Influence of T-Shape Tip Clearance on Energy Performance and Broadband Noise for a NACA0009 Hydrofoil

Abstract

1. Introduction

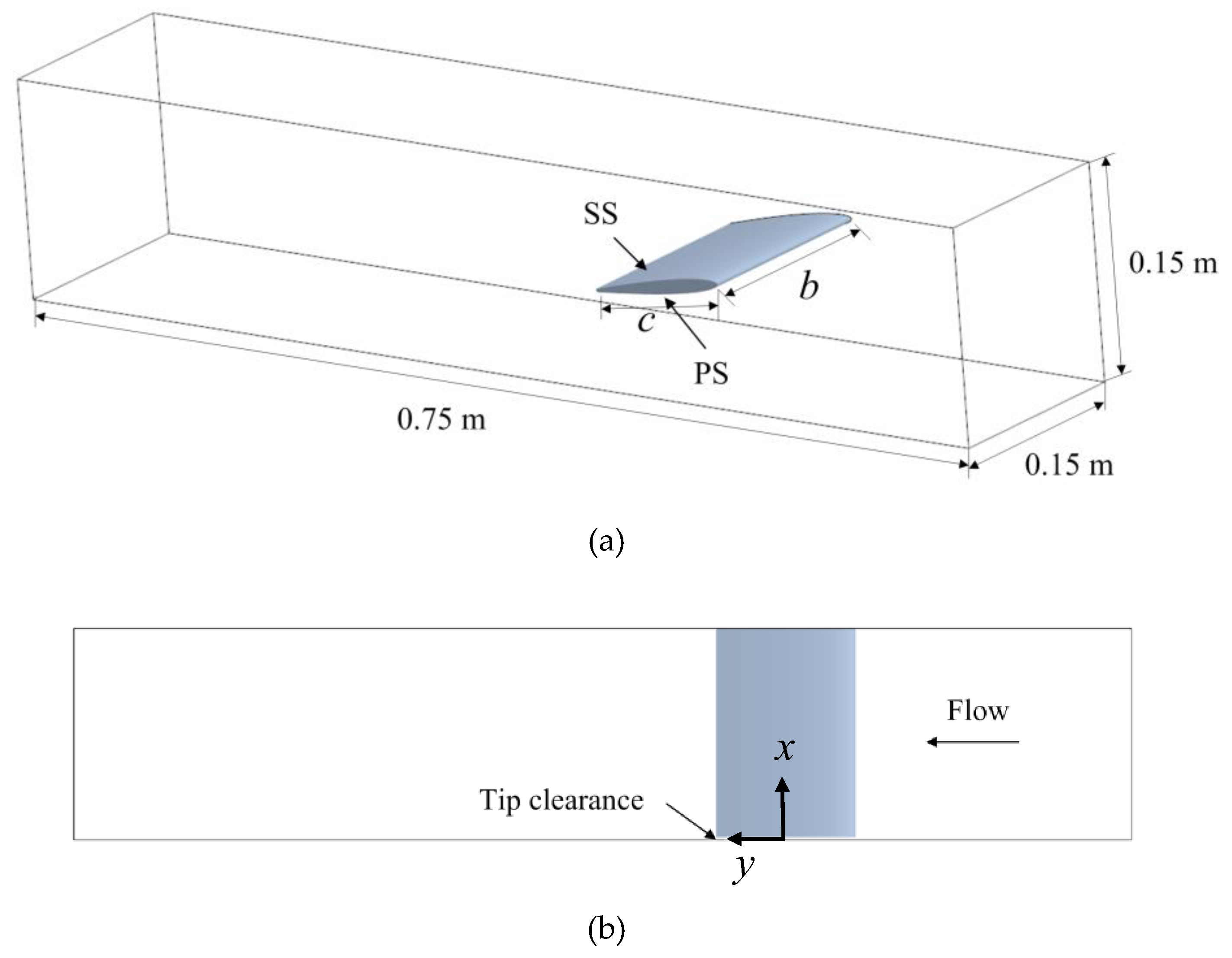

