1. Introduction

Aeroengines are a typical kind of time-varying, complex and uncertain nonlinear system [

1]. Their mathematical model mainly includes state-space models and aero-thermodynamic models. On the basis of those two kinds of model, the concept of fuzziness is introduced, hence the fuzzy model for aeroengines is established through environment parameters, performance data and knowledge based on human experience.

After Zadeh established fuzzy theory [

2], new theories and applications such as fuzzy control, fuzzy identification and fuzzy algorithms have been gradually formed [

3]. Fuzzy relations generalize the concept of classical relations by admitting partial relations among elements. As a result, fuzzy relations can be used in modeling vague relationships between objects [

4]. The “if–then” fuzzy rule is one of the most popular fuzzy relations, and is used to form the T–S fuzzy model to approximate nonlinear systems [

5]. By establishing multiple local linear models connected through membership functions, a global fuzzy model has been formed. The method of establishing a T–S fuzzy model from data was based on the idea of constructing continuous structures and identifying parameters [

6]. The identification of the T–S fuzzy model included model structures and parameter identification [

7]. As described by Abonyi [

8], parameter identification of the premise part of the rule and the conclusion part of the rule were carried out separately [

9]. This idea not only simplifies the steps of model identification, but also improves generalization ability [

10]. The least square method is usually used to identify the subsequent parameters of the T–S fuzzy model. For parameter identification of the T–S fuzzy model’s antecedent part, reasonable parameters are often obtained by fuzzy clustering analysis. However, fuzzy clustering criteria are not unique [

11]. Different researchers use different clustering domains, different clustering algorithms and clustering effectiveness indexes to determine the number of rules. The fuzzy c-means FCM algorithm is a kind of fuzzy clustering algorithm widely used in the identification of the T–S fuzzy model.

The advantage of the FCM algorithm is that it not only can improve the generalization ability of the T–S fuzzy model, but it can also solve the problem of the number of rules that increase with the rising complexity of the system. For this reason, it is widely used in engineering. Gao used the FCM algorithm to identify the antecedent part of the fuzzy model, and established an accurate model of a stripper temperature system [

12]. Zhao used the FCM algorithm to determine the reference values of boiler operation parameters and obtained a more reasonable reference value model [

13]. Li used the FCM algorithm to identify the antecedent parameters of the T–S fuzzy model and established the temperature system of the boiler steam turbine [

14]. Research to improve the FCM algorithm is still ongoing. Moêz proposed a fuzzy C regression algorithm combined with a particle swarm optimization algorithm to identify the antecedent parameters of the T–S fuzzy model and make the partition space more reasonable [

15]. Mohamed proposed a joint FCM algorithm to reduce the sensitivity of the FCM algorithm to noise data and make the model more accurate and reliable [

16].

Evaluating clustering results under different clustering numbers, namely, the clustering effectiveness is an important research problem [

17]. In this regard, scholars construct validity functions to evaluate clustering, such as the Hubert statistics index for the hard c-means (HCM) algorithm [

18], the Xie index for the FCM algorithm [

19], and so on. Through numerical analysis, mathematicians have proposed a maximum number of clusters to determine the search scope [

20]. Bezdek adopted the F-statistic to judge the best clustering number from the perspective of mathematical statistics. Sun further proposed mixed F-statistics, highlighting the influence of small components on total weight, so as to ensure a higher degree of classification [

21].

For the strong nonlinear systems such as aeroengines, researchers have carried out related work based on the above modeling ideas. In order to study the fault diagnosis technology of aeroengines, Wang [

22] constructed three fuzzy sub-models and constructed the fuzzy model in full envelope by using the triangular membership function. The advantage of this modeling method is that it is easy to implement and simple, but the disadvantage is that it does not take into account the influence of nonlinear relationships between the antecedents of fuzzy rules on the model. Meanwhile, to study the fault diagnosis of aircraft engines, Zhai [

23] adopted generalized distances to determine the clustering center, then constructed the T–S fuzzy model. The likely benefit of this approach are realizing a complete coverage of the full envelope with the least amount of division, while the dynamic characteristics of the engine are not considered. Under different import environment conditions, engine dynamic characteristics vary greatly. Without taking into account the dynamic characteristics, it is difficult to ensure the accuracy of the model. Cai [

24] used the input and output data of an aeroengine to identify the structure and parameters of the T–S fuzzy model through the least square method to improve the model accuracy. However, this method is highly dependent on data, difficult to train and does not guarantee generalization.

In this paper, in order to simulate engine strong nonlinear dynamics with high accuracy and fidelity and low complexity, we explored T–S fuzzy modeling for engines by using a clustering and identification approach. Via clustering of the engine dynamics, we formed a series of rough T–S fuzzy models for aircraft engine nonlinear dynamics in the flight envelope. For each rough T–S fuzzy model, the maximum–minimum distance-based fuzzy c-means (MMD-FCM) algorithm was proposed to determine the fuzzy rule numbers and consequent engine linear models. Input and output sequences of aircraft engines were employed to identify the premise parameters with the least square method (LSM).

This paper offers three main contributions. First, clustering with dominant poles of engine linear models in the entire flight envelope guarantees that similar dynamics of engines can be simulated by a T–S fuzzy model, and this T–S fuzzy model can have fewer fuzzy rules, which is beneficial to reducing model complexity. Second, the proposed MMD-FCM algorithm guarantees that the clustering process that determines the fuzzy rule numbers and consequent engine linear models in each T–S fuzzy model is stable and more reasonable. Third, the identification of steady and transient data improves the accuracy of the T–S fuzzy model during the engine dynamic process.

2. Main Philosophy of T–S Fuzzy Modeling for Aircraft Engines

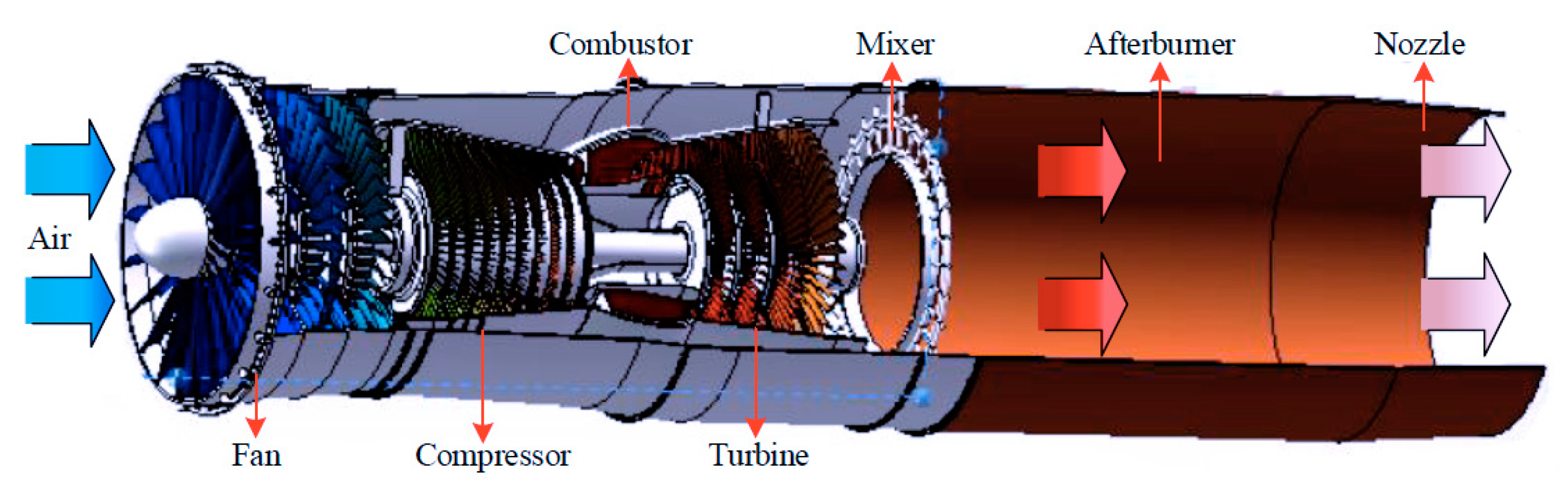

Aircraft engines are a complex aero-thermodynamic system.

