1. Introduction

The building sector accounts for 40% of the final energy consumption and 36% of carbon dioxide (CO

2) emissions in Lithuania and other European Union (EU) countries [

1]. About 26% of all final energy consumption in the EU is needed for space heating and DHW [

2]. In recent years, the European Commission (EC) has set a new target of reducing carbon dioxide emissions by 90% for the building sector by the year 2050 [

3]. As reported in the 2014/15 European work program, more than 17% of the primary energy savings potential of the EU for 2050 [

4] is related to the building retrofit.

The Heat Pump (HP) is an environmentally friendly and renewable energy technology that exploits renewable heat energy from the ground, air or water for building or industrial applications by reversing the natural heat flow from a lower to a higher useful temperature [

5]. In an electrically-powered HP, the amount of transferred heat can be three or four times larger than the electrical power consumed, resulting in a coefficient of performance (COP) value of 3 to 4. The seasonal coefficient of performance (SCOP) describes the average COP during a heating season.

Alongside the COP and SCOP, another important parameter should also be considered when describing the energy performance of HPs, namely their seasonal performance factor (SPF). This SPF is the ‘net seasonal coefficient of performance in active mode’ defined as the ratio between annual usable energy provided by the HP and the annual energy supplied to the whole heating and/or DHW system under real operating conditions [

6].

As reported by Zimny et al. [

7], the theoretical understanding of the HP system allows the construction of the first device in the second half of the nineteenth century; however, industrial-scale applications were only introduced after World War I. At this time electric drivers for compressors became a standard, making smaller-sized devices possible.

In 1945, John Sumner, the City Electrical Engineer for Norwich, installed an experimental water-source HP (WSHP). It fed the central heating system, using a nearby river to heat new Council administrative buildings [

8]. It demonstrated a seasonal coefficient of performance (SPF) of 3.42 and average thermal delivery of 147 kW, as well as a peak output of 234 kW. Despite the efficiency and effectiveness of the system, it was not widely accepted in the UK because of the relative availability of low-cost fossil fuels, such as coal at the time, and later North Sea oil and gas.

The new technology was widely adopted in Switzerland due to the shortage of fossil fuels. One HP of a 100 kW output was installed in the Zurich City Hall in 1938, and 35 HP devices were installed in Switzerland between 1938 and 1945 [

9]. The development of HP technologies decreased due to the drop in fossil fuel prices after the World War II, demonstrating further growth only after the oil crises in 1973 and 1979 [

10,

11]. Within the next two decades, several countries launched programs supporting research on HP technologies, national HP associations were created, quality guidelines and certification protocols of products were developed, leading to more technologically mature products appearing in the market.

The European Heat Pump Association (EHPA) in 2018 reported that the European HP sales grew by more than 10% for the third year in a row in 2017. After 1.1 million HP units sold in Europe in 2017, the total number of units in the continent reached 10.6 million within 20 years, with a 5% total share of installed capacity in the building market. Contribution from these installations led to the reduction of carbon emissions by 29.8 Mt, while generating 116 TWh of energy. This in turn accounted for 148 TWh of energy saved, while creating a total of 54,000 full-time equivalent jobs in Europe. France, Italy and Spain are the leaders in Europe’s HP markets, with a 50% share of total units sold. The top 10 countries, including Sweden, Germany, Norway, Finland, Denmark, Switzerland and Austria as well, sell 90% of all units. In terms of market penetration, Norway, Estonia and Finland are the leaders of sales on a per capita basis [

12].

The first Lithuanian study on HP was presented at the end of the twentieth century when A. Zukauskas [

13] reported the monograph entitled “Energy transfer process in heat pumps”. That was the beginning of HP research in Lithuania. At the beginning of this twenty-first century, a series of different studies were conducted [

5,

14,

15,

16,

17,

18,

19,

20,

21,

22], mainly due to the price increase of energy produced in conventional ways (i.e., district heating, solid fuels and natural gas). These studies were focused on the potential energy savings and environmental aspects of HPs.

In Lithuania the HP market emerged only in 2002 and its popularity has been constantly increasing. However, the market was still limited at the time, and it did not grow significantly until 2013, when due to other factors resulting from the global financial crisis of 2007–08, the HP market recorded substantial growth. Financial confidence of households has led to increased acquisition of relatively more expensive and yet easier to maintain systems. Growing housing completions also helped the market to boost the usage of HPs. Price decrease and stimulating economic factors pushed up the market growth [

5,

23].

According to the study published in 2016 [

5], the majority of end-users were affluent, and the obtaining of HPs was an issue of status and comfort. Approximately one-third of HPs sold in 2013 were installed into new buildings, which constitutes to approximately 4% of all new heating systems installations. The new housing segment share decreased moderately compared to the previous decade. HPs nowadays are technologically well-developed and therefore popular between consumers. The technology has found its way to industrial and transport applications as well [

7].

The aim of this paper is to provide a critical review of HP technologies in buildings, using Lithuania as a cold climate case study, to outline the factors hindering HP market growth, as well as provide insights on the new technologies unlocking new potential uses for HP technology.

In

Section 2 we discuss the main characteristics of HPs. In

Section 3 we provide an overview of the climatic, technical and legal aspects of the HP market in Lithuania, as well as introduce detailed case studies on several HP installations. In

Section 4 we discuss performance and application issues with regard to the heat source, looking into ASHPs, GSHPs and WSHPs. Future trends for HP technology development and applications are discussed in

Section 5, and the conclusions are provided in

Section 6.

2. Classification, Operating Principles and Performance Efficiency of HPs

HP technology is commonly classified according to its source, function, type of energy and application as described below:

heat source: air, ground, water, solar heat, waste water etc.

function: cooling, heating, cooling and heating, DHW heating etc.

type of energy supplied to a HP: electric, mechanical, thermally driven (natural gas, propane, solar heated water, geothermal heated water etc.).

application: residential, commercial, industrial, district heating etc.

