Parametric Optimisation of an ORC in a Wood Chipboard Production Facility to Recover Waste Heat Produced from the Drying and Steam Production Process

Abstract

1. Introduction

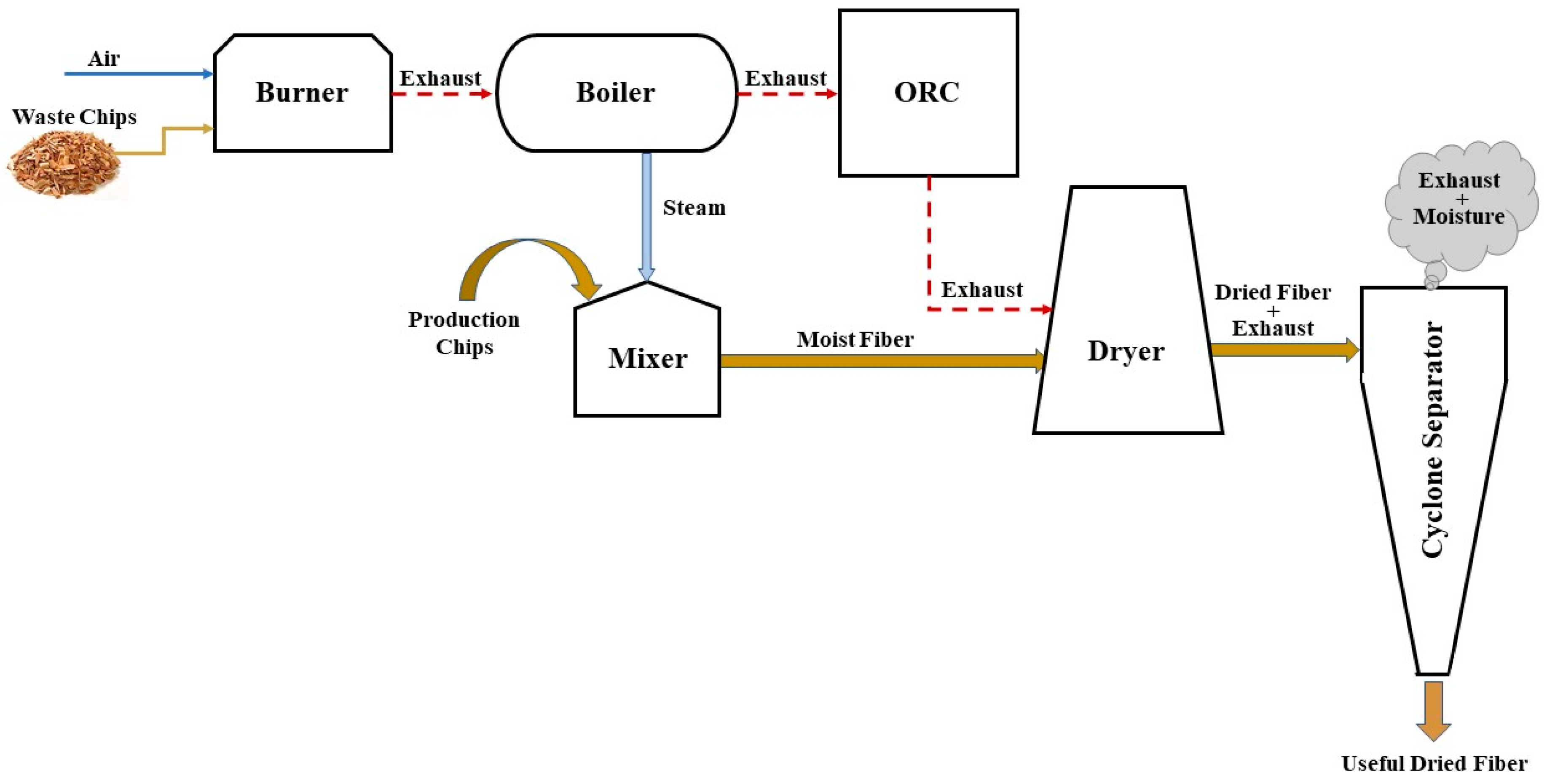

2. Cogeneration Cycle (CC)

3. Organic Rankine Cycle (ORC)

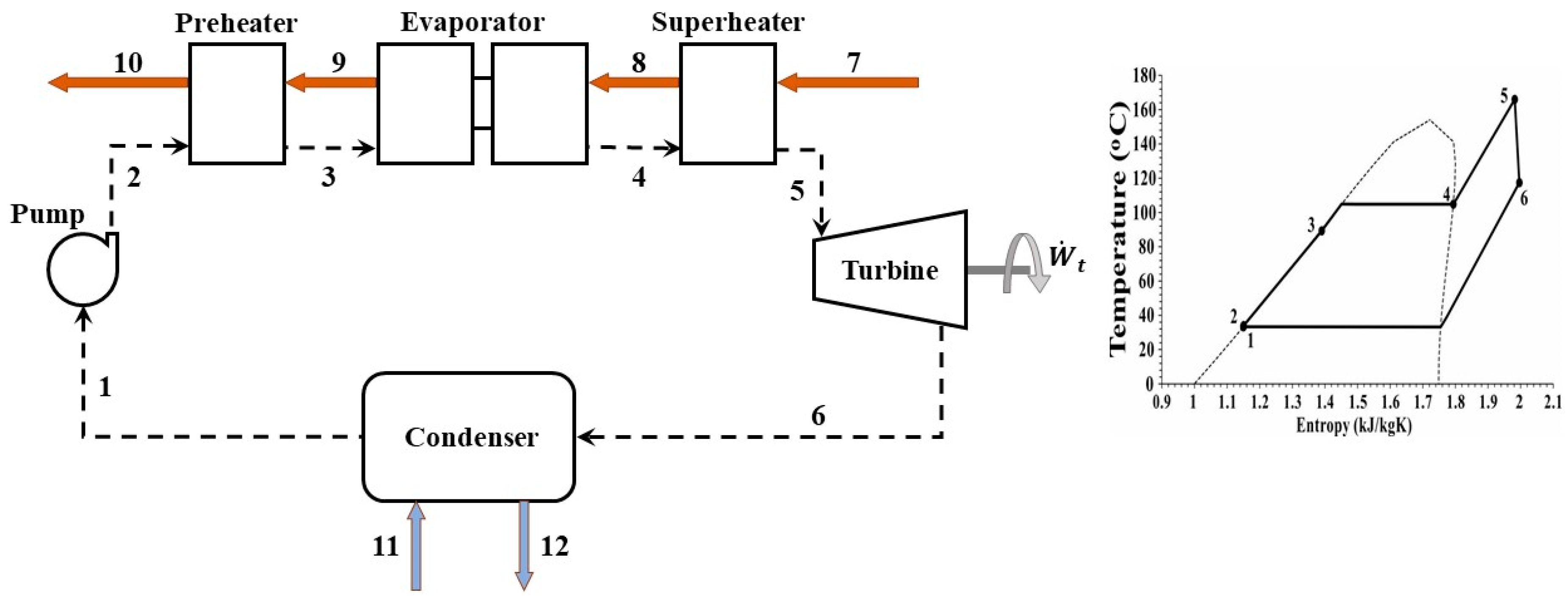

3.1. Description of the ORC

3.2. Working Fluids of the ORC

4. Mathematical Model

5. Results and Discussion

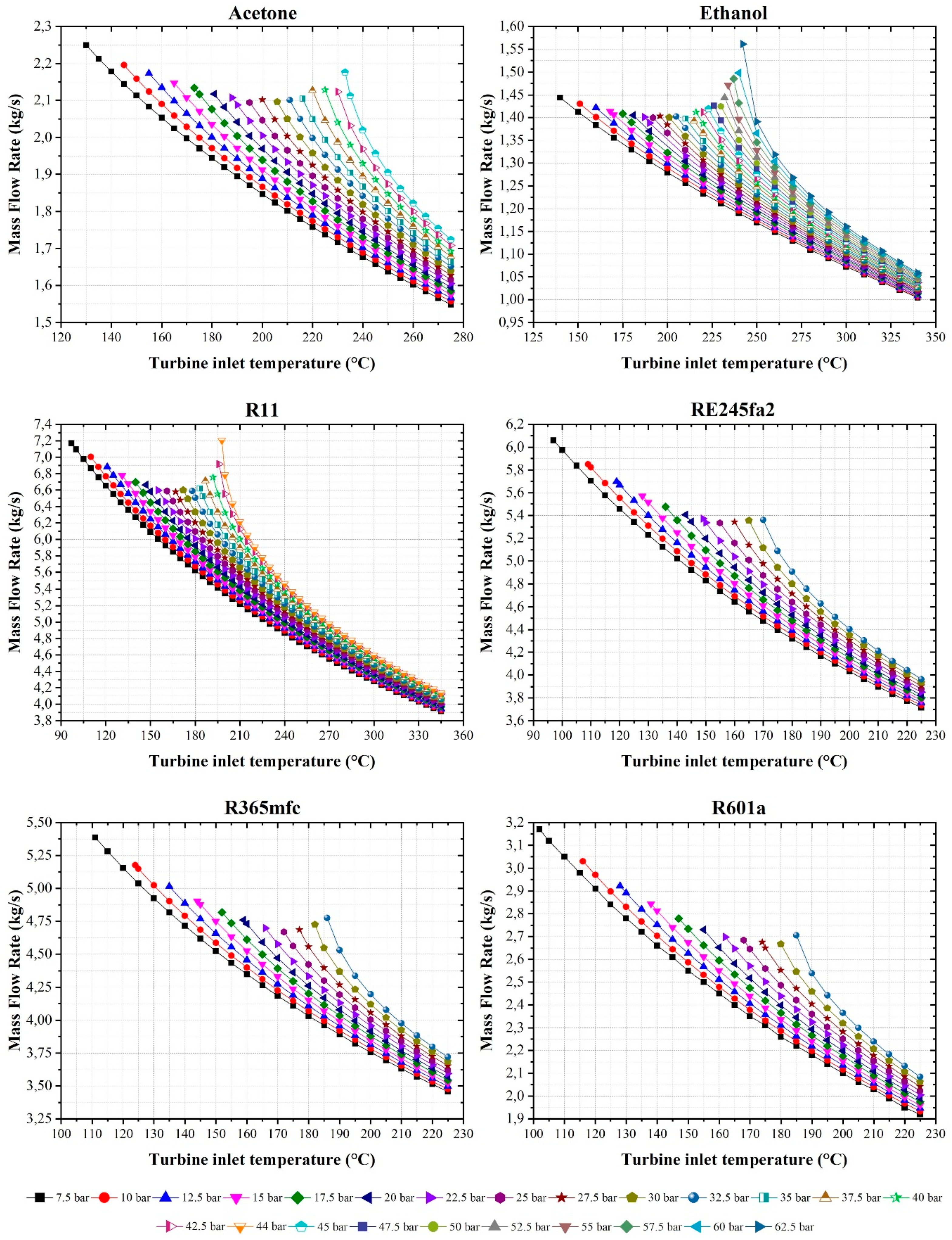

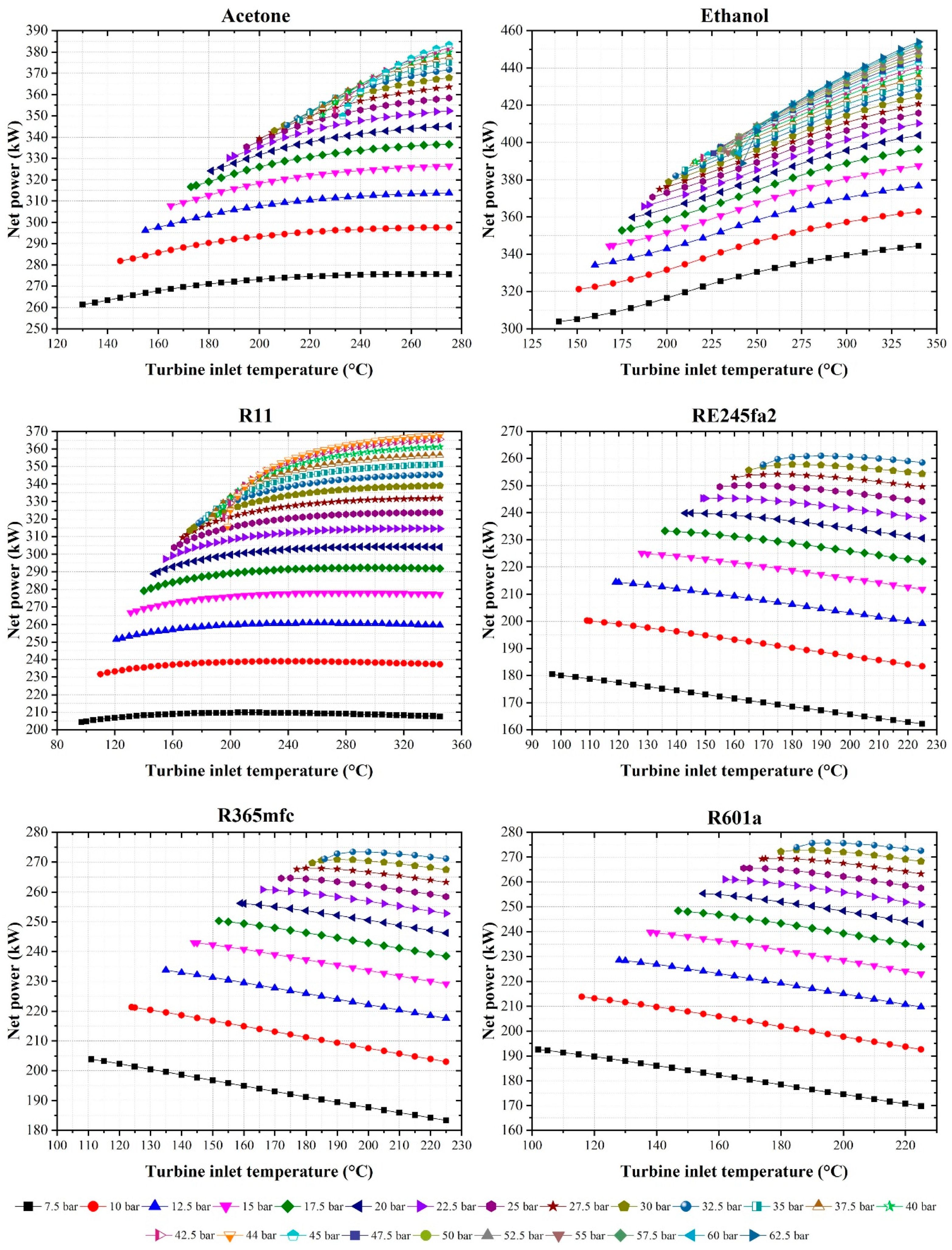

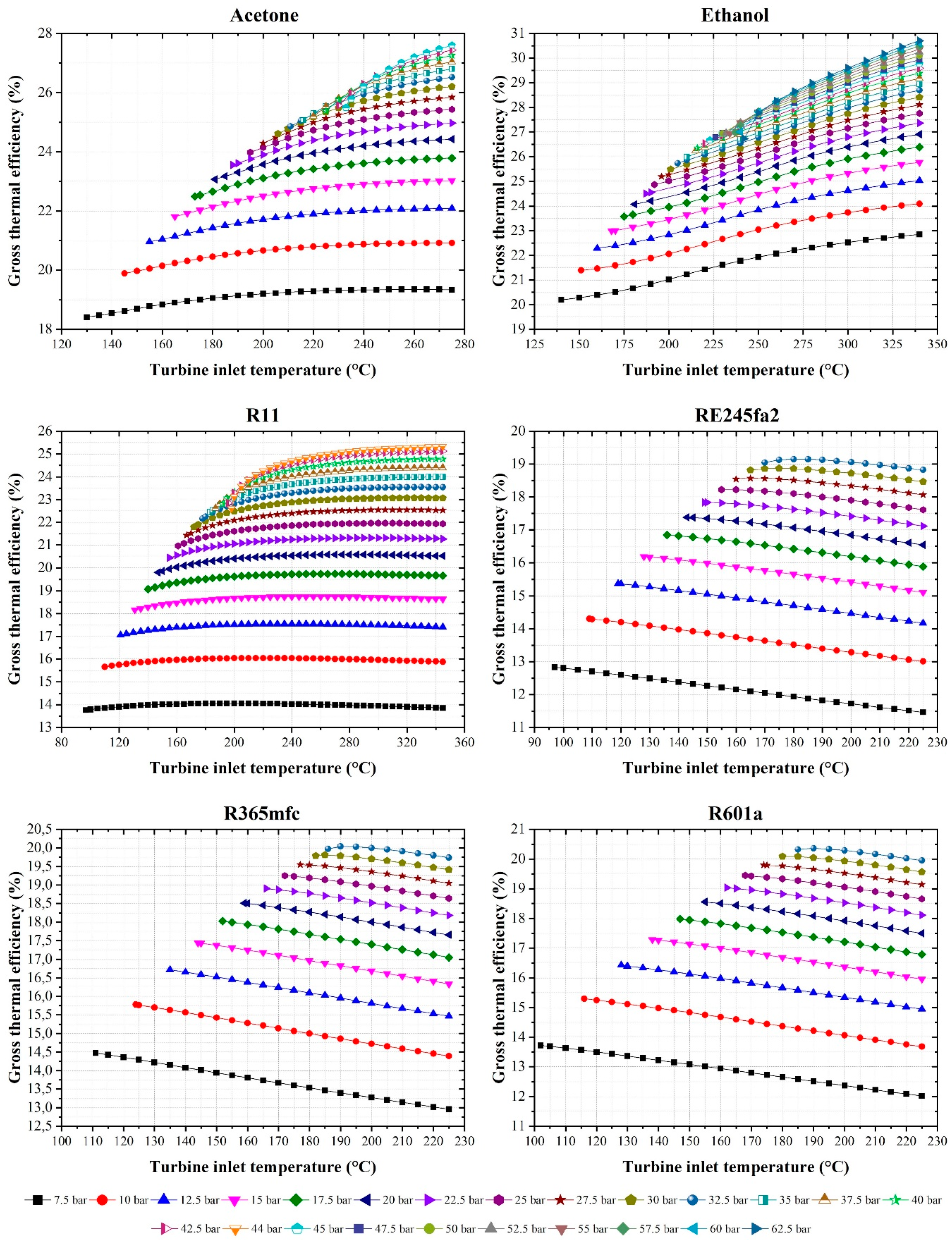

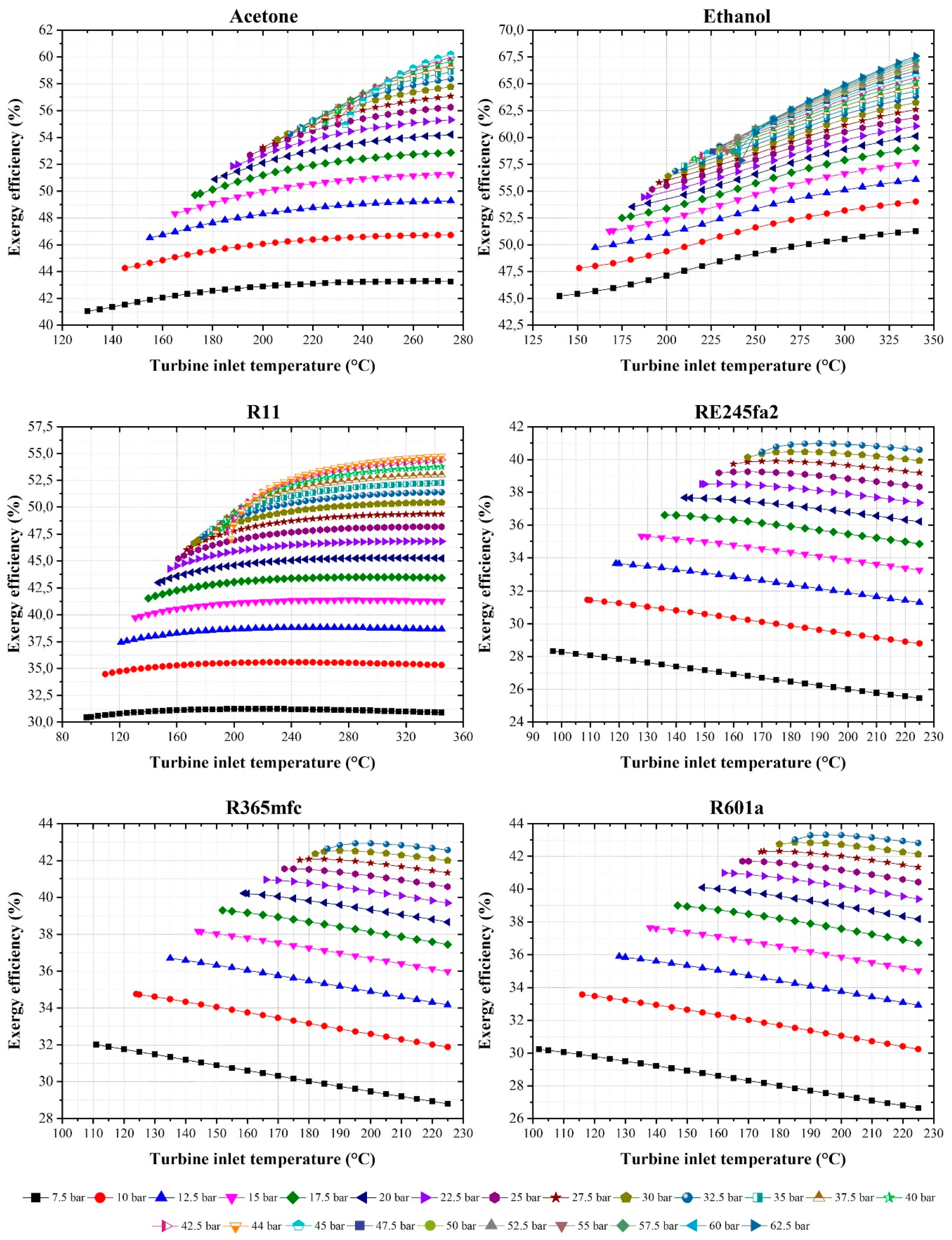

5.1. Parametric Optimisation Results of the ORC

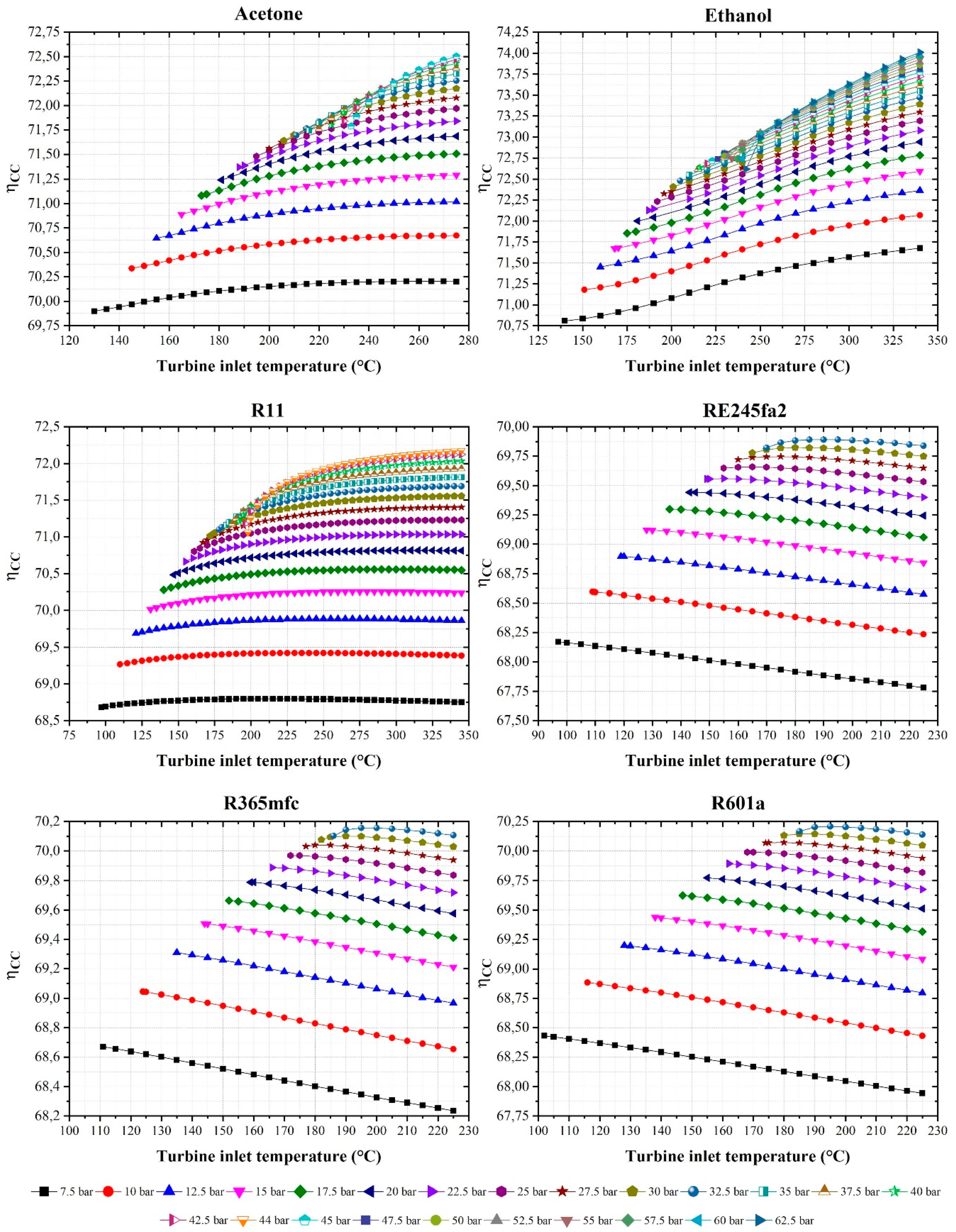

