On the Kaiser Effect of Rock under Cyclic Loading and Unloading Conditions: Insights from Acoustic Emission Monitoring

Abstract

:1. Introduction

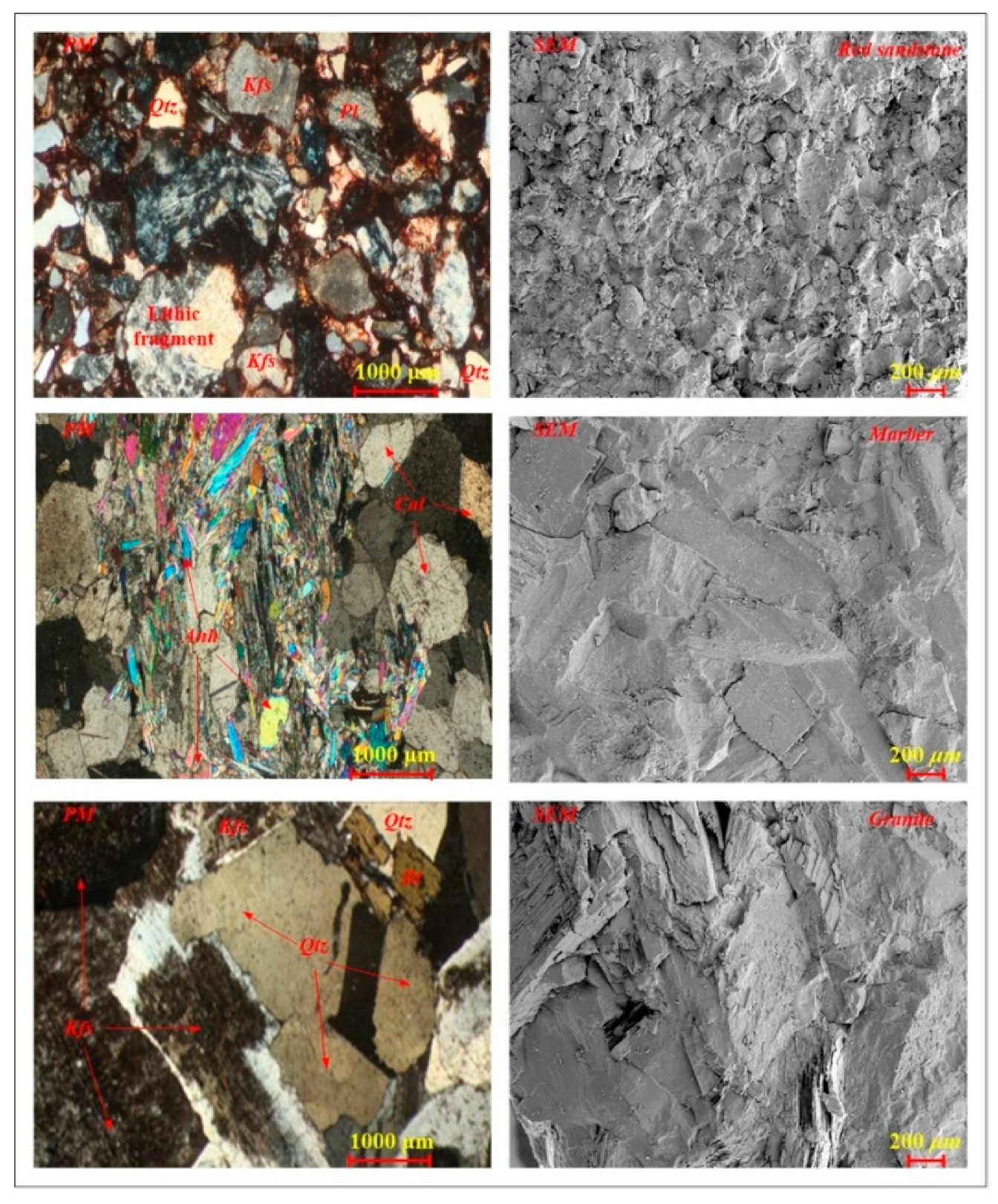

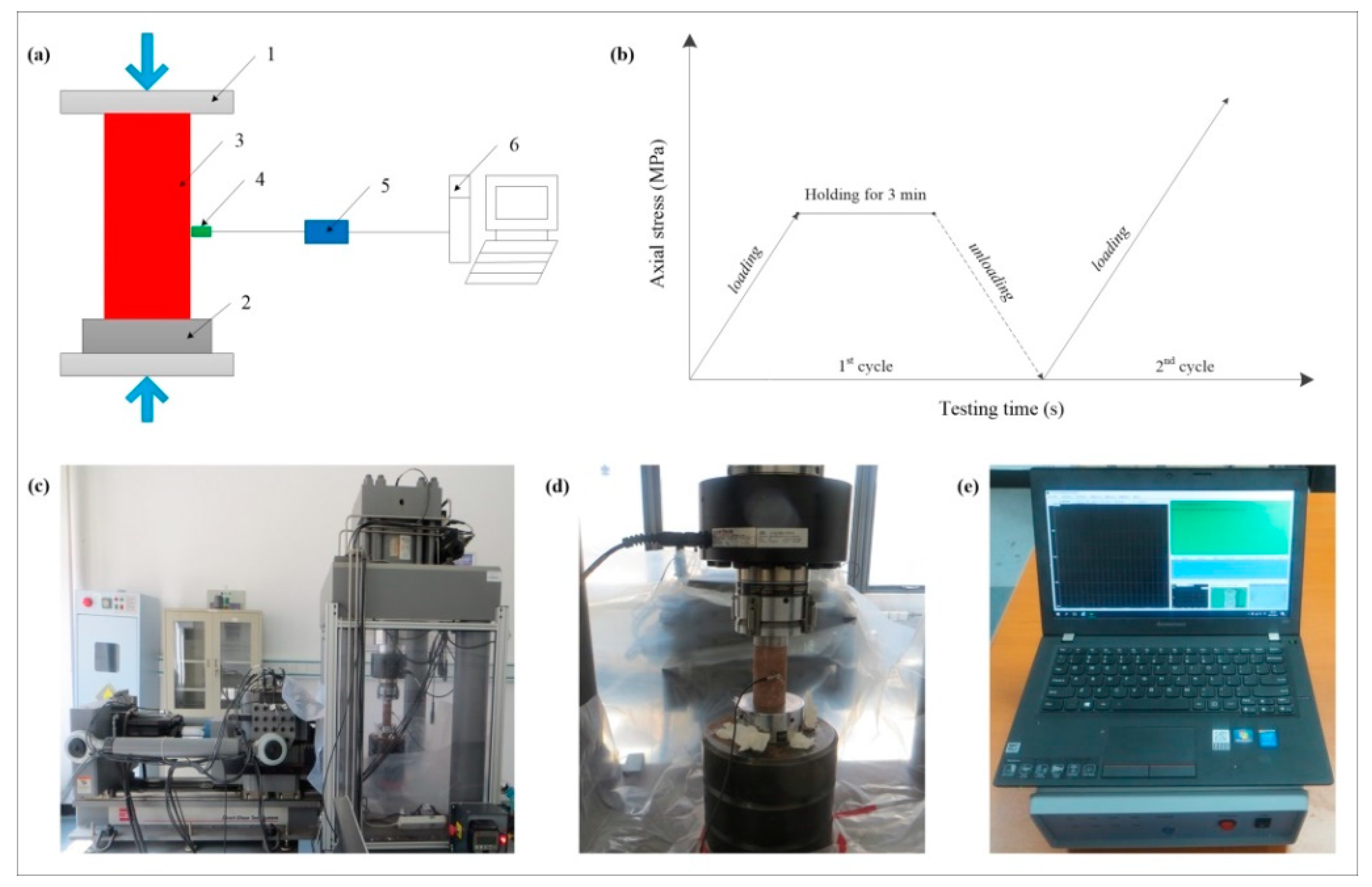

2. Materials and Methods

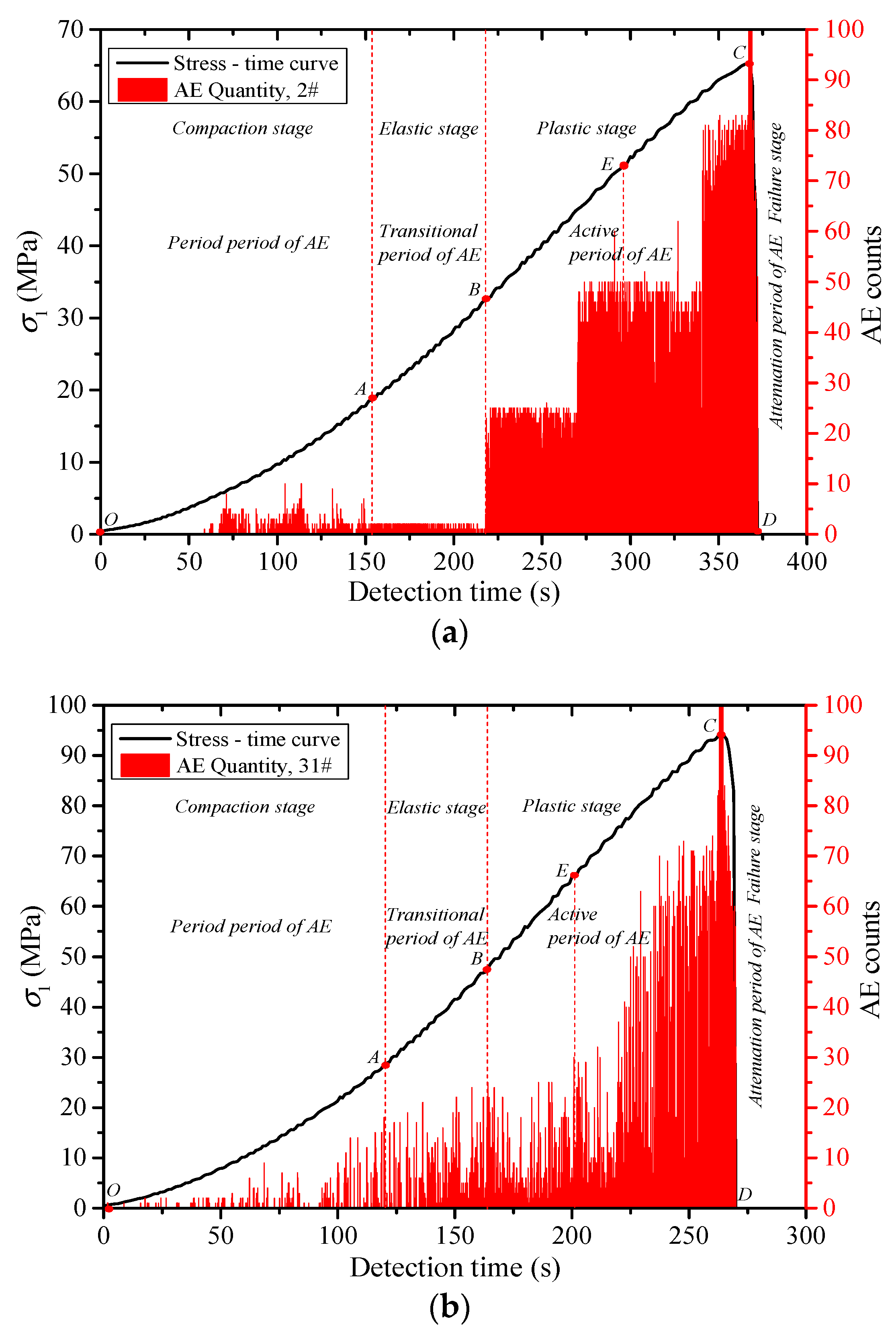

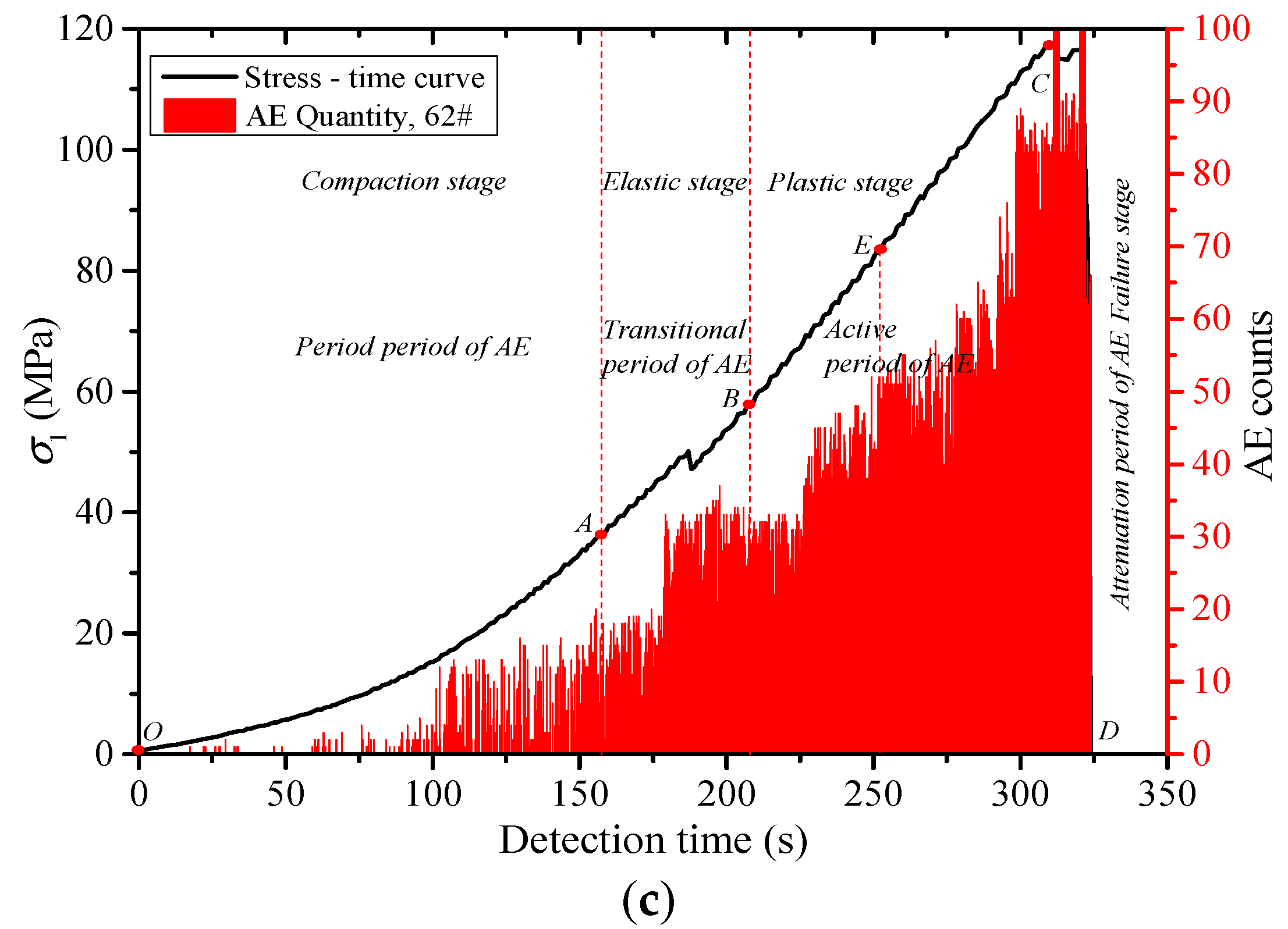

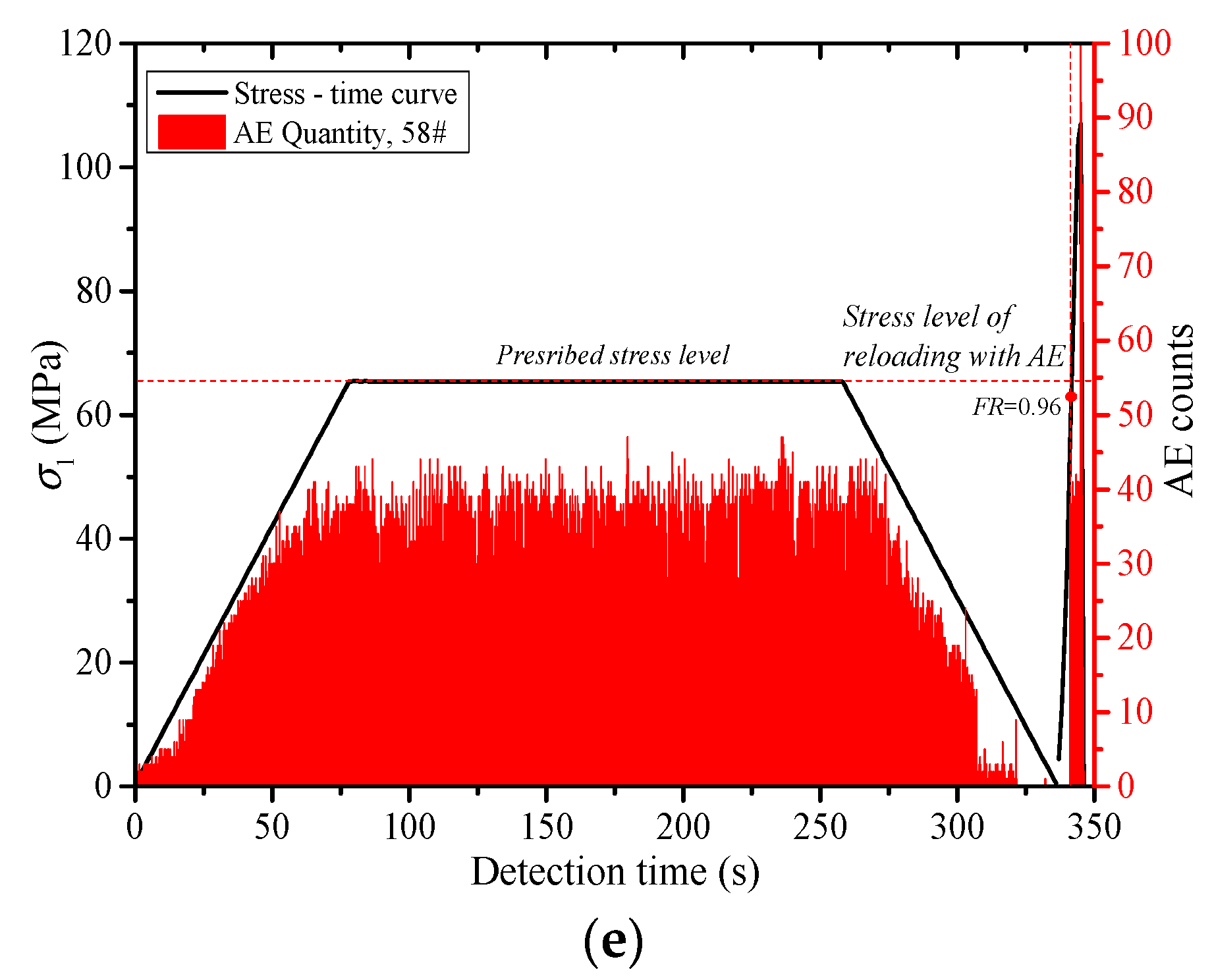

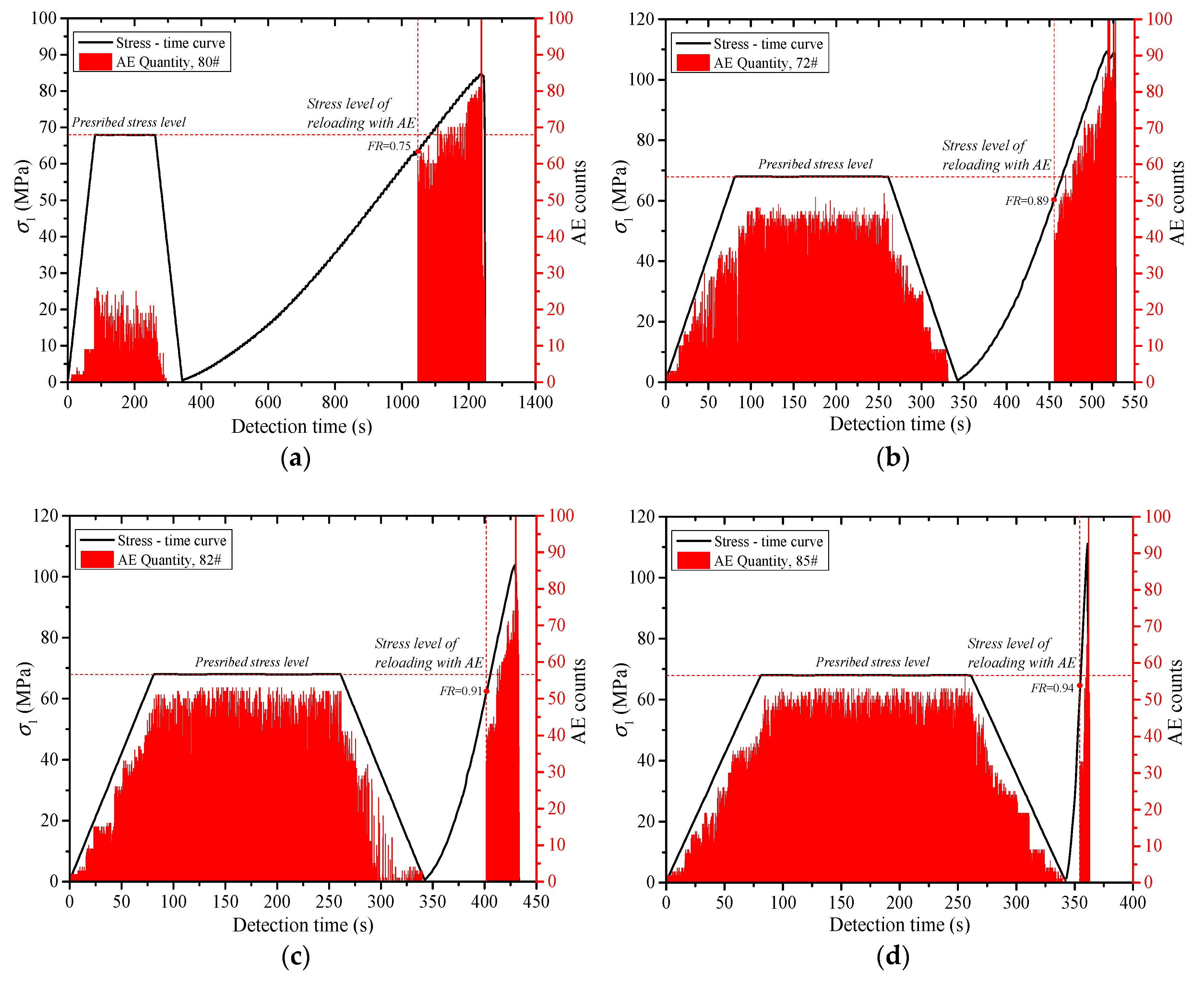

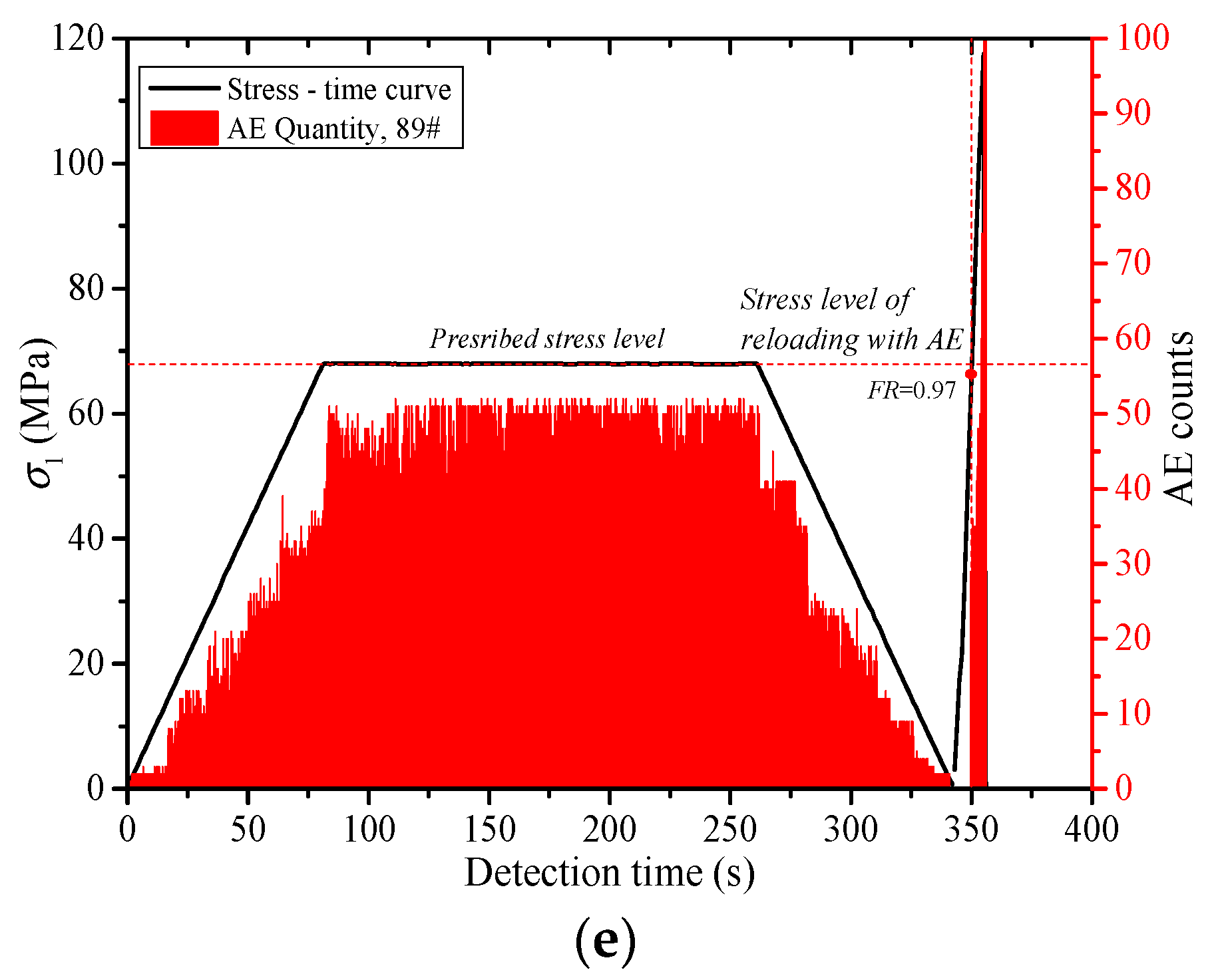

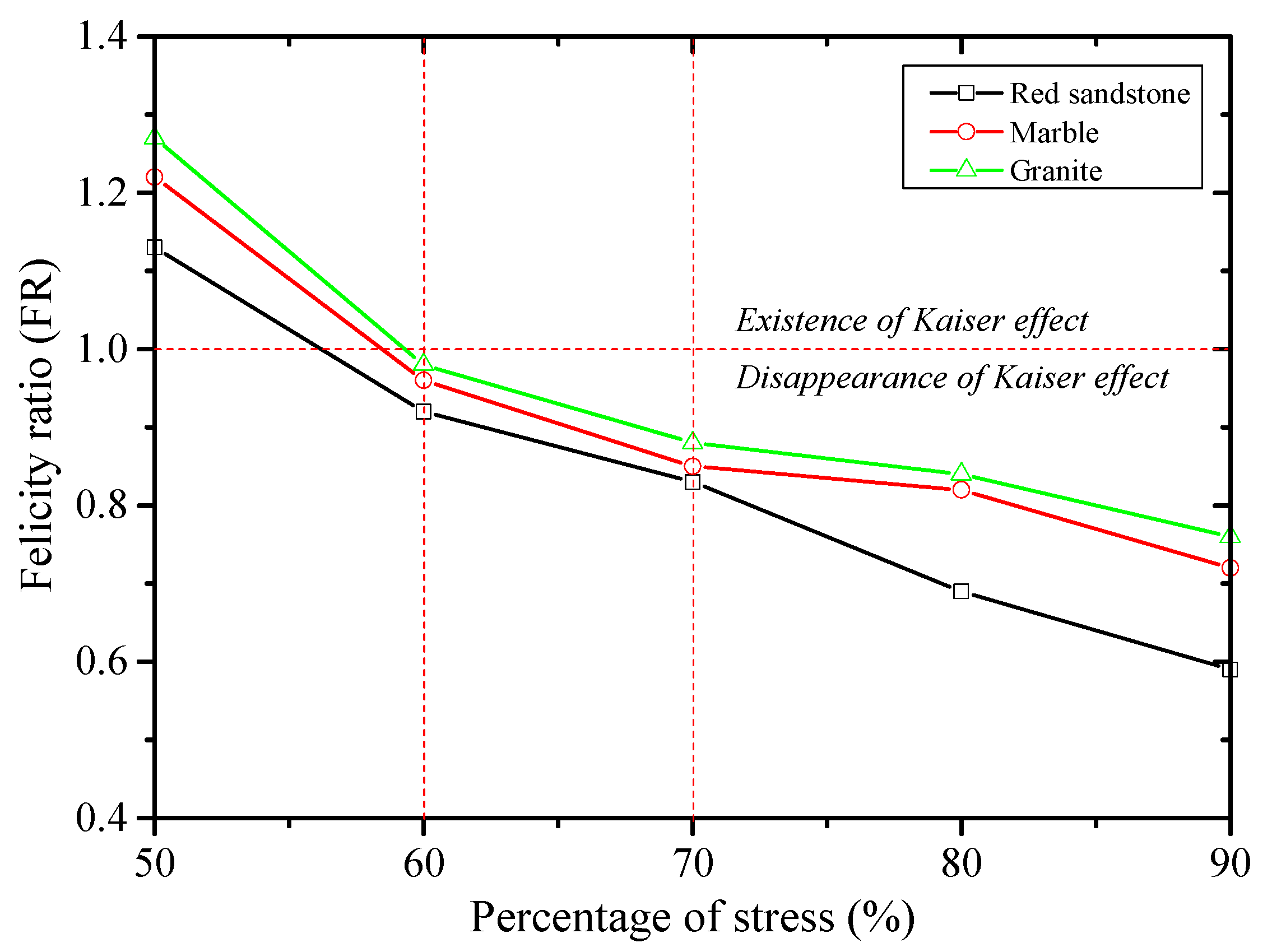

3. Results

4. Discussion

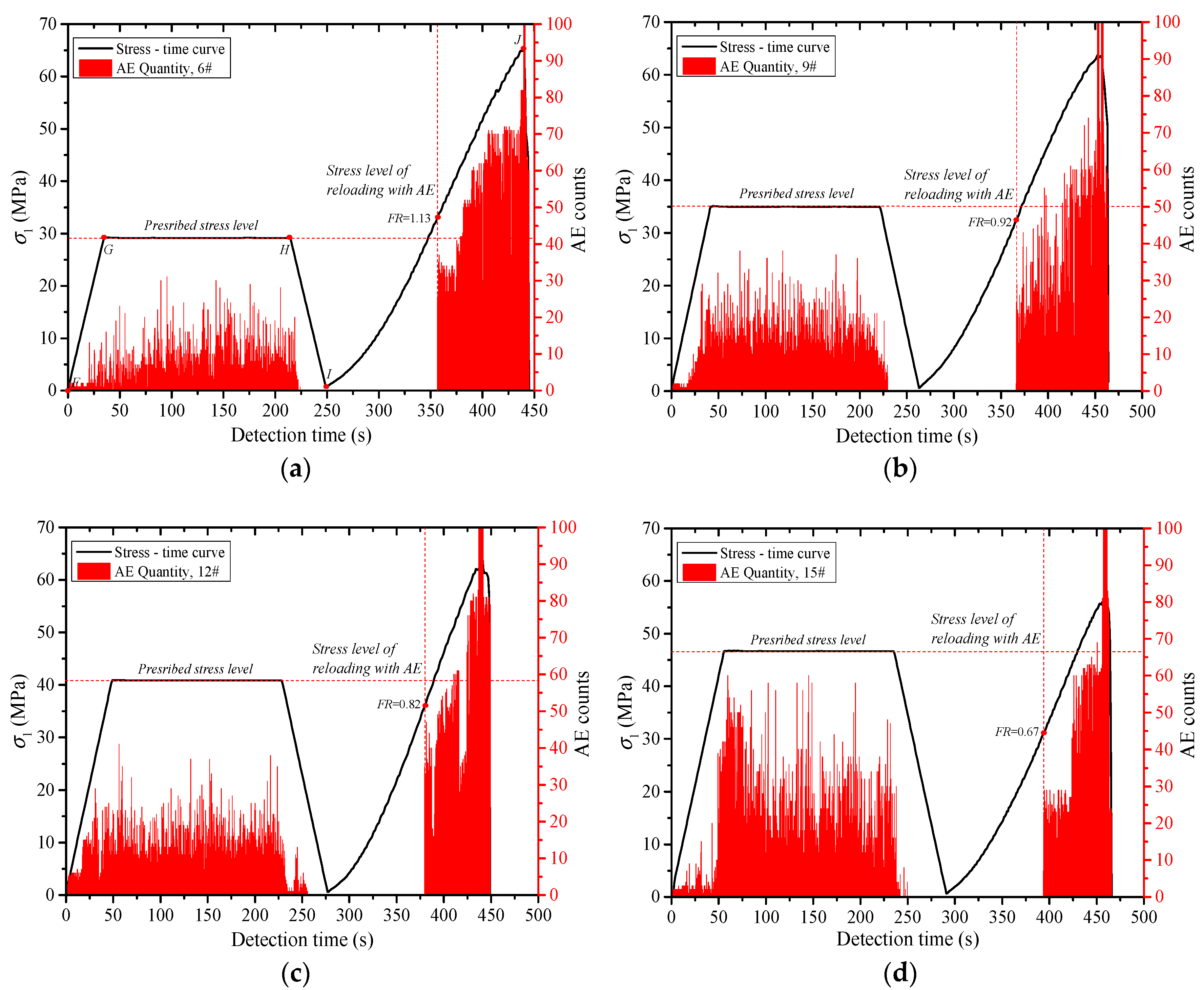

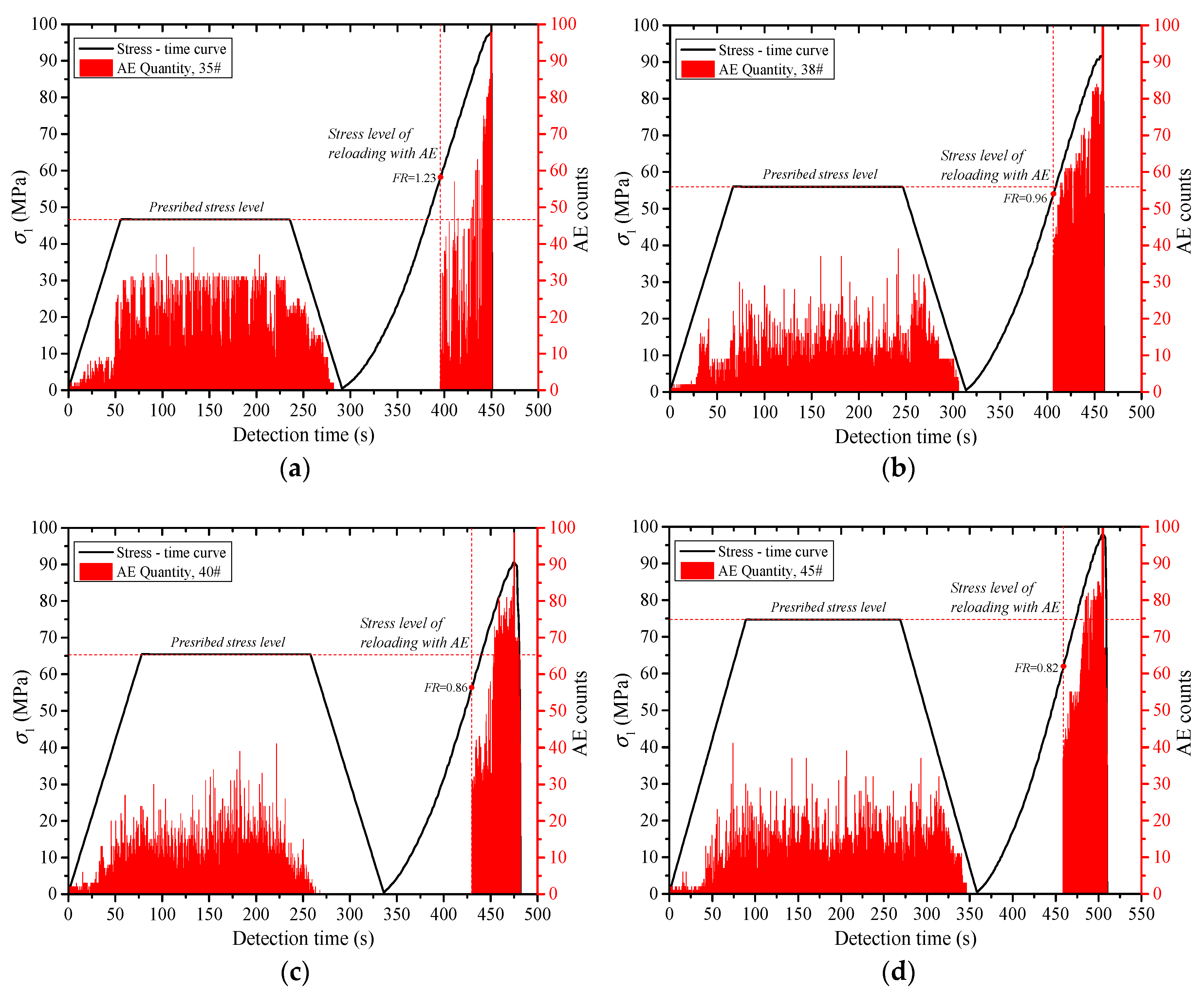

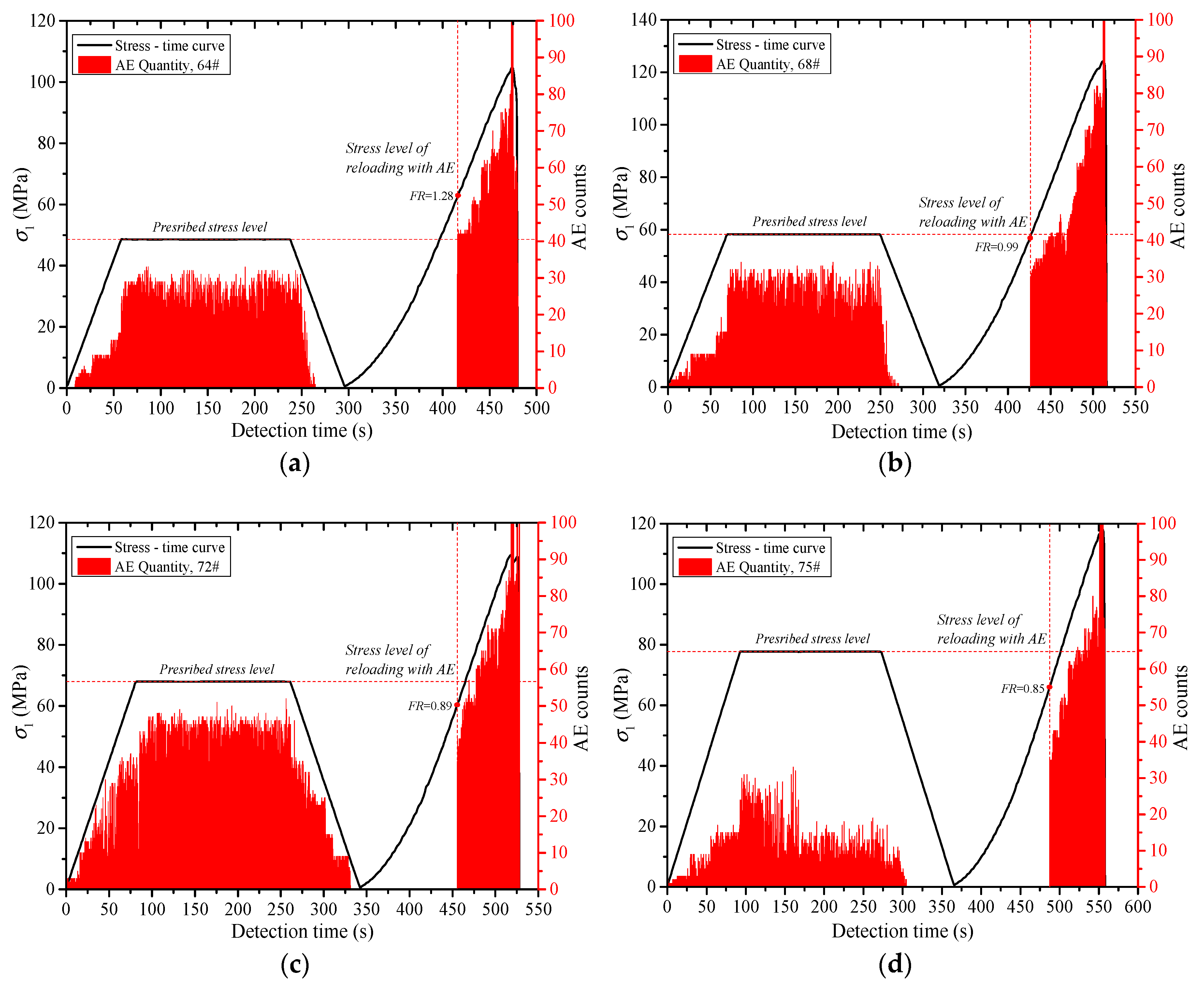

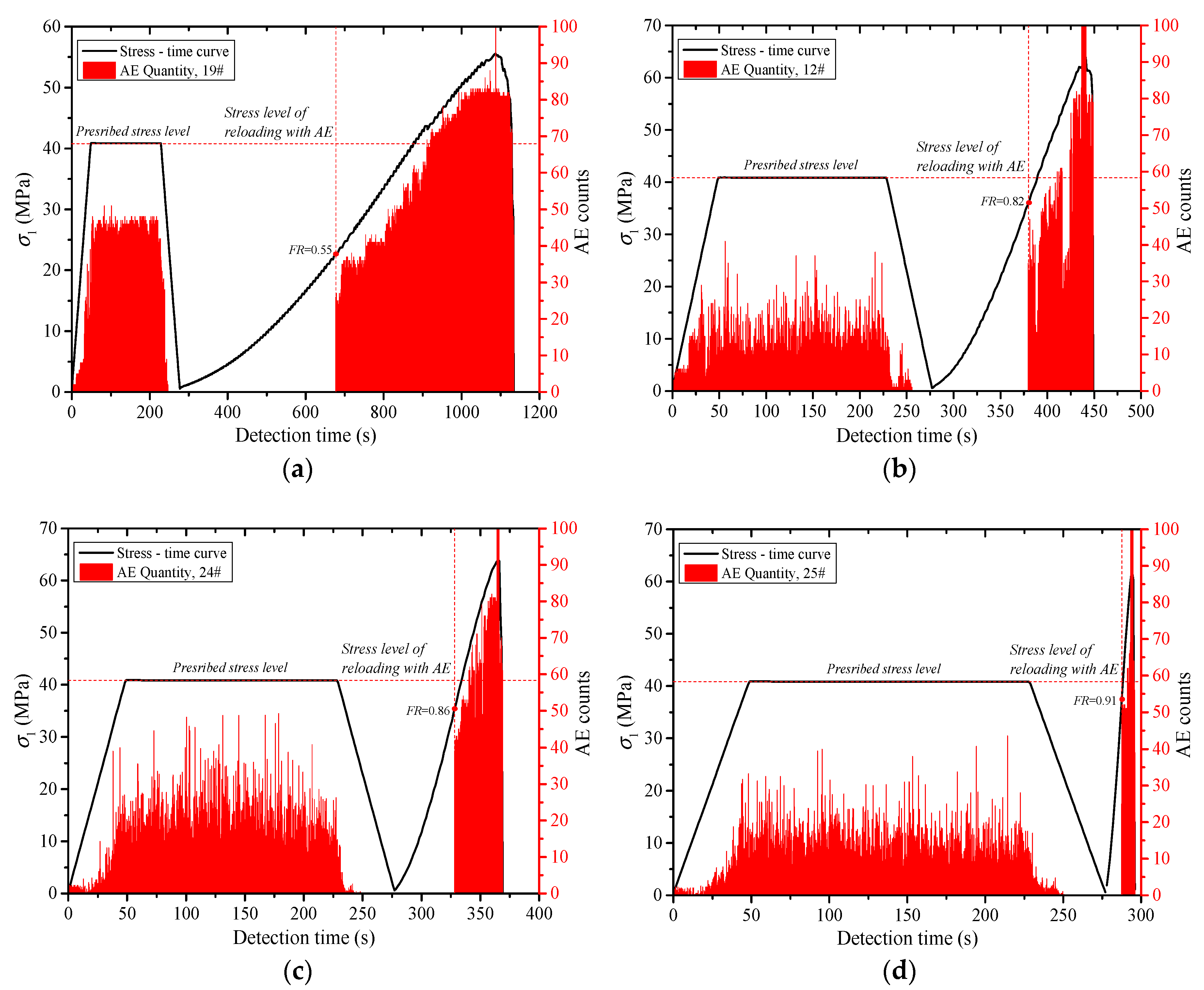

4.1. Effect of Stress Level on the Kaiser Effect

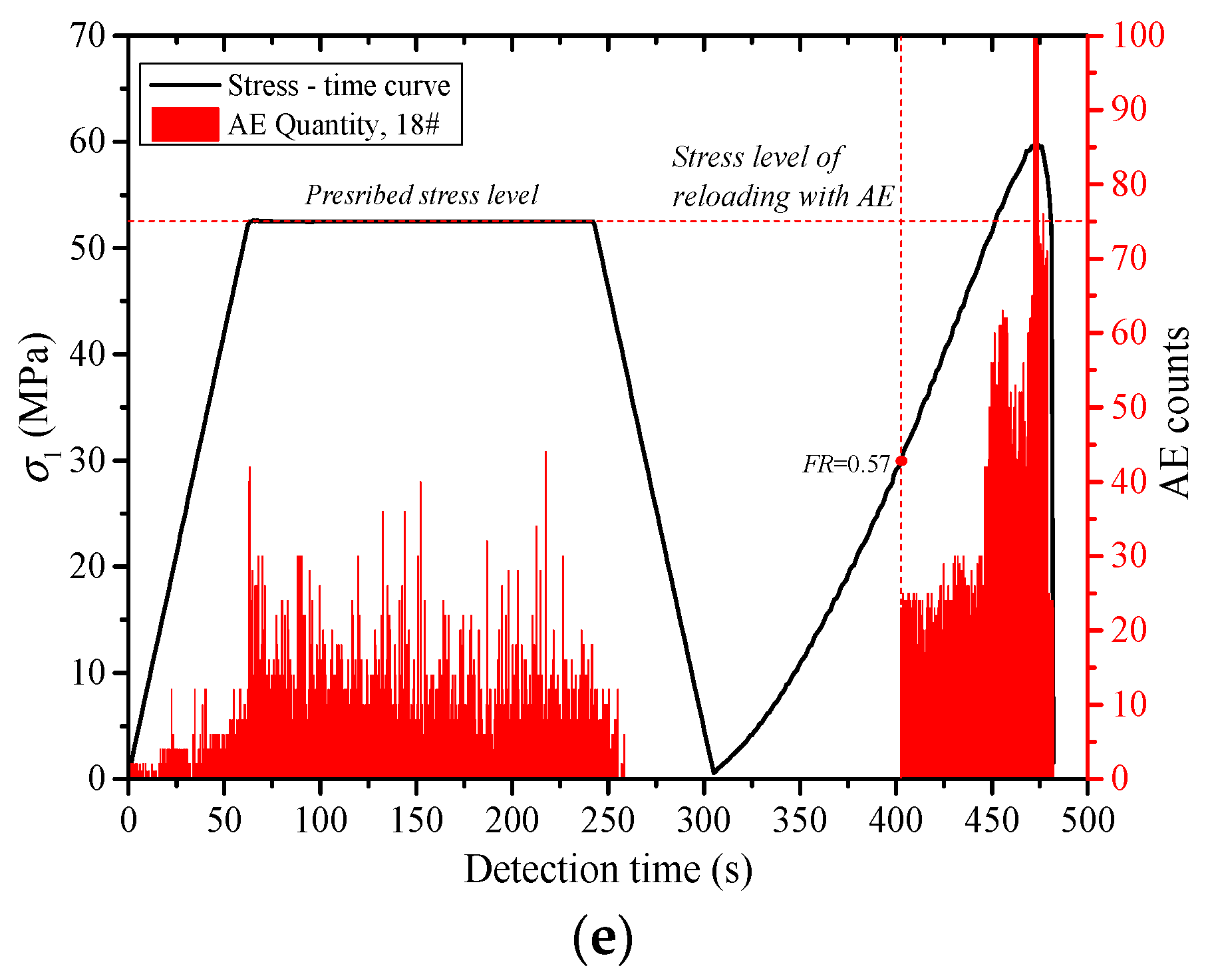

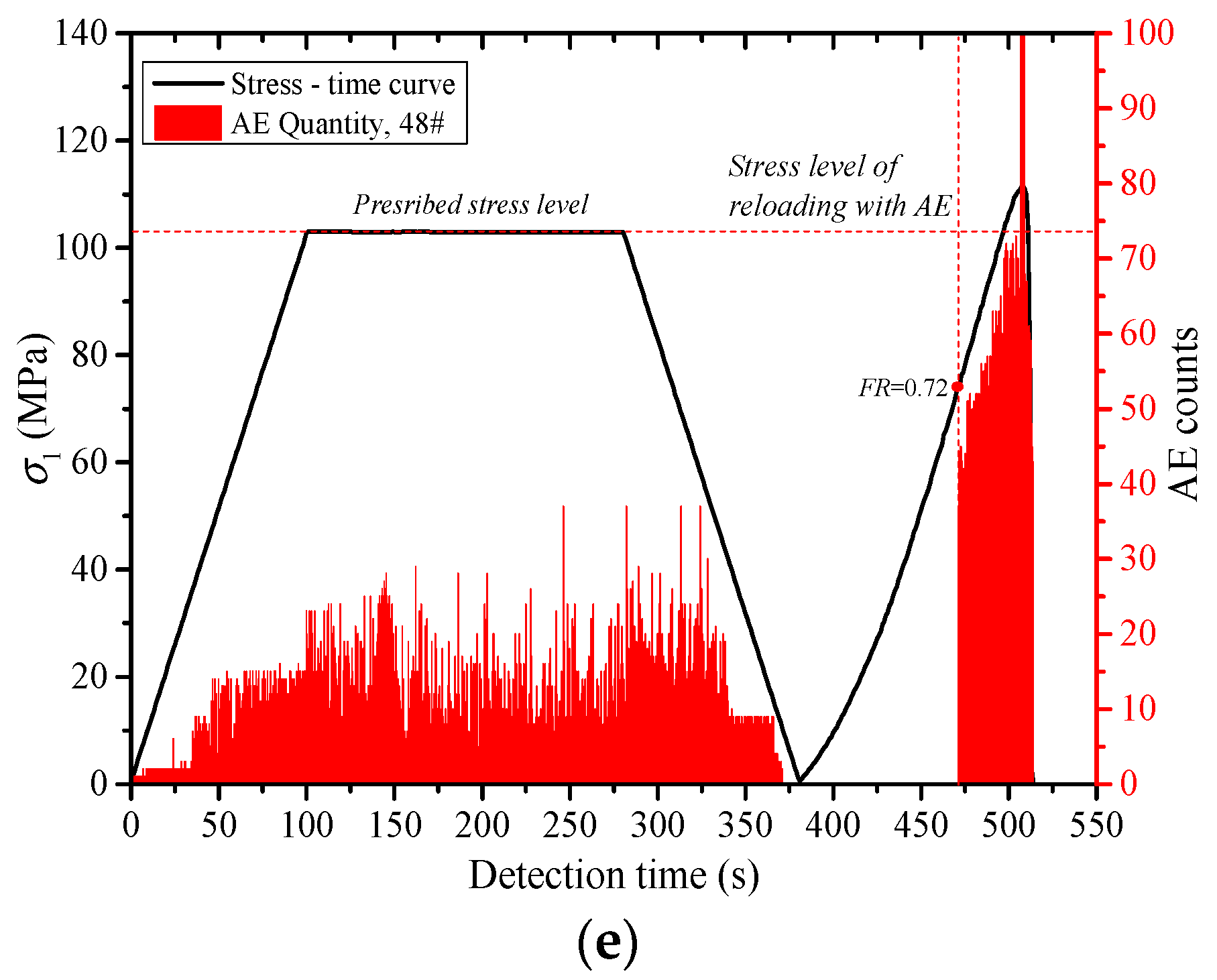

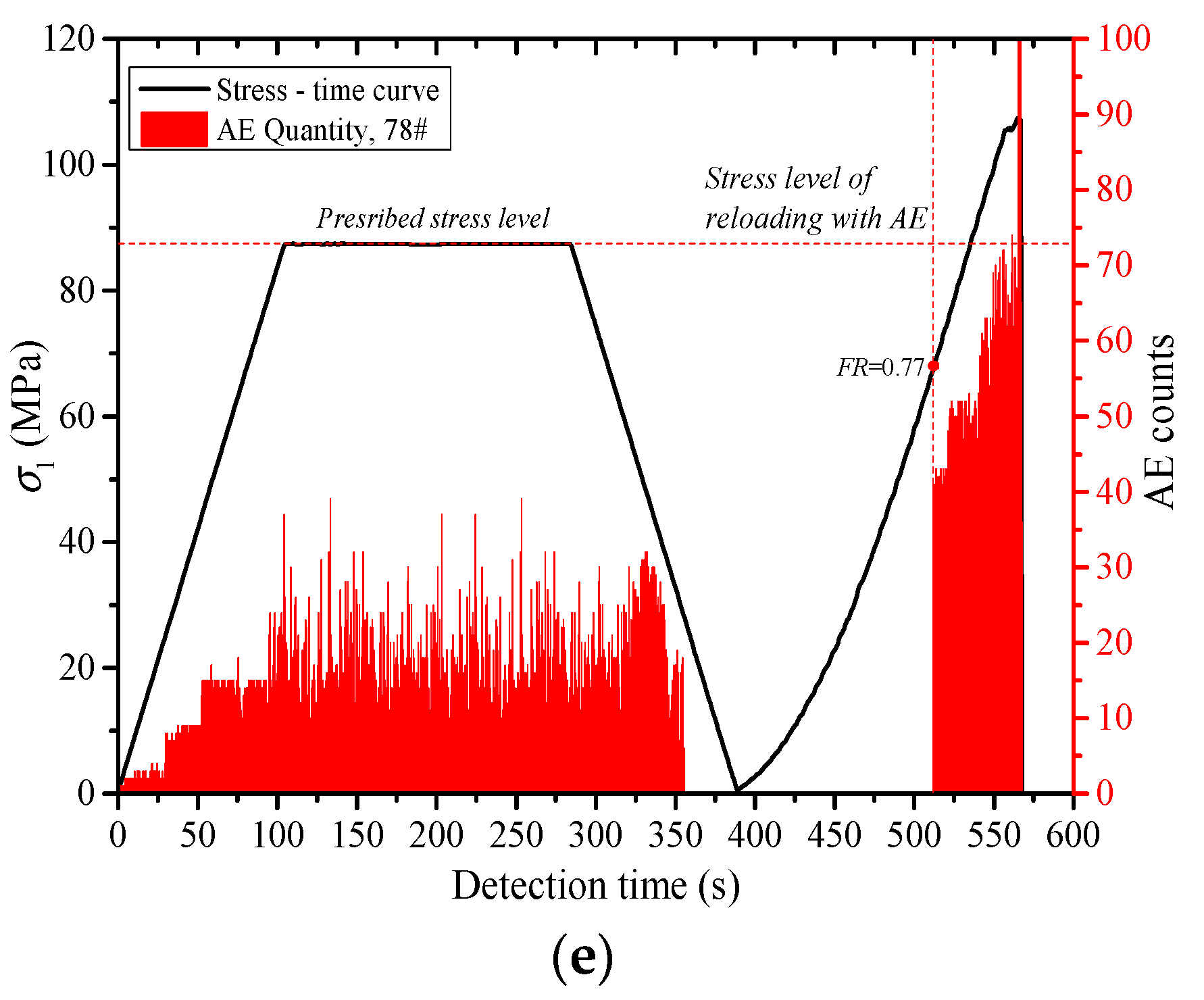

