Additive Aerodynamic and Thermal Effects of a Central Guide Post and Baffle Installed in a Solar Updraft Tower

Abstract

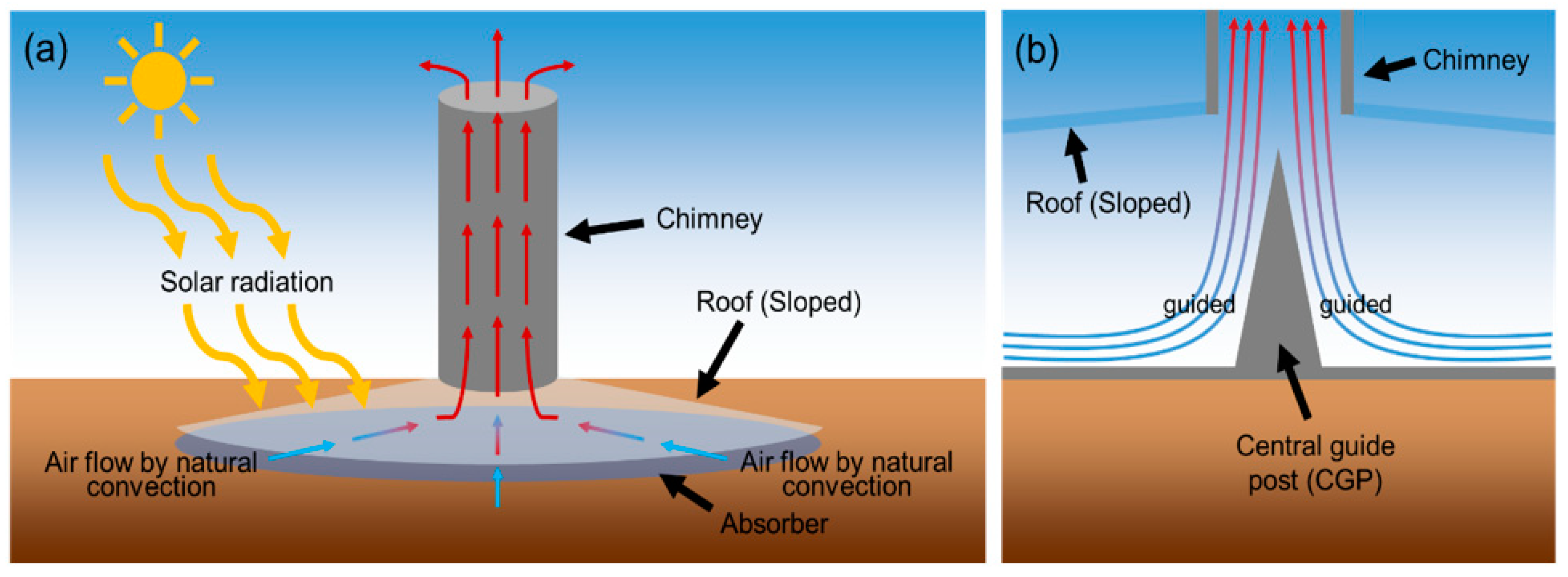

:1. Introduction

2. Theoretical Background

3. Methods

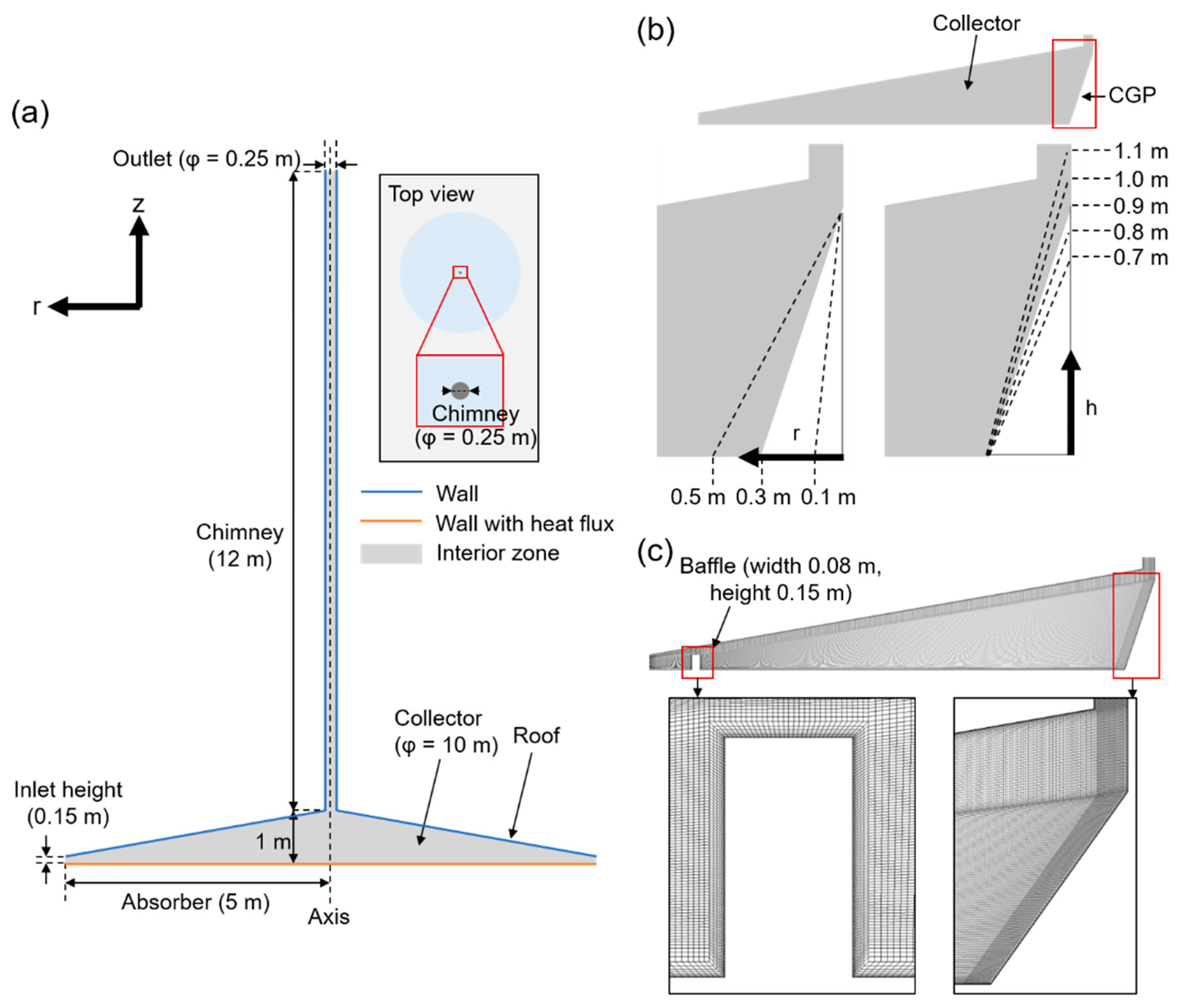

Computational Models and Boundary Conditions

4. Results and Discussion

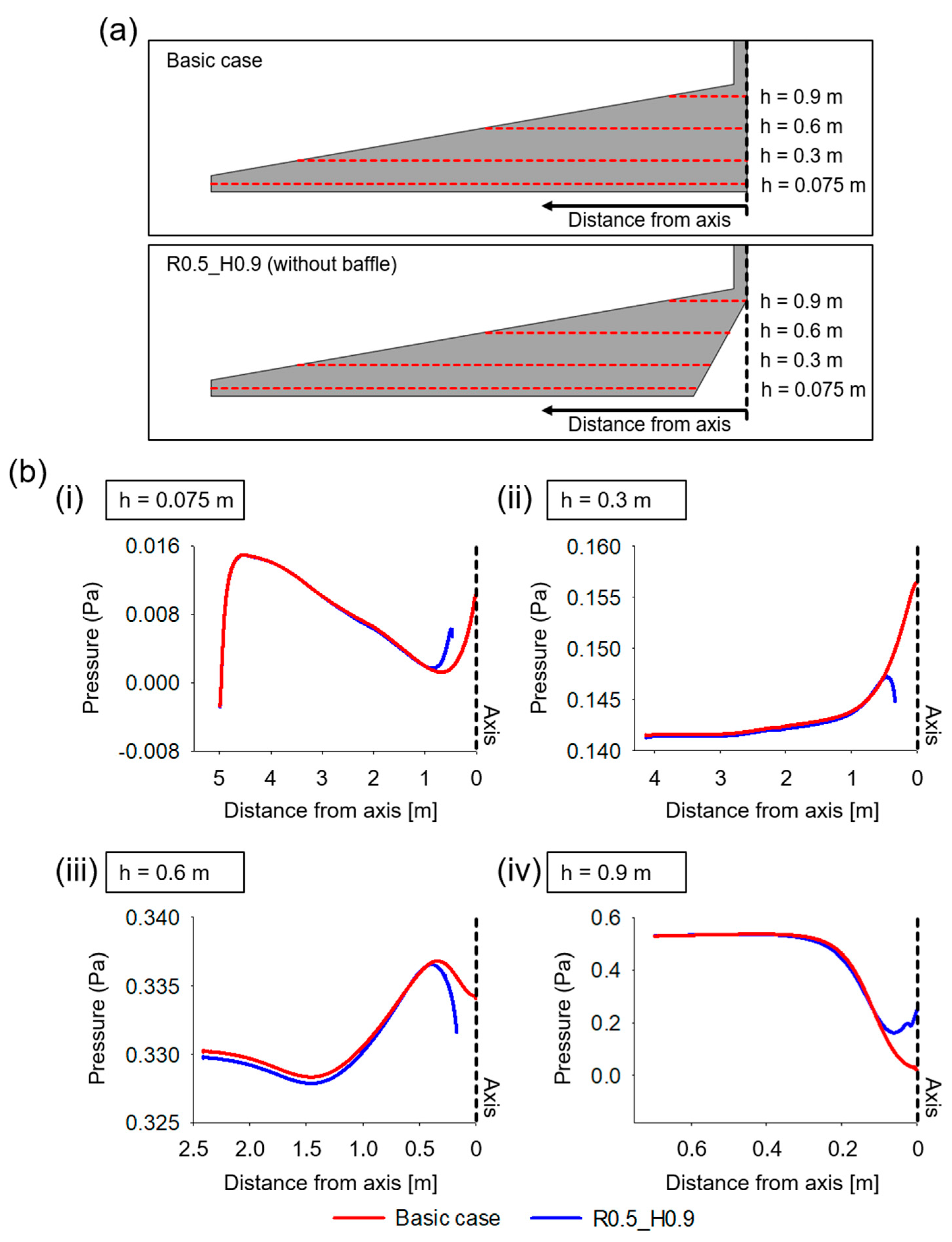

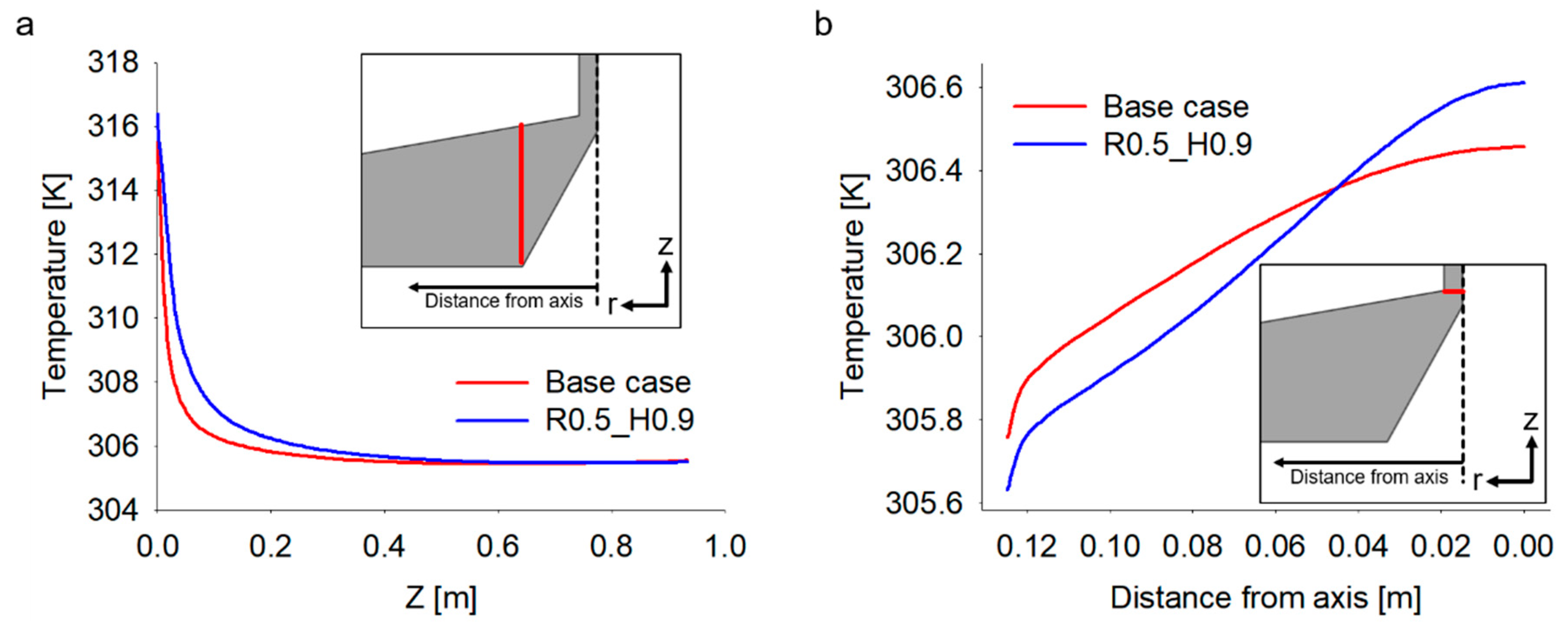