2. Research Object and T-Shape Tip

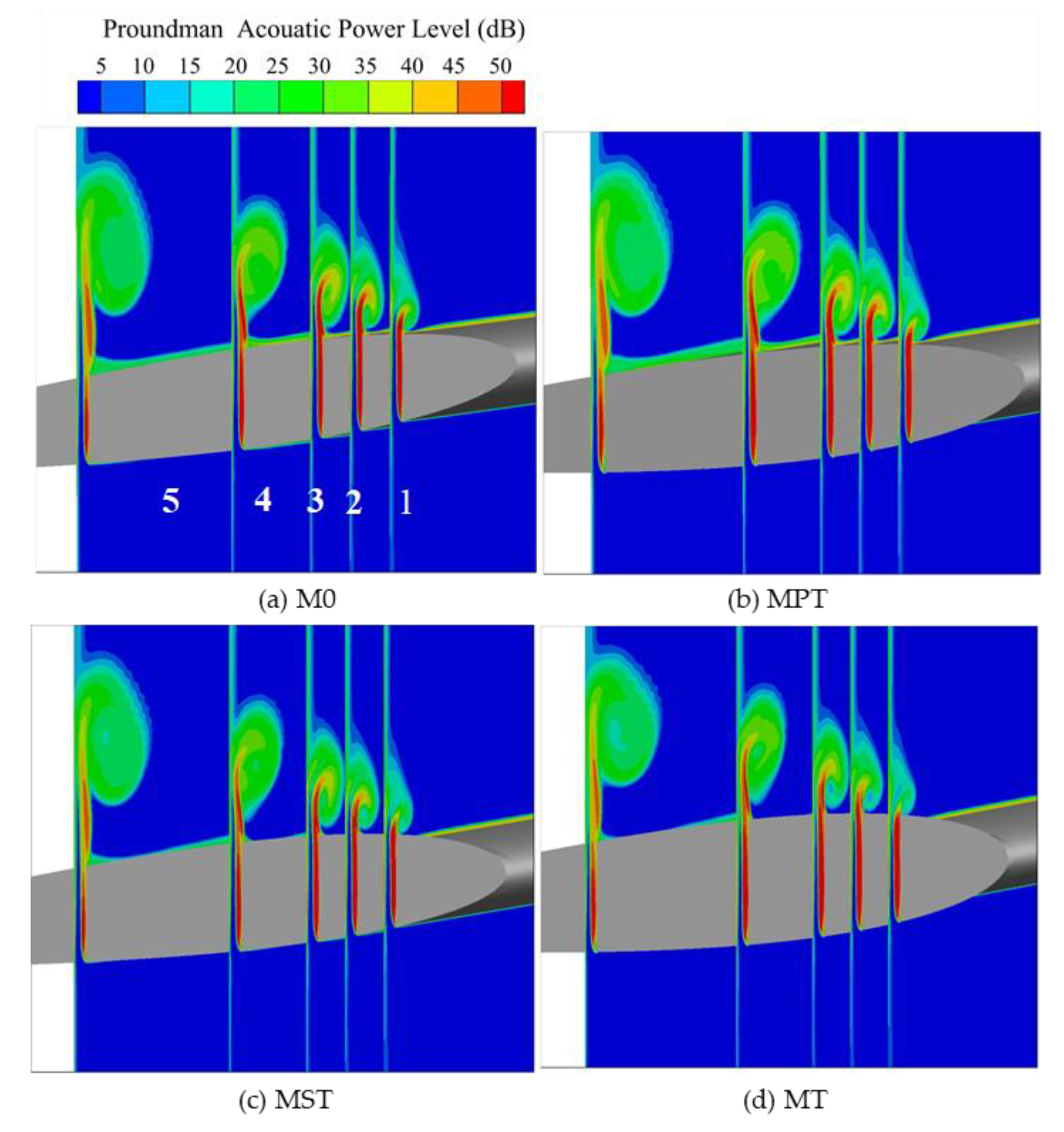

2.1. Physical Model of NACA0009 Hydrofoil

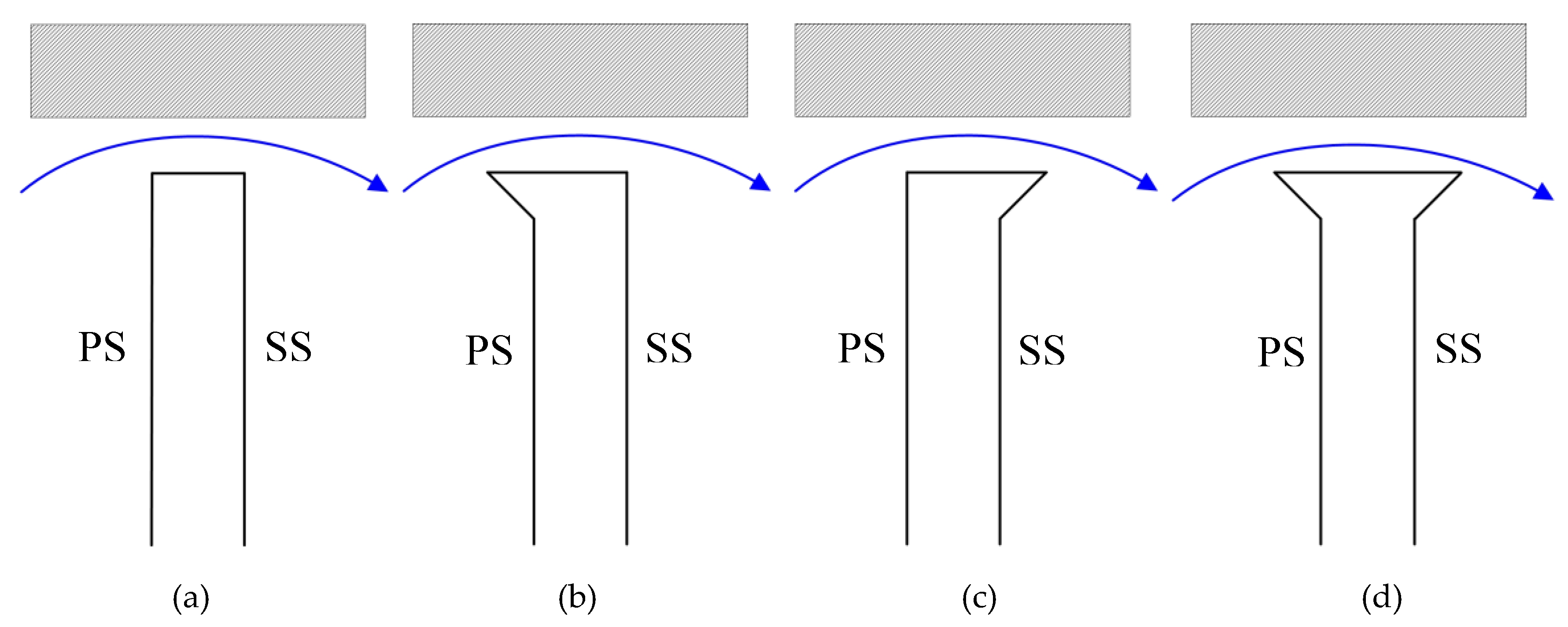

