Product Characteristics of Torrefied Wood Sawdust in Normal and Vacuum Environments

Abstract

1. Introduction

2. Materials and Methods

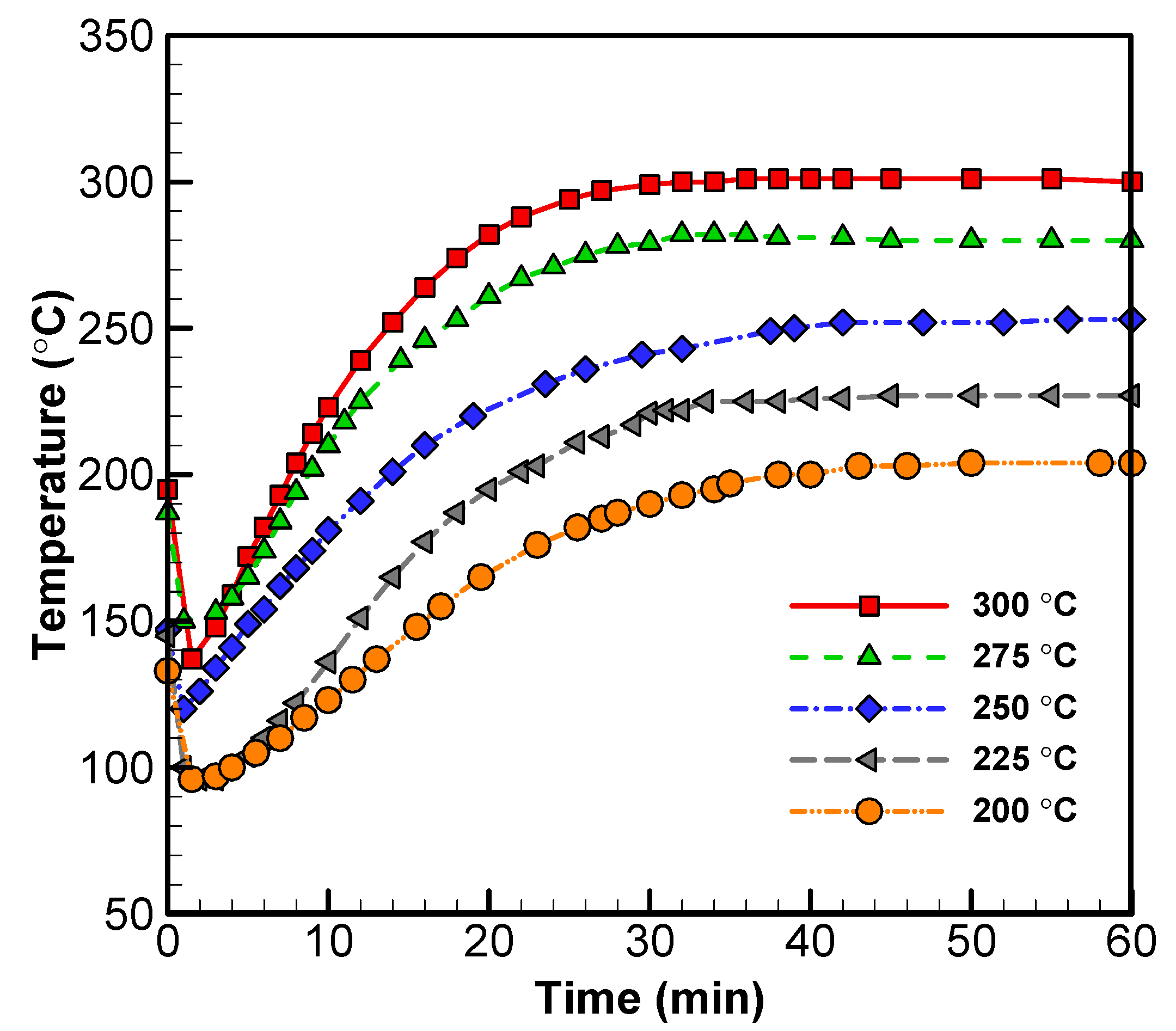

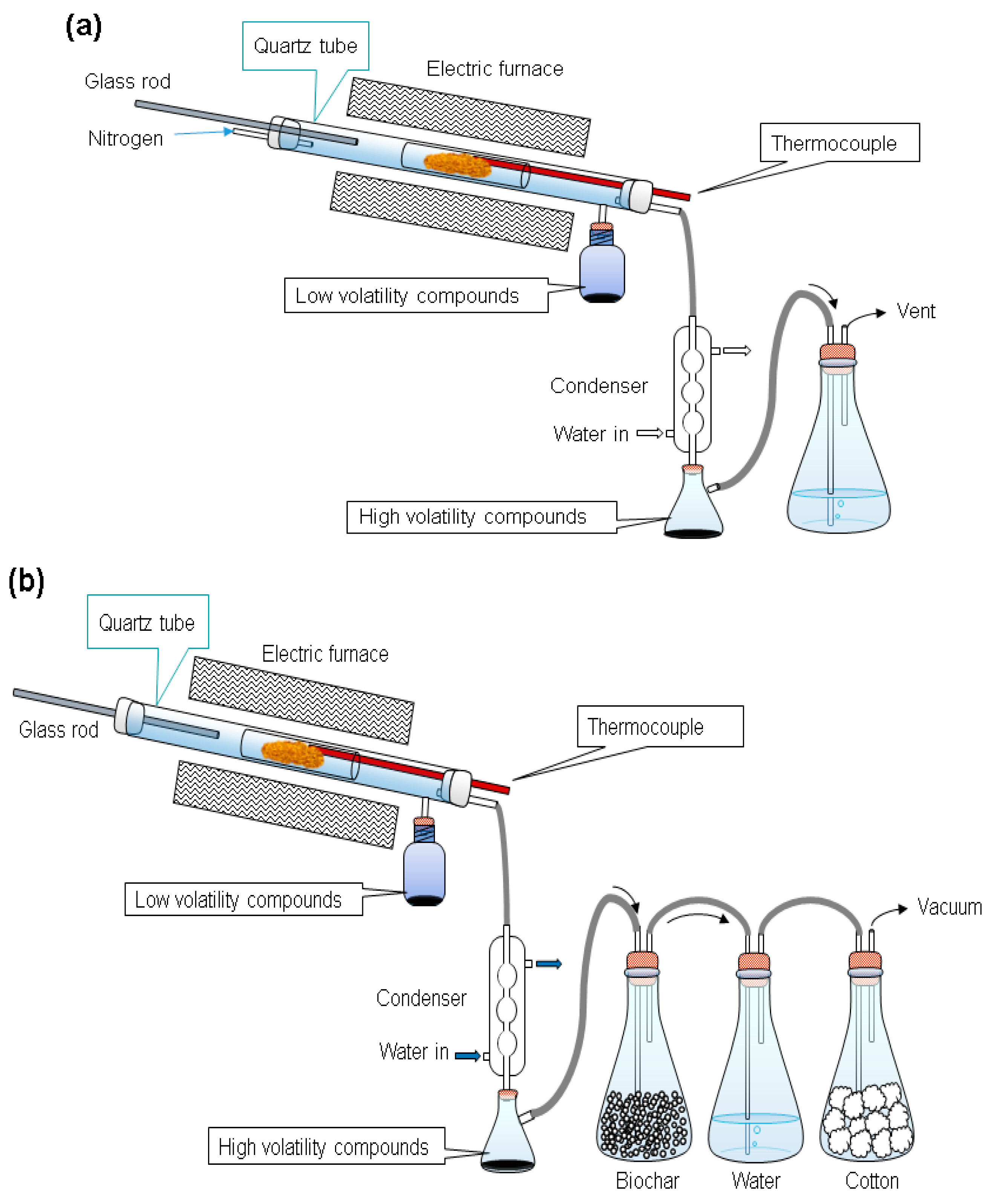

2.1. Parameters for Torrefaction with a Vacuum and a Nitrogen System

2.2. Sample Analysis

3. Results and Discussion

3.1. Proximate Analysis for Wood Sawdust

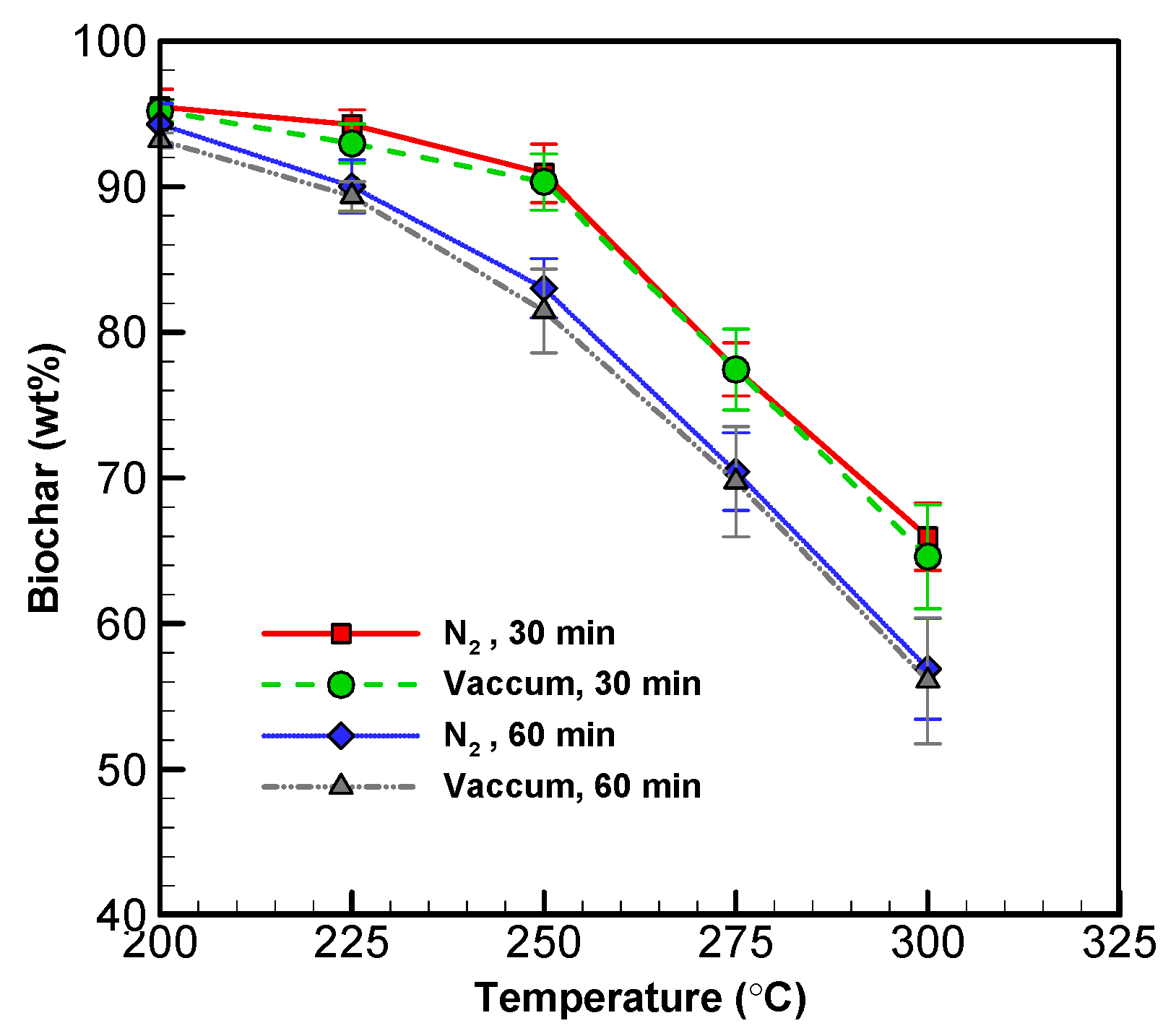

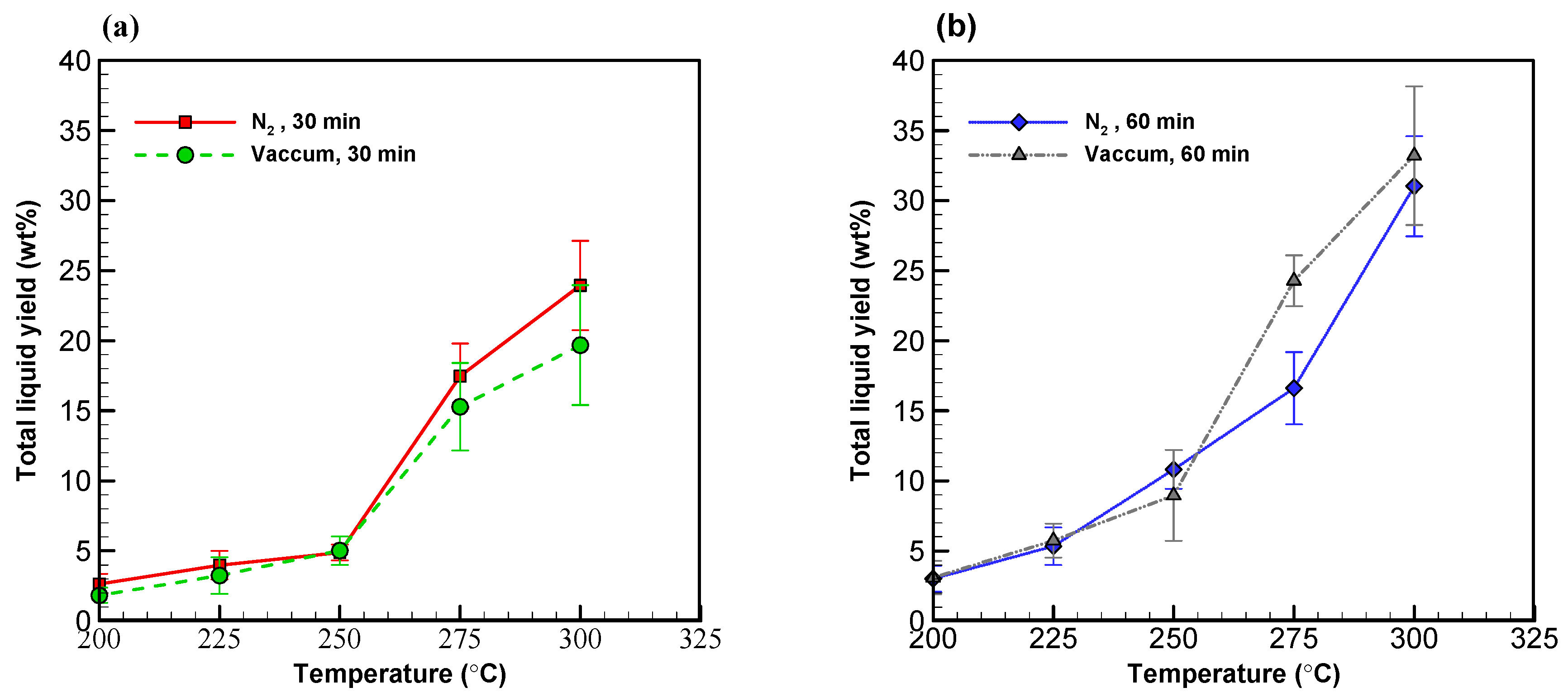

3.2. The Effect of Vacuum on Product Yields

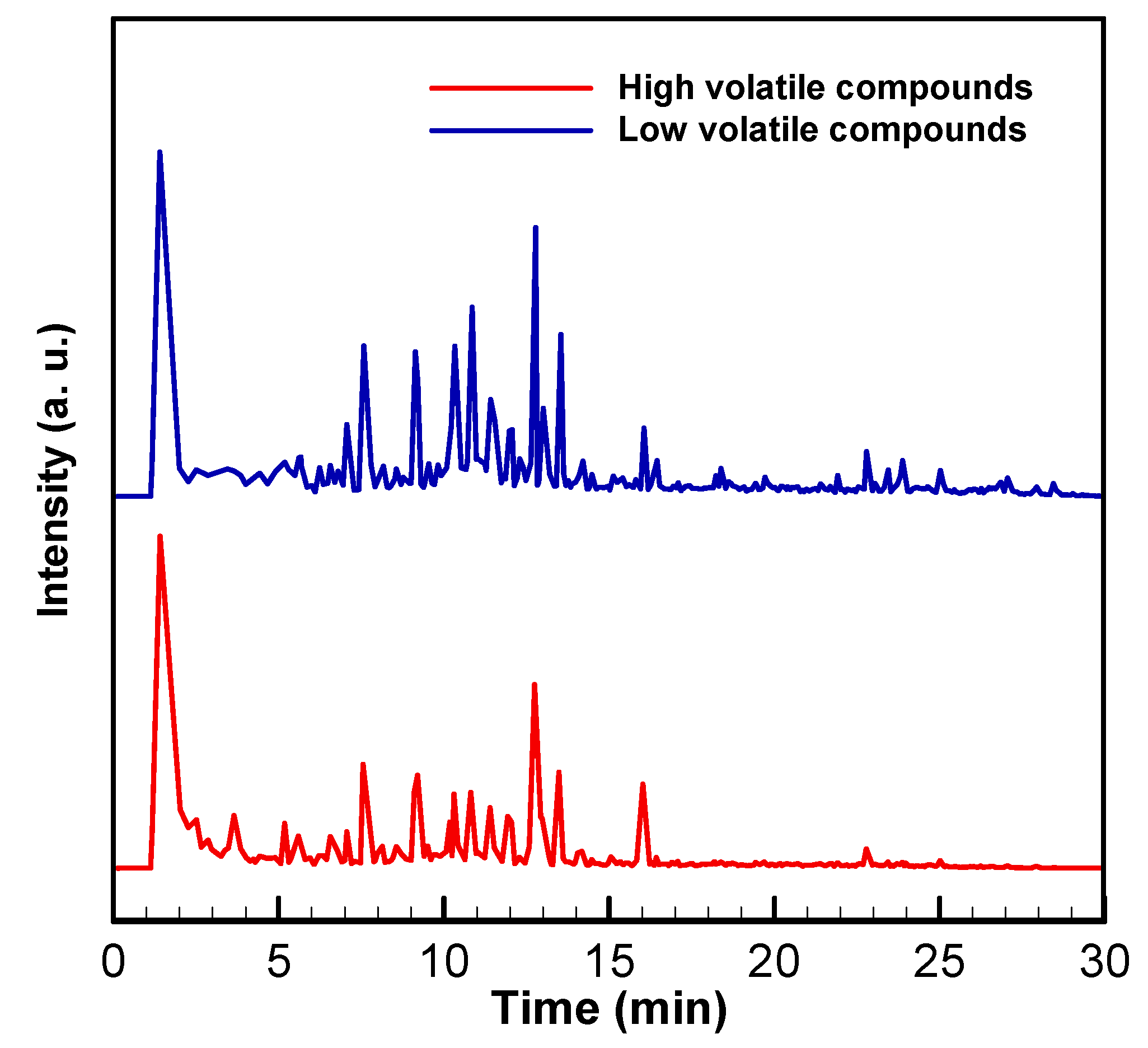

3.3. GC/MS Analysis of Liquid Compounds