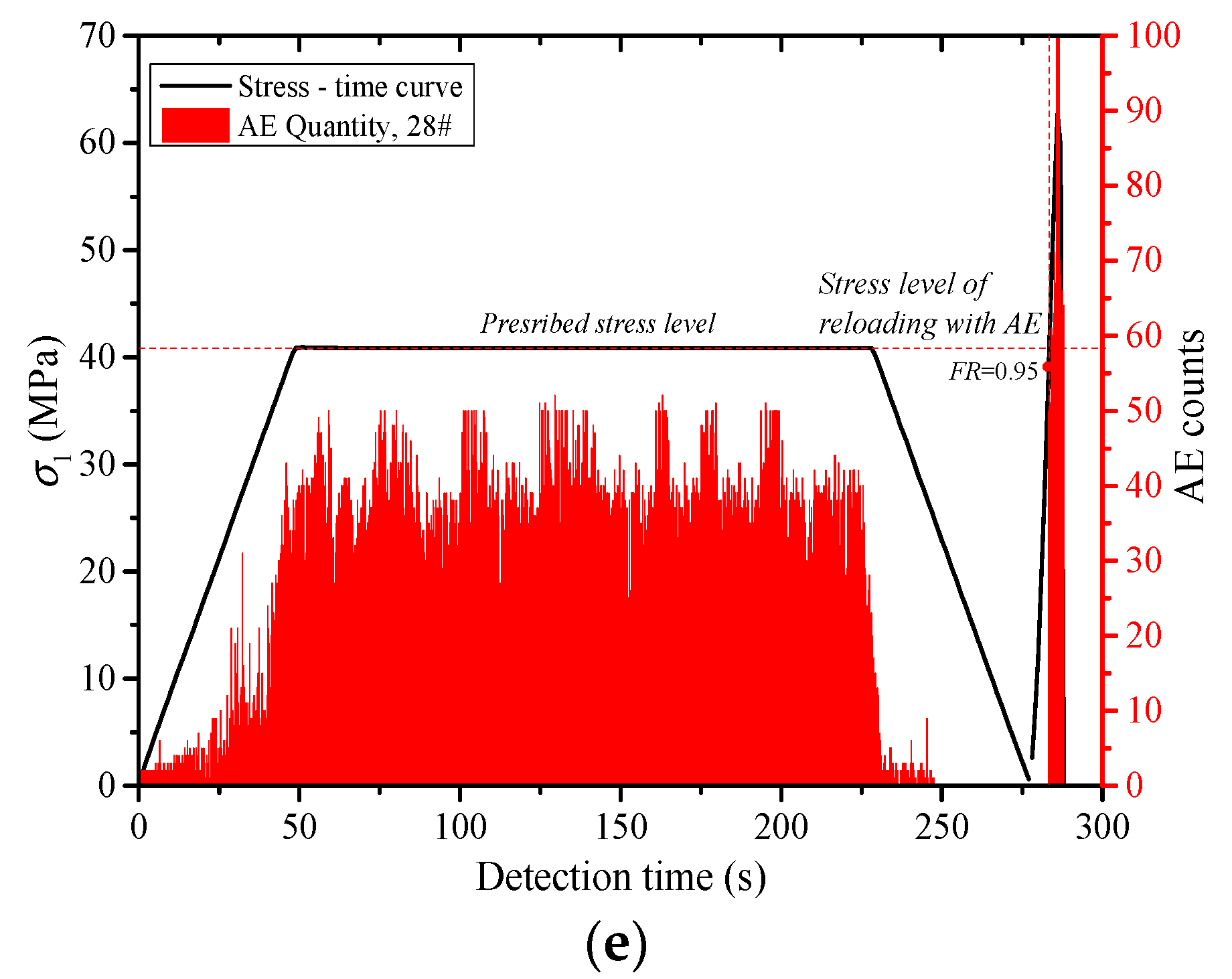

4.2. Effect of Loading Rate on the Kaiser Effect

5. Conclusions

- (1)

- The acoustic emission under uniaxial compression displays obvious stages. The acoustic emission evolution of three types of rocks corresponds to the compaction stage, elastic stage, yield stage and post-peak stress drop stage of the rock deformation and failure process, which is divided into quiet period, transition period, active period and decay period of the acoustic emission. Through the cyclic loading test, the generation of the friction-type acoustic emission can be effectively inhibited, which is beneficial to the identification of the stress point of the Kaiser effect in the subsequent reloading stage.

- (2)

- The Kaiser effect of the rock is greatly affected by the loading stress level (σA). When σA ≤ 0.5 σc, the Kaiser effect occurs obviously after the first loading stress