halford-Maw, P.A.; Hill, J.; Tinsley, M.R.; Johnson, B.R.; Scott, S.K.; Kiss, I.Z.; Gaspar, V.; Kiss, I. Control of Chaos in Combustion Reactions. J. Phys. Chem. A 2000, 104, 9944–9952. [Google Scholar] [CrossRef]

- Gotoda, H.; Nikimoto, H.; Miyano, T.; Tachibana, S. Dynamic properties of combustion instability in a lean premixed gas-turbine combustor. Chaos: Interdiscip. J. Nonlinear Sci. 2011, 21, 13124. [Google Scholar] [CrossRef]

- Gottwald, G.A.; Melbourne, I. On the implementation of the 0-1 test for chaos. SIAM J. Appl. Dyn. Syst. 2009, 8, 129–145. [Google Scholar] [CrossRef]

- Gottwald, G.A.; Melbourne, I. On the validity of the 0-1 test for chaos. Nonlinearity 2009, 22, 1367–1382. [Google Scholar] [CrossRef]

- Ding, S.-L.; Song, E.-Z.; Yang, L.-P.; Litak, G.; Yao, C.; Ma, X.-Z. Investigation on nonlinear dynamic characteristics of combustion instability in the lean-burn premixed natural gas engine. Chaos Solitons Fractals 2016, 93, 99–110. [Google Scholar] [CrossRef]

- Ding, S.-L.; Song, E.-Z.; Yang, L.-P.; Litak, G.; Wang, Y.-Y.; Yao, C.; Ma, X.-Z. Analysis of chaos in the combustion process of premixed natural gas engine. Appl. Therm. Eng. 2017, 121, 768–778. [Google Scholar] [CrossRef]

- Liping, Y.; Xiuzhen, M.; Enzhe, S. Influence of Mixture Quality on Nonlinear Combustion Process of Natural Gas Engine. In Proceedings of the International Conference on Intelligent System Design & Engineering Application (IEEE), Changsha, China, 13–14 October 2010. [Google Scholar] [CrossRef]

- Dong, Z.; Liu, M. Intelligent Diagnosis Method of High Temperature and Low Oxygen Flame Images; Electronic Industry Press: Beijing, China, 2012; pp. 40–100. [Google Scholar]

- Yang, W.; Blasiak, W. Chemical Flame Length and Volume in Liquified Propane Gas Combustion Using High-Temperature and Low-Oxygen-Concentration Oxidizer. Energy & Fuels 2004, 18, 1329–1335. [Google Scholar]

- Fleury, A.; Trigo, F.; Pacífico, A.; Martins, F. An inference model for combustion diagnostics in an experimental oil furnace. Expert Syst. 2017, 35, e12245. [Google Scholar] [CrossRef]

- Hernandez, R.; Ballester, J. Flame imaging as a diagnostic tool for industrial combustion. Combust. Flame 2008, 155, 509–528. [Google Scholar] [CrossRef]

| Name | Kinematic Viscosity | Surface Tension | Flash Point | Thermal Value | Condensation Point | Cetane Number |

|---|---|---|---|---|---|---|

| Waste oil biodiesel | 4.61 m2/s | 28.3 mN/m | 152 °C | 38.98 MJ/kg | 6 °C | 51 |

| Gray Scale | Oxygen Enrichment Concentration | ||||

|---|---|---|---|---|---|

| 21% | 25% | 28% | 31% | 33% | |

| 70 | 1.3260 | 1.3187 | 1.2078 | 1.7055 | 1.9866 |

| 170 | 0.9812 | 0.6193 | 0.3063 | 3.0770 | 2.8896 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, S.; Li, F.; Xiao, Q.; Xu, J.; Wang, H.; Wang, H. Experimental Demonstration of Deterministic Chaos in a Waste Oil Biodiesel Semi-Industrial Furnace Combustion System. Energies 2019, 12, 4479. https://doi.org/10.3390/en12234479

Gao S, Li F, Xiao Q, Xu J, Wang H, Wang H. Experimental Demonstration of Deterministic Chaos in a Waste Oil Biodiesel Semi-Industrial Furnace Combustion System. Energies. 2019; 12(23):4479. https://doi.org/10.3390/en12234479

Chicago/Turabian StyleGao, Shengyang, Fashe Li, Qingtai Xiao, Jianxin Xu, Huage Wang, and Hua Wang. 2019. "Experimental Demonstration of Deterministic Chaos in a Waste Oil Biodiesel Semi-Industrial Furnace Combustion System" Energies 12, no. 23: 4479. https://doi.org/10.3390/en12234479

APA StyleGao, S., Li, F., Xiao, Q., Xu, J., Wang, H., & Wang, H. (2019). Experimental Demonstration of Deterministic Chaos in a Waste Oil Biodiesel Semi-Industrial Furnace Combustion System. Energies, 12(23), 4479. https://doi.org/10.3390/en12234479