Performance Evaluation and Prediction of BIPV Systems under Partial Shading Conditions Using Normalized Efficiency

Abstract

1. Introduction

2. Performance Comparison of the OBIPV System by Operation Method Using NE*

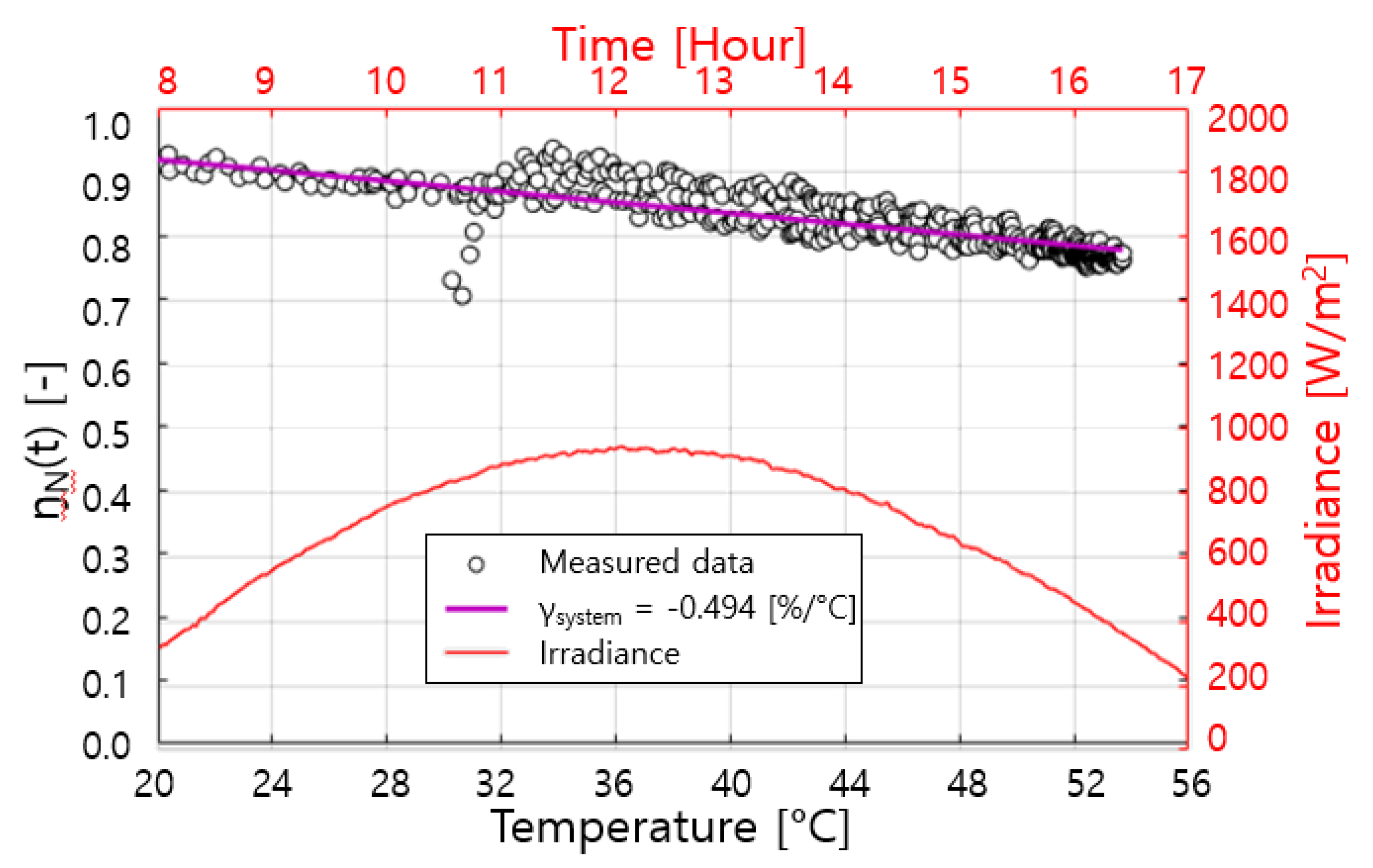

2.1. Calculation of Temperature-Corrected Normalized Efficiency

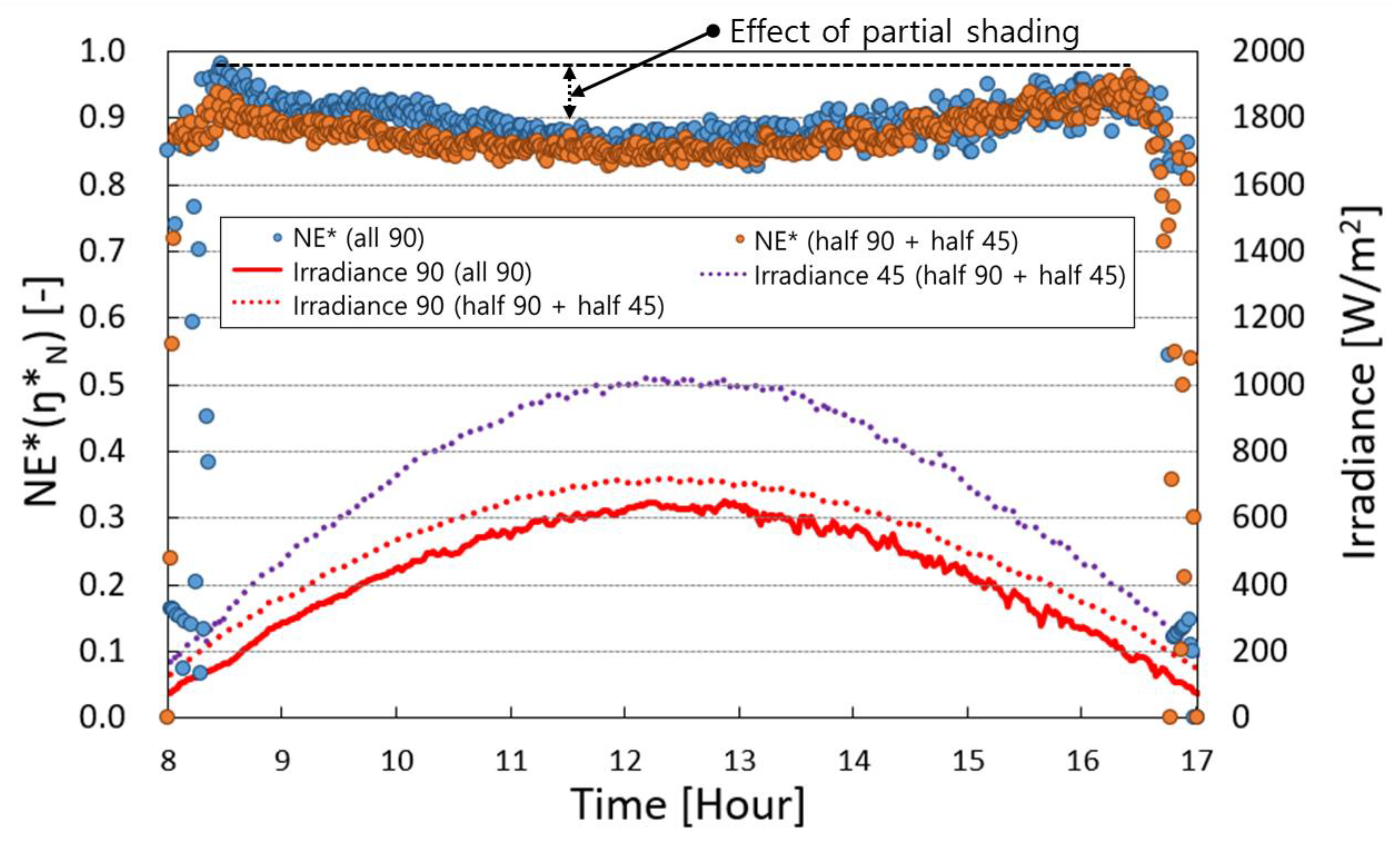

2.2. Performance Comparison of Operable BIPV System by Operation Method

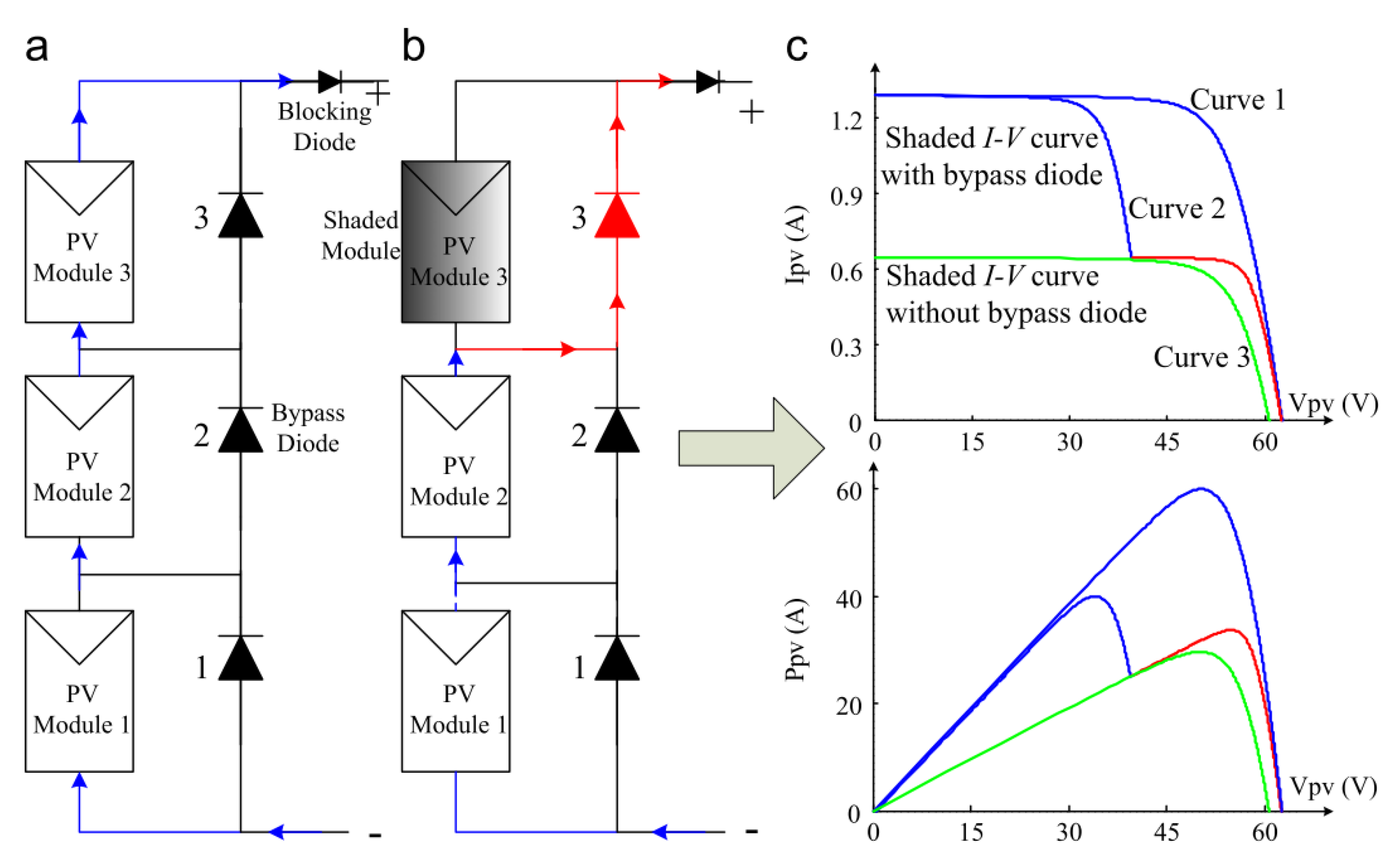