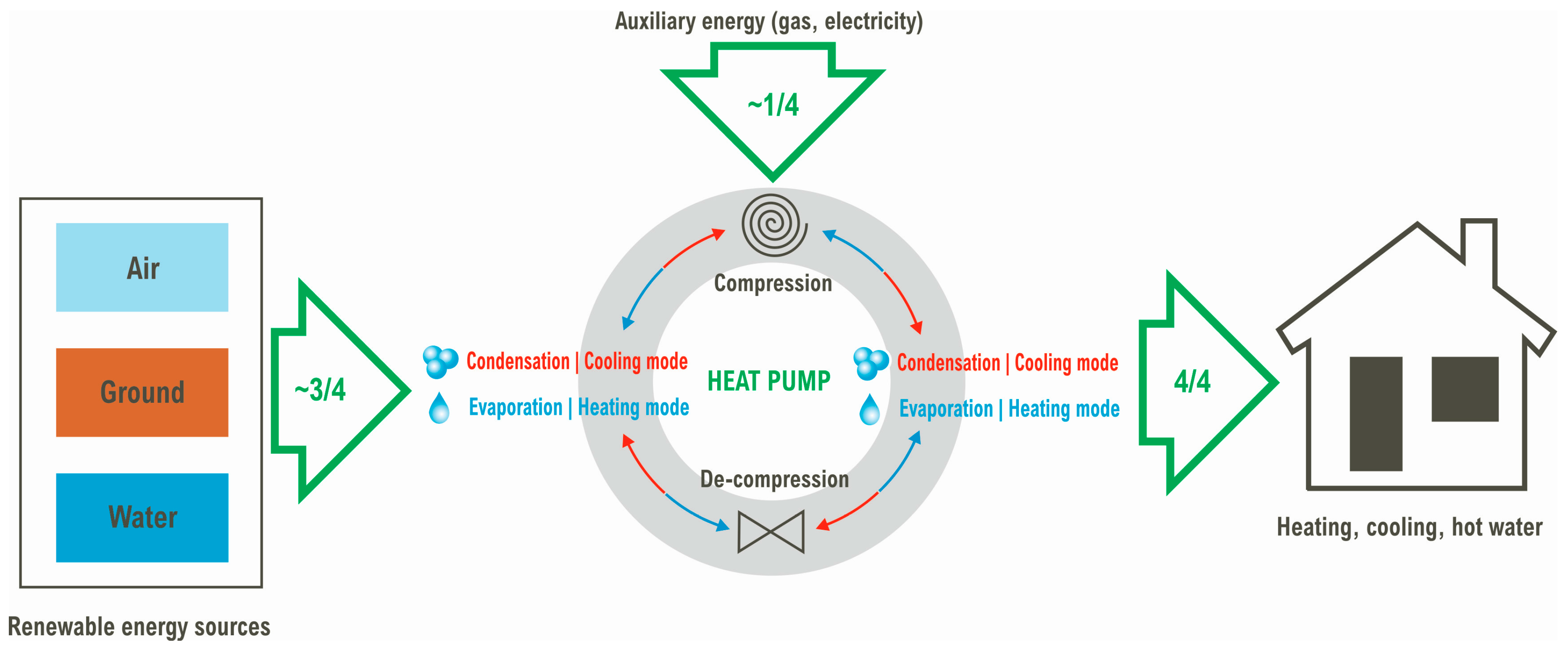

The operation principle of the HP is shown in

Figure 1. Energy transfer in the HP is based on the phase change of refrigerant under the constant thermodynamic cycle. The heat is extracted from the source and transferred to the building energy systems. Reverse cycle HPs have a cooling ability as well, by changing the flow direction of the refrigerant, resulting in heat extraction from the building and rejection to the outside source [

24,

25].

Four main components incorporated within the HP are: the compressor, an expansion valve and two heat exchangers for evaporation and condensation (

Figure 1). The main auxiliary components are fans, piping, controls and housing. HP for heating purposes operates as per the following steps:

In the evaporator, the liquid refrigerant extracts heat from a heat source and evaporates. After the evaporator refrigerant is in the state of low-pressure vapor, then the temperature increases slightly.

The refrigerant in vapor state flows into the electrical compressor; here the pressure is increased, resulting in the increase of the temperature.

High temperature vapor flows to the condenser. The heat transfer to the building’s heating system causes the refrigerant to cool down and condensate to high pressure and temperature liquid.

Hot liquid runs through an expansion valve, where its pressure is reduced, in turn lowering the temperature. The refrigerant returns to the evaporator and the cycle is repeated.

Desuperheaters are included in some HPs performing as an auxiliary heat exchanger supplying heat to a DHW tank (up to 65–70 °C). The desuperheater is placed at the compressor’s exit; it transfers thermal energy of compressed vapor to water that circulates through a hot water tank, therefore reducing or eliminating the energy required for DHW heating [

25].

The most common type of HP classification is according to the heat source. In general, there are three principal types of HPs based on heat source: an air source heat pump (ASHP), ground source heat pump (GSHP) and the water source heat pump (WSHP), and they are described in the following sections.

The other heat sources are worth mentioning too: waste water, industrial waste heat, geothermal water flue gas, district cooling or solar heat. These HP technologies are very promising, but still have limited use.

2.1. Air Source Heat Pump (ASHP)

Air Source Heat Pump (ASHPs) use the ambient air as a heat source. ASHPs (air to air or air to water) utilizing ambient heat are less efficient compared to other types of HPs, when the outside air temperature is lower than −10 °C. They can also be noisy according to the study [

26] performed in Sweden, reporting the average sound level of tested ASHP outdoor units of 61 dB. However, the performance of the ASHP has improved significantly in recent years. Due to better performance of compressors, heat exchangers and refrigerants, modern ASHPs can operate at outside air temperatures as low as −15 °C to −30 °C, subject to the manufacturer and region of distribution. These features, alongside the lower investments and easier installation, made ASHPs more cost-effective in recent years. These units are widely used in residential houses in Scandinavian countries [

27,

28,

29,

30]. In recent years this is also reflected in the sales of HPs in Lithuania [

5,

12].

However, as reported in [

31], in the Finnish cold climate, typical SPF values of ASHP were: 1.8–2.2 for air to air HPs. The study in Canada [

25] showed that equivalent COPs of ASHPs for various heating systems are 2.3–3.5. The analysis of ASHP system in the single family building in Latvia showed that the system can reach an SPF of 3.43, with a lowest COP of 2.6 during the coldest month of January [

32]. The other case studies in Latvia [

33] showed that the SPF of an ASHP varies from 2.45 to 2.62 for average outside air temperatures, respectively, within +2.4 °C and +6.0 °C. These studies suggest that during the cold months ASHPs can operate with an average SPF from 2.93 to 3.2 in a cold climate.

The current level of technical development of ASHP units still suggests these HPs are to be used as a supportive heating source in cold climates. In most cases, ASHP-based systems must be equipped with an additional electric heater or other source of energy to be utilized during the coldest periods of winter.

2.2. Ground Source Heat Pump (GSHP)

The Ground Source Heat Pump (GSHP) uses the ground as a heat source; therefore it consists of heat exchanging loops installed in a horizontal, vertical or oblique fashion. A much lower variation of the source temperature on a daily basis throughout the year is common for GSHP installations compared to the ambient air installations [

34]. The threshold depth of relatively stable ground temperature is considered 0.8 m [

35], yet it depends on such factors as solar radiation patterns, air temperature variations, average snow cover, precipitation and the thermal properties of the soil [

25]. It has been also reported that ground temperature variations are more pronounced on a seasonal basis rather than on a daily basis [

36]. When the range between inside and outside temperatures is large, as is the case for the ASHP, more energy is required to provide the same amount of heat, which reduces the COP [

37]. Operation of GSHPs are usually less affected by excessive temperature differences.

The studies in Finland and Canada showed that typical SPF values for GSHP are 2.6–3.6, while the equivalent COP of GSHP for various heating systems can vary between 3 and 5 in cold climates [

25,

31].

