Thermal Analysis of the Factors Influencing Junction Temperature of LED Panel Sources

Abstract

1. Introduction

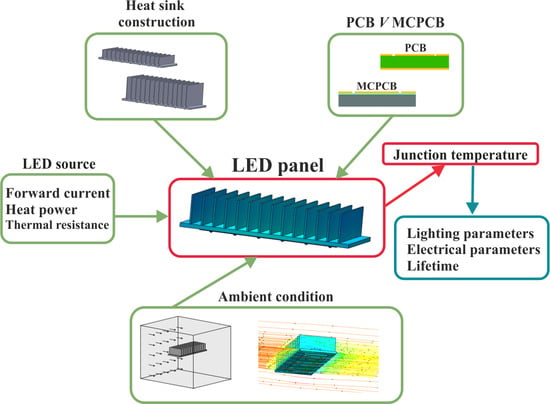

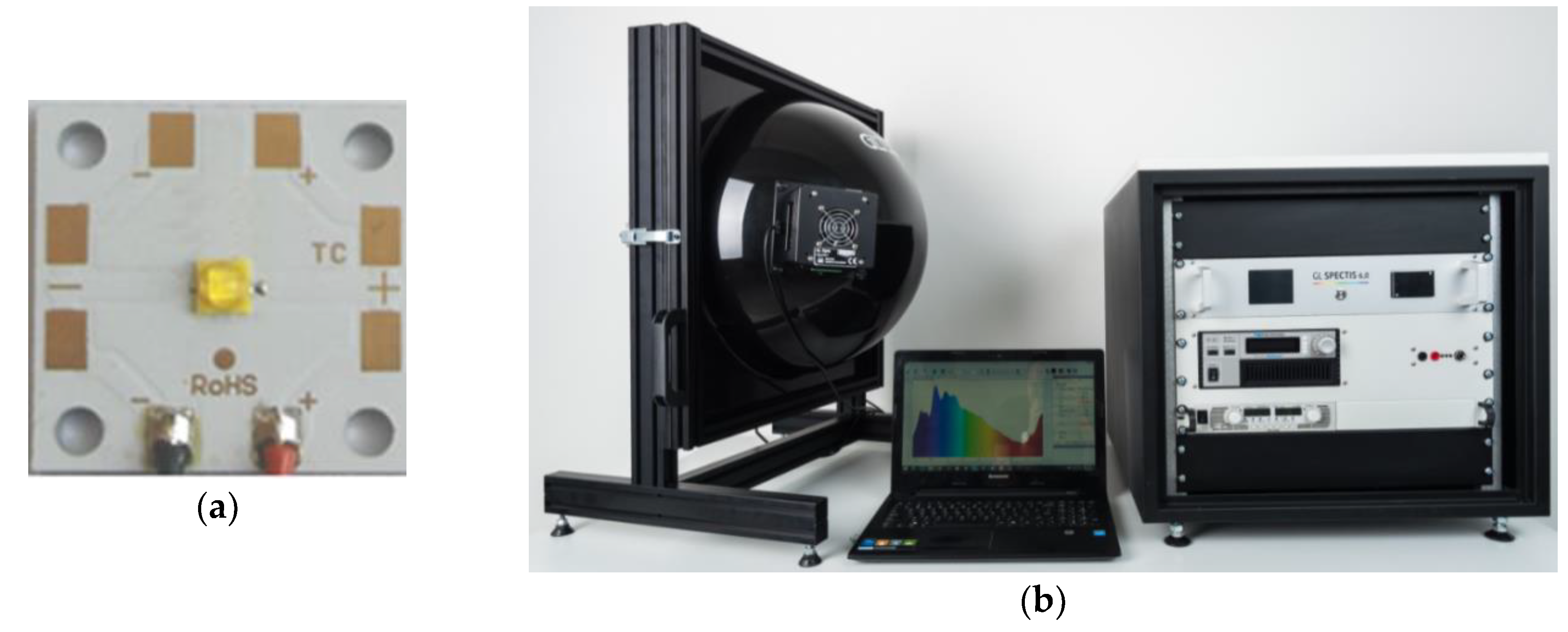

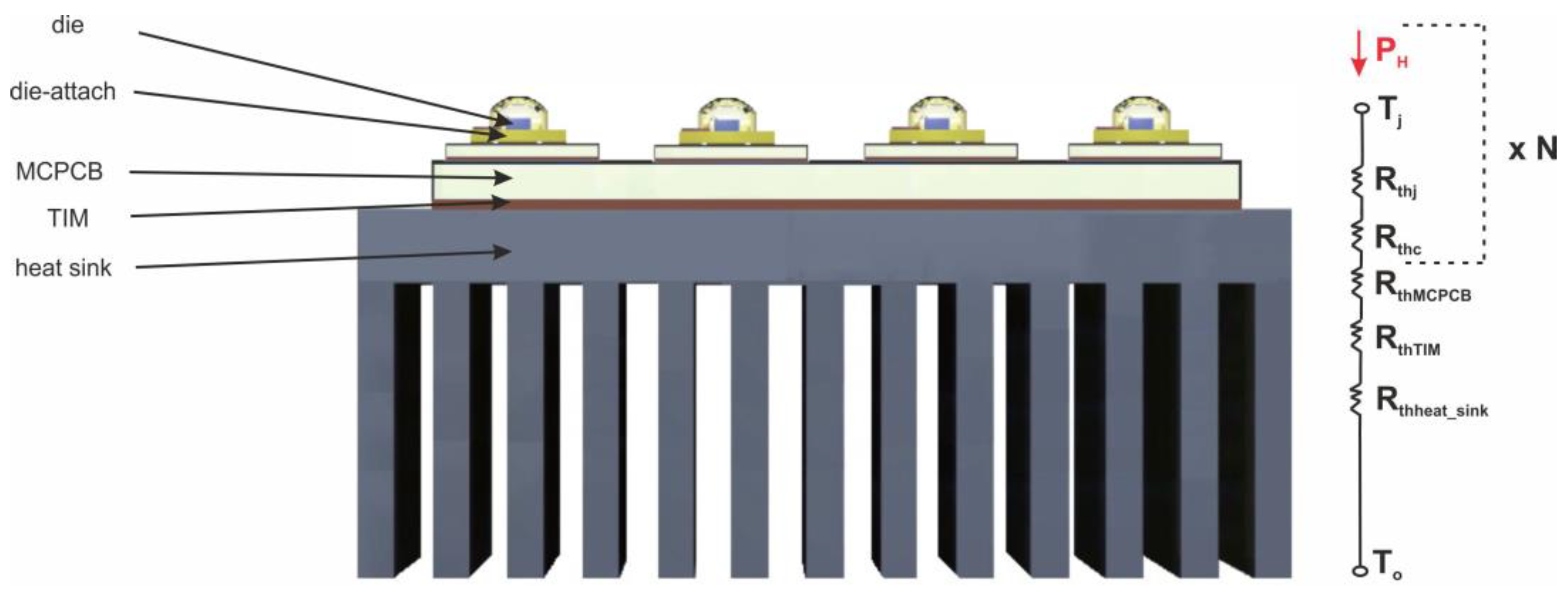

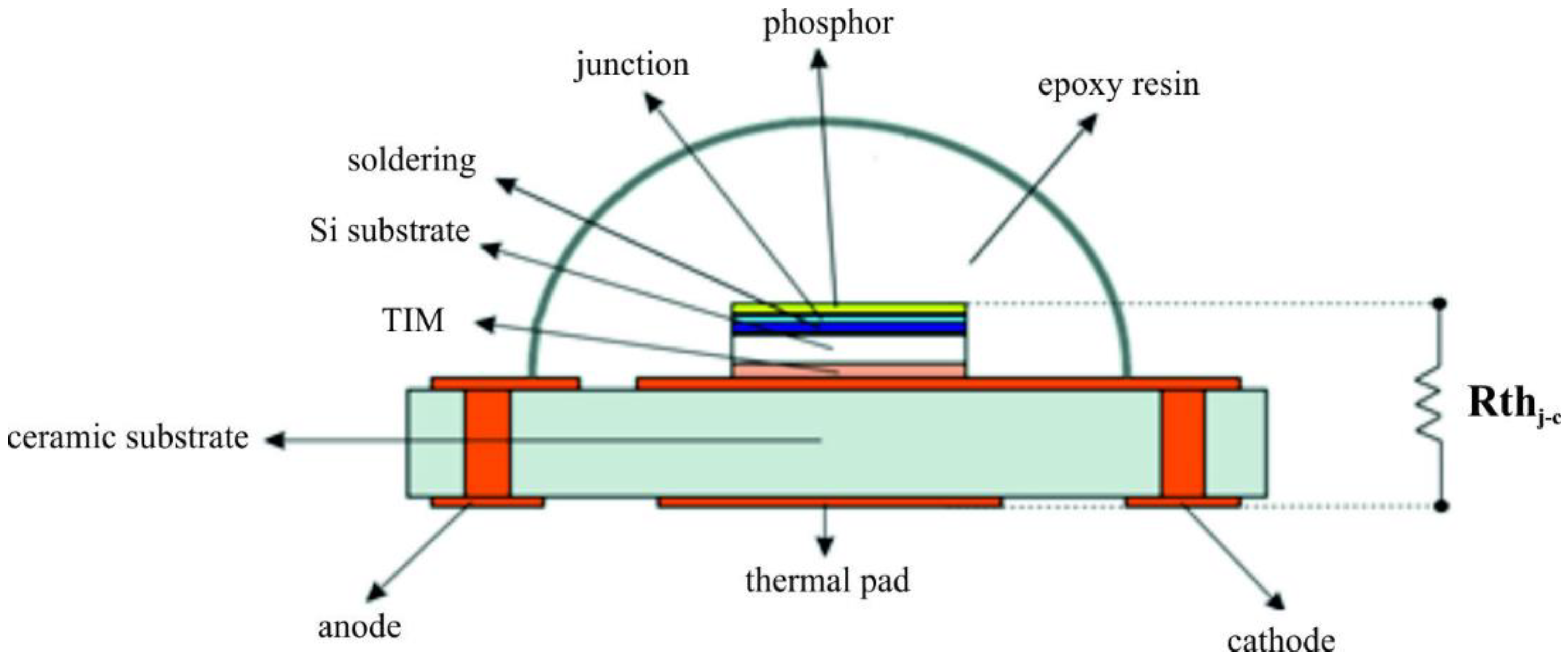

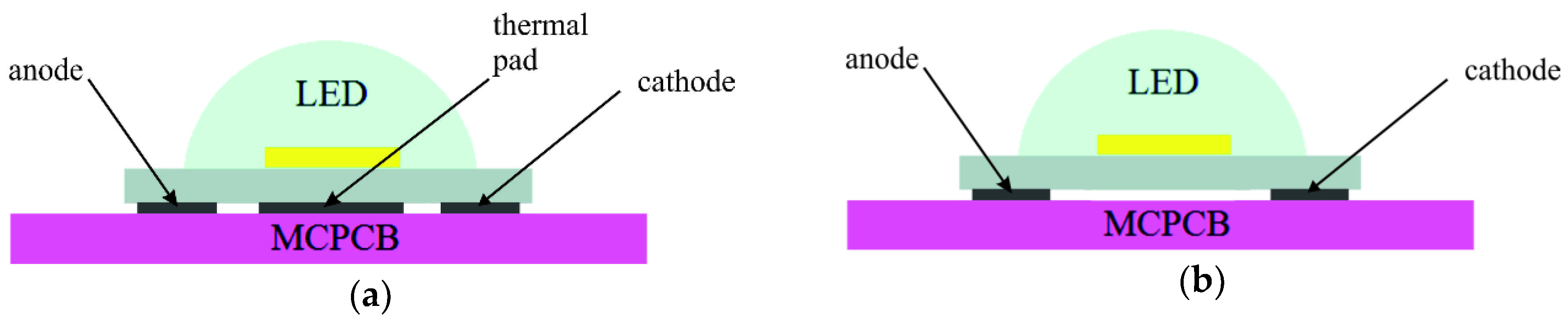

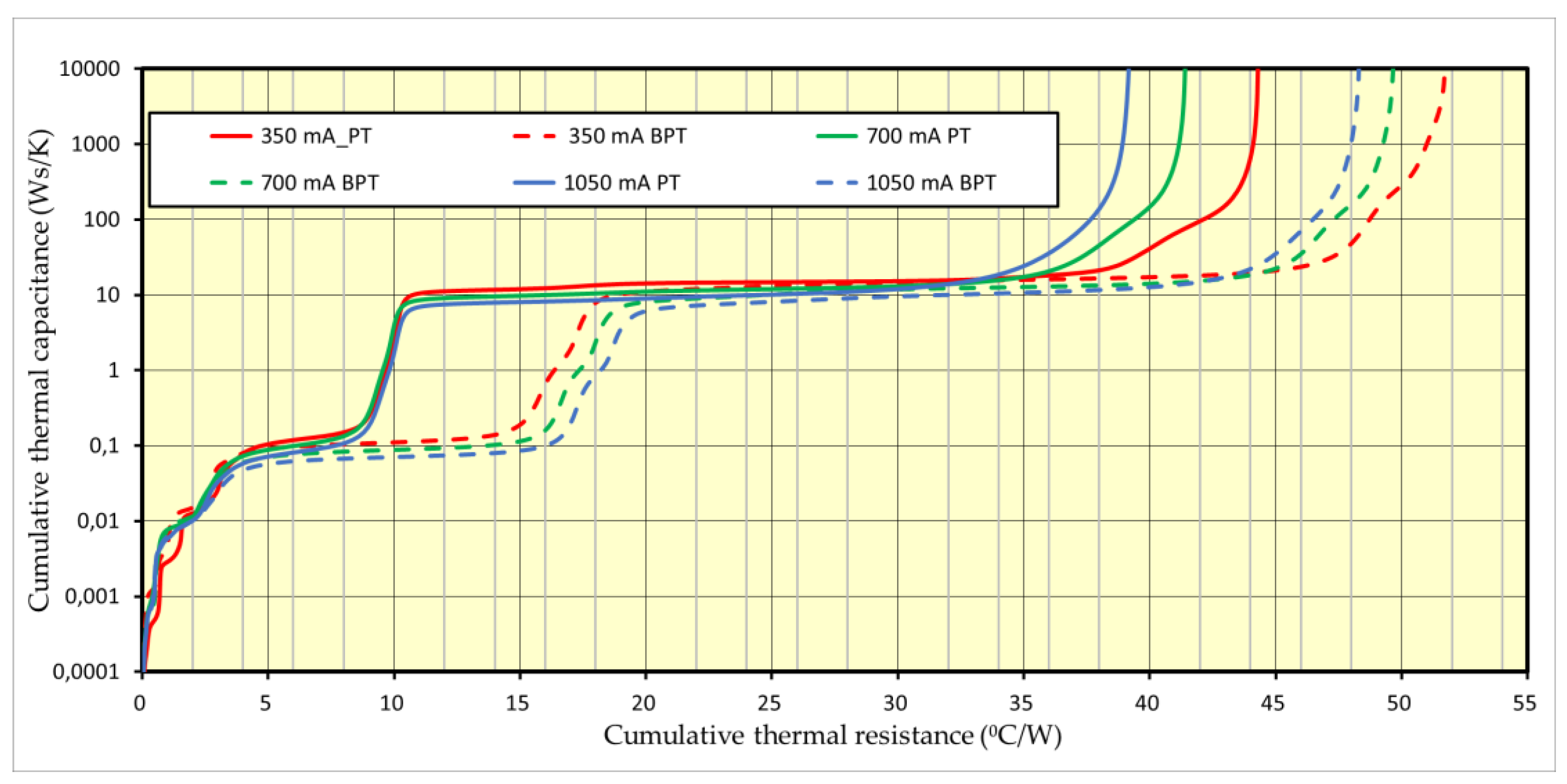

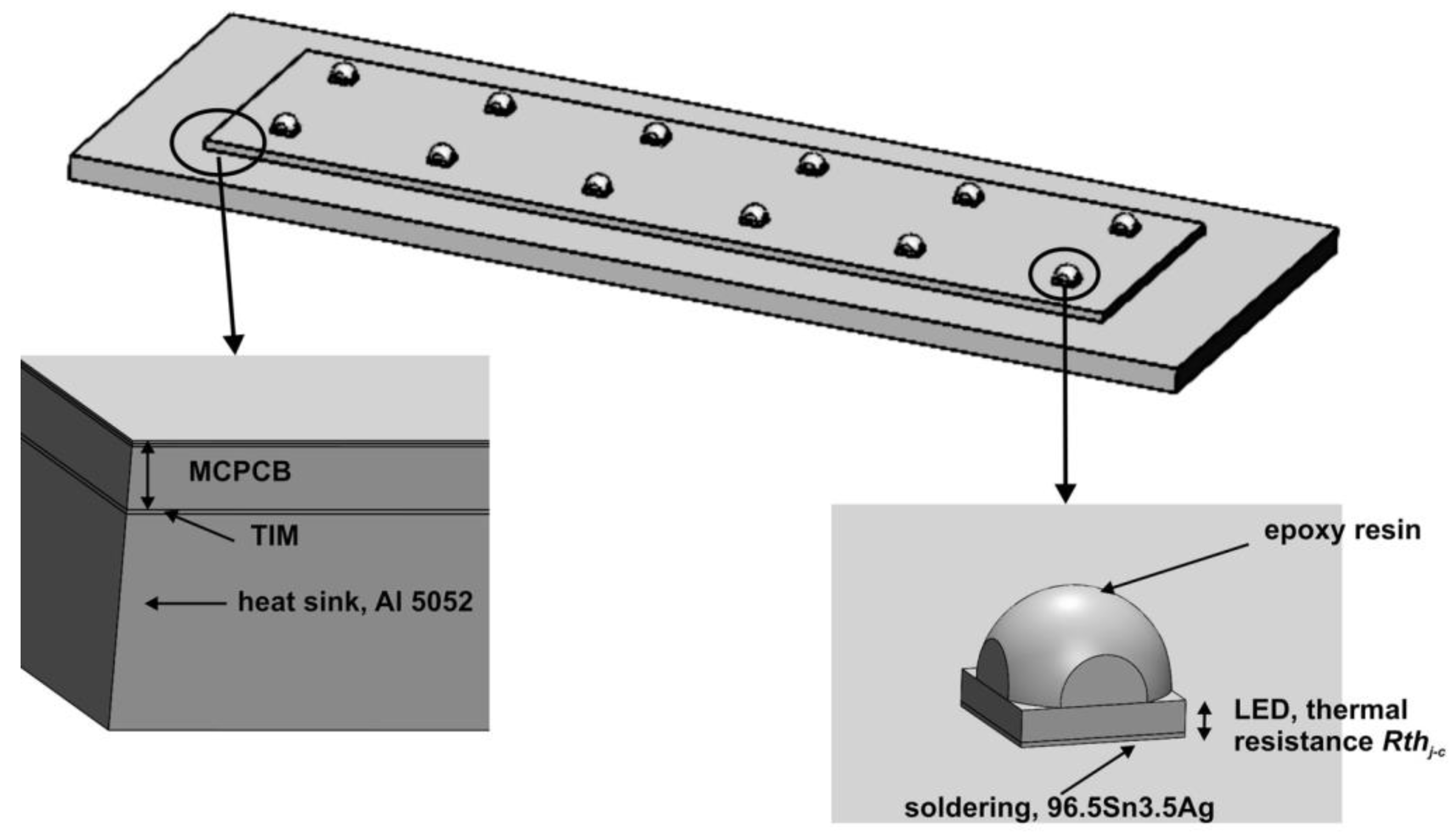

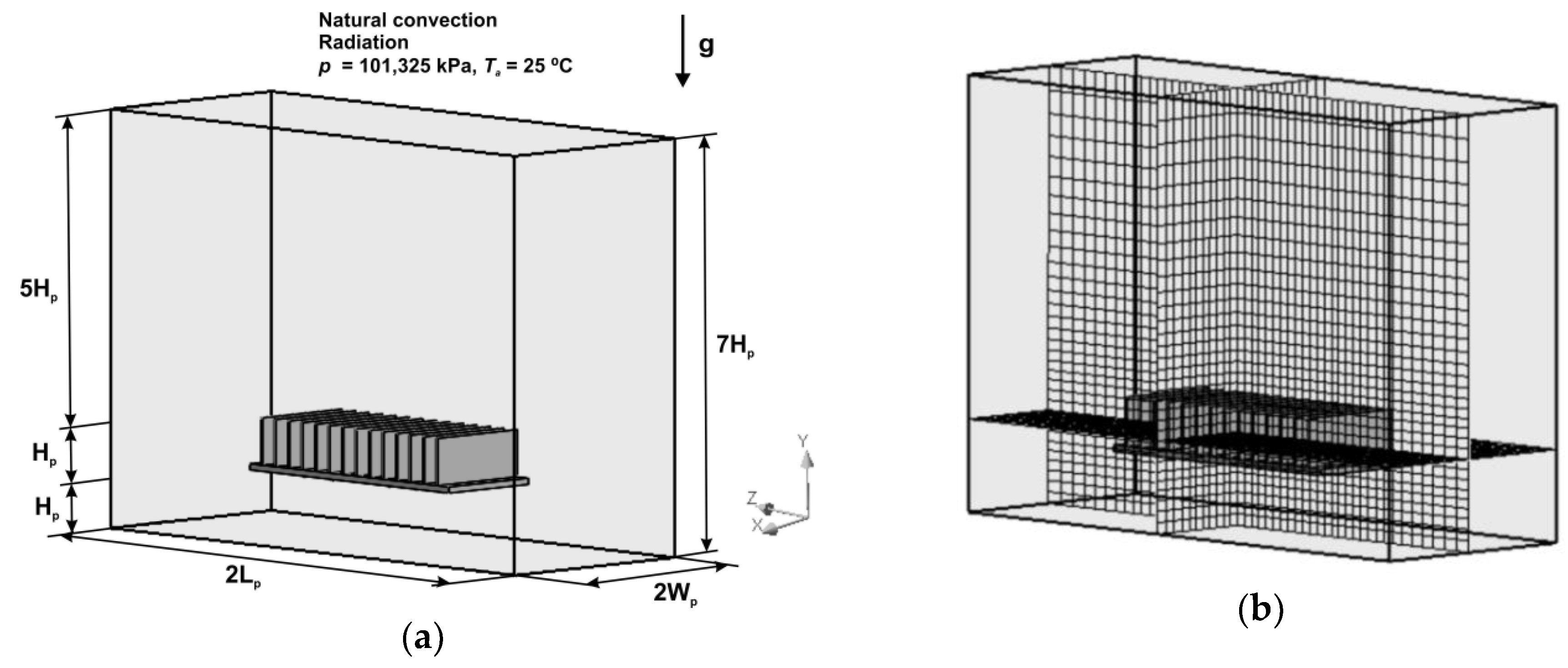

2. LED Panel Thermal Model

3. Thermal Analysis of LED Panel Elements

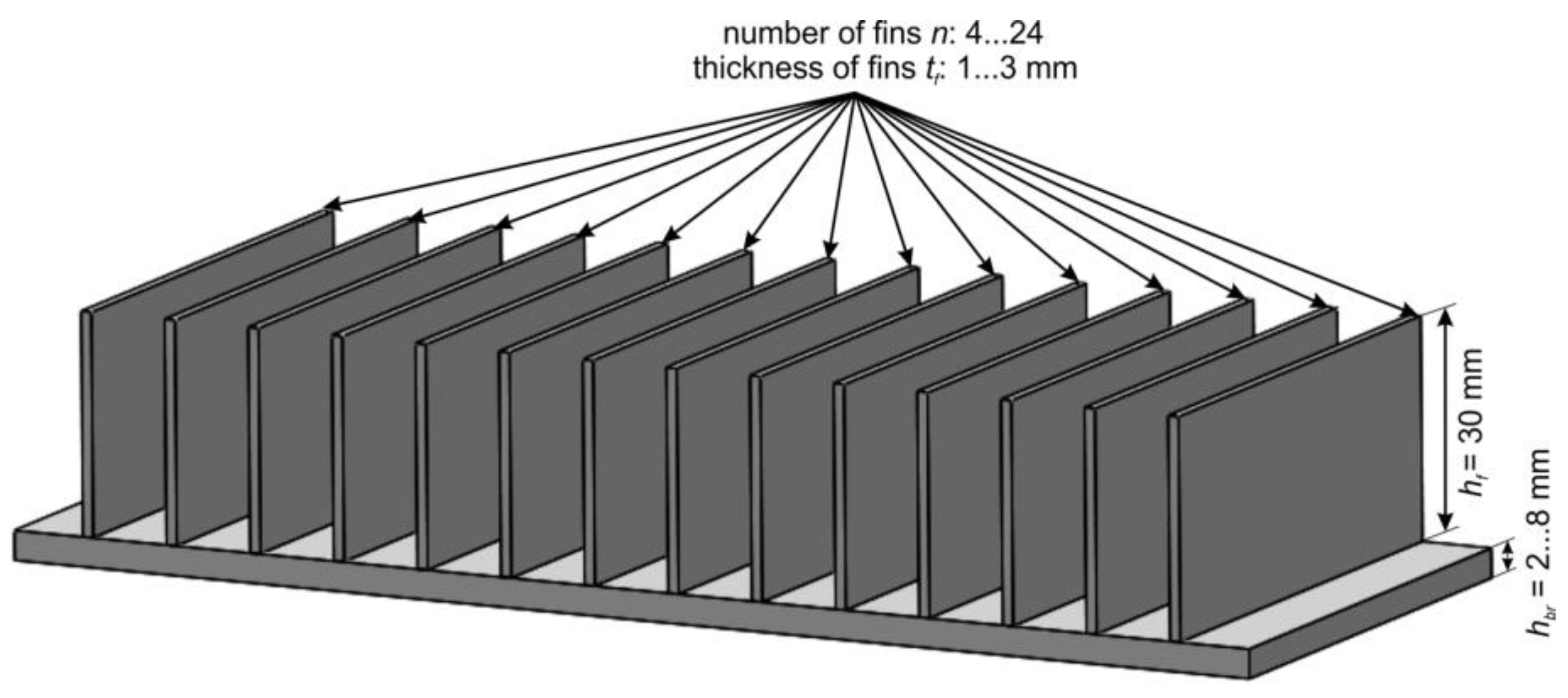

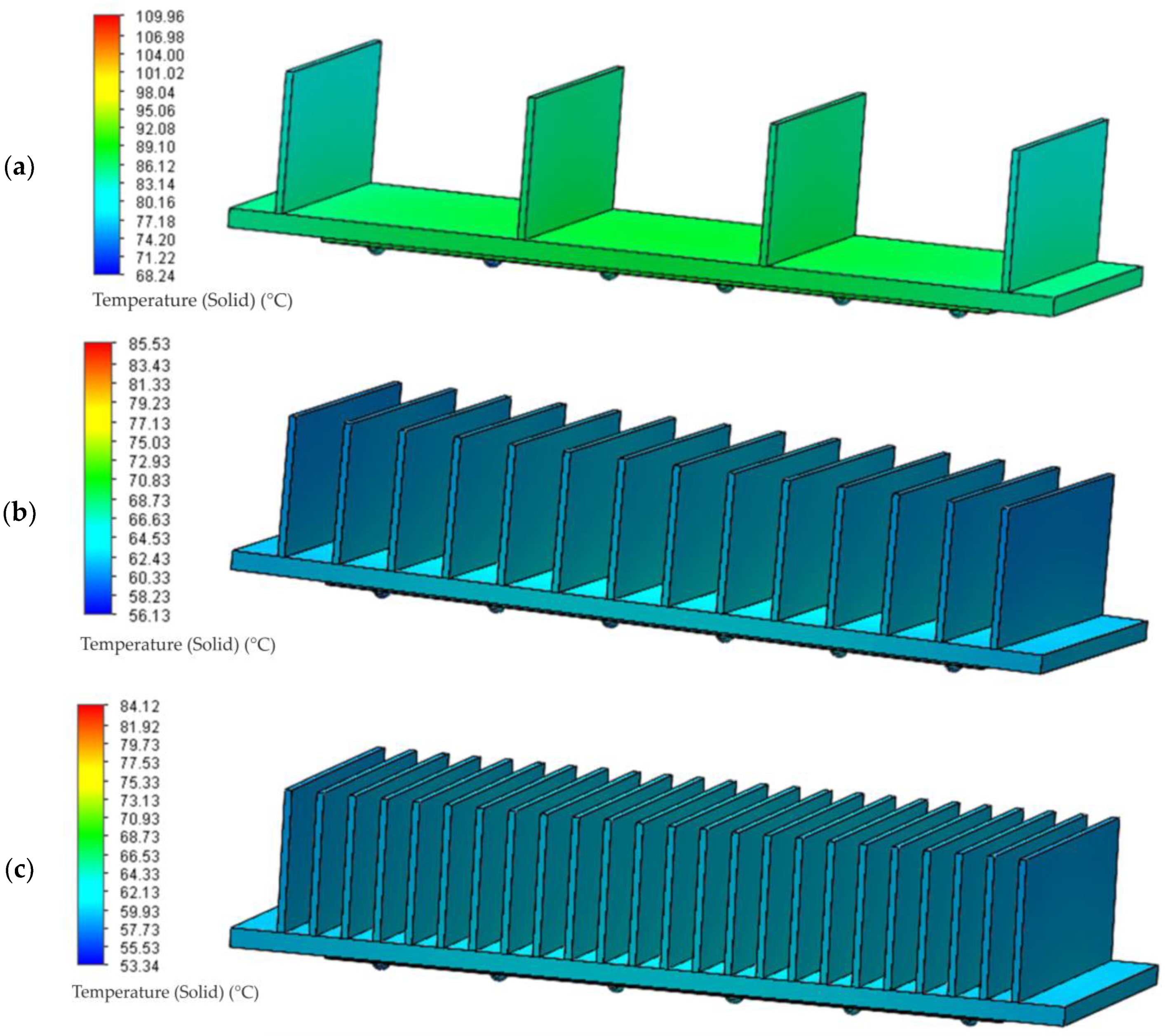

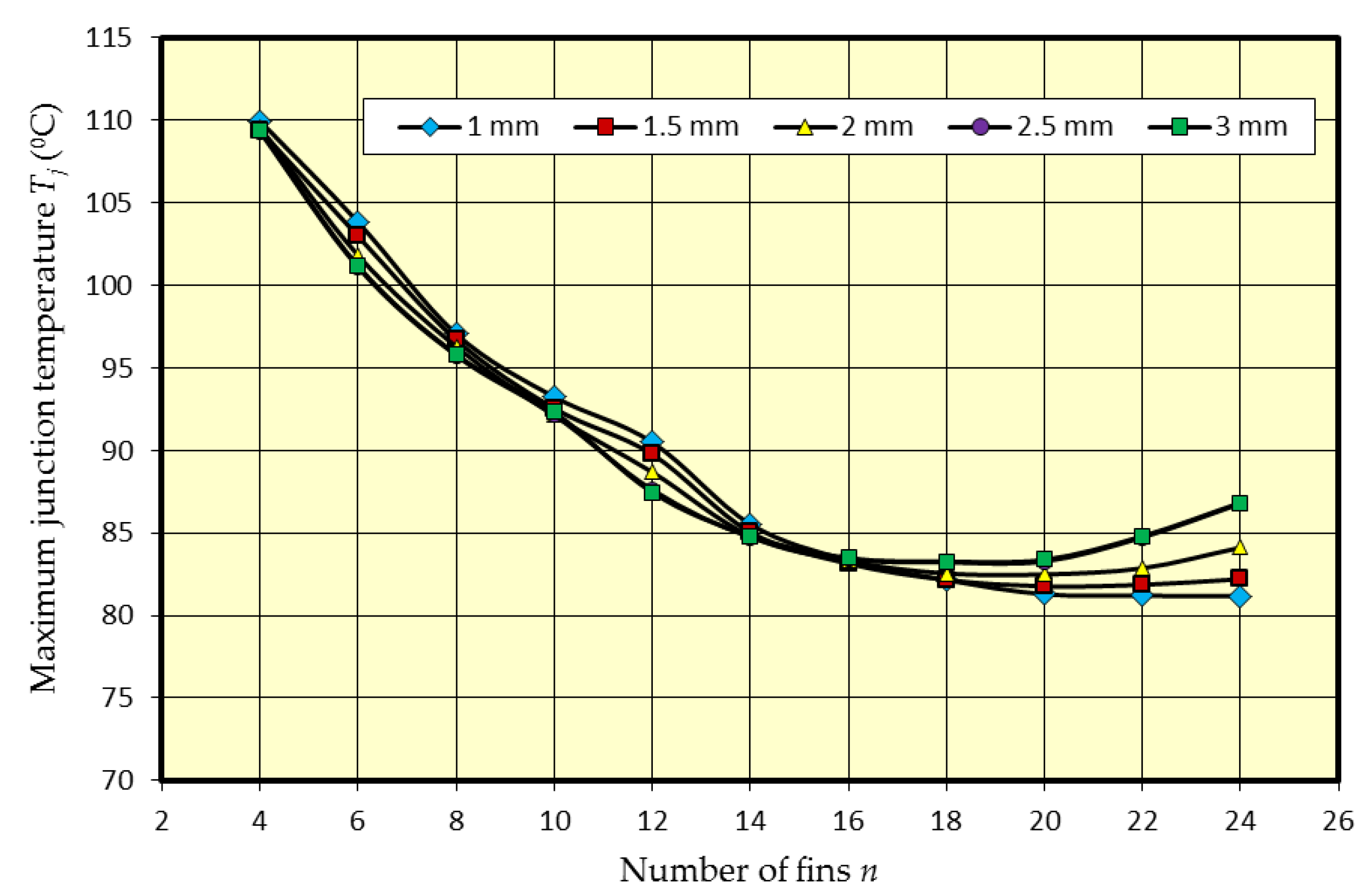

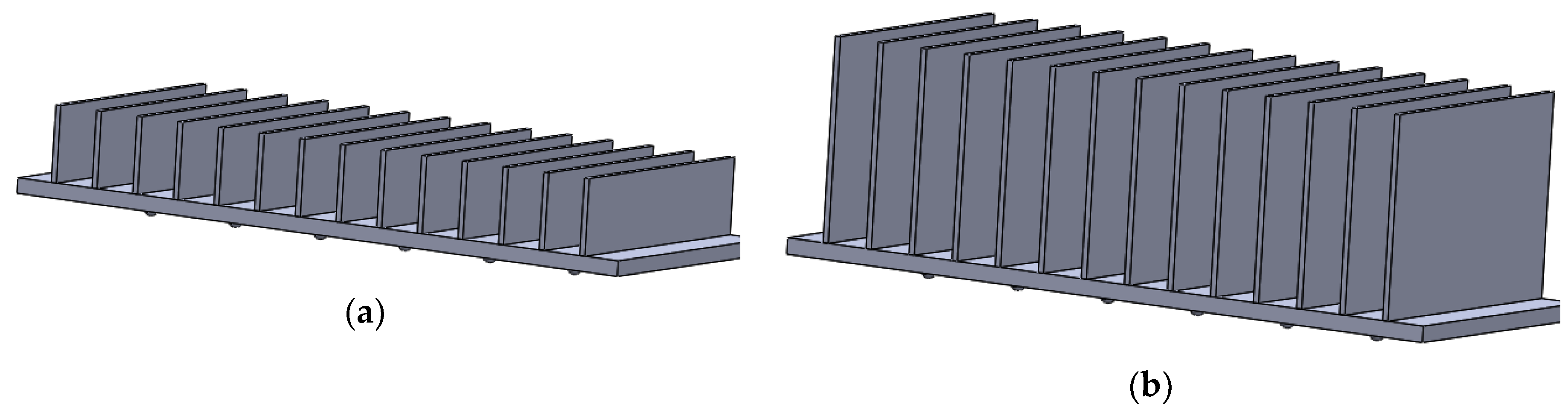

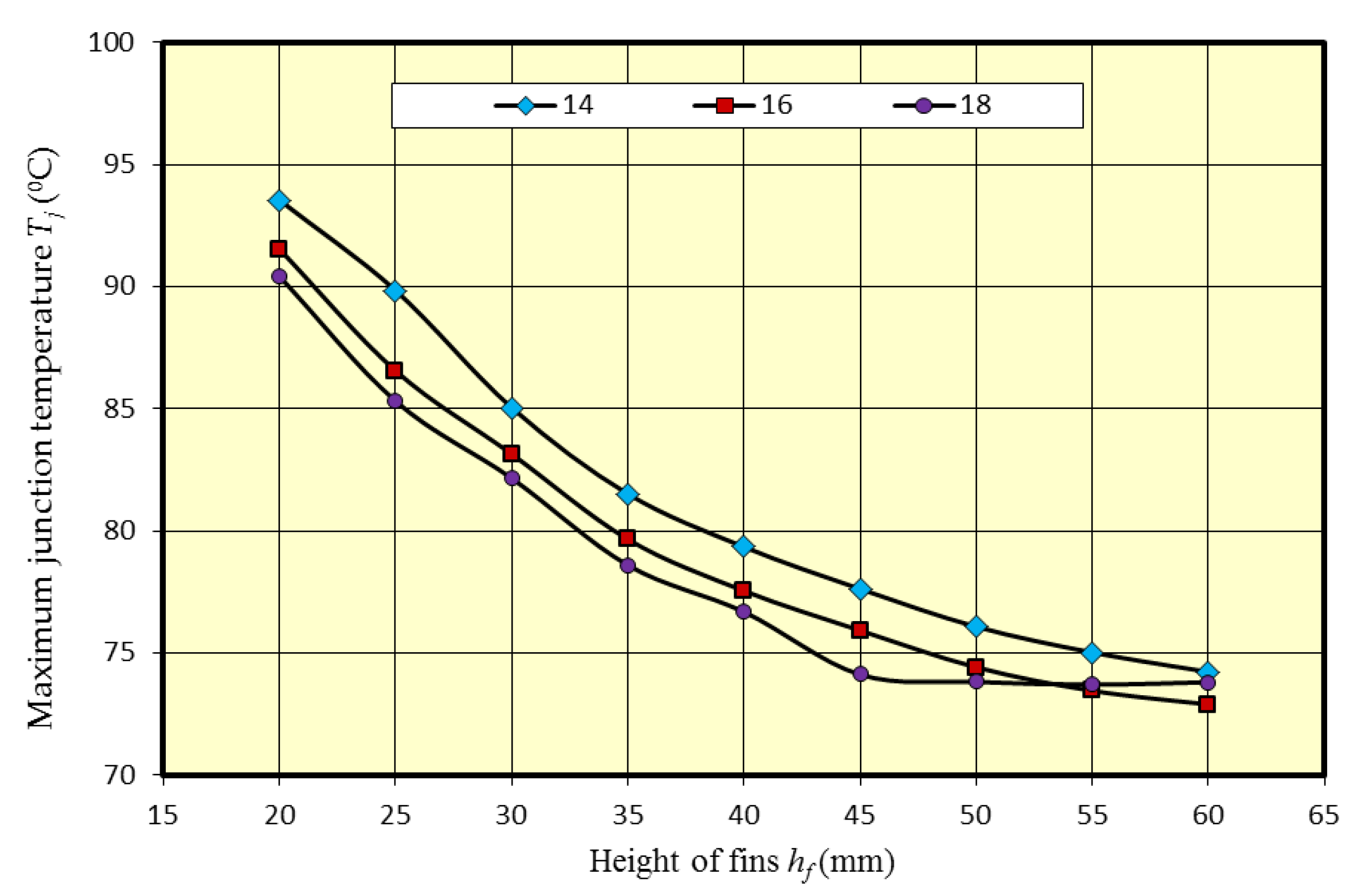

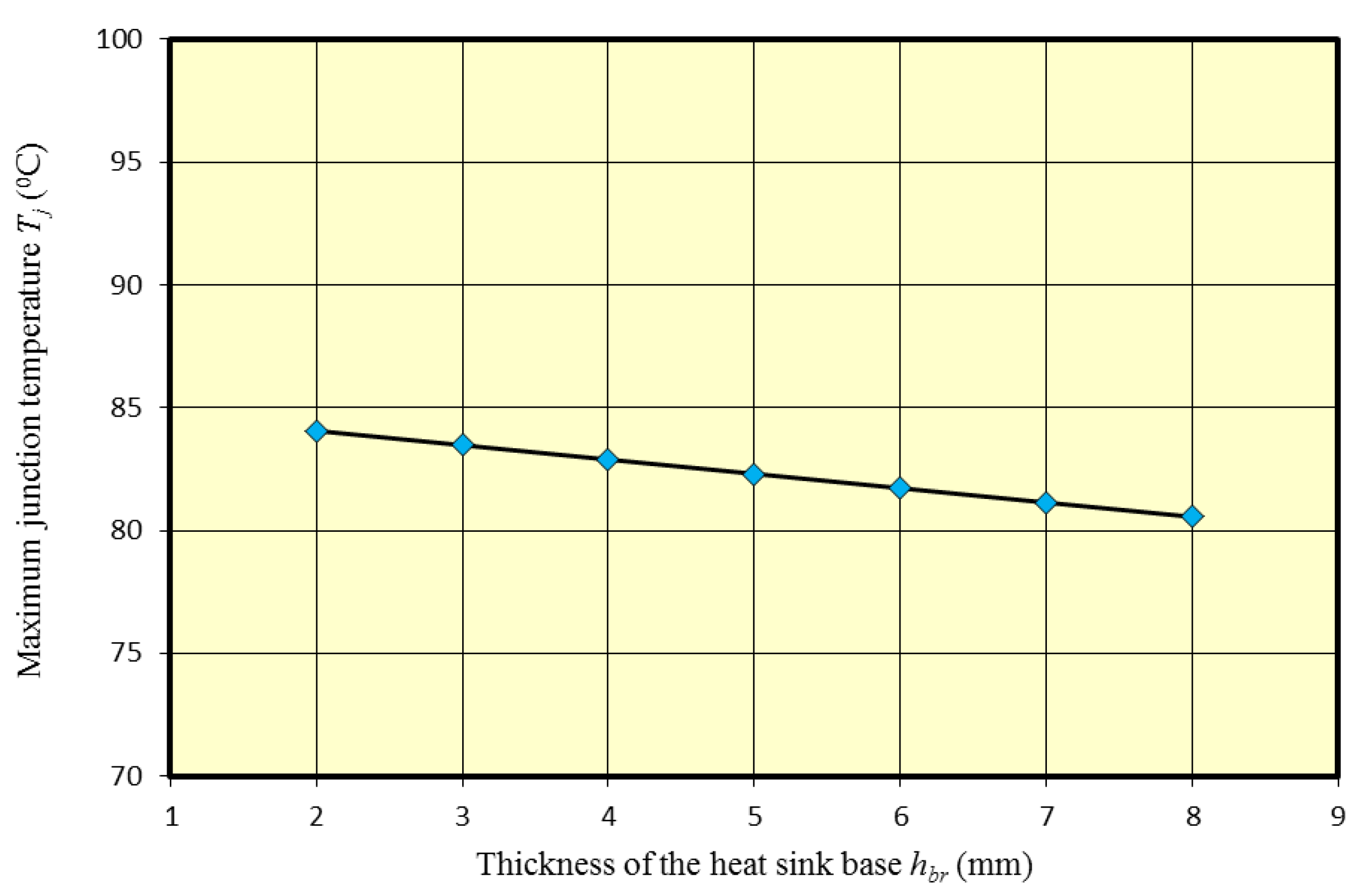

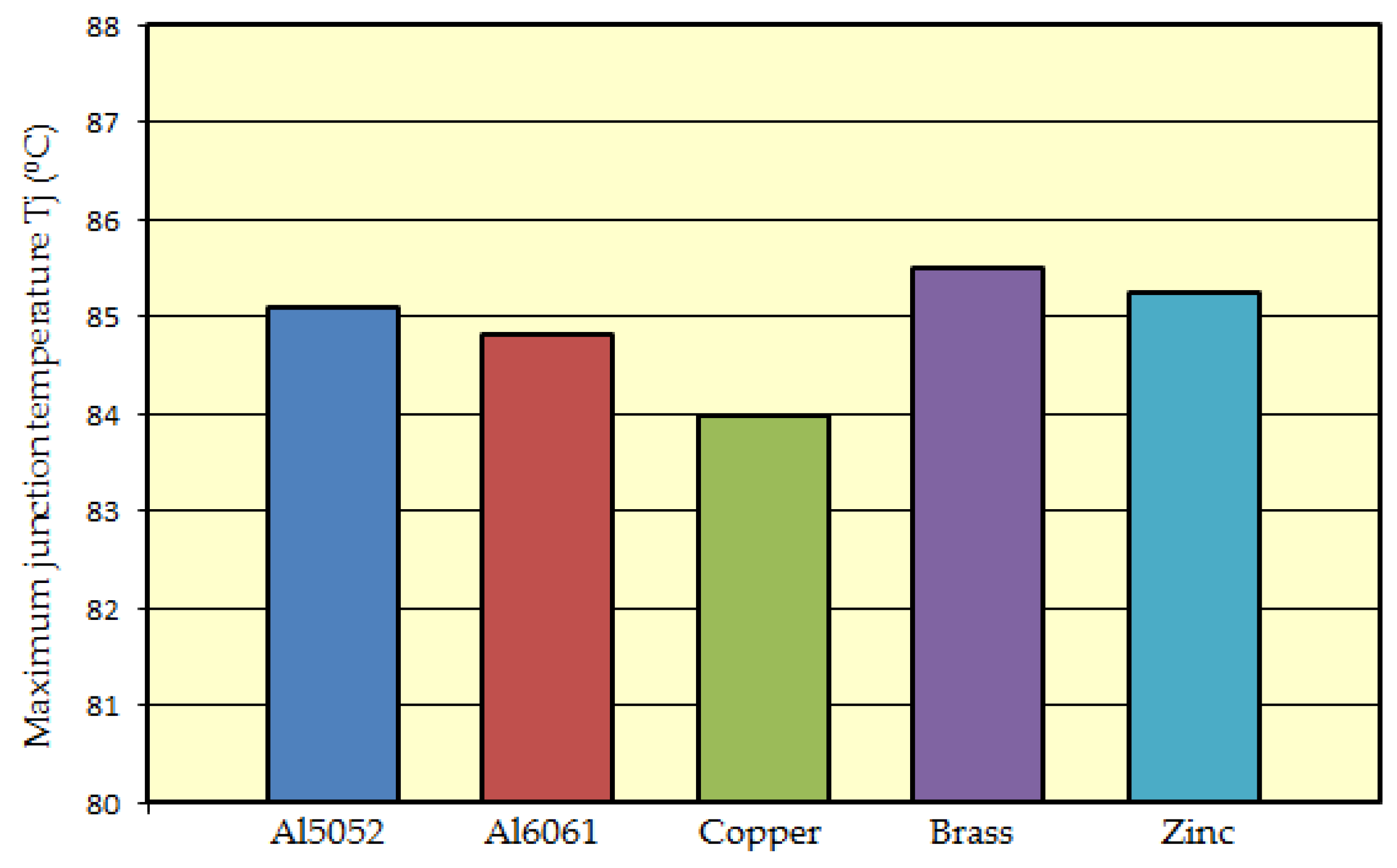

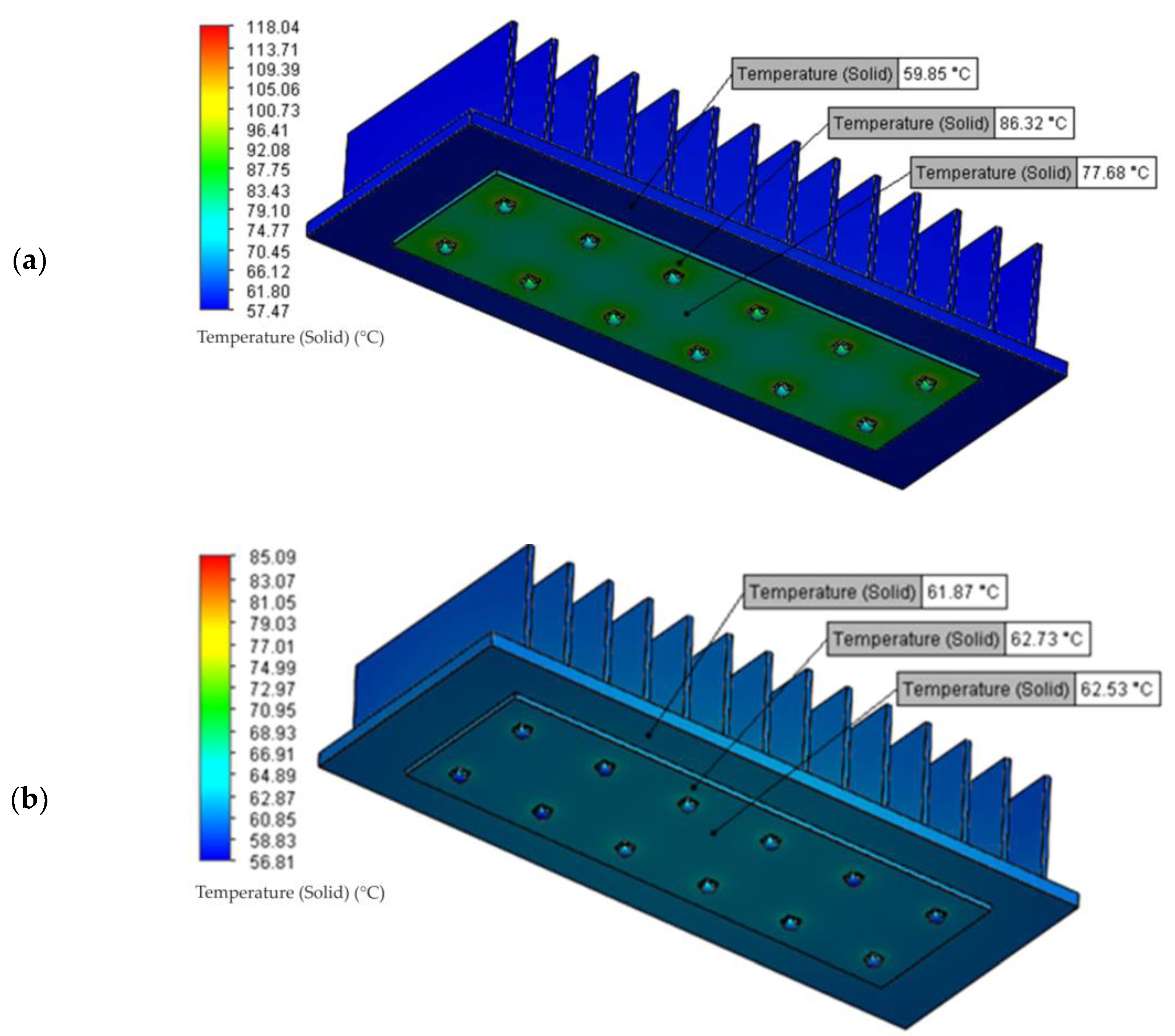

3.1. Influence of Radiator Construction

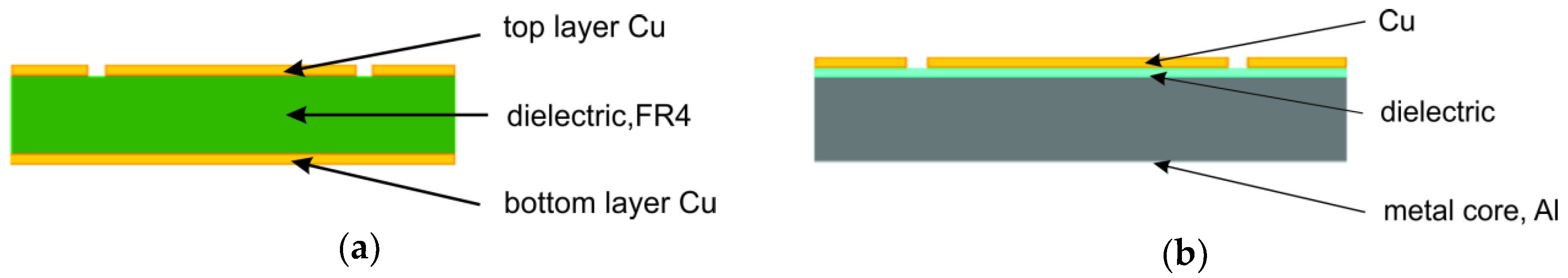

3.2. Influence of the Printed Circuit (FR4 v MCPCB)

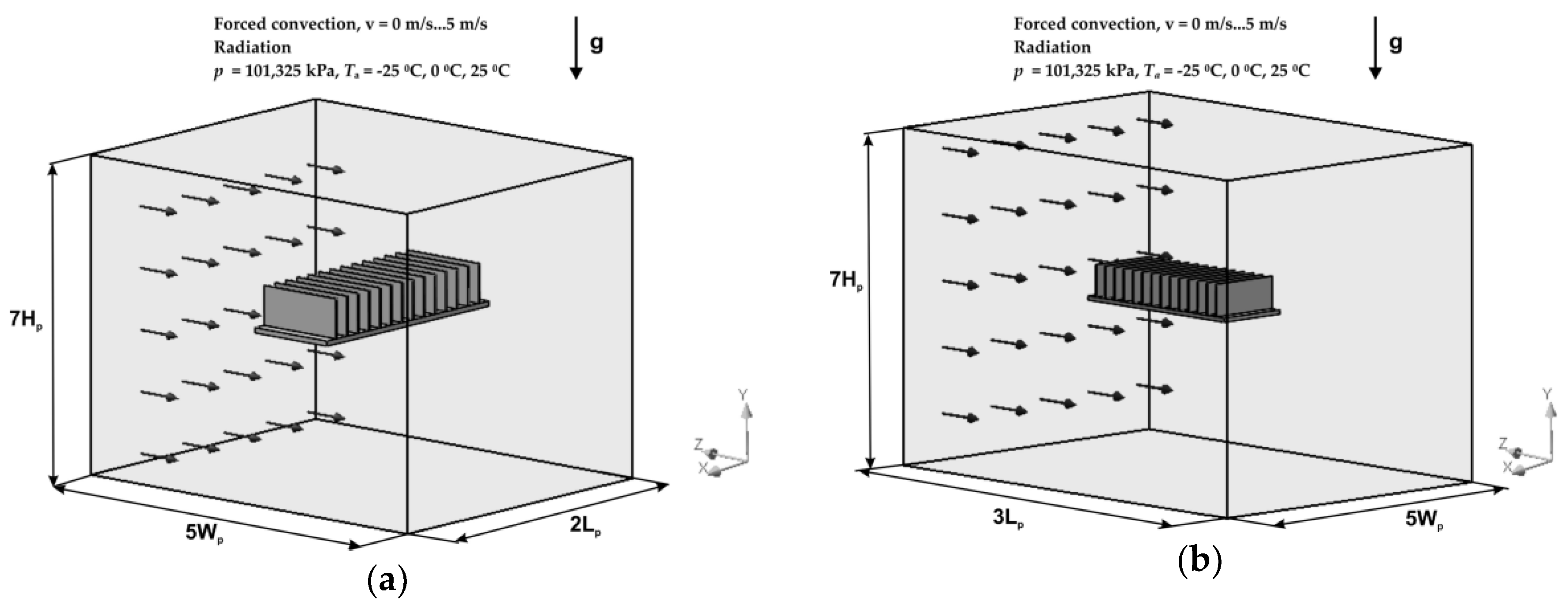