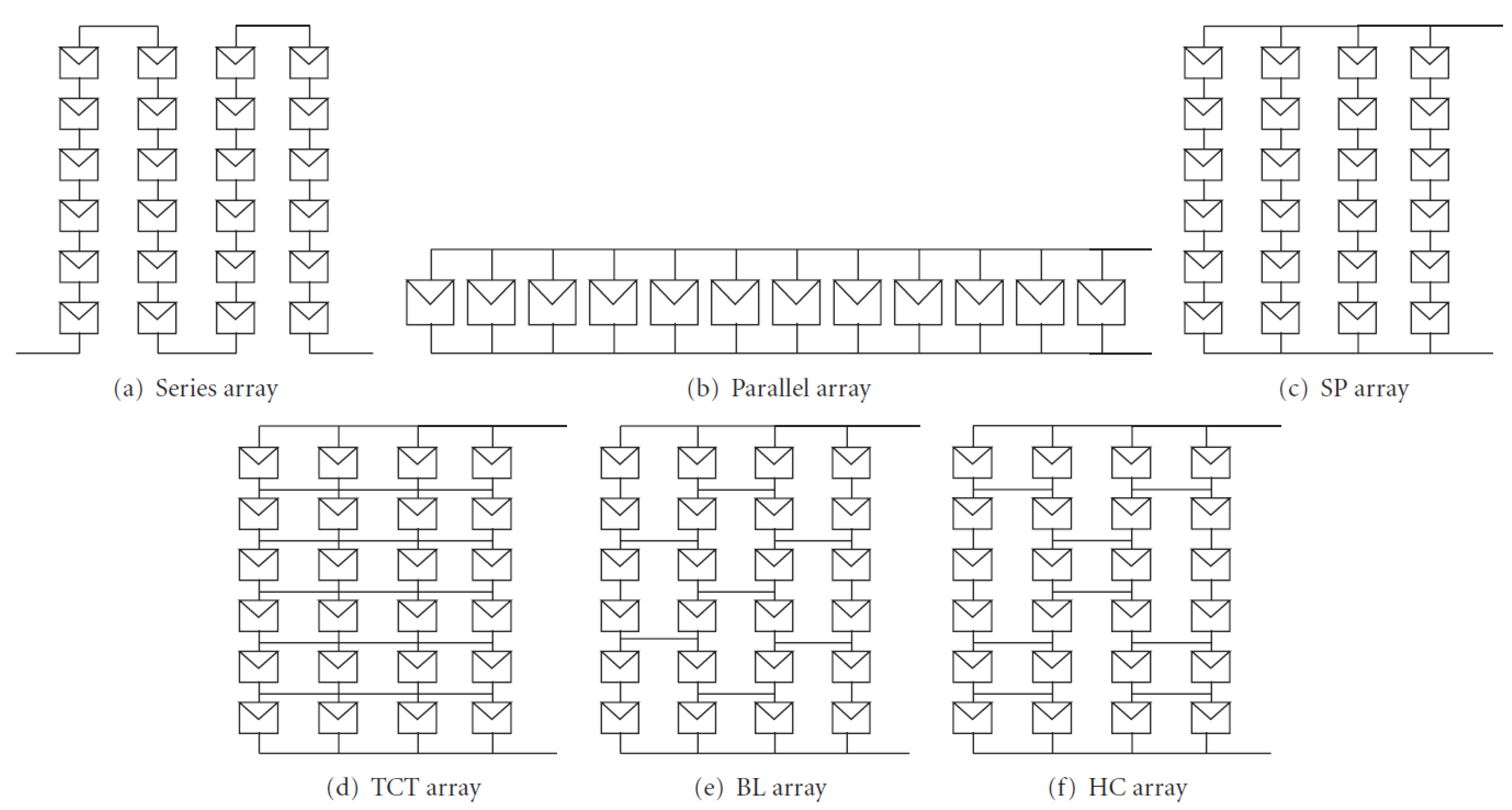

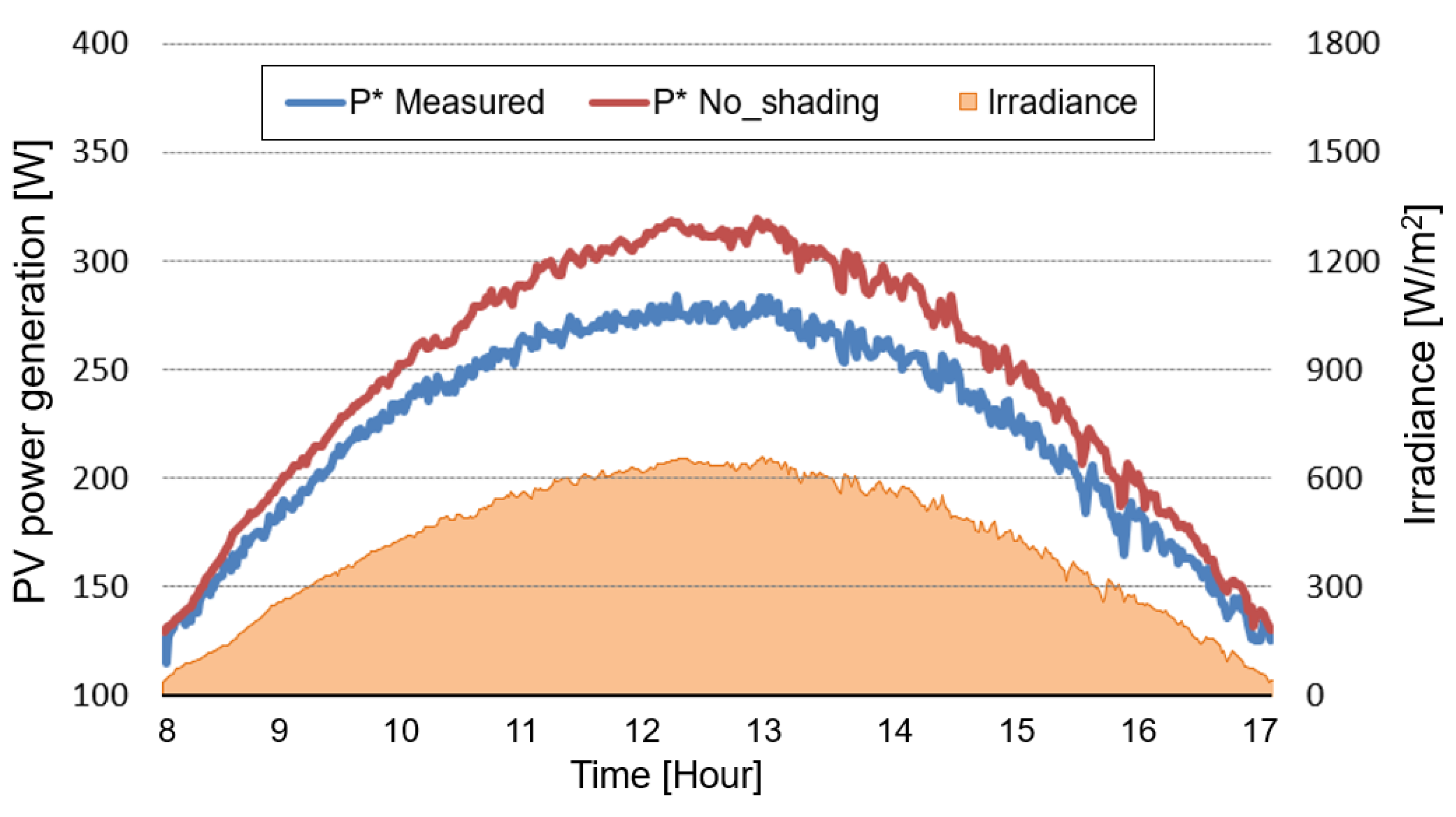

2.3. The Effect of Partial Shading on the Performance of Power Generation

3. Prediction of PV Power Generation Using Normalized Efficiency

3.1. Method of Prediction of PV System Performance of Power Generation Using Normalized Efficiency

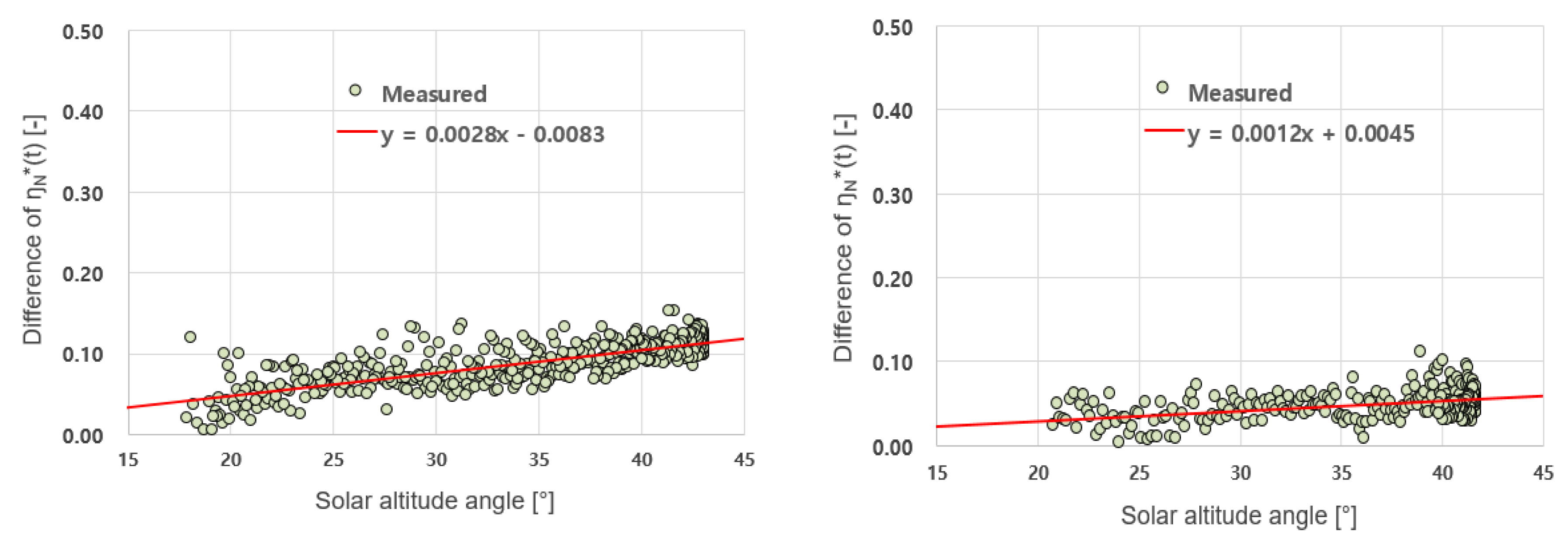

3.2. Impact of Partial Shading Depending on Solar Altitude Angle

4. Performance Prediction of OBIPV System with Partial Shading