Higher installation cost of GSHP due to drilling compared to ASHP in most cases is compensated by higher performance. However, the cost also depends upon soil properties, and because Lithuania has mainly soft soils, this results in affordable drilling [

5].

2.3. Water Source Heat Pump (WSHP)

A typical WSHP uses water as a heat source brought directly to the HP unit. If there is no barrier between the water heat source (ground water or surface water body) and the evaporator of the HP, the term “open-loop” is applied for this type of HP.

Several factors need to be considered in open-loop installations, and water quality is one of the most important ones. It affects the operation of the heat exchanger between the refrigerant and groundwater, and may lead to its fouling, corrosion and blockage. The second important factor is the adequacy of available water volume and flow rate. The required flow rate through the primary heat exchanger between the refrigerant and groundwater is usually within 5.5 and 11 l/min per system cooling ton (0.027 and 0.054 L/s-kW) [

38]. The demand of water amount can be significant, and it can be regulated by local water resource regulations. The third important factor is handling of the discharged water. There are two options: The groundwater can be re-injected into the ground through separate wells, or it can be discharged into the surface water basins, i.e., rivers, lakes, etc. The feasibility of open-loop systems depends on the local codes and regulations [

39].

The main advantage of WSHP in comparison to GSHP is lower installation costs. Also, it has better thermodynamic performance than closed-loop systems because of wells that supply groundwater at ground temperature and the heat exchanger delivers heat-transfer liquid at temperatures other than ground temperature. Also, the system can be combined with a potable water supply well, in turn decreasing operating costs if water was already pumped for other purposes, such as irrigation [

39].

The study in Romania [

40] showed that the average COP of WSHPs is similar to that of the GSHPs, reaching up to 4.

3. HPs Technology in Lithuania

Lithuania is situated in a colder climate zone where the use of HPs is mainly for heating and DHW, with a limited cooling application. Because of low traditional energy prices and a well-developed district heating network, the HPs were mainly adopted on the Lithuanian market only at the beginning of this century, and then they demonstrated slow growth in the number of installations.

3.1. Climatic Conditions in Lithuania

The Lithuanian climate is considered typical of the central and Nordic European continental climate. Summers are warm and dry, while winters are cold and sometimes severe. The coldest month is January; its daytime temperatures are usually around −5 °C, but for shorter periods air temperatures can be around −20 °C. Heavy snowfall or even snowstorms are usually expected. Because of the proximity to the Baltic Sea, weather is windy, cold and humid. Air temperature in summer during the day reaches 20–25 °C and can go over 30 °C for a period of a few days or weeks. The warmest month of the year is July, with its average temperature of 20 °C.

On the other hand, climate change is evident, and winters in Lithuania are getting warmer with only a few days or weeks of snowfall within the past decade. However, according to the study published by Nikulin et al. [

41], in the future, climate change will result in more frequent strong winter frosts, while the day temperature range is expected to splay out.

According to Lithuanian building codes, climatic data for the heating, ventilation, and air conditioning (HVAC) design has not changed since the 1990s [

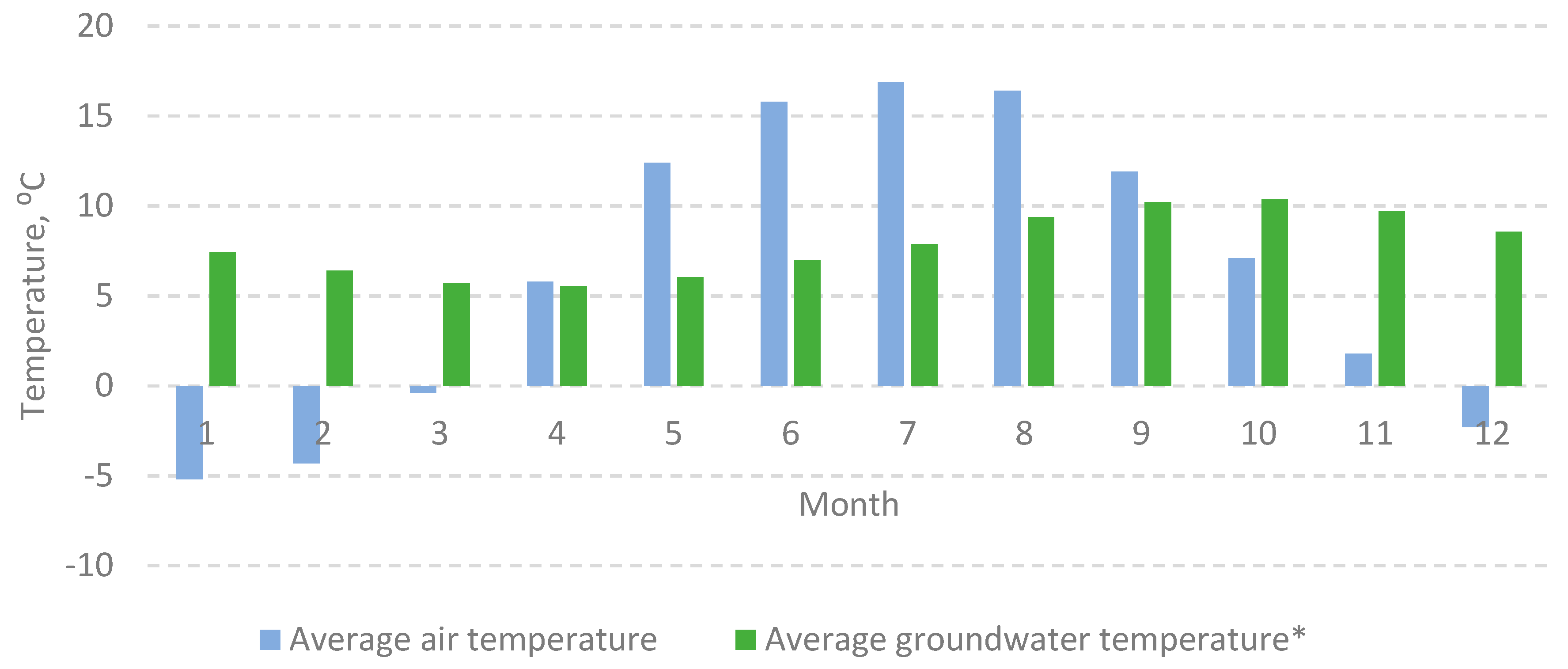

42]. The average temperatures in Kaunas City, located in central Lithuania, and the average groundwater temperature, are presented in

Figure 2. These temperatures are representative of the average temperature of the whole of Lithuania.

3.2. HP Related Environmental, Technical and Legal Aspects of Lithuanian Market

The biggest part of the building stock in Lithuania was built in the second part of the twentieth century. About 60% of the Lithuanian population resides in multi-apartment buildings constructed during 1961–1990. About 40% of people live in one or two-family buildings. Only about 0.2% buildings are non-residential. Compared to the other EU countries with similar climate conditions, energy consumption for residential heating is approximately 1.8 times higher in Lithuania [

43]. Many thousands of twentieth century buildings need renovation for better energy efficiency.