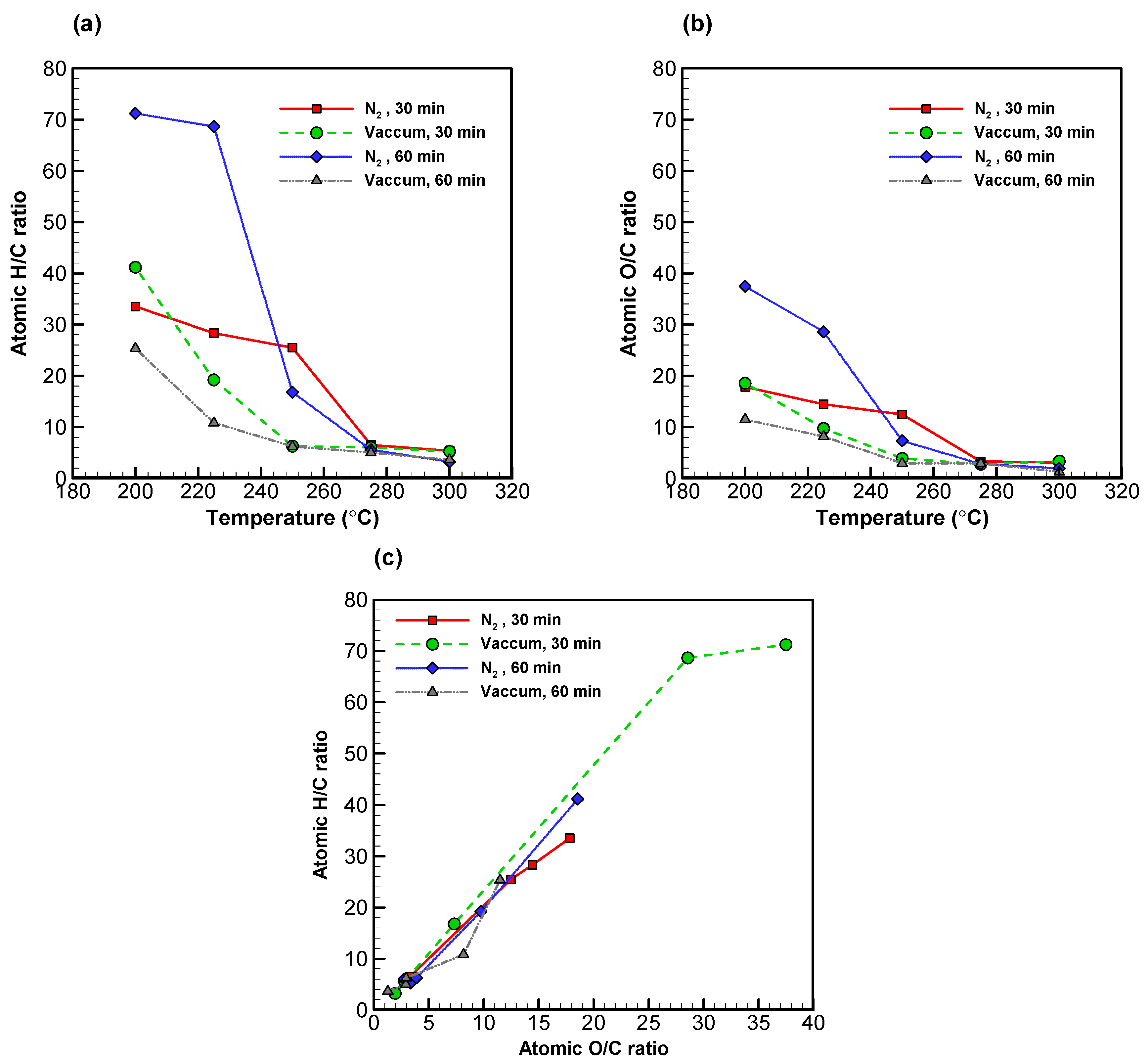

3.4. Elemental Analysis of Solid and Liquid Products

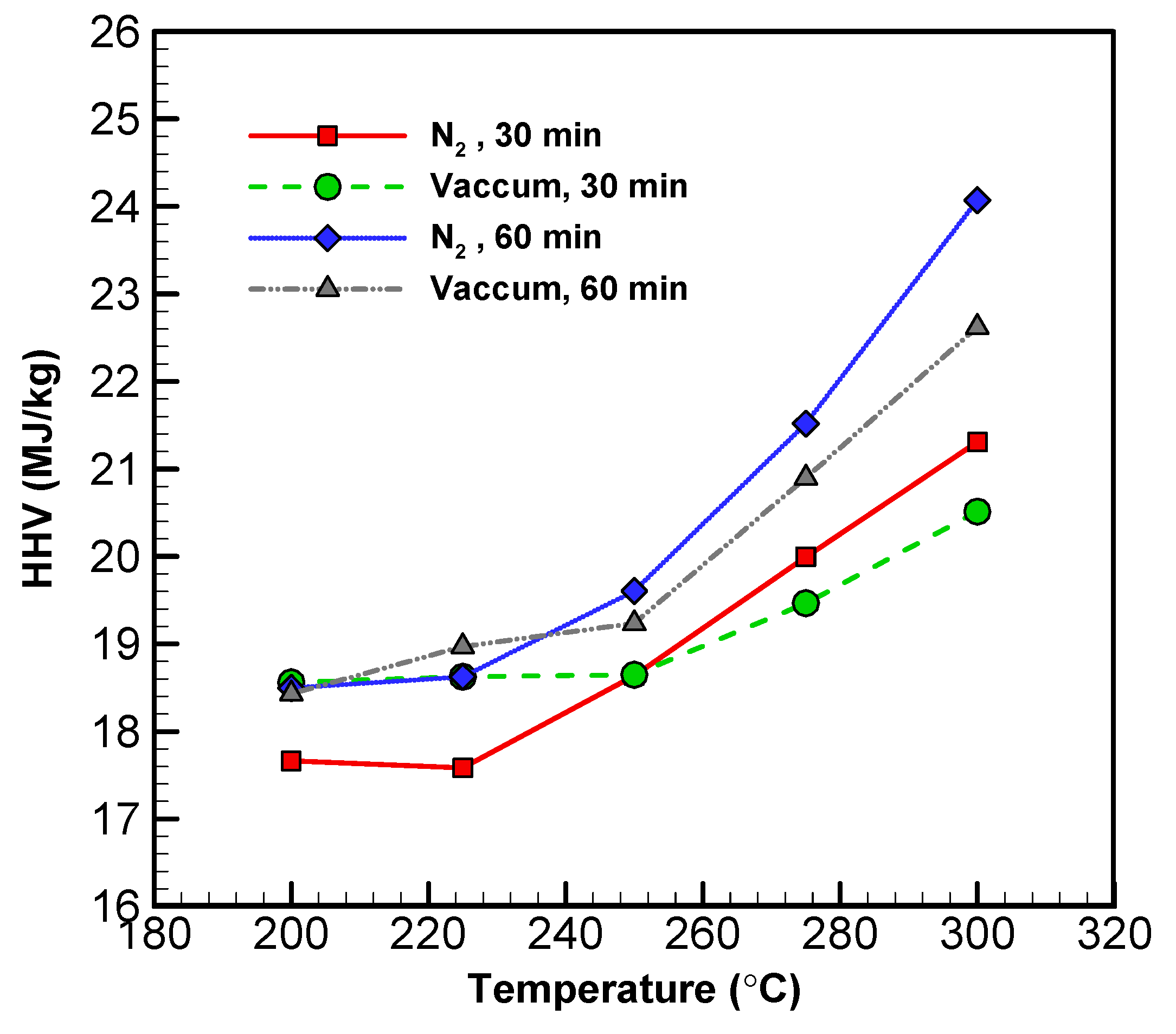

3.5. Higher Heating Value Analysis

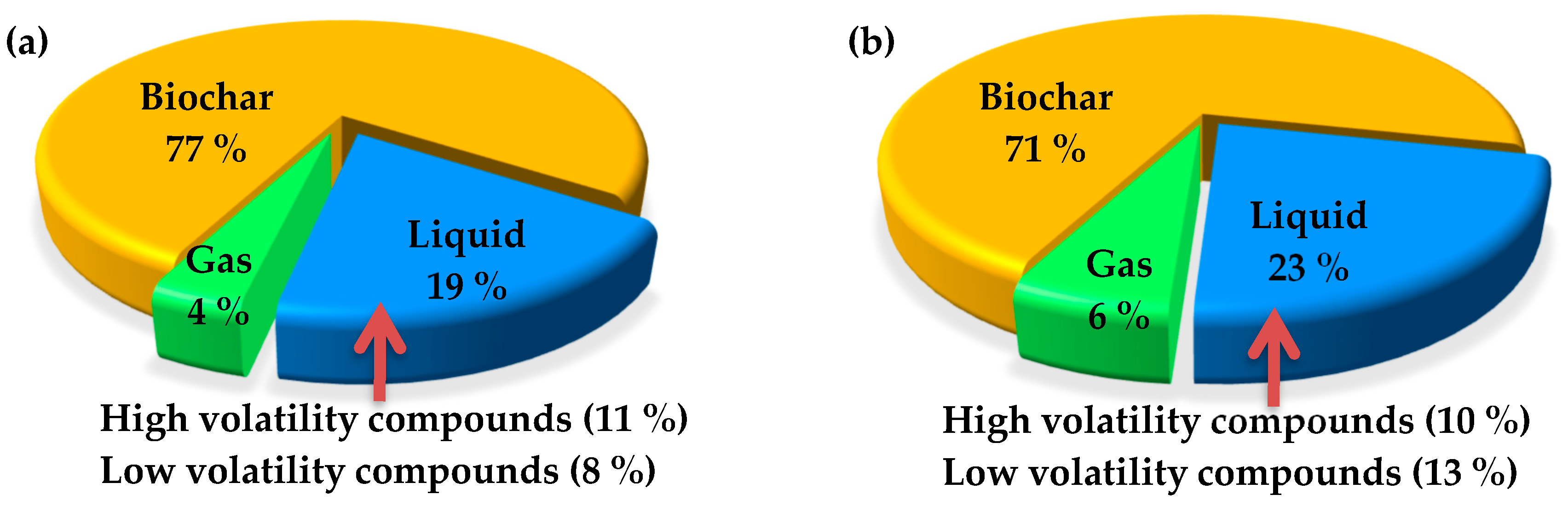

3.6. Biomass Energy Conversion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Operating Conditions | Temp. (°C) | Low Volatility Compounds | High Volatility Compounds | ||

|---|---|---|---|---|---|

| 60 min | 30 min | 60 min | 30 min | ||

| N2 | 200 | 95.03 | 85.55 | 97.94 | 95.11 |

| 300 | 24.6 | 49.12 | 62.06 | 61.32 | |

| Vacuum | 200 | - | - | 98.65 | 89.54 |