4.1. Validation Test of Performance of Power Generation Prediction Method Using NE

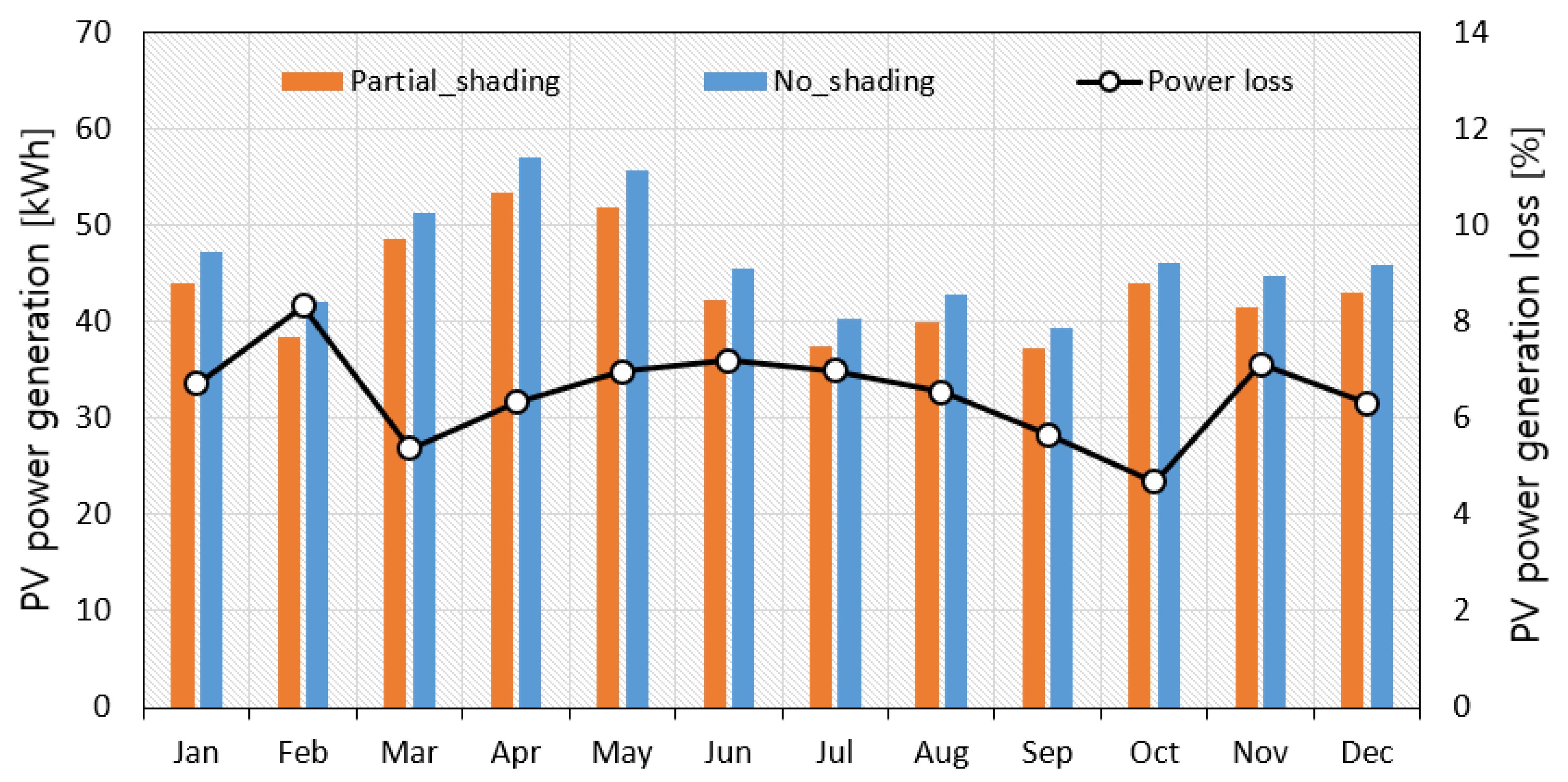

4.2. Prediction of the OBIPV System Performance of Power Generation with Partial Shading

5. Conclusions

- If the operating angle of the BIPV system was operated differently, the normalized efficiency was lower compared to the BIPV system operated at a fixed operating angle by calculating NE*. This result was because the voltage of the module decreased as the irradiance of some modules in the OBIPV system dropped, and eventually, the performance of the power generation of the entire array decreased. Therefore, by calculating NE*, we were able to determine the optimum operation method of the OBIPV system.

- The NE* analysis of the OBIPV system found that the distribution of NE* decreased during the daytime. As a result of this investigation, it was found that partial shading was caused by the spherical structure on the upper part of the PV overhang for design purposes, and the effect of this partial shading increased in proportion to the solar altitude.

- The change of NE* depending on the solar altitude angle was predicted by regression analysis, and the regression analysis result was reflected in the power generation estimation method using NE*. Validation tests were performed based on measured data which were measured for two months in November and December. The differences between the measured power generation and the predicted power generation were 3% and 2% in November and December, respectively.

- Using NE* to predict the annual performance of power generation with or without the partial shading of the OBIPV system, it is predicted that the electrical output will be reduced annually by 36 kWh/yr (6.5%) due to the effect of partial shading.

Author Contributions

Funding

Conflicts of Interest

References

- Tracking Clean Energy Progress: 2017; International Energy Agency: Paris, France, 2017.

