Current-Limiting Soft Starting Method for a High-Voltage and High-Power Motor

Abstract

:1. Introduction

2. Method Principle

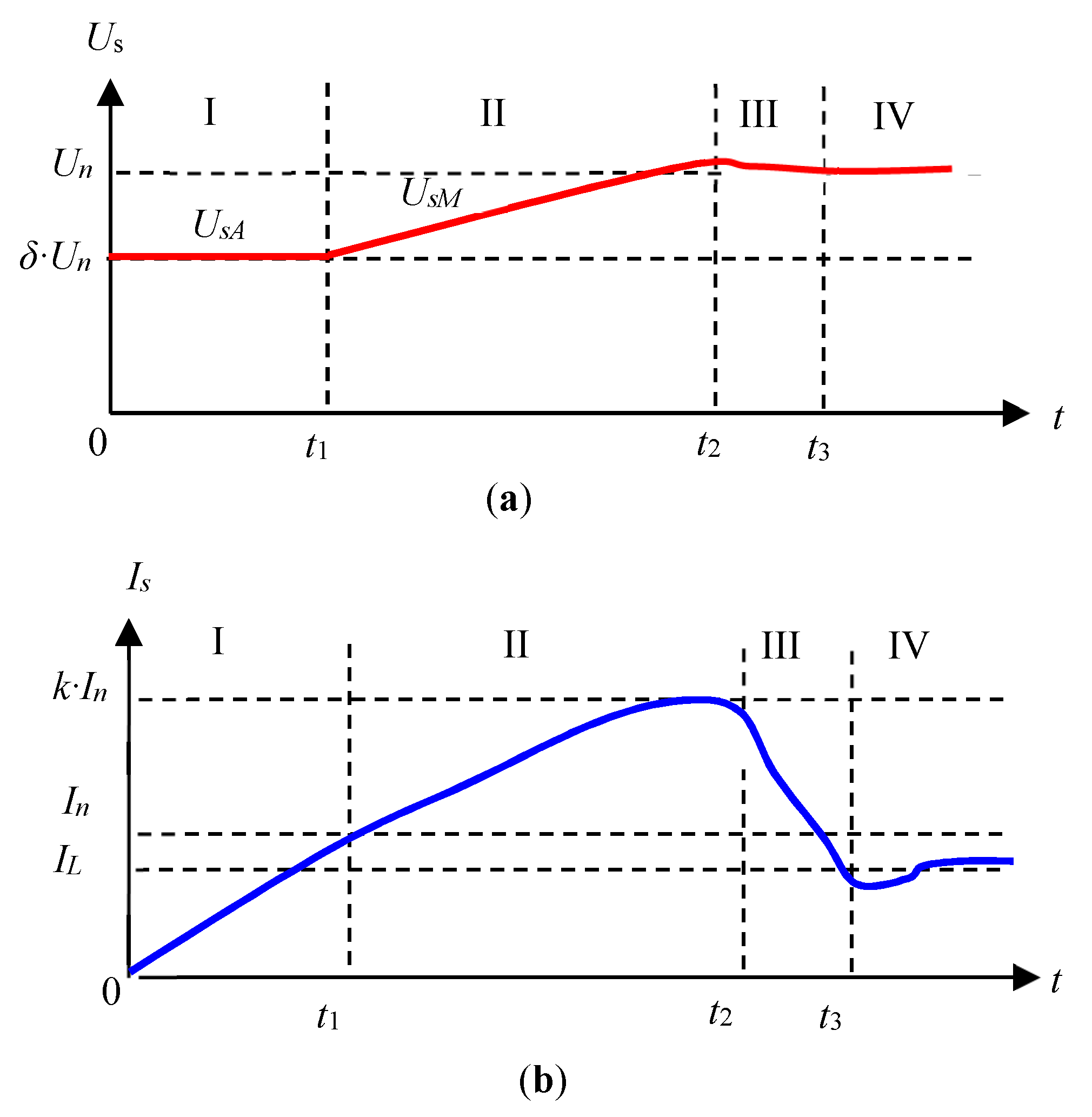

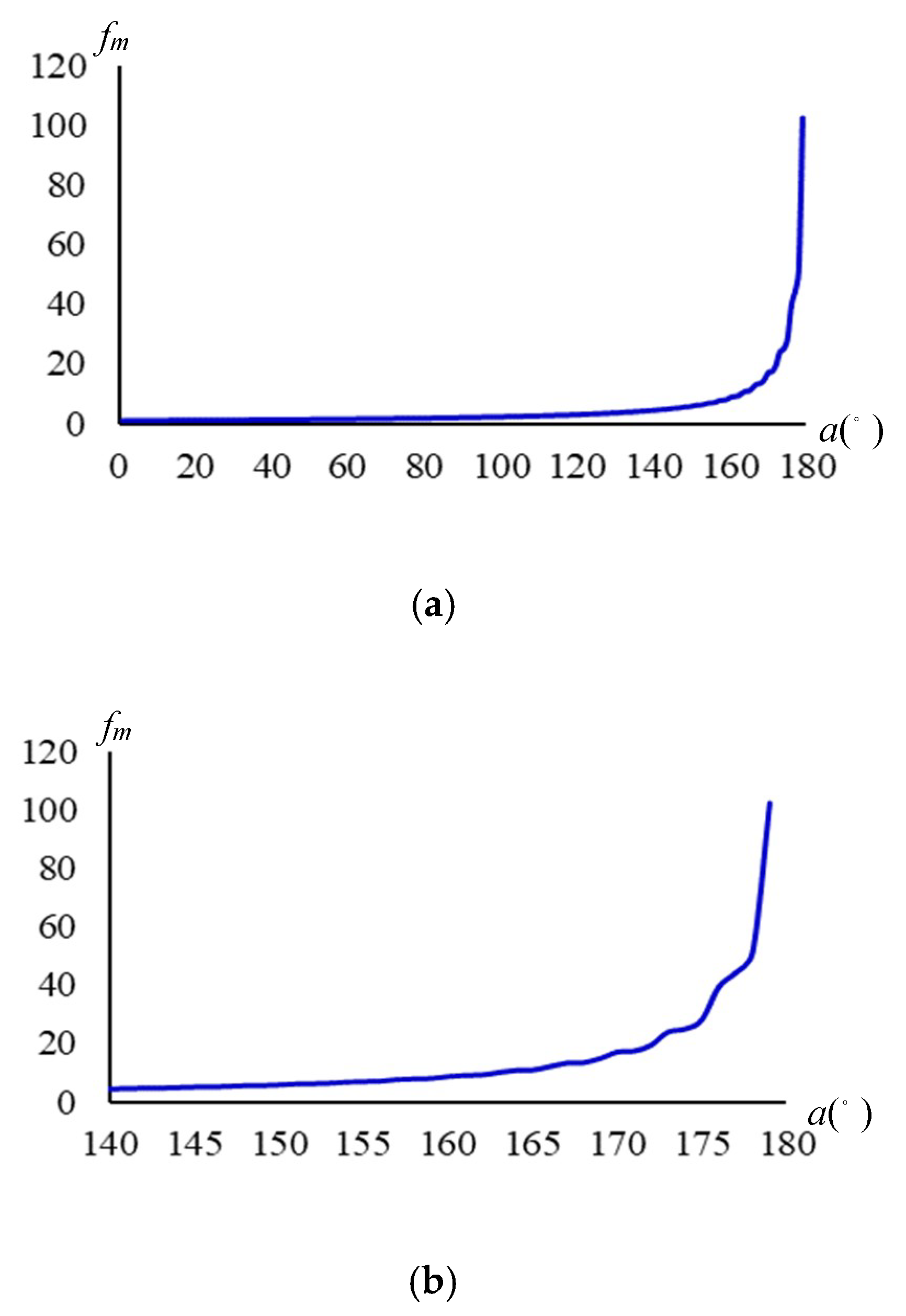

2.1. Current-Limiting Starting Characteristic Curve

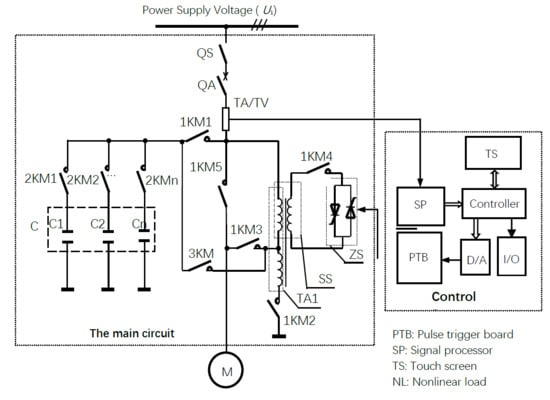

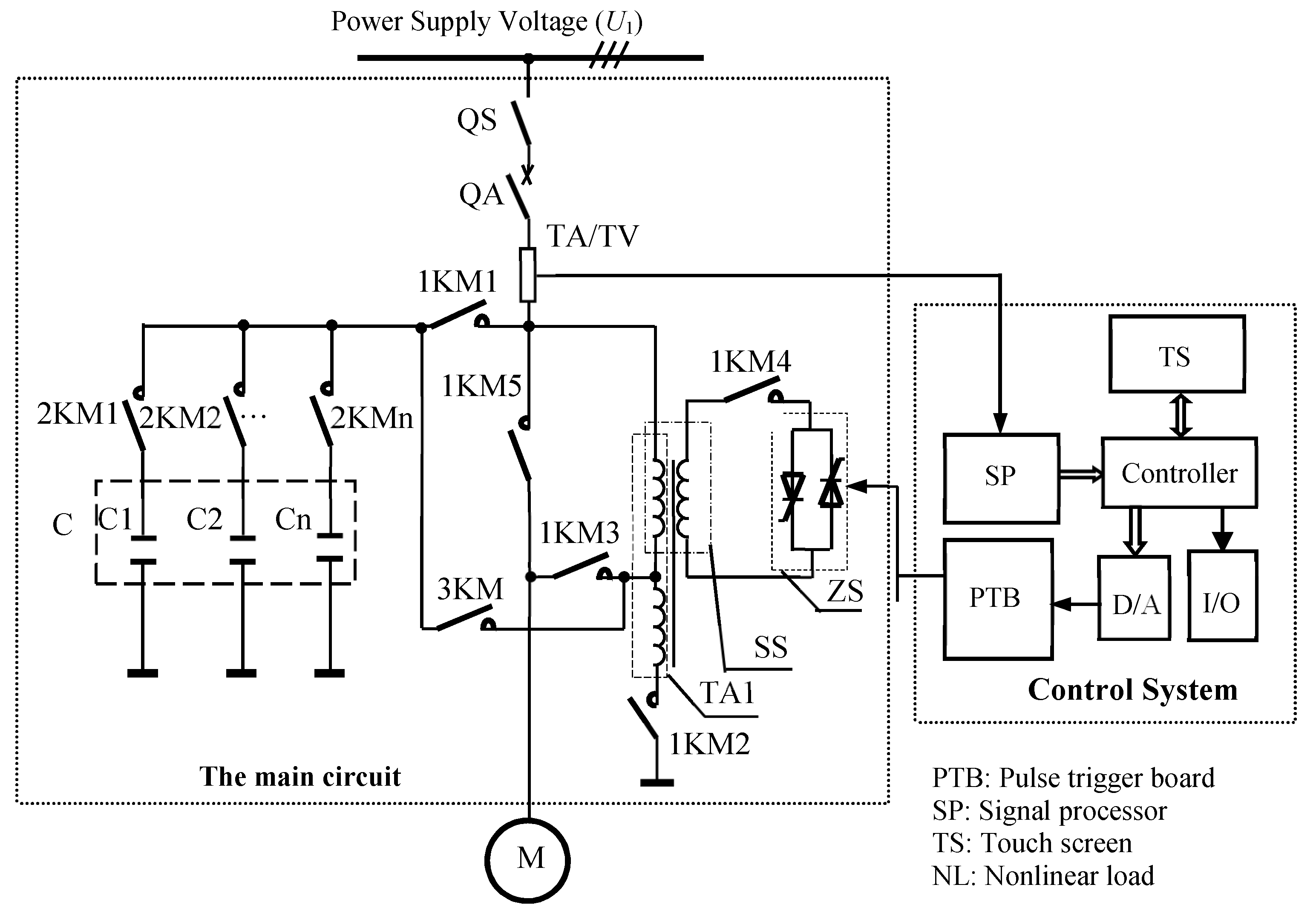