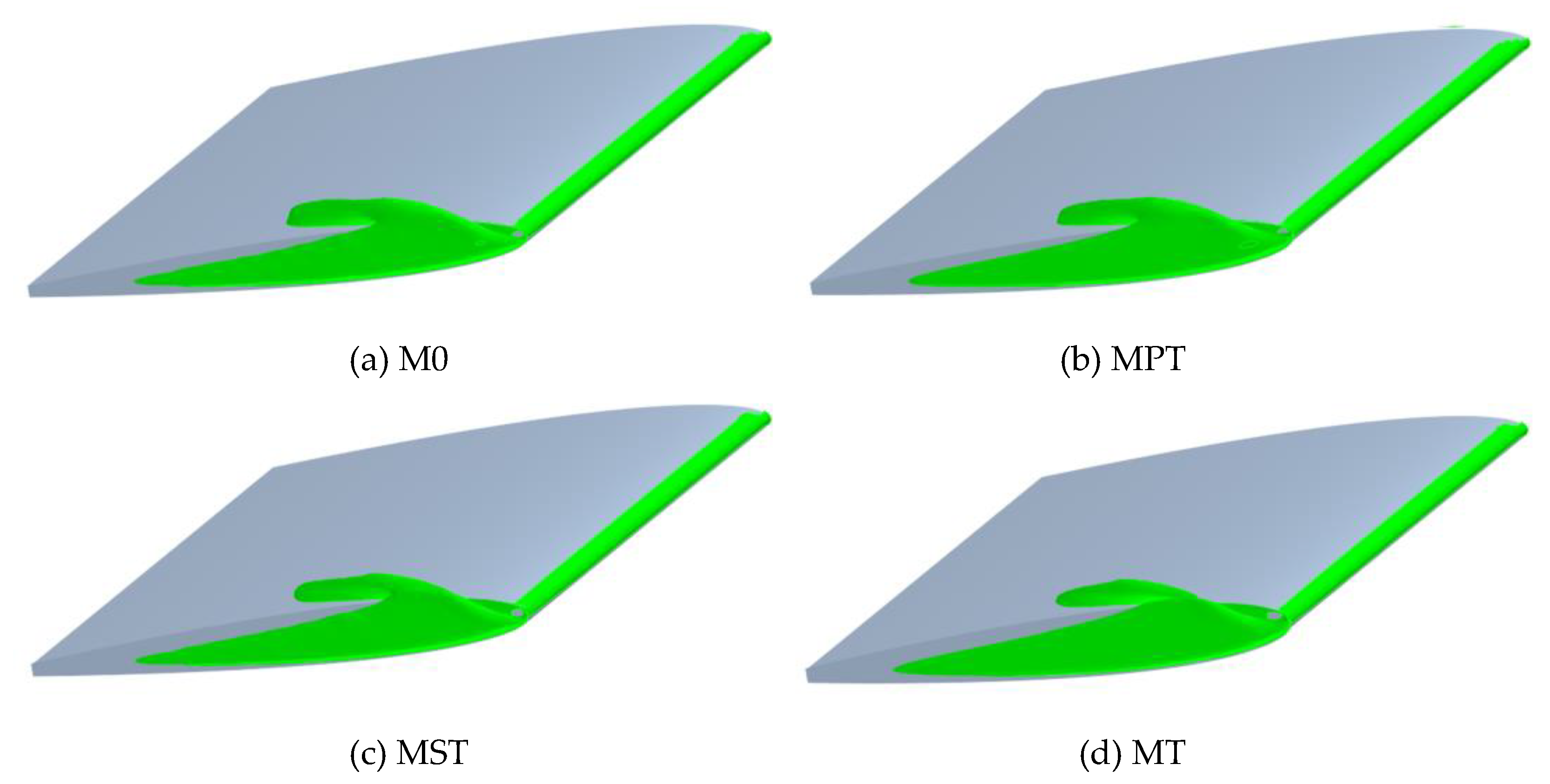

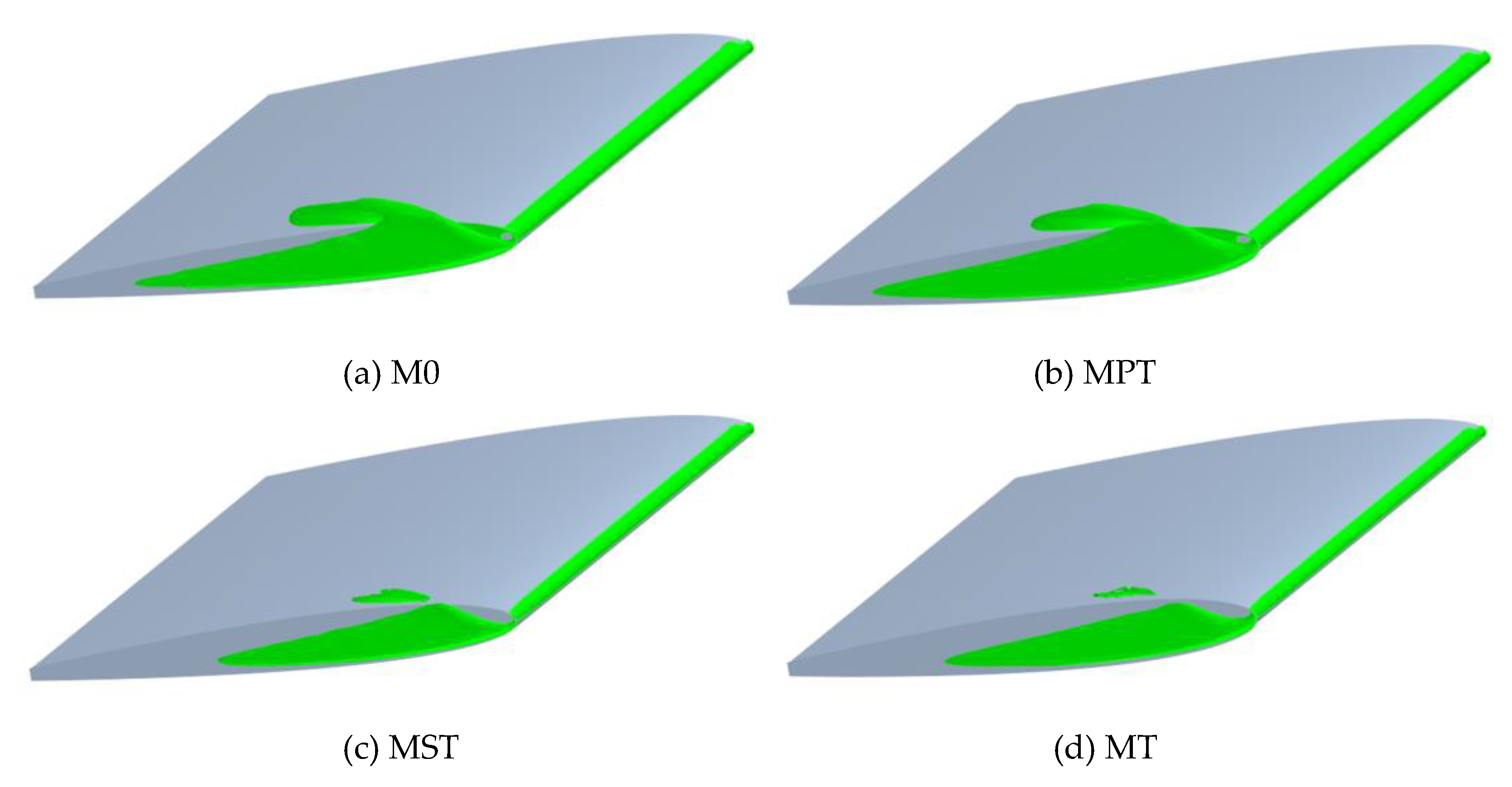

2.2. T-Shape Tips

3. Numerical Setting and Validation