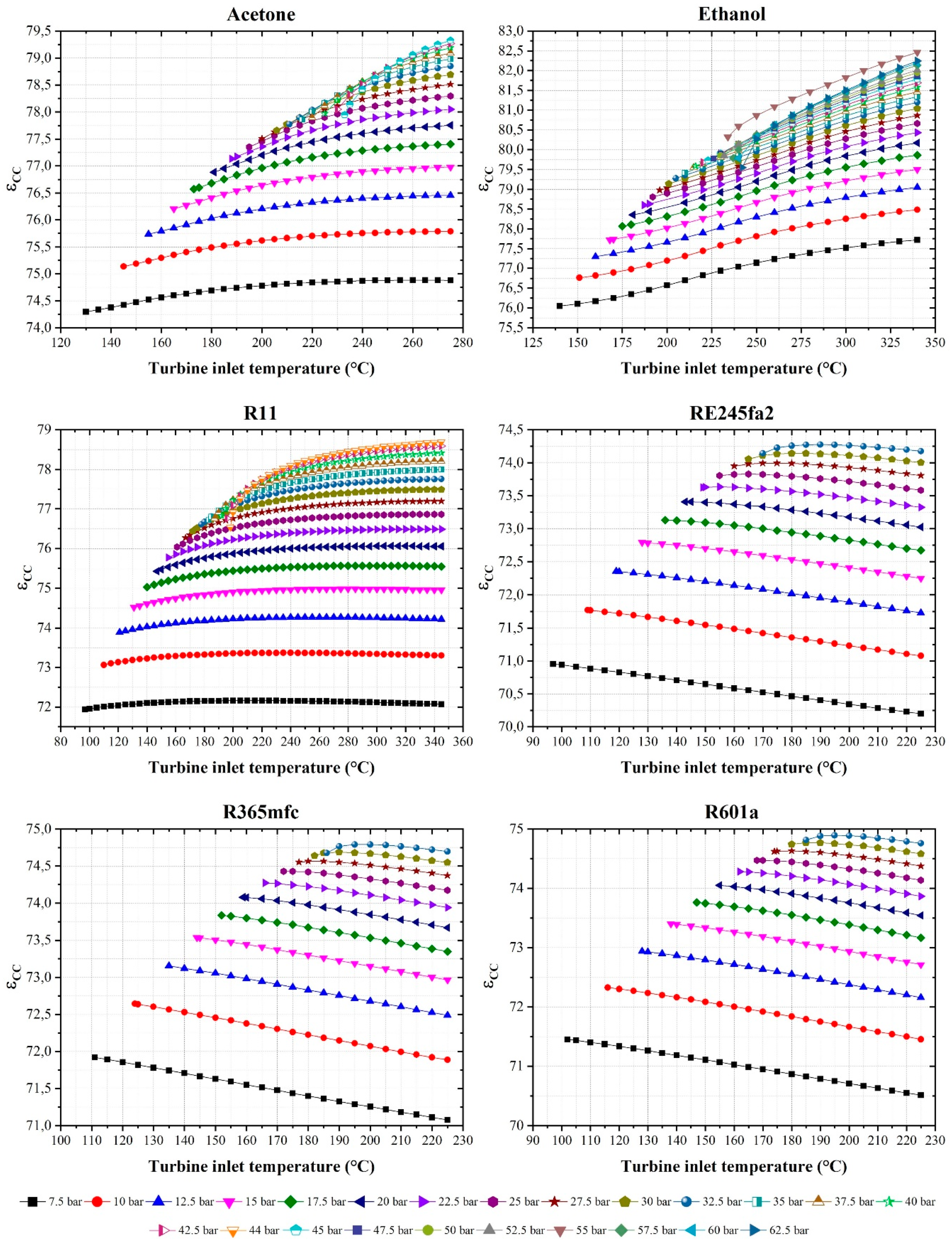

5.2. Performance Parameters of the Cogeneration Cycle

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| exergy flow (kW) | |

| heat flow (kW) | |

| ambient temperature (°C) | |

| power (kW) | |

| mass flow rate (kg/s) | |

| CC | cgeneration cycle |

| GWP | global warming potential |

| enthalpy (kJ/kg) | |

| ODP | ozone depletion potential |

| ORC | organic Rankine cycle |

| P | pressure (bar) |

| low heating value | |

| temperature (°C) | |

| entropy (kJ/kgK) | |

| Greek letters | |

| specific exergy (kJ/kg) | |

| exergetic efficiency (%) | |

| burner effectiveness (%) | |

| thermal efficiency (%) | |

| Subscripts | |

| boiling | |

| condensing | |