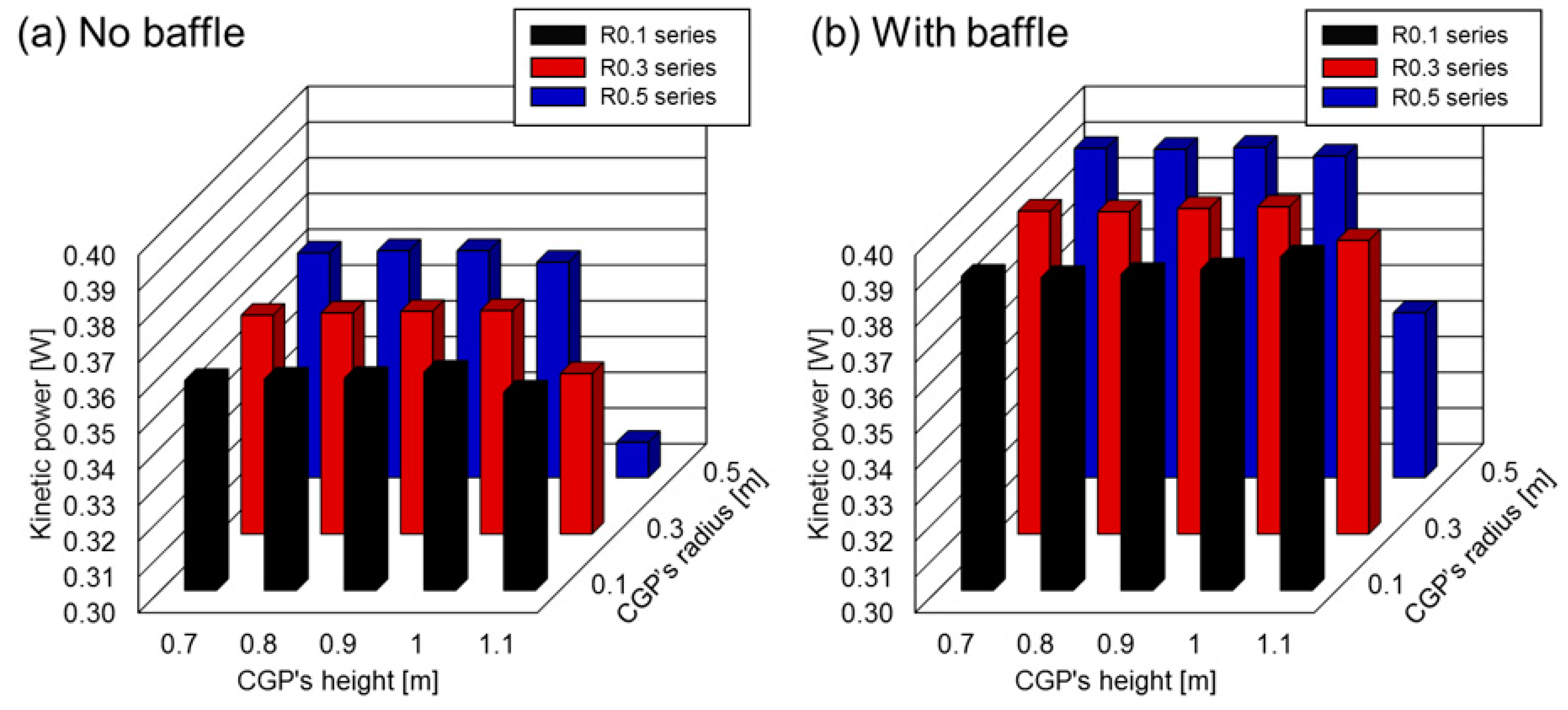

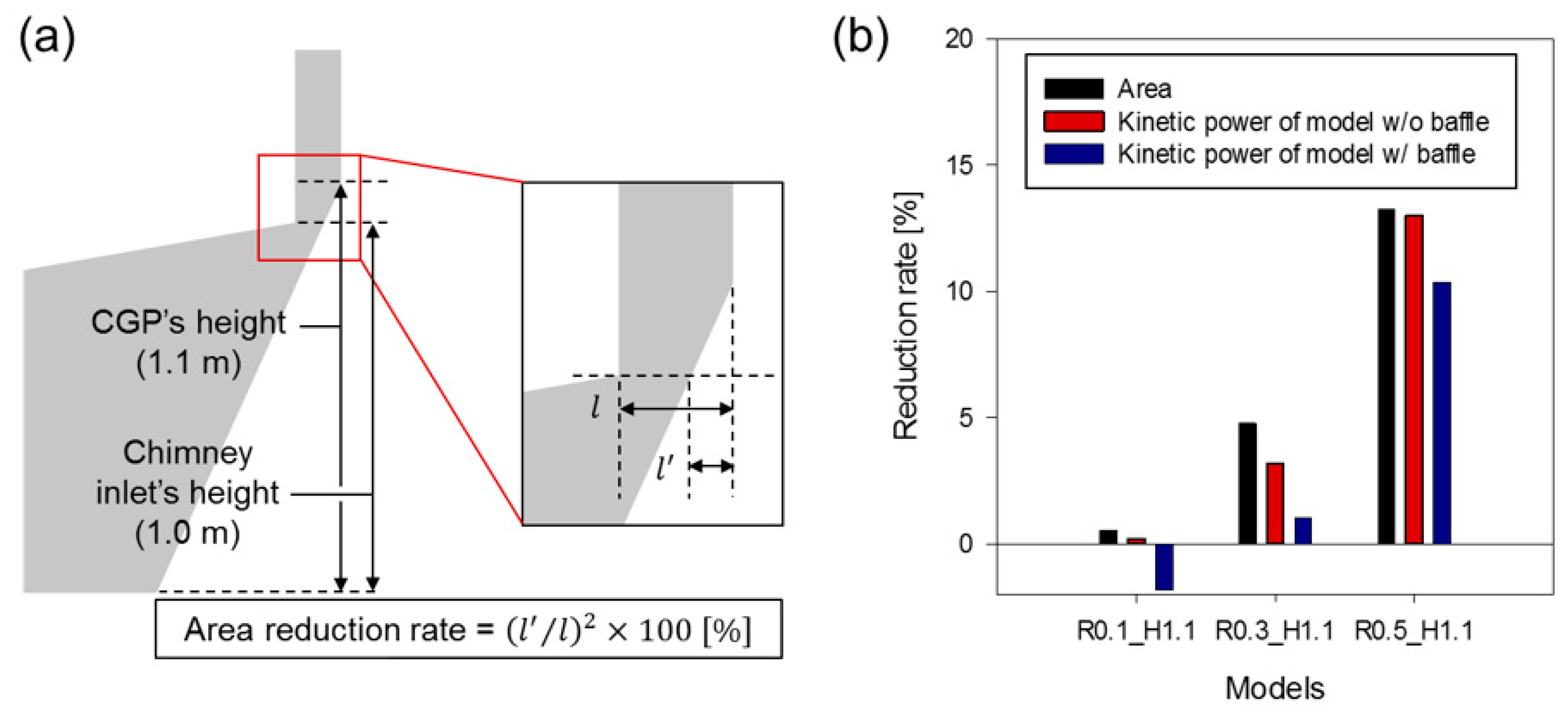

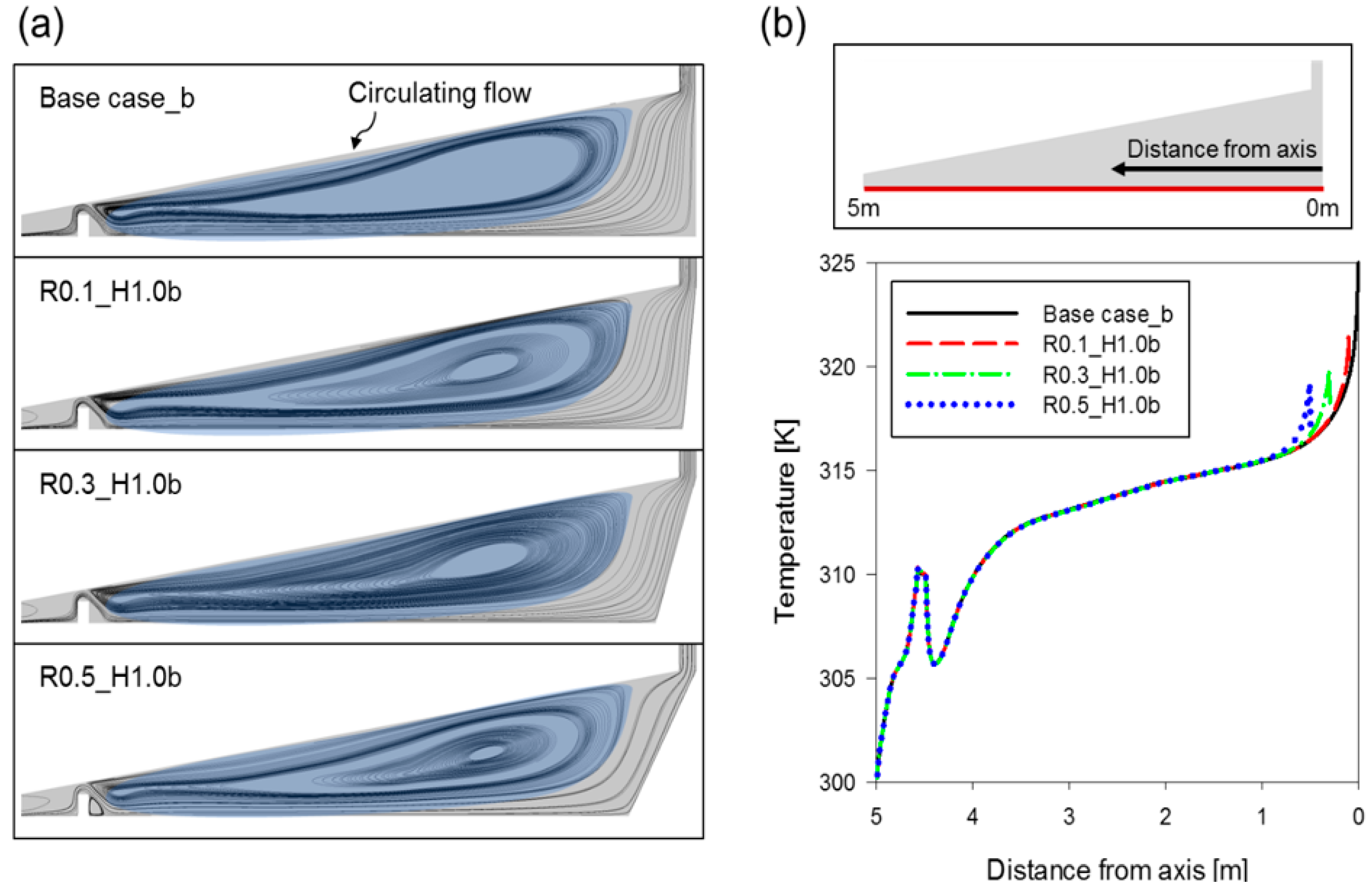

4.1. Positive and Negative Effects of CGP

4.2. Cooperative Effect of CGP and Baffle

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Specific heat | J/kg K | |

| Gravitational acceleration | m/s2 | |

| Turbulent kinetic energy | m2/s2 | |

| P | Kinetic power | W ( |

| Static pressure | Pa | |