3.1. Numerical Method

3.2. Mesh Indepedence

3.3. Validation of Numerical Results

4. Result and Discussion

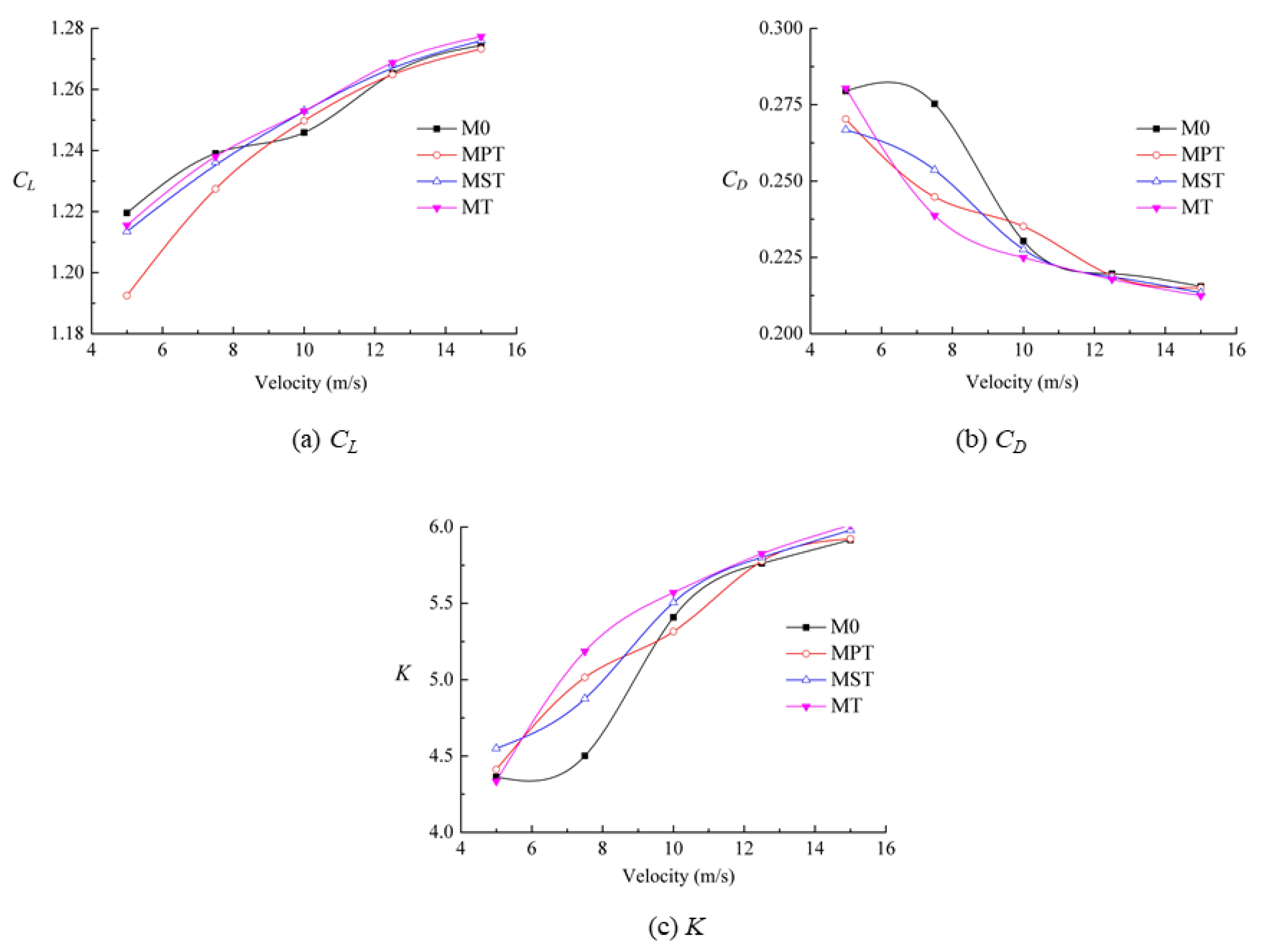

4.1. Energy Performance