The district heating network in Lithuania covers more than 55% of the total thermal market, and the average price is 0.048 €/kWh, excluding 9% VAT (1 September 2019). In recent years, the district heating energy price dropped by about 12% [

44]. Switching from natural gas to bio fuel reduced the district heating energy price significantly in the last five years. Due to a dramatic decline in oil and natural gas prices, conventional fuel prices decreased by up to 35% in the last five years as well. About 25% of thermal energy in Lithuania is produced by burning bio fuels, followed by natural gas and oil, with the share of 12% and 5%, respectively. Electrical heating is rarely used as a main source for space heating.

In 2019 natural gas prices in Lithuania varied from 0.37 to 0.55 €/m

3 excluding 21% VAT, depending on consumption per calendar year. Electricity prices varied from 0.072 to 0.122 €/kWh, excluding 21% VAT, depending on a selected tariff [

45]. Despite a small fluctuation in recent years, evidence shows that conventional energy prices are on a growing curve at the moment.

According to Lithuanian legislation it is recommended to start the heating season after three consecutive days with an average outdoor air temperature below +10 °C. At present, the heating season starts by October the fifteenth and ends by April the fifteenth. During this period, the average outdoor air temperature is approx. 0 °C [

46]. Indoor air temperature for residential and public buildings should be within +18 to +22 °C.

The survey performed in 2016 showed that major Lithuanian cities and two thirds of the population use district heating, while 18% are using gas heating and 15% has solid fuel-based systems, wood logs and charcoal [

47]. Other heat sources such as electricity, geothermal heating or pellet burning were indicated by a very small proportion of the population.

According to the results of the survey, the choice of the heating method is influenced by the price, availability and convenience. Accordingly, the priority for these heating criteria, heating and availability, was provided by 42% and 39% of respondents during the survey. The comfort was especially emphasized by those residents whose home was heated by natural gas (44%), but the price was also a very important factor for them (38%) [

47].

Costs of heating and other energy needs for buildings are of the most important factors that influence the renewable energy market. It is evident that in most cases the growth of these markets depends upon subsidies. In Lithuania, limited subsidy systems and funds for renewable energy installations existed since 2005. Depending on a project, it is possible to apply for a subsidy covering from 40% to 100% of initial costs. For example, it is possible to get a subsidy up to 50% for a single family building, up to 40% for a multifamily building and up to 100% for hospitals.

About 8938 units of different HPs were sold in 2017 in Lithuania [

12], a country with a population of three million. It shows that HPs have become the most popular choice within newly constructed, single-family residential buildings and their owners. Current trends indicate that HPs are also slowly replacing gas and solid fuel boilers, as well as district heating in existing buildings. Compared to previous years the sales of HPs in 2017 increased significantly. This growth can be attributed to increased efficiency and reduced capital expenses for ASHP installations. On the other hand, the price reduction of solar photovoltaic systems and new storage technologies helped to grow, not only installations of solar photovoltaic systems, but HPs as well.

According to the study from 2016 [

5] it is anticipated that the market of the HP will be consistent in Lithuania until 2020, and within the next five years the adoption rate will remain steady. This is the result of the increasing popularity of HP technology and its competitive life-cycle costs.

A new Lithuanian HP and ventilation association with 20 members has been founded at the beginning of 2017, striving to promote the technical and economic progress of the Lithuanian HP industry. One of the main tasks of the newly established association is to develop and promote a fair and favorable public opinion about HPs, and to raise awareness about the environmental benefits of these systems.

3.3. Case Studies—Representative Implementation of HPs in Lithuania

Despite the HP market in Lithuania appeared only at the beginning of this century, it is growing slowly, and some studies and good practice examples are presented in the following sections.

3.3.1. Small Capacity Single-Family Building HP Installations

In last decade some studies of HPs in single family buildings in Lithuania were presented. A case study by Jonynas et al. [

16] presented an SPF for a real GSHP system. This GSHP system was designed and installed in 2006 for an individual house of 180 m

2 with a low temperature underfloor heating system and DHW preparation (

Figure 3). The investment in the 11 kW GSHP was 15,292 € in 2006. The main purpose of the research study was to explore the seasonal SPF of GSHP. Manufacturer and installer documented COP for the equipment to be 4.5 or even higher. The results of 20-month analysis showed that the SPF has reached 3.02 only and the price of heat energy was 0.031 €/kWh in 2009. In this case there was no economic benefit to use GSHP compared to conventional heating systems.

It is evident that the analyzed GSHP system was not a good design, probably the main problem was the insufficient horizontal ground collector system. On the other hand, this GSHP is still in operation with the 10 years SPF of 2.47 with no significant maintenance expenditure during the last decade (see

Figure 3).

A study performed by Zekas and Martinaitis [

17] reported the use of a GSHP of 15.9 kW capacity in an individual house of 175 m

2 with a low temperature underfloor heating system and DHW supply. The study showed that prevailing COP was from 3.7 to 3.9 which was reached during various characteristic periods of the heating season. In this case the higher efficiency of GSHP was reached due to some important energy needs being excluded, namely energy for DHW, circulation pumps, control equipment, as well as heat losses of the DHW storage tank.

Aleksandravicius and Zinevicius [

18] presented a comparison of an HP and gas boiler heating system with investments of 9372 € for the 13.0 kW GSHP and 1100 € for the gas boiler heating system. The systems were analyzed for the heating purposes of a single-family house of 175 m

2. The calculations were carried out using the prices of the natural gas, electricity and equipment of the year 2012. Results showed that the operation cost of the HP system was 495 €/year and that of the gas boiler system was 3735 €/year. The SPF over the heating season (from October 2007 to April 2008) was 3.95. The study reported that in the short run the gas boiler system looked more financially attractive, but in the long run (10 years) it will be 2.6 times more expensive.

It can be observed that in this study the investments of GSHP were 37% lower than it was presented by other researches [

16,

17] and the calculation method of SPF was not reported.

In 2015 one study [

19] of a 7.4 kW variable-speed low temperature ASHP showed that for the heating mode the COP varied from 1.98 to 3.05 as the outdoor temperature changed from −7.0 °C to +5.0 °C. In this case, at the end of the heating season (heating season was assumed to begin on October 1st and end on May 21st) the total electricity consumption turned out to be 1737 kWh and the total heating output was 5927 kWh, leading to an SPF of 3.41 without taking frosting into account. Consideration of frosting in a simulation model was proven to be significant, resulting in the SPF decrease to 2.86.

A study in 2016 [

47] of different heating systems for a B-class energy performance single family building of 150 m

2 with four inhabitants and with total energy needs for heating and DHW of 20 MWh, showed that solid fuel is still the cheapest way to heat the building in Lithuania. As expected, comparison of capital expenses for solid fuel, natural gas, pellet burning system installations and HP systems was unfavorable to HPs. Nevertheless, HPs outperform conventional systems from the perspective of 10 years’ operating expenses, equal to 0.034 €/kWh. The study in 2018 of seven different heating systems for an A-class energy performance single-family building of 150 m

2 with total energy needs for heating and DHW of 15 MWh showed almost the same results [

48].