| critical | |

| destruction | |

| exit | |

| inlet | |

| maximum | |

| heat transfer surface | |

| waste wood chips |

References

- Aghbashlo, M.; Tabatabaei, M.; Soltanian, S.; Ghanavati, H.; Dadak, A. Comprehensive exergoeconomic analysis of a municipal solid waste digestion plant equipped with a biogas genset. Waste Manag. 2019, 87, 485–498. [Google Scholar] [CrossRef] [PubMed]

- Aghbashlo, M.; Tabatabaei, M.; Soltanian, S.; Ghanavati, H. Biopower and biofertilizer production from organic municipal solid waste: An exergoenvironmental analysis. Renew. Energy 2019, 143, 64–76. [Google Scholar]

- Koc, Y.; Yagli, H.; Ozdes, E.O.; Baltacioglu, E.; Koc, A. Thermodynamic Analysis of Solid Waste and Energy Consumption to Reduce the Effects of an Electric Arc Furnace (EAF) on the Environment. J. Glob. Warm. (in press).

- Koç, A.; Yağlı, H.; Koç, Y.; Uğurlu, İ. Dünyada ve Türkiye’de Enerji Görünümünün Genel Değerlendirilmesi. Eng. Mach. Mag. 2018, 59, 86–114. [Google Scholar]

- Ekmekçi, Ī.; Yetisken, Y.; Çamdali, Ü. Mass balance modeling for electric arc furnace and ladle furnace system in steelmaking facility in Turkey. J. Iron Steel Res. Int. 2007, 14, 1–6. [Google Scholar]

- Olmez, G.M.; Dilek, F.B.; Karanfil, T.; Yetis, U. The environmental impacts of iron and steel industry: A life cycle assessment study. J. Clean. Prod. 2016, 130, 195–201. [Google Scholar]

- Rana, A.; Kalla, P.; Csetenyi, L.J. Recycling of dimension limestone industry waste in concrete. Int. J. Min. Reclam. Environ. 2017, 31, 231–250. [Google Scholar]

- Singh, N.; Hui, D.; Singh, R.; Ahuja, I.P.S.; Feo, L.; Fraternali, F. Recycling of plastic solid waste: A state of art review and future applications. Compos. Part B Eng. 2017, 115, 409–422. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, X.; Li, Y.; Li, X. Waste incineration industry and development policies in China. Waste Manag. 2015, 46, 234–241. [Google Scholar]

- Joshi, O.; Grebner, D.L.; Khanal, P.N. Status of urban wood-waste and their potential use for sustainable bioenergy in Mississippi. Resour. Conserv. Recycl. 2015, 102, 20–26. [Google Scholar]