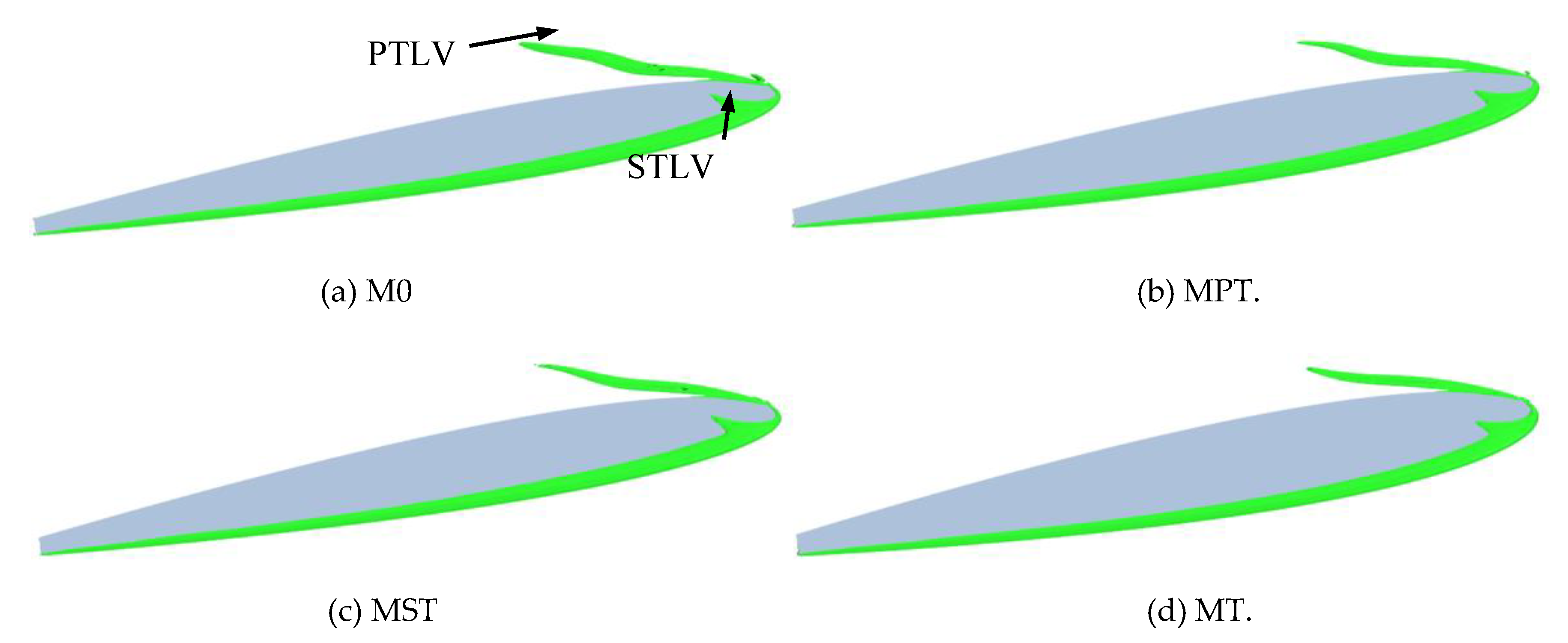

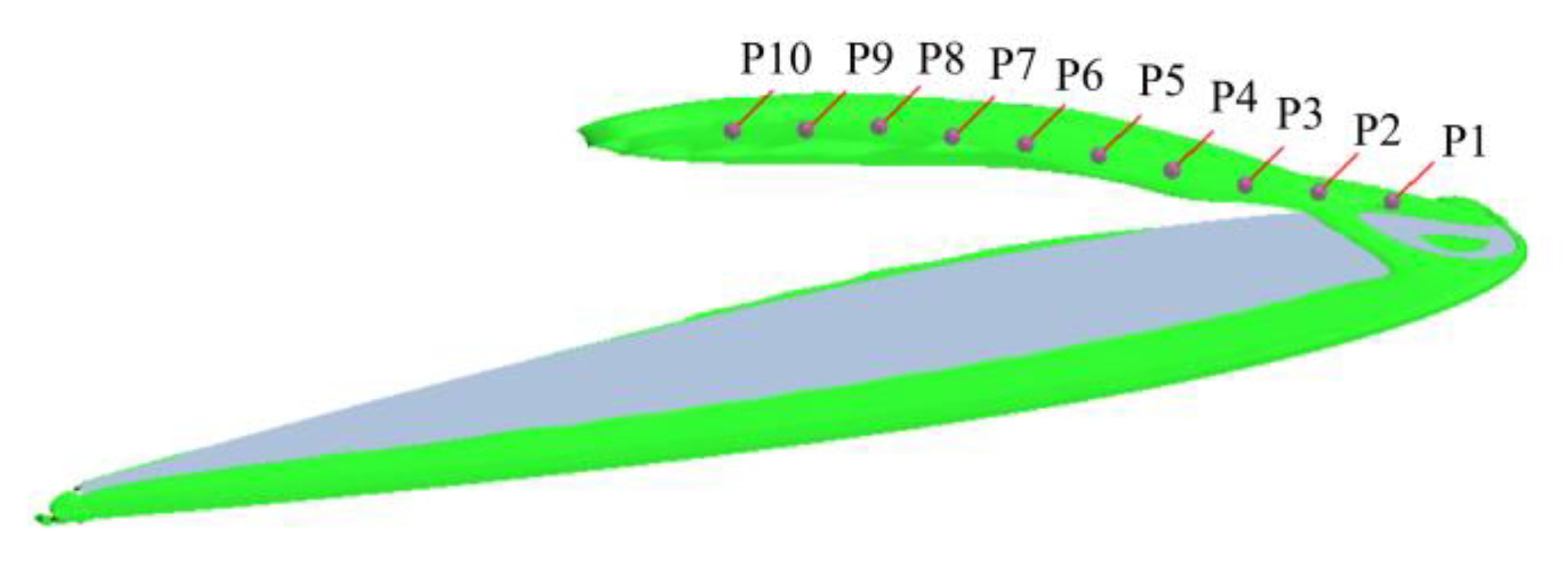

4.2. Flow Patterns in the Gap

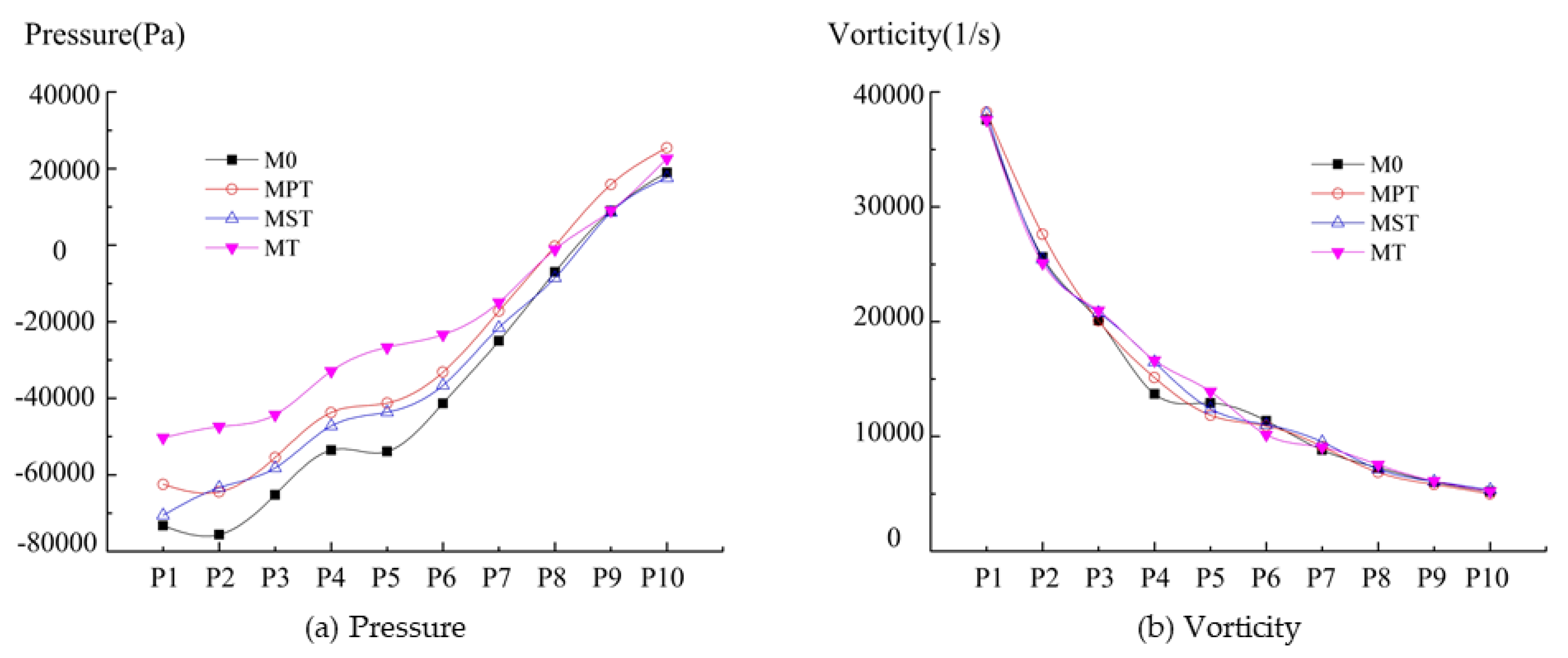