| 225 | - | - | 82.34 | 91.91 | |

| 300 | 14.3 | 15.68 | 45.33 | 44.28 | |

References

- Zachos, J.; Pagani, M.; Sloan, L.; Thomas, E.; Billups, K. Trends, Rhythms, and Aberrations in Global Climate 65 Ma to Present. Science 2001, 292, 686. [Google Scholar] [CrossRef]

- Hansen, J.; Ruedy, R.; Sato, M.; Lo, K. Global surface temperature change. Rev. Geophys. 2010, 48. [Google Scholar] [CrossRef]

- Dai, A. Increasing drought under global warming in observations and models. Nat. Clim. Chang. 2012, 3, 52. [Google Scholar] [CrossRef]

- John, R.P.; Anisha, G.S.; Nampoothiri, K.M.; Pandey, A. Micro and macroalgal biomass: A renewable source for bioethanol. Bioresour. Technol. 2011, 102, 186–193. [Google Scholar] [CrossRef]

- Parikka, M. Global biomass fuel resources. Biomass Bioenergy 2004, 27, 613–620. [Google Scholar] [CrossRef]

- Long, H.; Li, X.; Wang, H.; Jia, J. Biomass resources and their bioenergy potential estimation: A review. Renew. Sustain. Energy Rev. 2013, 26, 344–352. [Google Scholar] [CrossRef]

- Prins, M.J.; Ptasinski, K.J.; Janssen, F.J.J.G. Torrefaction of wood. Part 2. Analysis of products. J. Anal. Appl. Pyrolysis 2006, 77, 35–40. [Google Scholar] [CrossRef]