| Total pressure | Pa | |

| Space coordinates | m | |

| Temperature | K | |

| Time | sec | |

| Velocity components | m/s | |

| Dimensionless wall distance | - | |

| Coefficient of thermal expansion | K−1 | |

| Turbulent dissipation rate | m2/s3 | |

| Thermal conductivity | W/m K | |

| Viscosity | kg/m s | |

| Turbulent viscosity | kg/m s | |

| Density | kg/m3 | |

| σk, σε | Turbulent Prandtl numbers for and, respectively | - |

References

- Haaf, W.; Friedrich, K.; Mayr, G.; Schlaich, J. Part I: Principle and Construction of the Pilot Plant in Manzanares. Int. J. Sol. Energy 1983, 2, 3–20. [Google Scholar] [CrossRef]

- Xu, Y.; Zhou, X. Performance of divergent-chimney solar power plants. Sol. Energy 2018, 170, 379–387. [Google Scholar] [CrossRef]

- Koonsrisuk, A. Comparison of conventional solar chimney power plants and sloped solar chimney power plants using second law analysis. Sol. Energy 2013, 98, 78–84. [Google Scholar] [CrossRef]

- Al-Kayeim, H.H.; Aurybi, M.A.; Gilani, S.I.U. Influence of canopy condensate film on the performance of solar chimney power plant. Renew. Energy 2019, 136, 1012–1021. [Google Scholar] [CrossRef]

- Zhou, X.; Xiao, B.; Liu, W.; Guo, X.; Yang, J.; Fan, J. Comparison of classical solar chimney power system and combined solar chimney system for power generation and seawater desalination. Desalination 2010, 250, 249–256. [Google Scholar] [CrossRef]

- Shahizare, B.; Nazri Bin Nik Ghazali, N.; Chong, W.; Tabatabaeikia, S.; Izadyar, N. Investigation of the Optimal Omni-Direction-Guide-Vane Design for Vertical Axis Wind Turbines Based on Unsteady Flow CFD Simulation. Energies 2016, 9, 146. [Google Scholar] [CrossRef]