- Yang, T.; Athienitis, A.K. A review of research and developments of building-integrated photovoltaic/thermal (BIPV/T) systems. Renew. Sustain. Energy Rev. 2016, 66, 886–912. [Google Scholar] [CrossRef]

- Belussi, L.; Barozzi, B.; Bellazzi, A.; Danza, L.; Devitofrancesco, A.; Fanciulli, C.; Ghellere, M.; Guazzi, G.; Meroni, I.; Salamone, F.; et al. A review of performance of zero energy buildings and energy efficiency solutions. J. Build. Eng. 2019, 25, 100772. [Google Scholar] [CrossRef]

- Biyik, E.; Araz, M.; Hepbasli, A.; Shahrestani, M.; Yao, R.; Shao, L.; Essah, E.; Oliveira, A.C.; del Cano, T.; Rico, E. A key review of building integrated photovoltaic (BIPV) systems. Eng. Sci. Technol. Int. J. 2017, 20, 833–858. [Google Scholar] [CrossRef]

- Kim, J.-H.; Kim, H.-R.; Kim, J.-T. Analysis of photovoltaic applications in zero energy building cases of IEA SHC/EBC Task 40/Annex 52. Sustainability 2015, 7, 8782–8800. [Google Scholar] [CrossRef]

- Tahri, A.; Oozeki, T.; Draou, A. Monitoring and evaluation of photovoltaic system. Energy Procedia 2013, 42, 456–464. [Google Scholar] [CrossRef]

- Silva, E.N.M.; Rodrigues, A.B.; da Guia da Silva, M. Stochastic assessment of the impact of photovoltaic distributed generation on the power quality indices of distribution networks. Electr. Power Syst. Res. 2016, 135, 59–67. [Google Scholar] [CrossRef]

- Rezk, H.; Tyukhov, I.; Al-Dhaifallah, M.; Tikhonov, A. Performance of data acquisition system for monitoring PV system parameters. Measurement 2017, 104, 204–211. [Google Scholar] [CrossRef]

- Whitaker, C.M.; Townsend, T.U.; Newmiller, J.D.; King, D.L.; Boyson, W.E.; Kratochvil, J.A.; Collier, D.E.; Osborn, D.E. Application and validation of a new PV performance characterization method, In proceedings of the Conference Record of the Twenty Sixth IEEE Photovoltaic Specialists Conference, Anaheim, CA, USA, 29 September–3 October 1997; pp. 1253–1256. [Google Scholar]

- Kurtz, S.; Newmiller, J.; Kimber, A.; Flottemesch, R.; Riley, E.; Dierauf, T.; McKee, J.; Krishnani, P. Analysis of Photovoltaic System Energy Performance Evaluation Method; Technical report No. 5200-60628; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2013; pp. 1–54.

- Kratochvil, J.A.; Boyson, W.E.; King, D.L. Photovoltaic Array Performance Model; Sandia National Laboratories: Albuquerque, NM, USA, 2004.

- Touati, F.; Al-Hitmi, M.A.; Chowdhury, N.A.; Hamad, J.A.; San Pedro Gonzales, A.J.R. Investigation of solar PV performance under Doha weather using a customized measurement and monitoring system. Renew. Energy 2016, 89, 564–577. [Google Scholar] [CrossRef]

- Omer, S.A.; Wilson, R.; Riffat, S.B. Monitoring results of two examples of building integrated PV (BIPV) systems in the UK. Renew. Energy 2003, 28, 1387–1399. [Google Scholar] [CrossRef]

- Mellit, A.; Tina, G.M.; Kalogirou, S.A. Fault detection and diagnosis methods for photovoltaic systems: A review. Renew. Sustain. Energy Rev. 2018, 91, 1–17. [Google Scholar] [CrossRef]

- Salem, T.; Kinab, E. Analysis of building-integrated photovoltaic systems: A case study of commercial buildings under mediterranean climate. Procedia Eng. 2015, 118, 538–545. [Google Scholar] [CrossRef][Green Version]

- Lee, H.M.; Yoon, J.H.; Kim, S.C.; Shin, U.C. Operational power performance of south-facing vertical BIPV window system applied in office building. Sol. Energy 2017, 145, 66–77. [Google Scholar] [CrossRef]

- Bingöl, O.; Özkaya, B. Analysis and comparison of different PV array configurations under partial shading conditions. Sol. Energy 2018, 160, 336–343. [Google Scholar] [CrossRef]

- Daliento, S.; Chouder, A.; Guerriero, P.; Pavan, A.M.; Mellit, A.; Moeini, R.; Tricoli, P. Monitoring, Diagnosis, and Power Forecasting for Photovoltaic Fields: A Review. Int. J. Photoenergy 2017, 2017, 1–13. [Google Scholar] [CrossRef]