- Grilc, M.; Likozar, B.; Levec, J. Kinetic model of homogeneous lignocellulosic biomass solvolysis in glycerol and imidazolium-based ionic liquids with subsequent heterogeneous hydrodeoxygenation over NiMo/Al2O3 catalyst. Catal. Today 2015, 256, 302–314. [Google Scholar] [CrossRef]

- Grilc, M.; Likozar, B.; Levec, J. Simultaneous liquefaction and hydrodeoxygenation of lignocellulosic biomass over NiMo/Al2O3, Pd/Al2O3, and Zeolite Y catalysts in hydrogen donor solvents. ChemCatChem 2016, 8, 180–191. [Google Scholar] [CrossRef]

- Grilc, M.; Likozar, B.; Levec, J. Hydrotreatment of solvolytically liquefied lignocellulosic biomass over NiMo/Al2O3 catalyst: Reaction mechanism, hydrodeoxygenation kinetics and mass transfer model based on FTIR. Biomass Bioenergy 2014, 63, 300–312. [Google Scholar] [CrossRef]

- Chen, W.-H.; Hsu, H.-J.; Kumar, G.; Budzianowski, W.M.; Ong, H.C. Predictions of biochar production and torrefaction performance from sugarcane bagasse using interpolation and regression analysis. Bioresour. Technol. 2017, 246, 12–19. [Google Scholar] [CrossRef]

- Song, X.; Yang, Y.; Zhang, M.; Zhang, K.; Wang, D. Ultrasonic pelleting of torrefied lignocellulosic biomass for bioenergy production. Renew. Energy 2018, 129, 56–62. [Google Scholar] [CrossRef]

- Chen, W.-H.; Zhuang, Y.-Q.; Liu, S.-H.; Juang, T.-T.; Tsai, C.-M. Product characteristics from the torrefaction of oil palm fiber pellets in inert and oxidative atmospheres. Bioresour. Technol. 2016, 199, 367–374. [Google Scholar] [CrossRef]

- Lu, J.-J.; Chen, W.-H. Product yields and characteristics of corncob waste under various torrefaction Atmospheres. Energies 2014, 7, 13. [Google Scholar] [CrossRef]

- Chen, W.-H.; Cheng, W.-Y.; Lu, K.-M.; Huang, Y.-P. An evaluation on improvement of pulverized biomass property for solid fuel through torrefaction. Appl. Energy 2011, 88, 3636–3644. [Google Scholar] [CrossRef]

- Xing, X.; Fan, F.; Jiang, W. Characteristics of biochar pellets from corn straw under different pyrolysis temperatures. R. Soc. Open Sci. 2018, 5. [Google Scholar] [CrossRef]

- Santos, L.B.; Striebeck, M.V.; Crespi, M.S.; Capela, J.M.V.; Ribeiro, C.A.; De Julio, M. Energy evaluation of biochar obtained from the pyrolysis of pine pellets. J. Therm. Anal. Calorim. 2016, 126, 1879–1887. [Google Scholar] [CrossRef]

- Wang, Z.; Dunn, J.B.; Han, J.; Wang, M.Q. Effects of co-produced biochar on life cycle greenhouse gas emissions of pyrolysis-derived renewable fuels. Biofuels Bioprod. Biorefining 2014, 8, 189–204. [Google Scholar] [CrossRef]

- Sajdak, M.; Muzyka, R.; Hrabak, J.; Różycki, G. Biomass, biochar and hard coal: Data mining application to elemental composition and high heating values prediction. J. Anal. Appl. Pyrolysis 2013, 104, 153–160. [Google Scholar] [CrossRef]

- Bridgeman, T.G.; Jones, J.M.; Shield, I.; Williams, P.T. Torrefaction of reed canary grass, wheat straw and willow to enhance solid fuel qualities and combustion properties. Fuel 2008, 87, 844–856. [Google Scholar] [CrossRef]

- Sun, J.; He, F.; Pan, Y.; Zhang, Z. Effects of pyrolysis temperature and residence time on physicochemical properties of different biochar types. Acta Agric. Scand. Sect. B Soil Plant Sci. 2017, 67, 12–22. [Google Scholar] [CrossRef]

- Bach, Q.-V.; Chen, W.-H.; Chu, Y.-S.; Skreiberg, Ø. Predictions of biochar yield and elemental composition during torrefaction of forest residues. Bioresour. Technol. 2016, 215, 239–246. [Google Scholar] [CrossRef]

- Chen, W.-H.; Chu, Y.-S.; Lee, W.-J. Influence of bio-solution pretreatment on the structure, reactivity and torrefaction of bamboo. Energy Convers. Manag. 2017, 141, 244–253. [Google Scholar] [CrossRef]

- Couhert, C.; Salvador, S.; Commandré, J.M. Impact of torrefaction on syngas production from wood. Fuel 2009, 88, 2286–2290. [Google Scholar] [CrossRef]

- Dhanavath, K.N.; Bankupalli, S.; Bhargava, S.K.; Parthasarathy, R. An experimental study to investigate the effect of torrefaction temperature on the kinetics of gas generation. J. Environ. Chem. Eng. 2018, 6, 3332–3341. [Google Scholar] [CrossRef]

- Chen, D.; Gao, A.; Ma, Z.; Fei, D.; Chang, Y.; Shen, C. In-depth study of rice husk torrefaction: Characterization of solid, liquid and gaseous products, oxygen migration and energy yield. Bioresour. Technol. 2018, 253, 148–153. [Google Scholar] [CrossRef]

- Fisher, T.; Hajaligol, M.; Waymack, B.; Kellogg, D. Pyrolysis behavior and kinetics of biomass derived materials. J. Anal. Appl. Pyrolysis 2002, 62, 331–349. [Google Scholar] [CrossRef]

- Elliott, D.C. Historical developments in hydroprocessing bio-oils. Energy Fuels 2007, 21, 1792–1815. [Google Scholar] [CrossRef]

- Lin, B.-J.; Colin, B.; Chen, W.-H.; Pétrissans, A.; Rousset, P.; Pétrissans, M. Thermal degradation and compositional changes of wood treated in a semi-industrial scale reactor in vacuum. J. Anal. Appl. Pyrolysis 2018, 130, 8–18. [Google Scholar] [CrossRef]

- Garcìa-Pérez, M.; Chaala, A.; Pakdel, H.; Kretschmer, D.; Roy, C. Vacuum pyrolysis of softwood and hardwood biomass: Comparison between product yields and bio-oil properties. J. Anal. Appl. Pyrolysis 2007, 78, 104–116. [Google Scholar] [CrossRef]

- Murwanashyaka, J.N.; Pakdel, H.; Roy, C. Step-wise and one-step vacuum pyrolysis of birch-derived biomass to monitor the evolution of phenols. J. Anal. Appl. Pyrolysis 2001, 60, 219–231. [Google Scholar] [CrossRef]

- Pakdel, H.; Roy, C. Separation and characterization of steroids in biomass vacuum pyrolysis oils. Bioresour. Technol. 1996, 58, 83–88. [Google Scholar] [CrossRef]

- Chen, W.-H.; Kuo, P.-C. Torrefaction and co-torrefaction characterization of hemicellulose, cellulose and lignin as well as torrefaction of some basic constituents in biomass. Energy 2011, 36, 803–811. [Google Scholar] [CrossRef]

- Chen, W.-H.; Tu, Y.-J.; Sheen, H.-K. Impact of dilute acid pretreatment on the structure of bagasse for bioethanol production. Int. J. Energy Res. 2010, 34, 265–274. [Google Scholar] [CrossRef]

- ASTM D 1744-13—Standard Test Method for Determination of Water in Liquid Petroleum Products by Karl Fischer Reagent (Withdrawn 2016); ASTM International: West Conshohocken, PA, USA, 2013. [CrossRef]

- Scholz, E. Karl Fischer titration: determination of water. In Springer Science & Business Media; Springer: Berlin/Heidelberg, Germany, 2012; ISBN 978-3-642-69991-7. [Google Scholar]