Figure 1 depicts the major structure of a turbofan engine, a kind of aircraft engine comprising an inlet, fan, compressor, combustor, high-pressure turbine, low-pressure turbine, afterburner and nozzle.

Consider a turbofan engine described as a series of T–S fuzzy models

as

where

is the number of fuzzy rules,

is the premises without dependence on the system state,

is the antecedent fuzzy set,

is time,

is the engine state,

is the control input,

is the engine output and

,

,

and

are the known real matrices with appropriate dimensions.

Hence, by using a weighted-average defuzzifier, the global T–S fuzzy model can be inferred as

where

with

,

and

. Here,

and

is the degree of membership function of

in the fuzzy sets

, while

is a Gaussian function.

Remark 1. Since the dynamic characteristics of aircraft engines vary significantly and nonlinearly under different inlet conditions and different operation conditions, a single T–S fuzzy model has difficulty precisely describing the engine behaviors in the full flight envelope. In this paper, we intend to adopt multiple T–S fuzzy modelsto simulate more comprehensive engine dynamics in the full flight envelope.

Based on this modeling philosophy, we propose the following approach to the engine T–S fuzzy modeling:

Step 1. Under an operating condition, linearize an aircraft engine to a state space and adopt the dominant eigenvalue of the system matrix to demonstrate the engine dynamics.

Step 2. For a given number of the engine T–S fuzzy model , cluster the engine dynamics to determine the sub-region of the flight envelop in which the T–S fuzzy model works.

Step 3. In each sub-region, use the mixed-F statistic method to determine the number of fuzzy rules required to guarantee the engine dynamics in each rule are distinguished.

Step 4. In each sub-region, use an improved fuzzy C-means (FCM) to determine the consequence (the engine state-space model) in the rule.

Step 5. Using the data from the engine static and dynamic process and the least square method, modify the engine’s T–S fuzzy model.

In

Section 3, we will present the details of the above modeling steps.