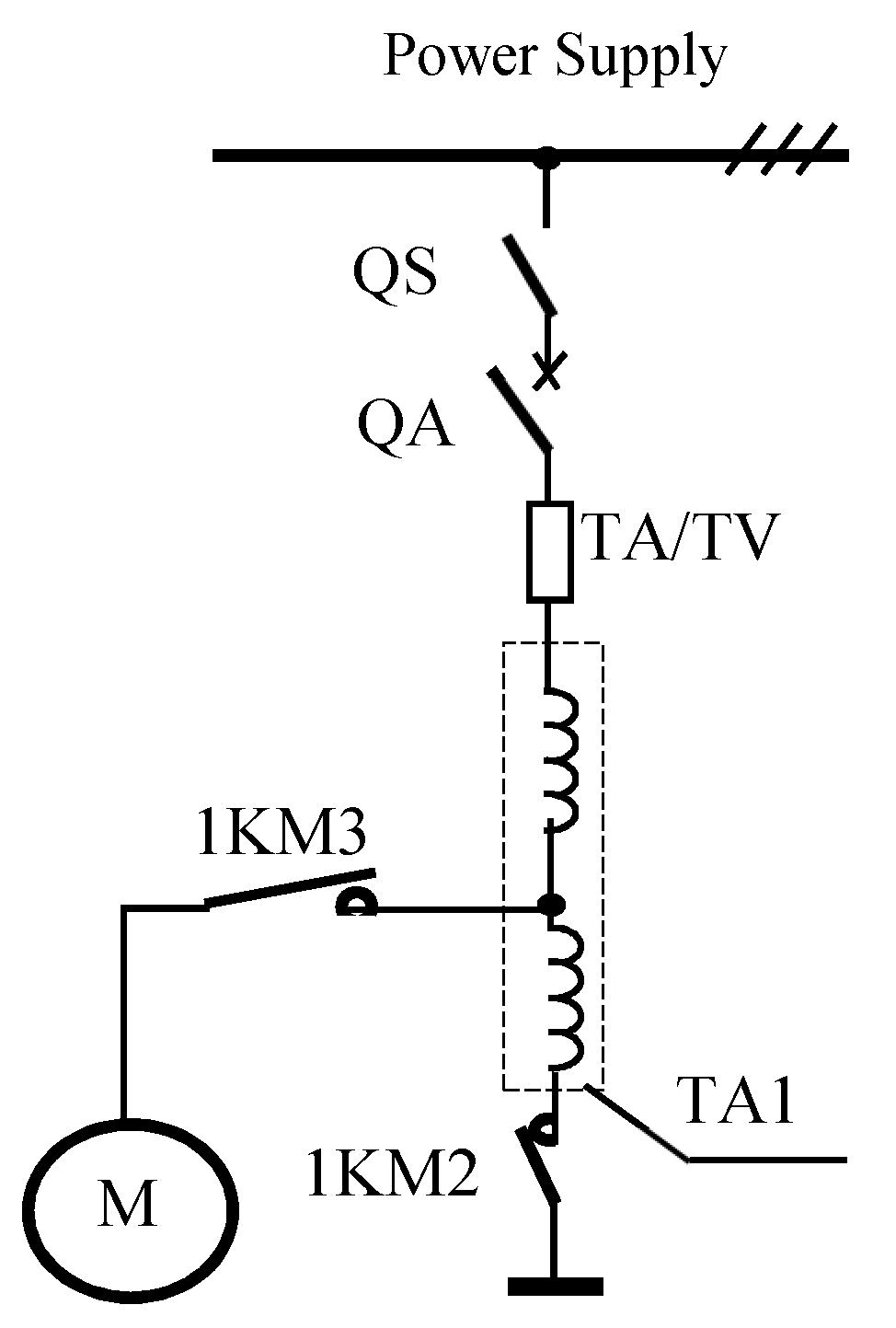

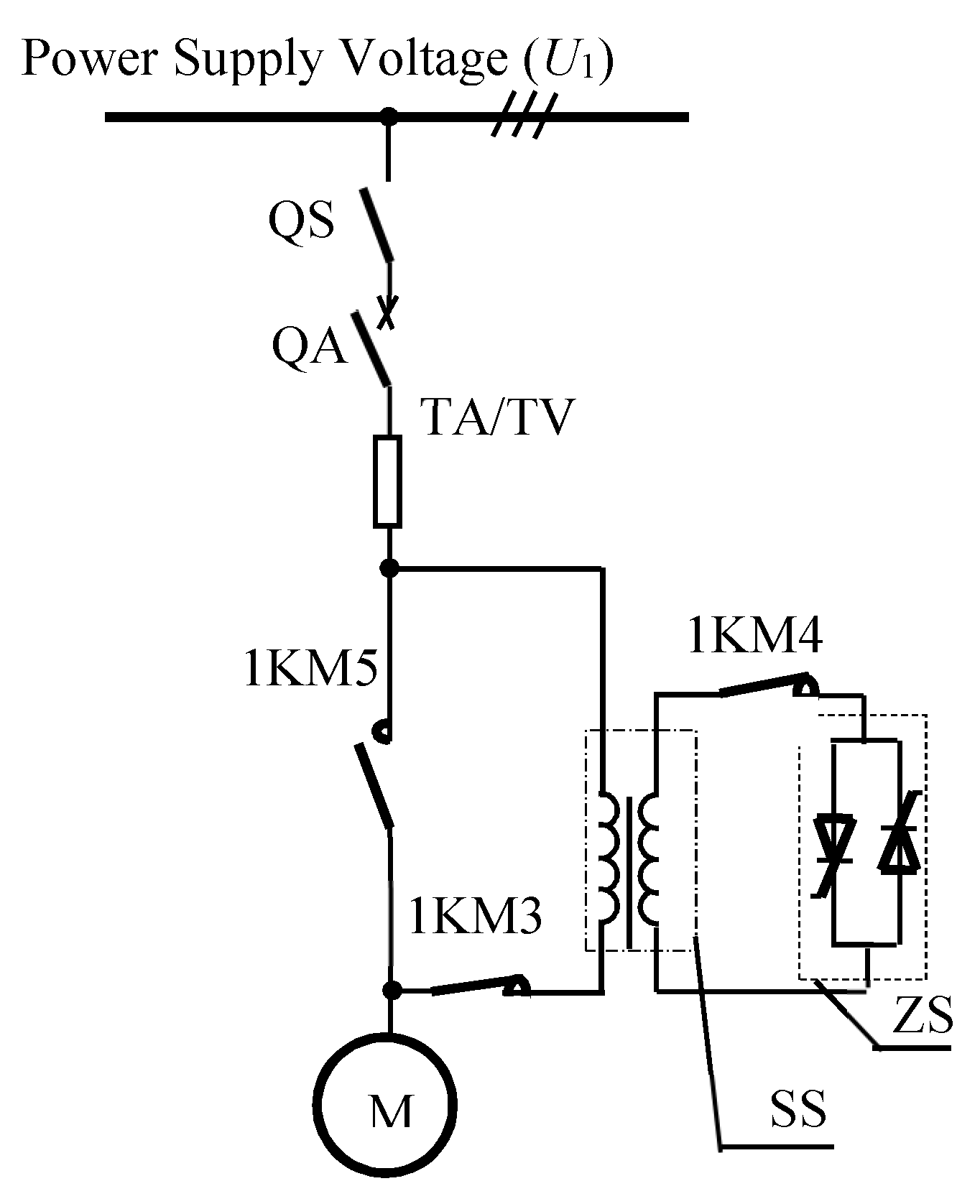

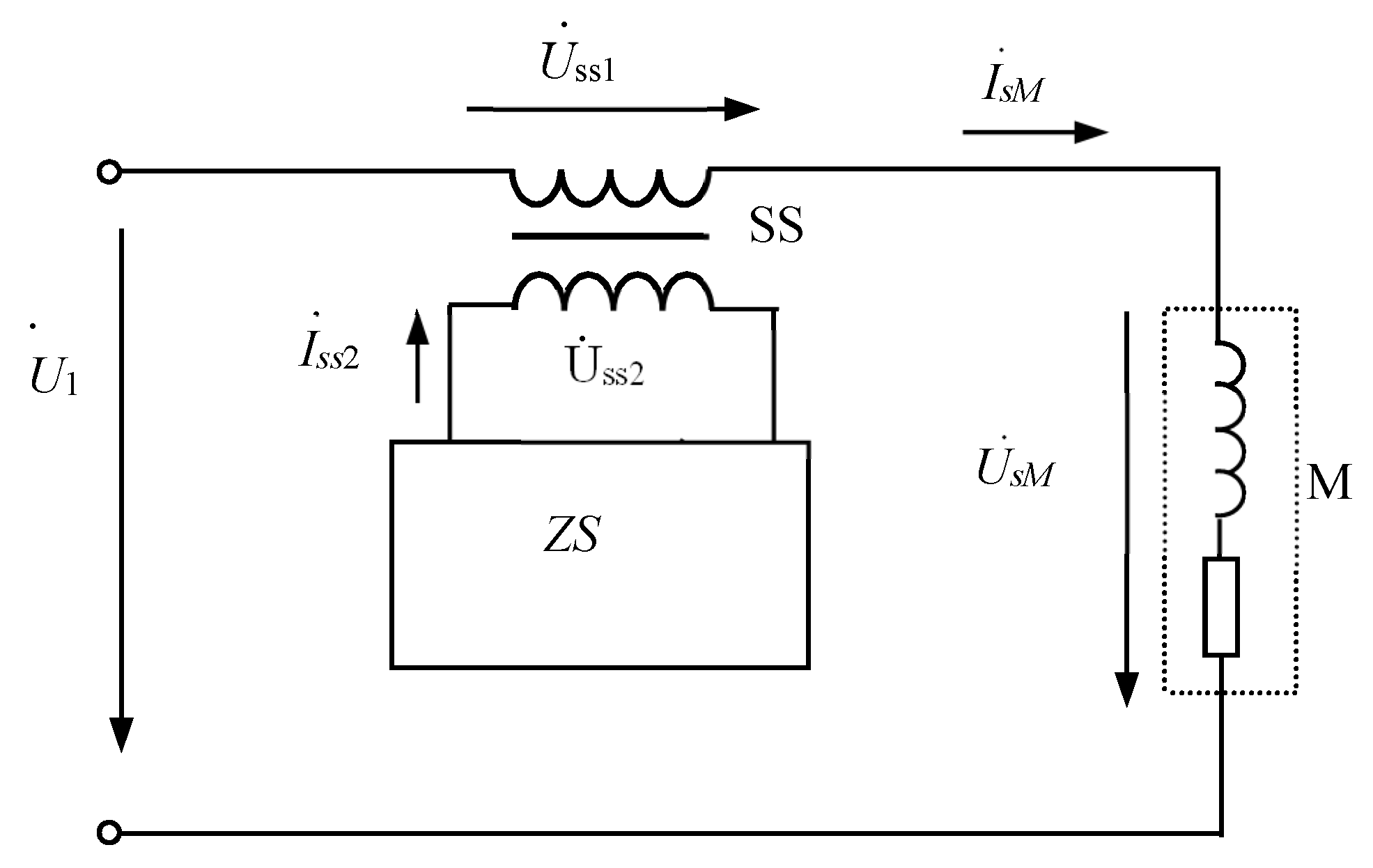

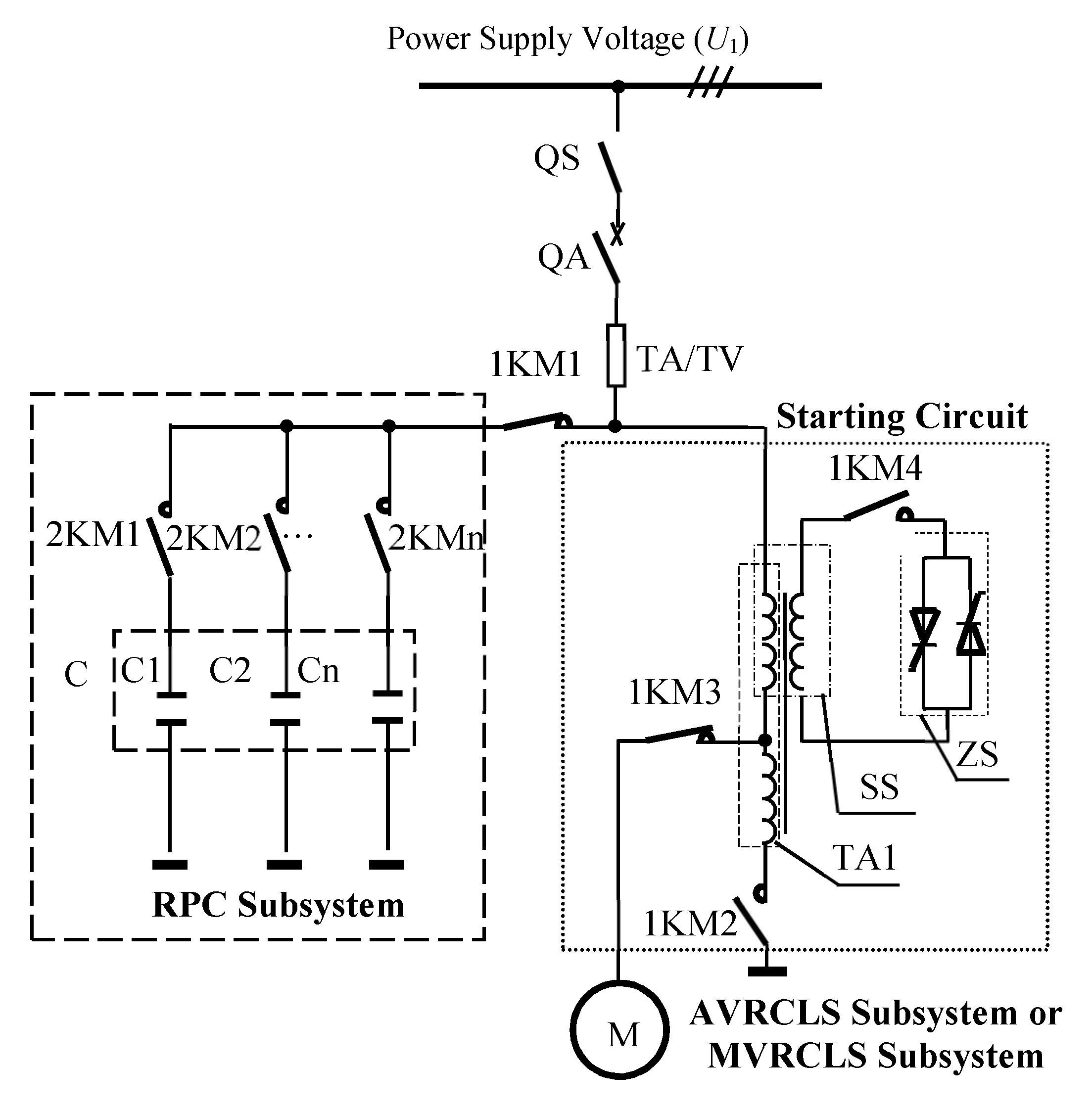

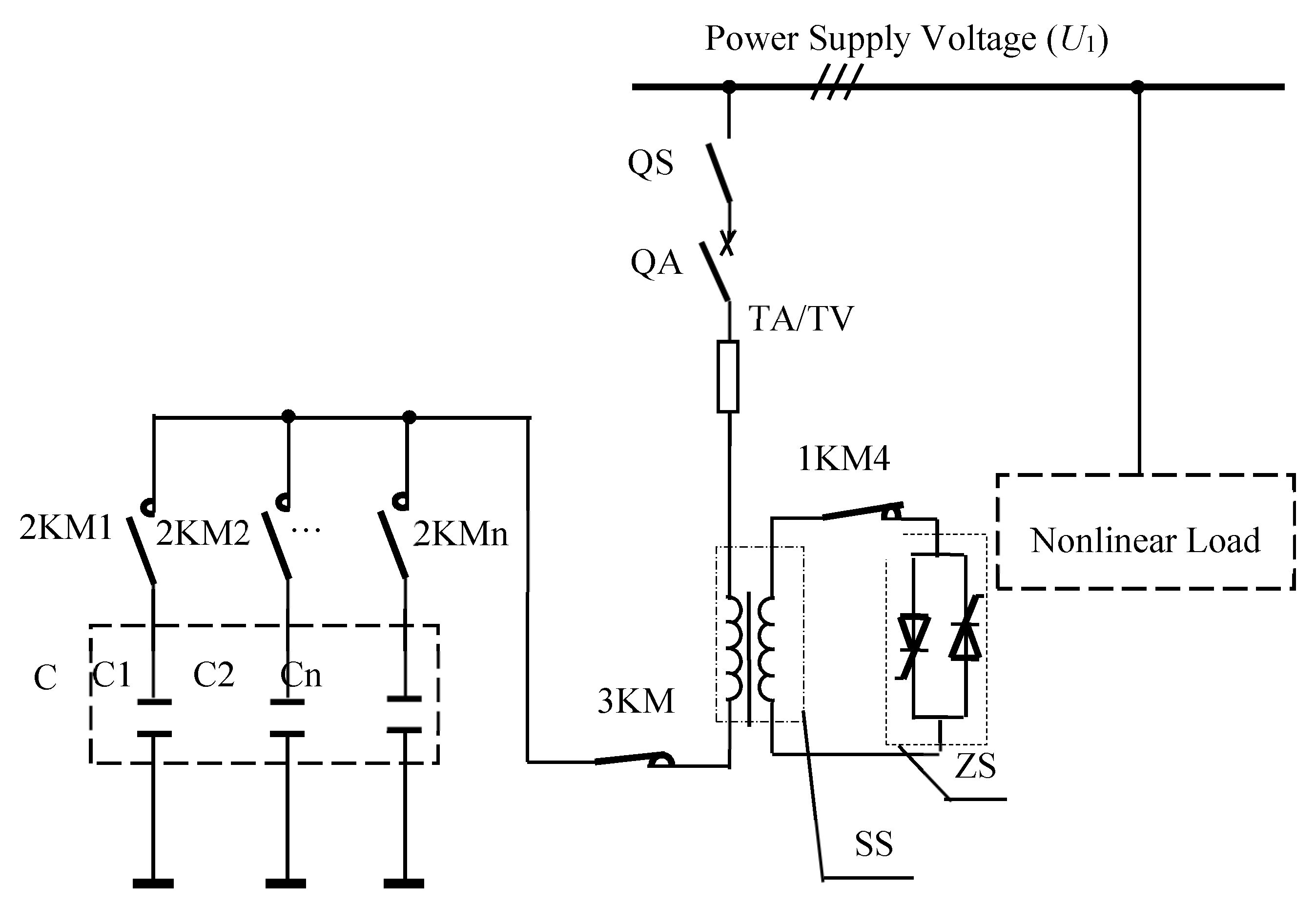

2.2. Topologial Structure

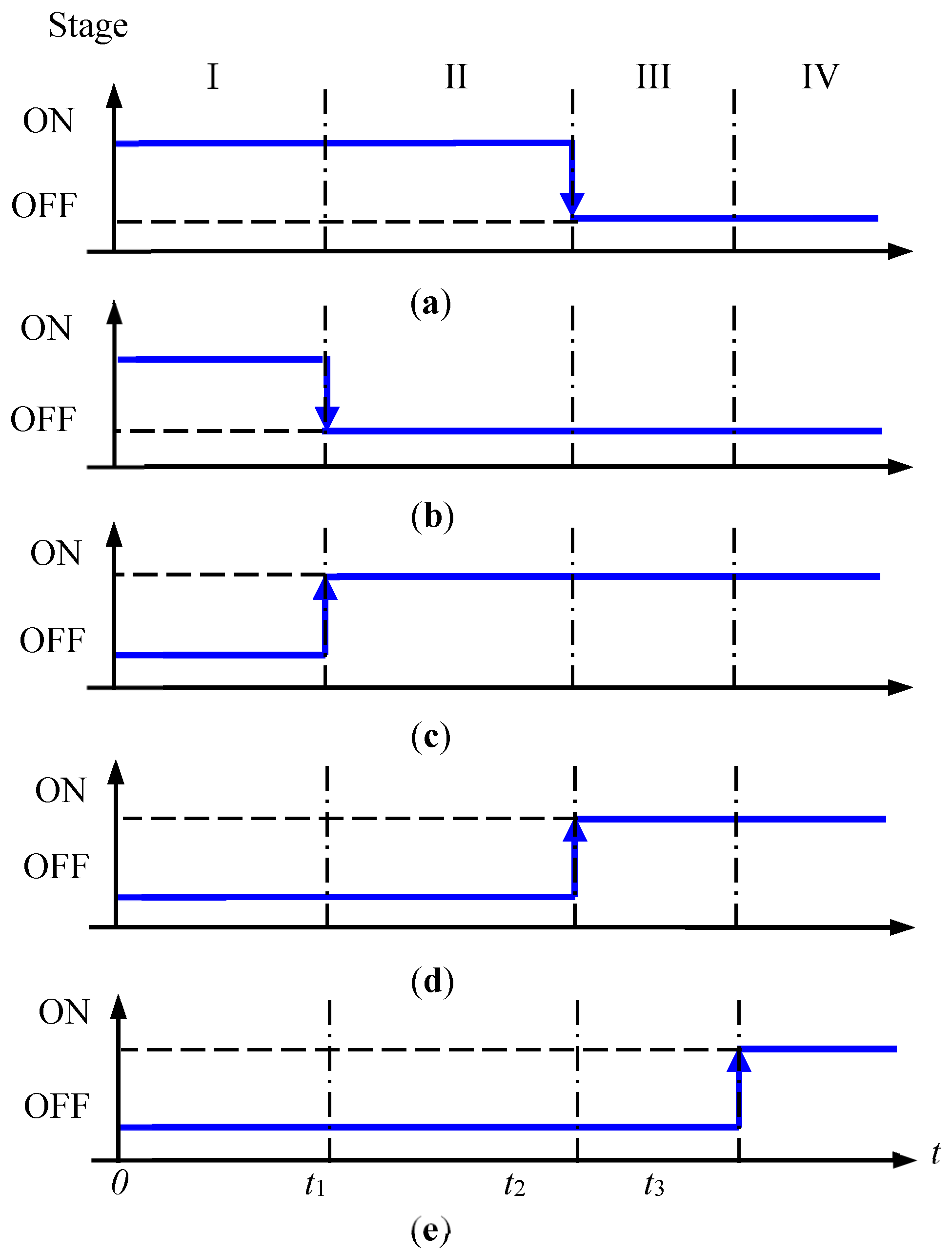

2.3. Functional Logic Switching Strategy

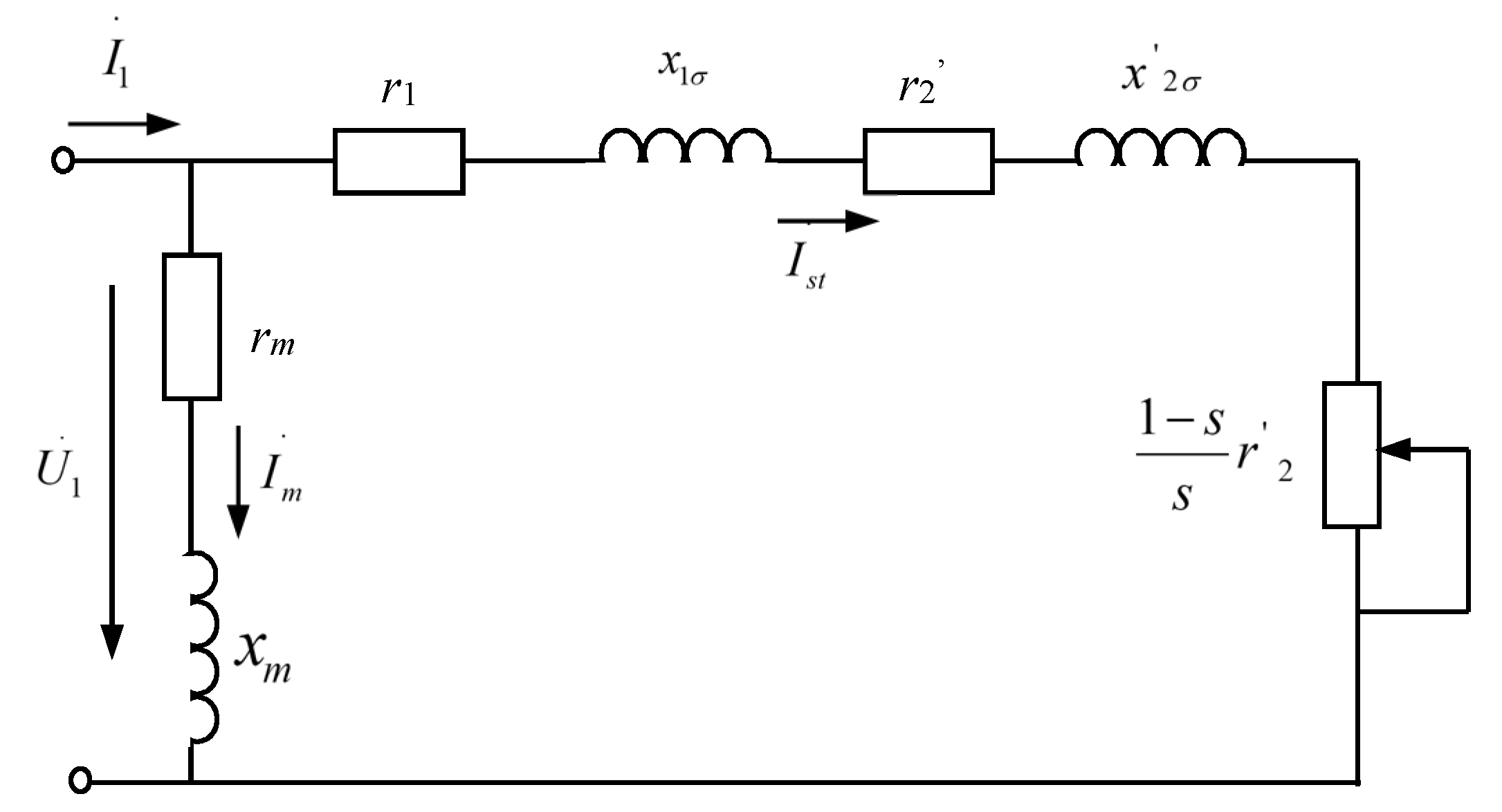