- Herteleer, B.; Huyck, B.; Catthoor, F.; Driesen, J.; Cappelle, J. Normalised efficiency of photovoltaic systems: Going beyond the performance ratio. Sol. Energy 2017, 157, 408–418. [Google Scholar] [CrossRef]

- IEC 61724-1:2017. Photovoltaic System Performance—Part 1: Monitoring; CENELEC: Brussels, Belgium, 2017. [Google Scholar]

- Timothy, D.; Growitz, A.; Kurtz, S.; Cruz, J.L.B.; Riley, E.; Hansen, C. Weather-Corrected Performance Ratio; Technical Report No. 5200-57991; National Renewable Energy Laboratory (NREL): Golden, CO, USA, April 2013.

- van Sark, W.; Nordmann, T.; Clavadetscher, L.; Green, M. Analysis of Long-Term Performance of PV Systems; International Energy Agency: Paris, France, 2014. [Google Scholar]

- Ishaque, K.; Salam, Z. A review of maximum power point tracking techniques of PV system for uniform irradiation and partial shading condition. Renew. Sustain. Energy Rev. 2013, 19, 475–488. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes, 4th ed.; Wiley: Hoboken, NJ, USA, 2013. [Google Scholar]

- Ramaprabha, R.; Mathur, B.L. A comprehensive review and analysis of solar photovoltaic array configurations under partial shaded conditions. Int. J. Photoenergy 2012, 1–16. [Google Scholar] [CrossRef]

- Huld, T.; Gottschalg, R.; Beyer, H.G.; Topič, M. Mapping the performance of PV modules, effects of module type and data averaging. Sol. Energy 2010, 84, 324–338. [Google Scholar] [CrossRef]

- Huld, T.; Friesen, G.; Skoczek, A.; Kenny, R.P.; Sample, T.; Field, M.; Dunlop, E.D. A power-rating model for crystalline silicon PV modules. Sol. Energy Mater. Sol. Cells 2011, 95, 3359–3369. [Google Scholar] [CrossRef]

- Ramos, G.; Bandera, C. Validation of calibrated energy models: Common errors. Energies 2017, 10, 1587. [Google Scholar]

- Lee, C.; Lee, H.; Choi, M.; Yoon, J. Design optimization and experimental evaluation of photovoltaic double skin facade. Energy Build. 2019, 109314. [Google Scholar] [CrossRef]

- ASHRAE IWEC2 Weather Files for International Locations. Available online: http://ashrae.whiteboxtechnologies.com/IWEC2 (accessed on 15 April 2019).

| Measurement Item | Equipment (Manufacturer) | Specifications |

|---|---|---|

| Irradiance | SMP11 (Kipp & Zonen) | Classification to ISO 9060: Secondary standard Spectral range: 285 nm to 2800 nm Output range: −200 to 2000 W/m2 Temperature dependence of sensitivity: <1% |

| Temperature | T-type thermocouple | Temperature range: −270 °C to 370 °C Accuracy: ±1.0 °C |

| Data logger | GL840 (Graphtec) | Input voltage range: 20mV to 100 V Accuracy: ±0.1% voltage, ±1.55 °C temperature |

| Jan | Feb | Mar | Apr | May | Jun | Jul | Aug | Sep | Oct | Nov | Dec | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Close | 110 | 98 | 101 | 94 | 78 | 60 | 55 | 64 | 69 | 103 | 104 | 107 |

| Open | 96 | 96 | 119 | 132 | 129 | 104 | 92 | 98 | 90 | 107 | 94 | 91 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, C.-s.; Lee, H.-m.; Choi, M.-j.; Yoon, J.-h. Performance Evaluation and Prediction of BIPV Systems under Partial Shading Conditions Using Normalized Efficiency. Energies 2019, 12, 3777. https://doi.org/10.3390/en12193777

Lee C-s, Lee H-m, Choi M-j, Yoon J-h. Performance Evaluation and Prediction of BIPV Systems under Partial Shading Conditions Using Normalized Efficiency. Energies. 2019; 12(19):3777. https://doi.org/10.3390/en12193777

Chicago/Turabian StyleLee, Chul-sung, Hyo-mun Lee, Min-joo Choi, and Jong-ho Yoon. 2019. "Performance Evaluation and Prediction of BIPV Systems under Partial Shading Conditions Using Normalized Efficiency" Energies 12, no. 19: 3777. https://doi.org/10.3390/en12193777

APA StyleLee, C.-s., Lee, H.-m., Choi, M.-j., & Yoon, J.-h. (2019). Performance Evaluation and Prediction of BIPV Systems under Partial Shading Conditions Using Normalized Efficiency. Energies, 12(19), 3777. https://doi.org/10.3390/en12193777