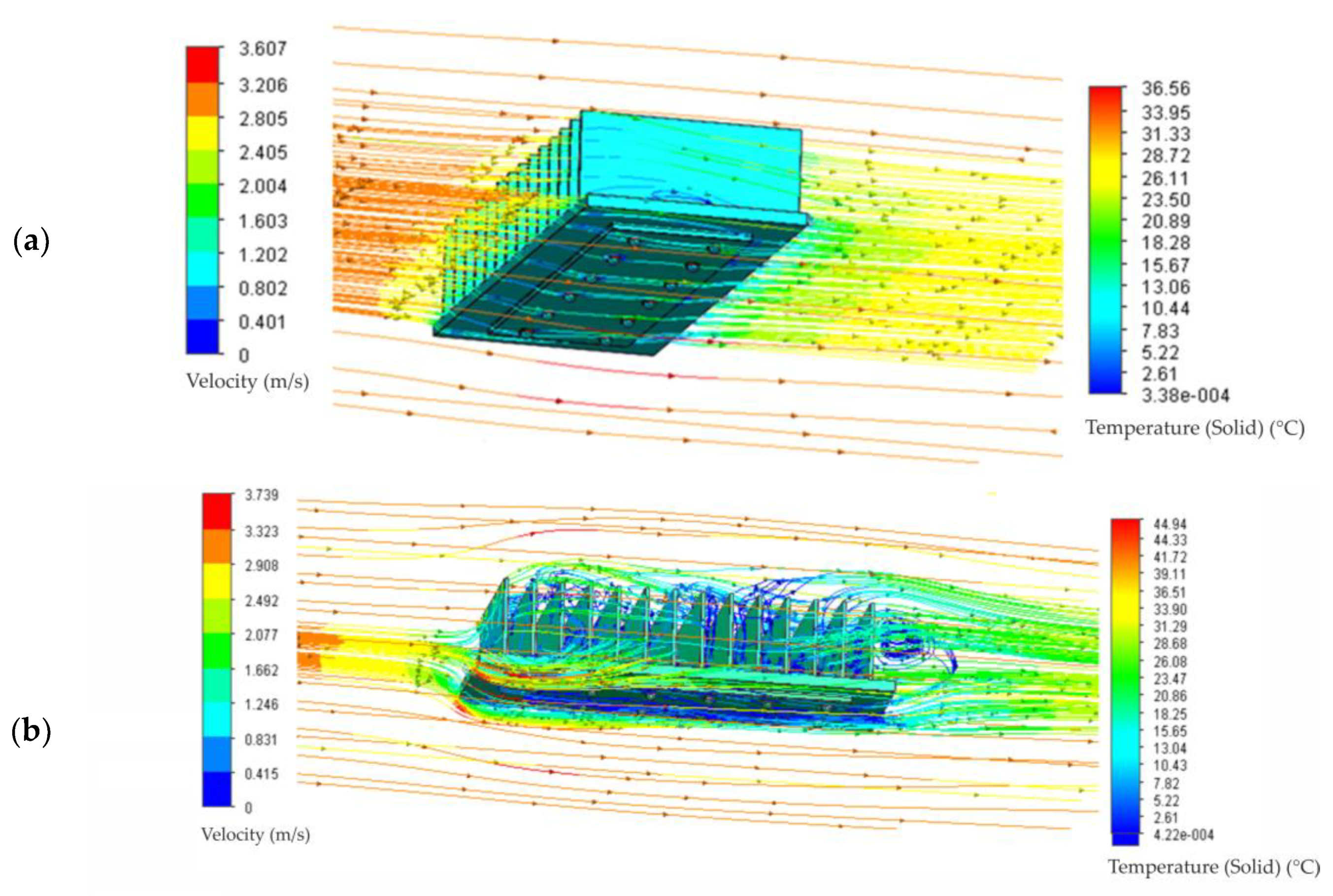

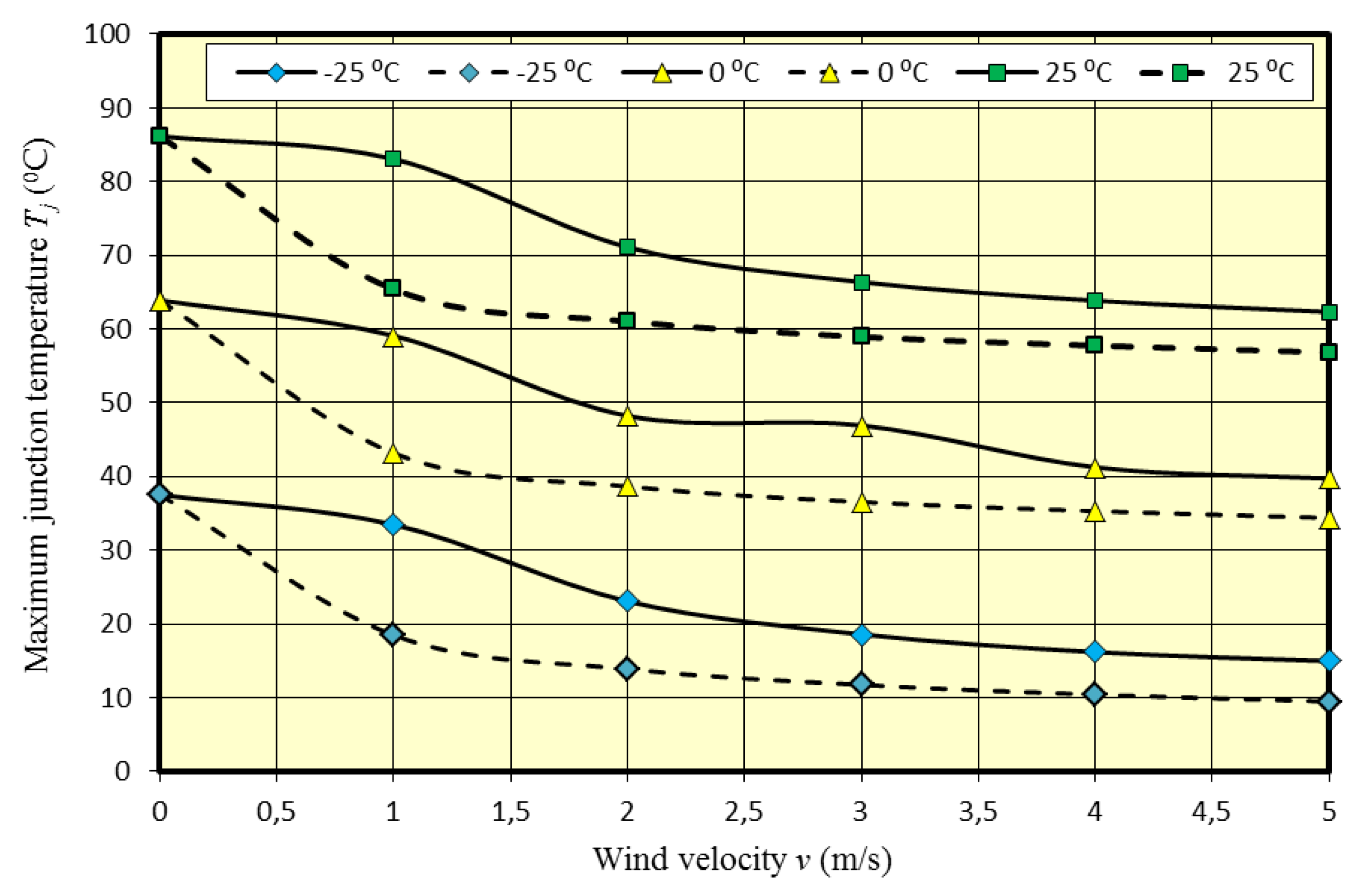

3.3. The Influence of Ambient Conditions

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Byung-Lip, A.; Ji-Woo, P.; Seunghwan, Y.; Jonghun, K.; Seung-Bok, L.; Cheol-Yong, J. Savings in Cooling Energy with a Thermal Management System for LED Lighting in Office Buildings. Energies 2015, 8, 6658–6671. [Google Scholar]

- Jagerbrand, A. LED (Light-Emitting Diode) Road Lighting in Practice: An Evaluation of Compliance with Regulations and Improvements for Further Energy Savings. Energies 2016, 9, 357. [Google Scholar] [CrossRef]

- Barroso, A.; Dupuis, P.; Alonso, C.; Jammes, B.; Seguier, L.; Zissis, G. A characterization framework to optimize LED luminaire’s luminous efficacy. In Proceedings of the 2015 IEEE Industry Applications Society Annual Meeting, Addison, TX, USA, 18–22 October 2015; pp. 905–913. [Google Scholar]

- Lasance, C.; Poppe, A. Thermal Management for LED Applications; Springer Science, Business Media: New York, NY, USA, 2014. [Google Scholar]