3. Analysis of Mechanisms

3.1. Mechanism of Direct Starting

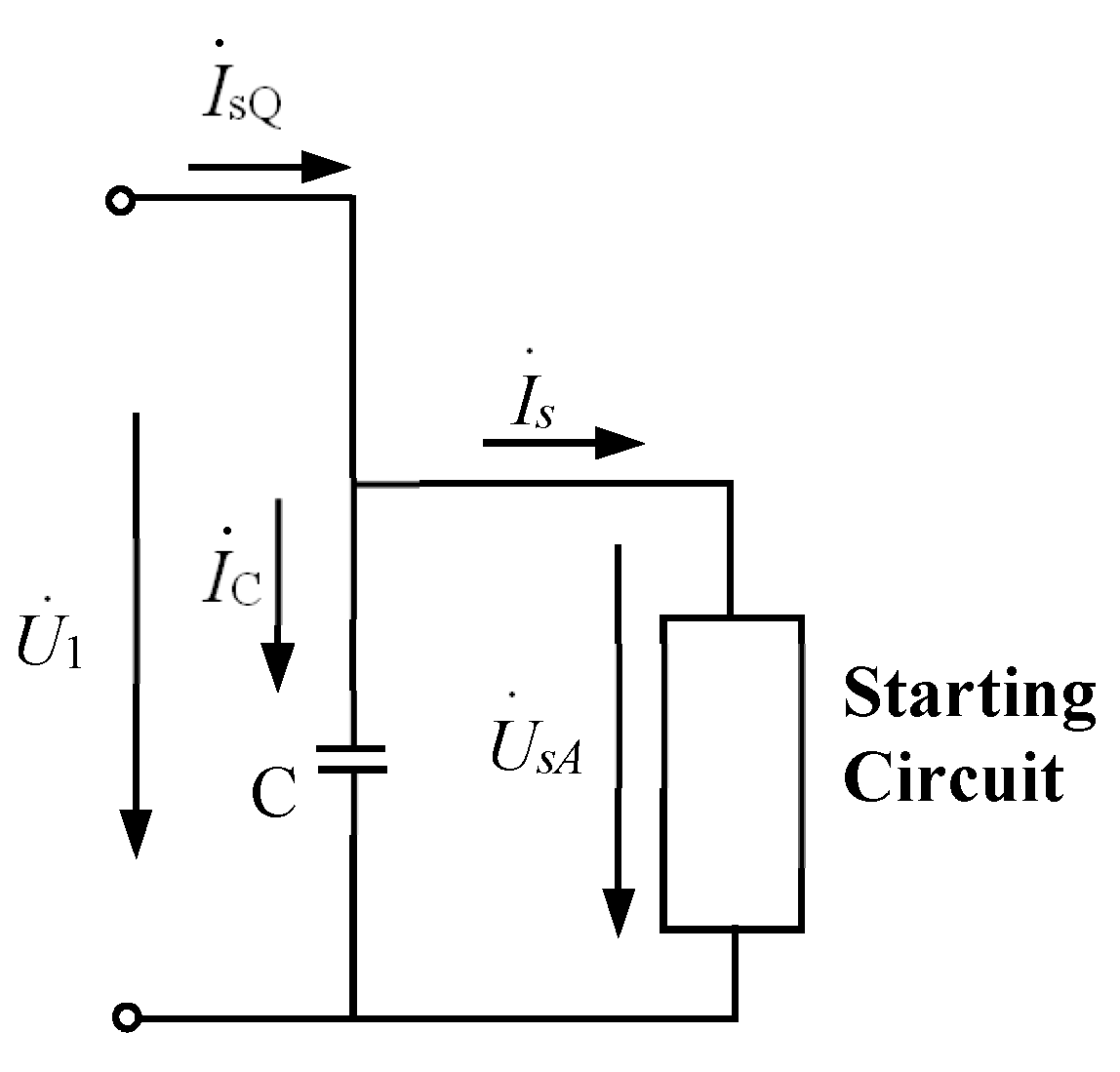

3.2. Mechanism of the AVRCLS Subsystem

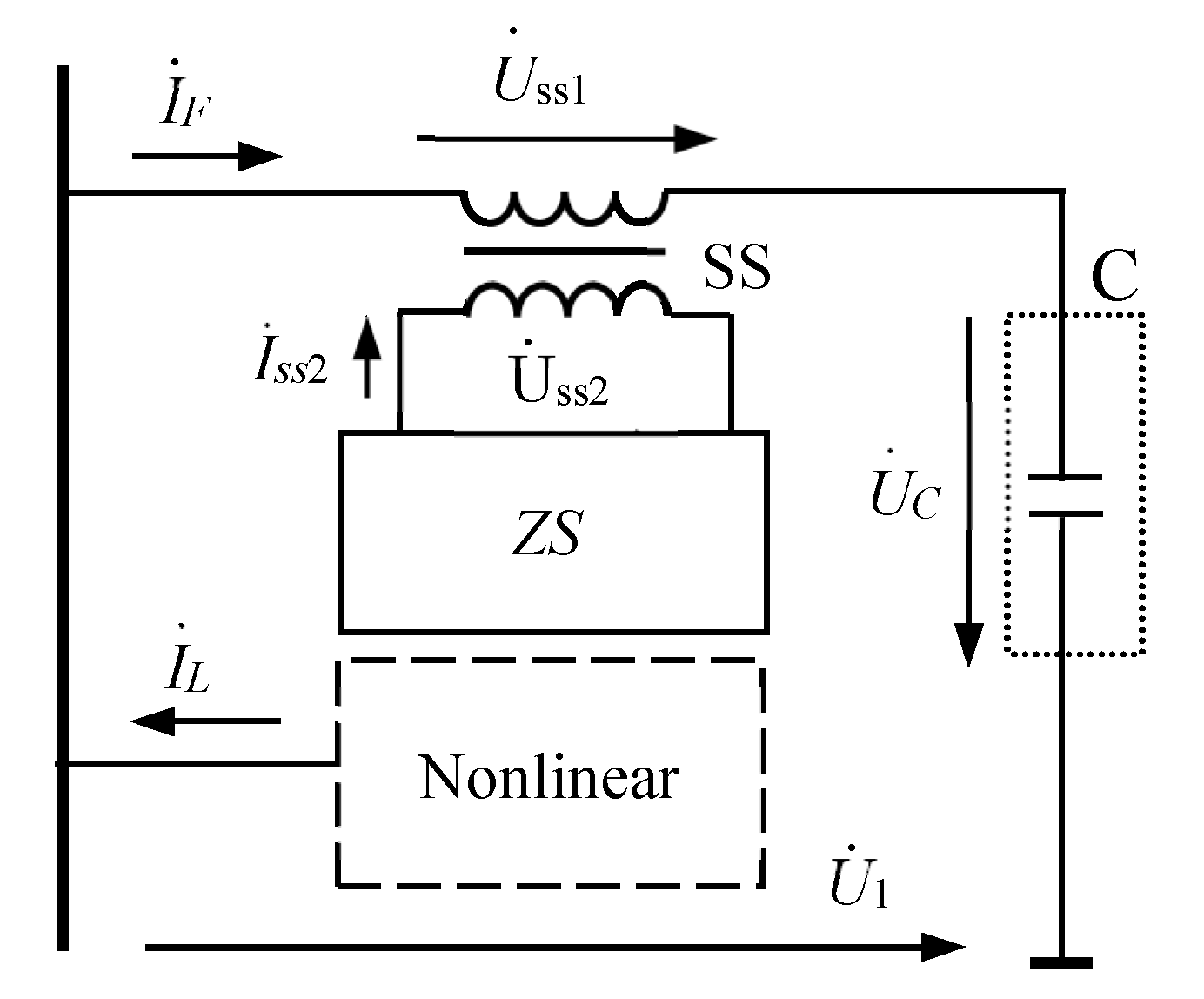

3.3. Mechanism of the MVRCLS Subsystem

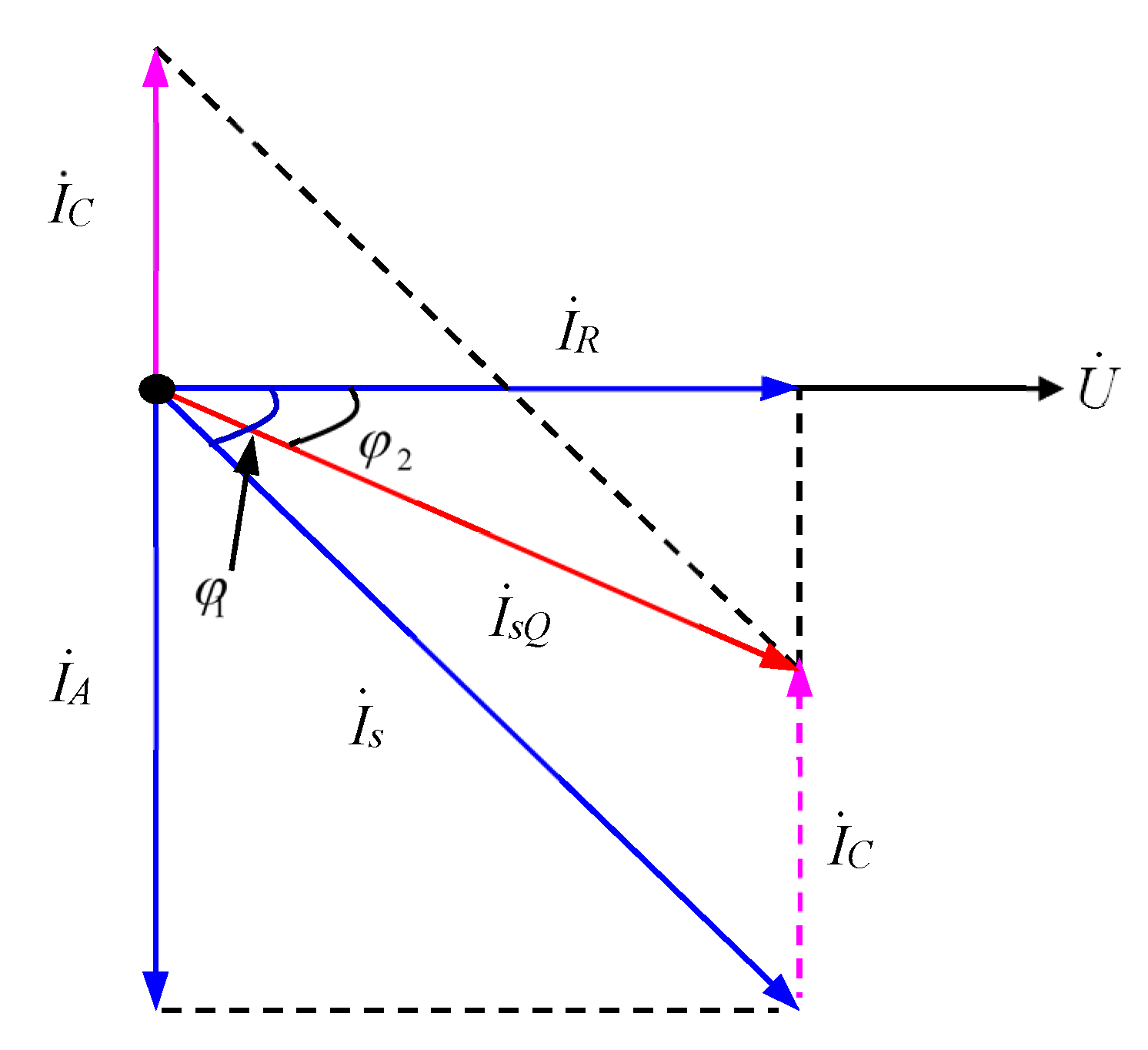

3.4. Mechanism of the RPC Subsystem

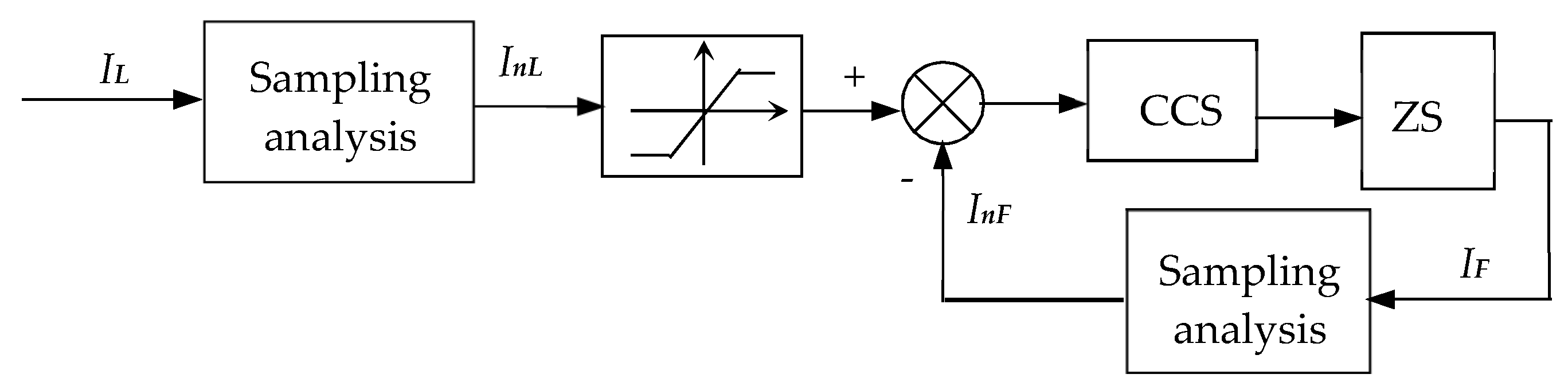