level is exceeded during reloading. When σA = 0.6 σc, whether the Kaiser effect appears or not is closely related to lithology. The greater the hardness of the rock, the more obvious the Kaiser effect. When σA ≥ 0.7σc, the Kaiser effect disappears. Usually, the dilatancy stress (cyclic peak stress) does not exceed 70% of the uniaxial compressive strength (σc) of the rock, and the stress point can be the threshold to determine whether the Kaiser effect occurs.

- (3)

- The higher the loading rate (lr) is, the larger the growth rate of the existing micro cracks and the new cracks in the rock specimens is. The greater the degree of the damage in the rock is, the more the quantity of the acoustic emissions is. With the increase of lr, the Felicity rate (FR) increases, and the Kaiser effect appears easily. When lr < 0.01 mm/s, the effect of lr on FR is relatively large. FR increased rapidly along with the increase of lr. When lr ≥ 0.01 mm/s, FR increased slowly as lr increased.

Author Contributions

Funding

Conflicts of Interest

References

- Seto, M.; Utagawa, M.; Katsuyama, K.; Nag, D.K.; Vutukuri, V.S. In situ stress determination by acoustic emission technique. Int. J. Rock Mech. Min. Sci. 2007, 34, 281–296. [Google Scholar] [CrossRef]

- Jin, Y.; Qi, Z.L.; Chen, M.; Zhang, G.Q.; Xu, G.Q. Time-sensitivity of the Kaiser effect of acoustic emission in limestone and its application to measurements of in situ stress. Pet. Sci. 2009, 6, 176–180. [Google Scholar] [CrossRef]

- Chmel, A.; Shcherbakov, I. A comparative acoustic emission study of compression and impact fracture in granite. Int. J. Rock Mech. Min. 2003, 64, 56–59. [Google Scholar] [CrossRef]