- Khudyakova, G.I.; Danilova, D.A.; Khasanov, R.R. The use of urban wood waste as an energy resource. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2017; Volume 72, p. 012026. [Google Scholar]

- Dahou, T.; Dutournié, P.; Limousy, L.; Bennici, S.; Perea, N. Recovery of Low-Grade Heat (Heat Waste) from a Cogeneration Unit for Woodchips Drying: Energy and Economic Analyses. Energies 2019, 12, 501. [Google Scholar]

- Al-Hamamre, Z.; Saidan, M.; Hararah, M.; Rawajfeh, K.; Alkhasawneh, H.E.; Al-Shannag, M. Wastes and biomass materials as sustainable-renewable energy resources for Jordan. Renew. Sustain. Energy Rev. 2017, 67, 295–314. [Google Scholar]

- Hossain, M.U.; Leu, S.Y.; Poon, C.S. Sustainability analysis of pelletized bio-fuel derived from recycled wood product wastes in Hong Kong. J. Clean. Prod. 2016, 113, 400–410. [Google Scholar]

- Tozlu, A.; Özahi, E.; Abuşoğlu, A. Waste to energy technologies for municipal solid waste management in Gaziantep. Renew. Sustain. Energy Rev. 2016, 54, 809–815. [Google Scholar] [CrossRef]

- Nunes, L.J.; Godina, R.; Matias, J.C.; Catalão, J.P. Evaluation of the utilization of woodchips as fuel for industrial boilers. J. Clean. Prod. 2019, 223, 270–277. [Google Scholar] [CrossRef]

- Nunes, L.J.; Godina, R.; Matias, J.C.; Catalão, J.P. Economic and environmental benefits of using textile waste for the production of thermal energy. J. Clean. Prod. 2018, 171, 1353–1360. [Google Scholar]

- Barrier, C.; Ghaffariyan, M.R. A Short Review of Artificial Wood Drying Practice in France; Forest Industries Research Center: Maroochydore, Australia, 2018. [Google Scholar]

- Yağlı, H. Basit ve rejeneratif organik Rankine çevrimi (ORC) tasarımları kullanılarak biyogaz yakıtlı ısı-güç kombine (CHP) motorunun atık ısısının geri dönüştürülebilirliği, enerji ve ekserji analizi. Ph.D. Thesis, Iskenderun Technical University, İskenderun, Turkey, 2018. [Google Scholar]

- Bademlioglu, A.H.; Yamankaradeniz, R.; Kaynakli, O. Exergy Analysis of the Organic Rankine Cycle Based on the Pinch Point Temperature Difference. J. Therm. Eng. 2019, 5, 157–165. [Google Scholar]

- Koç, Y.; Yağlı, H. Isı-Güç Kombine Sistemlerinde Kullanılan Kalina Çevriminin Enerji ve Ekserji Analizi. Politeknik Dergisi. (in press). [CrossRef]

- Koç, Y.; Yağlı, H.; Koç, A. Exergy analysis and performance improvement of a subcritical/supercritical organic rankine cycle (ORC) for exhaust gas waste heat recovery in a biogas fuelled combined heat and power (CHP) engine through the use of regeneration. Energies 2019, 12, 575. [Google Scholar] [CrossRef]

- Yagli, H.; Koc, A.; Karakus, C.; Koc, Y. Comparison of toluene and cyclohexane as a working fluid of an organic Rankine cycle used for reheat furnace waste heat recovery. Int. J. Exergy 2016, 19, 420–438. [Google Scholar]

- Bilgiç, H.H.; Yağlı, H.; Koç, A.; Yapıcı, A. Deneysel bir organik Rankine çevriminde yapay sinir ağları (YSA) yardımıyla güç tahmini. Selçuk Üniversitesi Mühendislik, Bilim ve Teknoloji Dergisi 2016, 4, 7–17. [Google Scholar]

- Noussan, M.; Abdin, G.C.; Poggio, A.; Roberto, R. Biomass-fired CHP and heat storage system simulations in existing district heating systems. Appl. Thermal Eng. 2014, 71, 729–735. [Google Scholar] [CrossRef]

- Uris, M.; Linares, J.I.; Arenas, E. Feasibility assessment of an Organic Rankine Cycle (ORC) cogeneration plant (CHP/CCHP) fueled by biomass for a district network in mainland Spain. Energy 2017, 133, 969–985. [Google Scholar]

- Safari, F.; Dincer, I. Development and analysis of a novel biomass-based integrated system for multigeneration with hydrogen production. Int. J. Hydrog. Energy 2019, 44, 3511–3526. [Google Scholar]

- Ghasemi, A.; Heidarnejad, P.; Noorpoor, A. A novel solar-biomass based multi-generation energy system including water desalination and liquefaction of natural gas system: Thermodynamic and thermoeconomic optimization. J. Clean. Prod. 2018, 196, 424–437. [Google Scholar]

- Khanmohammadi, S.; Atashkari, K. Modeling and multi-objective optimization of a novel biomass feed polygeneration system integrated with multi effect desalination unit. Therm. Sci. Eng. Prog. 2018, 8, 269–283. [Google Scholar] [CrossRef]

- Yağlı, H.; Koç, Y.; Koç, A.; Görgülü, A.; Tandiroğlu, A. Parametric optimization and exergetic analysis comparison of subcritical and supercritical organic Rankine cycle (ORC) for biogas fuelled combined heat and power (CHP) engine exhaust gas waste heat. Energy 2016, 111, 923–932. [Google Scholar] [CrossRef]

- Desideri, A.; Gusev, S.; Van den Broek, M.; Lemort, V.; Quoilin, S. Experimental comparison of organic fluids for low temperature ORC (organic Rankine cycle) systems for waste heat recovery applications. Energy 2016, 97, 460–469. [Google Scholar]

- Dickes, R.; Dumont, O.; Daccord, R.; Quoilin, S.; Lemort, V. Modelling of organic Rankine cycle power systems in off-design conditions: An experimentally-validated comparative study. Energy 2017, 123, 710–727. [Google Scholar] [CrossRef]

- Peris, B.; Navarro-Esbrí, J.; Molés, F.; Mota-Babiloni, A. Experimental study of an ORC (organic Rankine cycle) for low grade waste heat recovery in a ceramic industry. Energy 2015, 85, 534–542. [Google Scholar]

- Yang, S.C.; Hung, T.C.; Feng, Y.Q.; Wu, C.J.; Wong, K.W.; Huang, K.C. Experimental investigation on a 3 kW organic Rankine cycle for low-grade waste heat under different operation parameters. Appl. Therm. Eng. 2017, 113, 756–764. [Google Scholar] [CrossRef]

- Navarro-Esbrí, J.; Molés, F.; Peris, B.; Mota-Babiloni, A.; Kontomaris, K. Experimental study of an Organic Rankine Cycle with HFO-1336mzz-Z as a low global warming potential working fluid for micro-scale low temperature applications. Energy 2017, 133, 79–89. [Google Scholar] [CrossRef]