- Islam, M.A.; Asif, M.; Hameed, B.H. Pyrolysis kinetics of raw and hydrothermally carbonized Karanj (Pongamia pinnata) fruit hulls via thermogravimetric analysis. Bioresour. Technol. 2015, 179, 227–233. [Google Scholar] [CrossRef]

- Konopel’ko, N.A.; Shakhov, E.M.J.F.D. Rarefied gas flow into a vacuum from a plane long channel closed at one end. Fluid Dyn. 2016, 51, 552–560. [Google Scholar] [CrossRef]

- ElhusseinŞahin, S.J.H.; Transfer, M. Drying behaviour, effective diffusivity and energy of activation of olive leaves dried by microwave, vacuum and oven drying methods. Heat Mass Transf. 2018, 54, 1901–1911. [Google Scholar] [CrossRef]

- González Martínez, M.; Dupont, C.; Thiéry, S.; Meyer, X.-M.; Gourdon, C. Impact of biomass diversity on torrefaction: Study of solid conversion and volatile species formation through an innovative TGA-GC/MS apparatus. Biomass Bioenergy 2018, 119, 43–53. [Google Scholar] [CrossRef]

- Zhang, L.; Li, K.; Zhu, X. Study on two-step pyrolysis of soybean stalk by TG-FTIR and Py-GC/MS. J. Anal. Appl. Pyrolysis 2017, 127, 91–98. [Google Scholar] [CrossRef]

- Xin, X.; Pang, S.; de Miguel Mercader, F.; Torr, K.M. The effect of biomass pretreatment on catalytic pyrolysis products of pine wood by Py-GC/MS and principal component analysis. J. Anal. Appl. Pyrolysis 2019, 138, 145–153. [Google Scholar] [CrossRef]

- Kim, J.-Y.; Hwang, H.; Park, J.; Oh, S.; Choi, J.W. Predicting structural change of lignin macromolecules before and after heat treatment using the pyrolysis-GC/MS technique. J. Anal. Appl. Pyrolysis 2014, 110, 305–312. [Google Scholar] [CrossRef]

- Chen, W.-H.; Wang, C.-W.; Kumar, G.; Rousset, P.; Hsieh, T.-H. Effect of torrefaction pretreatment on the pyrolysis of rubber wood sawdust analyzed by Py-GC/MS. Bioresour. Technol. 2018, 259, 469–473. [Google Scholar] [CrossRef]

- Cai, W.; Fivga, A.; Kaario, O.; Liu, R. Effects of Torrefaction on the Physicochemical Characteristics of Sawdust and Rice Husk and Their Pyrolysis Behavior by Thermogravimetric Analysis and Pyrolysis–Gas Chromatography/Mass Spectrometry. Energy Fuels 2017, 31, 1544–1554. [Google Scholar] [CrossRef]

- Apicella, B.; Tregrossi, A.; Popa, C.; Mennella, V.; Ciajolo, A.; Russo, C. Study on the separation and thin film deposition of tarry aromatics mixtures (soot extract and naphthalene pitch) by high-vacuum heating. Fuel 2017, 209, 795–801. [Google Scholar] [CrossRef]

- Horike, S.; Ayano, M.; Tsuno, M.; Fukushima, T.; Koshiba, Y.; Misaki, M.; Ishida, K. Thermodynamics of ionic liquid evaporation under vacuum. Phys. Chem. Chem. Phys. 2018, 20, 21262–21268. [Google Scholar] [CrossRef]

- Yao, M.; Woo, Y.C.; Tijing, L.D.; Choi, J.-S.; Shon, H.K. Effects of volatile organic compounds on water recovery from produced water via vacuum membrane distillation. Desalination 2018, 440, 146–155. [Google Scholar] [CrossRef]

- Rahman, S.; Helleur, R.; MacQuarrie, S.; Papari, S.; Hawboldt, K. Upgrading and isolation of low molecular weight compounds from bark and softwood bio-oils through vacuum distillation. Sep. Purif. Technol. 2018, 194, 123–129. [Google Scholar] [CrossRef]

- Nsaful, F.; Collard, F.-X.; Görgens, J.F. Lignocellulose thermal pretreatment and its effect on fuel properties and composition of the condensable products (tar precursors) from char devolatilization for coal substitution in gasification application. Fuel Process. Technol. 2018, 179, 334–343. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Boardman, R.D.; Wright, C.T. Response surface analysis of elemental composition and energy properties of corn stover during torrefaction. J. Biobased Mater. Bioenergy 2012, 6, 25–35. [Google Scholar] [CrossRef]

- Pimchuai, A.; Dutta, A.; Basu, P. Torrefaction of agriculture residue to enhance combustible properties. Energy Fuels 2010, 24, 4638–4645. [Google Scholar] [CrossRef]

- Chew, J.J.; Doshi, V. Recent advances in biomass pretreatment—Torrefaction fundamentals and technology. Renew. Sustain. Energy Rev. 2011, 15, 4212–4222. [Google Scholar] [CrossRef]

- Martín-Lara, M.A.; Ronda, A.; Zamora, M.C.; Calero, M. Torrefaction of olive tree pruning: Effect of operating conditions on solid product properties. Fuel 2017, 202, 109–117. [Google Scholar] [CrossRef]

- Chen, W.-H.; Liu, S.-H.; Juang, T.-T.; Tsai, C.-M.; Zhuang, Y.-Q. Characterization of solid and liquid products from bamboo torrefaction. Appl. Energy 2015, 160, 829–835. [Google Scholar] [CrossRef]

- Adams, P.; Bridgwater, T.; Lea-Langton, A.; Ross, A.; Watson, I. Chapter 8—Biomass conversion technologies. In Greenhouse Gases Balances of Bioenergy Systems; Academic Press: Cambridge, MA, USA, 2018; pp. 107–139. ISBN 9780081010365. [Google Scholar] [CrossRef]

- Roddy, D.J. Biomass in a petrochemical world. Interface Focus 2013, 3, 20120038. [Google Scholar] [CrossRef] [PubMed]

- Popa, V.I. 1-Biomass for fuels and biomaterials. In Biomass as Renewable Raw Material to Obtain Bioproducts of High-Tech Value; Elsevier: Amsterdam, The Netherlands, 2018; pp. 1–37. [Google Scholar] [CrossRef]

- Chen, D.; Gao, A.; Cen, K.; Zhang, J.; Cao, X.; Ma, Z. Investigation of biomass torrefaction based on three major components: Hemicellulose, cellulose, and lignin. Energy Convers. Manag. 2018, 169, 228–237. [Google Scholar] [CrossRef]

| Wood Sawdust | |

|---|---|

| Proximate Analysis (wt%) | |

| Volatility matter (VM) | 74.57 ± 3.89 |

| Fixed carbon (FC) | 16.41 ± 3.51 |

| Moisture | 7.72 ± 1.25 |

| Ash | 1.30 ± 0.73 |

| Fiber Analysis (wt%) | |

| Hemicellulose | 27.58 ± 4.72 |

| Cellulose | 46.32 ± 4.10 |

| Lignin | 8.17 ± 2.33 |

| Other | 16.71 ± 3.47 |

| Elemental Analysis (wt%, Dry-Ash-Free) | |

| C | 47.07 ± 2.55 |

| H | 6.10 ± 1.82 |

| N | 0.43 ± 0.21 |

| O (by difference) | 46.40 ± 4.44 |

| HHV (MJ kg−1, dry basis) | 17.68 ± 1.35 |

| Operating Conditions | Duration (min) | Temp. (°C) | Solid Yield | Liquid Yield | ||

|---|---|---|---|---|---|---|

| Biochar (wt%) | Low Volatility Compounds (wt%) | High Volatility Compounds (wt%) | Total (wt%) | |||

| N2 (0.1 L/min) | 30 | 200 | 95.47 ± 1.22 | 1.92 ± 0.21 | 0.72 ± 0.32 | 2.64 ± 0.72 |