3. Engine T–S Fuzzy Modeling

3.1. Engine Dynamic Clustering Based on K-Means Algorithm

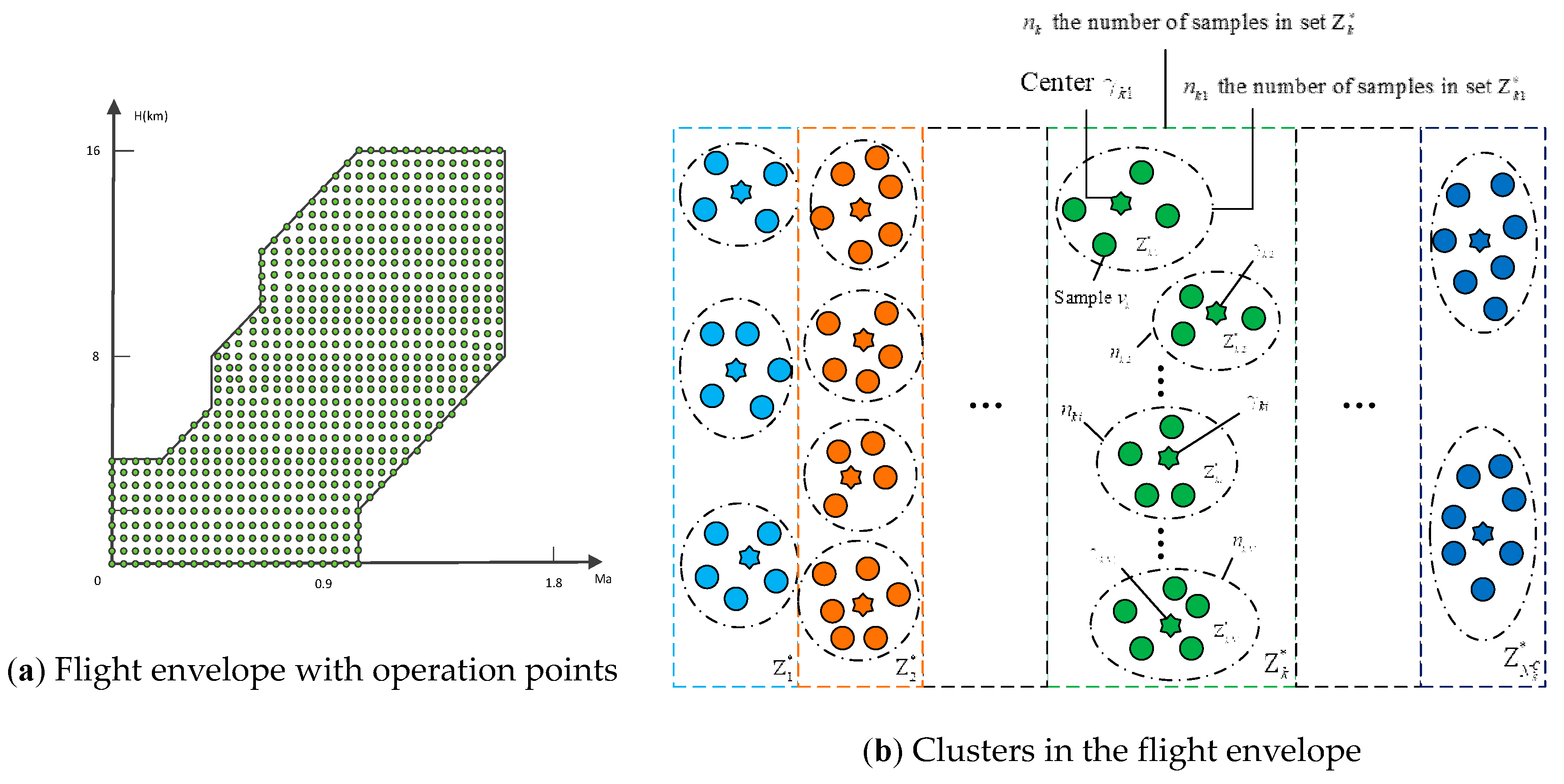

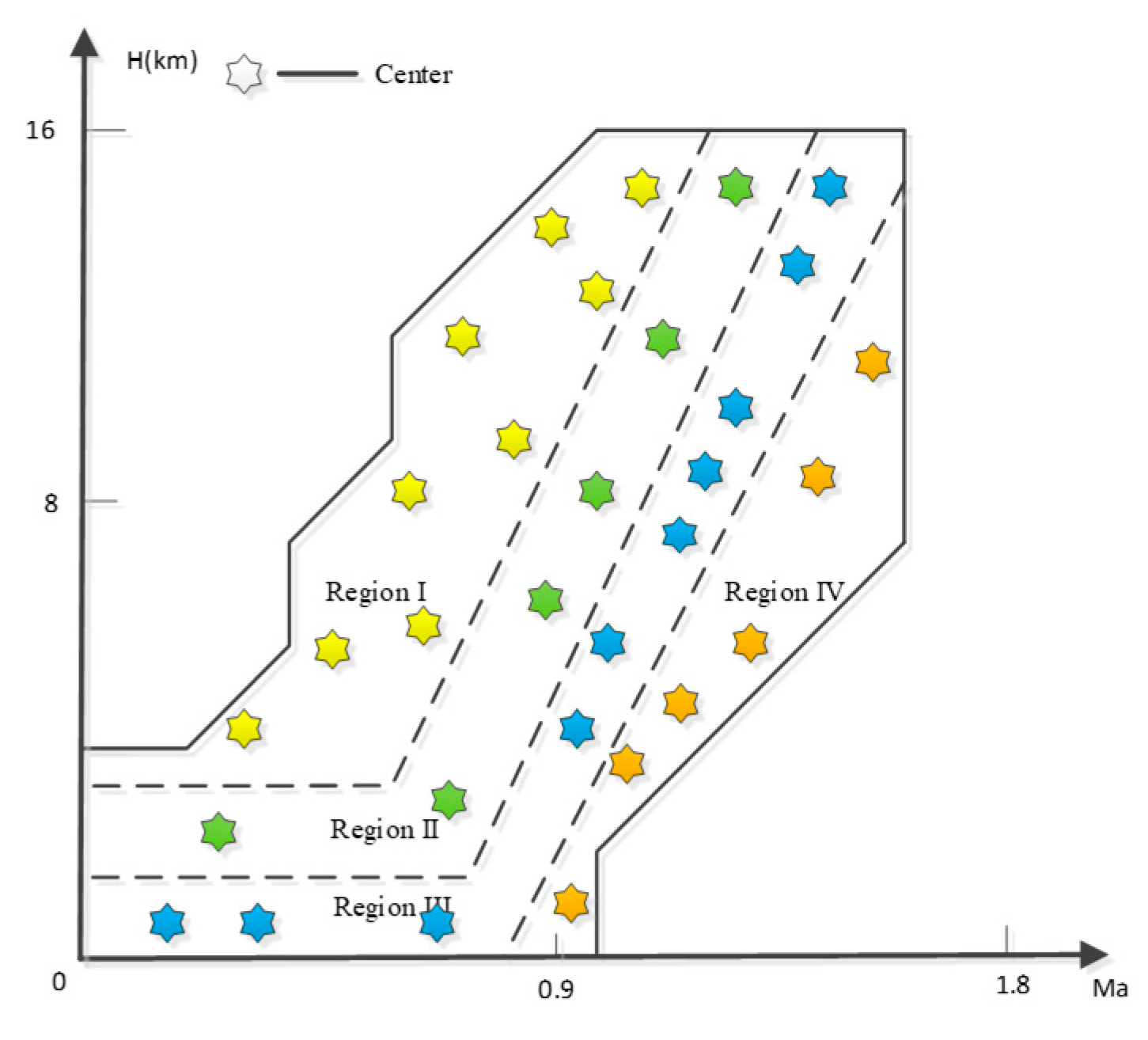

Under an operation point in the flight envelope (shown in

Figure 2a), an aircraft engine is described as

where

,

,

,

and

are constant matrices with appropriate dimensions. The eigenvalue of

is

,

. For all

, we define the dominant pole

where

is the real part of a complex number. Therefore, the sample set of engine dynamics is

. Suppose that all samples in the set

are clustered into

and the sample number in the cluster

is

.

Define the value function as

where

is the cluster center of all samples in cluster

. By a K-means clustering algorithm [

25], we obtain

which minimizes the value function

and the corresponding clustering sets

.

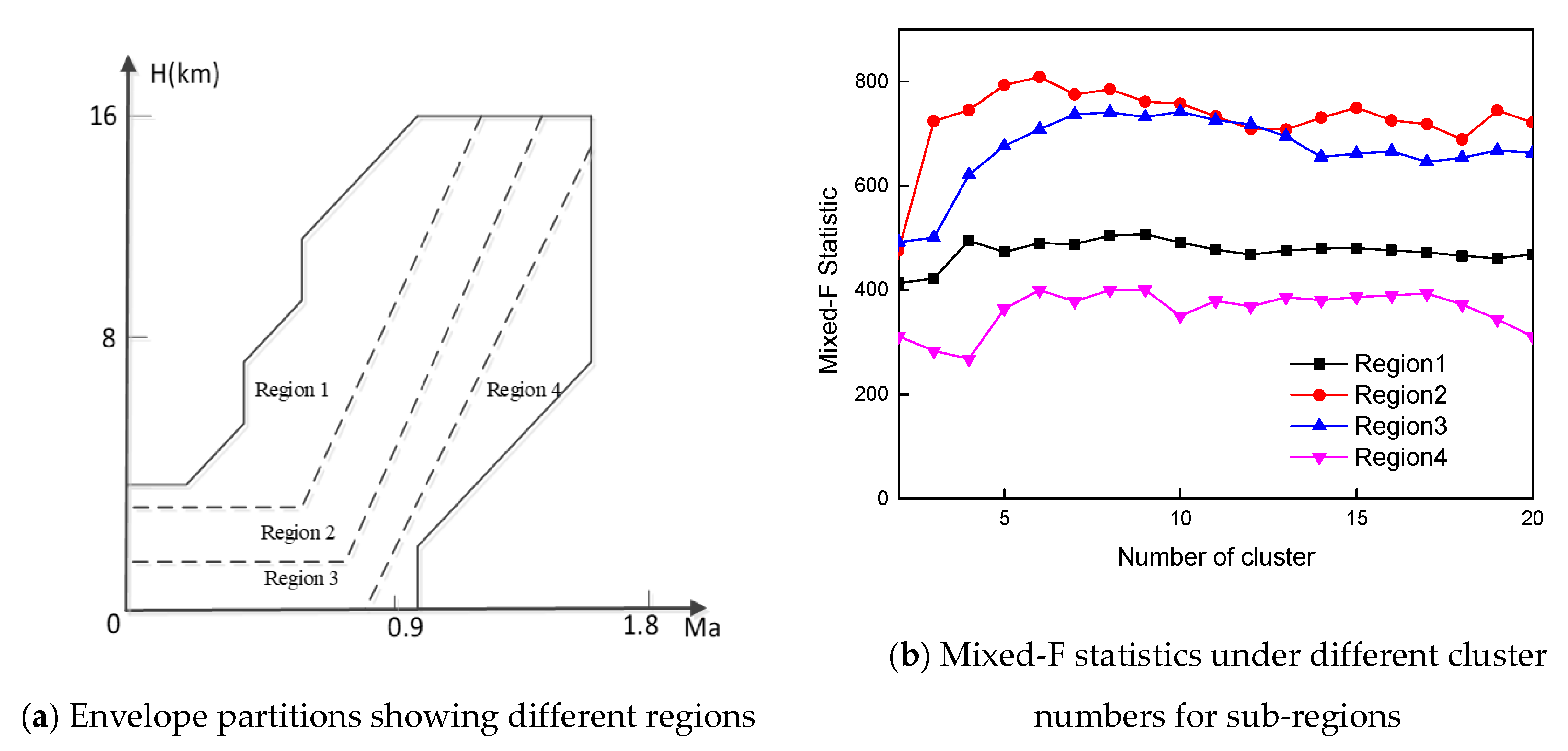

Remark 2. By clustering , we actually gather the similar dynamics of an engine together in the flight envelope. If the matrix depends on the flight height and Mach number of an engine operation, this clustering means we divide the flight envelope (Figure 2a) into sub-regions . For each sub-region, the T–S fuzzy model in Equation (1) is established to simulate the engine behavior. To show the details of clustering clearer, we neglect the real shape of these sub-regions and demonstrate them with rectangles as shown in Figure 2b. Moreover, Figure 2b also illustrates the clustering details in the sub-regions in Section 3.2. 3.2. Determination of Fuzzy Rule Number Based on Mixed-F Statistics

Next, we use the mixed-F statistics-based FCM algorithm to determine an optimal fuzzy rule number , in Equation (1). Therefore, is also the number of clustering class.