3.3.2. Multifamily and Public Building Installations

Some analyses and good practice examples of HP systems in multifamily buildings and public buildings in recent years are presented here.

In 2011 the analysis of ASHP usage in an Alytus City multifamily building was presented [

20]. It showed that compared to district heating prices, the use of ASHP for heating needs in apartment buildings is not economically viable. Without the full building retrofit, in the analyzed case ASHP could save from 7 to 9% of heating cost per multifamily building per year, depending on the interest rate on the loan. In spite of their technical development in most cases, ASHP can be used only as a supportive heating source in Lithuania for a standard but not renovated multifamily building. However, in recent years a series of different ASHPs and even GSHPs were installed in renovated multifamily buildings.

A case study of GSHP installation for heating and cooling purposes in the building of logistics center was presented in 2015 [

21]. A new approach was applied to the construction of the logistic center with the underfloor heating area of 5200 m

2 and a total building volume of 42,000 m

3. A shallow geothermal plant consisted of two HP units (total capacity of 134 kW), using 16 boreholes of 150 m depth with “U-type” heat exchanging loops. Fan coils were applied for cooling for the office part of the building. Total investment was 251,000 €. The commitment to the customer was that the heating and cooling expenses shall not exceed 10,000 €/year at an electricity price of 0.13 €/kWh.

The heating season of 2013/2014 was relatively warm and was characterized by 3200 degree-days instead of the average annual value of 3870. Heating in the logistics center started in October 2013, before the finalizing of the construction work. The temperatures in the office and warehouse spaces were set at 21 °C and 18.5 °C, respectively. The supply water temperature of the heating system in the office did not exceed 30 °C, and 28 °C in the stock. Stable indoor temperatures were maintained, according to the normal heating curve algorithm, additionally adjusting the temperature in every room by thermostatic valves of the floor heating system. The average temperature of water-glycol in the shallow geothermal loop was at least 4 °C. The HP system was automatically shut down at an average three days outdoor temperature of 14 °C.

Energy performance of the building during the heating season was evaluated by the set of energy meters. It showed that the production of thermal energy by HPs was 178.8 MWh, consumption of electricity by HPs was 29.5 MWh, resulting in a COP value of 6.06, excluding the energy used by the circulation pump. Considering the energy for circulators, the SPF of one heating season was 5.57. Total heating expenses for space heating was 4170 € for the whole heating season.

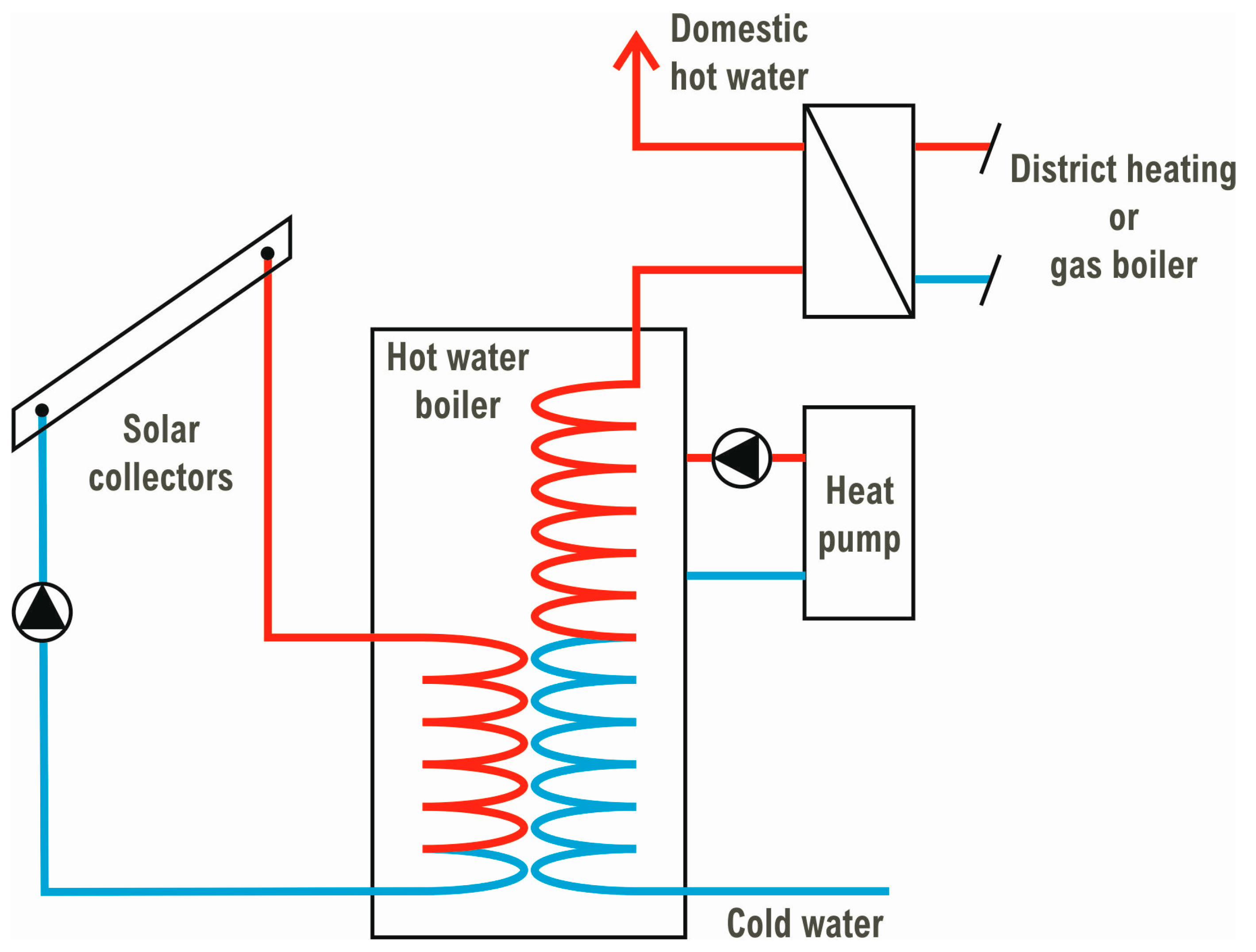

Seventeen projects with ASHP systems (from 15 to 90 kW) and solar thermal systems (from 20 to 210 m

2) were implemented in Lithuanian hospital buildings by using Swiss and Lithuanian state funding in 2016. Most of these systems were designed only for DHW applications. All of these systems were fully automated with solar thermal systems used as the primary energy source, and HPs in operation as a supportive system (

Figure 4).

Analysis of three different systems in 2018 showed that the SPF of HPs varies from 2.42 to 2.61, due to the requirements of the high temperature of DHW (50–60 °C) [

49]. Systems for DHW and swimming pool heating were the most efficient (SPF-2.61). However, in the analyzed cases HPs operate only up to the outdoor temperature of −10 °C. When the temperature is lower than −10 °C it is more efficient to use district heating or gas boiler energy.

