1. Introduction

CO

2 sequestration is a proposed technology to rapidly help reach the 1.5 °C goal outlined in the Paris agreement, under the condition that storage volumes accept gigatons of CO

2. The capacity estimates for each new storage site are limited, among other factors, by the geomechanical constraint of ensuring containment. A chosen reservoir must have a sealing caprock and not be divided into too many pressure compartments, which are sub-volumes delimited by faults which effectively act as closed boundary conditions. When evaluating the larger volume and less homogeneous reservoirs, the presence of more faults becomes inevitable. It is, therefore, vital to understand, as thoroughly as possible, how these faults behave under changing stress distributions linked to the injection of CO

2, so as to plan the operations in the best possible manner to minimize leakage risk and optimize storage [

1,

2]. The most critical mechanism for leak initiation from a reservoir is assumed to be the shear stress evolution close to faults towards the critical slip value, upon an increase in the pore pressure inside the reservoir as CO

2 is injected from one or several wells. If the fault slip happens, the permeability of or along the fault may increase, initiating a leakage across or along the fault [

3].

In most computer simulation tools, faults are modeled as 1D lines in 2D domains or 2D planes in 3D domains. Many simulation tools employ one or other variations on the finite element method, with a coupling between the reservoir flow and the geomechanical model [

4,

5,

6,

7]. Even though the slip area of faults is extremely localized in the fault gouge, the examination of real faults shows that they are much more complex, with structure evolving outwards from a thin core to a process zone with fractures [

8]. This structure on each side of the fault gouge has recently been incorporated in more advanced models. An example of such an approach is the use of the Cosserat extension of elasticity [

9]. It is shown that this process zone may have different mechanical properties and permeabilities than the host rock, which could, therefore, lead to stress concentration and affect the permeability evolution during CO

2 injection [

10,

11,

12]. Stress and permeability evolution, in and around a fault during reservoir pressure changes, are complex problems, and have been addressed in recent years by several authors [

13,

14]. There is, however, room for improvement in our understanding of the governing factors such as variation of fault angles and the effect of stress history from reservoir depletion during previous oil and gas production.