3.5. Mechanism of the Power Filtering Subsystem

4. Simulation and Experimental Evaluation

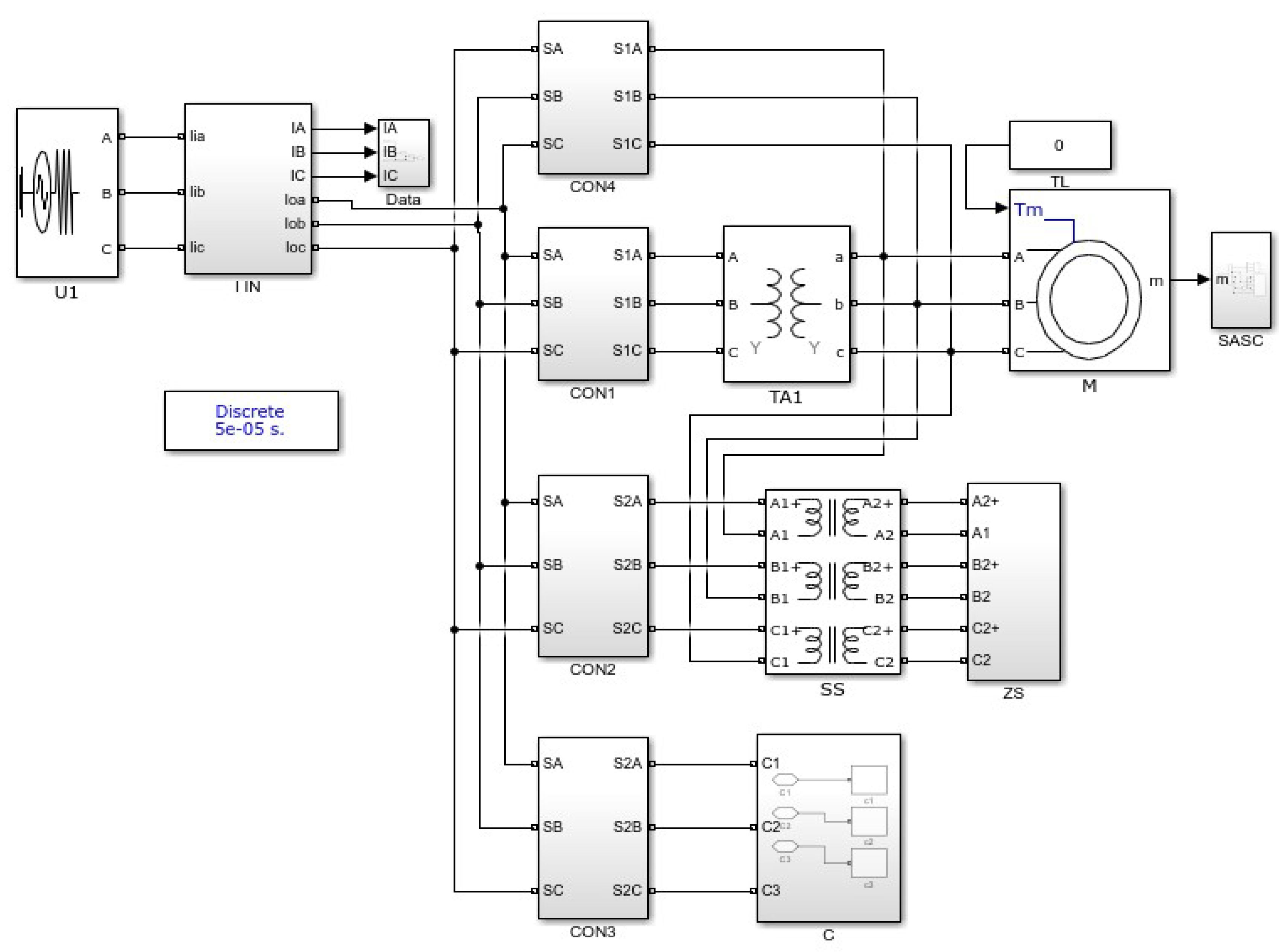

4.1. Simulation System on Current-Limiting Soft Starting

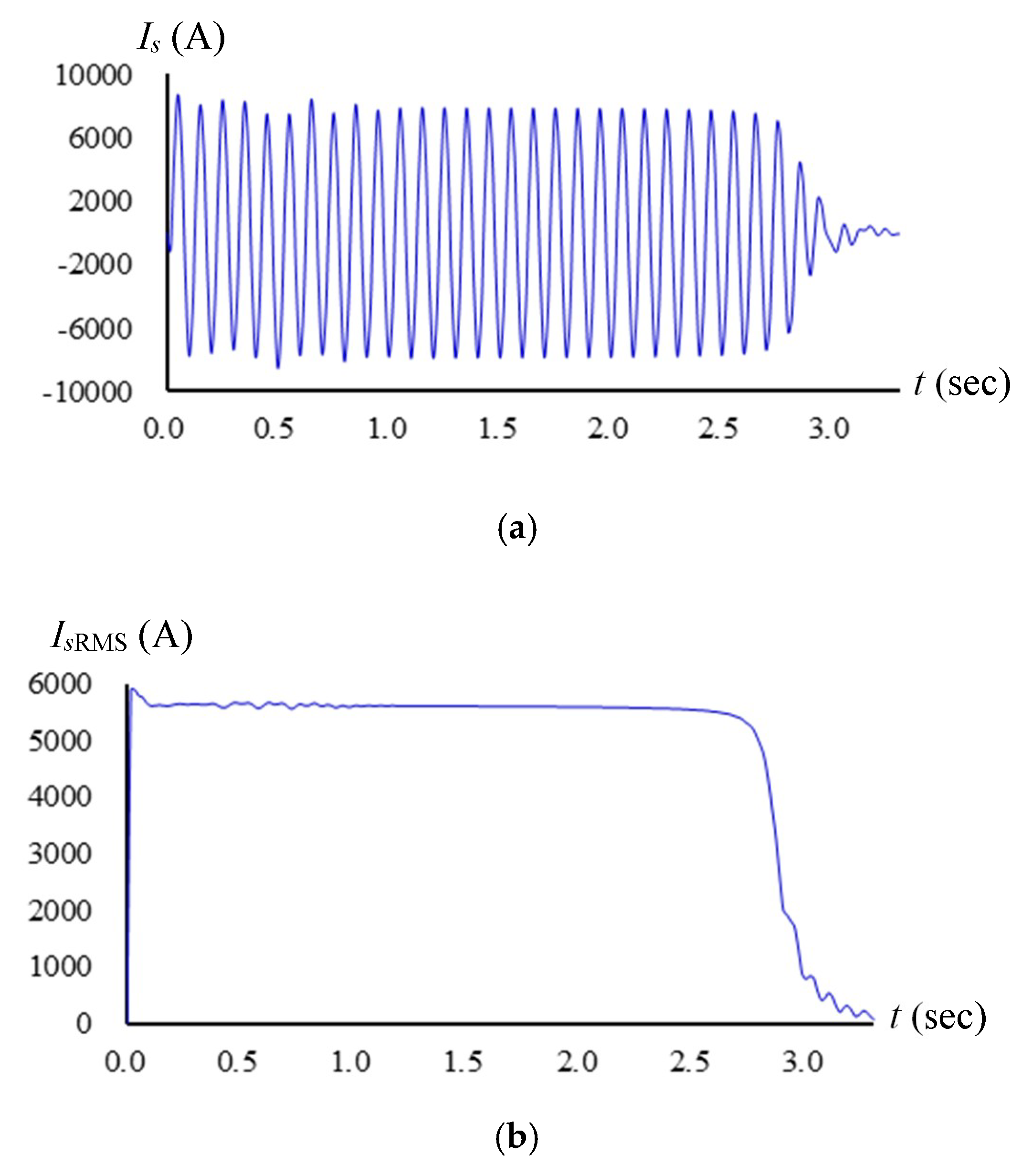

4.2. Simulation Results on Direct Starting

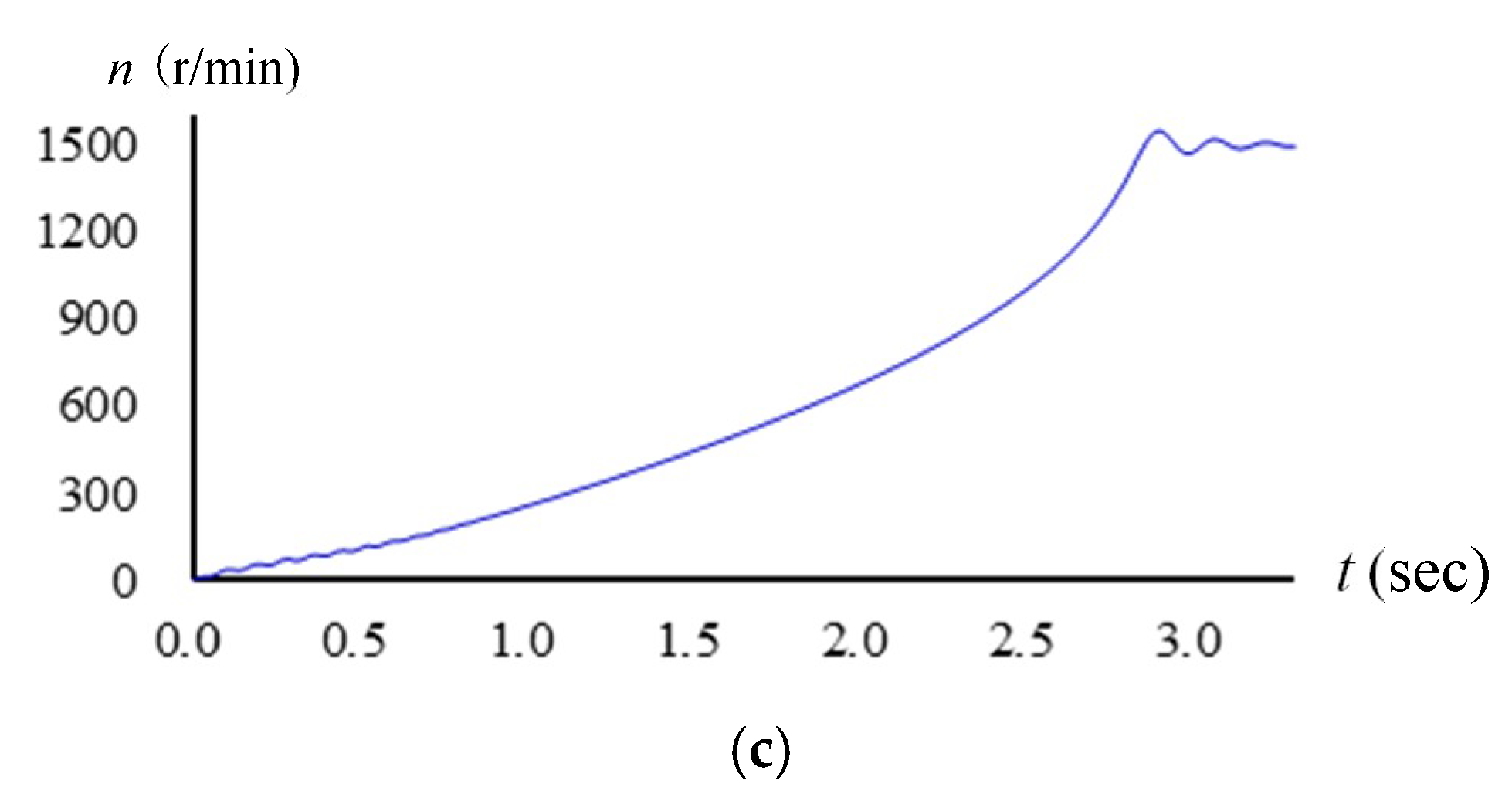