- Damani, A.; Sondergeld, C.H.; Rai, C.S. Experimental investigation of in situ and injection fluid effect on hydraulic fracture mechanism using acoustic emission in Tennessee sandstone. J. Pet. Sci. Eng. 2018, 171, 315–324. [Google Scholar] [CrossRef]

- Alkan, H.; Cinar, Y.; Pusch, G. Rock salt dilatancy boundary from combined acoustic emission and triaxial compression tests. Int. J. Rock Mech. Min. 2007, 44, 108–119. [Google Scholar] [CrossRef]

- Kim, J.S.; Lee, K.S.; Cho, W.J.; Choi, H.J.; Cho, G.C. A comparative evaluation of stress-strain and acoustic emission methods for quantitative damage assessments of brittle rock. Rock Mech. Rock Eng. 2015, 48, 495–508. [Google Scholar] [CrossRef]

- He, Q.Y.; Li, Y.C.; She, S. Mechanical Properties of Basalt Specimens Under Combined Compression and Shear Loading at Low Strain Rates. Rock Mech. Rock Eng. 2019, 1–12. [Google Scholar] [CrossRef]

- Li, Y.C.; Sun, S.Y.; Tang, C.A. Analytical prediction of the shear behaviour of rock joints with quantified waviness and unevenness through wavelet analysis. Rock Mech. Rock Eng. 2019, 1–13. [Google Scholar] [CrossRef]

- Li, N.; Zhang, S.C.; Zou, Y.S.; Ma, X.F.; Zhang, Z.P.; Li, S.H.; Chen, M.; Sun, Y.Y. Acoustic emission response of laboratory hydraulic fracturing in layered shale. Rock Mech. Rock Eng. 2018, 51, 3395–3406. [Google Scholar] [CrossRef]

- Khazaei, C.; Hazzard, J.; Chalaturnyk, R. Damage quantification of intact rocks using acoustic emission energies recorded during uniaxial compression test and discrete element modeling. Comput. Geotech. 2015, 67, 94–102. [Google Scholar] [CrossRef]

- Zhang, Z.P.; Zhang, R.; Xie, H.P.; Liu, J.F.; Were, P. Differences in the acoustic emission characteristics of rock salt compared with granite and marble during the damage evolution process. Environ. Earth Sci. 2015, 73, 6987–6999. [Google Scholar] [CrossRef]

- Zhang, J.; Ai, C.; Li, Y.W.; Che, M.G.; Gao, R.; Zeng, J. Energy-based brittleness index and acoustic emission characteristics of anisotropic coal under triaxial stress condition. Rock Mech. Rock Eng. 2018, 51, 3343–3360. [Google Scholar] [CrossRef]

- Goodman, R.E. Subaudible noise during compression of rocks. Geol. Soc. Am. Bull. 1963, 74, 487–490. [Google Scholar] [CrossRef]

- Yamshchikov, V.S.; Shkuratnik, V.L.; Lavrov, A.V. Memory effects in rocks (review). J. Min. Sci. 1994, 30, 463–473. [Google Scholar] [CrossRef]

- Filimonov, Y.L.; Lavrov, A.V.; Shafarenko, Y.M.; Shkuratnik, V.L. Memory effects in rock salt under triaxial stress state and their use for stress measurement in a rock mass. Rock Mech. Rock Eng. 2001, 34, 275–291. [Google Scholar] [CrossRef]

- Lavrov, A. Fracture-induced physical phenomena and memory effects in rocks: A review. Strain 2005, 41, 135–149. [Google Scholar] [CrossRef]