- Soroureddin, A.; Mehr, A.S.; Mahmoudi, S.M.S.; Yari, M. Thermodynamic analysis of employing ejector and organic Rankine cycles for GT-MHR waste heat utilization: A comparative study. Energy Convers. Manag. 2013, 67, 125–137. [Google Scholar] [CrossRef]

- Cao, Y.; Gao, Y.; Zheng, Y.; Dai, Y. Optimum design and thermodynamic analysis of a gas turbine and ORC combined cycle with recuperators. Energy Convers. Manag. 2016, 116, 32–41. [Google Scholar] [CrossRef]

- Khaljani, M.; Saray, R.K.; Bahlouli, K. Comprehensive analysis of energy, exergy and exergo-economic of cogeneration of heat and power in a combined gas turbine and organic Rankine cycle. Energy Convers. Manag. 2015, 97, 154–165. [Google Scholar]

- Li, P.; Han, Z.; Jia, X.; Mei, Z.; Han, X.; Wang, Z. Analysis and comparison on thermodynamic and economic performances of an organic Rankine cycle with constant and one-dimensional dynamic turbine efficiency. Energy Convers. Manag. 2019, 180, 665–679. [Google Scholar]

- White, M.T.; Sayma, A.I. Simultaneous cycle optimisation and fluid selection for ORC systems accounting for the effect of the operating conditions on turbine efficiency. Front. Energy Res. 2019, 7, 50. [Google Scholar]

- Pezzuolo, A.; Benato, A.; Stoppato, A.; Mirandola, A. The ORC-PD: A versatile tool for fluid selection and Organic Rankine Cycle unit design. Energy 2016, 102, 605–620. [Google Scholar] [CrossRef]

- Yari, M.; Mehr, A.S.; Zare, V.; Mahmoudi, S.M.S.; Rosen, M.A. Exergoeconomic comparison of TLC (trilateral Rankine cycle), ORC (organic Rankine cycle) and Kalina cycle using a low grade heat source. Energy 2015, 83, 712–722. [Google Scholar]

- Yang, A.; Su, Y.; Chien, I.L.; Jin, S.; Yan, C.; Shen, W. Investigation of an energy-saving double-thermally coupled extractive distillation for separating ternary system benzene/toluene/cyclohexane. Energy 2019, 186, 115756. [Google Scholar]

- Mahlia, T.M.I.; Syaheed, H.; Abas, A.E.; Kusumo, F.; Shamsuddin, A.H.; Ong, H.C.; Bilad, M.R. Organic rankine cycle (ORC) system applications for solar energy: Recent technological advances. Energies 2019, 12, 2930. [Google Scholar]

- Lecompte, S.; Ntavou, E.; Tchanche, B.; Kosmadakis, G.; Pillai, A.; Manolakos, D.; De Paepe, M. Review of experimental research on supercritical and transcritical thermodynamic cycles designed for heat recovery application. Appl. Sci. 2019, 9, 2571. [Google Scholar]

- Invernizzi, C.; Binotti, M.; Bombarda, P.; Di Marcoberardino, G.; Iora, P.; Manzolini, G. Water mixtures as working fluids in organic rankine cycles. Energies 2019, 12, 2629. [Google Scholar]

- Chatzopoulou, M.A.; Simpson, M.; Sapin, P.; Markides, C.N. Off-design optimisation of organic Rankine cycle (ORC) engines with piston expanders for medium-scale combined heat and power applications. Appl. Energy 2019, 238, 1211–1236. [Google Scholar]

- Valencia, G.; Fontalvo, A.; Cárdenas, Y.; Duarte, J.; Isaza, C. Energy and exergy analysis of different exhaust waste heat recovery systems for natural gas engine based on ORC. Energies 2019, 12, 2378. [Google Scholar]

- Yang, J.; Ye, Z.; Yu, B.; Ouyang, H.; Chen, J. Simultaneous experimental comparison of low-GWP refrigerants as drop-in replacements to R245fa for Organic Rankine cycle application: R1234ze (Z), R1233zd (E), and R1336mzz (E). Energy 2019, 173, 721–731. [Google Scholar]

- Song, C.; Gu, M.; Miao, Z.; Liu, C.; Xu, J. Effect of fluid dryness and critical temperature on trans-critical organic Rankine cycle. Energy 2019, 174, 97–109. [Google Scholar]

- Zhi, L.H.; Hu, P.; Chen, L.X.; Zhao, G. Parametric analysis and optimization of transcritical-subcritical dual-loop organic Rankine cycle using zeotropic mixtures for engine waste heat recovery. Energy Convers. Manag. 2019, 195, 770–787. [Google Scholar]

- Wang, D.; Ling, X.; Peng, H. Performance analysis of double organic Rankine cycle for discontinuous low temperature waste heat recovery. Appl. Therm. Eng. 2012, 48, 63–71. [Google Scholar] [CrossRef]

- Yamada, N.; Mohamad, M.N.A.; Kien, T.T. Study on thermal efficiency of low-to medium-temperature organic Rankine cycles using HFO− 1234yf. Renew. Energy 2012, 41, 368–375. [Google Scholar]

- Wang, E.H.; Zhang, H.G.; Fan, B.Y.; Ouyang, M.G.; Zhao, Y.; Mu, Q.H. Study of working fluid selection of organic Rankine cycle (ORC) for engine waste heat recovery. Energy 2011, 36, 3406–3418. [Google Scholar]

- Chys, M.; van den Broek, M.; Vanslambrouck, B.; De Paepe, M. Potential of zeotropic mixtures as working fluids in organic Rankine cycles. Energy 2012, 44, 623–632. [Google Scholar]

- Marion, M.; Voicu, I.; Tiffonnet, A.L. Study and optimization of a solar subcritical organic Rankine cycle. Renew. Energy 2012, 48, 100–109. [Google Scholar]

- Xi, H.; Li, M.J.; He, Y.L.; Zhang, Y.W. Economical evaluation and optimization of organic Rankine cycle with mixture working fluids using R245fa as flame retardant. Appl. Therm. Eng. 2017, 113, 1056–1070. [Google Scholar]

- Tiwari, D.; Sherwani, A.F.; Kumar, N. Optimization and thermo-economic performance analysis of organic Rankine cycles using mixture working fluids driven by solar energy. Energy Sources Part A: Recovery Util. Environ. Eff. 2019, 41, 1890–1907. [Google Scholar]

- Tchanche, B.F.; Papadakis, G.; Lambrinos, G.; Frangoudakis, A. Fluid selection for a low-temperature solar organic Rankine cycle. Appl. Therm. Eng. 2009, 29, 2468–2476. [Google Scholar]