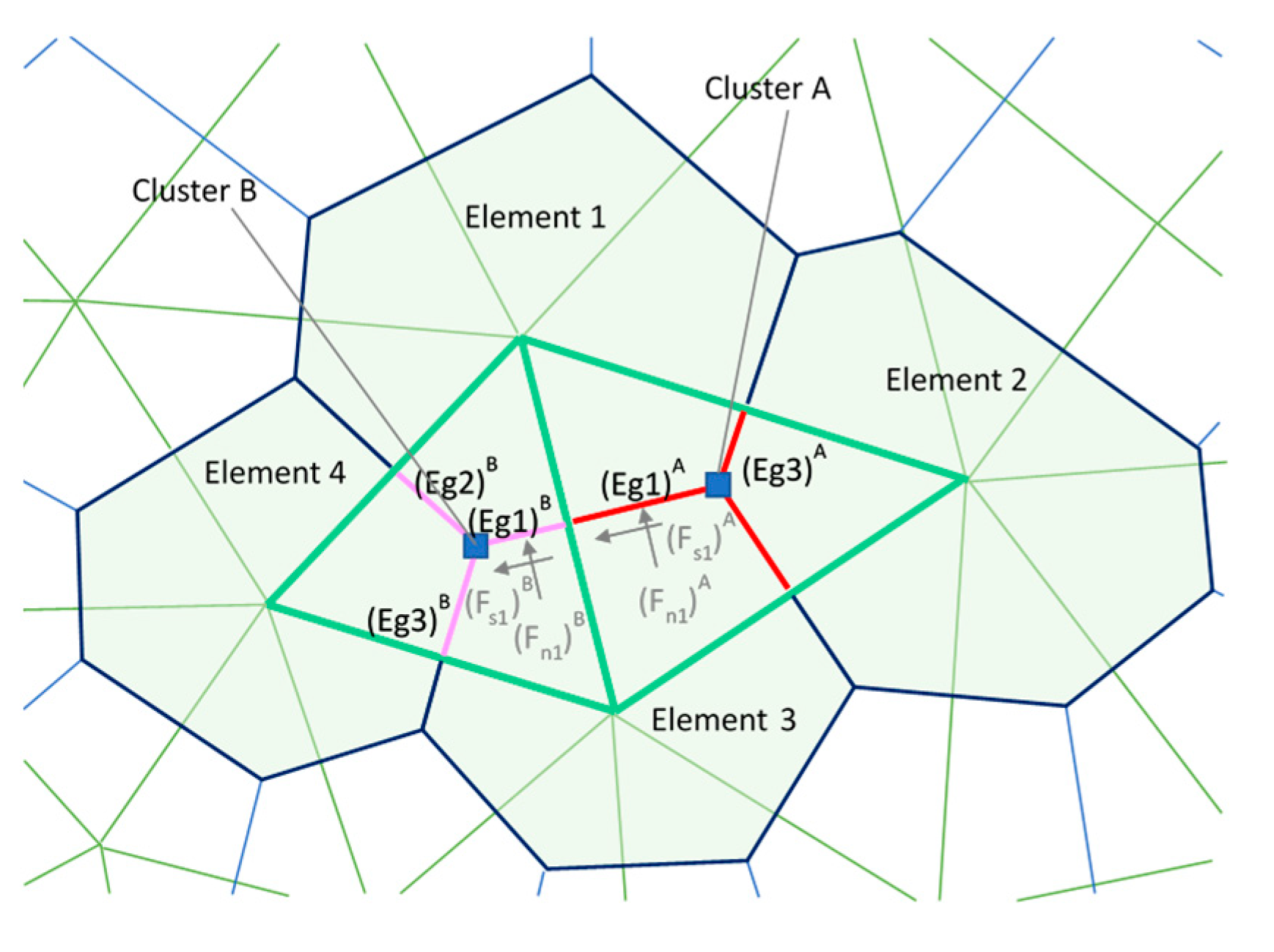

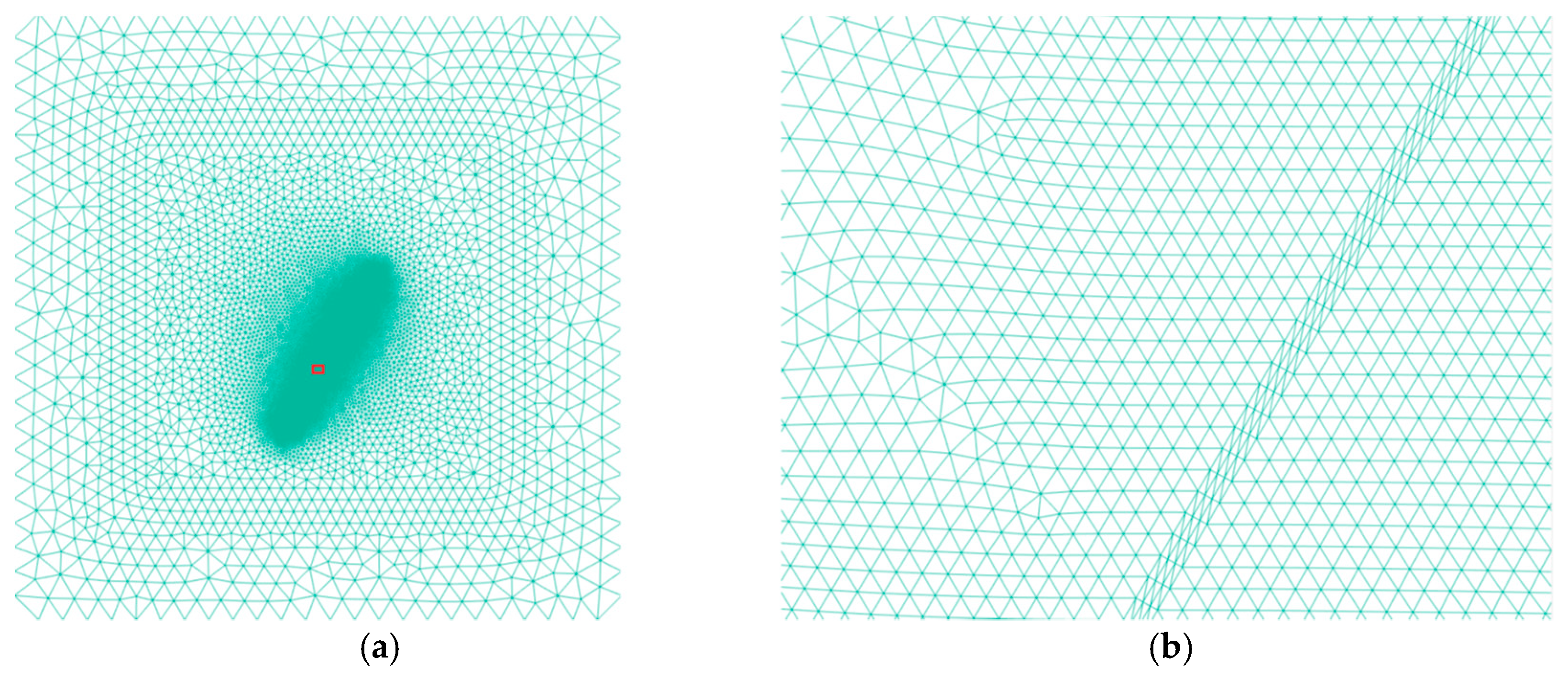

The MDEM (Modified Discrete Element Method) is a hybrid finite element method/discrete element method (FEM/DEM) hydro-mechanical model, developed at SINTEF. When failure conditions are met, the elements are redefined from a Voronoi tessellation on the basis of triangular elements. These clusters are used to define the contact lines (in 2D, planes in 3D) potentially failing to create fractures (

Figure 1). When the failure criterion is reached, the mechanical properties of the failed elements are changed to model the behavior of a fracture. The failed elements behave as standard discrete element codes, their interaction being based on normal and tangential contact forces. This allows for element clusters to separate, stress to redistribute, and shear forces to build up on the failed clusters. A mechanical aperture can be calculated, which, therefore, could be used to update the permeability of the failed element. The code was successfully used to simulate extended leak-off tests [

15].

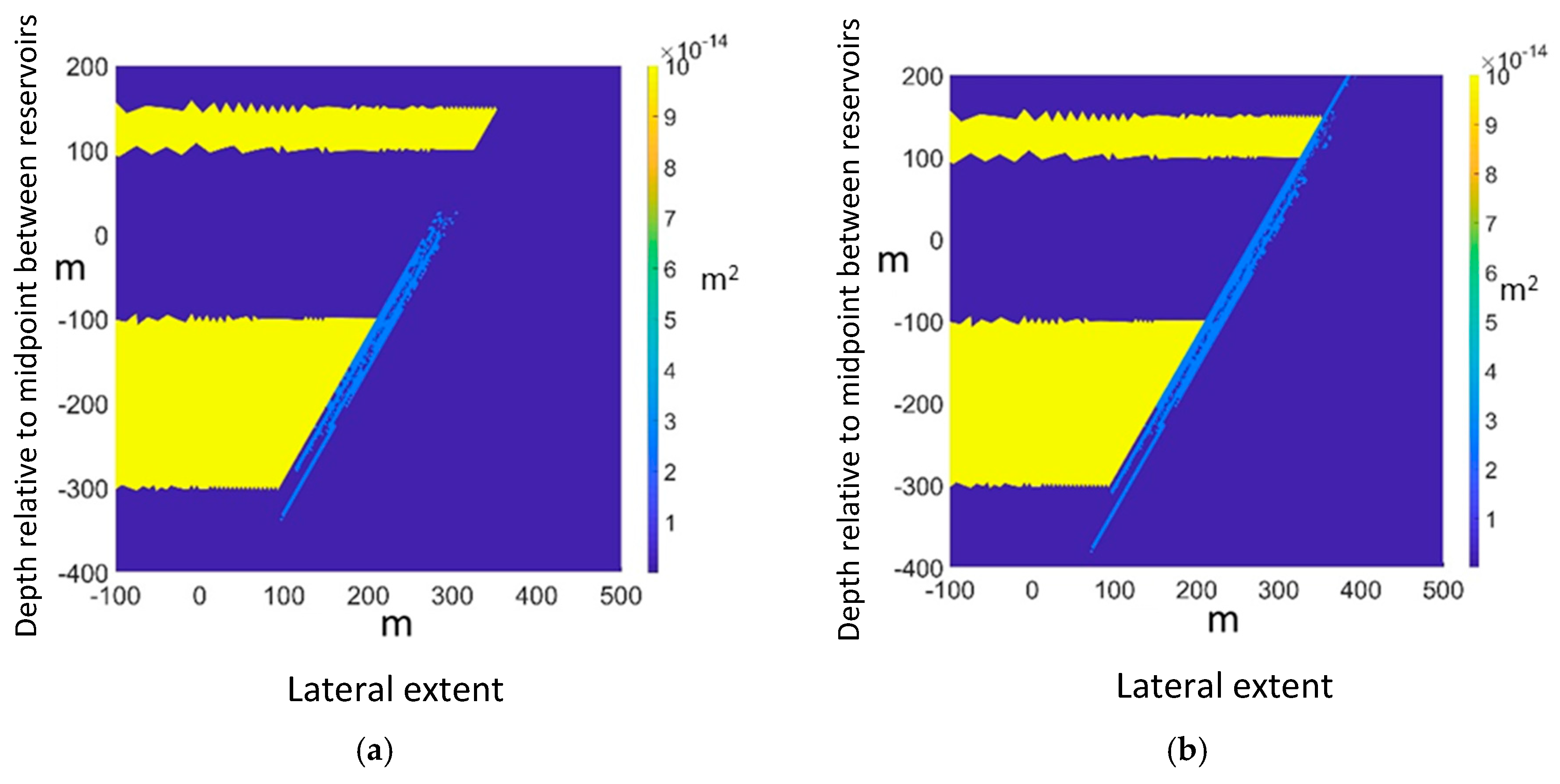

Fluid flow is calculated by coupling MDEM to SINTEF’s MRST (Matlab Reservoir Simulation Tool) reservoir simulator, or as in the present study, TOUGH2, a reservoir simulator developed at the Lawrence Berkeley National Laboratory. Fracture permeability can be monitored in MDEM by tracking the fracture aperture in both tensile and shear mode [