4.3. Simulation Results on Current-limiting Soft Starting

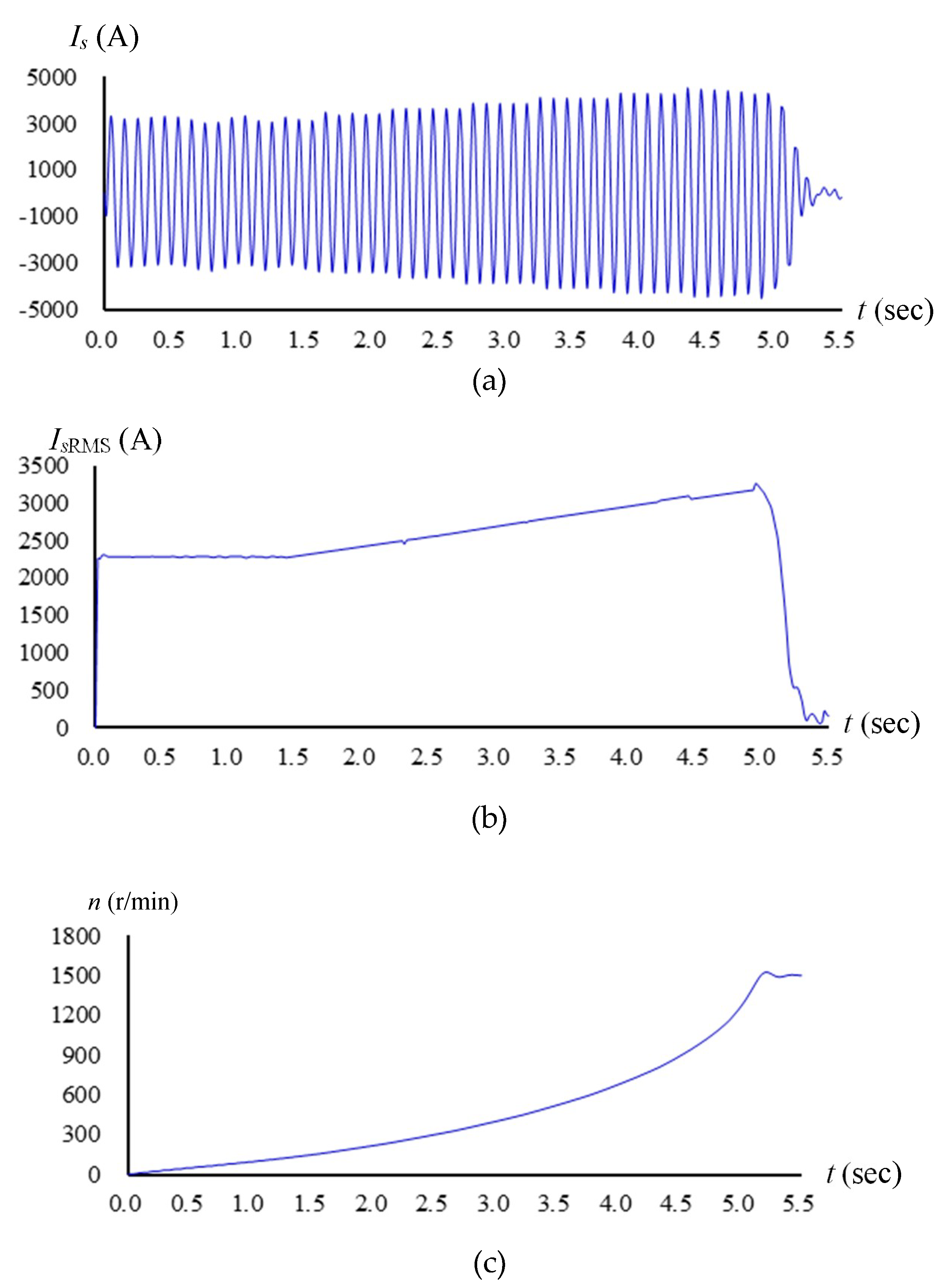

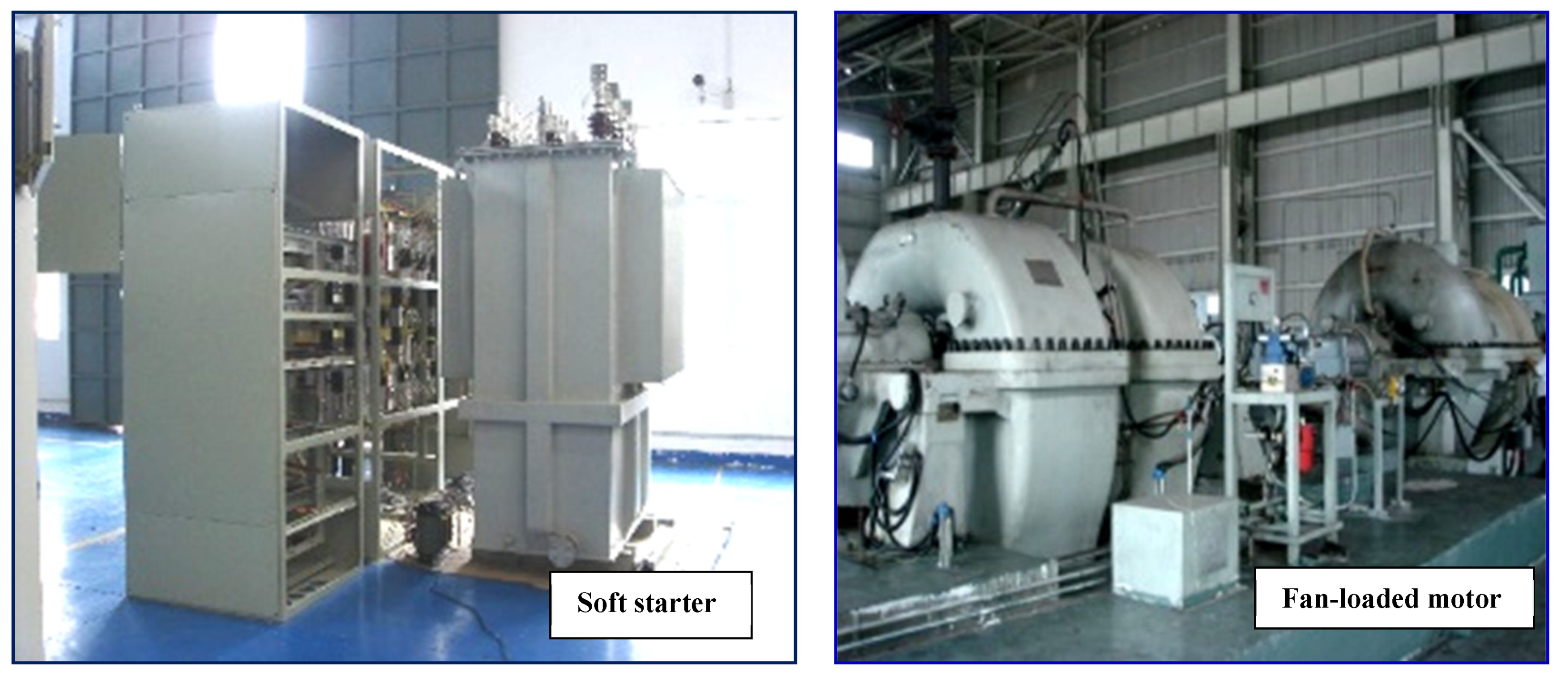

4.4. Experimental Evaluatiom on Soft Starting

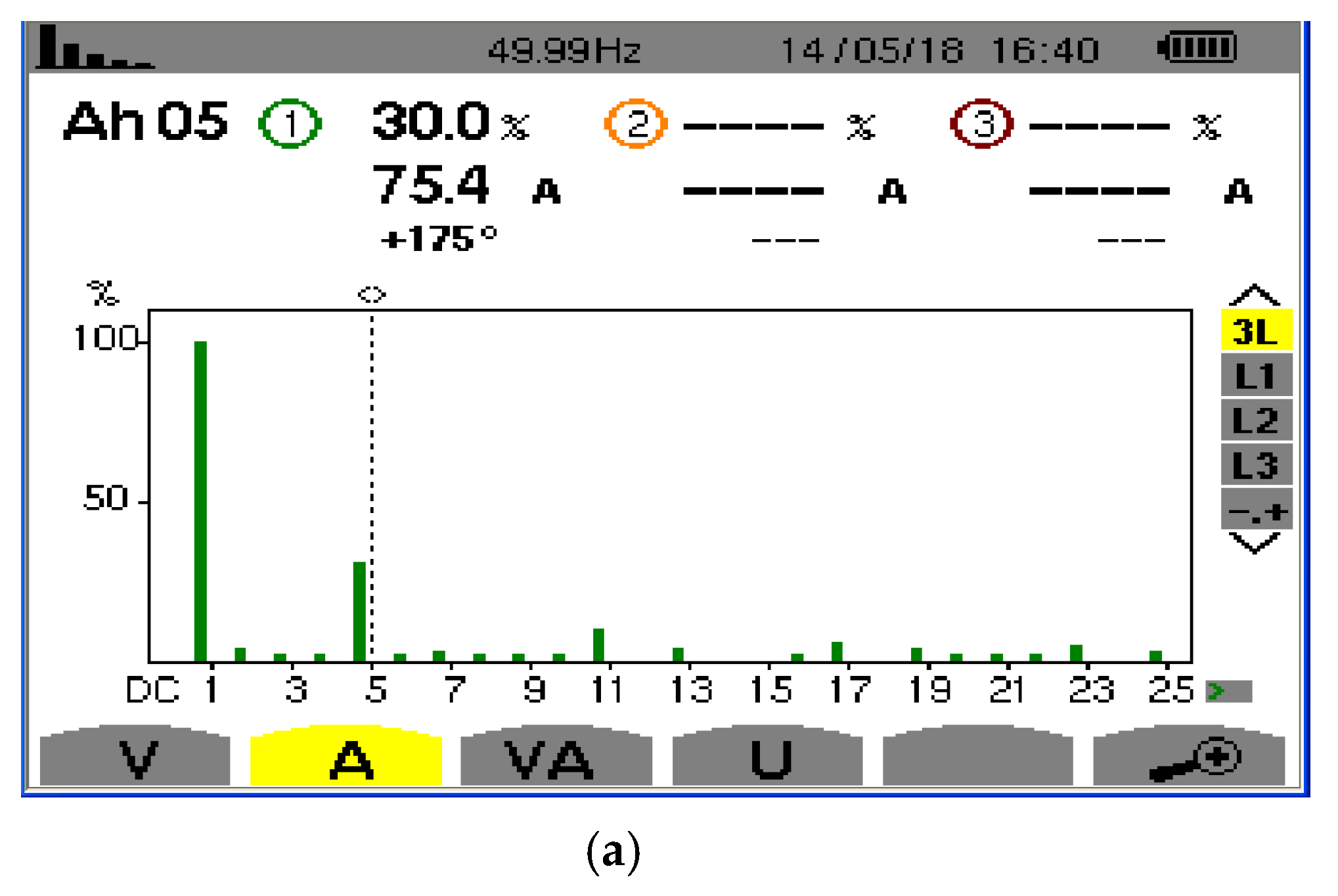

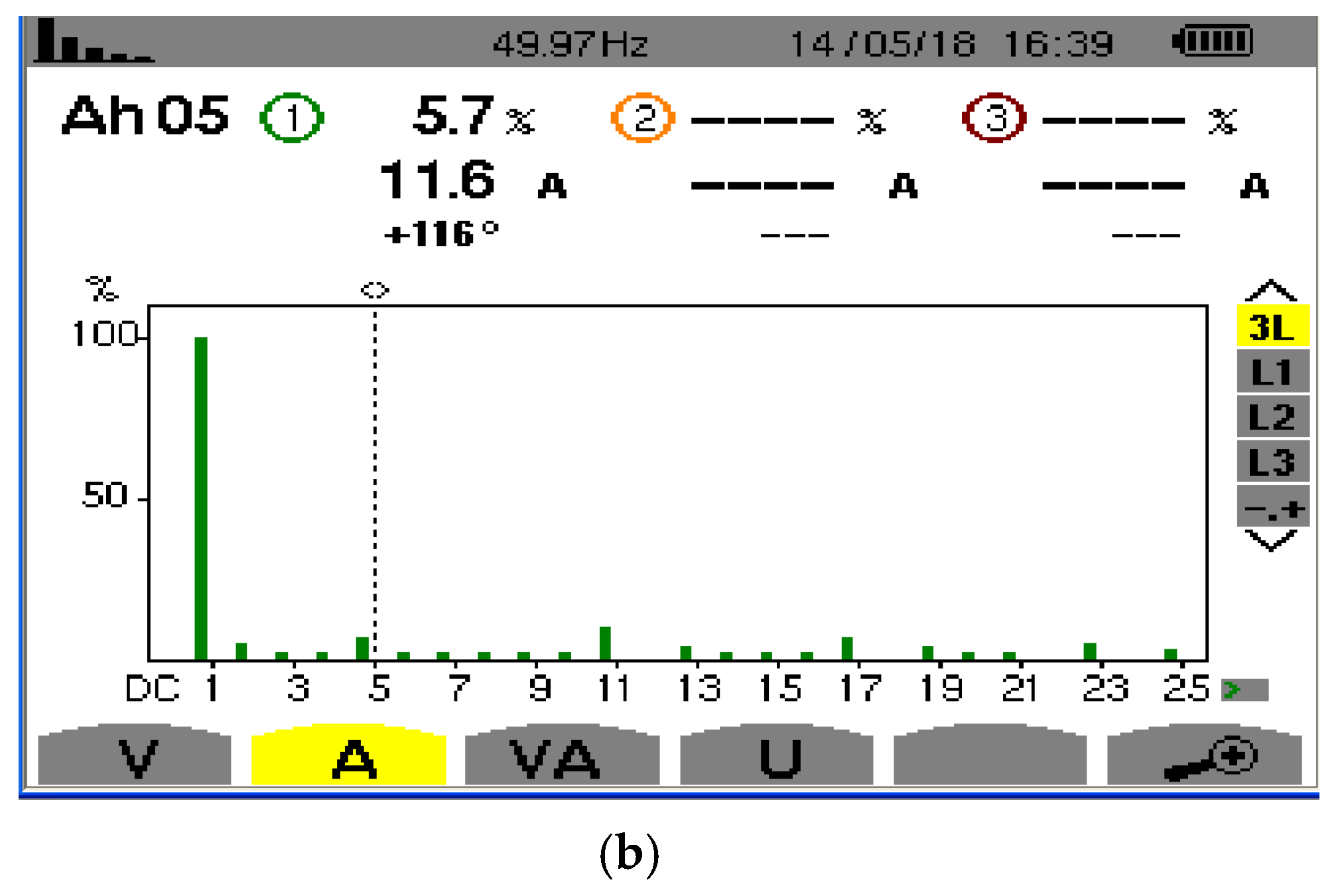

4.5. Experimental Evaluation of the Power Filtering Subsystem

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| PLC | Programmable Logic Controller |

| AVRCLS | Autotransformer voltage reduction–current limiting starting |

| MVRCLS | Magnetron voltage regulation–current limiting starting |

| RPC | Reactive power compensation |

| TS | Touch screen |

| D/A | Digital analog converter |

| I/O | Digital input and output |

| RMS | Root mean square |

References

- Goh, H.H.; Kok, B.C.; Looi, M.S. A study of induction motor starting methods in terms of power quality. In Proceedings of the 3rd Engineering Conference on Advancement in Mechanical and Manufacturing for Sustainable Environment, Kuching, Sarawak, Malaysia, 14–16 April 2010; pp. 18–29. [Google Scholar]