4.3. Curle Surface Acoustic Power Characteristic

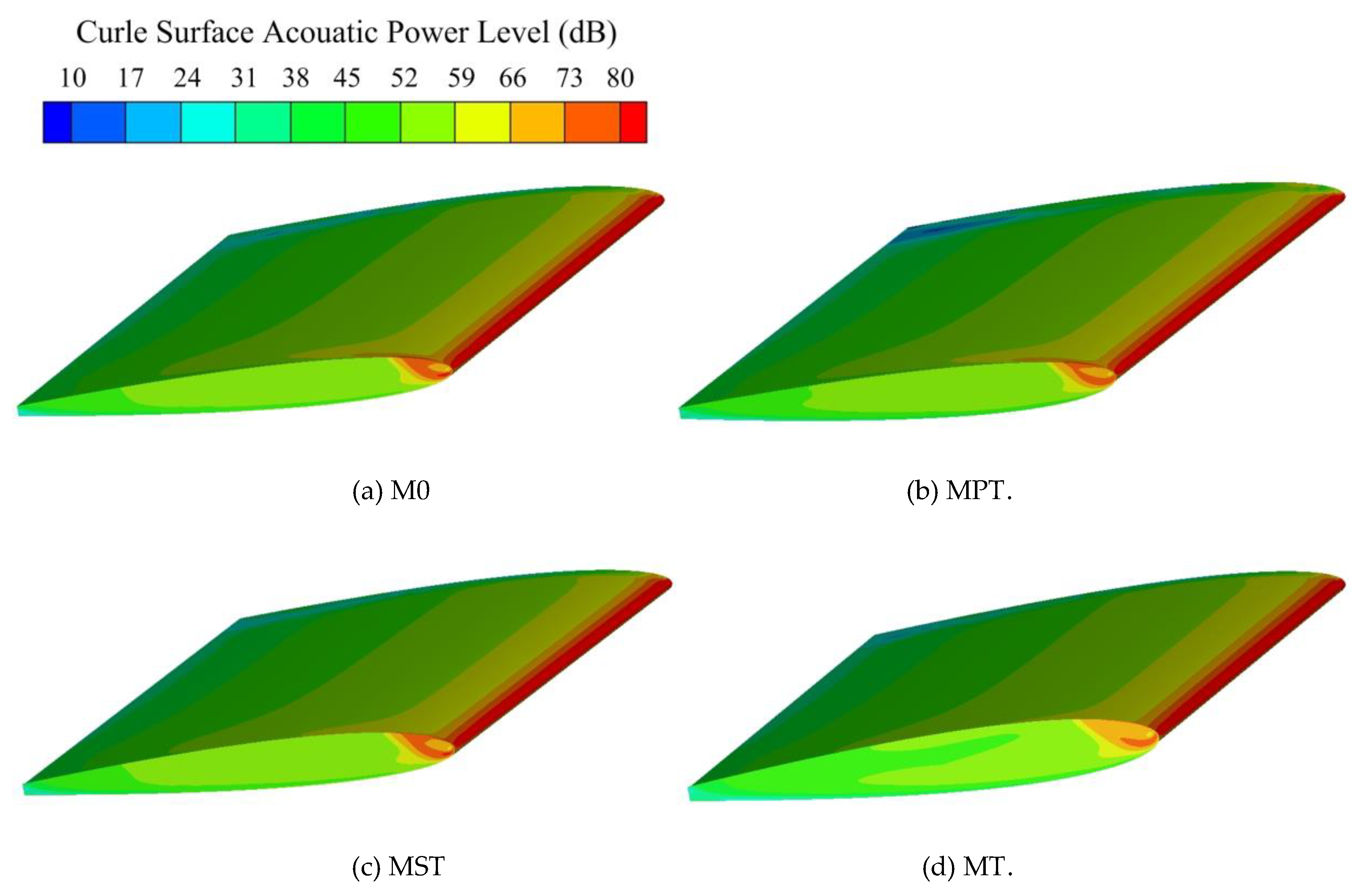

4.4. Proudman Acoustic Power Characteristic

5. Conclusions

- (1)