16]. The hydraulic aperture is calculated as a function of the mechanical aperture that could be decomposed into its initial aperture, the aperture due to normal opening and the aperture due to shear-induced dilatancy. MDEM calculates the tensile opening, and shear dilatancy based on the local stress state and pore pressure at every time step, where the upscaled permeability of a failed element is a function of the hydraulic aperture. The coupling between TOUGH2 and MDEM is a two-way explicit sequential, where the permeability and porosity field is sent to TOUGH2, which calculates the flow and sends back an updated pore pressure field to MDEM. MDEM will then solve for displacement and check for element failure, before updating the permeability and porosity fields. For a more detailed description of MDEM and its coupling to TOUGH2 see [

17]. MDEM is designed as an explicit fracturing numerical tool. The objective of the study presented here is to design simple simulations highlighting for a case study the evolution of permeability or hydraulic conductivity along a fault, depending on the stress history of the reservoir intended for CO

2 storage. This stress history is a direct consequence of the pressure variation in the reservoir, either as a result of prior hydrocarbon production or simply as a function of CO

2 injection alone. The process zone alongside the fault core is a region with pre-existing fractures; a mechanism for increased permeability could be by the increase of the fracture connectivity. This is assumed to occur as effective stresses evolve with decreasing and increasing pore pressure due to reservoir depletion followed by, or just due to, the continuous CO

2 injection in the reservoir. Note that in this study, dynamic evolution of fracture permeability is not calculated; rather, a track is kept of the initiation and propagation of fractures, where connectivity in a fracture chain imparts it a fixed, increased associated permeability. In reality, dynamic opening and shearing of fractures would make the chain permeability evolve with changing stresses, potentially increasing beyond the predictions in this study. On the other hand, shearing might reduce individual hydraulic conductivity of fractures, by mismatch of displaced asperities on the fracture faces, having moved relative to each other.