- Tuncay, E.; Ulusay, R. Relation between Kaiser effect levels and pre-stresses applied in the laboratory. Int. J. Rock Mech. Min. 2008, 45, 524–537. [Google Scholar] [CrossRef]

- Tuncay, E.; Obara, Y. Comparison of stresses obtained from acoustic emission and compact conical-ended borehole overcoring techniques and an evaluation of the Kaiser effect level. Bull. Eng. Geol. Environ. 2012, 71, 367–377. [Google Scholar] [CrossRef]

- Bai, X.; Zhang, D.M.; Wang, H.; Li, S.J.; Rao, Z. A novel in situ stress measurement method based on acoustic emission Kaiser effect: A theoretical and experimental study. R. Soc. Open Sci. 2018, 5, 1–17. [Google Scholar] [CrossRef]

- Manthei, G. Characterization of acoustic emission sources in a rock salt specimen under triaxial compression. Bull. Seismol. Soc. Am. 2005, 95, 1674–1700. [Google Scholar] [CrossRef]

- Rao, M.V.M.S.; Ramana, Y.V. A study of progressive failure of rock under cyclic loading by ultrasonic and AE monitoring techniques. Rock Mech. Rock Eng. 1992, 25, 237–251. [Google Scholar] [CrossRef]

- Yoshikawa, S.; Mogi, K. A new method for estimation of the crustal stress from cored rock samples: Laboratory study in the case of uniaxial compression. Tectonophysics 1981, 74, 323–339. [Google Scholar] [CrossRef]

- Kurita, K.; Fujii, N. Stress memory of crystalline rocks in acoustic emission. Geophys. Res. Lett. 1979, 6, 9–12. [Google Scholar] [CrossRef]

- Lockner, D.A. The role of acoustic emission in the study of rock fracture. Int. J. Rock Mech. Min. Geomech. Abstr. 1993, 30, 893–899. [Google Scholar] [CrossRef]

- Hsieh, A.; Dight, P.; Dyskin, A.V. The rock stress memory unrecoverable by the Kaiser effect method. Int. J. Rock Mech. Min. 2015, 75, 190–195. [Google Scholar] [CrossRef]

- Lavrov, A. The Kaiser effect in rocks: Principles and stress estimation techniques. Int. J. Rock Mech. Min. 2003, 40, 151–171. [Google Scholar] [CrossRef]

- Li, C.; Norlund, E. Experimental verification of the Kaiser effect in rocks. Rock Mech. Rock Eng. 1993, 26, 333–351. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, Y.L.; Yu, R.R.; Hu, L.Q.; Irfan, M. Effect of loading rate on the Felicity effect of three rock types. Rock Mech. Rock Eng. 2017, 50, 1673–1681. [Google Scholar] [CrossRef]

- Meng, Q.B.; Zhang, M.W.; Han, L.J.; Pu, H.; Nie, T.Y. Effects of acoustic emission and energy evolution of rock specimens under the uniaxial cyclic loading and unloading compression. Rock Mech. Rock Eng. 2016, 49, 3873–3886. [Google Scholar] [CrossRef]

- Meng, Q.B.; Zhang, M.W.; Han, L.J.; Pu, H.; Nie, T.Y. Acoustic emission characteristics of red sandstone specimens under uniaxial cyclic loading and unloading compression. Rock Mech. Rock Eng. 2018, 51, 969–988. [Google Scholar] [CrossRef]

- Lavrov, A. Kaiser effect observation in brittle rock cyclically loaded with different loading rates. Mech. Mater. 2001, 33, 669–677. [Google Scholar] [CrossRef]

- Cai, M.; Kaiser, P.K.; Suorineni, F.; Su, K. A study on the dynamic behavior of the Meuse/Haute-Marne argillite. Phys. Chem. Earth 2007, 32, 907–916. [Google Scholar] [CrossRef]

- Zhang, Q.B.; Zhao, J. A review of dynamic experimental techniques and mechanical behaviour of rock materials. Rock Mech. Rock Eng. 2014, 47, 1411–1478. [Google Scholar] [CrossRef]

- Martin, C.D. Seventeenth Canadian geotechnical colloquium: The effect of cohesion loss and stress path on brittle rock strength. Can. Geotech. J. 1997, 34, 698–725. [Google Scholar] [CrossRef]

- Ganne, P.; Vervoort, A.; Wevers, M. Quantification of pre-peak brittle damage: Correlation between acoustic emission and observed micro-fracturing. Int. J. Rock Mech. Min. 2007, 44, 720–729. [Google Scholar] [CrossRef]

- Yu, R.G.; Tian, Y.; Wang, X.X. Relation between stresses obtained from Kaiser effect under uniaxial compression and hydraulic fracturing. Rock Mech. Rock Eng. 2015, 48, 397–401. [Google Scholar] [CrossRef]

- Kranz, R.L. Crack growth and development during creep of Barre granite. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1979, 16, 23–35. [Google Scholar] [CrossRef]

- Yamamuro, J.A.; Lade, P.V. Effects of strain rate on instability of granular soils. Geotech. Test. J. 2014, 16, 304–313. [Google Scholar]

- Chong, K.P.; Boresi, A.P. Strain rate dependent mechanical properties of new albany reference shale. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1990, 27, 199–205. [Google Scholar] [CrossRef]

- Peng, S.S.; Podnieks, E.R. Relaxation and the behavior of failed rock. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1972, 9, 699–700. [Google Scholar] [CrossRef]

- Blanton, T.L. Effect of strain rates from 10−2 to 10/s in triaxial compression tests on three rocks. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1981, 18, 47–62. [Google Scholar] [CrossRef]

| Serial Number of Rock Sample | Prescribed Stress (σA, MPa) | ||||||

| 0.5 σc | 0.6 σc | 0.7 σc | 0.8 σc | 0.9 σc | |||

| Loading rate (lr, mm/s) | Red sandstone | 0.005 | 4–6 | 7–9 | 10–12 | 13–15 | 16–18 |

| Marble | 34–36 | 37–39 | 40–42 | 43–45 | 46–48 | ||

| Granite | 64–66 | 67–69 | 70–72 | 73–75 | 76–78 | ||

| Serial Number of Rock Sample | Loading Rate (lr, mm/s) | ||||||

| 0.001 | 0.005 | 0.01 | 0.05 | 0.1 | |||

| Prescribed stress (σA, MPa) | Red sandstone | 0.7σc | 19–21 | 10–12 | 22–24 | 25–27 | 28–30 |

| Marble | 49–51 | 40–42 | 52–54 | 55–57 | 58–60 | ||

| Granite | 79–81 | 70–72 | 82–84 | 85–87 | 88–90 | ||

| Felicity Rate (FR) | Loading Rate (lr, mm/s) | ||||||

| 0.001 | 0.005 | 0.01 | 0.05 | 0.1 | |||

| Loading rate (lr, mm/s) | Red sandstone | 0.005 | 0.55, 0.61, 0.53 | 0.83, 0.84, 0.82 | 0.87, 0.86, 0.86 | 0.91, 0.88, 0.91 | 0.95, 0.94, 0.93 |

| Marble | 0.69, 0.65, 0.66 | 0.86, 0.85, 0.85 | 0.90, 0.88, 0.87 | 0.93, 0.92, 0.91 | 0.96, 0.95, 0.94 | ||

| Granite | 0.73, 0.75, 0.71 | 0.88, 0.87, 0.89 | 0.91, 0.92, 0.92 | 0.94, 0.93, 0.95 | 0.97, 0.97, 0.98 | ||

| Serial Number of Rock Sample | Loading Rate (lr, mm/s) | ||||||

| 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | |||

| Prescribed stress level (σA, MPa) | Red sandstone | 0.7 σc | 1.14, 1.11, 1.13 | 0.95, 0.90, 0.92 | 0.83, 0.84, 0.82 | 0.71, 0.69, 0.67 | 0.60, 0.59, 0.57 |

| Marble | 1.21, 1.23, 1.22 | 0.97, 0.96, 0.95 | 0.86, 0.85, 0.85 | 0.82, 0.81, 0.82 | 0.72, 0.72, 0.72 | ||

| Granite | 1.28, 1.26, 1.27 | 0.97, 0.99, 0.98 | 0.88, 0.87, 0.89 | 0.84, 0.83, 0.85 | 0.76, 0.75, 0.77 | ||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, Q.; Chen, Y.; Zhang, M.; Han, L.; Pu, H.; Liu, J. On the Kaiser Effect of Rock under Cyclic Loading and Unloading Conditions: Insights from Acoustic Emission Monitoring. Energies 2019, 12, 3255. https://doi.org/10.3390/en12173255

Meng Q, Chen Y, Zhang M, Han L, Pu H, Liu J. On the Kaiser Effect of Rock under Cyclic Loading and Unloading Conditions: Insights from Acoustic Emission Monitoring. Energies. 2019; 12(17):3255. https://doi.org/10.3390/en12173255

Chicago/Turabian StyleMeng, Qingbin, Yanlong Chen, Mingwei Zhang, Lijun Han, Hai Pu, and Jiangfeng Liu. 2019. "On the Kaiser Effect of Rock under Cyclic Loading and Unloading Conditions: Insights from Acoustic Emission Monitoring" Energies 12, no. 17: 3255. https://doi.org/10.3390/en12173255

APA StyleMeng, Q., Chen, Y., Zhang, M., Han, L., Pu, H., & Liu, J. (2019). On the Kaiser Effect of Rock under Cyclic Loading and Unloading Conditions: Insights from Acoustic Emission Monitoring. Energies, 12(17), 3255. https://doi.org/10.3390/en12173255