- Gao, R.; Liu, K.; Li, A.; Fang, Z.; Yang, Z.; Cong, B. Study of the shape optimization of a tee guide vane in a ventilation and air-conditioning duct. Build. Environ. 2018, 132, 345–356. [Google Scholar] [CrossRef]

- Hu, S.; Leung, D.Y.C.; Chen, M.Z.Q.; Chan, J.C.Y. Effect of guide wall on the potential of a solar chimney power plant. Renew. Energy 2016, 96, 209–219. [Google Scholar] [CrossRef]

- Lee, S.; Kim, Y.; Park, J. Numerical Investigation on the Effects of Baffles with Various Thermal and Geometrical Conditions on Thermo-Fluid Dynamics and Kinetic Power of a Solar Updraft Tower. Energies 2018, 11, 2230. [Google Scholar] [CrossRef]

- Kim, S.; Lee, S.; Park, J.Y. Thermo-fluid dynamic effects of the radial location of the baffle installed in a solar updraft tower. Energies 2019, 12, 1340. [Google Scholar] [CrossRef]

- ANSYS Fluent Theory Guide v17.1; ANSYS Inc.: Canonsburg, PA, USA, 2016.

- Chergui, T.; Larbi, S.; Bouhdjar, A. Thermo-hydrodynamic aspect analysis of flows in solar chimney power plants—A case study. Renew. Sustain. Energy Rev. 2010, 14, 1410–1418. [Google Scholar] [CrossRef]

- Borgnakke, C.; Sonntag, R.E. Fundamentals of Thermodynamics, 8th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Bardina, J.E.; Huang, P.G.; Coakley, T.J. Turbulence Modeling Validation, Testing, and Development. Nasa Tech. Memo. 1997, 8–20. [Google Scholar]

- Ayadi, A.; Nasraoui, H.; Bouabidi, A.; Driss, Z.; Bsisa, M.; Abid, M.S. Effect of the turbulence model on the simulation of the air flow in a solar chimney. Int. J. Therm. Sci. 2018, 130, 423–434. [Google Scholar] [CrossRef]

- Ming, T.; de Richter, R.K.; Meng, F.; Pan, Y.; Liu, W. Chimney shape numerical study for solar chimney power generating systems. Int. J. Energy Res. 2013, 37, 310–322. [Google Scholar] [CrossRef]

- Tingzhen, M.; Wei, L.; Guoling, X.; Yanbin, X.; Xuhu, G.; Yuan, P. Numerical simulation of the solar chimney power plant systems coupled with turbine. Renew. Energy 2008, 33, 897–905. [Google Scholar] [CrossRef]

- Fathi, N.; McDaniel, P.; Aleyasin, S.S.; Robinson, M.; Vorobieff, P.; Rodriguez, S.; de Oliveira, C. Efficiency enhancement of solar chimney power plant by use of waste heat from nuclear power plant. J. Clean. Prod. 2018, 180, 407–416. [Google Scholar] [CrossRef]

- Ahsan, M. Numerical analysis of friction factor for a fully developed turbulent flow using k–ε turbulence model with enhanced wall treatment. Beni-Suef Univ. J. Basic Appl. Sci. 2014, 3, 269–277. [Google Scholar] [CrossRef]

- ANSYS Fluent User’s Guide; ANSYS Inc.: Canonsburg, PA, USA, 2013.

- Nia, E.S.; Ghazikhani, M. Numerical investigation on heat transfer characteristics amelioration of a solar chimney power plant through passive flow control approach. Energy Convers. Manag. 2015, 105, 588–595. [Google Scholar] [CrossRef]

- Zhou, X.; Xu, Y. Solar updraft tower power generation. Sol. Energy 2016, 128, 95–125. [Google Scholar] [CrossRef]

- Aponte, R.D.; Teran, L.A.; Grande, J.F.; Coronado, J.J.; Ladino, J.A.; Larrahondo, F.J.; Rodríguez, S.A. Minimizing erosive wear through a CFD multi-objective optimization methodology for different operating points of a Francis turbine. Renew. Energy 2020, 145, 2217–2232. [Google Scholar] [CrossRef]