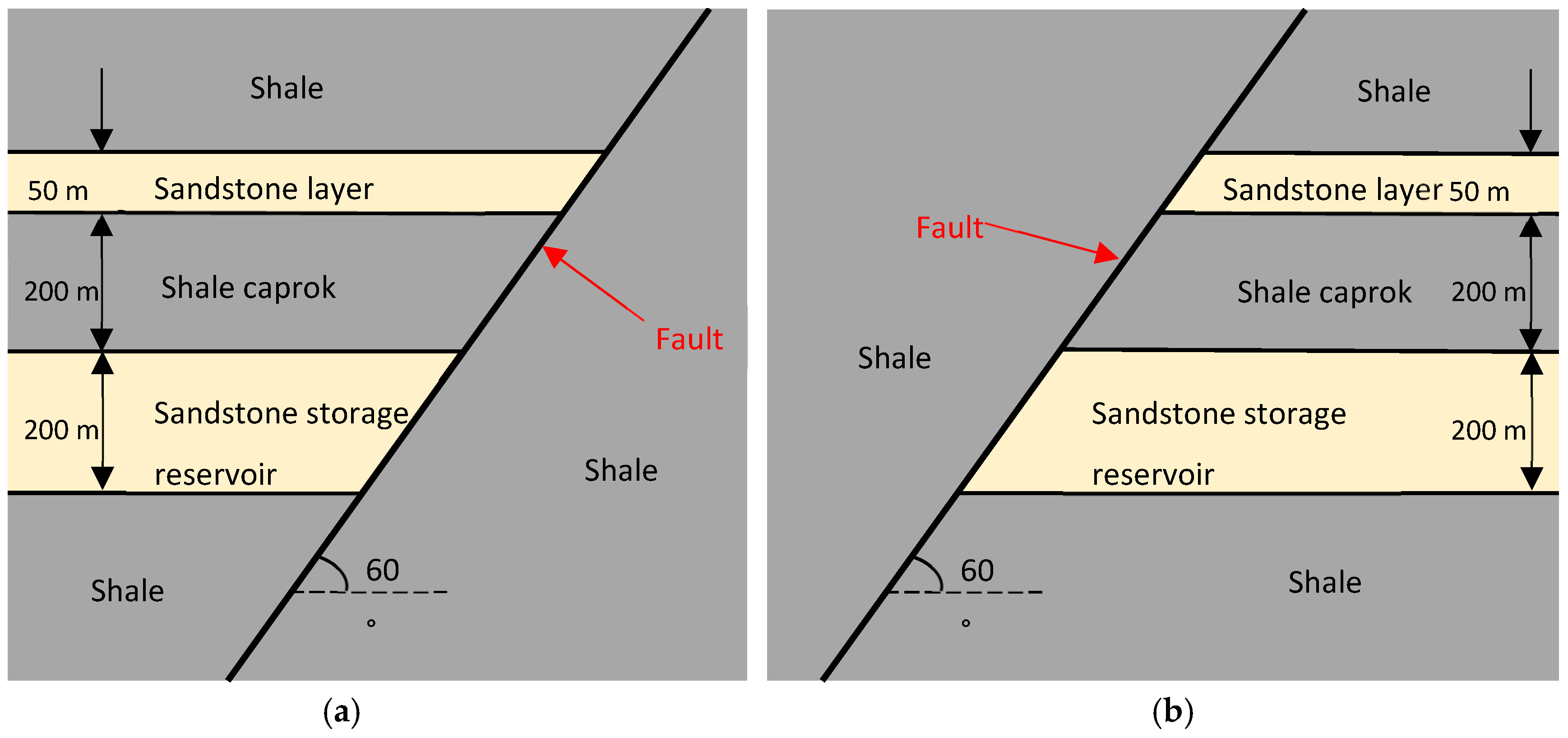

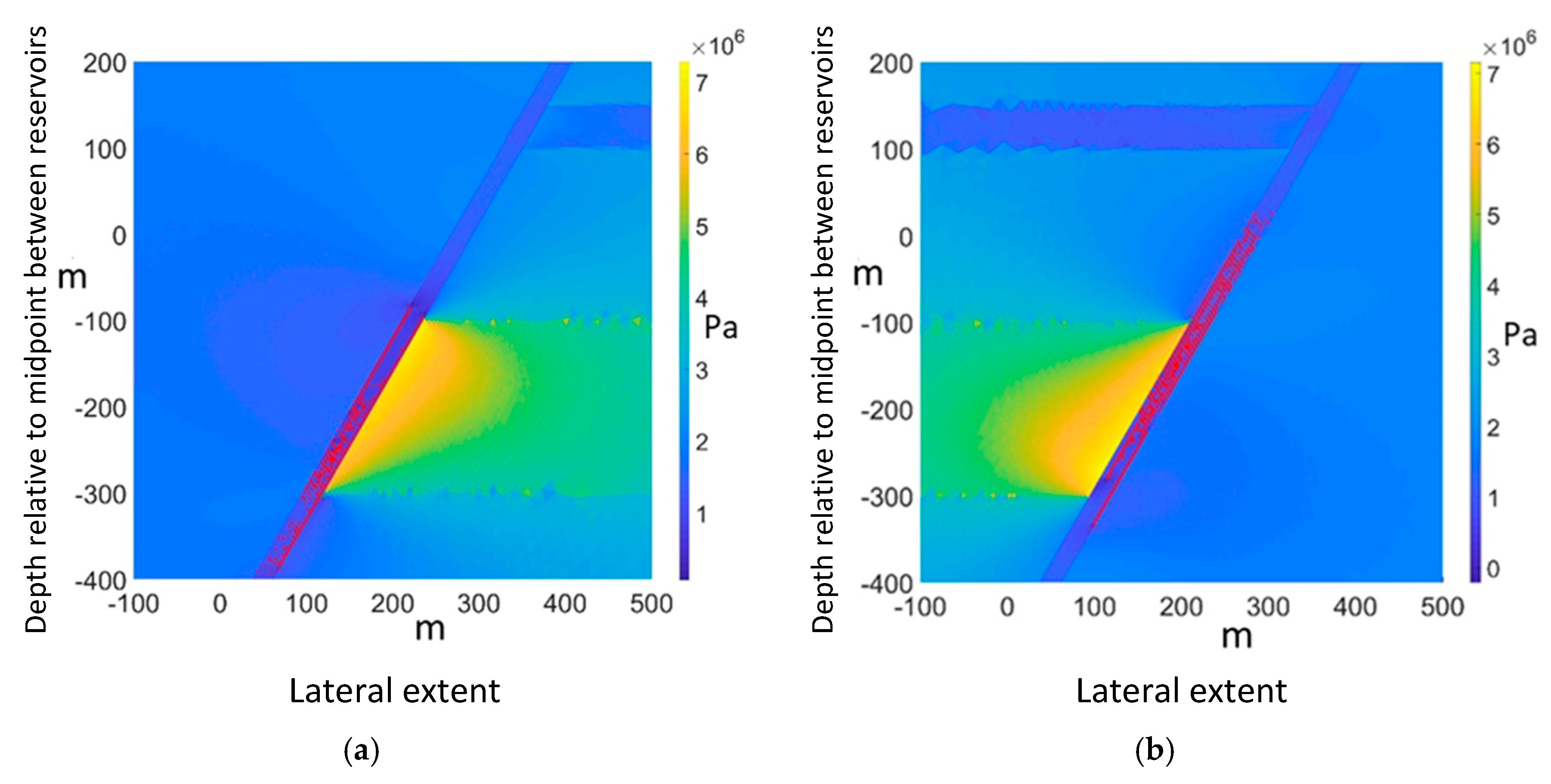

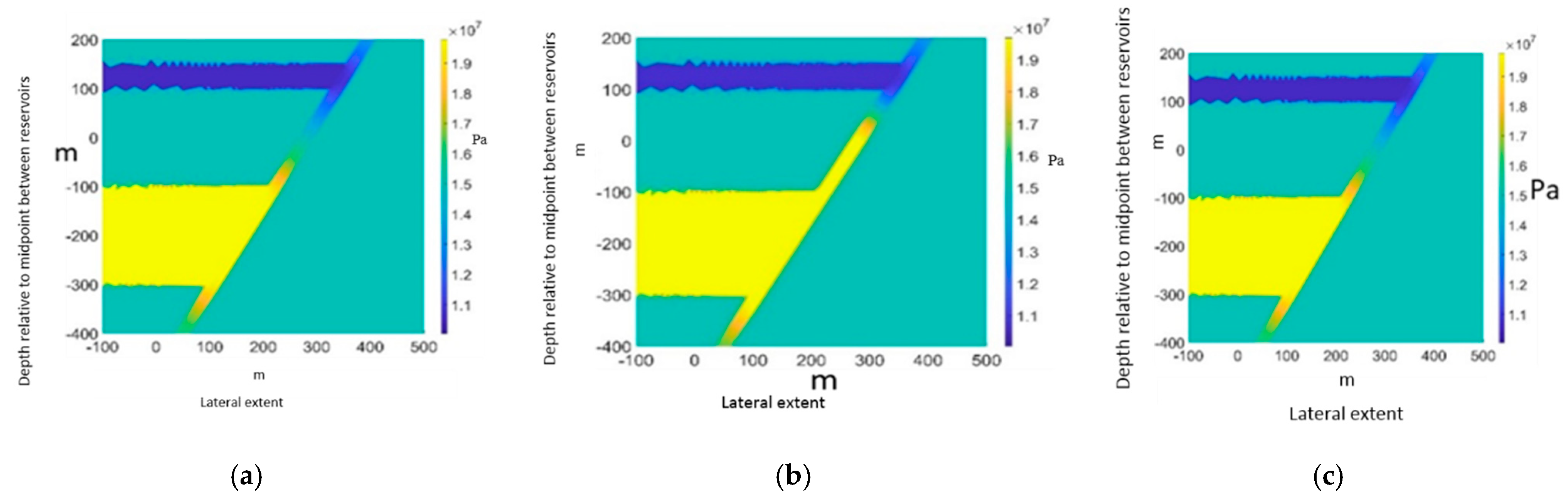

In the chosen model configuration, one fault bounds a sandstone reservoir, penetrating the overlying shale caprock and ending in a shallower sandstone reservoir (

Figure 2). The fault makes an angle of 60° with the horizontal axis; two cases are simulated, one where the reservoir constitutes a hanging wall (to the left of the fault if the fault resembles the slash character "/") and one where the reservoir constitutes a footwall of the fault (to the right of the same fault topology). The two sandstone layers are embedded in the shale formations. The upper reservoir has a thickness of 50 m and the lower one has a thickness of 200 m. The two reservoirs are separated by a caprock layer which has a thickness of 200 m. To avoid side effects, both reservoirs are assumed to have an infinite length on the left (right) side of the fault, and the fault is assumed to have an infinite length as well.