- The impact of the T-shape tip on lift coefficient, drag coefficient and ratio of lift coefficient to drag coefficient is complex. Under all inlet velocities, the MST model effectively improves ratio of lift coefficient to drag coefficient with maximum promotion of 4.26%. In addition, the ratio of lift coefficient to drag coefficient for the MT model obviously increases when the inlet velocity is 7.5 m/s, 10 m/s, 12.5 m/s and 15 m/s, and the maximum promotion is 15.21% at 7.5 m/s.

- (2)

- The T-shape tip can suppress the TLV, which makes the vortex area decrease with a maximum drop of 5.02%. The three optimization configurations improve the pressure along the PTLV trajectory near the leading edge.

- (3)

- The MPT and MT have good suppression effect on the hydrofoil dipole noise, and reduce the maximum Curle AP of the foil with 2.64% and 3.03%, respectively.

- (4)

- Compared with the original foil M0, the MST model obviously reduces the area of the Proudman AP by 6.55% for 55 dB. However, the optimization models of the MPT and MT cannot effectively reduce the total area of the Proudman AP.

Author Contributions

Funding

Conflicts of Interest

References

- Li, X.; Jiang, Z.; Zhu, Z.; Si, Q.; Li, Y. Entropy generation analysis for the cavitating head-drop characteristic of a centrifugal pump. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2018, 232, 4637–4646. [Google Scholar] [CrossRef]

- Li, X.; Gao, P.; Zhu, Z.; Li, Y. Effect of the blade loading distribution on hydrodynamic performance of a centrifugal pump with cylindrical blades. J. Mech. Sci. Technol. 2018, 32, 1161–1170. [Google Scholar] [CrossRef]

- Liu, M.; Tan, L.; Cao, S. Theoretical model of energy performance prediction and BEP determination for centrifugal pump as turbine. Energy 2019, 172, 712–732. [Google Scholar] [CrossRef]

- Tan, L.; Zhu, B.; Cao, S.; Wang, Y.; Wang, B. Numerical simulation of unsteady cavitation flow in a centrifugal pump at off-design conditions. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2014, 228, 1994–2006. [Google Scholar]

- Tan, L.; Zhu, B.; Wang, Y.; Cao, S.; Gui, S. Numerical study on characteristics of unsteady flow in a centrifugal pump volute at partial load condition. Eng. Comput. 2015, 32, 1549–1566. [Google Scholar] [CrossRef]

- Zhang, W.; Yu, Z.; Li, Y. Application of a non-uniform bubble model in a multiphase rotodynamic pump. J. Pet. Sci. Eng. 2019, 173, 1316–1322. [Google Scholar] [CrossRef]

- Zhang, W.; Yu, Z.; Li, Y.; Yang, J.; Ye, Q. Numerical analysis of pressure fluctuation in a multiphase rotodynamic pump with air–water two-phase flow. Oil Gas Sci. Technol. 2019, 74, 18. [Google Scholar] [CrossRef]

- Li, X.-S.; Song, Y.; Hao, Z.-R.; Gu, C.-W. Cavitation Mechanism of Oil-Film Bearing and Development of a New Gaseous Cavitation Model Based on Air Solubility. J. Tribol. 2012, 134, 031701. [Google Scholar] [CrossRef]

- Wang, Y.; Ren, X.; Li, X.; Gu, C. Numerical investigation of air-oil-thermal coupling mechanism in floating ring. J. Tribol. 2018, 140, 031701. [Google Scholar]

- Liu, M.; Tan, L.; Cao, S. Cavitation-vortex-turbulence interaction and one-dimensional model prediction of pressure for hydrofoil ALE15 by large eddy simulation. ASME J. Fluids Eng. 2019, 141, 021103. [Google Scholar] [CrossRef]

- Cheng, H.Y.; Bai, X.R.; Long, X.P.; Ji, B.; Peng, X.X.; Farhat, M. Large eddy simulation of the tip-leakage cavitating flow with an insight on how cavitation influences vorticity and turbulence. Appl. Math. Model. 2020, 77, 788–809. [Google Scholar] [CrossRef]

- Liu, Y.; Tan, L.; Wang, B. A Review of Tip Clearance in Propeller, Pump and Turbine. Energies 2018, 11, 2202. [Google Scholar] [CrossRef]

- Wu, H.; Miorini, R.L.; Katz, J. Measurements of the tip leakage vortex structures and turbulence in the meridional plane of an axial water-jet pump. Exp. Fluids 2011, 50, 989–1003. [Google Scholar] [CrossRef]

- Wu, H.; Tan, D.; Miorini, R.L.; Katz, J. Three-dimensional flow structures and associated turbulence in the tip region of a waterjet pump rotor blade. Exp. Fluids 2011, 51, 1721–1737. [Google Scholar] [CrossRef]

- Zhang, D.; Shi, W.; Pan, D.; Dubuisson, M. Numerical and Experimental Investigation of Tip Leakage Vortex Cavitation Patterns and Mechanisms in an Axial Flow Pump. J. Fluids Eng. 2015, 137, 121103. [Google Scholar] [CrossRef]