| Radius of CGP | Height of CGP | Model Name | |

|---|---|---|---|

| No Baffle | With Baffle | ||

| - | - | Base Case | Base Case_b |

| 0.1 | 0.7 | R0.1_H0.7 | R0.1_H0.7b |

| 0.8 | R0.1_H0.8 | R0.1_H0.8b | |

| 0.9 | R0.1_H0.9 | R0.1_H0.9b | |

| 1 | R0.1_H1.0 | R0.1_H1.0b | |

| 1.1 | R0.1_H1.1 | R0.1_H1.1b | |

| 0.3 | 0.7 | R0.3_H0.7 | R0.3_H0.7b |

| 0.8 | R0.3_H0.8 | R0.3_H0.8b | |

| 0.9 | R0.3_H0.9 | R0.3_H0.9b | |

| 1 | R0.3_H1.0 | R0.3_H1.0b | |

| 1.1 | R0.3_H1.1 | R0.3_H1.1b | |

| 0.5 | 0.7 | R0.5_H0.7 | R0.5_H0.7b |

| 0.8 | R0.5_H0.8 | R0.5_H0.8b | |

| 0.9 | R0.5_H0.9 | R0.5_H0.9b | |

| 1 | R0.5_H1.0 | R0.5_H1.0b | |

| 1.1 | R0.5_H1.1 | R0.5_H1.1b | |

| No Baffle | With Baffle | |||||

|---|---|---|---|---|---|---|

| Model | Kinetic Power [W] | Increase Rate Compared to ‘Base Case’ | Model | Kinetic Power [W] | Increase Rate Compared to ‘Base Case_b’ | Increase Rate Compared to ‘Base Case’ |

| Base case | 0.3561 | 0% | Base case_b | 0.3861 | 0% | 8.4275% |

| R0.1_H0.7 | 0.3587 | 0.7282% | R0.1_H0.7b | 0.3879 | 0.4626% | 8.9291% |

| R0.1_H0.8 | 0.3591 | 0.8380% | R0.1_H0.8b | 0.3875 | 0.3604% | 8.8182% |

| R0.1_H0.9 | 0.3593 | 0.8861% | R0.1_H0.9b | 0.3884 | 0.5827% | 9.0593% |

| R0.1_H1.0 | 0.3610 | 1.3794% | R0.1_H1.0b | 0.3897 | 0.9169% | 9.4216% |

| R0.1_H1.1 | 0.3554 | −0.1912% | R0.1_H1.1b | 0.3932 | 1.8407% | 10.4233% |

| R0.3_H0.7 | 0.3612 | 1.4208% | R0.3_H0.7b | 0.3903 | 1.0753% | 9.5934% |

| R0.3_H0.8 | 0.3618 | 1.6048% | R0.3_H0.8b | 0.3901 | 1.0307% | 9.5450% |

| R0.3_H0.9 | 0.3623 | 1.7245% | R0.3_H0.9b | 0.3911 | 1.2763% | 9.8114% |

| R0.3_H1.0 | 0.3625 | 1.7913% | R0.3_H1.0b | 0.3915 | 1.3882% | 9.9326% |

| R0.3_H1.1 | 0.3449 | −3.1653% | R0.3_H1.1b | 0.3821 | −1.0373% | 7.3028% |

| R0.5_H0.7 | 0.3628 | 1.8789% | R0.5_H0.7b | 0.3921 | 1.5381% | 10.0952% |

| R0.5_H0.8 | 0.3635 | 2.0588% | R0.5_H0.8b | 0.3919 | 1.4799% | 10.0321% |

| R0.5_H0.9 | 0.3635 | 2.0611% | R0.5_H0.9b | 0.3924 | 1.6187% | 10.1826% |

| R0.5_H1.0 | 0.3603 | 1.1635% | R0.5_H1.0b | 0.3900 | 0.9927% | 9.5039% |

| R0.5_H1.1 | 0.3099 | −12.9939% | R0.5_H1.1b | 0.3461 | −10.3604% | −2.8061% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.; Kim, S.; Chae, J.; Park, J.Y. Additive Aerodynamic and Thermal Effects of a Central Guide Post and Baffle Installed in a Solar Updraft Tower. Energies 2019, 12, 3506. https://doi.org/10.3390/en12183506

Lee S, Kim S, Chae J, Park JY. Additive Aerodynamic and Thermal Effects of a Central Guide Post and Baffle Installed in a Solar Updraft Tower. Energies. 2019; 12(18):3506. https://doi.org/10.3390/en12183506

Chicago/Turabian StyleLee, Seungjin, Saerom Kim, Jonghyun Chae, and Joong Yull Park. 2019. "Additive Aerodynamic and Thermal Effects of a Central Guide Post and Baffle Installed in a Solar Updraft Tower" Energies 12, no. 18: 3506. https://doi.org/10.3390/en12183506

APA StyleLee, S., Kim, S., Chae, J., & Park, J. Y. (2019). Additive Aerodynamic and Thermal Effects of a Central Guide Post and Baffle Installed in a Solar Updraft Tower. Energies, 12(18), 3506. https://doi.org/10.3390/en12183506