- Leśko, M.; Baran, K.; Wachta, H.; Różowicz, A. A Concept of an Adaptive Luminaire with Variable Luminous Intensity Distribution. In Proceedings of the 2018 VII. Lighting Conference of the Visegrad Countries (Lumen V4), Trebic, Czech Republic, 18–20 September 2018; pp. 1–4. [Google Scholar]

- Khanh, T.; Bodrogi, P.; Vinh, Q.; Winkle, H. LED Lighting. Technology and Perception; Wiley-VCH Verlag GmbH: Darmstadt, Germany, 2015. [Google Scholar]

- Yang, K.; Chung, C.; Tu, C.; Wong, C.; Yang, T.; Lee, M. Thermal spreading resistance characteristics of a high power light emitting diode module. Appl. Ther. Eng. 2014, 70, 361–368. [Google Scholar] [CrossRef]

- Bridges, J. Extend the life of LEDs through thermal design. LEDs Magazine, 2015; 84–86. [Google Scholar]

- Chajed, S.; Xi, Y.; Li, Y.; Gessmann, T.; Schubert, E. Influence of junction temperature on chromaticity and color-rendering properties of trichromatic white-light sources based on light-emitting diodes. J. Appl. Phys. 2005, 97, 39–42. [Google Scholar]

- Oleksy, M.; Kraśniewski, J.; Janke, W. Wpływ temperatury na charakterystyki optyczne i elektryczne diod LED mocy. Przegląd Elektrotechniczny 2014, 9, 83–85. (In Polish) [Google Scholar]

- Ahn, B.; Park, J.; Yoo, S.; Kim, J.; Jeong, H.; Leigh, S.; Jang, C. Synergetic Effect between Lighting Efficiency Enhancement and Building Energy Reduction Using Alternative Thermal Operating System of Indoor LED Lighting. Energies 2015, 8, 8736–8748. [Google Scholar] [CrossRef]

- Kudsieh, N.; Khizar, M.; Raja, M.Y.A. Thermal modeling of specialty heat-sinks for low-cost COP packaging of high-power LEDs. In Proceedings of the 2012 IEEE 9th International Conference on High Capacity Optical Networks and Enabling Technologies (HONET), Istanbul, Turkey, 12–14 December 2012. [Google Scholar]

- Poppe, A.; Farkas, G.; Gaal, L.; Hantos, G.; Hegedus, J.; Rencz, M. Multi-Domain Modelling of LEDs for Supporting Virtual Prototyping of Luminaires. Energies 2019, 12, 1909. [Google Scholar] [CrossRef]

- Tzeng, S.; Jeng, T.; Wang, Y. The cooling Design of a High-Speed Rotating Axis with Ribbed Turbulators. IJETI 2013, 3, 38–48. [Google Scholar]