- Zhang, D.; Shi, W.; Van Esch, B.B.; Shi, L.; Dubuisson, M. Numerical and experimental investigation of tip leakage vortex trajectory and dynamics in an axial flow pump. Comput. Fluids 2015, 112, 61–71. [Google Scholar] [CrossRef]

- Dreyer, M.; Decaix, J.; Münch-Alligné, C.; Farhat, M. Mind the gap: A new insight into the tip leakage vortex using stereo-PIV. Exp. Fluids 2014, 55, 1–13. [Google Scholar] [CrossRef]

- Gopalan, S.; Katz, J.; Liu, H.L. Effect of Gap Size on Tip Leakage Cavitation Inception, Associated Noise and Flow Structure. J. Fluids Eng. 2002, 124, 994–1004. [Google Scholar] [CrossRef]

- Liu, Y.; Tan, L. Tip clearance on pressure fluctuation intensity and vortex characteristic of a mixed flow pump as turbine at pump mode. Renew. Energy 2018, 129, 606–615. [Google Scholar] [CrossRef]

- Hao, Y.; Tan, L.; Yue, H.; Lei, T. Symmetrical and unsymmetrical tip clearances on cavitation performance and radial force of a mixed flow pump as turbine at pump mode. Renew. Energy 2018, 127, 368–376. [Google Scholar] [CrossRef]

- Liu, Y.; Tan, L. Spatial–Temporal Evolution of Tip Leakage Vortex in a Mixed-Flow Pump with Tip Clearance. J. Fluids Eng. 2019, 141, 081302. [Google Scholar] [CrossRef]

- Guo, Q.; Zhou, L.; Wang, Z. Numerical evaluation of the clearance geometries effect on the flow field and performance of a hydrofoil. Renew. Energy 2016, 99, 390–397. [Google Scholar] [CrossRef]

- Okita, K.; Ugajin, H.; Matsumoto, Y. Numerical Analysis of the Influence of the Tip Clearance Flows on the Unsteady Cavitating Flows in a Three-Dimensional Inducer. J. Hydrodyn. 2009, 21, 34–40. [Google Scholar] [CrossRef]

- Zhang, J.; Fan, H.; Zhang, W.; Xie, Z. Energy performance and flow characteristics of a multiphase pump with different tip clearance sizes. Adv. Mech. Eng. 2019, 11, 1–14. [Google Scholar] [CrossRef]

- Decaix, J.; Balarac, G.; Dreyer, M.; Farhat, M.; Munch, C. RANS and LES computations of the tip-leakage vortex for different gap widths. J. Turbul. 2015, 16, 309–341. [Google Scholar] [CrossRef]

- Decaix, J.; Dreyer, M.; Balarac, G.; Farhat, M.; Münch, C. RANS computations of a confined cavitating tip-leakage vortex. Eur. J. Mech.-B/Fluids 2018, 67, 198–210. [Google Scholar] [CrossRef]

- Gearhart, W.S. Tip clearance cavitation in shrouded underwater propulsors. J. Aircr. 1966, 3, 185–192. [Google Scholar] [CrossRef]

- Laborde, R.; Chantrel, P.; Mory, M. Tip Clearance and Tip Vortex Cavitation in an Axial Flow Pump. J. Fluids Eng. 1997, 119, 680–685. [Google Scholar] [CrossRef]

- Liu, Y.; Tan, L. Method of C groove on vortex suppression and energy performance improvement for a NACA0009 hydrofoil with tip clearance in tidal energy. Energy 2018, 155, 448–461. [Google Scholar] [CrossRef]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Mishra, A.A.; Mukhopadhaya, J.; Iaccarino, G.; Alonso, J. Uncertainty estimation module for turbulence model predictions in SU2. AIAA J. 2018, 57, 1066–1077. [Google Scholar] [CrossRef]

- Ringwall, E. Aeroacoustic Sound Sources around the Wheels of a Passenger Car-A Computational Fluid Dynamics Study Using Steady State Models to Evaluate Main Sources of Flow Noise. Master’s Thesis, Department of Applied Mechanics Chalmers University of Technology, Gothenburg, Sweden, 2017. [Google Scholar]

| Items | Elements | CD | CL |

|---|---|---|---|

| Mesh 1 | 2715286 | 0.307 | 1.233 |

| Mesh 2 | 5500833 | 0.23 | 1.246 |

| Mesh 3 | 6899538 | 0.23 | 1.246 |

| Scheme Item | MPT | MST | MT | |

|---|---|---|---|---|

| ΔSAP% (Hydrofoil) | Maximum SAP | −2.64 | 0.03 | −3.03 |

| Average SAP | −0.50 | −0.04 | −0.97 | |

| ΔSAP% (Tip) | Maximum SAP | −2.11 | −0.81 | −4.75 |

| Average SAP | −1.92 | 0.33 | −1.74 | |

| ΔSAP% (Side wall) | Maximum SAP | 0.20 | −0.39 | −0.43 |

| Average SAP | −0.12 | −0.01 | −0.12 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Z.; Han, Y.; Tan, L.; Huang, C. Influence of T-Shape Tip Clearance on Energy Performance and Broadband Noise for a NACA0009 Hydrofoil. Energies 2019, 12, 4066. https://doi.org/10.3390/en12214066

Huang Z, Han Y, Tan L, Huang C. Influence of T-Shape Tip Clearance on Energy Performance and Broadband Noise for a NACA0009 Hydrofoil. Energies. 2019; 12(21):4066. https://doi.org/10.3390/en12214066

Chicago/Turabian StyleHuang, Zhenwei, Yadong Han, Lei Tan, and Chuibing Huang. 2019. "Influence of T-Shape Tip Clearance on Energy Performance and Broadband Noise for a NACA0009 Hydrofoil" Energies 12, no. 21: 4066. https://doi.org/10.3390/en12214066

APA StyleHuang, Z., Han, Y., Tan, L., & Huang, C. (2019). Influence of T-Shape Tip Clearance on Energy Performance and Broadband Noise for a NACA0009 Hydrofoil. Energies, 12(21), 4066. https://doi.org/10.3390/en12214066