| 225 | 94.26 ± 1.01 | 2.34 ± 0.24 | 1.64 ± 0.43 | 3.98 ± 1.02 | ||

| 250 | 90.92 ± 2.11 | 2.50 ± 0.35 | 2.37 ± 0.15 | 4.88 ± 0.57 | ||

| 275 | 77.46 ± 1.82 | 6.11 ± 1.61 | 11.36 ± 1.25 | 17.48 ± 2.32 | ||

| 300 | 65.97 ± 2.31 | 8.01 ± 2.37 | 15.93 ± 2.52 | 23.94 ± 3.19 | ||

| N2 (0.1 L/min) | 60 | 200 | 94.29 ± 1.42 | 0.32±0.38 | 2.69 ± 0.42 | 3.01 ± 0.93 |

| 225 | 90.02 ± 1.83 | 2.92 ± 0.82 | 2.41 ± 0.45 | 5.33 ± 1.34 | ||

| 250 | 83.03 ± 2.03 | 3.26 ± 0.87 | 7.55 ± 0.64 | 10.81 ± 1.38 | ||

| 275 | 70.44 ± 2.67 | 3.82 ± 1.32 | 12.79 ± 2.21 | 16.61 ± 2.58 | ||

| 300 | 56.91 ± 3.47 | 9.65 ± 2.53 | 21.38 ± 3.52 | 31.03 ± 3.57 | ||

| Vacuum | 30 | 200 | 95.20 ± 0.73 | - | 1.83 ± 0.54 | 1.83 ± 0.54 |

| 225 | 92.97 ± 1.34 | - | 3.24 ± 1.32 | 3.24 ± 1.32 | ||

| 250 | 90.33 ± 1.93 | 0.54 ± 0.92 | 4.48 ± 0.74 | 5.02 ± 1.02 | ||

| 275 | 77.45 ± 2.78 | 1.65 ± 0.72 | 13.63 ± 1.84 | 15.28 ± 3.13 | ||

| 300 | 64.61 ± 3.67 | 4.98 ± 2.77 | 14.70 ± 3.52 | 19.68 ± 4.28 | ||

| Vacuum | 60 | 200 | 93.19 ± 0.50 | - | 3.09 ± 1.19 | 3.09 ± 1.19 |

| 225 | 89.34 ± 1.02 | - | 5.74 ± 1.21 | 5.74 ± 1.21 | ||

| 250 | 81.47 ± 3.88 | 0.65 ± 0.21 | 8.32 ± 3.31 | 8.97 ± 3.25 | ||

| 275 | 69.76 ± 3.78 | 5.11 ± 0.92 | 19.17 ± 0.58 | 24.28 ± 1.82 | ||

| 300 | 56.08 ± 4.33 | 8.61 ± 3.53 | 24.61 ± 3.82 | 33.21 ± 4.95 | ||

| Bio-Low Volatility Compounds Fraction | Formula | N2 (300 °C, 60 min) | Vacuum (300 °C, 60 min) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Low Volatility Compounds | High Volatility Compounds | Low Volatility Compounds | High Volatility Compounds | ||||||

| RT | % | RT | % | RT | % | RT | % | ||

| Furfura | C5H4O2 | 1.699 | 1.38 | 1.612 | 9.32 | - | - | - | - |

| 2-Furancarboxaldehyde | C5H4O2 | 2.276 | 1.08 | 2.274 | 3.13 | - | - | 2.272 | 2.18 |

| 1,2-Cyclopentanedione | C5H6O2 | 2.908 | 1.65 | 2.872 | 1.64 | 2.859 | 1.00 | 2.875 | 1.17 |

| 2-methoxy-Phenol | C7H8O2 | 3.674 | 2.03 | 3.650 | 2.70 | 3.649 | 0.74 | 3.650 | 2.06 |

| Maltol | C6H6O3 | 3.903 | 1.04 | 3.858 | 0.81 | 3.856 | 0.55 | 3.856 | 0.71 |

| Creosol | C8H10O2 | 5.219 | 1.12 | 5.185 | 1.78 | 5.186 | 0.72 | 5.183 | 1.43 |

| 1,2-Benzenediol | C6H6O2 | 6.407 | 1.38 | 6.159 | 0.63 | 6.236 | 0.67 | 6.215 | 0.42 |

| 4-ethyl-2-methoxy-Phenol | C9H12O2 | 6.604 | 0.97 | 6.565 | 1.09 | 6.564 | 0.51 | 6.563 | 0.63 |

| 2-Methoxy-4-vinylphenol | C9H10O2 | 7.106 | 1.10 | 7.059 | 0.76 | 7.066 | 1.28 | 7.061 | 0.82 |

| 2,6-dimethoxy-phenol | C8H10O3 | 7.719 | 4.48 | 7.559 | 3.05 | - | - | - | - |

| Eugenol | C10H12O2 | 7.847 | 0.52 | 7.792 | 0.56 | 7.798 | 0.67 | 7.791 | 0.69 |

| 2-methoxy-4-propyl-phenol | C10H14O2 | 8.028 | 0.55 | 7.988 | 0.43 | - | - | - | - |

| Vanillin | C8H8O3 | 8.354 | 1.09 | 8.133 | 0.43 | 8.172 | 0.83 | 8.137 | 0.55 |

| trans-isoeugenol | C10H12O2 | 8.600 | 0.56 | 8.564 | 0.47 | 8.566 | 0.53 | 8.563 | 0.52 |

| 3,5-Dimethoxy-4-hydroxytoluene | C9H12O3 | 9.253 | 3.83 | 9.102 | 1.74 | 9.136 | 1.97 | 9.104 | 1.30 |

| 2-methoxy-4-(1-propenyl)-Phenol | C10H12O2 | 9.295 | 1.55 | 9.201 | 1.31 | 9.217 | 1.28 | 9.204 | 1.36 |

| Apocynin | C9H10O3 | 9.724 | 1.12 | 9.503 | 0.44 | 9.547 | 0.64 | 9.511 | 0.53 |

| 2,6-dimethoxy-4-(2-propenyl)-Phenol | C11H14O3 | - | - | 11.389 | 0.69 | 11.413 | 1.22 | 11.395 | 0.83 |

| 4-hydroxy-3,5-dimethoxy-Benzaldehyde | C9H10O4 | - | - | 11.911 | 0.71 | 11.985 | 1.17 | 11.936 | 1.17 |

| 2,6-Dimethoxy-4-(prop-1-en-1-yl)phenol | C11H14O3 | 12.893 | 4.72 | 12.727 | 2.29 | 12.781 | 3.32 | 12.744 | 2.99 |

| 4-Hydroxy-2-methoxycinnamaldehyde | C10H10O3 | - | - | 12.901 | 0.24 | - | - | 12.935 | 1.21 |

| 2,9-Dimethyl-2,3,4,5,6,7-hexahydro-1H-2-benzazonine | C14H21N | 15.877 | 0.33 | - | - | 15.817 | 0.32 | - | - |

| 3,5-Dimethoxy-4-hydroxycinnamaldehyde | C11H12O4 | 16.181 | 0.85 | 15.966 | 0.50 | 16.058 | 1.27 | - | - |

| gamma-phenyl-carbonic acid | C10H10O2 | - | - | 16.424 | 0.17 | - | - | - | - |

| n-Hexadecanoic acid | C16H32O2 | 16.522 | 0.65 | - | - | 16.452 | 0.51 | - | - |

| 4,4’-(1-methylethylidene)bisphenol | C15H16O2 | - | - | 18.166 | 0.05 | 18.235 | 0.37 | - | - |

| Oleic Acid | C18H34O2 | 18.446 | 0.54 | - | - | 18.385 | 0.49 | - | - |

| Octadecanoic acid | C19H36O2 | 18.727 | 0.14 | 18.687 | 0.10 | 18.695 | 0.13 | - | - |

| Dehydroabietic acid | C20H28O2 | 20.998 | 0.06 | - | - | 20.981 | 0.14 | - | - |

| Condition | Duration (min) | Temp. (°C) | Solid | Liquid | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Biochar(wt%, Dry Basis) | Low Volatility Compounds (wt%) | High Volatility Compounds (wt%) | |||||||||||||||