4. Discussion

The numerical model presented in this article focuses on the process or shear zone on each side of a fault core. The fault reactivation in terms of the classical description of the shear displacement across a discontinuity was not addressed here, but rather the more gradual increase in the hydraulic conductivity through percolation of fracture propagation in the process zone was attempted to be described using a hybrid modeling approach. This approach is supported by recent laboratory evidence, suggesting the possibility of fracturing along a fault prior to the reactivation of the core gouge [

24]. On the one hand, the process zone was not explicitly implemented as a discrete fracture network (although this is definitely a possible alternative using the MDEM tool, provided one has a given geological observation of such a network to mimic with some degree of simplification) but rather as an upscaled continuum damaged shale model. To easily explore the influence of the stress concentration, in addition to stress history on the possible fracture propagation in the process zone, an artificial case was chosen with only one fault present. The modeled domain was also much simplified with two high-permeability rectangular reservoirs, where the deeper one served as a source and the shallower as a sink for the leakage flow modelling, using the TOUGH2 software. Another simplification in the model was the elimination of the presence of high permeability sandstone layers beyond the fault; in essence, the modeled single fault has an infinite throw [

6]. This allowed for saving computing time so as not to have to consider cases only producing through-going fractures, establishing positive hydraulic conductivity between what could be considered as separate pressure compartments in the overall available storage volume. This last point should; however, be retained for future work, since it could contribute to the de-risking along-fault permeability enhancement by creating a fluid short-circuit, inhibiting fracture propagation in the unwanted direction upwards, parallel to the fault.

The simulation results illustrate that, should the process zone fracture before a large-scale fault core slip occur (with or without dilation), this may result in only partial fault "reactivation", in the sense of increased along-fault permeability. For any significant leakage to occur from the storage reservoir to a sensitive, shallower high-permeability spill layer, fracture propagation needs to occur all the way up to the shallower reservoir. Of course, this risk could vary both ways depending on the geochemical reactions in the fracture along the way up, which would depend on mineralogy, flow velocity, and scCO

2 to brine miscibility. This also implies that for serious leakage to occur from an underground storage site in this manner, major faults must be present, or at least a system of linked (linkable) faults with the ability to transport the CO

2 all the way up to sensitive shallow reservoirs. This may have been the case in the compromised In-Salah pilot [

3]. The presence of thin shale layers, as is the case in the Sleipner storage reservoir [

25] and the Decatur pilot [

26], without faults acting as sub-vertical "elevators", does not present the same risk as their failure (be it due to pressurizing of the lowest high-permeability compartment or from stress history prior to the start of the storage injection) only imply nearly parallel filling of closed vertical compartments. This may or may not reduce the total theoretical storage capacity of the site.

Induced stress concentration close to a fault depends, as the results presented here point to, not only on the critical orientation of the fault but very much on the pore pressure history of the considered reservoir: the situation is markedly different for the injection into a depleted reservoir than the injection over the hydrostatic pressure as would be the case in a virgin aquifer. The fracturing threshold also depends on the position of the reservoir, for constant absolute fault orientation or inclination with respect to vertical, being in the footwall or hanging wall, reverses the direction of fracture propagation. Of course, in a field case, the injection reservoir will most probably be contained by a pair of critically oriented faults, among other faults oriented at various angles. Should the simple simulations presented here hold water for more complex cases, this would imply that the injection point placement is crucial and should be chosen as far as possible from the main fault whose orientation is such that fracturing will propagate upwards. This may not always be possible when reservoir geometry, especially the tilt, comes into consideration as buoyancy may direct the plume towards the "dangerous" fault; in such a case, several injection wells may be preferred or adding pressure-relief wells. Naturally, in the presented simulations, the fault orientation was made "critical" by adjusting the mechanical properties of the formations, which will depart from many field examples. We think, though, that this does not depart from generality by being completely equivalent to another combination of fault orientation and set of formation parameters which will be encountered in the field.