- David, G.; Michel, F.; Sanchez, L. Waste heat recovery projects using Organic Rankine Cycle technology–Examples of biogas engines and steel mills applications. In Proceedings of the 2011 World Engineers Convention, Geneva, Switzerland, 4–9 September 2011. [Google Scholar]

- Gu, Z.; Sato, H. Performance of supercritical cycles for geothermal binary design. Energy Convers. Manag. 2002, 43, 961–971. [Google Scholar]

- Capata, R.; Gagliardi, L. Experimental investigation on the Reynolds dependence of the performance of branched heat exchangers working with organic fluids. Int. J. Heat Mass Transf. 2019, 140, 129–138. [Google Scholar]

- Cengel, Y.A.; Boles, M.A. Thermodynamics: An Engineering Approach, 6th ed.; McGraw-Hill Inc.: New York, NY, USA, 2008. [Google Scholar]

- Bejan, A.; Tsatsaronis, G.; Moran, M. Thermal Design and Optimization; John Wiley: New York, NY, USA, 1996. [Google Scholar]

- Dincer, I.; Rosen, M.A. Exergy: Energy, Environment and SUSTAINABLE Development, 2nd ed.; Elsevier: Oxford, UK, 2013. [Google Scholar]

- Kotas, T.J. The Exergy Method of Thermal Plant Analysis; Elsevier: Oxford, UK, 2013. [Google Scholar]

- Kahraman, N.; Cengel, Y.A.; Wood, B.; Cerci, Y. Exergy analysis of a combined RO, NF, andEDR desalination plant. Desalination 2005, 171, 217–232. [Google Scholar] [CrossRef]

- Kahraman, N.; Cengel, Y.A. Exergy analysis of a MSF distillation plant. Energy Conv. Manag. 2005, 46, 2625–2636. [Google Scholar]

- Yağlı, H.; Karakuş, C.; Koç, Y.; Çevik, M.; Uğurlu, İ.; Koç, A. Designing and exergetic analysis of a solar power tower system for Iskenderun region. Int. J. Exergy 2019, 28, 96–112. [Google Scholar] [CrossRef]

- Koc, Y.; Kose, O.; Yagli, H. Exergy analysis of a natural gas fuelled gas turbine based cogeneration cycle. Int. J. Exergy 2019, 30, 103–125. [Google Scholar]

- Loni, R.; Kasaeian, A.B.; Mahian, O.; Sahin, A.Z. Thermodynamic analysis of an organic rankine cycle using a tubular solar cavity receiver. Energy Convers. Manag. 2016, 127, 494–503. [Google Scholar]

- Dumont, O.; Dickes, R.; De Rosa, M.; Douglas, R.; Lemort, V. Technical and economic optimization of subcritical, wet expansion and transcritical Organic Rankine Cycle (ORC) systems coupled with a biogas power plant. Energy Convers. Manag. 2018, 157, 294–306. [Google Scholar]

| Parameter | Value | Unit |

|---|---|---|

| Burned waste chip amount | 967 | kg/h |

| Moist fibre amount (relative humidity 100%) | 2765.841 | kg/h |

| Useful dried fibre amount (relative humidity 11%) | 1681.106 | kg/h |

| Exhaust gas mass flow | 7.68 | kg/s |

| Steam mass flow | 0.815 | kg/s |

| Burner exit temperature | 600 | °C |

| Boiler exit temperature | 350 | °C |

| ORC exit temperature | 160 | °C |

| Dryer exit temperature | 60 | °C |

| Parameter | Value | Unit |

|---|---|---|

| Isentropic efficiency of the pump [36,37,38,39] | 80 | % |

| Isentropic efficiency of the turbine [30,40,41,42] | 88 | % |

| Cooling water inlet temperature | 20 | °C |

| Exhaust gas inlet temperature | 350 | °C |

| Exhaust gas outlet temperature | 160 | °C |

| Exhaust gas mass flow rate | 7.68 | kg/s |

| Name | ODP | GWP | Type | |||||

|---|---|---|---|---|---|---|---|---|

| °C | bar | °C | bar | °C | - | - | - | |

| Acetone | 56 | 0.38 | 234.90 | 46.00 | 276.00 | n.a. | n.a. | wet |

| Ethanol | 78.00 | 0.11 | 241.56 | 62.68 | 376.00 | n.a. | n.a. | wet |

| R11 | 23.00 | 1.26 | 197.96 | 44.07 | 351.85 | 1 | 4600 | isentropic |

| RE245fa2 | 28.89 | 1.04 | 171.73 | 34.33 | 226.85 | 0 | 812 | dry |

| R365mfc | 39.82 | 0.693 | 186.85 | 32.66 | 226.85 | 0 | 825 | dry |

| R601a | 27.40 | 1.09 | 187.20 | 33.78 | 226.00 | 0 | ~20 | dry |

| Name | ||||||||

|---|---|---|---|---|---|---|---|---|

| °C | bar | kg/s | kW | % | % | % | % | |

| Acetone | 275 | 45.0 | 1.72 | 383.32 | 26.73 | 60.18 | 72.50 | 79.30 |

| Ethanol | 340 | 62.5 | 1.06 | 453.91 | 30.01 | 67.56 | 74.01 | 82.24 |

| R11 | 345 | 44.0 | 4.14 | 368.00 | 24.33 | 54.77 | 72.18 | 78.70 |

| RE245fa2 | 190 | 32.5 | 4.63 | 260.96 | 18.20 | 41.00 | 69.90 | 74.28 |

| R365mfc | 195 | 32.5 | 4.34 | 273.40 | 19.10 | 42.93 | 70.16 | 74.80 |

| R601a | 195 | 32.5 | 2.44 | 275.86 | 19.24 | 43.31 | 70.21 | 74.90 |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koç, Y. Parametric Optimisation of an ORC in a Wood Chipboard Production Facility to Recover Waste Heat Produced from the Drying and Steam Production Process. Energies 2019, 12, 3656. https://doi.org/10.3390/en12193656

Koç Y. Parametric Optimisation of an ORC in a Wood Chipboard Production Facility to Recover Waste Heat Produced from the Drying and Steam Production Process. Energies. 2019; 12(19):3656. https://doi.org/10.3390/en12193656

Chicago/Turabian StyleKoç, Yıldız. 2019. "Parametric Optimisation of an ORC in a Wood Chipboard Production Facility to Recover Waste Heat Produced from the Drying and Steam Production Process" Energies 12, no. 19: 3656. https://doi.org/10.3390/en12193656

APA StyleKoç, Y. (2019). Parametric Optimisation of an ORC in a Wood Chipboard Production Facility to Recover Waste Heat Produced from the Drying and Steam Production Process. Energies, 12(19), 3656. https://doi.org/10.3390/en12193656