- Thankachan, J.; George, S. A novel switching scheme for three phase PWM AC Chopper fed induction motor. In Proceedings of the 2012 IEEE 5th India International Conference on Power Electronics (IICPE), Delhi, India, 6–8 December 2012; pp. 1–4. [Google Scholar]

- Zhang, Q.; Tong, J.; Lu, Y.; Liu, B. A simple asynchronous motor soft start method and its application. In Proceedings of the 2017 32nd Youth Academic Annual Conference of Chinese Association of Automation (YAC), Hefei, China, 19–21 May 2017; pp. 1074–1078. [Google Scholar]

- Shang, M.; Lin, G.M.; Guo, Q.H.; Sun, Y.T. The boot method analysis of three-phase asynchronous motor. Appl. Mech. Mater. 2013, 401–403, 308–311. [Google Scholar] [CrossRef]

- Ming, K.; Wang, X.; Li, Z.; Nie, P. Asynchronous operation characteristics and soft-starting method for the brushless doubly-fed motor. IET Electr. Power Appl. 2017, 11, 1276–1283. [Google Scholar]

- Jiang, C.; Rui, Y. Design of a new type of mechanical controllable soft start transmission. J. Mech. Eng. 2017, 53, 83–91. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, L.; Huang, Y.; Lu, Y.; Zhu, Y. Half-soft starting control of switched reluctance motor using discrete position signal processing. Cluster Comput. 2017, 20, 3185–3198. [Google Scholar] [CrossRef]

- Chen, T.; Song, Z.Y.; Zhan, Y.Q.; Chao, T. Comparison of super large motor starting ways. Value Eng. 2014, 31, 96–98. [Google Scholar]

- Corral-Hernandez, J.A.; Antonino-Daviu, J.A. Thorough validation of a rotor fault diagnosis methodology in laboratory and field soft-started induction motors. Chin. J. Electr. Eng. 2018, 4, 66–72. [Google Scholar]

- Liu, E.P.; Jia, C.L.; Li, J.; Chen, M.S. Research on the oscillations during the soft starting of induction motor controlled by thyristors. Electr. Drive 2011, 8, 48–51. [Google Scholar]

- Xia, Y.; Han, Y.; Xu, Y.; Ai, M. Analyzing temperature rise and fluid flow of high-power-density and high-voltage induction motor in the starting process. IEEE Access 2019, 7, 35588–35595. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, S.; Li, X.; Yang, F.; Zhou, D. Full voltage starting method of high-power asynchronous motor considering electromagnetic transient process. High Voltage Eng. 2013, 39, 464–473. [Google Scholar]

- Yuan, Y.; Wang, Y.; Peng, W.; Yan, J. Research on high motor soft starter based on variable reactor. Electr. Power Autom. Equip. 2007, 11, 38–41. [Google Scholar]

- Yuan, Y.; Xia, Z.; Wang, Y.; Yuan, P.; Peng, W. A soft starter of three phase asynchronous motor. In Proceedings of the 2007 IEEE Power Electronics Specialists Conference, Orlando, FL, USA, 17–21 June 2007; pp. 563–567. [Google Scholar]

- Wang, Y.F.; Yuan, Y.X.; Xu, Y. Research on a novel soft starting method of super high-power and high-voltage motor. Appl. Mech. Mater. 2013, 263–266, 604–609. [Google Scholar] [CrossRef]

- Sundareswaran, K.; Nayak, P.S. Ant colony based feedback controller design for soft-starter fed induction motor drive. Appl. Soft Comput. 2012, 12, 1566–1573. [Google Scholar] [CrossRef]

- Chang, Y.; Yuan, Y.; Chen, J.; Huang, W. Research and design of an intelligent liquid-state soft starter. In Proceedings of the International Conference on Electrical Control Engineering, Wuhan, China, 25–27 June 2010. [Google Scholar]

- Chen, J.; Peng, Y.; Yuan, Y.; Tan, S.; Zhou, S.; Chen, G. Development of magnetron soft start device based on PLC 200. Wuhan Ligong Daxue Xuebao (J. Wuhan Univ. Technol.) 2010, 32, 93–94. [Google Scholar]

- Yu, M.; Tian, C.; Chen, B. A novel induction motor soft starter based on magnetically controlled reactor. In Proceedings of the IEEE Conference on Industrial Electronics Applications, Singapore, Singapore, 24–26 May 2006. [Google Scholar]

- Hu, H.M.; Mao, C.X.; Lu, J.M.; Yu, Y.X. The torque oscillation study in the motor soft starting process with discrete variable frequency method. In Proceedings of the International Conference on Electrical Machines Systems, Wuhan, China, 17–20 October 2008. [Google Scholar]

- Wei, G.; Chu, J.; Gan, S. Starting performance research of a high-power middle-voltage induction motor soft starter based on the on-off transformer. In Proceedings of the IEEE International Symposium on Industrial Electronics, Montreal, Canada, 9–13 July 2006. [Google Scholar]

- Yuan, Y.; Xiao, Y. Research on one kind of variable reactor. In Proceedings of the International Workshop on Intelligent Systems Applications, Wuhan, China, 23–24 May 2009. [Google Scholar]

- Chang, Y.F.; Yuan, Y.X.; Yan, X.U.; Huang, W.C. Topological structure and impedance conversion analysis of power electronic reactor. Power Electron. 2012, 46, 21–22. [Google Scholar]

- Huang, W.; Yuan, Y.; Chang, Y. A novel soft start method based on auto-transformer and magnetic control. In Proceedings of the IEEE International Conference on Industrial Technology, Taipei, Taiwan, 14–17 March 2016. [Google Scholar]

- Tan, S.; Zhou, S.; Yuan, Y.; Jiang, X. Design on controller of magnetic controlled soft starting for middle-high voltage motor. In Proceedings of the 2010 The 2nd Conference on Environmental Science and Information Application Technology, Wuhan, China, 17–18 July 2010; pp. 478–481. [Google Scholar]

- Tan, S.; Zhang, Z.; Jing, C.; Yuan, Y.; Gang, C. Design on Intelligent Controller of Magnetic Starting for Reactive Compensation. In Proceedings of the International Conference on Applied Informatics and Communication, Xi’an, China, 20–21 August 2011; pp. 600–607. [Google Scholar]

- Wang, Y.F.; Yuan, Y.X.; Chang, Y.F.; Yan, X.U. A novel soft starting integration current-limiting, reactive power compensation for super high-power and high-voltage motor filtering. Wuhan Ligong Daxue Xuebao (J. Wuhan Univ. Technol.) 2013, 35, 140–143. [Google Scholar]

- Kim, J.-C.; Kwak, S.; Kim, T. Power factor control method based on virtual capacitors matrix rectifiers. IEEE Access 2019, 7, 12484–12494. [Google Scholar] [CrossRef]

- Wang, Y.; Yuan, Y.; Chen, J. A novel electromagnetic coupling reactor based passive dynamic tunable function. Energies 2018, 11, 1647. [Google Scholar] [CrossRef]

- Jibhakate, C.N.; Chaudhari, M.A.; Renge, M.M. Reactive power compensation using driven by nine switch ac-dc-ac converter. IEEE Access 2017, 6, 1312–1320. [Google Scholar] [CrossRef]

- Sarkar, M.N.I.; Meegahapola, L.G.; Datta, M. Reactive power management in renewable grids: A review of grid-codes, renewable generators, support devices, control strategies algorithms. IEEE Access 2018, 6, 41458–41489. [Google Scholar] [CrossRef]

- Cortes, B.; Araujo, L.R.; Penido, D.R.R. Passive filters design applied to an electrical system. IEEE Lat. Am. Trans. 2018, 16, 1992–1999. [Google Scholar] [CrossRef]

| Electrical Parameters | Power (kVA) | 19,000 |

| Voltage (kV) | 10 | |

| Frequency (Hz) | 50 | |

| Equivalent Circuit Values | Stator Resistance (Ω) | 0.124 |

| Stator Leakage inductance (mH) | 1.125 | |

| Rotor Resistance (Ω) | 0.123 | |

| Rotor Leakage inductance (mH) | 1.125 | |

| Mutual inductance (mH) | 0.716 | |

| Mechanical Parameters | Inertia (kg·m2) | 703.87 |

| Friction | 0.00 | |

| Pole Pairs | 2 |

| t1 (s) | t2 (s) | δ | Isamax (A) |

|---|---|---|---|

| 0.1 | 4.5 | 0.7 | 4729 |

| 0.1 | 4 | 0.7 | 4849 |

| 0.2 | 4.5 | 0.4 | 5113 |

| 0.2 | 4.5 | 0.5 | 4908 |

| 0.5 | 4.5 | 0.7 | 4731 |

| 1 | 4.5 | 0.7 | 4733 |

| 1 | 6 | 0.6 | 2987 |

| Time for Starting (s) | Starting Motor Current (A) | State |

|---|---|---|

| 34 (t1) | 2550 | Autotransformer voltage reduction-current limiting starting (STAGE I, 0~t1) |

| 92 (t2) | 2400 | Magnetron voltage regulation-current limiting (STAGE II: t1~t2) |

| 145 (t3) | 2100 | End of starting process (STAGE III: t2~t3) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Yin, K.; Yuan, Y.; Chen, J. Current-Limiting Soft Starting Method for a High-Voltage and High-Power Motor. Energies 2019, 12, 3068. https://doi.org/10.3390/en12163068

Wang Y, Yin K, Yuan Y, Chen J. Current-Limiting Soft Starting Method for a High-Voltage and High-Power Motor. Energies. 2019; 12(16):3068. https://doi.org/10.3390/en12163068

Chicago/Turabian StyleWang, Yifei, Kaiyang Yin, Youxin Yuan, and Jing Chen. 2019. "Current-Limiting Soft Starting Method for a High-Voltage and High-Power Motor" Energies 12, no. 16: 3068. https://doi.org/10.3390/en12163068

APA StyleWang, Y., Yin, K., Yuan, Y., & Chen, J. (2019). Current-Limiting Soft Starting Method for a High-Voltage and High-Power Motor. Energies, 12(16), 3068. https://doi.org/10.3390/en12163068