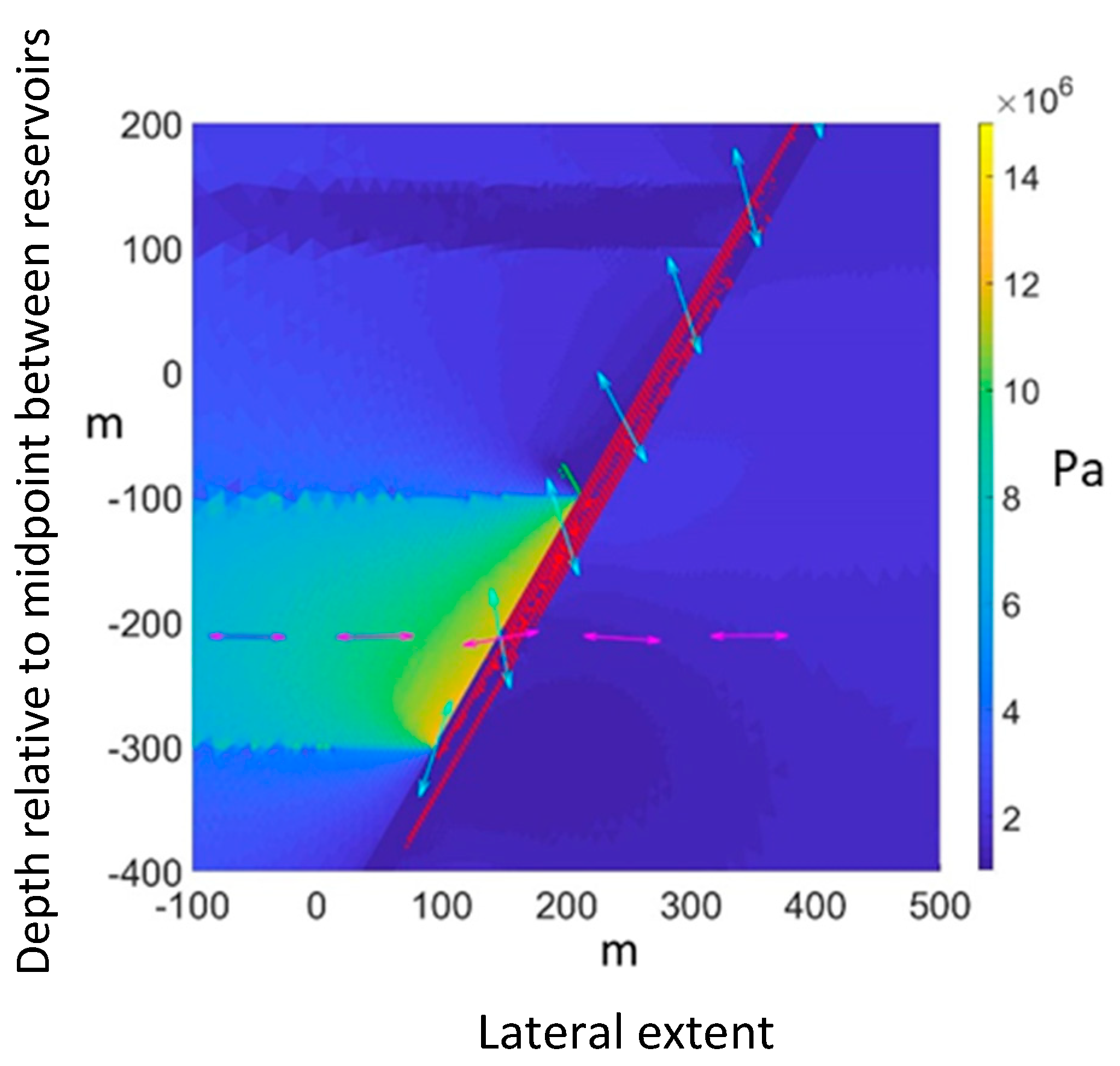

Stress concentration effects translate into inhomogeneous shear stress on the fault plane, again leading to non-uniform "activation" of the fault. This is readily illustrated by plotting the principal stress components along chosen lines crossing the simulation domain (

Figure 10), highlighting the stress tensor rotation, and thus, varying the degree of shear stress on the fault plane. In our model, the narrow fault core, usually filled with gouge and traditionally interpreted in terms of lithology as a mixture of sand and clay (for sandstone reservoirs surrounded by shale, at least), is omitted; the proportion of clay in the gouge is usually taken to scale with the throw of the fault. However, little is known about a generic relation to the mechanical properties. The mechanism for whole-scale reactivation of a fault through a slip of its narrow core implies that the failure envelope will be reached upon pore pressure increase relatively uniformly over large stretches of the fault. In addition, the effect of shear failure may trigger shear-enhanced dilation or not, the degree of mineralization, and thus cohesion is not trivial to access, and classical fault reactivation neglects the deformation or the resistance to deformation in the rubble or process zone. It will be interesting to later add to our simple model a variety of possible fault core properties in order to assess the effect on mobilization of the process zone and propensity to large-scale permeability increase (according to laboratory experiments [

27], stress hysteresis would also play a significant role on the permeability changes in the fault core). The core permeability may increase, accompanying shear-triggered dilation, or, for weak clayey cores, decrease upon further grain crushing and reduced porosity.

The presence of the process zone in our simulation is, we believe, essential to take field-scale geomechanical modeling to the next level; this is essential to de-risk studies of CO

2 storage correctly without being overly conservative in the pressure-limited capacity estimates. For future detailed case studies, more detailed fault and reservoir geometries could contribute to reducing the uncertainty in the output results [

5]. In this paper, the geometry and extent of the process zone were taken as approximate representations of average observations in outcrop systems, with the total thickness of the fault taken as 25 m.

The effect of stress hysteresis on our results could be summed up as follows:

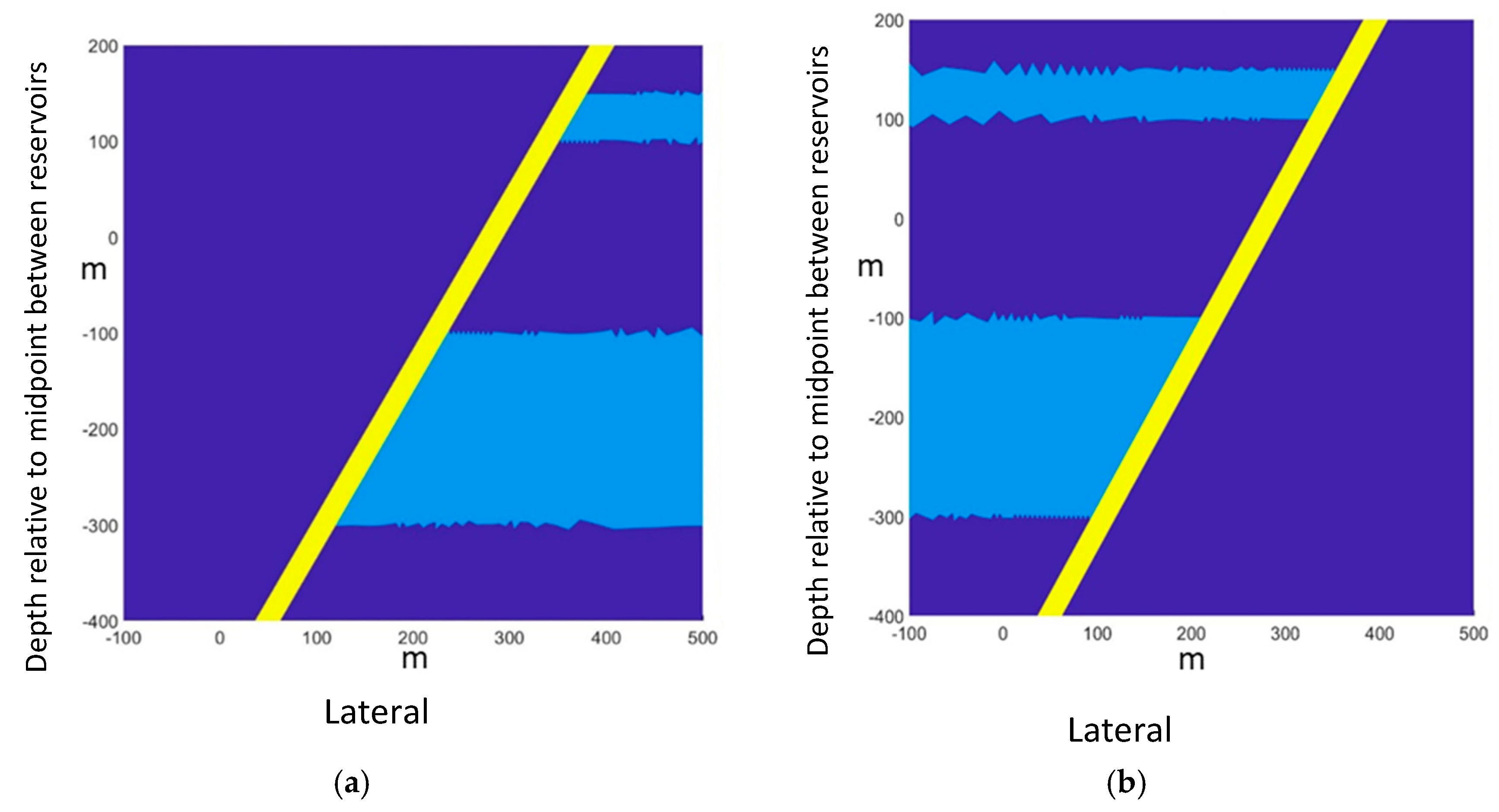

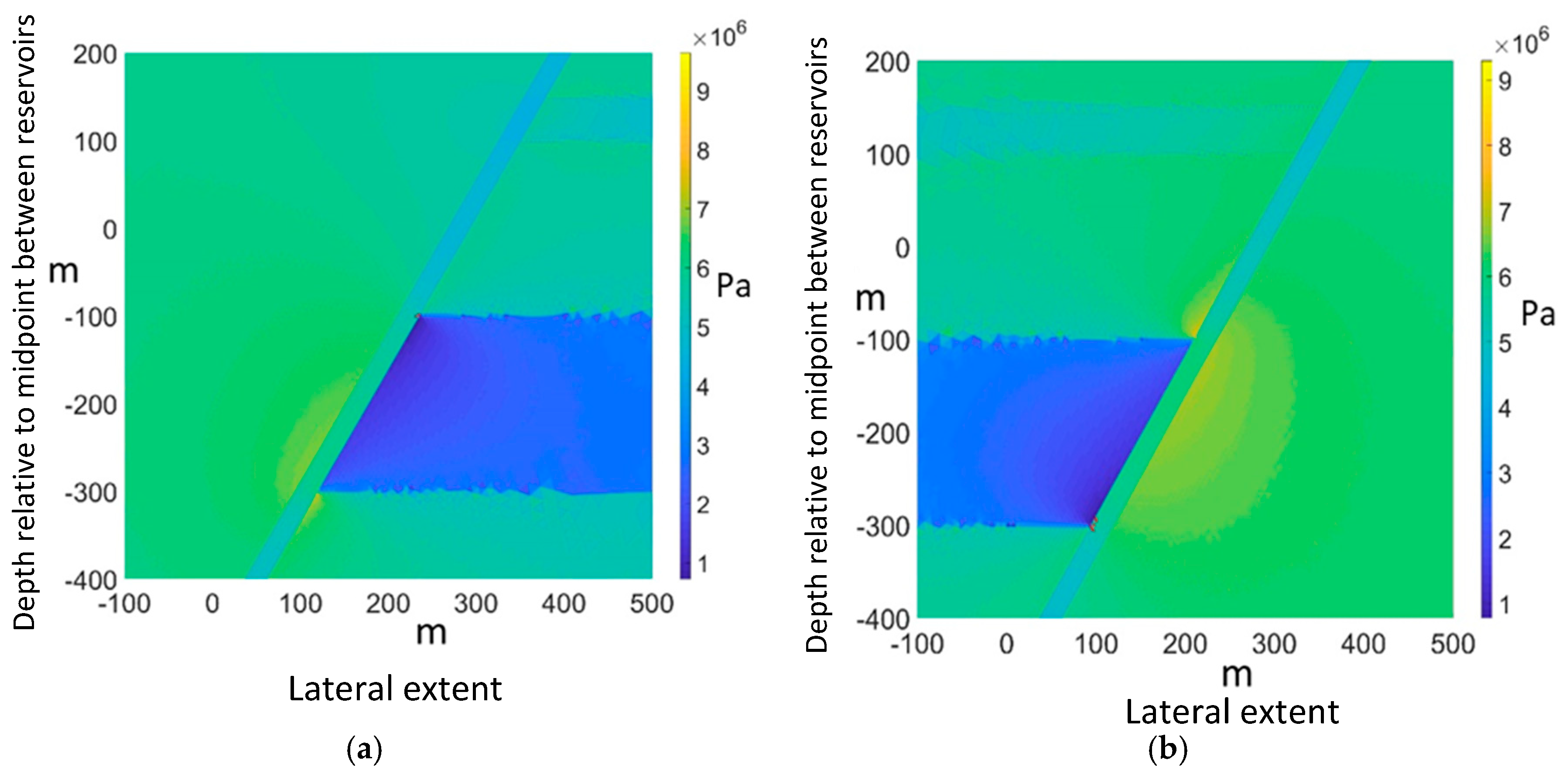

4.1. Depletion of the Lower Reservoir Followed by Injection

The primary mechanism for leakage from the lower to the upper reservoir is shearing at the fault during the depletion part, for a reservoir in the hanging wall of the fault; this is intuitively what one would expect considering a deflating reservoir pulling down the overburden, with static side-burden. Stress arching on the fault will tend to make the reservoir side slide down as a rigid body relative to the footwall in the shale. One can also understand the lack of further fracturing when "inflating" the reservoir back to its initial pore pressure; increasing pore pressure will at first only reduce the effective stress components, and hence, the shear stress. However, the presence of a more complex fault system, with sub-faults branching off might change this simple conceptual picture, with perhaps the tensile opening of the sub fault upon shearing of the main fault. This is something that our MDEM tool can readily handle, given the correct input of the fault system geometry.

The situation is changed for the case where the lower reservoir sits in the footwall of the fault, in terms of propagation of fractures towards the upper reservoir. Depletion induces fractures primarily in the process zone’s deeper side, propagating down into the underburden. The same conceptual picture of a rigid body sliding down could be evoked to see that this will first increase the shear at the "narrower" lower part of the reservoir being squeezed against the fault (this is only a very naïve understanding of the deformation process, since in reality there is a gradient of deformation steered mainly by the boundary conditions imposed on the whole simulation domain).

The relevance for CO2 storage of the depletion case is especially interesting, since intuitively, these reservoirs are seen as good candidates, provided storage capacity is as required. The reason is that the well, and pipeline infrastructure is already in place for the oil and gas exploitation that depleted the reservoirs in the first place. Additionally, low in-situ pore pressure leaves a larger margin for storage without getting to values above what the total system experienced in geological times, where sealing was proven from the very presence of hydrocarbons. Our study shows that this is not necessarily true, due to the possibility of fracturing along the bounding faults upon depletion; this fracturing may have gone unnoticed since the production flow generates a pressure gradient towards the wells and not the faults. Thus, this fracturing action upon depletion would only be noticed by passive seismic monitoring, which is not in place everywhere, certainly not offshore. However, once the pressure builds up with CO2 injection, the fractures would manifest themselves and leakage occurs.