- Shen, Q.; Sun, D.; Xu, Y.; Jin, T.; Zhao, X. Orientation effects on natural convection heat dissipation of rectangular fin heat sinks mounted on LEDs. Int. J. Heat Mass Transf. 2014, 75, 462–469. [Google Scholar] [CrossRef]

- Gupta, D.; Venkataraman, V.; Nimje, R. CFD & Thermal Analysis of Heat Sink and its Application in CPU. Int. J. Emerg. Technol. Adv. Eng. 2014, 4, 198–202. [Google Scholar]

- Hyunjong, K.; Kyoung, J.; Yeonwon, L. Thermal Performance of Smart Heat Sinks for Cooling High Power LED Modules. In Proceedings of the 13th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, San Diego, CA, USA, 30 May–1 June 2012. [Google Scholar]

- Yieang, H.; Shengnan, S.; Hui, L.; Yunjie, G. Improved thermal design of fin heat sink for high-power LED lamp cooling. In Proceedings of the 17th International Conference on Electronic Packaging Technology, Wuhan, China, 16–19 August 2016; pp. 1069–1074. [Google Scholar]

- Cao, J. Study on Three-imensional Numerical Simulation of the Influence of Fin Spacing on the Power of Heat Sink and Heat Dissipation. In Proceedings of the Asia-Pacific Power and Energy Engineering Conference, Wuhan, China, 25–28 March 2011. [Google Scholar]

- Min, W.; Seung, W.; Yongchan, K. Optimal thermal design of a horizontal fin heat sink with a modified-opening model mounted on an LED module. Appl. Therm. Eng. 2015, 91, 105–115. [Google Scholar]

- Teeba, N.; Anithambigai, P.; Dinash, K.; Mutharasu, D. Influence of the Heat Sink Orientation and Fins Arrangement on the Thermal Behavior of High Power LED. In Proceedings of the 3rd Asia Symposium on Quality Electronic Design, Kuala Lumpur, Malaysia, 19–20 July 2011; pp. 21–24. [Google Scholar]

- Rong, W.; Jung, W. Analyzing the structural designs and thermal performance of nonmetal lighting devices of LED bulbs. Int. J. Heat Mass Transf. 2016, 99, 750–761. [Google Scholar]

- Sapia, C.; Sozio, G. CFD Transient Model of the Buoyancy Heat Transfer for a Heat Sink: Effects of Geometry Rotation, Thermal Investigations of ICs and Systems (THERMINIC). In Proceedings of the 2012 IEEE 18th International Workshop, Budapest, Hungary, 25–27 September 2012. [Google Scholar]

- Chein, R.; Chen, J. Numerical study of the inlet/outlet arrangement effect on microchannel heat sink performance. Int. J. Ther. Sci. 2009, 48, 1627–1638. [Google Scholar] [CrossRef]

- Della Torre, A.; Motenegro, G.; Onorati, A.; Khadilkar, S.; Icarelli, R. Multi-Scale CFD Modeling of Plate Heat Exchangers Including O set-Strip Fins and Dimple-Type Turbulators for Automotive Applications. Energies 2019, 12, 2965. [Google Scholar] [CrossRef]

- Andersson, B.; Andersson, R.; Hakansson, L.; Mortensen, M.; Sudiyo, R.; Wachem, B. Computational Fluid Dynamics for Engineers; Cambridge University Press: Edinburgh, UK, 2012. [Google Scholar]

- FloEFD. Technical Reference, Software Version 16, Mentor Graphics; Mentor Graphics Corporation: Wilsonville, OR, USA, 2016. [Google Scholar]

- LEDIL Strada 2x6. Available online: https://www.ledil.com/data/prod/Strada/Strada-IP-2x6-sfds.pdf (accessed on 2 August 2019).