The sanatorium Grand SPA Lithuania in Druskininkai City has the biggest installation of an HP system in the Baltic region. The project was funded using local and EU funds. The total heated area of this sanatorium complex is 20,000 m2. HPs (1300 kW) and the passive cooling system have been installed in the facility. The system’s purpose is heating, DHW, the preparation of hot mineral water and the heating of swimming pool water. Heating and cooling demand is satisfied by the combination of ASHP and brine/water HPs, that efficiently recover the energy of wastewater, exhaust air and geothermal energy (boreholes).

The systems implemented in the complex have the following features: brine/water HP with a total nominal power of 1014 kW; the field of geothermal bores (the total depth of 8320 m); natural cooling system using ground (the total capacity of 539 kW); DHW heating system; hot mineral water (up to 80 m

3 of hot water per day) and mud technology heat preparation systems; ASHP with a total nominal power of 264 kW (the exhaust air heat from recuperative ventilation system was used); and heat recovery from complex waste water system (power up to 400 kW) [

5].

The complex still has a possibility to use heating from a district heating network in the case of very low outdoor temperature or lower price compared to the HP system. HPs are covering more than 80% of the heating demand and 100% of the cooling demand, with a passive cooling capacity of approx. 500 kW.

Recently to the many small or medium size projects some new big HP projects in Lithuania were launched in 2018, including a possibility study for HP usage for district heating in Panevezys City. The aim of this study was to reduce the district heating production price. Two cases were analyzed: usage of return energy for HP and usage of wastewater energy for HP. Another 1 MW waste water HP project is going to be implemented in the company “Rokiskio Suris” by using company and EU funds for cheese production technology with an expected COP of more than 4.

5. Future Trends for HPs Usage

While the traditional ASHP, GSHP and WSHP techniques are well established, continuing research and development is focused on reducing installation costs, i.e., speed/ease of installation, solar heat HP, waste water HP, absorption/adsorption HP, combined photovoltaic and HP system efficiency, large-scale district cooling as well as foundations, diaphragm walls and a tunnel lining use for HP.

A study by David et al. [

50] in 2017 presented a review and roadmap of large-scale HP in district heating systems. The review found 149 units, operating at almost 80 locations in 11 European countries with an output capacity of 1580 MW. Approximately 1000 MW of the large-scale HP build in Sweden the 1980s were still operational. These HP could supply temperatures over 70 °C or even 90 °C, while still achieving a COP over 3. This comprehensive study demonstrates that the technical level of the existing large-scale HP is mature enough to make them suitable for replication in other countries such as Lithuania, where district heating networks are well developed.

Very promising technology and a new type of HP for residential systems is absorption/adsorption HP. These HPs use heat as their energy source and can be driven with a wide variant of heat sources, such as natural gas, propane, solar heat or geothermally-heated water.

A review of absorption heating technologies [

51] showed that they are becoming more and more important in energy conservation and emissions reduction. Large scale application has adopted absorption HPs relativity early, but civil applications developed less rapidly because of dependence on traditional heating systems and the popularity of electric-driven HPs. Significant work is still required before absorption heating systems are widely adopted.

A review by Saha et al. [

52] showed that adsorption HP systems are considered as a promising alternative to the mechanical systems. The environmental benefits of these thermally-driven HP are impressive. Difficulties in improving its performance are overcome day by day with the development of innovative adsorbents and system design.

Building foundations, diaphragm walls and tunnels have potential for the incorporation of a geothermal HP system into a structure. A construction of a building’s foundation requires excavation and/or drilling. Incorporation of a ground heat exchanger into the foundation excavation or boreholes significantly lowers the cost of installations in comparison with an installation of a conventional ground heat exchanger.

The use of foundations, diaphragm walls, tunnel linings, anchors and other underground geotechnical structures as energy geostructures significantly increases in Europe and all around the world. At first a foundation’s bearing slabs and a basement walls were used for energy exchange, afterwards bearing piles quickly followed (mid-1980s), diaphragm walls (mid-1990s) and then tunnels (early-2000s) [

53,

54,

55]. Each of these types is described in more detail in the following.

5.1. Energy Foundations and Diaphragm Walls

Pile foundations and diaphragm walls perform the dual function of exchanging heat and providing structural support, and are only installed at sites where pile foundations are already required; these systems provide the thermal performance of shallow geothermal energy systems at no additional drilling costs (

Table 2). There is a significant amount of cost saving if underground structures can be utilized as an energy source. Heat exchanging loops (absorber pipes) are installed within the reinforcement horizontally in slabs and pile rafts and vertically in diaphragm walls and pile foundations.

Underground energy geotechnical structures have the dual role of providing structural support and transfer heat with the surrounding ground to supply heat energy for the heating and cooling of buildings and deicing structures such as roads and bridges. The heat exchange is achieved by installing loops in the underground energy structures, in which heat is extracted or injected from or into the ground by a circulating fluid pumped by HP. These systems are categorized as low enthalpy geothermal energy systems and indeed work with HP technology [

56].