Define the value function as

where

is the weight matrix and

is the membership degree of a sample that belongs to the class

and satisfies

is the number of clustering center in sub-region

,

is the sample number in the sub-set

and

is fuzzy weight index:

Here, the Euclidean distance

is the distance between the sample

and the clustering center

in the sub-set

. It is worth noting that Equation (8) suggests the sub-set

is further clustered into

classes

.

In the sub-region

, suppose the clustering centers are

. According to Equations (7) and (8), we form a Lagrange equation:

where

is the Lagrange multiplier. Set the gradient of

to 0, namely,

giving us

Introduce Equations (15) into (14), giving us

Using Equations (13) and (16), this yields

Further, for the clustering number

in the sub-region

, we define the mixed-F statistic as

with

Here

is the sample number in the sub-set

, and

is the

entry of

and

Let , and using Equations (16)–(18) we can calculate a series of , namely, .

Define

and we obtain the optimal fuzzy rule number

in regard of the mixed-F statistic

.

Remark 3. In the FCM algorithm, the clustering number directly affects the performance of the T–S fuzzy model. Too many rules might lead to model redundancy, and fewer rules could cause poor accuracy in approximating the physical system with the fuzzy model. We adopt the mixed-F statistic as an index to seek an optimal . The numerator of the mixed-F statistic means the distance between classes, and the denominator means the distance between data points and clustering center. Therefore, the maximum of the mixed-F statistic implies the farthest distance between every pair of classes and the optimal classification.

3.3. Consequence Modeling Based on the MMD-FCM Algorithm

Using Equation (21), we determine an optimal fuzzy rule number for each fuzzy model . In this subsection, we propose the MMD-FCM algorithm for modeling the consequences of each fuzzy rule in .

In the sub-region , let the arbitrary vector , , as the initial of the first center , namely, .

Using

we determine the initial of the second center

. Let

and the

center

is

Using Equations (23)–(24), we can get all the initial centers

in

.

We regard as the initial centers and introduce it into Equation (16). Give by Equation (21) and choose the appropriate threshold value , and we can calculate membership matrix ;

Next we can calculate the value function using Equation (7). If , the algorithm stops; if not, continue to calculate using Equation (17). Repeat this process until satisfying .

Through the above process, optimal center in can be obtained. In , we linearize the nonlinear model of an aeroengine using the fitting method to get the corresponding linear model , , and .

Remark 4. The FCM algorithm uses the gradient method to search for optimal clustering [26]. The initials affect the searching gradient, and inappropriate initials will lead to unstable clustering results or local minimums. In this paper, we adopt the maximum and minimum distance (MMD) to obtain the appropriate initials for FCM [27]. The MMD collaborates with FCM, namely the MMD-FCM, to achieve a stable clustering result. 3.4. Model Parameter Identification with LSM

In order to make the T–S fuzzy model closer to the actual system, after determining the fuzzy consequent parts , , and , the parameter in a Gaussian function will be identified as a smooth parameter, and the selection of parameter will affect the smoothness of the system. A smaller may lead to a small fitting error, but it is difficult to generalize the data of non-training points. A larger may lead to a good generalization performance, but it could cause larger errors in the training data. Therefore, the appropriate parameter should be selected to maintain the balance between fitting and generalization. In this paper, the least square method is adopted to identify smooth parameters. Given the input sequence , we can achieve output sequence and define the value function , where is the output of fuzzy model with the input sequence . To minimize we should achieve a reasonable parameter . In order to avoid too large or too small of a parameter to affect the fitting and generalization performance of the fuzzy system, the upper and lower bounds of identification are set.