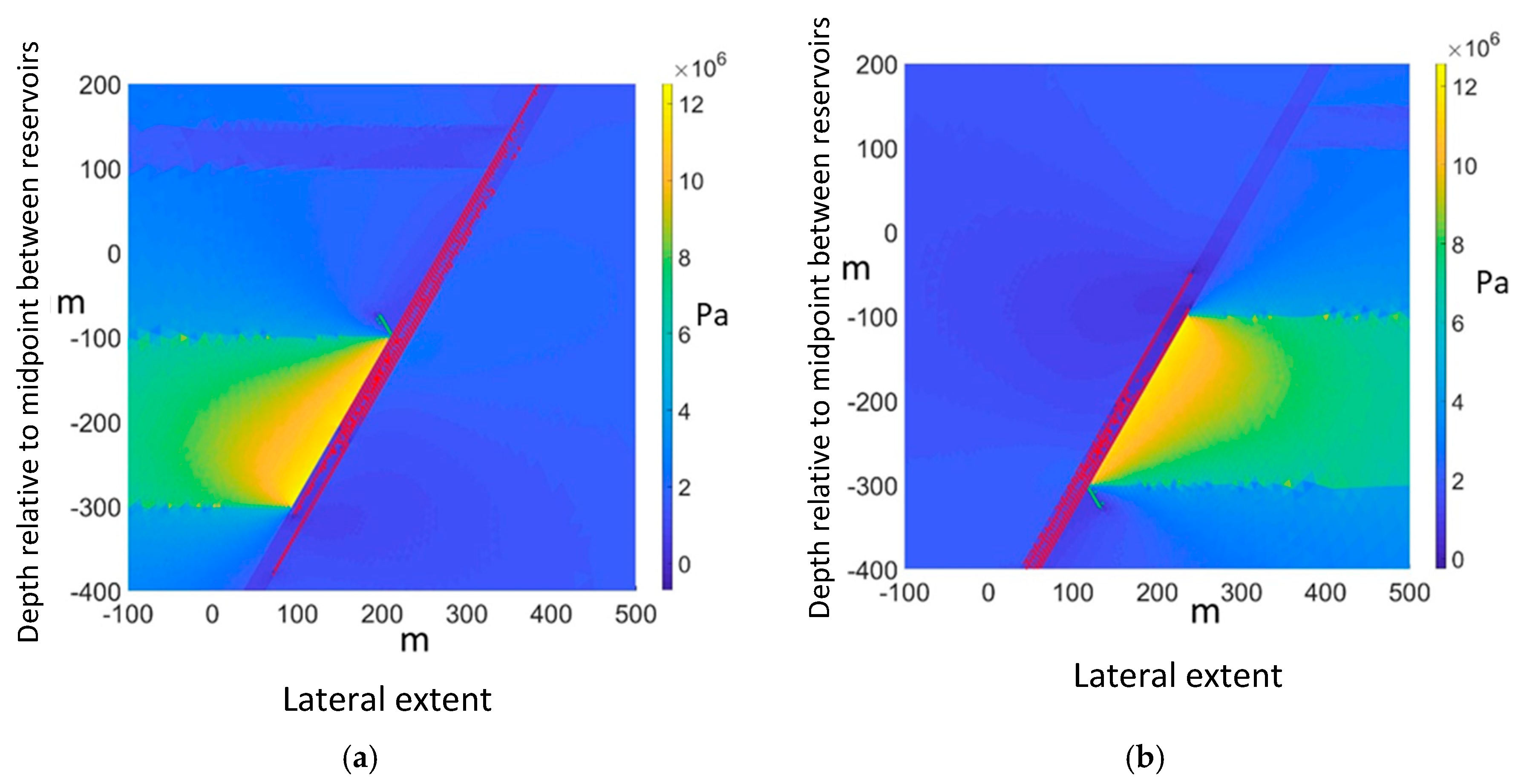

4.2. Aquifer Case: Injection Without Prior Depletion of the Lower Reservoir

Here, the picture is again reversed as compared to the cases with depletion. For reservoirs in the hanging wall, fractures only propagate down into the basement. It is as if the uniform pressurization of the reservoir has more consequence in the lower, narrower part where it pushes harder on the fault and basement. The results might be somewhat mitigated in a more realistic case with pore pressure gradients and stress variations with depth.

For the case where the lower reservoir sits in the footwall of the fault, fractures propagate upwards preferentially. However, the situation is less critical than for the analogous case of a reservoir in the hanging wall upon depletion, since effective negative stresses develop in the reservoir and hydraulic fracturing would rapidly set in and dominate the picture.

The pressure increase due to CO2 injection in our simulations is taken all the way up to (initial) in-situ minimum horizontal stress, 17 MPa. This would of course not be pursued in the field, where allowable pressure increases would be kept well below the fracturing limit. This strengthens the surprising conclusion in our study, that for the fault properties and chosen reservoir geometry and placement the aquifer case would be completely safe, while the depleted reservoir option may lead to along-fault leakage.

5. Conclusions

In this article, we demonstrate with a simplified model that the departure from a singular fault description (i.e., as a feature-less line in a 2D domain) towards including a structured process zone has consequences on the quantitative evaluation of the risk for developing a leakage path along the fault. The chosen strategy makes use of an explicit fracturing code developed at SINTEF, MDEM, coupled to a commercially available flow simulator, TOUGH2. The obtained results could be seen as a first study looking at a simple layout: two rectangular reservoirs potentially in hydraulic connection by a through-going, rectilinear fault. Geometry, mechanical properties of all layers and complexity (adding more faults) could readily be altered to suit any given site-study requirements.

Four simulation cases are presented in this paper: the first two cases look at re-pressurization of a depleted reservoir, adjacent to a fault linking the reservoir to a shallower reservoir. The two first cases differ in the placement of the deeper reservoir relative to the fault, being either the hanging wall or the footwall. Results show that during the depletion process, the stress concentration at the fault may induce fractures propagating up towards the shallower reservoir (hanging wall case) or down to deeper layers (footwall case). Upon re-pressurization, the increased permeability along the fault may lead to leakage to the shallower reservoir, acting as a sink (hanging wall case). The findings are reversed for the next two simulation cases, where the hanging wall and footwall reservoirs do not undergo prior depletion, but monotonous pressure increase. However, in these last two cases, no hydraulic communication is established with the upper reservoir, even when approaching hydraulic fracturing conditions.

The simulation method used in this paper also opens for parametric studies, where the interest will lie in mapping the equivalent process zone permeability to the corresponding input parameters such as fault orientation, reservoir thickness and permeability, shale and sandstone mechanical properties, and most importantly, the history of the pore pressure variation in the considered reservoir (and hence accompanying stress hysteresis in the whole system). In turn, a more explicit description of the process zone could easily be implemented, setting in pre-existing fractures in the zone instead of weakening its intact mechanical properties.

Varying the properties of the layers in the simulation yields a range where fracturing is likely to occur, and pressure communication risks are established. Combining this with more complex flow simulations, taking into account multi-phase, miscible, and reactive flow could further increase the predictive power of these simulations. Once these properties are known, an upscaling could be performed, such that a permeability along the fault as a function of stress state can be established and exported to more complex cases using standard finite element methods.