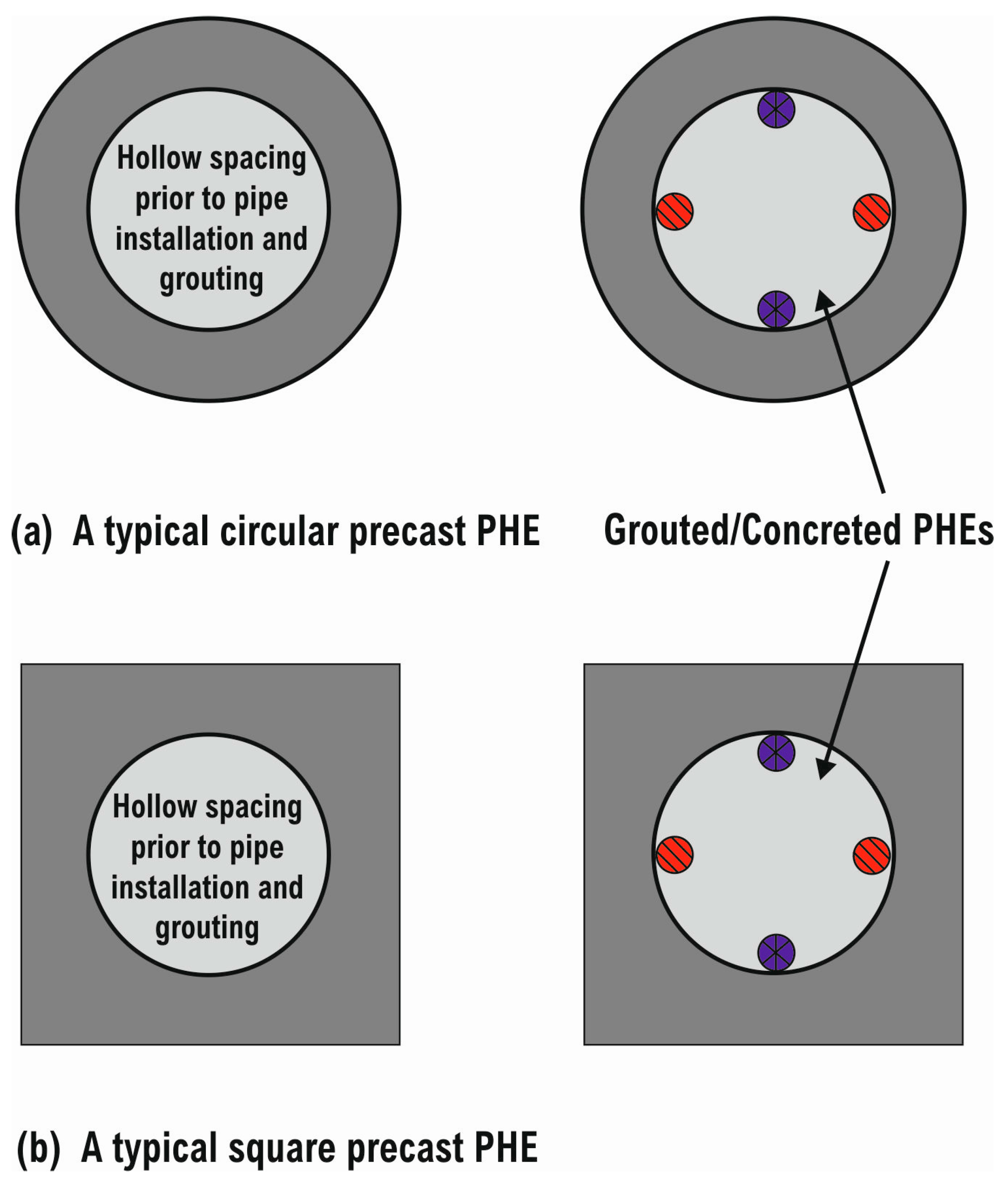

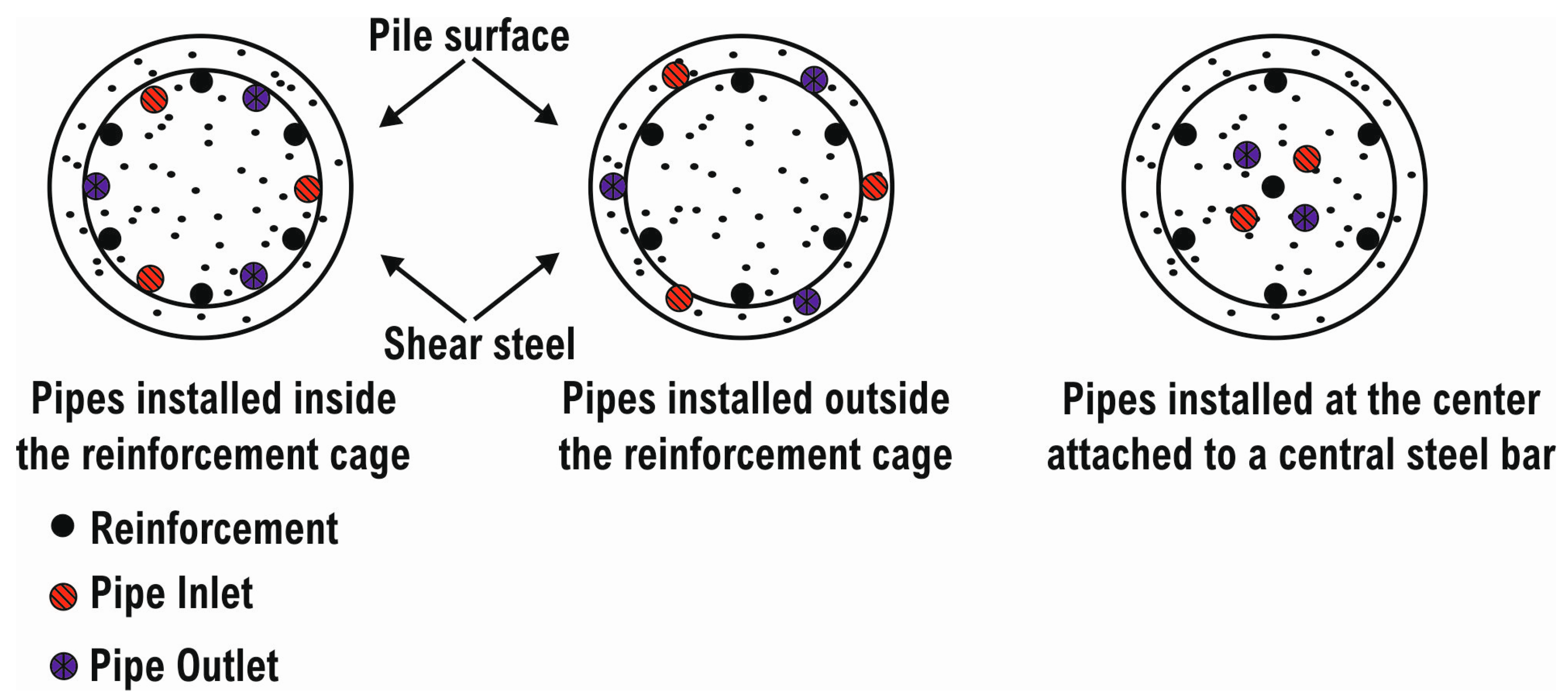

Energy piles also known as pile heat exchangers (PHEs) and thermal piles have particularly gained popularity in Europe due to their easy and quick installation. Existing pile installation techniques such as the driven technique (for precast pile) and bored technique (for cast in-situ pile) have been modified slightly to accommodate the installation of absorber pipes with reinforcement. Precast concrete energy piles with hollow central spaces can be built into the soil before installing the energy loops in the hollow space and filling it with cement mortar to ensure a good contact between these loops and the concrete pile. A typical cross-section of a precast energy pile is shown in

Figure 5. Steel piles can also be driven and filled with concrete. Additionally, the coring technique could also be employed to fit absorber pipes in the case of hardened concrete piles already installed in the ground.

In the bored technique, holes are bored in the ground and supported by a casing (in case of loose soil), followed by installing the reinforcement cage with absorber pipes attached prior to concreting. The loops (absorber pipes) are attached the reinforcement cage, either to the inner or outer surface, and the loops’ length is matched with the length of the reinforcement cage rather than the design thermal load in the bored piles, as shown in

Figure 6. Contiguous flight auger (CFA) piles intended for energy purposes consist of energy loops attached to a central steel bar to provide support to the loops when they are being pushed into fresh concrete. CFA piles are more common due to their fast installation. The pipes are pressurized and maintained at a nominal pressure of 8 bars (800 kPa), to prevent collapse due to concrete-imposed load during concreting in bored piles or when pipes are being pushed into concrete in CFA piles.