3.5. T–S Fuzzy Modeling Process

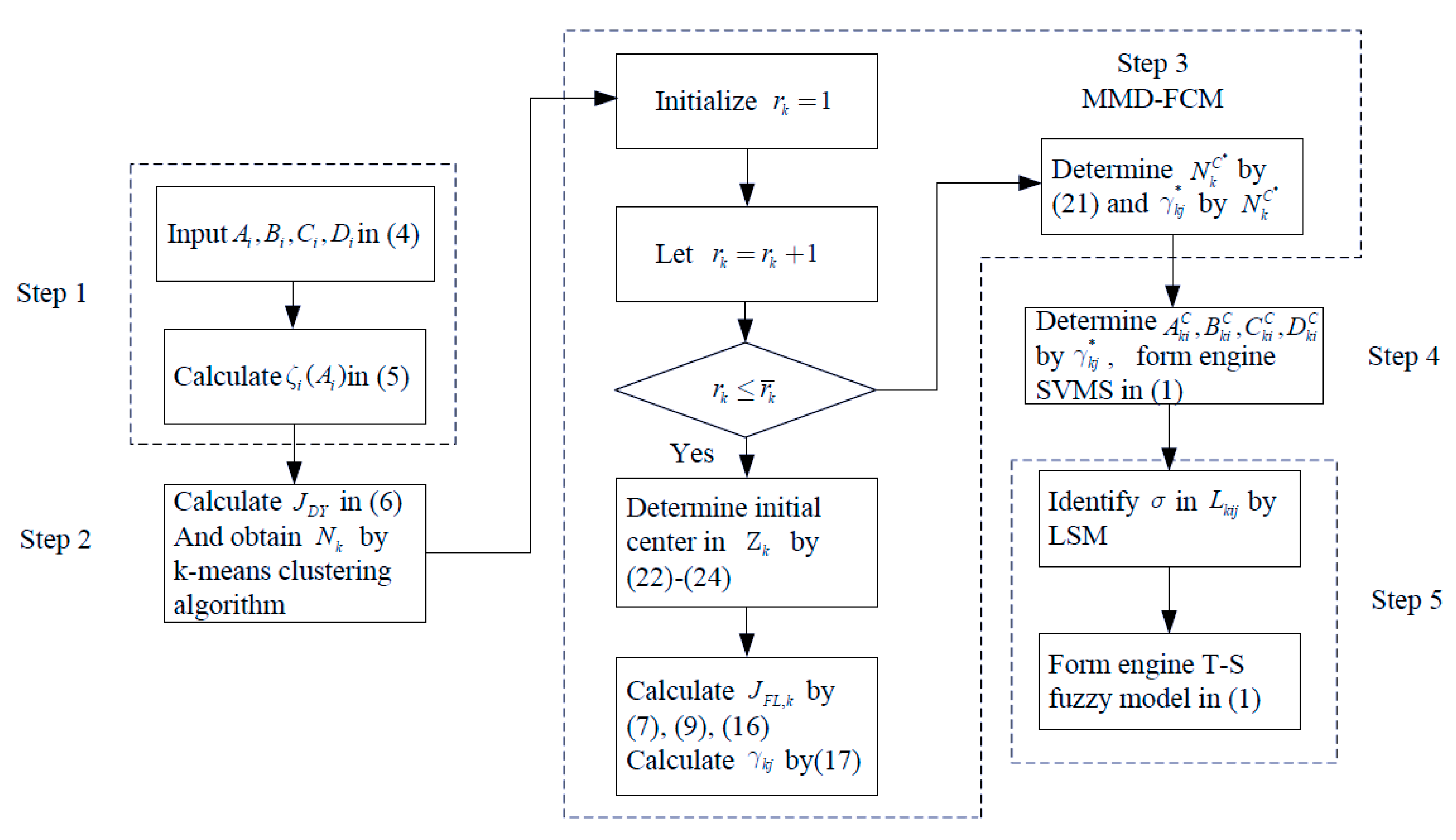

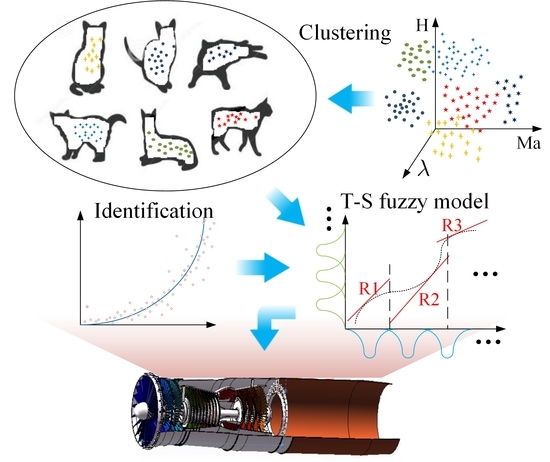

We summarize the engine’s T–S fuzzy modeling process in

Figure 3. As mentioned in

Section 2, the process of T–S fuzzy modeling for an engine involves five steps. In

Figure 3, we match the corresponding process blocks with the five steps. It is shown that the MMD-FCM is the core algorithm in the modeling. It is noted that, in this process,

is the upper bound of

. Let

and obtain the optimal

in (1,2

,

) by MMD-FCM. Therefore, when

, the search of

is ended and the transition occurs.