- Hsu, H.-C.; Huang, Y.-C. Numerical Simulation and Experimental Validation for the Thermal Analysis of a Compact LED Recessed Downlight with Heat Sink Design. Appl. Sci. 2017, 7, 4. [Google Scholar] [CrossRef]

- Guo, Y.; Pan, K.; Ren, G.; Yuan, F. Research on LED Temperature Characteristic and Thermal Analysis at Low Temperatures. In Proceedings of the International Conference on Electronic Packaging Technology & High Density Packaging, Guilin, China, 13–16 August 2012; pp. 1411–1415. [Google Scholar]

- Ye, H.; Kohl, S.; Zeijl, H.; Gielen, A. A review of passive thermal management of LED module. J. Semicond. 2011, 32, 014008-1–014008-4. [Google Scholar] [CrossRef]

- Poppe, A.; Lasence, C. On the standardization of thermal characterization of LEDs. In Proceedings of the 25th Annual IEEE Semiconductor Thermal Measurement and Management Symposium, San Jose, CA, USA, 15–19 March 2009; pp. 151–158. [Google Scholar]

- Pounds, D.; Bonner, R. High heat flux heat pipes embedded in metal core printed circuit boards for LED thermal management. In Proceedings of the 14th Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Orlando, FL, USA, 27–30 May 2014; pp. 267–271. [Google Scholar]

- Scheepers, G.; Visser, J. Detailed thermal modeling of high powered LEDs. In Proceedings of the 25th Annual IEEE Semiconductor Thermal Measurement and Management Symposium, San Jose, CA, USA, 15–19 March 2009; pp. 87–91. [Google Scholar]

- Yurtseven, M.B.; Mete, S.; Onaygil, S. The effects of temperature and driving current on the key parameters of commercially available high-power white LEDs. Lighting Res. Technol. 2016, 48, 943–965. [Google Scholar] [CrossRef]

- GL Opti Spheres. Available online: http://www.gloptic.com/wpcontent/uploads/2018/08/200931_Technical-Datasheet_SPHEREs.pdf (accessed on 2 August 2019).

- GL Spectis 6,0. Available online: http://www.gloptic.com/wp-content/uploads/2018/08/200930_Technical-Datasheet_SPECTIS-6-0.pdf (accessed on 2 August 2019).

- 5305 TECSource Arroy Instruments. Available online: http://www.arroyoinstruments.com/products/5305#tabs (accessed on 2 August 2019).

- Vakrilov, N.; Stoynova, A.; Kafadarova, N. Application of CFD Modeling to Solve Problems in Thermal Design of LED Applications in the Initial Project Phase. In Proceedings of the 40th International Spring Seminar on Electronics Technology (ISSE), Sofia, Bulgaria, 10–14 May 2017; pp. 1–6. [Google Scholar]

- Baran, K.; Wachta, H.; Leśko, M.; Różowicz, A. Research on thermal resistance Rthj-c of high power semiconductor light sources. In Proceedings of the 15th Conference on Computational Technologies in Engineering, AIP Conference Proceedings 2078, Mikolajki, Poland, 16–19 October 2018; p. 020047. [Google Scholar]

- Torzewicz, T.; Baran, K.; Raszkowski, T.; Samson, A.; Wachta, H.; Napieralski, A. Compact thermal modelling of power LED light source. In Proceedings of the IEEE 30th International Conference on Microelectronics (MIEL), Nis, Serbia, 9–11 October 2017; pp. 157–160. [Google Scholar]

- Torzewicz, T.; Janicki, M.; Napieralski, A. Experimental Determination of Junction-to-Case Thermal Resistance in LED Compact Thermal Models. In Proceedings of the 17th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), San Diego, CA, USA, 29 May–1 June 2018; pp. 768–772. [Google Scholar]

- JEDEC STANDARD. Transient Dual Interface Test Method for the Measurement of the Thermal Resistance Junction-to-Case of Semiconductor Devices with Heat Flow Through a Single Path; JESD51-14; JEDEC Solid State Technology Association: Arlington, VA, USA, 2010. [Google Scholar]

- JEDEC STANDARD. Two-Resistor Compact Thermal Model Guideline; JESD15-3; JEDEC Solid State Technology Association: Arlington, VA, USA, 2008. [Google Scholar]

- JEDEC STANDARD. Implementation of the Electrical Test Method for the Measurement of Real Thermal Resistance and Impedance of Light-Emitting Diodes with Exposed Cooling; JESD51-51; JEDEC Solid State Technology Association: Arlington, VA, USA, 2012. [Google Scholar]

- MCPCB Berquist. Available online: http://www.dm.henkel-dam.com/is/content/henkel/274-Henkel%20Bergquist%20LED%20Thermal%20Solutionspdf (accessed on 2 August 2019).

- T3Ster, Mentor Graphics. Available online: http://www.mentor.com/products/mechanical/products/upload/micred-hardware-products-thermal-transient-test-and-measurement-18fcbdfa-d43f-46ce-95ca-920bd098a0d0 (accessed on 2 August 2019).

- FloEFD Engineering Database. Available online: https://www.mentor.com/products/mechanical/floefd/ (accessed on 7 October 2019).

- Thermal Management of Cree XLamp LEDs. Available online: http://www.cree.com/led-components/media/documents/XLampThermal Management.pdf (accessed on 2 August 2019).

| Current IF (mA) | Temperature Tp (°C) | Electrical Power Pe (W) | Optical Power Po (W) | Heat Power PH (W) | Optical Efficiency ηo (%) |

|---|---|---|---|---|---|

| 350 | 25 | 1.01 | 0.50 | 0.51 | 49.83 |

| 45 | 0.99 | 0.49 | 0.50 | 49.39 | |

| 65 | 0.98 | 0.48 | 0.50 | 48.69 | |

| 85 | 0.97 | 0.46 | 0.51 | 47.70 | |

| 700 | 25 | 2.13 | 0.94 | 1.19 | 43.92 |

| 45 | 2.10 | 0.91 | 1.19 | 43.36 | |

| 65 | 2.08 | 0.88 | 1.20 | 42.54 | |

| 85 | 2.06 | 0.85 | 1.18 | 41.52 | |

| 1050 | 25 | 3.35 | 1.33 | 2.02 | 39.62 |

| 45 | 3.30 | 1.29 | 2.01 | 38.94 | |

| 65 | 3.26 | 1.24 | 2.02 | 38.09 | |

| 85 | 3.22 | 1.19 | 2.03 | 37.04 |

| Layer | Material | Thickness (mm) | Thermal conductivity k (W/mK) | Thermal resistance Rthj-c (°C/W) |

|---|---|---|---|---|

| Heat sink | Aluminum 5052 | 4 | 140 | - |

| TIM | Thermal grease | 0.1 | 3 | - |

| MCPCB | Cu | 0.035 | 400 | |

| Dielectric | 0.1 | 2 | - | |

| Aluminum 5052 | 1.5 | 140 | ||

| Soldering | 96.5Sn3.5Ag | 0.1 | 33 | |

| LED | - | - | - | 8.6 IF = 350 mA |

| 8.6 IF = 700 mA | ||||

| 8.8 IF = 1050 mA | ||||

| Lens | Epoxy resin | - | 0.2 | - |

| Material | Thermal Conductivity k (W/m·K) | Density ρ (kg/m3) |

|---|---|---|

| Al5052 | 140 | 2680 |

| Al6061 | 155 | 2700 |

| Copper | 400 | 8960 |

| Brass | 110 | 8400 |

| Zinc | 115 | 7140 |

| Layer/Material | Thermal Conductivity k (W/mK) | Thickness (µm) | |

|---|---|---|---|

| PCB | Top layer Cu | 400 | 70 |

| Dielectric, FR4 | 0.2 | 1588 | |

| Bottom layer Cu | 400 | 70 | |

| MCPCB | Cu | 400 | 35 |

| Dielectric | 2 | 100 | |

| Metal core, Al5052 | 140 | 1500 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baran, K.; Różowicz, A.; Wachta, H.; Różowicz, S.; Mazur, D. Thermal Analysis of the Factors Influencing Junction Temperature of LED Panel Sources. Energies 2019, 12, 3941. https://doi.org/10.3390/en12203941

Baran K, Różowicz A, Wachta H, Różowicz S, Mazur D. Thermal Analysis of the Factors Influencing Junction Temperature of LED Panel Sources. Energies. 2019; 12(20):3941. https://doi.org/10.3390/en12203941

Chicago/Turabian StyleBaran, Krzysztof, Antoni Różowicz, Henryk Wachta, Sebastian Różowicz, and Damian Mazur. 2019. "Thermal Analysis of the Factors Influencing Junction Temperature of LED Panel Sources" Energies 12, no. 20: 3941. https://doi.org/10.3390/en12203941

APA StyleBaran, K., Różowicz, A., Wachta, H., Różowicz, S., & Mazur, D. (2019). Thermal Analysis of the Factors Influencing Junction Temperature of LED Panel Sources. Energies, 12(20), 3941. https://doi.org/10.3390/en12203941