A large number of energy pile/wall installations are already operational, especially in the United Kingdom, Switzerland, Austria and Germany [

57,

58,

59,

60,

61,

62,

63,

64,

65]. However, deep and shallow foundations, energy piles and diaphragm walls bring new challenges to geotechnical pile design. During a heat exchange operation, the pile will expand and contract relative to the soil as heat is injected and extracted, respectively. These relative movements have the potential to alter the shear transfer mechanism at the pile-soil interface. Furthermore, the range of temperature increases near the pile surface, and though limited by practical operational guidelines, this can have a significant effect on pore pressure generation and soil strength.

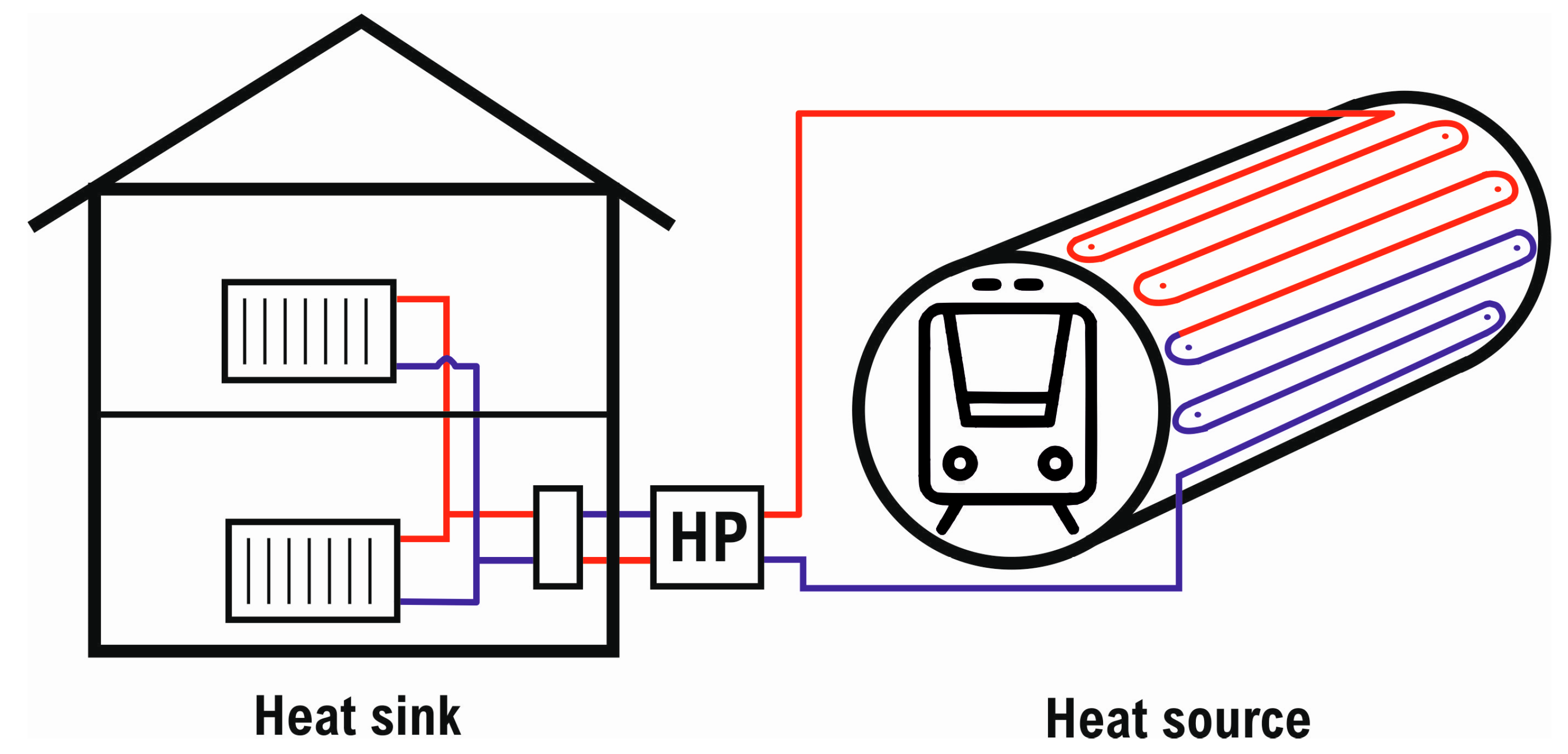

5.2. Energy Tunnels

An innovative and very promising technology is the use of energy from tunnels. In this case heat exchanging loops can be installed in a tunnel lining to allow heat exchange either with air or surrounding ground (

Figure 7). There are various tunnel techniques such as cut and cover, the tunnel boring method (TBM) and the new Austrian tunneling method (NATM). Energy loops (absorber pipes) can be installed on site and as a precast tunnel segment.

Energy tunnels have the advantage of using a larger volume of ground and surface for heat exchange in comparison to energy piles/walls. There are two types of energy tunnels, viz. cold and hot. In the case of a cold tunnel, the air temperature inside the tunnel is similar to the surrounding ground temperature, while in the hot tunnel, it is higher due to the movement of trains and applying brakes. The ventilation system required for hot tunnels can be partially substituted by a geothermal system [

55].

However, the practical implementation of energy tunnel technology is limited at the moment, and only few experimental energy tunnels have been trialed in Austria, Germany and Italy. This is a new technology which requires a business model to utilize the heat from energy tunnels by neighboring buildings and also the initial installation cost and the energy extraction strongly depends upon a specific site [

59,

66,

67].

Presently, design guidelines are not well defined, which can guide contractors to install heat exchanging loops in the tunnel lining without compromising the safety and serviceability of the tunnel. A number numerical studies have been reported which highlight various aspects of the energy tunnel behavior that should be taken into account by both contractors and design engineers planning and undertaking a project [

68].

6. Conclusions

The HPs in Lithuania and similar cold climate countries are accepted as one of the most outstanding technologies of heating in both residential and commercial buildings, because they provide high SPF, 1.8–3.4 for ASHP and 2.5–5.6 for GSHP and WSHP. However, the spread is large, because of different equipment, design and installation quality as well as maintenance. HP efficiency has increased significantly in last decade, particularly that of ASHP. This has influenced a growing popularity of these HPs in the residents’ building market.

While the traditional ASHP, GSHP and WSHP techniques are conventional, the ongoing research and development works are focused on the reduction of installation costs; i.e., decreasing of installation time and complexity, solar heat HP, waste water HP, absorption/adsorption HP, foundations, diaphragm walls, tunnel linings used for HP. Presently comprehensible design guides and standards are missing. These manuals have to cover a methodology for the establishing of thermal actions; how they should be performed in terms of safety and serviceability of the energy geostructure. There is an ongoing need to demonstrate the efficacy of building pile foundations as energy piles and energy tunnel systems considering investments, heat exchange potential and the impact of heat exchange operations on the structure itself.

The main factor hindering market growth in Lithuania is the high initial cost of these HPs. The payback period of HP systems in most cases is too long to ensure the stable growth of HP applications without governmental grants. Despite the long payback period the market of HP systems is slowly growing, and the trend continues towards larger HP systems in multifamily buildings, hospitals, hotels and other large complexes due to support from EU and other funds.