| C (%) | H (%) | O (%) | H/C Atom Ratio | O/C Atom Ratio | C (%) | H (%) | O (%) | H/C Atom Ratio | O/C Atom Ratio | C (%) | H (%) | O (%) | H/C Atom Ratio | O/C Atom Ratio | |||

| Raw | - | - | 47.70 | 6.19 | 45.67 | 1.54 | 0.71 | - | - | - | - | - | - | - | - | - | - |

| N2 (1 L/min) | 30 | 200 | 47.67 | 6.60 | 46.17 | 1.65 | 0.73 | 3.06 | 9.44 | 86.64 | 36.75 | 21.25 | 3.60 | 10.13 | 85.48 | 33.53 | 17.83 |

| 225 | 47.9 | 6.48 | 45.58 | 1.61 | 0.71 | 6.56 | 9.07 | 83.65 | 16.47 | 9.57 | 4.39 | 10.44 | 84.48 | 28.34 | 14.45 | ||

| 250 | 50.71 | 6.53 | 43.54 | 1.53 | 0.64 | 7.55 | 8.08 | 83.40 | 12.75 | 8.29 | 5.03 | 10.76 | 83.66 | 25.49 | 12.49 | ||

| 275 | 53.75 | 5.81 | 39.41 | 1.29 | 0.55 | 27.96 | 8.58 | 61.85 | 3.65 | 1.66 | 16.76 | 9.14 | 73.42 | 6.50 | 3.29 | ||

| 300 | 53.75 | 5.48 | 40.25 | 1.21 | 0.56 | 34.16 | 8.49 | 55.91 | 2.96 | 1.22 | 17.69 | 7.98 | 73.01 | 5.38 | 3.10 | ||

| N2 (1 L/min) | 60 | 200 | 50.01 | 6.27 | 43.17 | 1.49 | 0.64 | 3.50 | 11.35 | 84.22 | 38.64 | 18.06 | 3.41 | 11.78 | 84.31 | 41.16 | 18.56 |

| 225 | 49.48 | 5.92 | 44.02 | 1.42 | 0.66 | 7.58 | 9.95 | 81.77 | 15.64 | 8.10 | 6.37 | 10.27 | 82.74 | 19.21 | 9.75 | ||

| 250 | 49.06 | 5.66 | 44.79 | 1.37 | 0.68 | 30.62 | 8.22 | 59.94 | 3.20 | 1.47 | 14.81 | 7.80 | 76.47 | 6.28 | 3.88 | ||

| 275 | 55.22 | 5.59 | 38.52 | 1.20 | 0.52 | 49.90 | 7.79 | 40.54 | 1.86 | 0.61 | 19.23 | 9.73 | 70.53 | 6.03 | 2.75 | ||

| 300 | 52.20 | 4.90 | 42.19 | 1.11 | 0.60 | 50.39 | 7.45 | 40.84 | 1.76 | 0.61 | 16.84 | 7.44 | 75.16 | 5.26 | 3.35 | ||

| Vacuum | 30 | 200 | 48.67 | 6.37 | 44.46 | 1.56 | 0.69 | - | - | - | - | - | 1.75 | 10.46 | 87.39 | 71.22 | 37.48 |

| 225 | 48.24 | 6.48 | 45.16 | 1.60 | 0.70 | - | - | - | - | - | 2.22 | 12.79 | 84.49 | 68.65 | 28.57 | ||

| 250 | 48.21 | 6.04 | 45.37 | 1.49 | 0.71 | - | - | - | - | - | 8.18 | 11.53 | 79.76 | 16.80 | 7.32 | ||

| 275 | 54.21 | 6.36 | 38.92 | 1.40 | 0.54 | 52.14 | 7.21 | 39.16 | 1.64 | 0.56 | 18.88 | 8.81 | 70.87 | 5.56 | 2.81 | ||

| 300 | 54.45 | 5.75 | 39.34 | 1.26 | 0.54 | 53.83 | 7.41 | 37.24 | 1.64 | 0.51 | 25.73 | 7.00 | 67.05 | 3.24 | 1.95 | ||

| Vacuum | 60 | 200 | 47.36 | 5.78 | 46.24 | 1.45 | 0.73 | - | - | - | - | - | 5.39 | 11.47 | 82.49 | 25.36 | 11.49 |

| 225 | 49.87 | 5.95 | 43.65 | 1.42 | 0.66 | - | - | - | - | - | 7.71 | 7.01 | 83.89 | 10.83 | 8.17 | ||

| 250 | 51.65 | 5.76 | 42.22 | 1.33 | 0.61 | 55.51 | 7.12 | 34.87 | 1.53 | 0.47 | 18.14 | 9.50 | 71.06 | 6.24 | 2.94 | ||

| 275 | 54.30 | 5.42 | 39.72 | 1.19 | 0.55 | 52.53 | 7.00 | 39.12 | 1.59 | 0.56 | 18.62 | 7.84 | 72.53 | 5.02 | 2.92 | ||

| 300 | 56.35 | 5.15 | 38.00 | 1.09 | 0.51 | 53.09 | 7.01 | 38.28 | 1.57 | 0.54 | 32.66 | 9.97 | 55.99 | 3.64 | 1.29 | ||

| Condition | Time (min) | Temp. (°C) | Solid | Liquid | |

|---|---|---|---|---|---|

| Biochar HHV (Dry Basis) (MJ/kg) | Low Volatility Compounds HHV (MJ/kg) | High Volatility Compounds HHV (MJ/kg) | |||

| Raw | - | - | 17.687 | - | - |

| N2 (0.1 L/min) | 30 | 200 | 17.662 | 2.902 | 1.160 |

| 225 | 17.583 | 4.403 | 1.653 | ||

| 250 | 18.637 | 4.978 | 4.429 | ||

| 275 | 19.995 | 10.721 | 6.628 | ||

| 300 | 21.308 | 13.762 | 6.839 | ||

| N2 (0.1 L/min) | 60 | 200 | 18.496 | 3.533 | 1.021 |

| 225 | 18.624 | 5.197 | 1.026 | ||

| 250 | 19.605 | 9.644 | 5.499 | ||

| 275 | 21.518 | 17.685 | 6.425 | ||

| 300 | 24.071 | 19.205 | 6.816 | ||

| Vacuum | 30 | 200 | 18.561 | - | 1.455 |

| 225 | 18.624 | - | 1.533 | ||

| 250 | 18.647 | 15.600 | 1.776 | ||

| 275 | 19.465 | 19.034 | 6.724 | ||

| 300 | 20.512 | 19.101 | 9.131 | ||

| Vacuum | 60 | 200 | 18.431 | - | 2.801 |

| 225 | 18.970 | - | 5.047 | ||

| 250 | 19.235 | - | 5.804 | ||

| 275 | 21.698 | 19.726 | 6.921 | ||

| 300 | 22.521 | 19.450 | 9.333 | ||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chih, Y.-K.; Chen, W.-H.; Ong, H.C.; Show, P.L. Product Characteristics of Torrefied Wood Sawdust in Normal and Vacuum Environments. Energies 2019, 12, 3844. https://doi.org/10.3390/en12203844

Chih Y-K, Chen W-H, Ong HC, Show PL. Product Characteristics of Torrefied Wood Sawdust in Normal and Vacuum Environments. Energies. 2019; 12(20):3844. https://doi.org/10.3390/en12203844

Chicago/Turabian StyleChih, Yi-Kai, Wei-Hsin Chen, Hwai Chyuan Ong, and Pau Loke Show. 2019. "Product Characteristics of Torrefied Wood Sawdust in Normal and Vacuum Environments" Energies 12, no. 20: 3844. https://doi.org/10.3390/en12203844

APA StyleChih, Y.-K., Chen, W.-H., Ong, H. C., & Show, P. L. (2019). Product Characteristics of Torrefied Wood Sawdust in Normal and Vacuum Environments. Energies, 12(20), 3844. https://doi.org/10.3390/en12203844