5. Conclusions

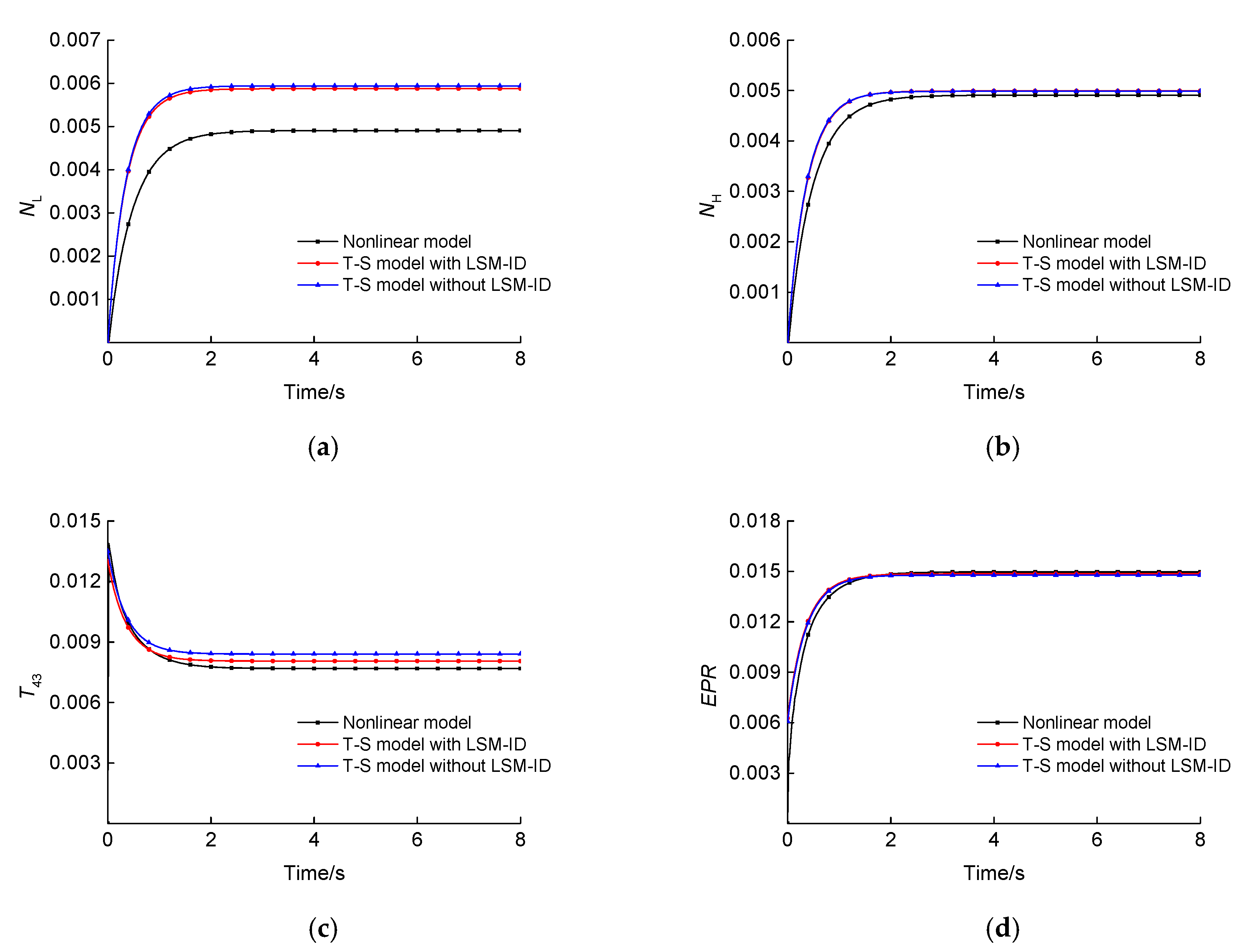

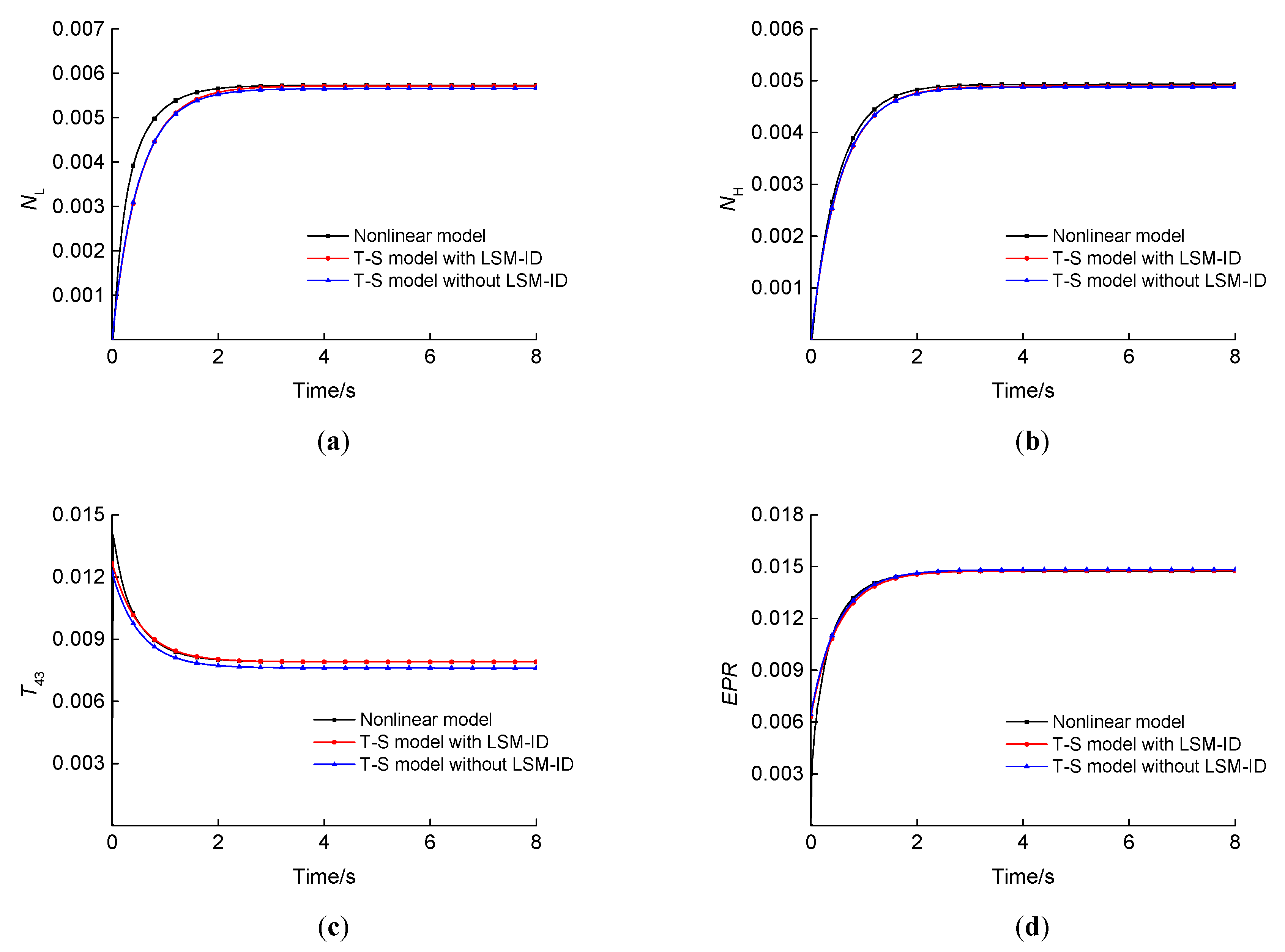

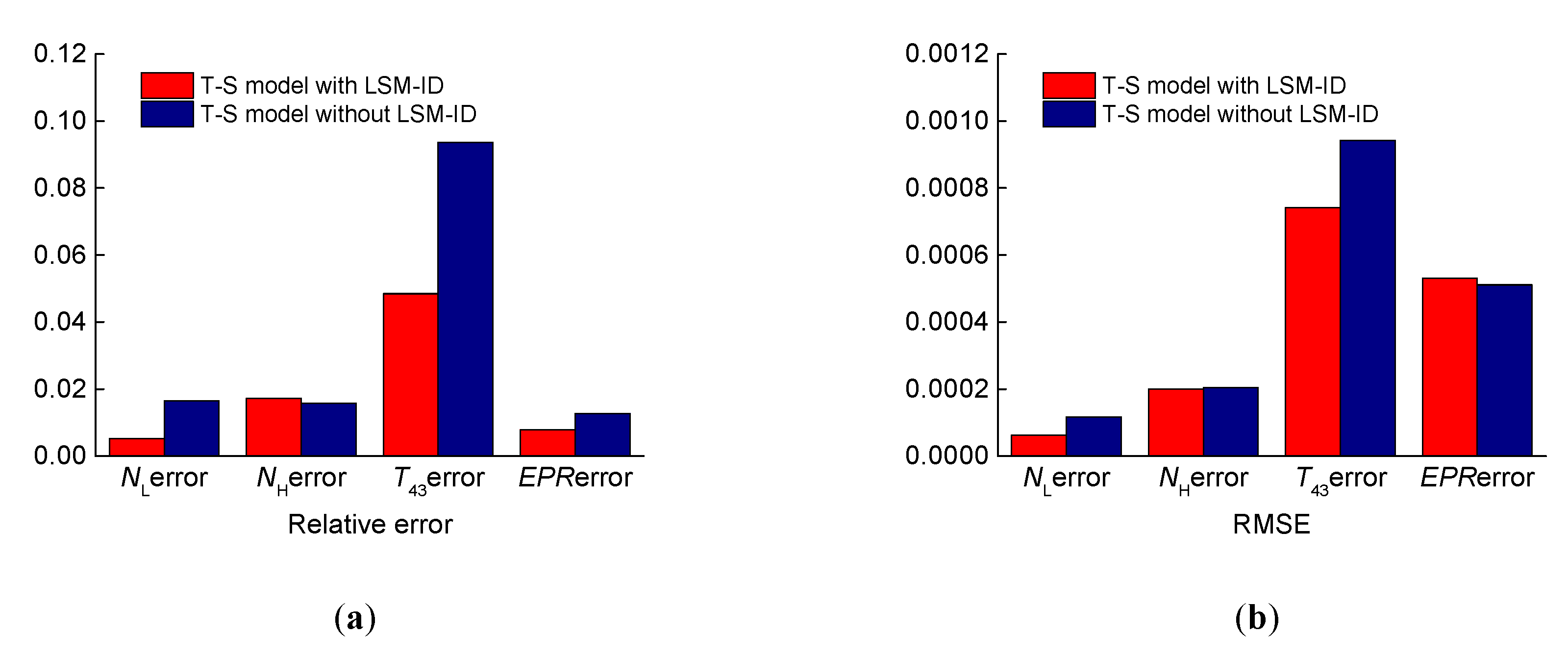

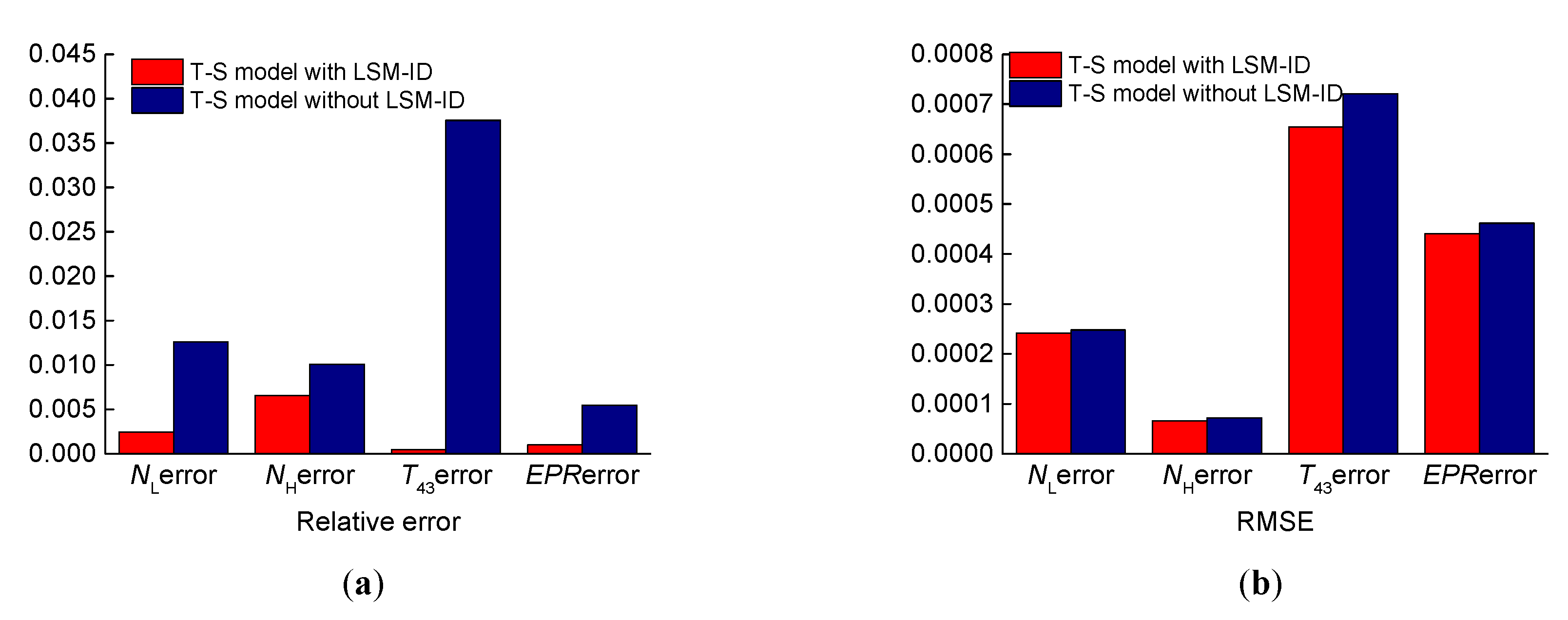

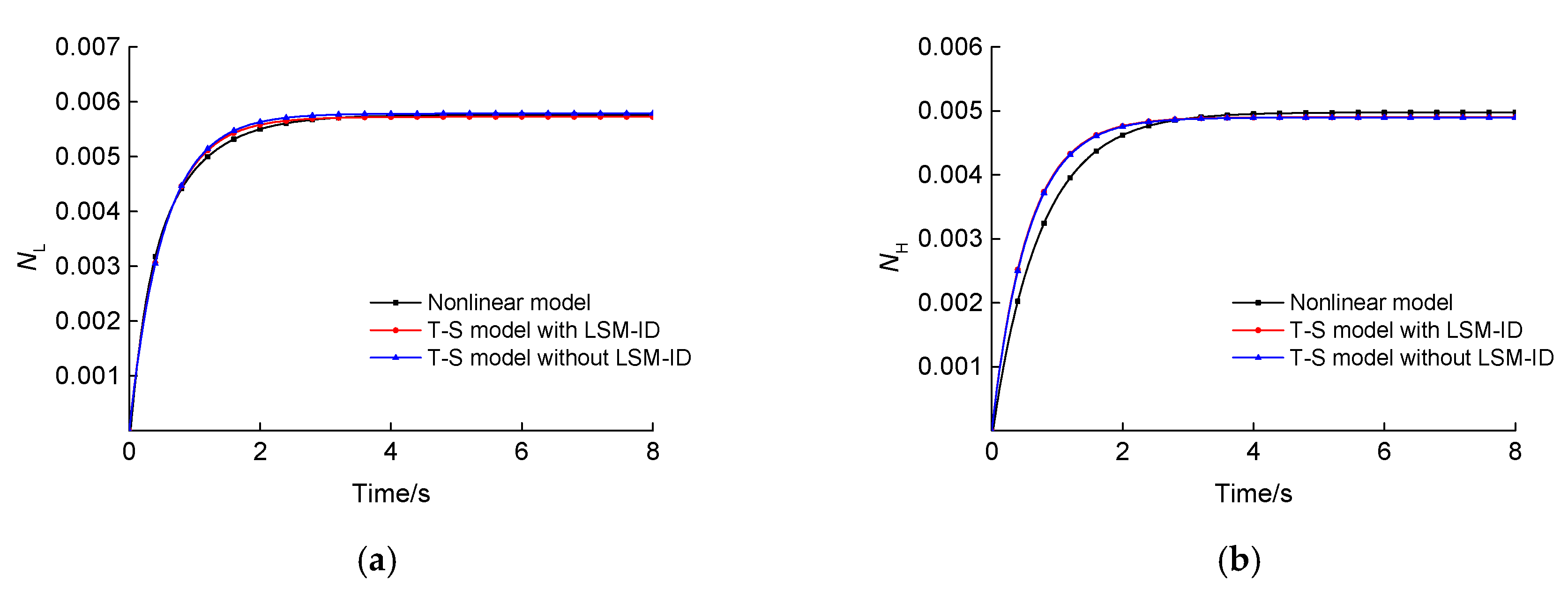

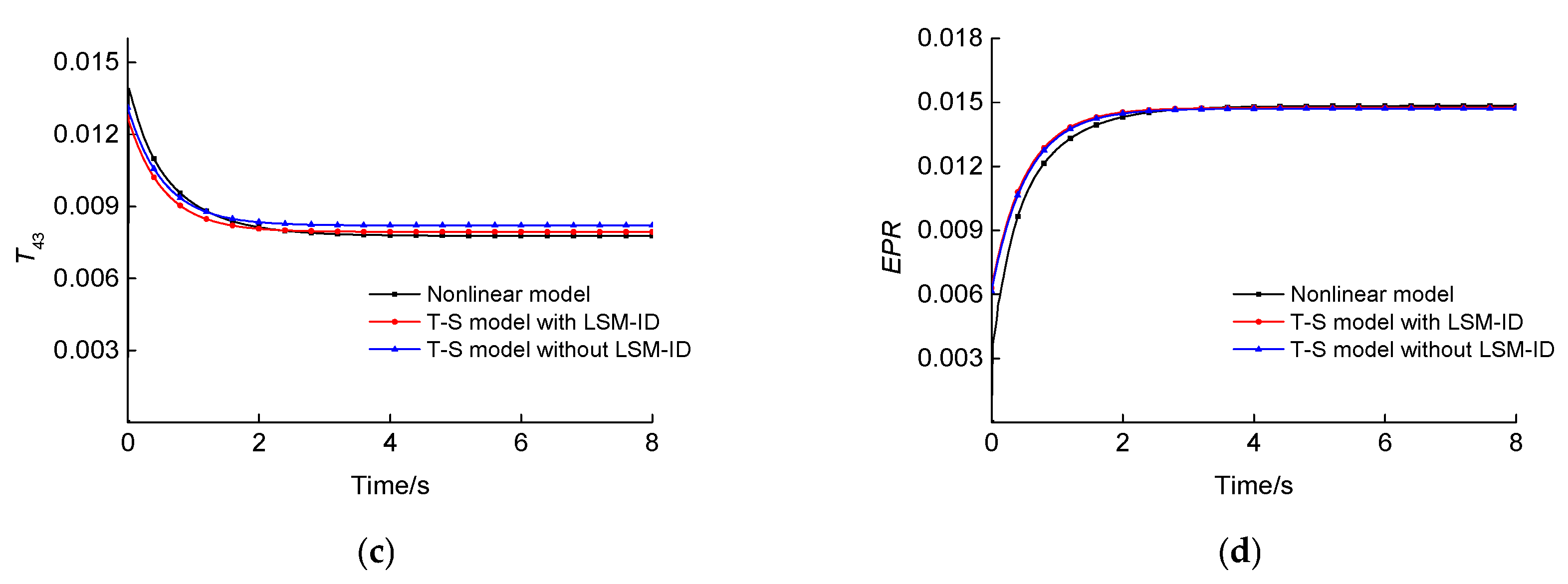

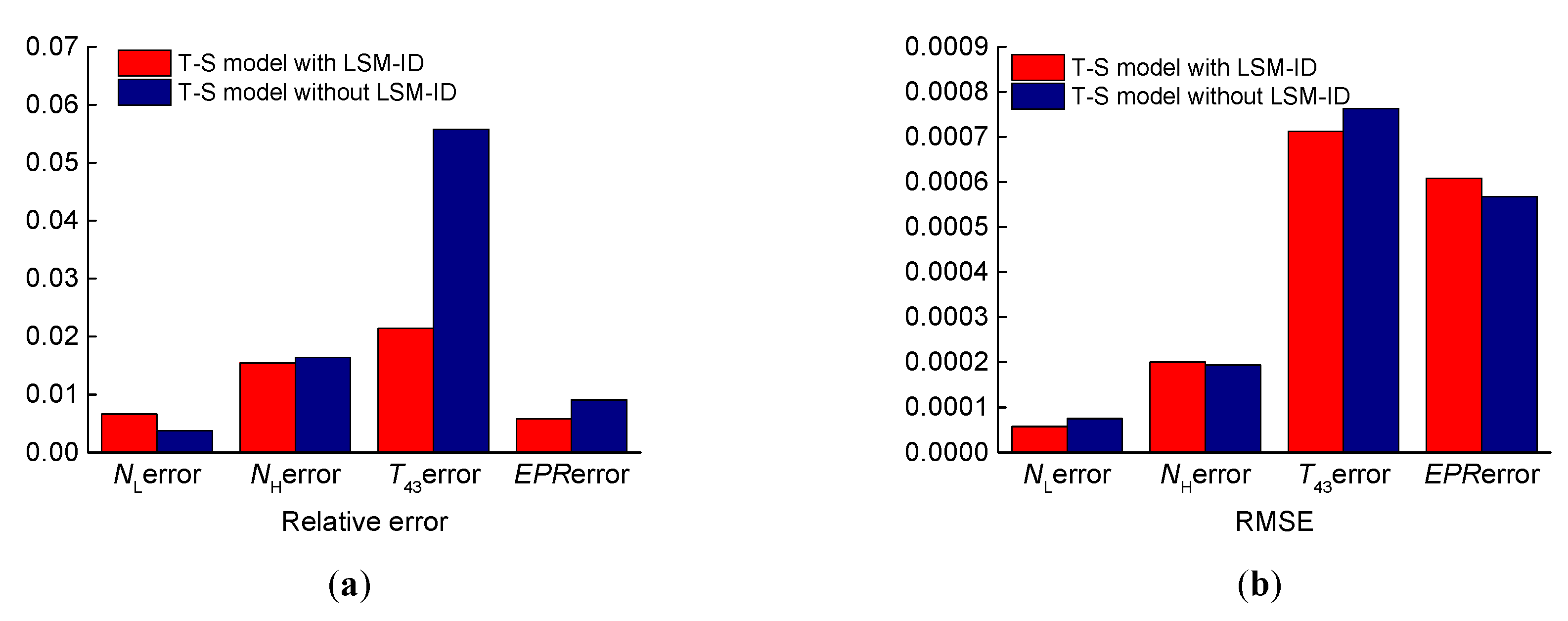

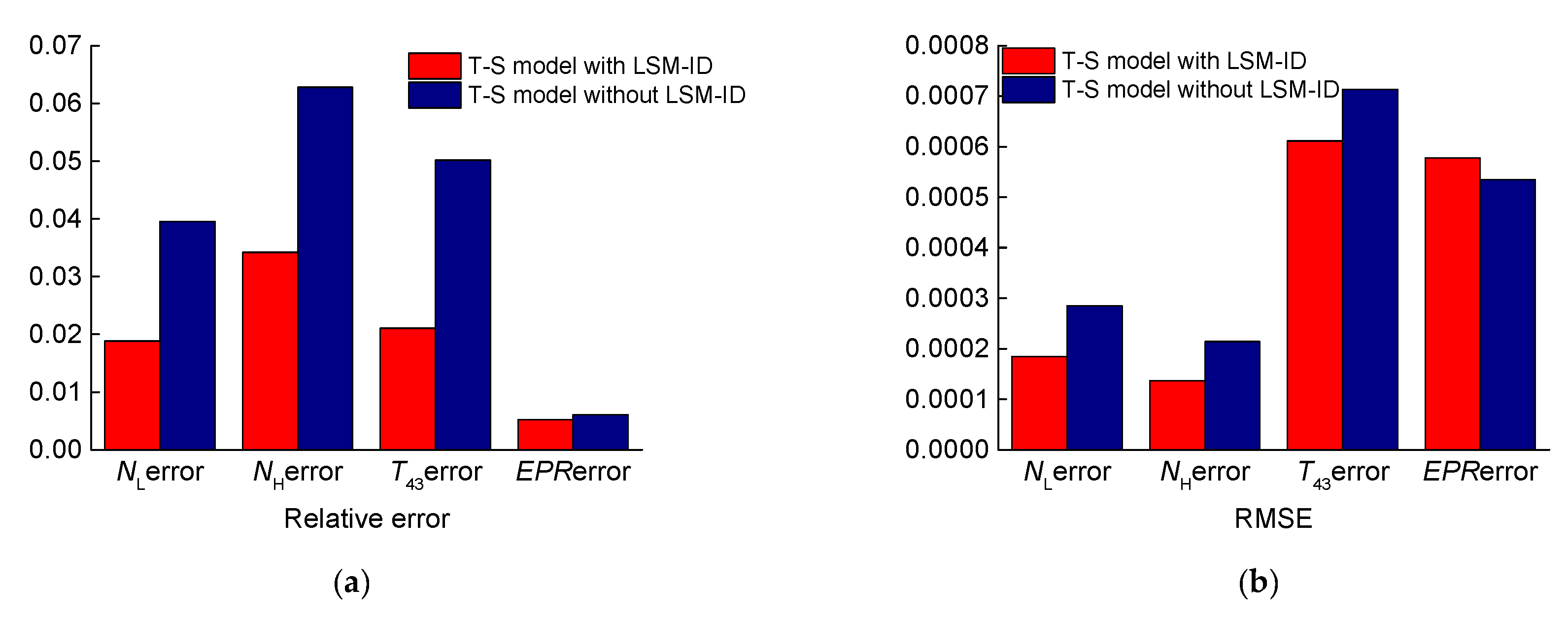

In this paper, an improved FCM algorithm was used to achieve the fuzzy division of a flight envelope, and the fuzzy division regions and clustering centers were obtained. The state-space model was used as the subsequent part of the T–S fuzzy model, and the weight of the T–S fuzzy model was identified, allowing the T–S fuzzy model of an aeroengine within the full envelope to be obtained. (1) By comparing with the nonlinear model, it was proven that this modeling method has good accuracy, and all the four steady-state outputs met an error of <5%. (2) The identification method proposed in this paper had high identification accuracy and strong generalization, so this identification algorithm can also be used for the identification of other complex nonlinear systems with time-varying uncertainties.

Via the positive results of the model verification, further efforts are encouraged. (1) The engine data in bench test data and flight data could be used for further model verification, which would facilitate the application of the resulting T–S fuzzy model to real turbofan engines. (2) The proposed modeling algorithm could be applied to nonlinear system with large-scale nonlinear dynamics, such as turboshaft engines, electric pumps and mechanical hydraulic systems.